Magnetic Reversal in Wiegand Wires Evaluated by First-Order Reversal Curves

Abstract

:1. Introduction

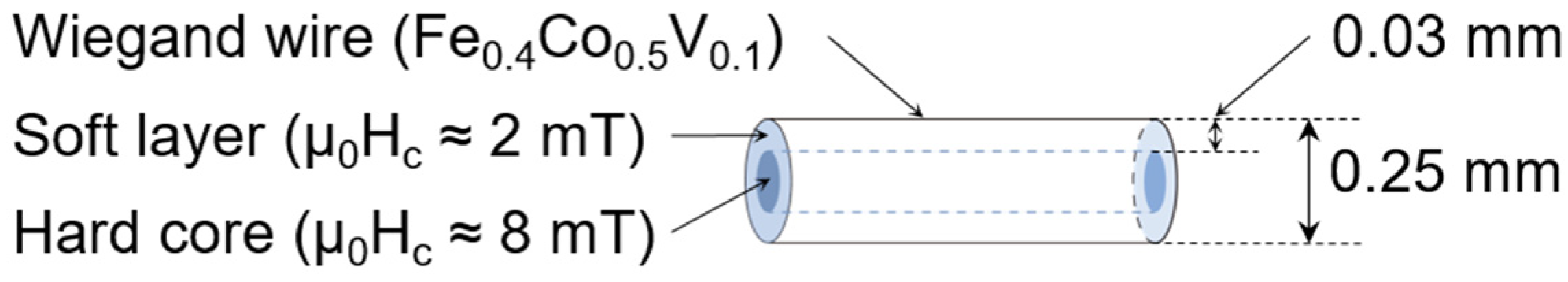

2. Materials and Methods

3. Results

