Noise Reduction Characteristics of Macroporous Asphalt Pavement Based on A Weighted Sound Pressure Level Sensor

Abstract

:1. Introduction

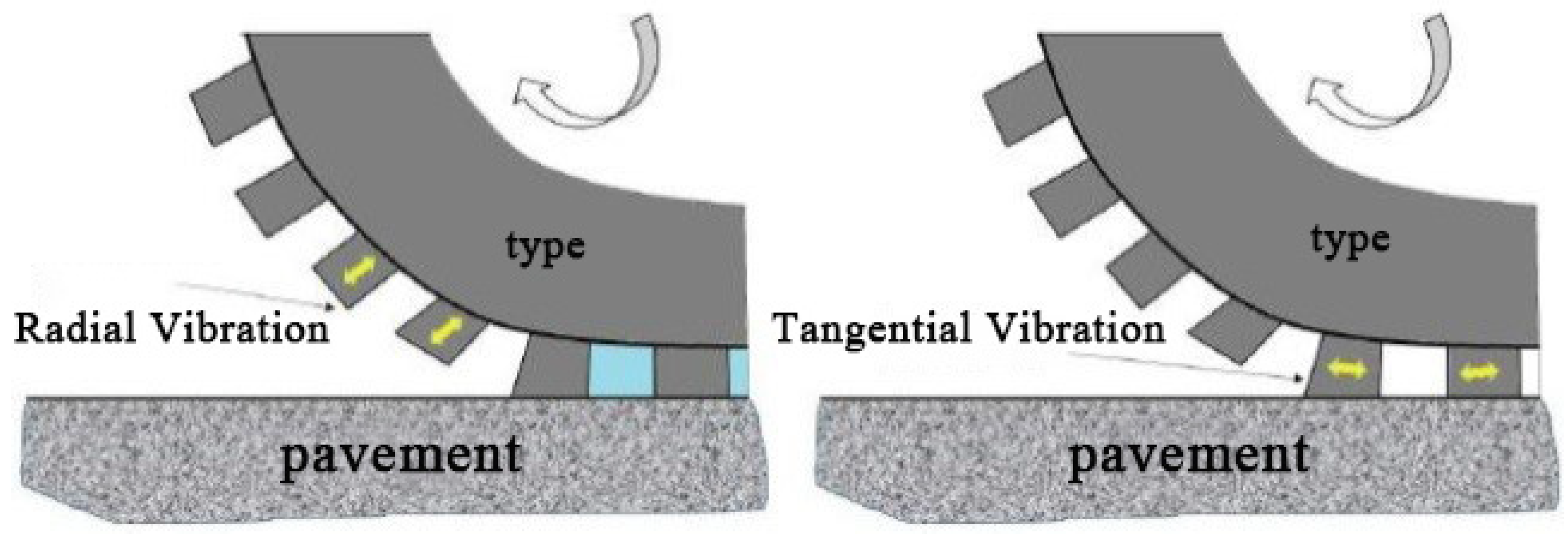

1.1. Tire Noise Generation Mechanism

1.2. Noise Evaluation Based on a Weighted Sound Pressure Level

2. Experiment

2.1. Material Design

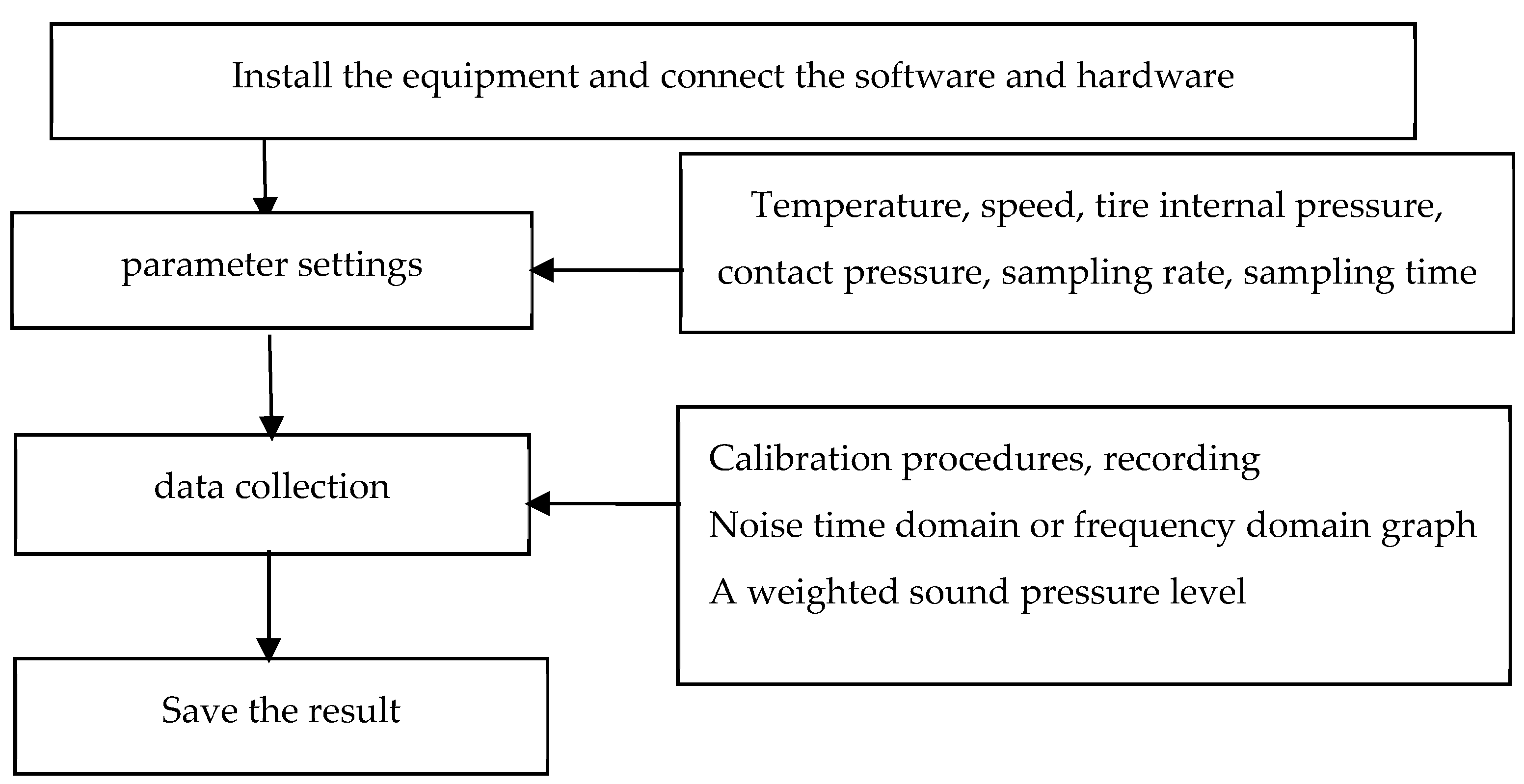

2.2. Experiment Procedure

- (1)

- Test condition

- (2)

- (3)

