Evaluation Approach of Fracture Behavior for Asphalt Concrete with Different Aggregate Gradations and Testing Temperatures Using Acoustic Emission Monitoring

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

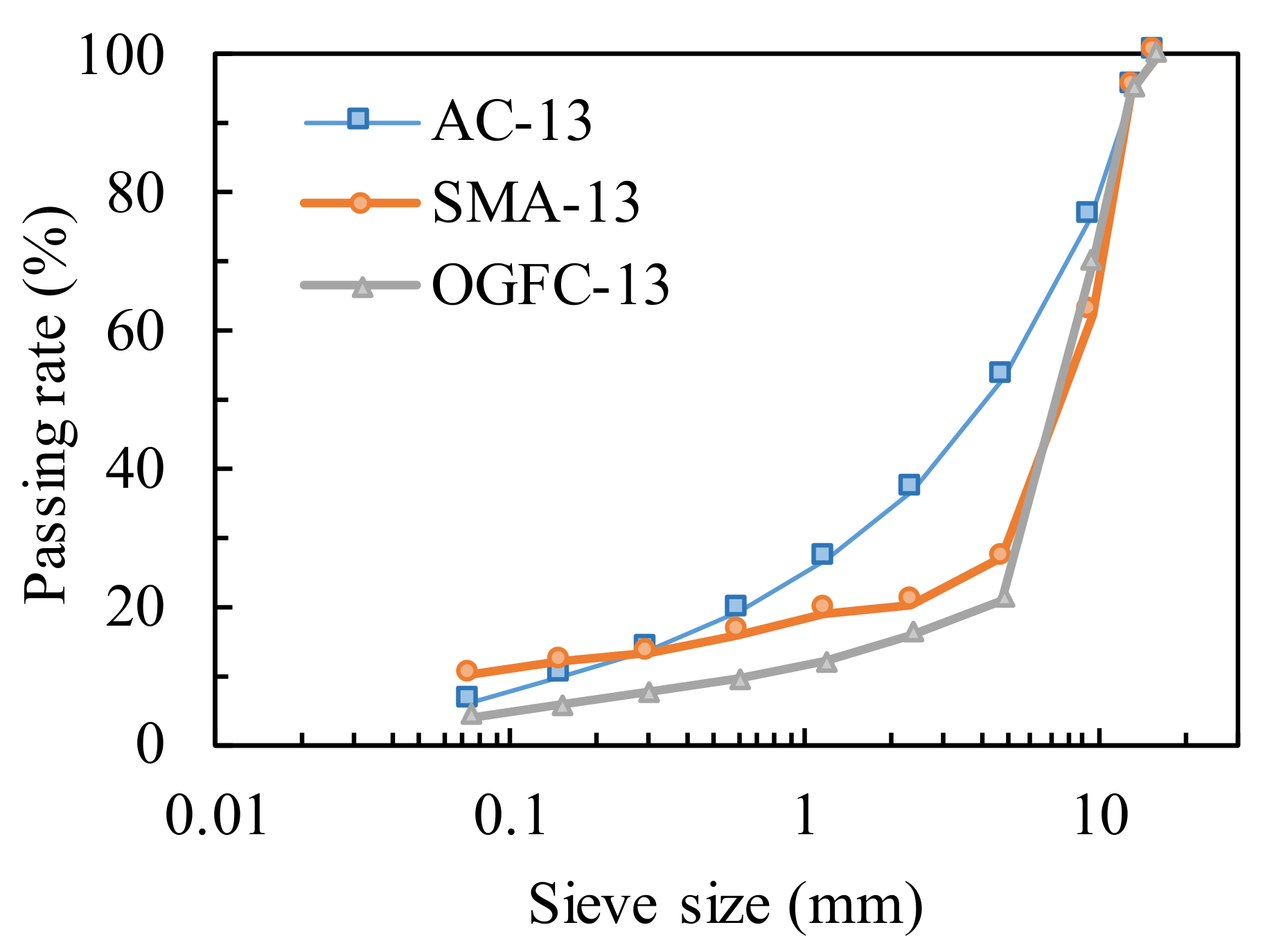

2.2. Aggregate Gradations and Specimens

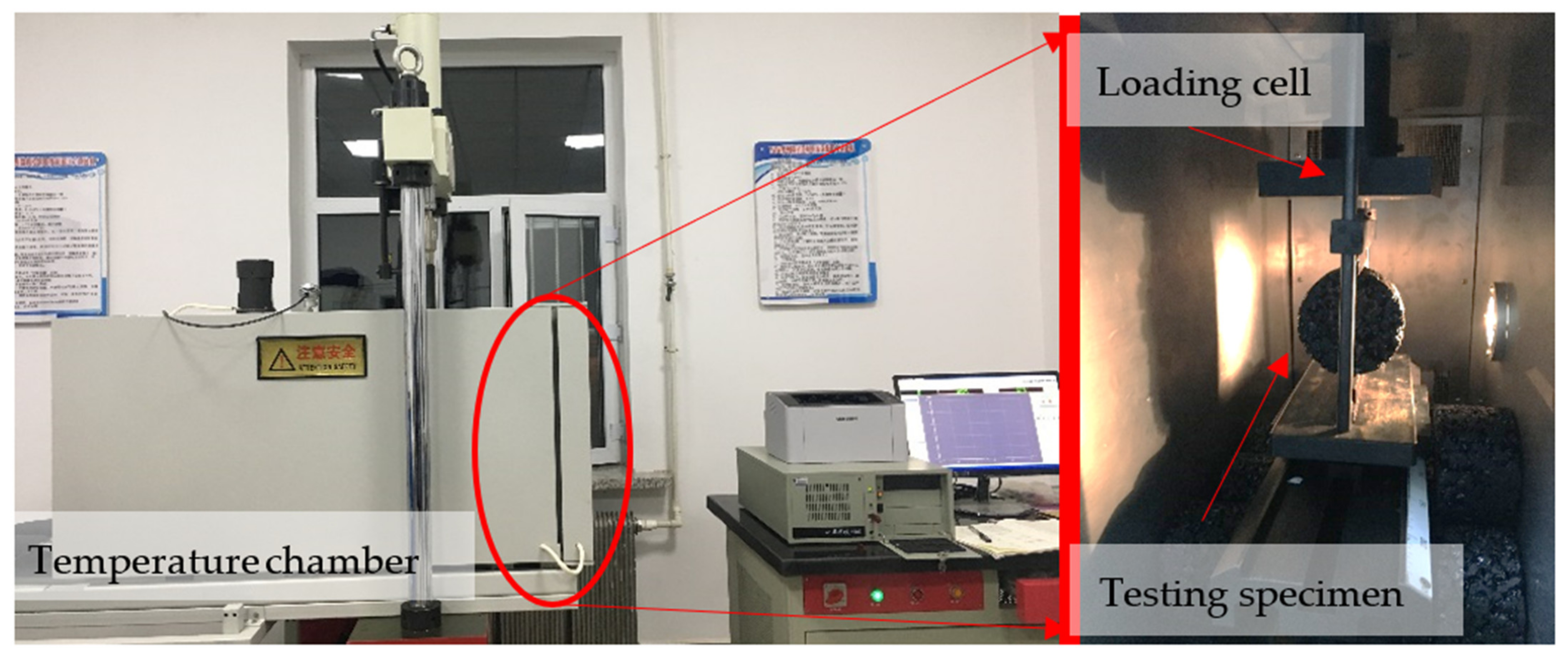