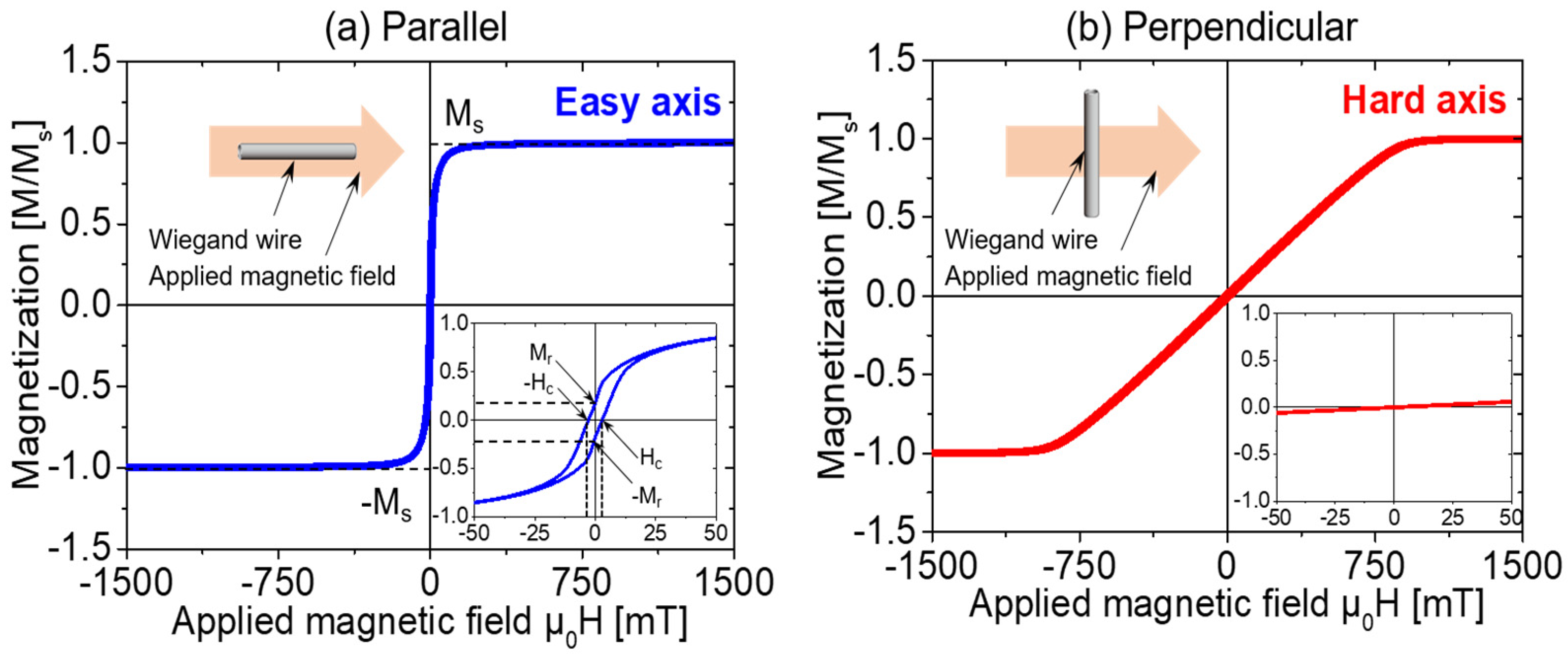

3.1. Magnetic Hysteresis Curves

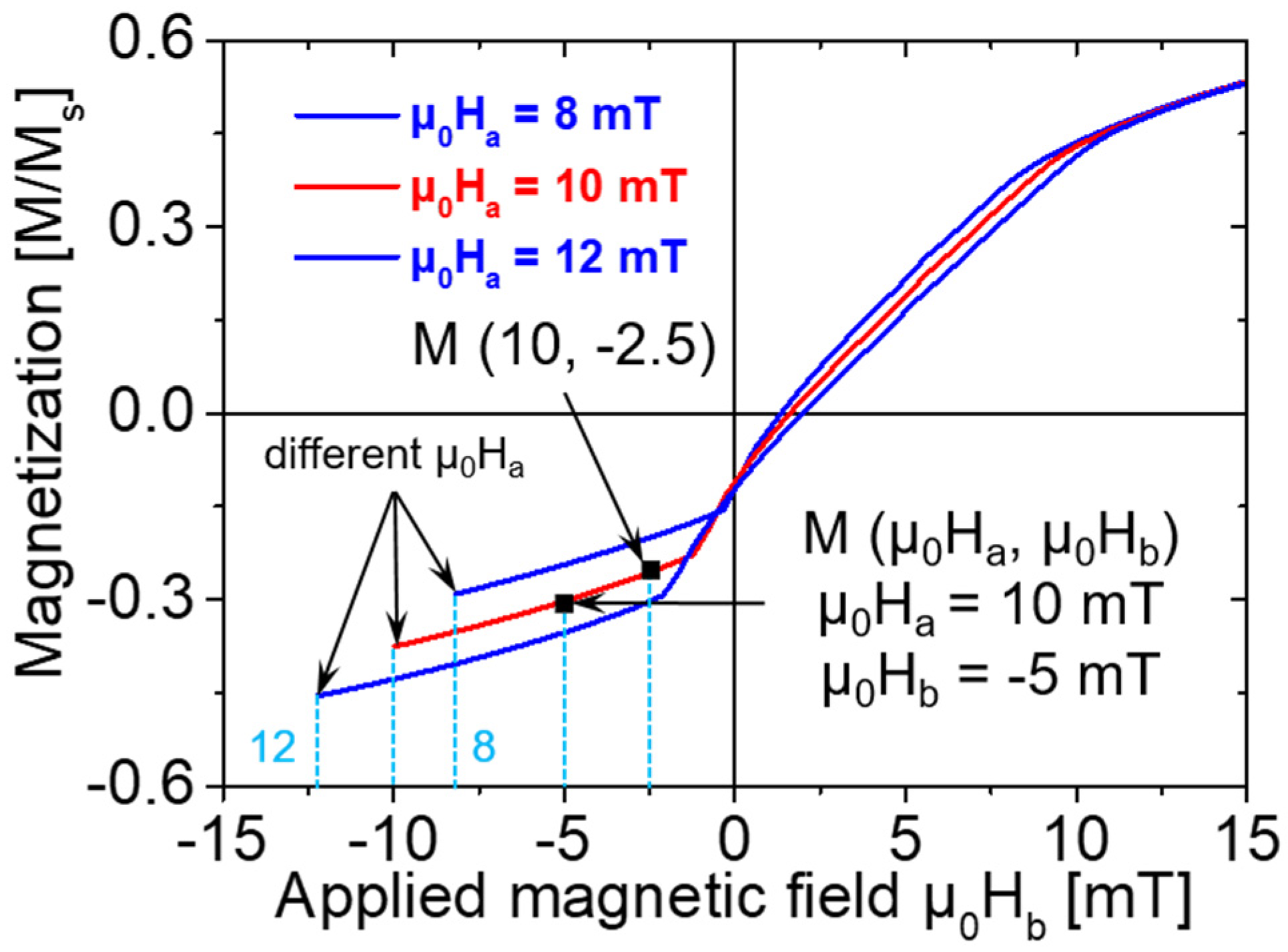

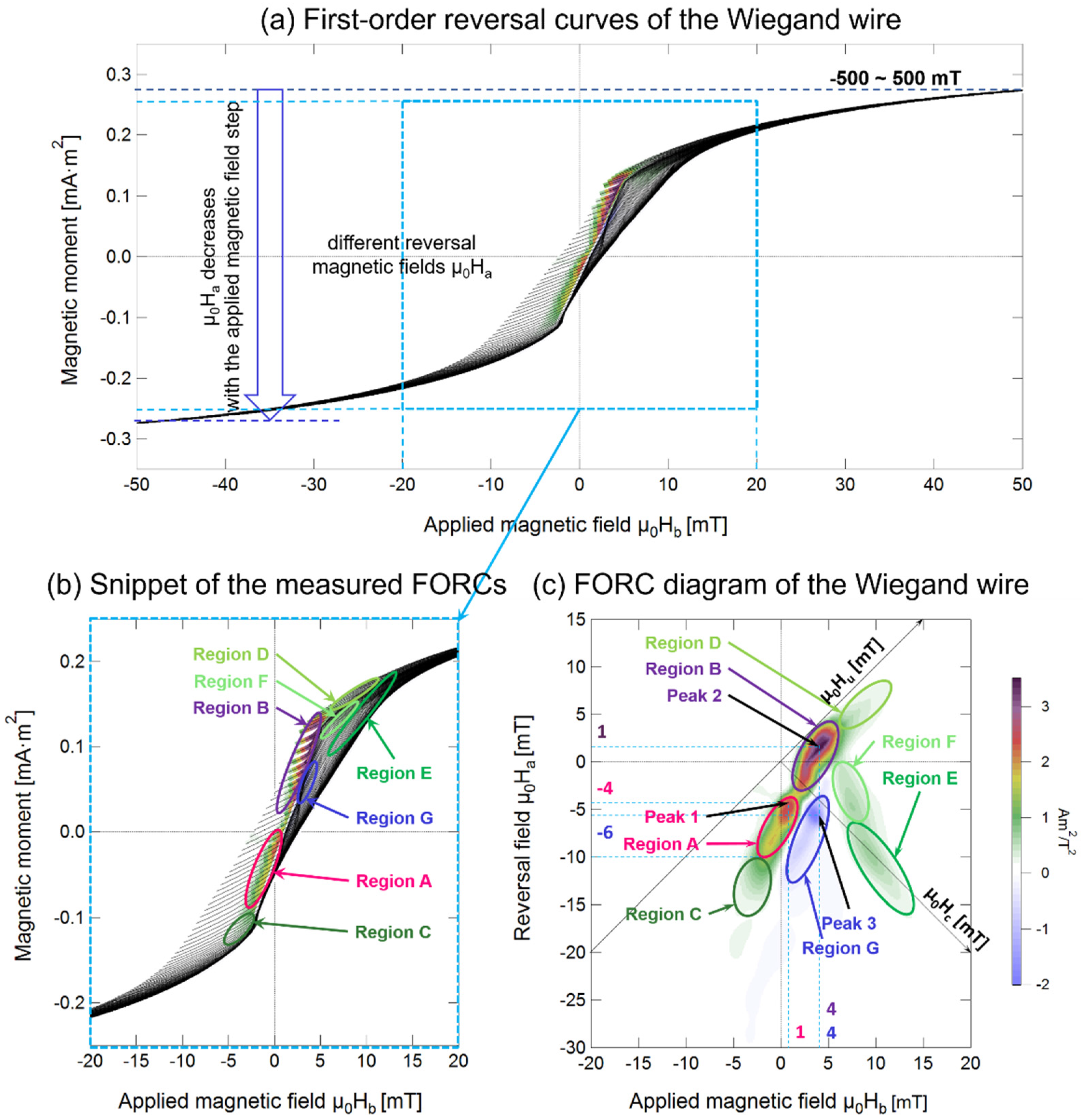

3.2. First-Order Reversal Curves