- Background noise measurement and modification

3. Result and Discussion

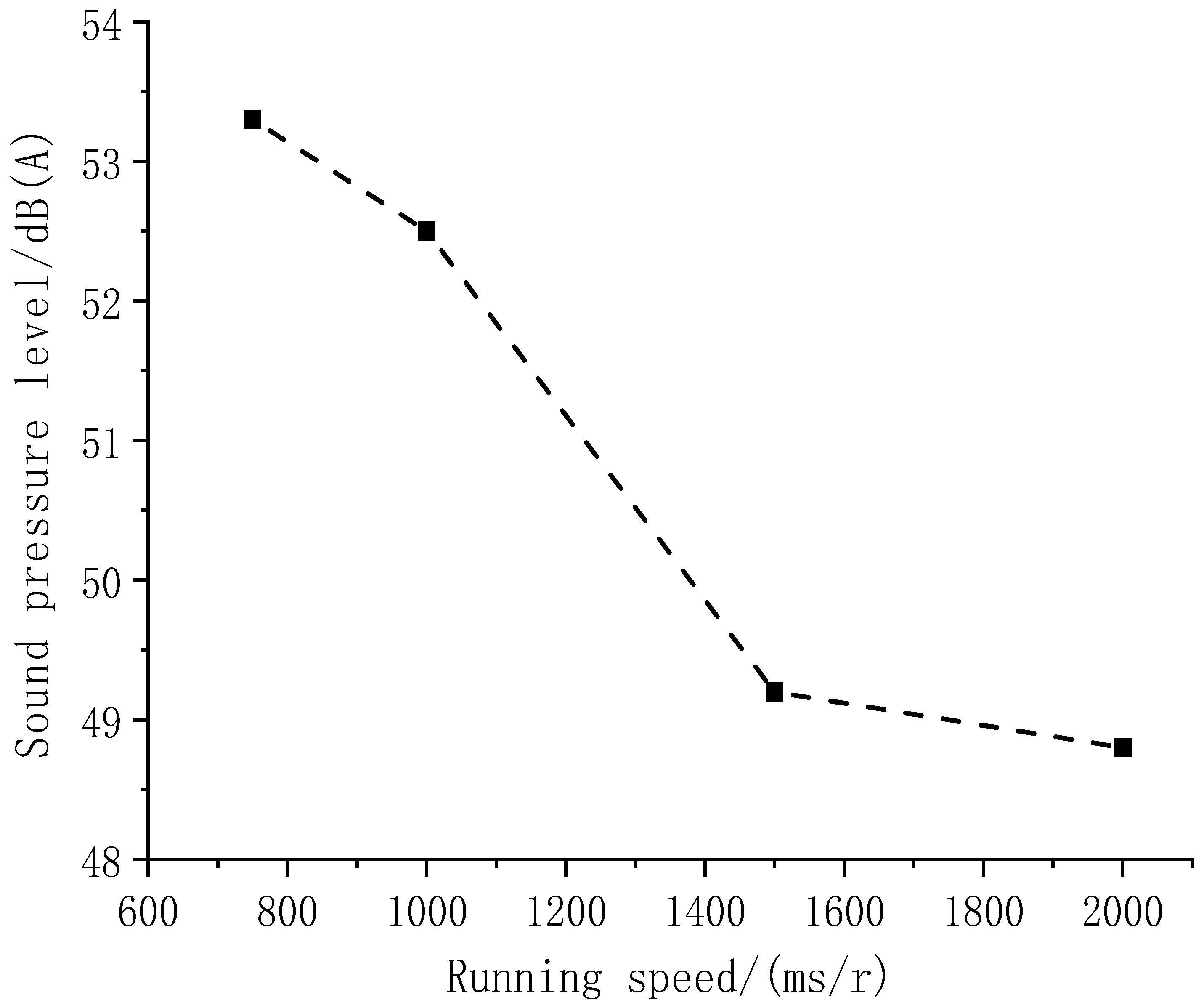

3.1. Impact of Driving Speed on Noise

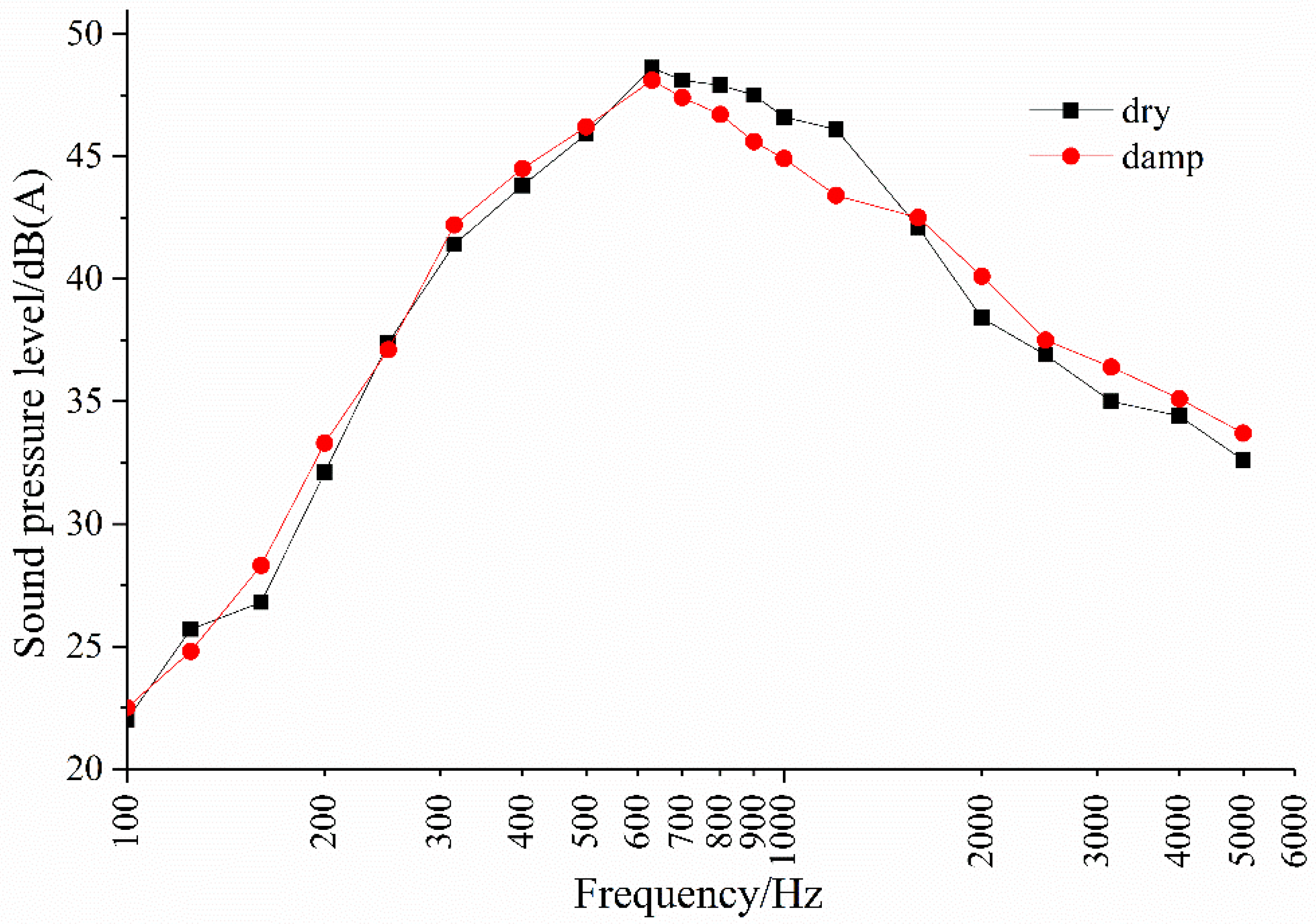

3.2. Impact of Wet and Dry Conditions on Noise

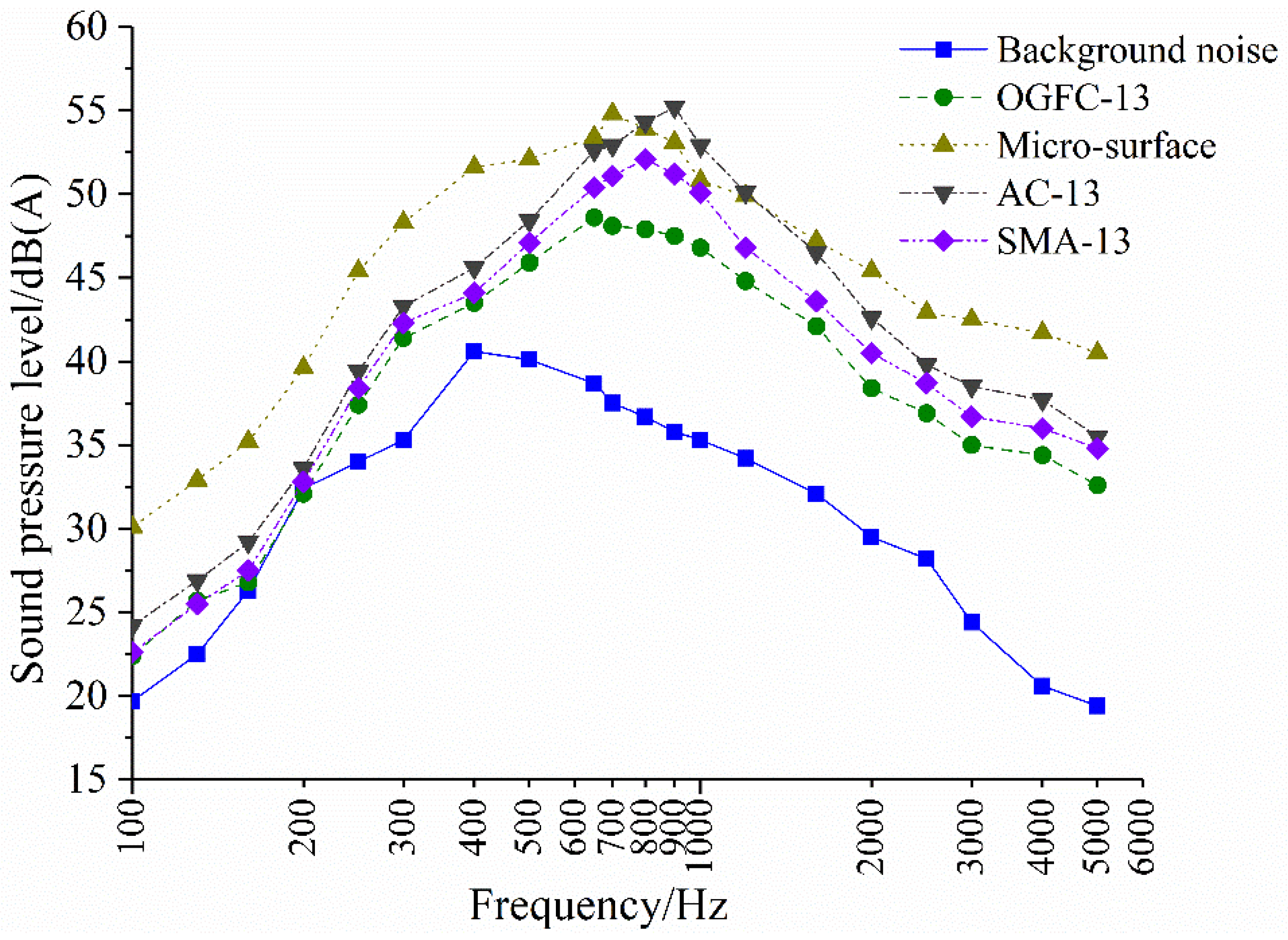

3.3. Impact of Mixture Type on Pavement Noise

3.4. Analysis on the Law of Pavement Noise Attenuation

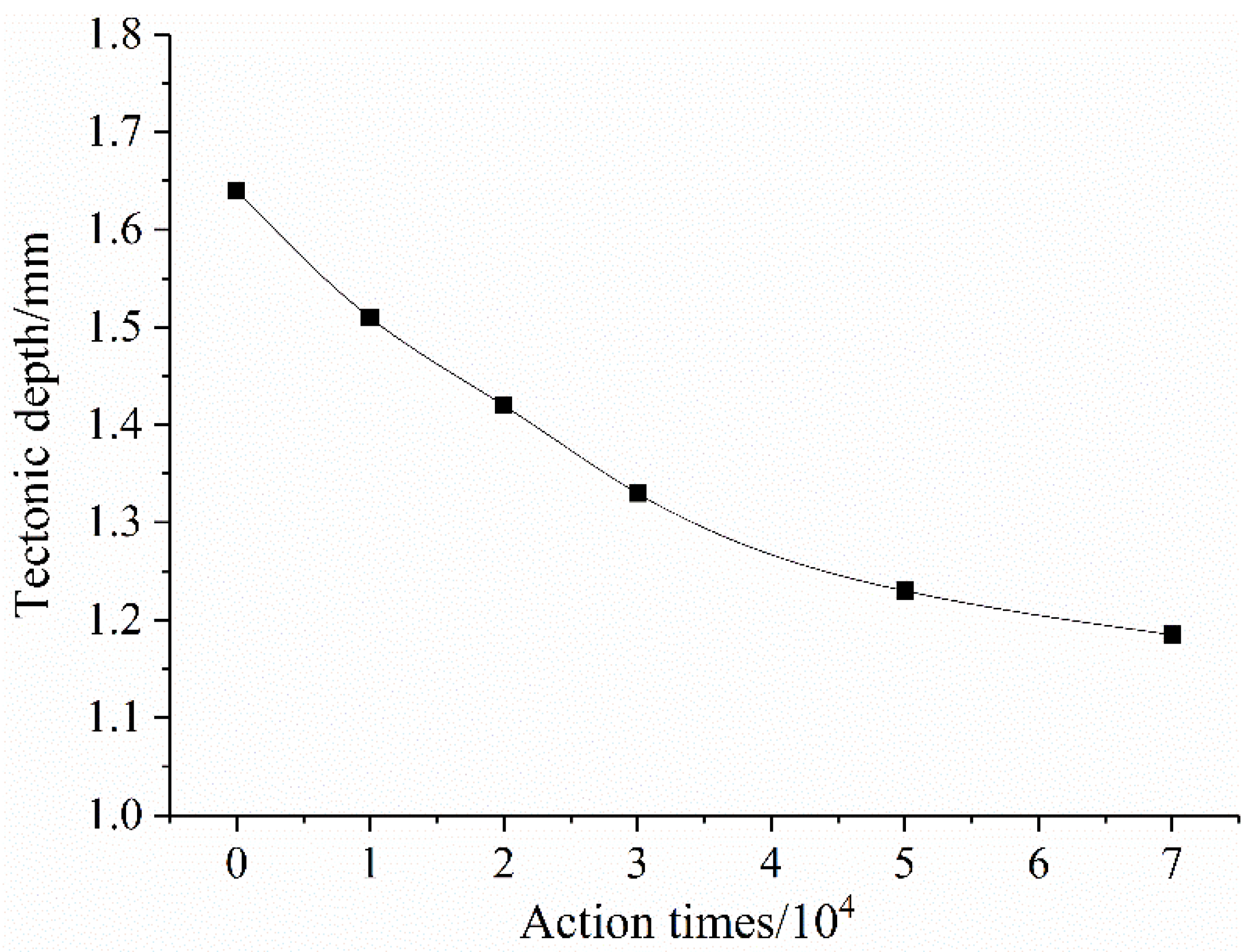

3.4.1. Impact of Tire Action Times on Noise Decay

3.4.2. Impact of Structural Depth on Noise Decay

4. Conclusions

- (1)

- OGFC tire or pavement noise increases with the increase in driving speed, and the noise structure is different at different speeds. OGFC pavement noise at low speeds increases the noise level in the high-frequency range due to tire or road sticky action. Regarding the noise at higher speeds, in addition to the effect of sticky action, there is also pumping noise and vibration noise from tire patterns, which violently beat the pavement.

