Homogeneity and Viscoelastic Behaviour of Bitumen Film in Asphalt Mixtures Containing RAP

Abstract

:1. Introduction

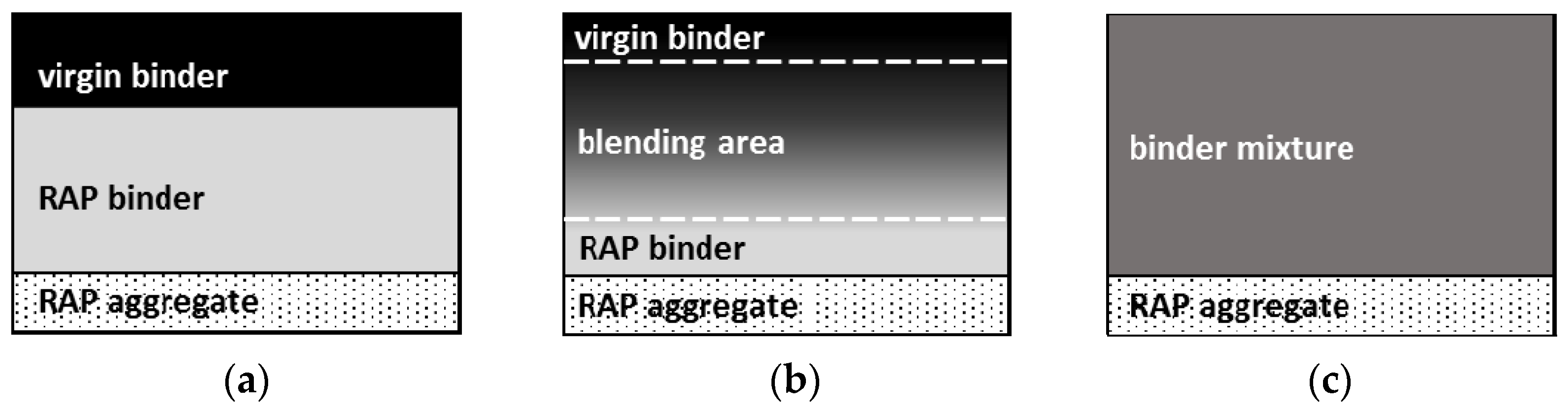

- I.

- Full blending—when the binder film is characterised by the same viscoelastic and chemical properties along its thickness;

- II.

- Partial blending—when the properties of the binder are different depending on the point in the binder film, but there is no strict interface between both binders;

- III.

- No blending—when virgin binder covers the RAP binder without blending and the RAP is then referred to as black aggregate or black rock.

