Experimental and Numerical Study on Interface Bond Strength and Anchorage Performance of Steel Bars within Prefabricated Concrete

Abstract

:1. Introduction

2. Experimental Program and Analysis of Test Results

2.1. Specimen Design and Fabrication

2.2. Materials Test and Properties

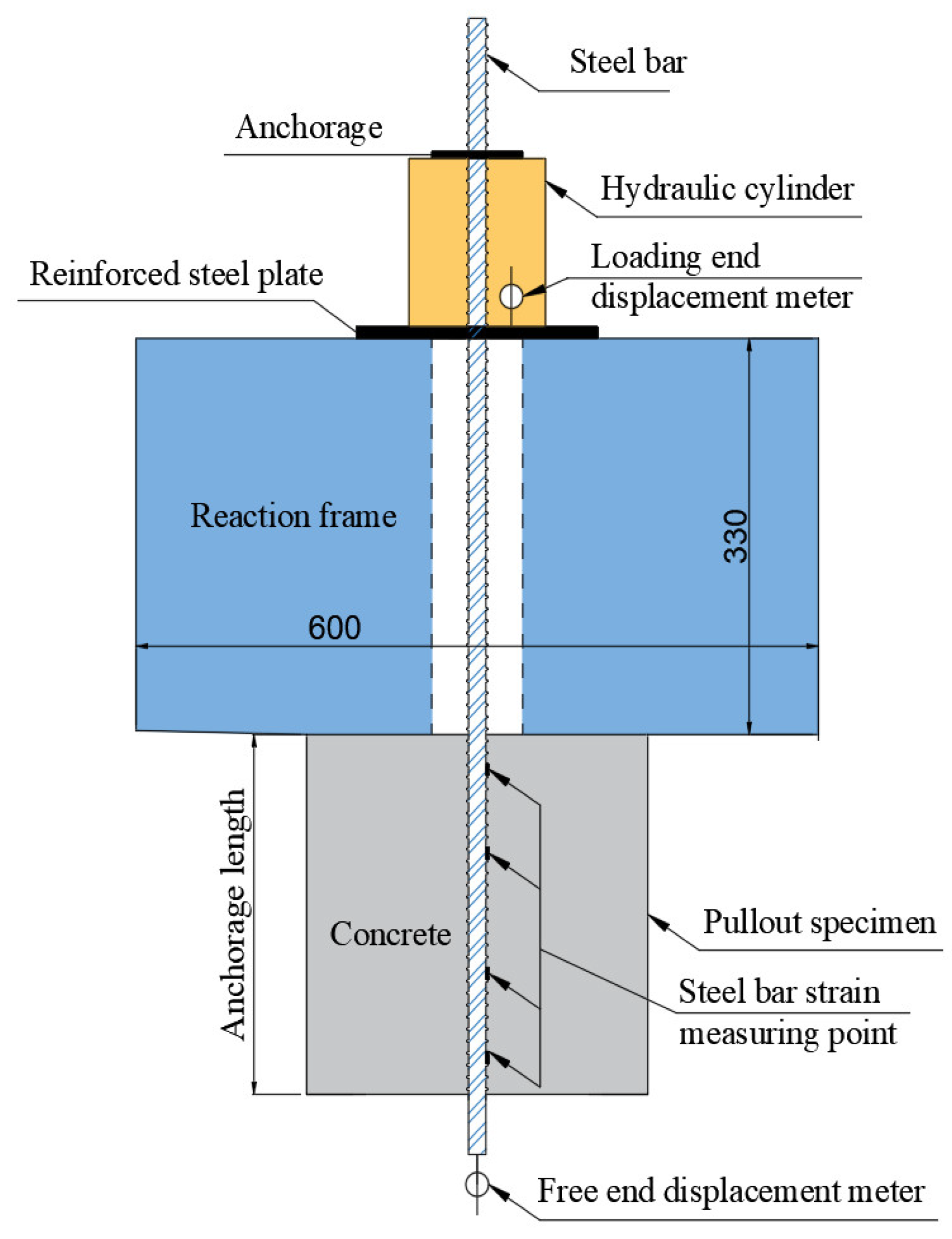

2.3. Test Instruments

2.4. Pull-Out Test Results

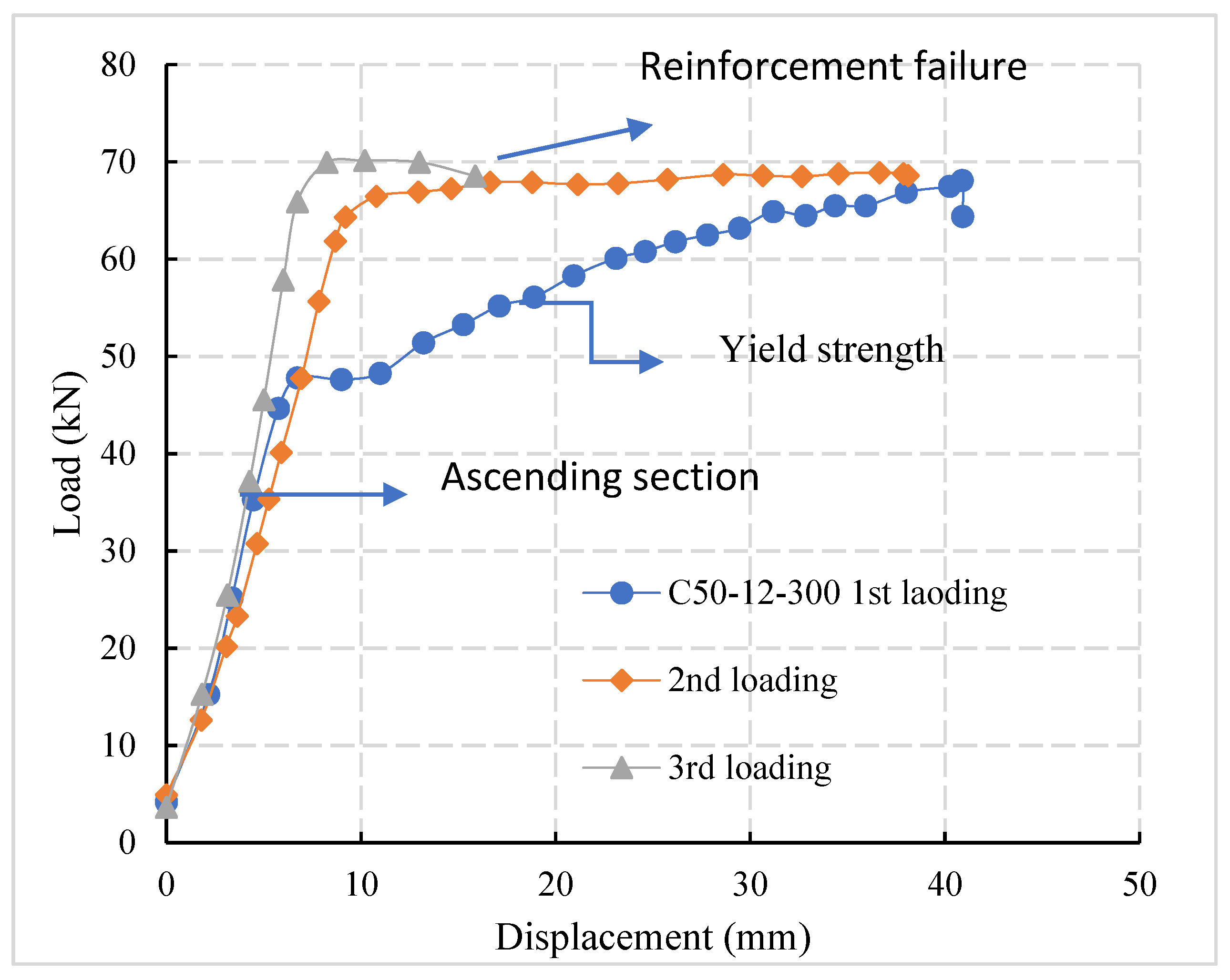