- (2)

- The noise reduction performance of OGFC comes from its porosity up to 20%, which effectively reduces air pump noise. SMA has a rich surface texture and high internal damping, and its noise reduction performance is inferior only to OGFC pavement. The higher noise at the micro-surface is due to the unevenness and nonuniformity of the pavement macroscopic structure. The noise reduction effect of different asphalt pavements is OGFC-13> SMA-13> AC-13> MS-III.

- (3)

- With the decrease in the structural depth, the OGFC pavement noise has an increasing tendency, and the OGFC pavement structural depth has a good quadratic parabolic relationship with the noise sound pressure level. In the later stage of the driving action, the noise reduction function of OGFC tends to disappear due to the speed of the connected pores. Meanwhile, the pavement noise characteristics are similar to those of densely graded asphalt pavement.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wolfgang, B. Traffic noise and risk of myocardial infarction. Epidemiology 2005, 16, 33–40. [Google Scholar]

- Yang, W.; He, J.; He, C.; Cai, M. Evaluation of urban traffic noise pollution based on noise maps. Transp. Res. Part D Transp. Environ. 2020, 87, 102516. [Google Scholar] [CrossRef]

- Iglesias-Merchan, C.; Laborda-Somolinos, R.; González-Ávila, S. Elena-Rosselló, R. Spatio-temporal changes of road traffic noise pollution at ecoregional scale. Environ. Pollut. 2021, 286, 117291. [Google Scholar] [CrossRef] [PubMed]

- Li, T.; Burdisso, R.; Sandu, C. Literature review of models on tire-pavement interaction noise. J. Sound Vib. 2018, 420, 357–445. [Google Scholar] [CrossRef]

- Lu, X.; Kang, J.; Zhu, P.; Cai, J.; Guo, F.; Zhang, Y. Influence of urban road characteristics on traffic noise. Transp. Res. Part D Transp. Environ. 2019, 75, 136–155. [Google Scholar] [CrossRef]

- Umeda, S.; Kawasaki, Y.; Kuwahara, M.; Iihoshi, A. Risk evaluation of traffic standstills on winter roads using a state space model. Transp. Res. Part C Emerg. Technol. 2021, 125, 103005. [Google Scholar] [CrossRef]

- Yu, H.Y.; Deng, G.S.; Wang, D.Y.; Zhang, Z.Y.; Oeser, M. Warm asphalt rubber: A sustainable way for waste tire rubber recycling. J. Cent. South Univ. 2020, 27, 3477–3498. [Google Scholar] [CrossRef]

- Bachok, K.S.R.; Hamsa, A.A.K.; Mohamed, M.Z.b.; Ibrahim, M. A theoretical overview of road hump effects on traffic noise in improving residential well-being. Transp. Res. Procedia 2017, 25, 3383–3397. [Google Scholar] [CrossRef]