2. Materials and Methods

2.1. Materials

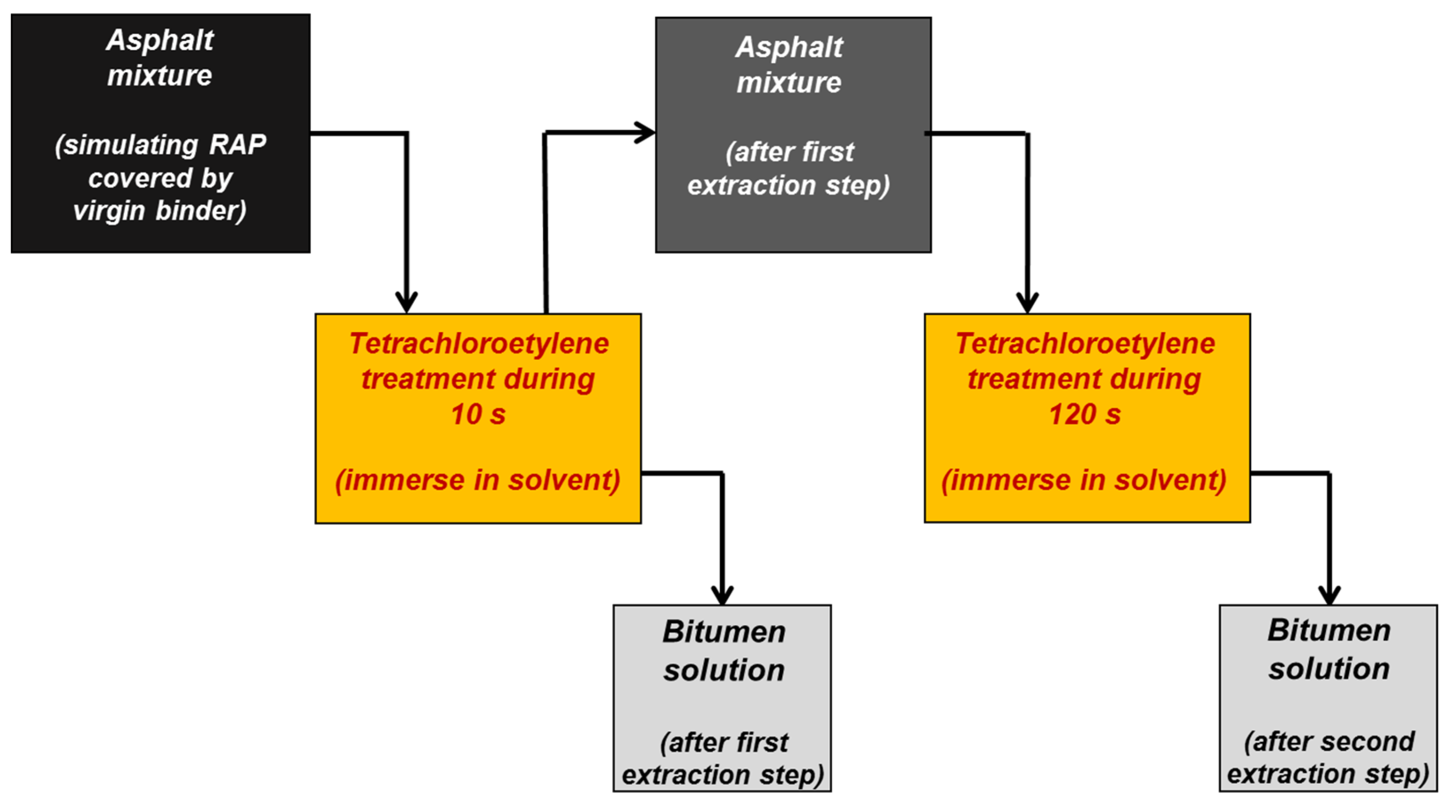

2.2. Staged Extraction Method

2.3. Rheological Tests

3. Results and Discussion

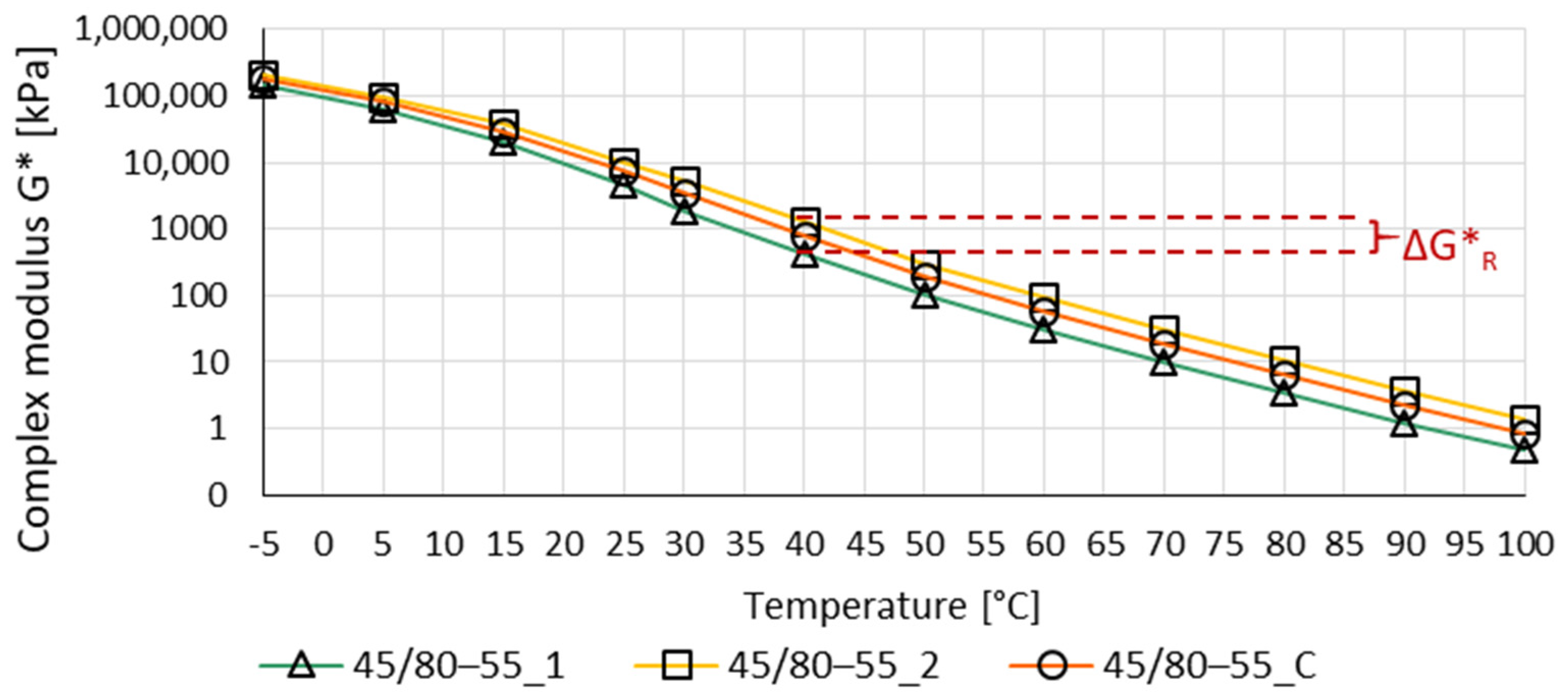

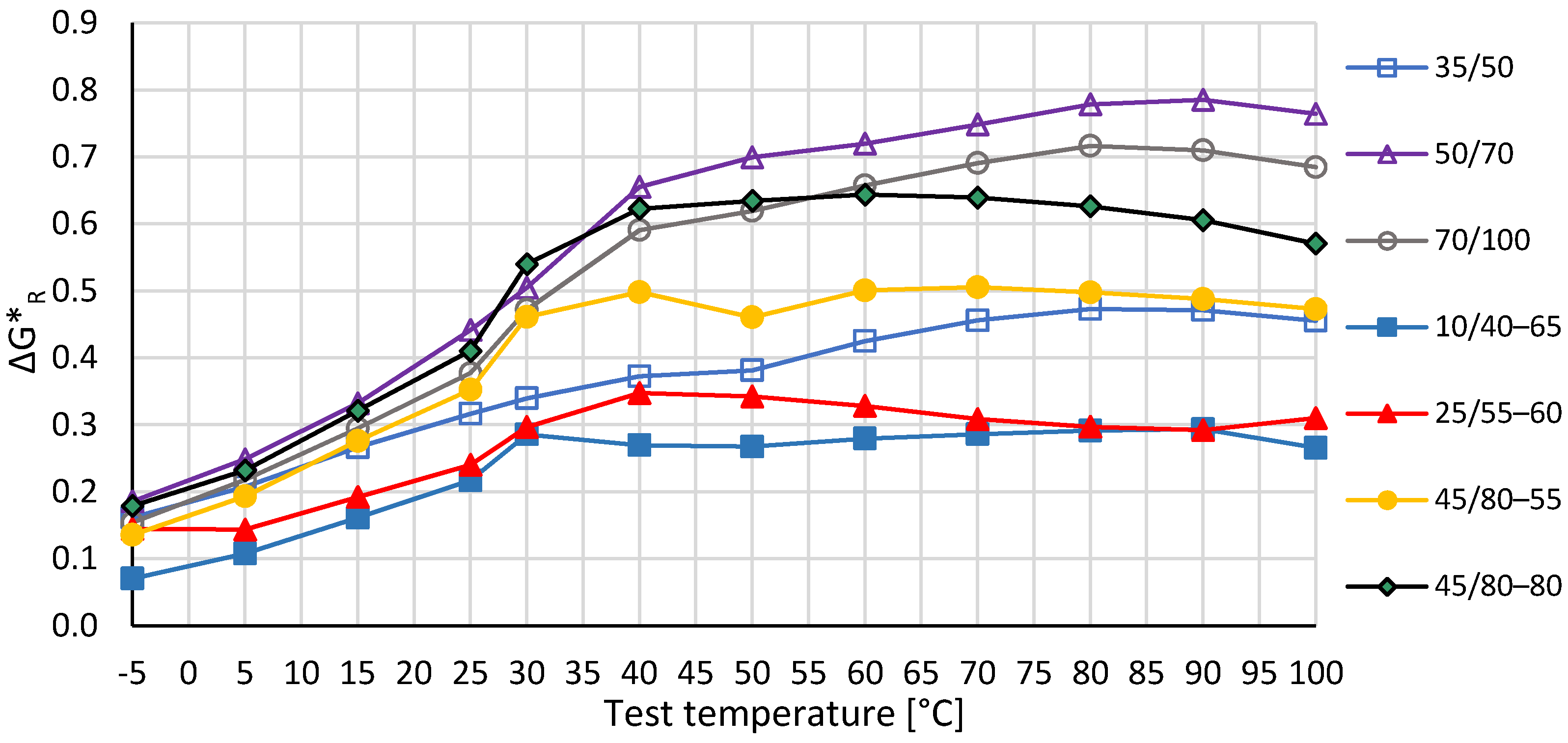

3.1. Complex Modulus and Phase Angle

3.2. Multiple Stress Creep Recovery Test—MSCR

4. Conclusions

- The internal layer of the bitumen film has properties similar to the binder-simulated RAP cluster, while the external layer has properties similar to fresh binder. The presented non-homogeneity of bitumen film proves no full blending of the binders is included in it.

- The ΔG* index allows for assessment of homogeneity of bitumen film based on the G* complex modulus from DSR tests. The binders from different bitumen layers should be extracted step by step. Thus, this indirectly allows us to assess the degree of blending of fresh binder and binder from RAP.