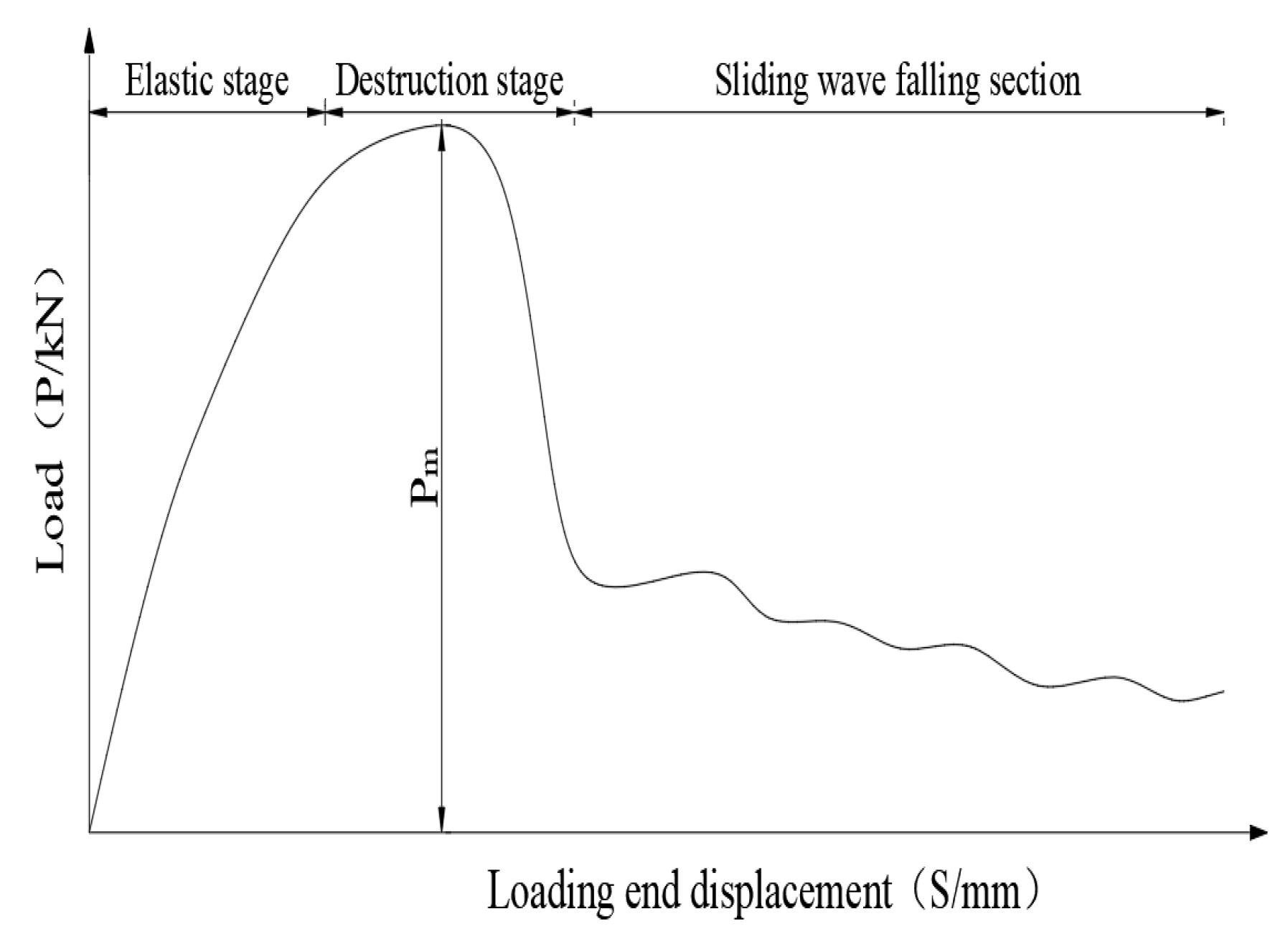

2.5. Load-Displacement Curves

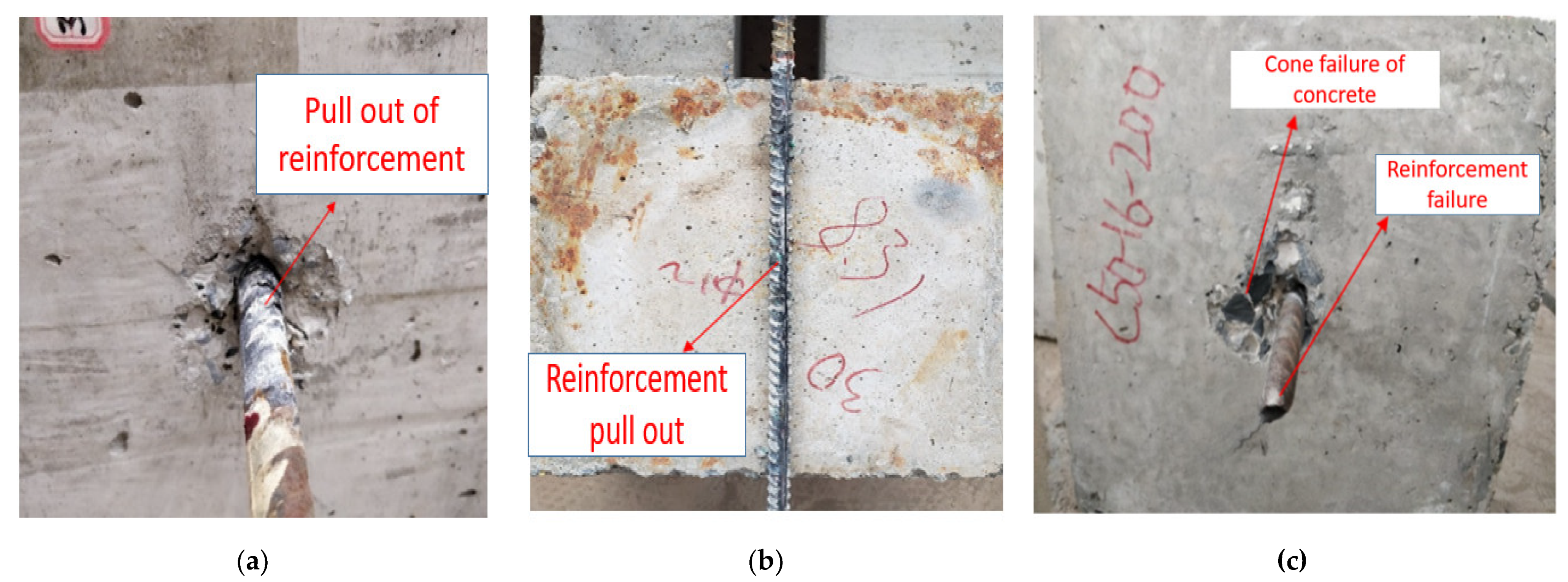

2.6. Failure Mode

- (1)

- Pull-out failure of reinforcement.

- (2)

- Tensile failure of the steel bar.