- Chen, L.; Cong, L.; Dong, Y.; Yang, G.; Tang, B.; Wang, X.; Gong, H. Investigation of influential factors of tire/pavement noise: A multilevel Bayesian analysis of full-scale track testing data. Constr. Build. Mater. 2021, 270, 121484. [Google Scholar] [CrossRef]

- Mohammadi, S.; Ohadi, A. A novel approach to design quiet tires, based on multi-objective minimization of generated noise. Appl. Acoust. 2021, 175, 107825. [Google Scholar] [CrossRef]

- Vázquez, V.F.; Hidalgo, M.E.; García-Hoz, A.M.; Camara, A.; Terán, F.; Ruiz-Teran, A.M.; Paje, S.E. Tire/road noise, texture, and vertical accelerations: Surface assessment of an urban road. Appl. Acoust. 2020, 160, 107153. [Google Scholar] [CrossRef]

- Ganji, M.R.; Golroo, A.; Sheikhzadeh, H.; Ghelmani, A.; Bidgoli, M.A. Dense-graded asphalt pavement macrotexture measurement using tire/road noise monitoring. Autom. Constr. 2019, 106, 102887. [Google Scholar] [CrossRef]

- Jin, J.; Gao, Y.; Wu, Y.; Li, R.; Liu, R.; Wei, H.; Qian, G.; Zheng, J. Performance evaluation of surface-organic grafting on the palygorskite nanofiber for the modification of asphalt. Constr. Build. Mater. 2021, 268, 121072. [Google Scholar] [CrossRef]

- Jin, J.; Gao, Y.; Wu, Y.; Liu, S.; Liu, R.; Wei, H.; Qian, G.; Zheng, J. Rheological and adhesion properties of nano-organic palygorskite and linear SBS on the composite modified asphalt. Powder Technol. 2021, 377, 212–221. [Google Scholar] [CrossRef]

- Yu, H.; Zhu, Z.; Leng, Z.; Wu, C.; Zhang, Z.; Wang, D.; Oeser, M. Effect of mixing sequence on asphalt mixtures containing waste tire rubber and warm mix surfactants. J. Clean. Prod. 2020, 246, 119008. [Google Scholar] [CrossRef]

- Yu, H.; Leng, Z.; Zhou, Z.; Shih, K.; Xiao, F.; Gao, Z. Optimization of preparation procedure of liquid warm mix additive modified asphalt rubber. J. Clean. Prod. 2017, 141, 336–345. [Google Scholar] [CrossRef]

- Li, D.; Leng, Z.; Zou, F.; Yu, H. Effects of rubber absorption on the aging resistance of hot and warm asphalt rubber binders prepared with waste tire rubber. J. Clean. Prod. 2021, 303, 127082. [Google Scholar] [CrossRef]

- Jin, J.; Liu, S.; Gao, Y.; Liu, R.; Huang, W.; Wang, L.; Xiao, T.; Lin, F.; Xu, L.; Zheng, J. Fabrication of cooling asphalt pavement by novel material and its thermodynamics model. Constr. Build. Mater. 2021, 272, 121930. [Google Scholar] [CrossRef]

- Yu, H.; Leng, Z.; Dong, Z.; Tan, Z.; Guo, F.; Yan, J. Workability and mechanical property characterization of asphalt rubber mixtures modified with various warm mix asphalt additives. Constr. Build. Mater. 2018, 175, 392–401. [Google Scholar] [CrossRef]

- Yu, H.; Deng, G.; Zhang, Z.; Zhu, M.; Gong, M.; Oeser, M. Workability of rubberized asphalt from a perspective of particle effect. Transp. Res. Part D Transp. Environ. 2021, 91, 102712. [Google Scholar] [CrossRef]

- Zhang, J.; Huang, W.; Hao, G.; Yan, C.; Lv, Q.; Cai, Q. Evaluation of open-grade friction course (OGFC) mixtures with high content SBS polymer modified asphalt. Constr. Build. Mater. 2021, 270, 121374. [Google Scholar] [CrossRef]

- Gołebiewski, R.; Makarewicz, R.; Nowak, M.; Preis, A. Traffic noise reduction due to the porous road surface. Appl. Acoust. 2003, 64, 481–494. [Google Scholar] [CrossRef]

- Paje, S.E.; Bueno, M.; Terán, F.; Viñuela, U. Monitoring road surfaces by close proximity noise of the tire/road interaction. J. Acoust. Soc. Am. 2007, 122, 2636–2641. [Google Scholar] [CrossRef]

- Dong, S.; Han, S.; Zhang, Q.; Han, X.; Zhang, Z.; Yao, T. Three-dimensional evaluation method for asphalt pavement texture characteristics. Constr. Build. Mater. 2021, 287, 122966. [Google Scholar] [CrossRef]

- Sandberg, U. Abatement of traffic, vehicle, and tire/road noise-The global perspective. Noise Control. Eng. J. 2001, 49, 170–181. [Google Scholar] [CrossRef]