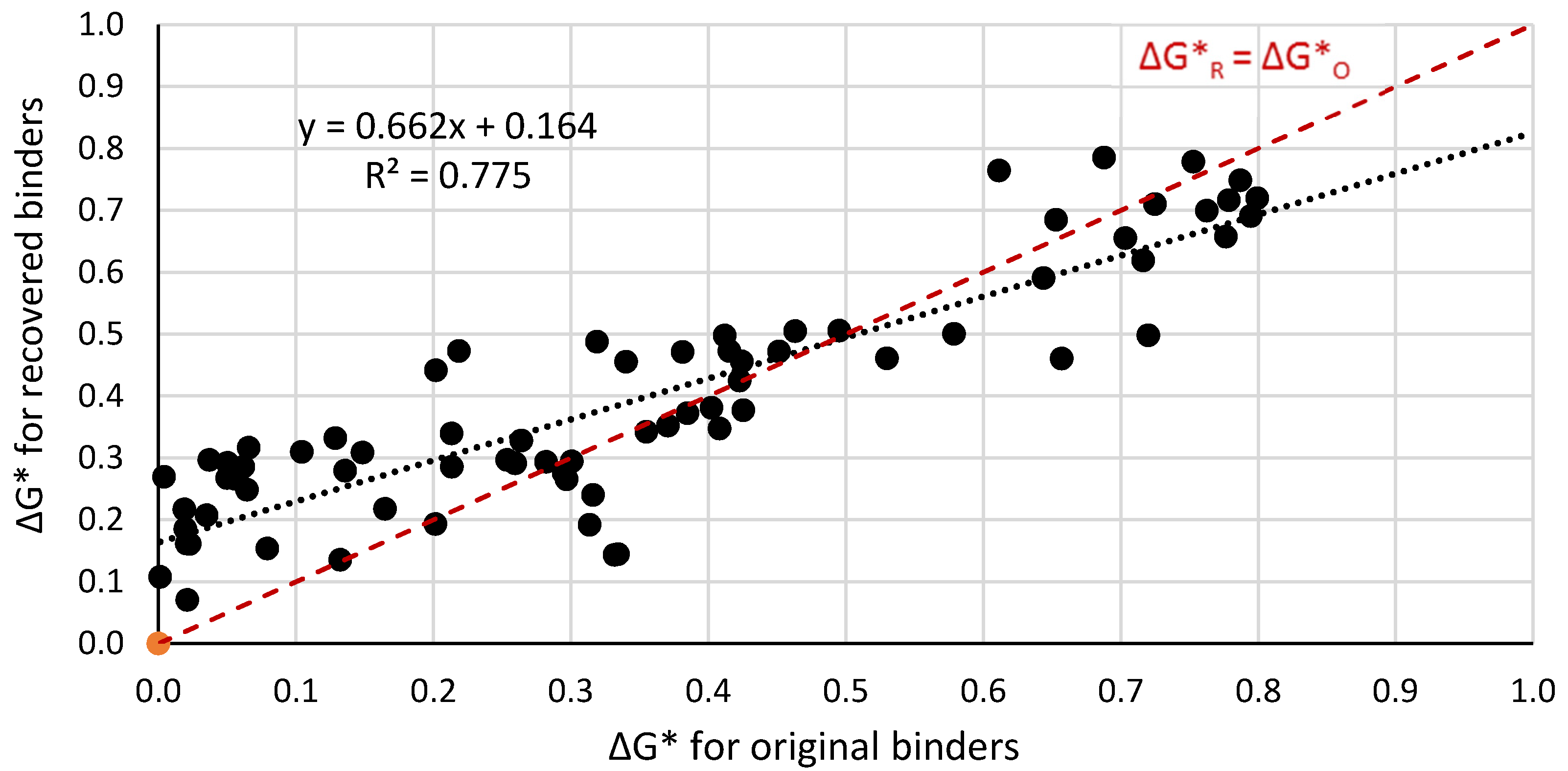

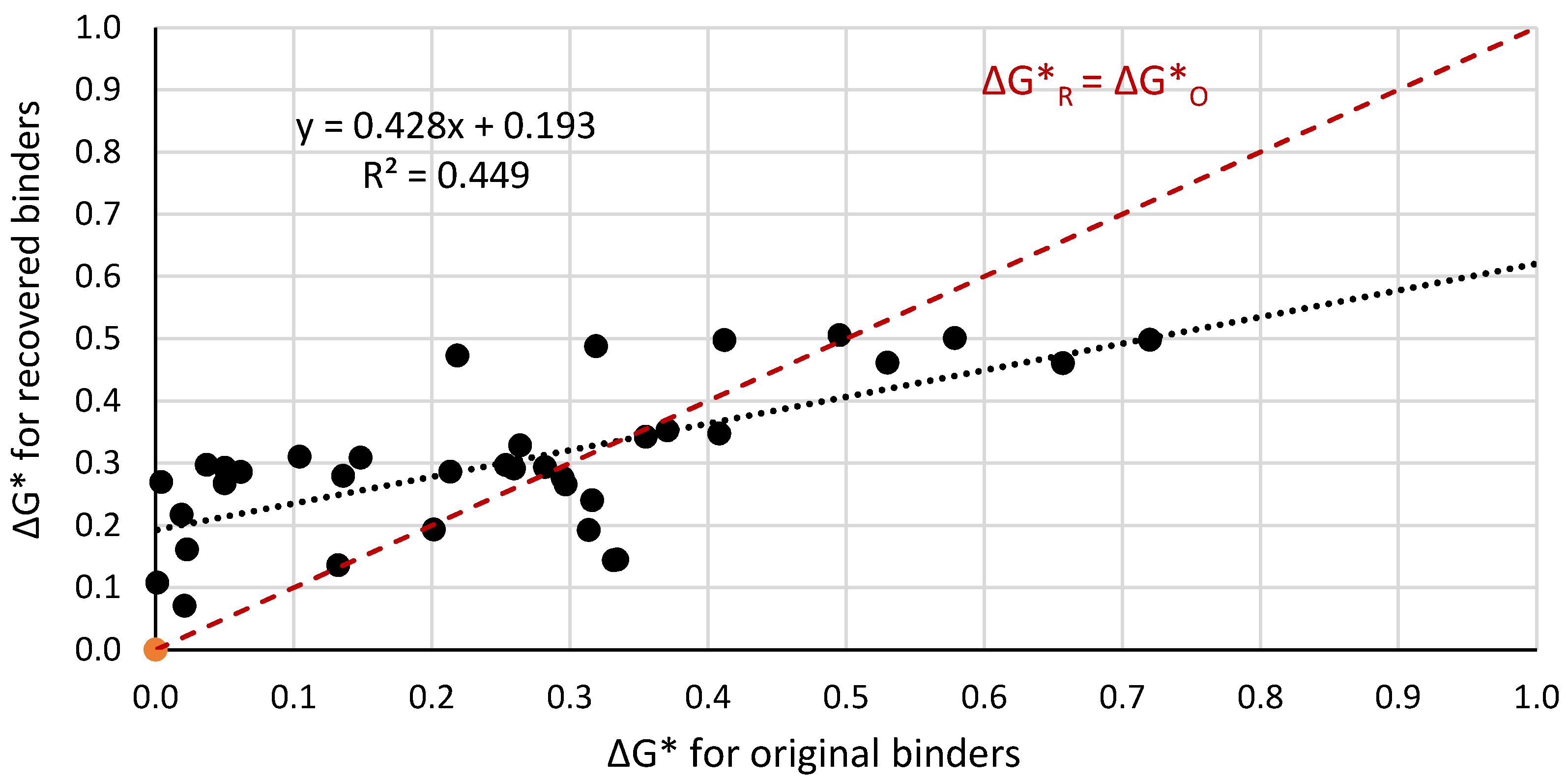

- In medium and high operating temperatures, the differences of viscoelastic properties along the thickness of the bitumen film increase together with an increase of the differences of properties of binders subjected to mixing. Statistical regression was set between the differences of complex modulus of the binders subjected to mixing and differences of complex modulus of binders come from the internal and the external layers of the bitumen film layers comprised of those binders.