2.3. Testing Procedure

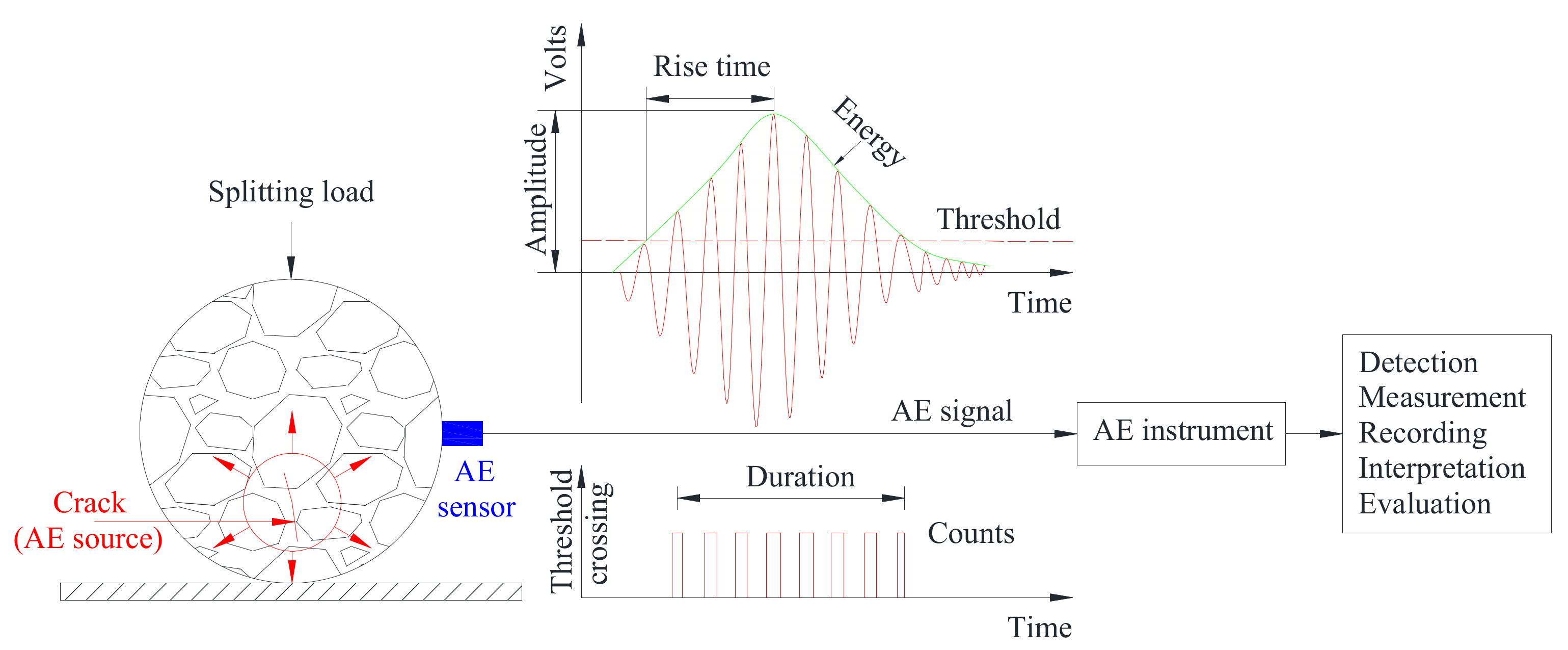

2.4. AE Parameters

3. Results and Discussions

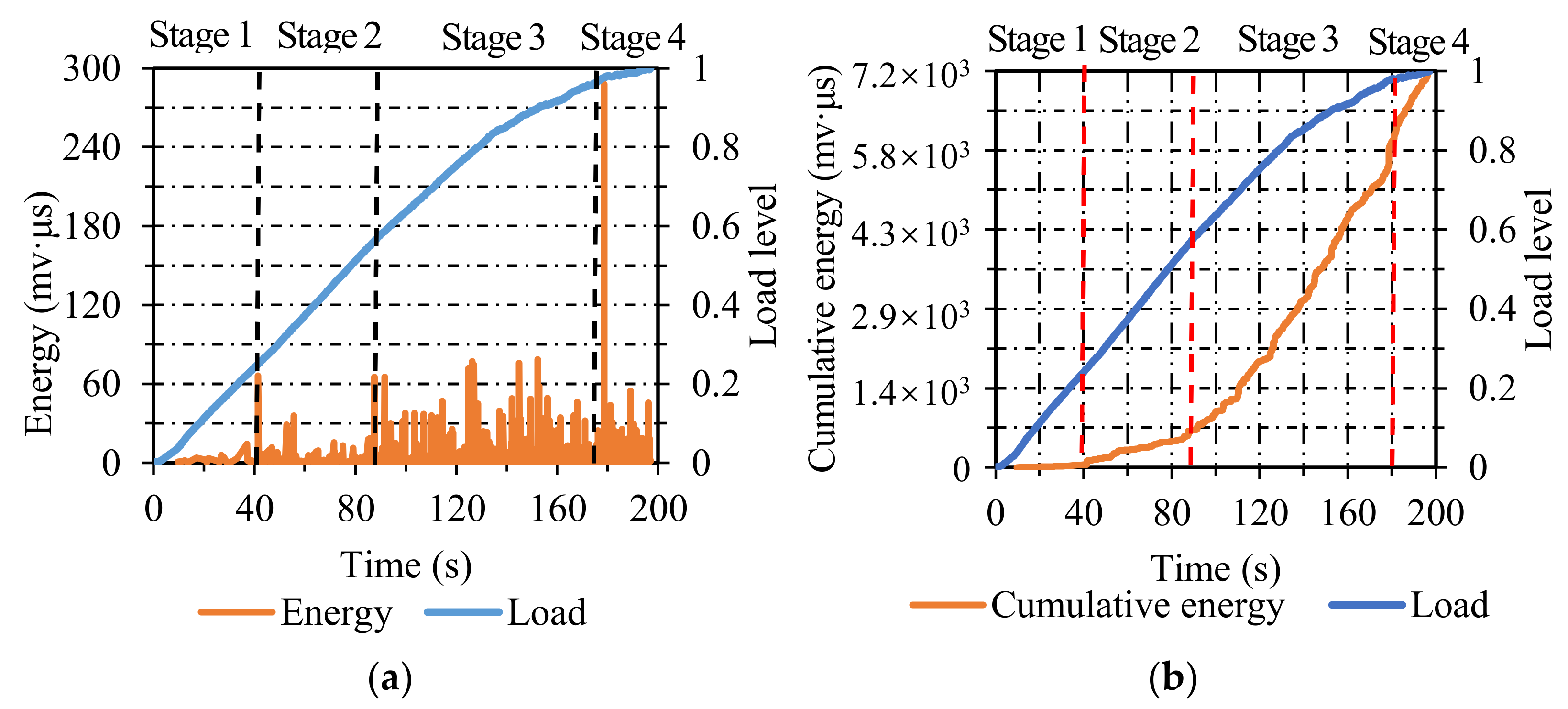

3.1. Effect of Gradation on Fracture Characteristics of Asphalt Concrete

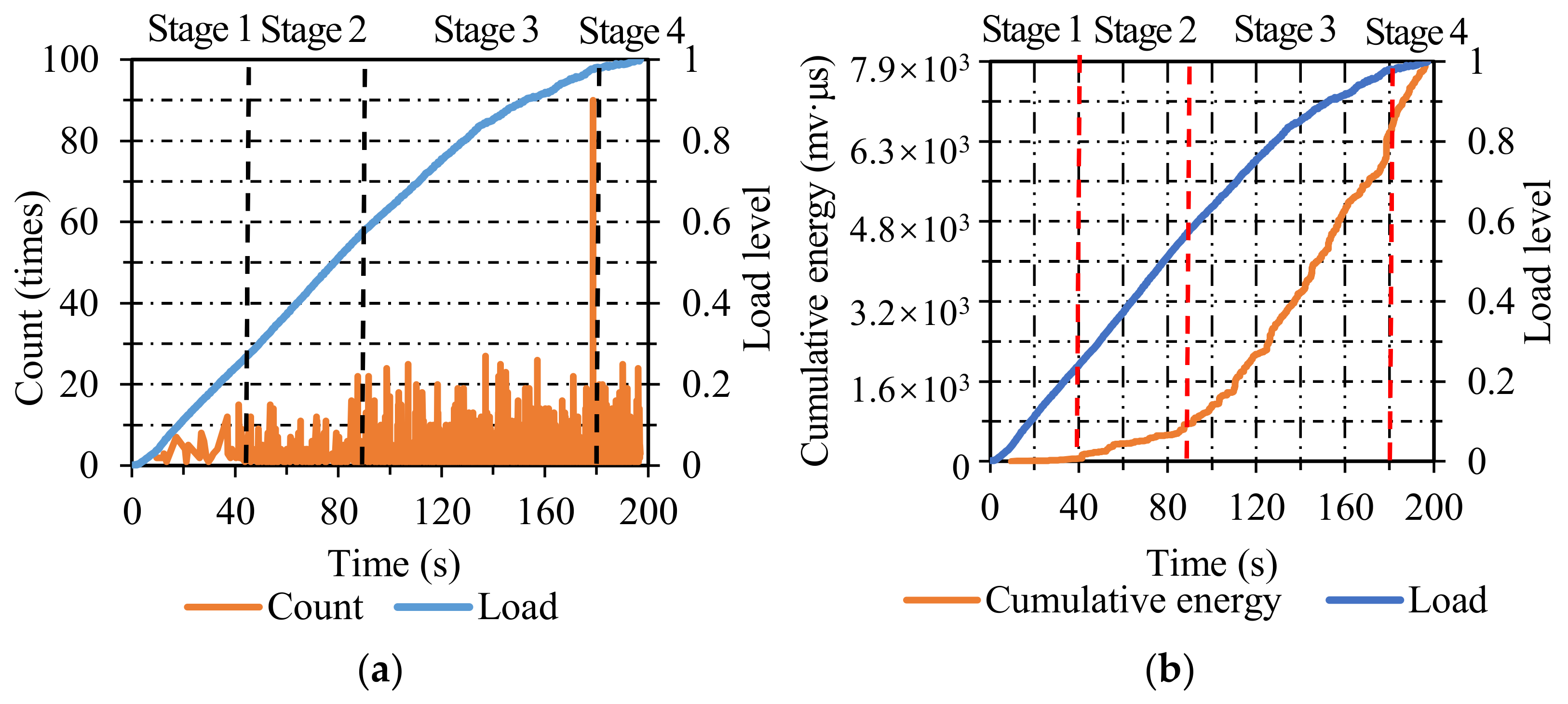

3.1.1. Dense-Graded Asphalt Concrete (AC)

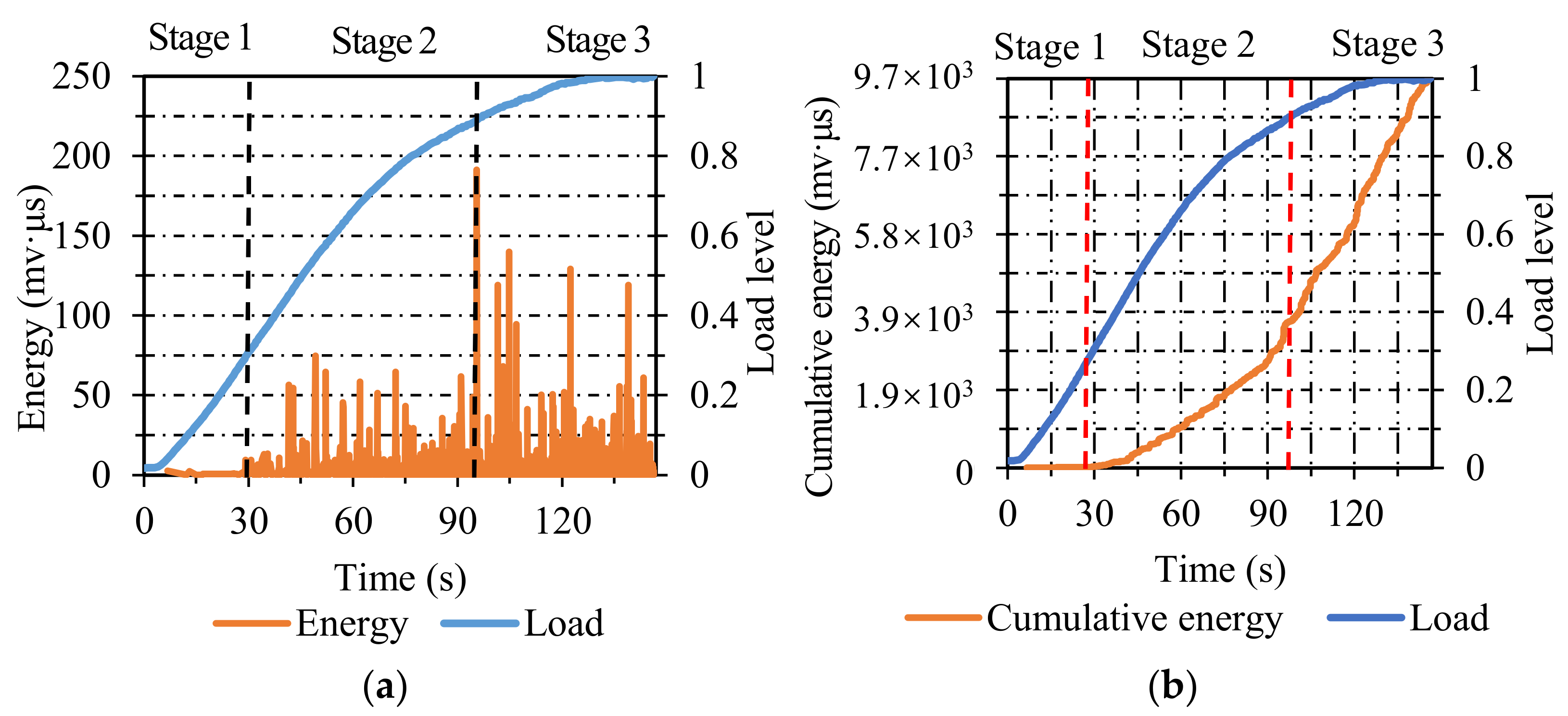