- Chen, D.; Ling, C.; Wang, T.; Su, Q.; Ye, A. Prediction of tire-pavement noise of porous asphalt mixture based on mixture surface texture level and distributions. Constr. Build. Mater. 2018, 173, 801–810. [Google Scholar] [CrossRef]

- Vaitkus, A.; Andriejauskas, T.; Vorobjovas, V.; Jagniatinskis, A.; Fiks, B.; Zofka, E. Asphalt wearing course optimization for road traffic noise reduction. Constr. Build. Mater. 2017, 152, 345–356. [Google Scholar] [CrossRef]

- Lee, S.-H.; Eum, K.-Y.; Le, T.H.M.; Park, D.-W. Evaluation on mechanical behavior of asphalt concrete trackbed with slab panel using full-scale static and dynamic load test. Constr. Build. Mater. 2021, 276, 122207. [Google Scholar] [CrossRef]

- Deng, Q.; Zhan, Y.; Liu, C.; Qiu, Y.; Zhang, A. Multiscale power spectrum analysis of 3D surface texture for prediction of asphalt pavement friction. Constr. Build. Mater. 2021, 293, 123506. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, Z.; Meng, X. Noise reduction characteristics of asphalt pavement based on indoor simulation tests. Constr. Build. Mater. 2019, 215, 285–297. [Google Scholar] [CrossRef]

- Mak, K.L.; Hung, W.T.; Lee, S.H. Exploring the impacts of road surface texture on tyre/road noise–A case study in Hong Kong. Transp. Res. Part D Transp. Environ. 2012, 17, 104–107. [Google Scholar] [CrossRef]

- Eisenblaetter, J.; Walsh, S.J.; Krylov, V.V. Air-related mechanisms of noise generation by solid rubber tyres with cavities. Appl. Acoust. 2010, 71, 854–860. [Google Scholar] [CrossRef] [Green Version]

- Ding, S.; Wang, K.C.P.; Yang, E.; Zhan, Y. Influence of effective texture depth on pavement friction based on 3D texture area. Constr. Build. Mater. 2021, 287, 123002. [Google Scholar] [CrossRef]

- Li, T. A state-of-the-art review of measurement techniques on tire–pavement interaction noise. Measurement 2018, 128, 325–351. [Google Scholar] [CrossRef]

- Liao, G.; Sakhaeifar, M.; Heitzman, M.; West, R.; Waller, B.; Wang, S.; Ding, Y. The effects of pavement surface characteristics on tire/pavement noise. Appl. Acoust. 2014, 76, 14–23. [Google Scholar] [CrossRef]

- Ling, S.; Yu, F.; Sun, D.; Sun, G.; Xu, L. A comprehensive review of tire-pavement noise: Generation mechanism, measurement methods, and quiet asphalt pavement. J. Clean. Prod. 2021, 287, 125056. [Google Scholar] [CrossRef]

- Neithalath, N.; Garcia, R.; Weiss, J.; Olek, J. Tire-Pavement Interaction Noise: Recent Research on Concrete Pavement Surface Type and Texture. In Proceedings of the 8th International Conference on Concrete Pavements, Colorado Springs, CO, USA, 14–18 August 2005; Volume 2, pp. 523–540. [Google Scholar]

- Irali, F.; Kivi, A.; Tighe, S.L.; Sangiorgi, C. Tire/Pavement Noise and Wearing Course Surface Characteristics of Experimental Canadian Road Pavement Sections. Can. J. Civ. Eng. 2015, 42, 818–825. [Google Scholar] [CrossRef]

| Test Item | Technical Requirement | Test Result | Monomial Assessment | |

|---|---|---|---|---|

| Unit | Design Requirement | |||

| Stone crushing value | % | ≤15 | 7.9 | Eligibility |

| Los Angeles abrasion loss | % | ≤22 | 9.4 | Eligibility |

| Apparent relative density | — | ≥2.60 | 2.888 | Eligibility |

| Adhesion to modified asphalt | Level | ≥5 | 5 | Eligibility |

| Polish value | — | ≥42 | 45 | Eligibility |

| Sample Specifications | 0–3 mm | |||

|---|---|---|---|---|

| Test Item | Technical Requirement | Test Result | Monomial Assessment | |

| Unit | Design Requirement | |||

| Apparent relative density | — | ≥2.50 | 2.909 | Eligibility |

| Robustness (>0.3 mm part) | % | ≤12 | 2.5 | — |

| Sand equivalent | % | ≥65 | 73 | Eligibility |

| Angularity (flow time) | s | ≥30 | 39.6 | Eligibility |

| Test Item | Technical Requirement | Test Result | Monomial Assessment | |

|---|---|---|---|---|

| Penetration 25 °C, 100 g, 5 s, 0.1 mm | 40 | 49 | Eligibility | |

| Ductility 5 °C, 5 cm/min, cm | ≥50 | 70 | Eligibility | |

| Softening point (°C) | ≥80 | >90 | Eligibility | |

| Flash point (°C) | ≥260 | 337 | Eligibility | |

| Viscosity 25 °C (N*m) | ≥25 | 28 | Eligibility | |

| Tenacity 25 °C (N*m) | ≥15 | 16 | Eligibility | |

| 60 °C dynamic viscosity (Pa.S) | >250,000 | >580,000 | Eligibility | |

| Rolling thin film oven test (RTFOT) Residue (163 °C, 85 min) | Mass change (%) | ±1.0 | −0.054 | Eligibility |