4. Discussion

4.1. Two-Layer Magnetic Structure and Its Magnetization Reversal

4.2. Interactions between the Two Layers

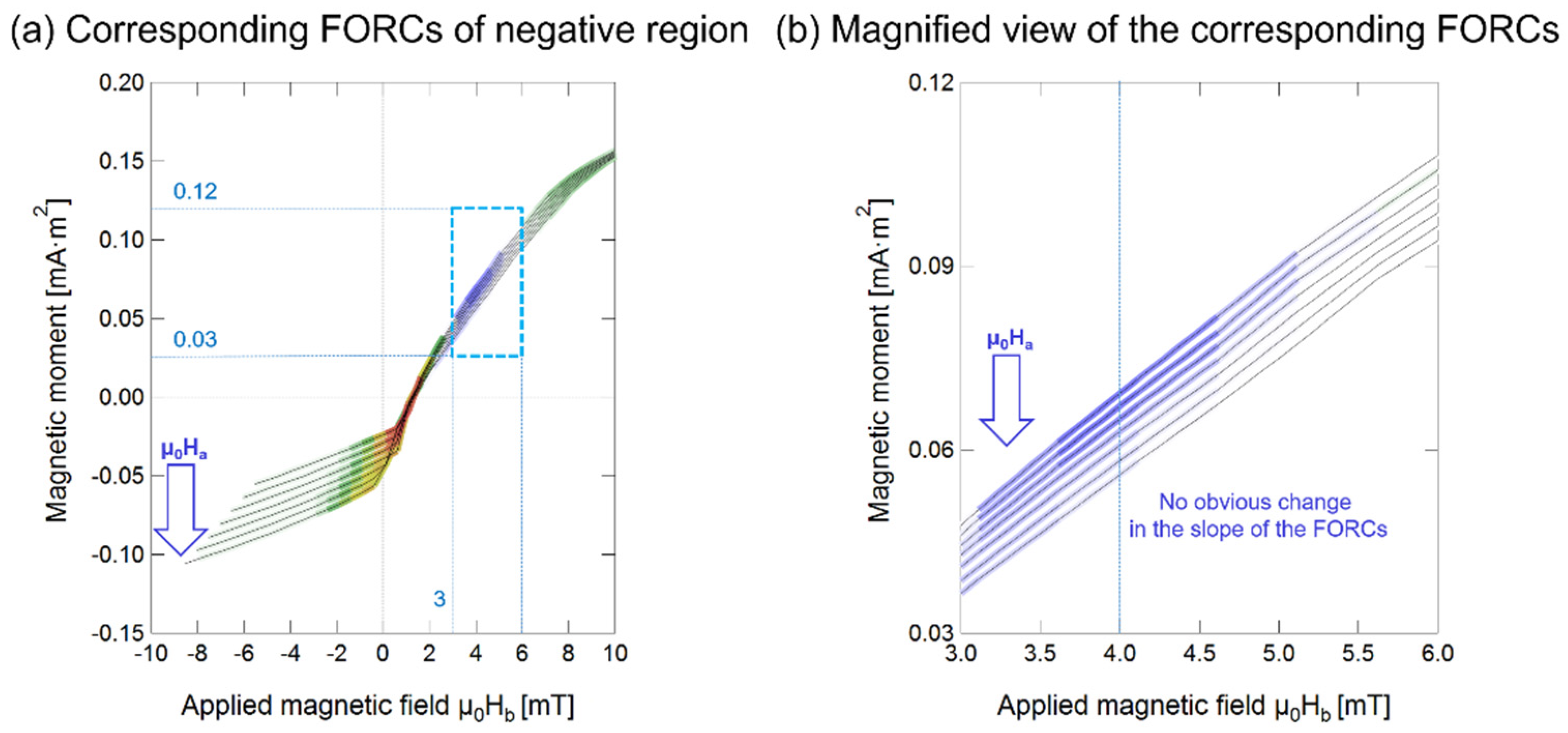

4.3. Negative Region in the FORC Diagram

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wiegand, J.R. Switchable Magnetic Device. U.S. Patent 4,247,601, 27 January 1981. [Google Scholar]