3.1.2. Stone Mastic Asphalt (SMA)

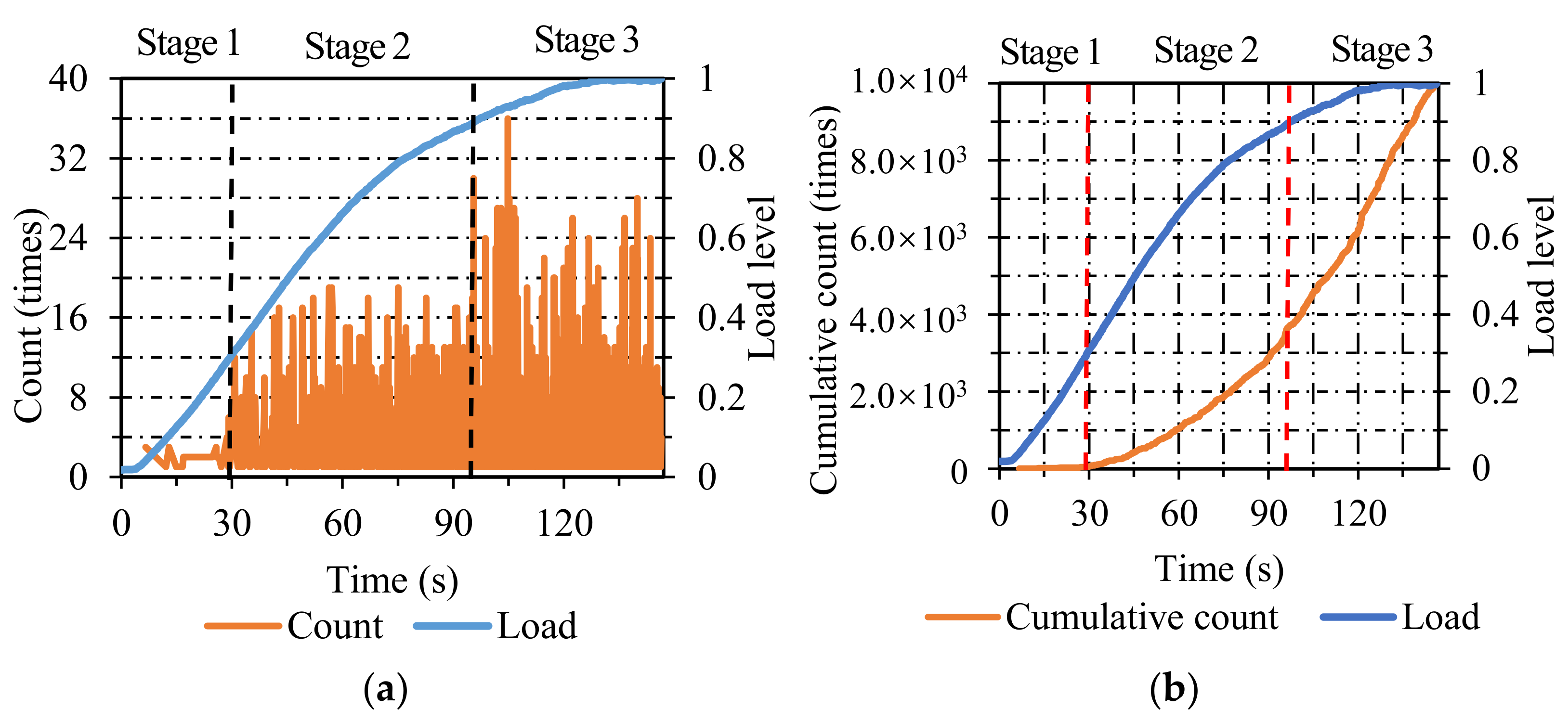

3.1.3. Open-Graded Friction Course (OGFC)

3.2. Effect of Testing Temperature on Fracture Characteristics of Asphalt Concrete

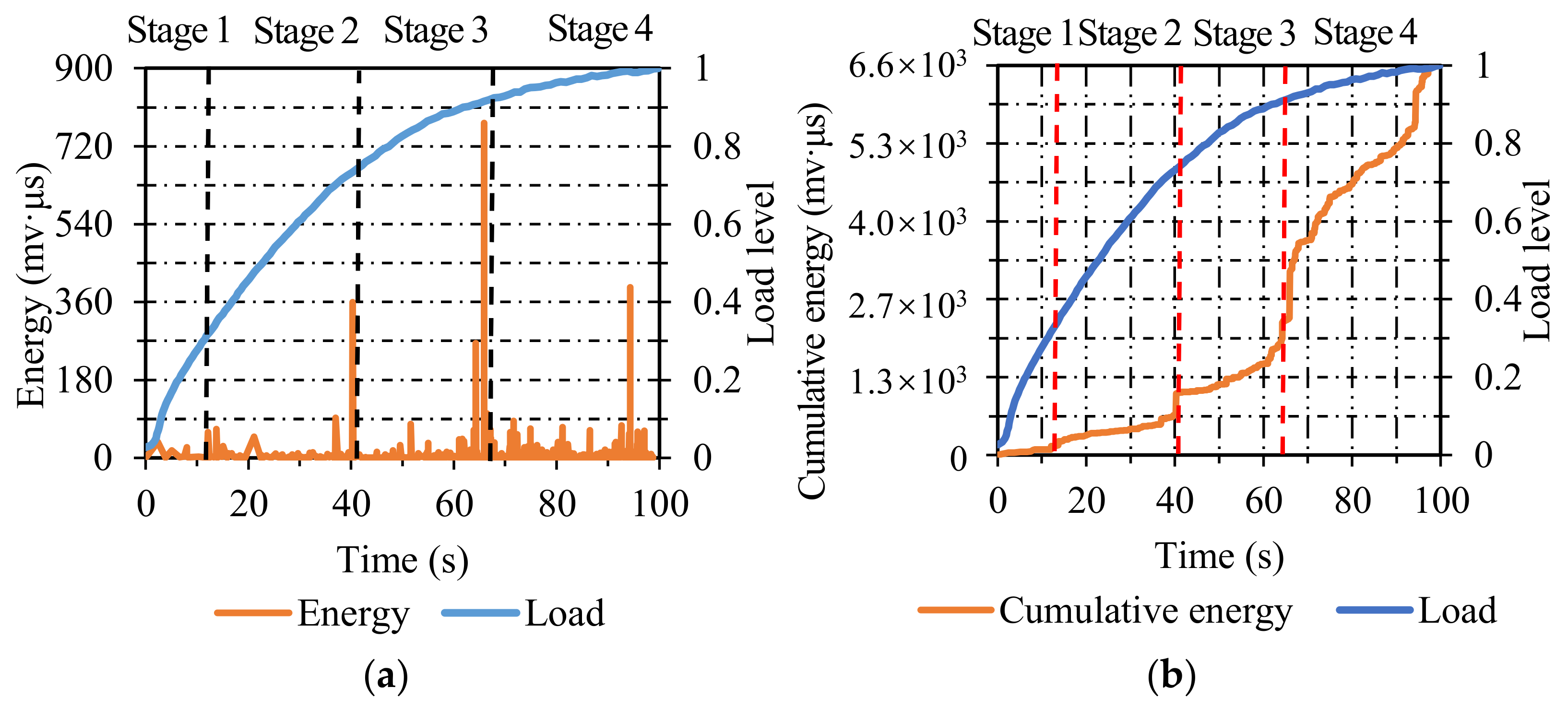

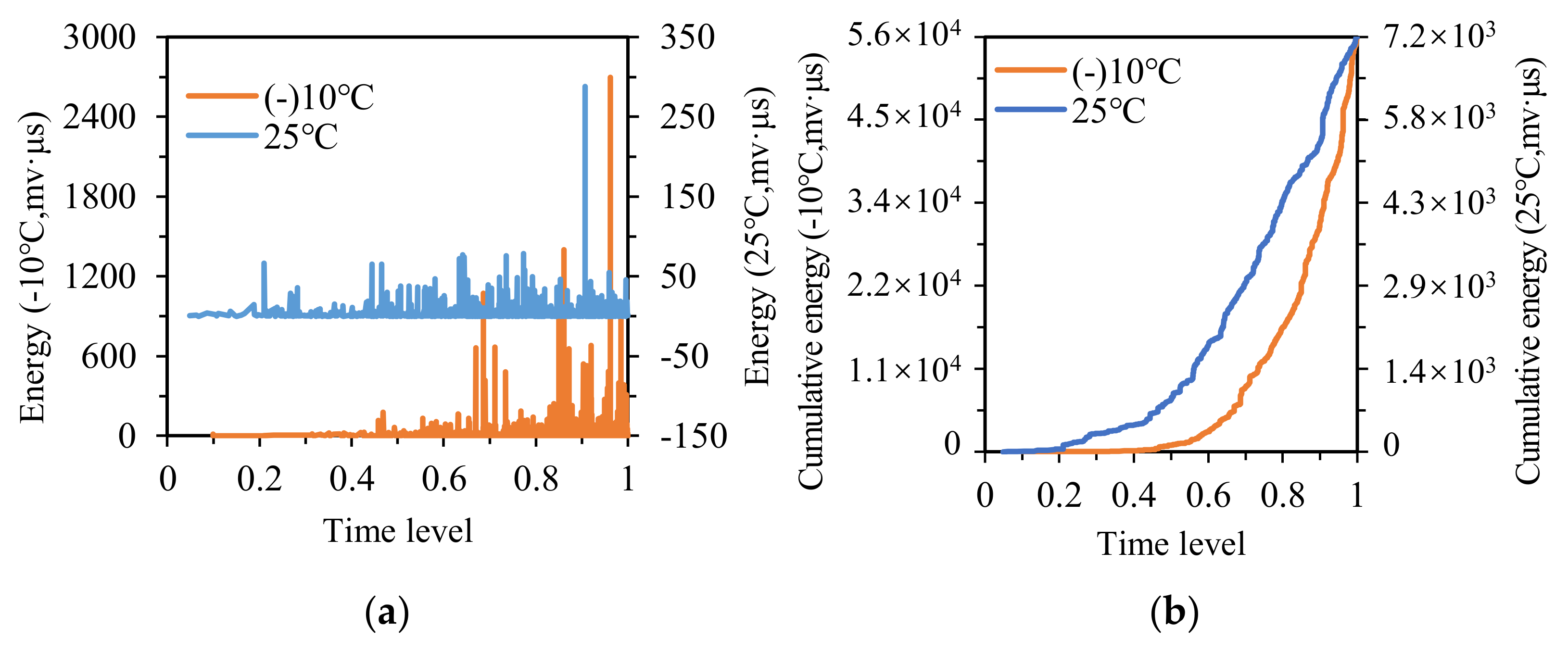

3.2.1. Dense-Graded Asphalt Concrete (AC)