| Penetration ratio (%) | ≥65 | 79.5 | Eligibility | |

| Test Item | Technical Requirement | Test Result | Monomial Assessment | |

|---|---|---|---|---|

| Penetration 25 °C, 100 g, 5 s, 0.1 mm | 40–60 | 54 | Eligibility | |

| Penetration index PI | ≥+0.0 | +0.17 | Eligibility | |

| Ductility 5 °C, 5 cm/min, cm | ≥20 | 34 | Eligibility | |

| Softening point (°C) | ≥75 | 86.5 | Eligibility | |

| Flash point (°C) | ≥230 | 340 | Eligibility | |

| Solubility (%) | ≥99 | 99.8 | Eligibility | |

| Storage stability *: 163 °C, 48 h, poor softening point °C | ≤2.0 | 1.2 | Eligibility | |

| Elastic recovery 25 °C, % | ≥90 | 96 | Eligibility | |

| Kinematic viscosity (Pa·s) | 135 °C | ≤3 | 2.38 | Eligibility |

| 165 °C | No requirement | 0.62 | ||

| Rolling thin film oven test (RTFOT) Residue (163 °C, 85 min) | Mass change (%) | ±1.0 | −0.016 | Eligibility |

| Ductility 5 °C, 5 cm/min, cm | ≥20 | 21 | Eligibility | |

| Penetration ratio (%) | ≥65 | 81.6 | Eligibility | |

| Test Item | Unit | Technical Requirement | Test Result | Monomial Assessment | |

|---|---|---|---|---|---|

| Residue on sieve (1.18 mm) sieve, no more than | % | ≤0.05 | 0.03 | Eligibility | |

| Particle charge | — | positive ion (+) | positive ion | Eligibility | |

| Viscosity (Asphalt Standard Viscometer C25,3) | s | 8–25 | 18 | Eligibility | |

| Evaporation residue | Residual content | % | ≥63 | 65.3 | Eligibility |

| Penetration (25 °C) | 0.1 mm | 40–150 | 79 | Eligibility | |

| Softening point | °C | ≥55 | 66.0 | Eligibility | |

| Ductility (5 °C) | cm | ≥25 | 51 | Eligibility | |

| Solubility | % | ≥97.5 | 99.7 | Eligibility | |

| Elastic recovery (10 °C) | % | ≥60 | 71 | Eligibility | |

| Storage stability (1 d) | % | ≤1 | 0.5 | Eligibility | |

| Sieve Mesh | 16 | 13.2 | 9.5 | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 | Asphalt-Aggregate Ratio (%) | Porosity (%) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| OGFC-13 | 100 | 95 | 55.9 | 11.8 | 11.4 | 11 | 8.4 | 7 | 5.5 | 4.2 | 5.2 | 21.6 |

| AC-13 | 100 | 90 | 68 | 38 | 24 | 15 | 10 | 7 | 5 | 4 | 4.3 | 3.8 |

| SMA-13 | 100 | 89 | 63 | 25 | 19 | 15 | 14 | 13 | 12 | 10 | 5.9 | 4.1 |

| MS-III | 100 | 100 | 100 | 90 | 70 | 50 | 34 | 25 | 18 | 15 | 7.2 | 3.8 |

| Difference Between the Measurement Noise and the Background Noise/dB(A) | 6–8 | 9–10 | >10 |

|---|---|---|---|

| Correction value | 1 | 0.5 | 0 |

| Pavement State | Sound Pressure Level/dB(A) | Noise Reduction Level/dB(A) |

|---|---|---|

| Dry | 49.2 | 0.6 |

| Wet | 49.8 |

| Gradation Type | Background Noise | OGFC-13 | MS-III | AC-13 | SMA-13 |

|---|---|---|---|---|---|

| Porosity /% | — | 21.6 | 3.8 | 3.8 | 4.1 |

| Structural depth/mm | — | 1.94 | 0.83 | 0.42 | 1.14 |

| Sound pressure level /dB(A) | 38.1 | 49.2 | 57.3 | 52.9 | 51.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lai, F.; Huang, Z.; Guo, F. Noise Reduction Characteristics of Macroporous Asphalt Pavement Based on A Weighted Sound Pressure Level Sensor. Materials 2021, 14, 4356. https://doi.org/10.3390/ma14164356

Lai F, Huang Z, Guo F. Noise Reduction Characteristics of Macroporous Asphalt Pavement Based on A Weighted Sound Pressure Level Sensor. Materials. 2021; 14(16):4356. https://doi.org/10.3390/ma14164356

Chicago/Turabian StyleLai, Feng, Zhiyong Huang, and Feng Guo. 2021. "Noise Reduction Characteristics of Macroporous Asphalt Pavement Based on A Weighted Sound Pressure Level Sensor" Materials 14, no. 16: 4356. https://doi.org/10.3390/ma14164356

APA StyleLai, F., Huang, Z., & Guo, F. (2021). Noise Reduction Characteristics of Macroporous Asphalt Pavement Based on A Weighted Sound Pressure Level Sensor. Materials, 14(16), 4356. https://doi.org/10.3390/ma14164356