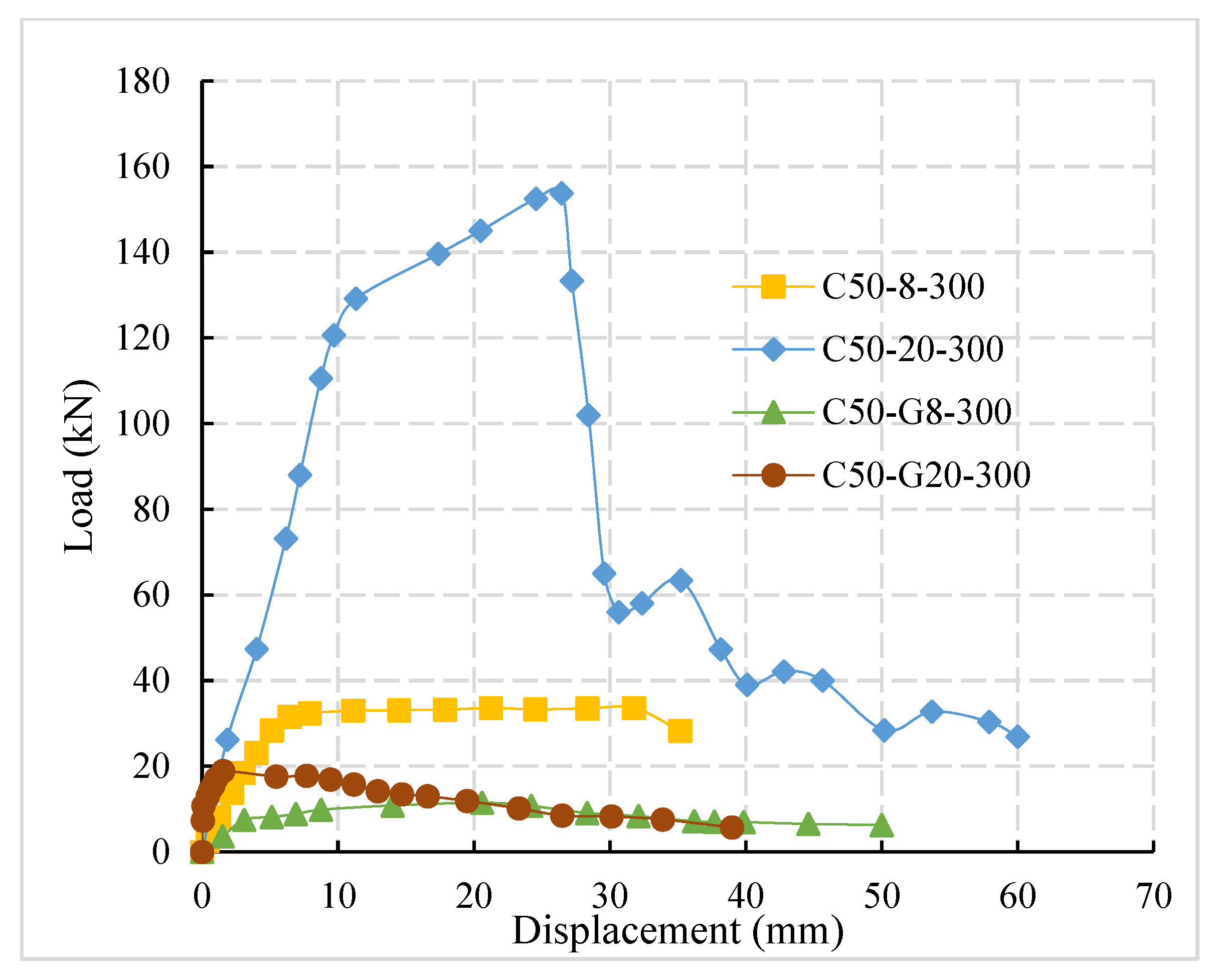

2.7. Analysis of Plain and Ribbed Steel Bar Diameter

3. Modelling