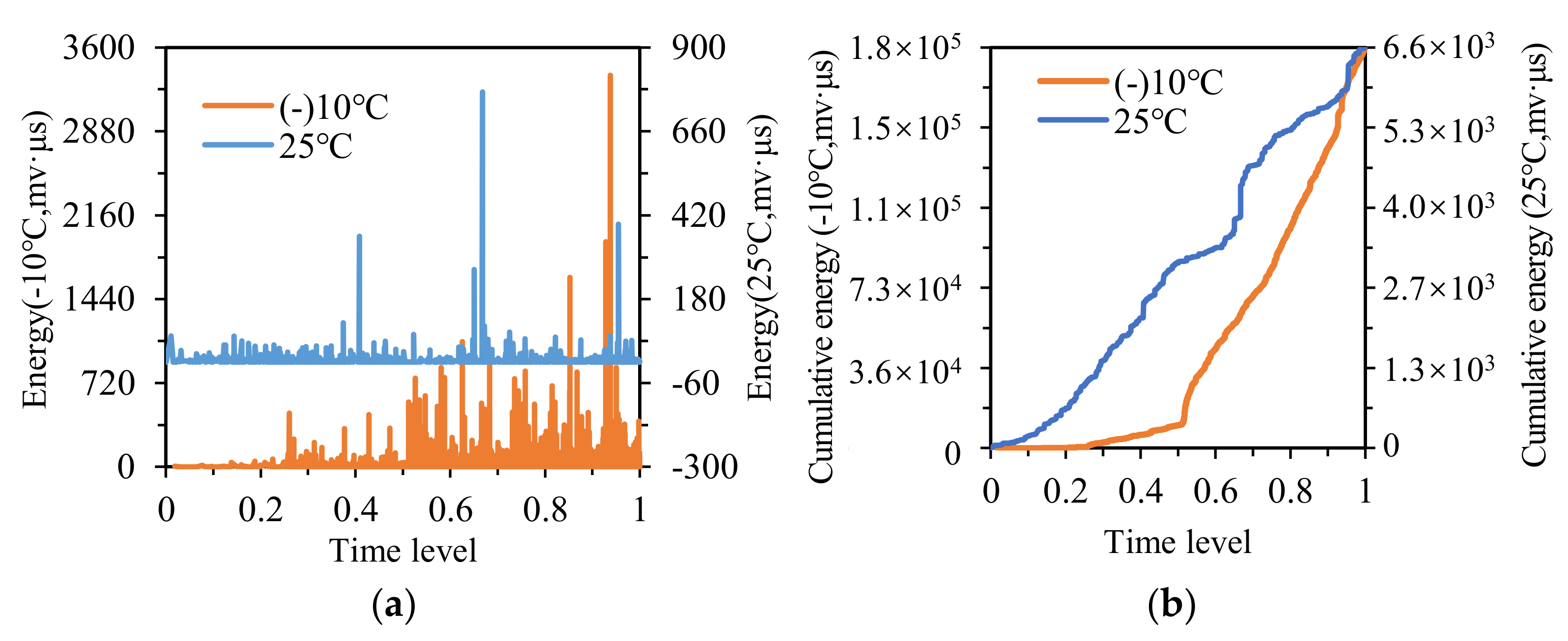

3.2.2. Stone Mastic Asphalt (SMA)

3.2.3. Open-Graded Friction Course (OGFC)

4. Conclusions

- Asphalt concrete with different aggregate gradations exhibited different fracture characteristics based on AE monitoring, and the comprehensive analysis of AE parameters and cumulative AE parameters can realize accurate identification of the damage process of asphalt concrete.

- The damage fracture of AC, SMA, and OGFC specimens can be divided into four, three, and four stages due to AE parameters, respectively. As for AC specimens, the fracture characteristics were manifested by the sudden fracture due to insufficient cohesion under critical load. The fracture process of SMA specimens was characterized by the stable propagation of cracks owing to the stable skeleton-dense structure. Due to the high voids content, the fracture characteristics of OGFC specimens were represented as the local failure caused by the stress concentration related to the skeleton-void structure throughout the IDT process.