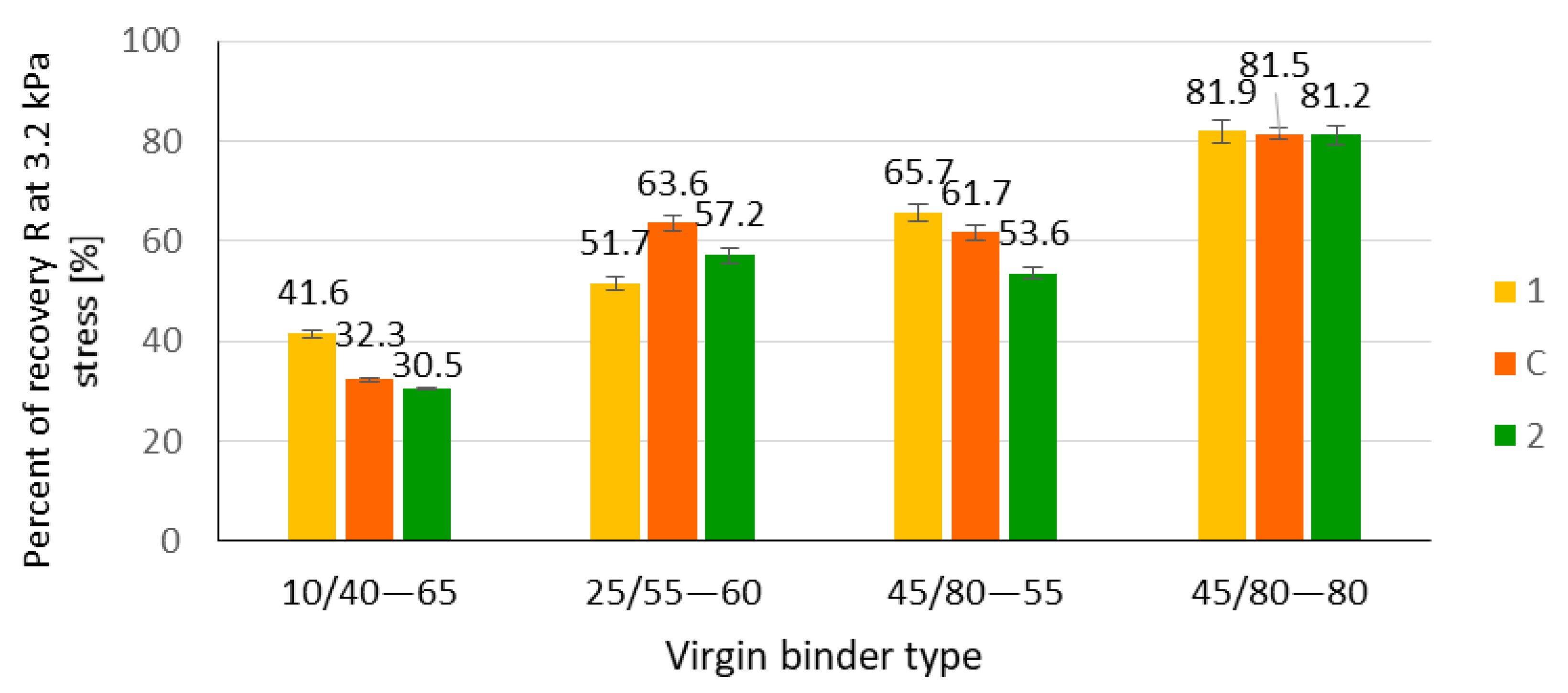

- The MSCR test analysis allowed us to recognise that the bitumen film in an asphalt mixture system varies in terms of elastic recovery and creep compliance properties, when polymer-modified bitumens are used.

- The staged extraction method proposed in this work can also be used to detect the presence of RAP in asphalt mixture. Currently, RAP in asphalt mixtures is mainly detected on the basis of petrographic analysis of the mineral aggregates. However, such analysis could be ineffective if RAP and virgin aggregates were characterised by the same petrographic stock. In such a case, binder properties analysis is the only option to detect RAP. Because of the proven non-homogeneity of the bitumen film in an asphalt mixture system, the presented method can be an effective tool to detect whether the asphalt mixture contains RAP.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Huang, B.; Li, G.; Vukosavljevic, D.; Shu, X.; Egan, B.K. Laboratory investigation of mixing hot-mix asphalt with reclaimed asphalt pavement. Transp. Res. Rec. 2005, 1929, 37–45. [Google Scholar] [CrossRef]

- Shirodkar, P.; Mehta, Y.; Nolan, A.; Sonpal, K.; Norton, A.; Tomlinson, C.; Dubois, E.; Sullivan, P.; Sauber, R. A study to determine the degree of partial blending of reclaimed asphalt pavement (RAP) binder for high RAP hot mix asphalt. Constr. Build. Mater. 2011, 25, 150–155. [Google Scholar] [CrossRef]

- Eddhahak-Ouni, A.; Dony, A.; Colin, J.; Mendez, S.; Navaro, J.; Drouadaine, I.; Bruneau, D. Experimental investigation of the homogeneity of the blended binder of a high rate recycled asphalt. Road Mater. Pavement Des. 2012, 13, 566–575. [Google Scholar] [CrossRef]

- Presti, D.L.; Vasconcelos, K.; Orešković, M.; Pires, G.M.; Bressi, S. On the degree of binder activity of reclaimed asphalt and degree of blending with recycling agents. Road Mater. Pavement Des. 2020, 21, 2071–2090. [Google Scholar] [CrossRef]

- Mangiafico, S.; Sauzéat, C.; Di Benedetto, H. Comparison of different blending combinations of virgin and RAP-extracted binder: Rheological simulations and statistical analysis. Constr. Build. Mater. 2019, 197, 454–463. [Google Scholar] [CrossRef]