- Wiegand, J.R.; Velinsky, M. Bistable Magnetic Device. U.S. Patent 3,820,090, 25 June 1974. [Google Scholar]

- Takahashi, K.; Takebuchi, A.; Yamada, T.; Takemura, Y. Power supply for medical implants by Wiegand pulse generated from a magnetic wire. J. Magn. Soc. Jpn. 2018, 42, 49–54. [Google Scholar] [CrossRef] [Green Version]

- Malmhall, R.; Mohri, K.; Humphrey, F.B.; Manabe, T.; Kawamura, H.; Yamasaki, J.; Ogasawara, I. Bistable magnetization reversal in 50 µm diameter annealed cold drawn amorphous wires. IEEE Trans. Magn. 1987, 23, 3242–3244. [Google Scholar] [CrossRef]

- Kohara, T.; Yamada, T.; Abe, S.; Kohno, S.; Kaneko, F.; Takemura, Y. Effective excitation by single magnet in rotation sensor and domain wall displacement of FeCoV wire. J. Appl. Phys. 2011, 109, 07E531. [Google Scholar] [CrossRef] [Green Version]

- Abe, S.; Matsushita, A. Pulse generating device with twisted ferromagnetic wire. In Proceedings of the 1st Sensor Symp., Tsukuba, Japan, June 1981; pp. 277–281. [Google Scholar]

- Matsushita, A.; Abe, S. Induced pulse voltage in twisted ferromagnetic wire. IEEJ Trans. A 1979, 99, 46. [Google Scholar]

- Takemura, Y.; Fujiyama, N.; Takebuchi, A.; Yamada, T. Battery-less hall sensor operated by energy harvesting from a single Wiegand pulse. IEEE Trans. Magn. 2017, 53, 4002706. [Google Scholar] [CrossRef] [Green Version]

- Serizawa, R.; Yamada, T.; Masuda, S.; Abe, S.; Kohno, S.; Kaneko, F.; Takemura, Y. Energy harvesting derived from magnetization reversal in FeCoV wire. In Proceedings of the IEEE Sensors, Taipei, Taiwan, 28–31 October 2012. [Google Scholar]

- Chang, C.-C.; Chang, J.-Y. Novel Wiegand effect-based energy harvesting device for linear positioning measurement system. In Proceedings of the Asia-Pacific Magnetic Recording Conference (APMRC), Shanghai, China, 15–17 November 2018. [Google Scholar]

- Yang, C.; Sakai, T.; Yamada, T.; Song, Z.; Takemura, Y. Improvement of pulse voltage generated by Wiegand sensor through magnetic-flux guidance. Sensors 2020, 20, 1408. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Roberts, A.P.; Pike, C.R.; Verosub, K.L. First-Order Reversal Curve Diagrams: A New Tool for Characterizing the Magnetic Properties of Natural Samples. J. Geophys. Res. 2000, 105, 28461–28475. [Google Scholar] [CrossRef]

- Dodrill, B.; Lindemuth, J.; Radu, C.; Reichard, H. White Paper: High-temperature FORC study of single- and multi-phase permanent magnets. MRS Bull. 2015, 40, 903–905. [Google Scholar] [CrossRef] [Green Version]

- Dodrill, B.; Ohodnicki, P.; Leary, A.; McHenry, M. High-Temperature First-Order-Reversal-Curve (FORC) Study of Magnetic Nanoparticle Based Nanocomposite Materials. MRS Adv. 2016, 1, 45–48. [Google Scholar] [CrossRef]

- Pike, C.R.; Roberts, A.P.; Dekkers, M.J.; Verosub, K.L. An investigation of multi-domain hysteresis mechanisms using FORC diagrams. Phys. Earth Planet. Inter. 2001, 126, 11–25. [Google Scholar] [CrossRef]

- Pike, C.R.; Roberts, A.P.; Verosub, K.L. Characterizing interactions in fine magnetic particle systems using first order reversal curves. J. Appl. Phys. 1999, 85, 6660–6667. [Google Scholar] [CrossRef] [Green Version]

- Harrison, R.J.; Feinberg, J.M. FORCinel: An Improved Algorithm for Calculating First-Order-ReversalCurve Distributions Using Locally Weighted Regression Smoothing. Geochem. Geophys. Geosyst. 2008, 9, 5. [Google Scholar] [CrossRef]