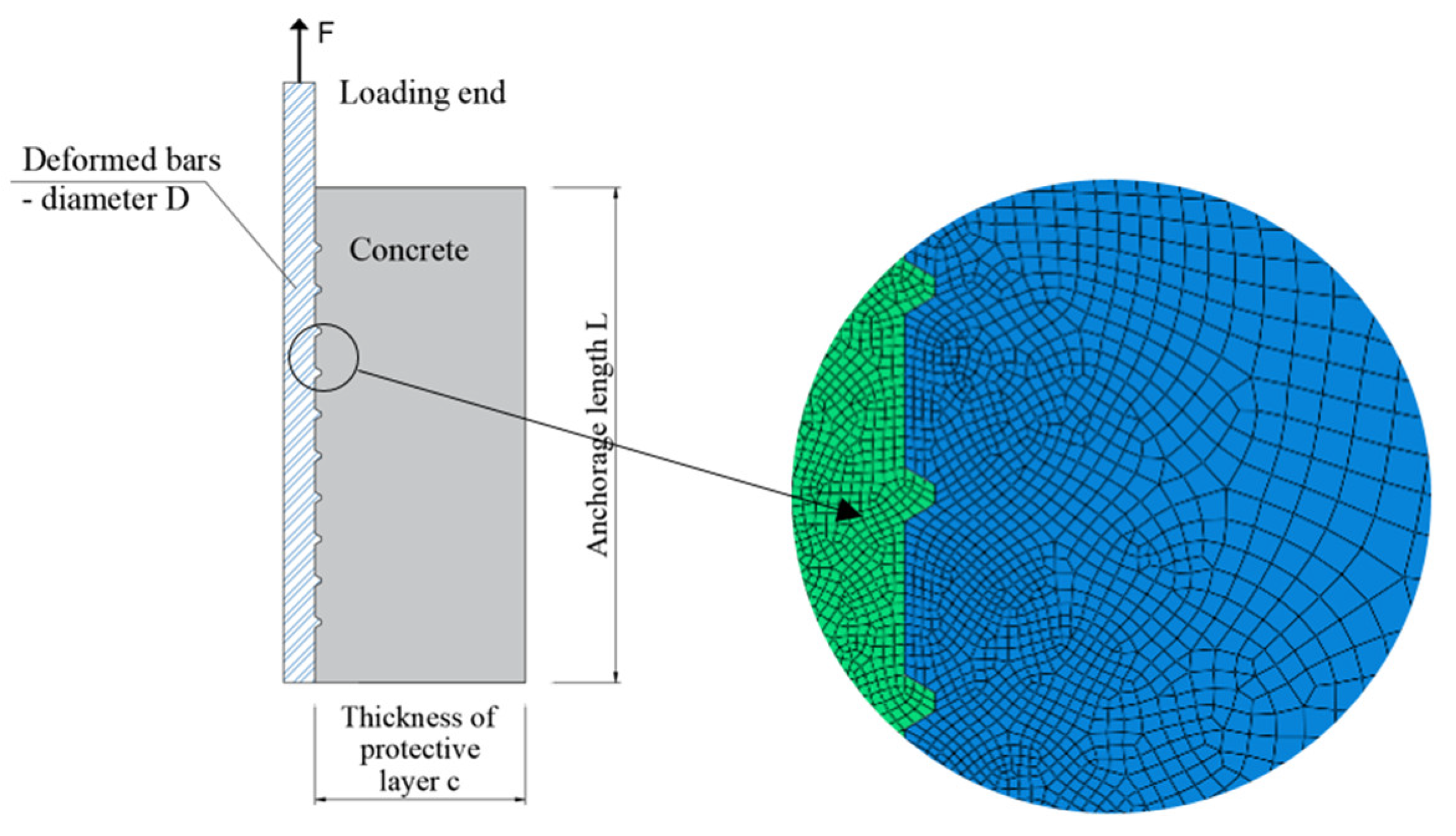

3.1. Specimen Design

3.2. Contact Problem Simulation