- Orešković, M.; Pires, G.M.; Bressi, S.; Vasconcelos, K.; Presti, D.L. Quantitative assessment of the parameters linked to the blending between reclaimed asphalt binder and recycling agent: A literature review. Constr. Build. Mater. 2020, 234, 117323. [Google Scholar] [CrossRef]

- Rad, F.Y. Estimating Blending Level of Fresh and RAP Binders in Recycled Hot Mix Asphalt; University of Wisconsin Madison: Madison, WI, USA, 2013. [Google Scholar]

- Newcomb, D.E.; Epps, J.A.; Zhou, F. Use of RAP & RAS in High Binder Replacement Asphalt Mixtures: A Synthesis; NAPA: Lanham, MD, USA, 2016. [Google Scholar]

- Carpenter, S.H.; Wolosick, J.R. Modifier influence in the characterization of hot-mix recycled material. Transp. Res. Rec. 1980, 777, 15–22. [Google Scholar]

- Noureldin, A.S.; Wood, L.E. Rejuvenator diffusion in binder film for hot-mix recycled asphalt pavement. Transp. Res. Rec. 1987, 1115, 51–61. [Google Scholar]

- Bowers, B.F.; Huang, B.; Shu, X.; Miller, B.C. Investigation of Reclaimed Asphalt Pavement blending efficiency through GPC and FTIR. Constr. Build. Mater. 2014, 50, 517–523. [Google Scholar] [CrossRef]

- Maciejewski, K.; Chomicz-Kowalska, A. Foaming Performance and FTIR Spectrometric Analysis of Foamed Bituminous Binders Intended for Surface Courses. Materials 2021, 14, 2055. [Google Scholar] [CrossRef] [PubMed]

- Abdalfattah, I.A.; Mogawer, W.S.; Stuart, K. Quantification of the degree of blending in hot-mix asphalt (HMA) with reclaimed asphalt pavement (RAP) using Energy Dispersive X-Ray Spectroscopy (EDX) analysis. J. Clean. Prod. 2021, 294, 126261. [Google Scholar] [CrossRef]

- Zou, G.; Zhang, J.; Li, Y.; Lin, Z. Quantitative characterize binder blending and diffusion in recycled asphalt mixture: An environmental-friendly solution using wooden cube and 3D fluorescence image technology. J. Clean. Prod. 2021, 293, 126204. [Google Scholar] [CrossRef]

- Zhao, S.; Nahar, S.N.; Schmets, A.J.; Huang, B.; Shu, X.; Scarpas, T. Investigation on the microstructure of recycled asphalt shingle binder and its blending with virgin bitumen. Road Mater. Pavement Des. 2015, 16, 21–38. [Google Scholar] [CrossRef]

- Riccardi, C.; Carrión, A.J.D.B.; Presti, D.L.; Falchetto, A.C.; Losa, M.; Wistuba, M. A new procedure to determine the rheological properties of RAP binder and corresponding bituminous blends. Constr. Build. Mater. 2017, 154, 361–372. [Google Scholar] [CrossRef]

- Mohajeri, M.; Molenaar, A.A.; Van de Ven, M.F. Experimental study into the fundamental understanding of blending be-tween reclaimed asphalt binder and virgin bitumen using nanoindentation and nano-computed tomography. Road Mater. Pavement Des. 2014, 15, 372–384. [Google Scholar] [CrossRef]

- Liphardt, A.; Radziszewski, P.; Król, J. Metoda oceny mieszalności lepiszczy w mieszankach mineralno-asfaltowych z destruktem. J. Civ. Eng. Environ. Arch. 2016, XXXIII, 259–266. [Google Scholar] [CrossRef]

- Zhao, S.; Huang, B.; Shu, X. Investigation on binder homogeneity of RAP/RAS mixtures through staged extraction. Constr. Build. Mater. 2015, 82, 184–191. [Google Scholar] [CrossRef]

- Zhao, S.; Huang, B.; Shu, X.; Woods, M.E. Quantitative evaluation of blending and diffusion in high RAP and RAS mixtures. Mater. Des. 2016, 89, 1161–1170. [Google Scholar] [CrossRef]

- McDaniel, R.; Anderson, M.R. Recommended Use of Reclaimed Asphalt Pavement in the Superpave Mix Design Methods: Guidelines; TRB National Academies: Washington, DC, USA, 2001. [Google Scholar]

- Cooley, A.L.; Williams, K. Development of Laboratory Mix Design; Mississippi Department of Transportation: Mississippi, MI, USA, 2013.

- Shirodkar, P.; Mehta, Y.; Nolan, A.; Dubois, E.; Reger, D.; McCarthy, L. Development of blending chart for different degrees of blending of RAP binder and virgin binder. Resour. Conserv. Recycl. 2013, 73, 156–161. [Google Scholar] [CrossRef]

- Milad, Z.A.; Walaa, S.M.; Nader, T. Local calibration of the Hirsch model to determine the degree of blending between aged and virgin asphalt binders. Road Mater. Pavement Des. 2021, 1–19. [Google Scholar] [CrossRef]

- Stimilli, A.; Virgili, A.; Canestrari, F. New method to estimate the “re-activated” binder amount in recycled hot-mix asphalt. Road Mater. Pavement Des. 2015, 16, 442–459. [Google Scholar] [CrossRef]

- Sreeram, A.; Leng, Z.; Zhang, Y.; Padhan, R.K. Evaluation of RAP binder mobilisation and blending efficiency in bituminous mixtures: An approach using ATR-FTIR and artificial aggregate. Constr. Build. Mater. 2018, 179, 245–253. [Google Scholar] [CrossRef]

- Pires, G.M.; Presti, D.L.; Airey, G.D. A practical approach to estimate the degree of binder activity of reclaimed asphalt materials. Road Mater. Pavement Des. 2021, 22, 1093–1116. [Google Scholar] [CrossRef]