- The energy and cumulative energy of AC, SMA, and OGFC specimens varied with temperature, and the SMA specimens displayed the best overall performance among these three kinds of asphalt concrete in terms of the distribution of AE parameters at different temperatures.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, J.; Zhou, Z.; Wu, J.; Hou, S.; Liu, M. Field and Laboratory Measurement of Albedo and Heat Transfer for Pavement Materials. Constr. Build. Mater. 2019, 202, 46–57. [Google Scholar] [CrossRef]

- Raschia, S.; Mignini, C.; Graziani, A.; Carter, A.; Perraton, D.; Vaillancourt, M. Effect of Gradation on Volumetric and Mechanical Properties of Cold Recycled Mixtures (CRM). Road Mater. Pavement Des. 2019, 20, S740–S754. [Google Scholar] [CrossRef]

- Silva, J.D.; Rodrigues, J.K.; de Carvalho, M.W.; Lucena, L.C.; Cavalcante, E.H. Mechanical Performance of Asphalt Mixtures Using Polymer-Micronized PET-Modified Binder. Road Mater. Pavement Des. 2018, 19, 1001–1009. [Google Scholar] [CrossRef]

- Polaczyk, P.; Polaczyk, P.; Ma, Y.; Xiao, R.; Hu, W.; Jiang, X.; Huang, B. Characterization of Aggregate Interlocking in Hot Mix Asphalt by Mechanistic Performance Tests. Road Mater. Pavement Des. 2021, 22, S498–S513. [Google Scholar] [CrossRef]

- Saha, G.; Biligiri, K.P. Novel Procedural Pragmatics of Dynamic Semi-Circular Bending Test for Fatigue Evaluation of Asphalt Mixtures. Road Mater. Pavement Des. 2019, 20, 454–461. [Google Scholar] [CrossRef]

- Yang, D.; Karimi, H.R.; Aliha, M.R.M. Comparison of Testing Method Effects on Cracking Resistance of Asphalt Concrete Mixtures. Appl. Sci. 2021, 11, 5094. [Google Scholar] [CrossRef]

- Zhu, Y.; Dave, E.V.; Rahbar-Rastegar, R.; Daniel, J.S.; Zofka, A. Comprehensive Evaluation of Low-Temperature Fracture Indices for Asphalt Mixtures. Road Mater. Pavement Des. 2017, 18, 467–490. [Google Scholar] [CrossRef]

- Gholizadeh, S.; Leman, Z.; Baharudin, B.T.H.T. A Review of the Application of Acoustic Emission Technique in Engineering. Struct. Eng. Mech. 2015, 54, 1075–1095. [Google Scholar] [CrossRef]

- Wu, C.; Gong, F.; Luo, Y. A New Quantitative Method to Identify the Crack Damage Stress of Rock Using AE Detection Parameters. Bull. Eng. Geol. Environ. 2021, 80, 519–531. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhang, Y.; Hussein, H.H.; Chen, G. Flexural Strengthening of Reinforced Concrete Beams or Slabs Using Ultra-High Performance Concrete (UHPC): A State of the Art Review. Eng. Struct. 2020, 205, 110035. [Google Scholar] [CrossRef]

- Chou, H.Y.; Mouritz, A.P.; Bannister, M.K.; Bunsell, A.R. Acoustic Emission Analysis of Composite Pressure Vessels under Constant and Cyclic Pressure. Compos. Part A Appl. Sci. Manuf. 2015, 70, 111–120. [Google Scholar] [CrossRef]

- Behnia, B.; Buttlar, W.; Reis, H. Evaluation of Low-Temperature Cracking Performance of Asphalt Pavements Using Acoustic Emission: A Review. Appl. Sci. 2018, 8, 306. [Google Scholar] [CrossRef] [Green Version]

- Arnold, J.W.; Behnia, B.; McGovern, M.E.; Hill, B.; Buttlar, W.G.; Reis, H. Quantitative Evaluation of Low-Temperature Performance of Sustainable Asphalt Pavements Containing Recycled Asphalt Shingles (RAS). Constr. Build. Mater. 2014, 58, 1–8. [Google Scholar] [CrossRef]

- Jiao, Y.; Liu, S.; Fu, L.; Shan, W. Fracture Monitoring of SBS and Crumb Rubber Modified Porous Asphalt Mixtures under Compression and Splitting Testing Using Acoustic Emission Technique. J. Mater. Civ. Eng. 2019, 31, 04019063. [Google Scholar] [CrossRef]

- Jiao, Y.; Zhang, Y.; Zhang, M.; Fu, L.; Zhang, L. Investigation of Fracture Modes in Pervious Asphalt under Splitting and Compression Based on Acoustic Emission Monitoring. Eng. Fract. Mech. 2019, 211, 209–220. [Google Scholar] [CrossRef]

- Jiao, Y.; Fu, L.; Shan, W.; Liu, S. Damage Fracture Characterization of Pervious Asphalt Considering Temperature Effect Based on Acoustic Emission Parameters. Eng. Fract. Mech. 2019, 210, 147–159. [Google Scholar] [CrossRef]

- Qiu, X.; Xu, J.; Xiao, S.; Yang, Q. Acoustic Emission Parameters and Waveforms Characteristics of Fracture Failure Process of Asphalt Mixtures. Constr. Build. Mater. 2019, 215, 135–147. [Google Scholar] [CrossRef]

- McGovern, M.E.; Behnia, B.; Buttlar, W.G.; Reis, H. Concrete Testing: Characterisation of Oxidative Ageing in Asphalt Concrete—Part 1: Ultrasonic Velocity and Attenuation Measurements and Acoustic Emission Response under Thermal Cooling. Insight 2013, 55, 596–604. [Google Scholar] [CrossRef]

- Sun, Z.; Behnia, B.; Buttlar, W.G.; Reis, H. Acoustic Emission Quantitative Evaluation of Rejuvenators to Restore Embrittlement Temperatures to Oxidized Asphalt Mixtures. Constr. Build. Mater. 2016, 126, 913–923. [Google Scholar] [CrossRef]

- Li, X.; Marasteanu, M.O. Investigation of Low Temperature Cracking in Asphalt Mixtures by Acoustic Emission. Road Mater. Pavement Des. 2006, 7, 491–512. [Google Scholar] [CrossRef]