3.3. Parameter Selection

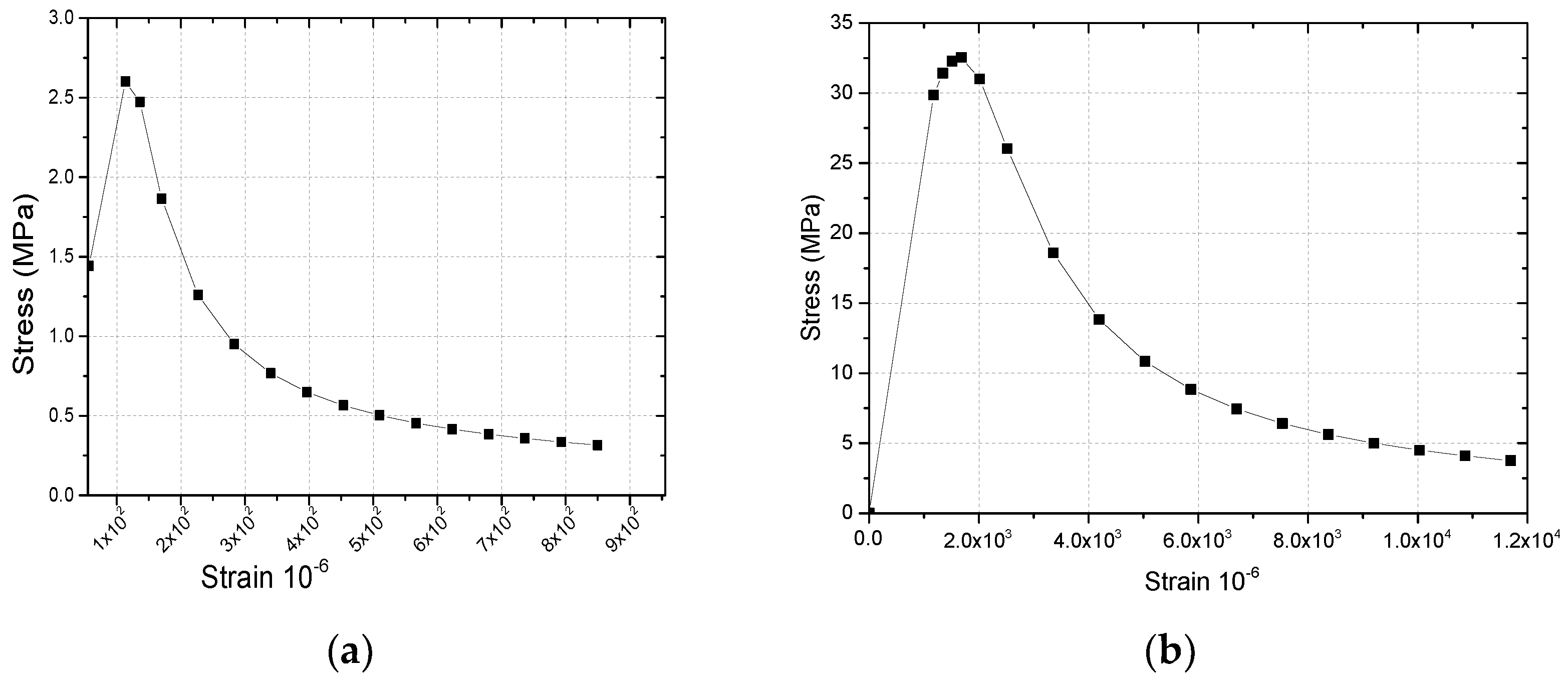

3.4. Material Constitutive Model

3.5. Finite Element