- Liphardt, A.; Radziszewski, P.; Krol, J. Binder Blending Estimation Method in Hot Mix Asphalt with Reclaimed Asphalt. Procedia Eng. 2015, 111, 502–509. [Google Scholar] [CrossRef] [Green Version]

- Bańkowski, W.; Krol, J.; Gałązka, K.; Liphardt, A.; Horodecka, R. Design and verification of bituminous mixtures with the increased content of reclaimed asphalt pavement. IOP Conf. Ser. Mater. Sci. Eng. 2018, 356, 012009. [Google Scholar] [CrossRef] [Green Version]

- Król, J.; Matraszek, K. Właściwości wysokopemperaturowe lepiszczy asfaltowych w badaniu cyklicznego pełzania z odprężeniem (MSCR). Drogownictwo 2012, 10, 321–324. [Google Scholar]

| Binder Type | Penetration (0.1 mm) | Softening Point (R&B) [°C] | Dynamic Viscosity in Temperature: (Pa·s) | |||

|---|---|---|---|---|---|---|

| 90 °C | 110 °C | 135 °C | ||||

| Paving bitumen | 20/30 | 23 | 63.0 | 57.9 | 8.3 | 1.5 |

| 35/50 | 41 | 55.0 | 22.1 | 3.9 | 0.7 | |

| 50/70 | 62 | 49.0 | 10.9 | 2.1 | 0.5 | |

| 70/100 | 85 | 46.0 | 6.7 | 1.4 | 0.3 | |

| PMB | 10/40–65 | 33 | 72.0 | 106.6 | 11.9 | 2.0 |

| 25/55–60 | 31 | 69.6 | 126.6 | 14.2 | 2.2 | |

| 45/80–55 | 60 | 67.6 | 62.6 | 7.0 | 1.2 | |

| HIMA | 45/80–80 | 51 | 89.6 | 129.5 | 13.6 | 1.7 |

| Virgin Binder Type | Binder Film Layer | ΔG*O Index (kPa) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Temperature (°C) | |||||||||||||

| −5 | 5 | 15 | 25 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | ||

| 35/50 | original | 0.161 | 0.207 | 0.266 | 0.316 | 0.339 | 0.372 | 0.381 | 0.425 | 0.456 | 0.473 | 0.471 | 0.455 |

| recovery | 0.021 | 0.035 | 0.056 | 0.066 | 0.213 | 0.385 | 0.402 | 0.423 | 0.424 | 0.415 | 0.381 | 0.340 | |

| 50/70 | original | 0.185 | 0.248 | 0.332 | 0.441 | 0.505 | 0.655 | 0.699 | 0.720 | 0.748 | 0.778 | 0.785 | 0.764 |

| recovery | 0.019 | 0.064 | 0.129 | 0.202 | 0.463 | 0.703 | 0.763 | 0.799 | 0.787 | 0.753 | 0.688 | 0.611 | |

| 70/100 | original | 0.154 | 0.218 | 0.295 | 0.377 | 0.472 | 0.591 | 0.619 | 0.657 | 0.691 | 0.716 | 0.710 | 0.685 |

| recovery | 0.079 | 0.165 | 0.301 | 0.425 | 0.451 | 0.644 | 0.716 | 0.776 | 0.795 | 0.779 | 0.725 | 0.653 | |

| Virgin Binder Type | Binder Film Layer | ΔG*O Index (kPa) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Temperature (°C) | |||||||||||||

| −5 | 5 | 15 | 25 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | ||

| 10/40–65 | original | 0.070 | 0.108 | 0.161 | 0.217 | 0.286 | 0.269 | 0.267 | 0.279 | 0.286 | 0.291 | 0.293 | 0.266 |

| recovery | 0.021 | 0.001 | 0.023 | 0.019 | 0.062 | 0.004 | 0.050 | 0.136 | 0.213 | 0.259 | 0.282 | 0.297 | |

| 25/55–60 | original | 0.145 | 0.144 | 0.192 | 0.240 | 0.297 | 0.347 | 0.342 | 0.328 | 0.308 | 0.297 | 0.292 | 0.310 |

| recovery | 0.334 | 0.332 | 0.314 | 0.316 | 0.254 | 0.408 | 0.355 | 0.264 | 0.148 | 0.037 | 0.050 | 0.104 | |

| 45/80–55 | original | 0.136 | 0.193 | 0.276 | 0.352 | 0.461 | 0.498 | 0.460 | 0.501 | 0.505 | 0.498 | 0.488 | 0.473 |

| recovery | 0.132 | 0.202 | 0.295 | 0.371 | 0.530 | 0.720 | 0.657 | 0.579 | 0.495 | 0.412 | 0.319 | 0.219 | |

| 45/80–80 | original | 0.179 | 0.232 | 0.321 | 0.410 | 0.690 | 0.623 | 0.634 | 0.644 | 0.639 | 0.626 | 0.605 | 0.570 |

| recovery | 0.235 | 0.366 | 0.549 | 0.690 | 0.699 | 0.765 | 0.615 | 0.409 | 0.157 | 0.114 | 0.371 | 0.584 | |

| Virgin Binder Type | Layer | Complex Modulus G* (kPa) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Temperature (°C) | |||||||||||||

| −5 | 5 | 15 | 25 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | ||

| 35/50 | 1 | 270,000 | 117,640 | 42,000 | 10,580 | 4328 | 991 | 248 | 71 | 21 | 6.2 | 2.0 | 0.7 |

| 2 | 391,600 | 189,680 | 77,560 | 21,920 | 9455 | 2335 | 598 | 189 | 59 | 19 | 6.0 | 2.0 | |