- Seo, Y.; Kim, Y.R. Using Acoustic Emission to Monitor Fatigue Damage and Healing in Asphalt Concrete. KSCE J. Civ. Eng. 2008, 12, 237–243. [Google Scholar] [CrossRef]

- Velasquez, R.; Turos, M.; Moon, K.H.; Zanko, L.; Marasteanu, M. Using Recycled Taconite as Alternative Aggregate in Asphalt Pavements. Constr. Build. Mater. 2009, 23, 3070–3078. [Google Scholar] [CrossRef]

- Behnia, B.; Dave, E.V.; Ahmed, S.; Buttlar, W.G.; Reis, H. Effects of Recycled Asphalt Pavement Amounts on Low-Temperature Cracking Performance of Asphalt Mixtures Using Acoustic Emissions. Transp. Res. Rec. 2011, 2208, 64–71. [Google Scholar] [CrossRef]

- Behnia, B.; Buttlar, W.G.; Reis, H. Cooling Cycle Effects on Low Temperature Cracking Characteristics of Asphalt Concrete Mixture. Mater. Struct. 2014, 47, 1359–1371. [Google Scholar] [CrossRef]

- Hill, B.; Oldham, D.; Behnia, B.; Fini, E.H.; Buttlar, W.G.; Reis, H. Evaluation of Low Temperature Viscoelastic Properties and Fracture Behavior of Bio-Asphalt Mixtures. Int. J. Pavement Eng. 2018, 19, 362–369. [Google Scholar] [CrossRef]

- Mahmoud, E.; Masad, E.; Nazarian, S. Discrete Element Analysis of the Influences of Aggregate Properties and Internal Structure on Fracture in Asphalt Mixtures. J. Mater. Civ. Eng. 2010, 22, 10–20. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Liu, H.; Wang, P.; Pei, J.; Bao, D.; Jin, L. Evaluation of Aggregate Gradation and Distributing Homogeneity Based on the Images of Asphalt Mixture. Road Mater. Pavement Des. 2017, 18, 119–129. [Google Scholar] [CrossRef]

- Ministry of Transport of the People’s Republic of China. Test Methods of Aggregate for Highway Engineering (JTG E42-2005); Ministry of Transport of the People’s Republic of China: Beijing, China, 2005.

- Ministry of Transport of the People’s Republic of China. Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering (JTG E20-2011); Ministry of Transport of the People’s Republic of China: Beijing, China, 2011.

- Ministry of Transport of the People’s Republic of China. Technical Specification for Construction of Highway Asphalt Pavements (JTG F 40-2004); Ministry of Transport of the People’s Republic of China: Beijing, China, 2004.

- ASTM. Standard Test Method for Indirect Tensile (IDT) Strength of Asphalt Mixtures; ASTM D-6931: West Conshohocken, PA, USA, 2003. [Google Scholar]

| Items | Coarse Aggregate | Fine Aggregate | Filler | Technical Criterion | Method |

|---|---|---|---|---|---|

| Crushing value (%) | 14.4 | - | - | ≤26 | T0316 |

| Los Angeles abrasion loss (%) | 18.6 | - | - | ≤28 | T0317 |

| Apparent specific gravity (%) | 3.21 | 2.95 | 2.73 | ≥2.5 | T0304 |

| Sand equivalent (%) | - | 82 | - | ≥60 | T0334 |

| Plasticity index (%) | -- | - | 2.8 | ≤4.0 | T0354 |

| Items | MA | Technical Criterion | SBS-MA | Technical Criterion | Method |

|---|---|---|---|---|---|

| Penetration (25 °C, 0.1 mm) | 72 | 60–80 | 64 | 60–80 | T0604 |

| Softening point (°C) | 47.5 | ≥45 | 64.2 | ≥55 | T0606 |

| Ductility (15 °C, cm) | 145 | ≥45 | - | - | T0605 |

| Ductility (5 °C, cm) | - | - | 34.5 | ≥30 | T0605 |

| Density (g/cm3) | 1.036 | - | 1.065 | - | T0603 |

| Flashing point (°C) | 275 | ≥260 | 264 | ≥230 | T0611 |

| Items | AC-13 | Technical Criterion | SMA-13 | Technical Criterion | OGFC-13 | Technical Criterion | Method |

|---|---|---|---|---|---|---|---|

| Air voids (%) | 3.9 | 3–5 | 3.3 | 3–4 | 20.8 | 18–25 | T0705 |

| Voids in mineral aggregates (%) | 13.56 | ≥13 | 19.54 | ≥17 | 31.73 | - | T0705 |

| Voids filled with asphalt (%) | 71.23 | 65–75 | 83.11 | 75–85 | 27.83 | - | T0705 |

| Theoretical maximum specific density | 2.522 | - | 2.551 | - | 2.602 | - | T0705 |

| Bulk specific gravity | 2.424 | - | 2.467 | - | 2.061 | - | T0705 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fu, L.; Jiao, Y.; Chen, X.; Zhang, M. Evaluation Approach of Fracture Behavior for Asphalt Concrete with Different Aggregate Gradations and Testing Temperatures Using Acoustic Emission Monitoring. Materials 2021, 14, 4390. https://doi.org/10.3390/ma14164390

Fu L, Jiao Y, Chen X, Zhang M. Evaluation Approach of Fracture Behavior for Asphalt Concrete with Different Aggregate Gradations and Testing Temperatures Using Acoustic Emission Monitoring. Materials. 2021; 14(16):4390. https://doi.org/10.3390/ma14164390

Chicago/Turabian StyleFu, Liuxu, Yubo Jiao, Xianhua Chen, and Mengsu Zhang. 2021. "Evaluation Approach of Fracture Behavior for Asphalt Concrete with Different Aggregate Gradations and Testing Temperatures Using Acoustic Emission Monitoring" Materials 14, no. 16: 4390. https://doi.org/10.3390/ma14164390

APA StyleFu, L., Jiao, Y., Chen, X., & Zhang, M. (2021). Evaluation Approach of Fracture Behavior for Asphalt Concrete with Different Aggregate Gradations and Testing Temperatures Using Acoustic Emission Monitoring. Materials, 14(16), 4390. https://doi.org/10.3390/ma14164390