- Egli, R. VARIFORC: An optimized protocol for calculating non-regular first-order reversal curve (FORC) diagrams. Glob. Planet. Chang. 2013, 110, 302–320. [Google Scholar] [CrossRef]

- Muxworthy, A.R.; Roberts, A.P. First-order reversal cure (FORC) diagram. In Encyclopedia of Geomagnetism and Paleomagnetism; Gubbins, D., Herrero-Bervera, E., Eds.; Springer: Berlin/Heidelberg, Germany, 2007; pp. 266–272. [Google Scholar]

- Heslop, D.; Muxworthy, A.R. Aspects of calculating first-order-reversal-curve distributions. J. Magn. Magn. Mater. 2005, 288, 155–167. [Google Scholar] [CrossRef] [Green Version]

- Pike, C.R.; Ross, C.A.; Scalettar, R.T.; Zimanyi, G. First-order reversal curve diagram analysis of a perpendicular nickel nanopillar array. Phys. Rev. B 2005, 71, 134407. [Google Scholar] [CrossRef] [Green Version]

- Acton, G.; Yin, Q.-Z.; Verosub, K.L.; Jovane, L.; Roth, A.; Jacobsen, B.; Ebel, D.S. Micromagnetic coercivity distributions and interactions in chondrules with implications for paleointensities of the early solar system. J. Geophys. Res. 2007, 112, B03S90. [Google Scholar] [CrossRef] [Green Version]

- Rong, C.-B.; Zhang, Y.; Kramer, M.J.; Ping, L.J. Correlation between microstructure and first-order magnetization reversal in the SmCo5/α-Fe nanocomposite magnets. Phys. Lett. A 2011, 375, 1329–1332. [Google Scholar] [CrossRef]

- Muxworthy, A.R.; King, J.G.; Heslop, D. Assessing the ability of first-order reversal curve (FORC) diagrams to unravel complex magnetic signals. J. Geophys. Res. 2005, 110, B01105. [Google Scholar] [CrossRef]

- Newell, A.J. FORCs, SORCs and Stoner-Wohlfarth Theory. In Proceedings of the AGU Fall Meeting Abstracts, San Francisco, CA, USA, 8–12 December 2003. GP31B-0748. [Google Scholar]

- Carvallo, C.; Muxworthy, A.R.; Dunlop, D.J. First-order reversal curve (FORC) diagrams of magnetic mixtures: Micromagnetic models and measurements. Phys. Earth Planet. Inter. 2006, 154, 308–322. [Google Scholar] [CrossRef]

- Muxworthy, A.R.; Heslop, D.; Williams, W. Influence of magnetostatic interactions on first-order-reversal-curve (FORC) diagrams: A micromagnetic approach. Geophys. J. Int. 2004, 158, 888–897. [Google Scholar] [CrossRef] [Green Version]

- Okamoto, S.; Yomogita, T.; Miyazawa, K.; Kikuchi, N.; Kitakami, O.; Watanabe, N.; Suita, N. First-order Reversal Curve (FORC) Analysis and Its Application for Permanent Magnet Materials. Mater. Jpn. 2017, 56, 533–540. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, C.; Kita, Y.; Song, Z.; Takemura, Y. Magnetic Reversal in Wiegand Wires Evaluated by First-Order Reversal Curves. Materials 2021, 14, 3868. https://doi.org/10.3390/ma14143868

Yang C, Kita Y, Song Z, Takemura Y. Magnetic Reversal in Wiegand Wires Evaluated by First-Order Reversal Curves. Materials. 2021; 14(14):3868. https://doi.org/10.3390/ma14143868

Chicago/Turabian StyleYang, Chao, Yuya Kita, Zenglu Song, and Yasushi Takemura. 2021. "Magnetic Reversal in Wiegand Wires Evaluated by First-Order Reversal Curves" Materials 14, no. 14: 3868. https://doi.org/10.3390/ma14143868

APA StyleYang, C., Kita, Y., Song, Z., & Takemura, Y. (2021). Magnetic Reversal in Wiegand Wires Evaluated by First-Order Reversal Curves. Materials, 14(14), 3868. https://doi.org/10.3390/ma14143868