| C | 296,800 | 136,200 | 51,760 | 14,672 | 6144 | 1536 | 415 | 132 | 41 | 13 | 4.2 | 1.5 | |

| 50/70 | 1 | 166,400 | 762,00 | 28,420 | 7514 | 3410 | 748 | 184 | 54 | 16 | 4.8 | 1.5 | 0.5 |

| 2 | 255,000 | 135,000 | 61,040 | 20,760 | 10,900 | 3384 | 922 | 284 | 89 | 29 | 9.2 | 3.0 | |

| C | 229,000 | 113,000 | 46,240 | 13,800 | 6562 | 1734 | 423 | 127 | 40 | 12 | 3.9 | 1.3 | |

| 70/100 | 1 | 167,200 | 73,300 | 26,220 | 6682 | 2686 | 584 | 140 | 39 | 11 | 3.2 | 1.0 | 0.4 |

| 2 | 238,200 | 121,000 | 51,660 | 15,920 | 7960 | 2274 | 584 | 178 | 54 | 17 | 5.3 | 1.7 | |

| C | 174,000 | 83,200 | 32,680 | 9348 | 4842 | 1172 | 275 | 84 | 25 | 7.6 | 2.3 | 0.8 | |

| Virgin Binder Type | Layer | Complex Modulus G* [kPa] | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Temperature [°C] | |||||||||||||

| −5 | 5 | 15 | 25 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | ||

| 10/40–65 | 1 | 175,000 | 74,280 | 24,180 | 5704 | 2176 | 482 | 115 | 32 | 9.8 | 3.1 | 1.0 | 0.4 |

| 2 | 205,800 | 95,180 | 35,040 | 9398 | 4200 | 896 | 213 | 62 | 19 | 6.0 | 1.9 | 0.7 | |

| C | 162,400 | 70,060 | 23,580 | 5836 | 2608 | 552 | 134 | 38 | 11 | 3.6 | 1.2 | 0.4 | |

| 25/55–60 | 1 | 79,157 | 41,041 | 17,000 | 4355 | 1942 | 471 | 117 | 34 | 11 | 3.7 | 1.2 | 0.4 |

| 2 | 110,458 | 57,110 | 26,460 | 7570 | 3844 | 1048 | 258 | 73 | 23 | 7.3 | 2.4 | 0.8 | |

| C | 95,749 | 49,568 | 20,784 | 5641 | 2703 | 702 | 174 | 50 | 16 | 5.3 | 1.8 | 0.7 | |

| 45/80–55 | 1 | 149,000 | 62,500 | 19,900 | 4612 | 1902 | 416 | 104 | 30 | 9.9 | 3.4 | 1.2 | 0.5 |

| 2 | 203,600 | 97,500 | 37,560 | 10,380 | 5498 | 1312 | 301 | 97 | 32 | 11 | 3.8 | 1.4 | |

| C | 183,000 | 81,660 | 29,080 | 7458 | 3558 | 769 | 190 | 58 | 19 | 6.4 | 2.3 | 0.9 | |

| 45/80–80 | 1 | 125,200 | 47,780 | 14,040 | 2998 | 871 | 213 | 58 | 20 | 7.8 | 3.2 | 1.4 | 0.6 |

| 2 | 189,000 | 81,480 | 29,400 | 7713 | 4265 | 894 | 253 | 90 | 34 | 14 | 5.7 | 2.4 | |

| C | 154,400 | 65,300 | 22,720 | 5622 | 2062 | 485 | 132 | 46 | 17 | 7.0 | 2.9 | 1.2 | |

| Dependent Variable | Qualitative Factors | |||||

|---|---|---|---|---|---|---|

| Virgin Binder Type | Virgin Binder Modification (Paving Binders/PMBs) | Test Temperature (−5–100 °C) | ||||

| p | Relevance | p | Relevance | p | Relevance | |

| ΔG*R | 0.000 | significant | 0.001 | significant | 0.000 | significant |

| Parameters | Paving Bitumen | PMB | Paving Bitumen and PMB |

|---|---|---|---|

| r (Pearson) | 0.948 | 0.670 | 0.881 |

| R2 | 0.900 | 0.449 | 0.775 |

| Correlation power | almost full | low | high |

| p | 0.000 | 0.000 | 0.000 |

| Correlation relevance | relevant | relevant | relevant |

| Dependent Variable | Qualitative Factors | |||

|---|---|---|---|---|

| Virgin Binder Type | Layer (Inter, Outer) of Binder Film | |||

| p | Relevance | p | Relevance | |

| R3,2 | 0.000 | very relevant | 0.001 | very relevant |

| JNR3,2 | 0.000 | very relevant | 0.001 | very relevant |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liphardt, A.; Radziszewski, P.; Król, J. Homogeneity and Viscoelastic Behaviour of Bitumen Film in Asphalt Mixtures Containing RAP. Materials 2021, 14, 4355. https://doi.org/10.3390/ma14164355

Liphardt A, Radziszewski P, Król J. Homogeneity and Viscoelastic Behaviour of Bitumen Film in Asphalt Mixtures Containing RAP. Materials. 2021; 14(16):4355. https://doi.org/10.3390/ma14164355

Chicago/Turabian StyleLiphardt, Adam, Piotr Radziszewski, and Jan Król. 2021. "Homogeneity and Viscoelastic Behaviour of Bitumen Film in Asphalt Mixtures Containing RAP" Materials 14, no. 16: 4355. https://doi.org/10.3390/ma14164355

APA StyleLiphardt, A., Radziszewski, P., & Król, J. (2021). Homogeneity and Viscoelastic Behaviour of Bitumen Film in Asphalt Mixtures Containing RAP. Materials, 14(16), 4355. https://doi.org/10.3390/ma14164355