Model Validation

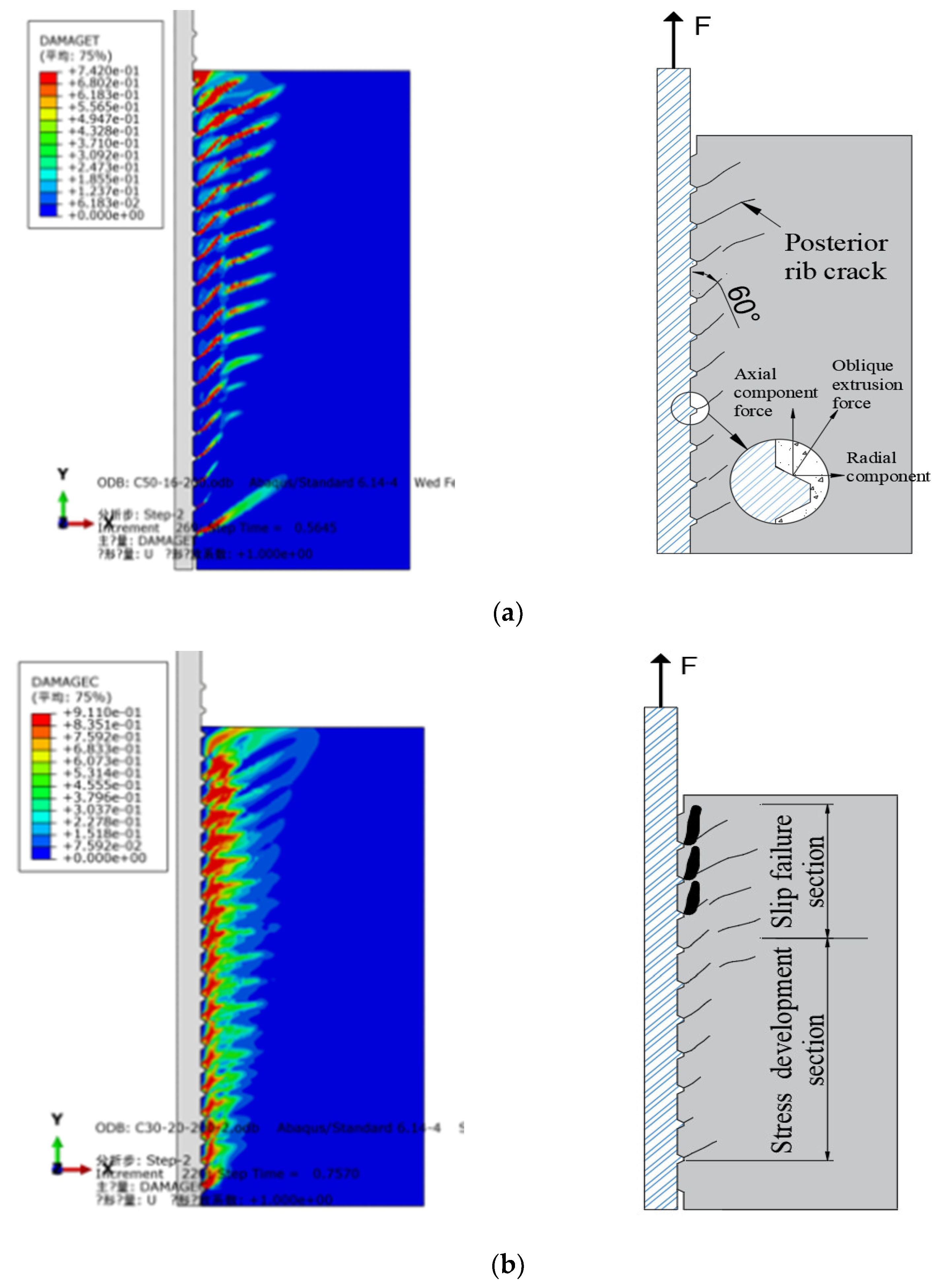

3.6. Analysis of Interface Bond Failure Process

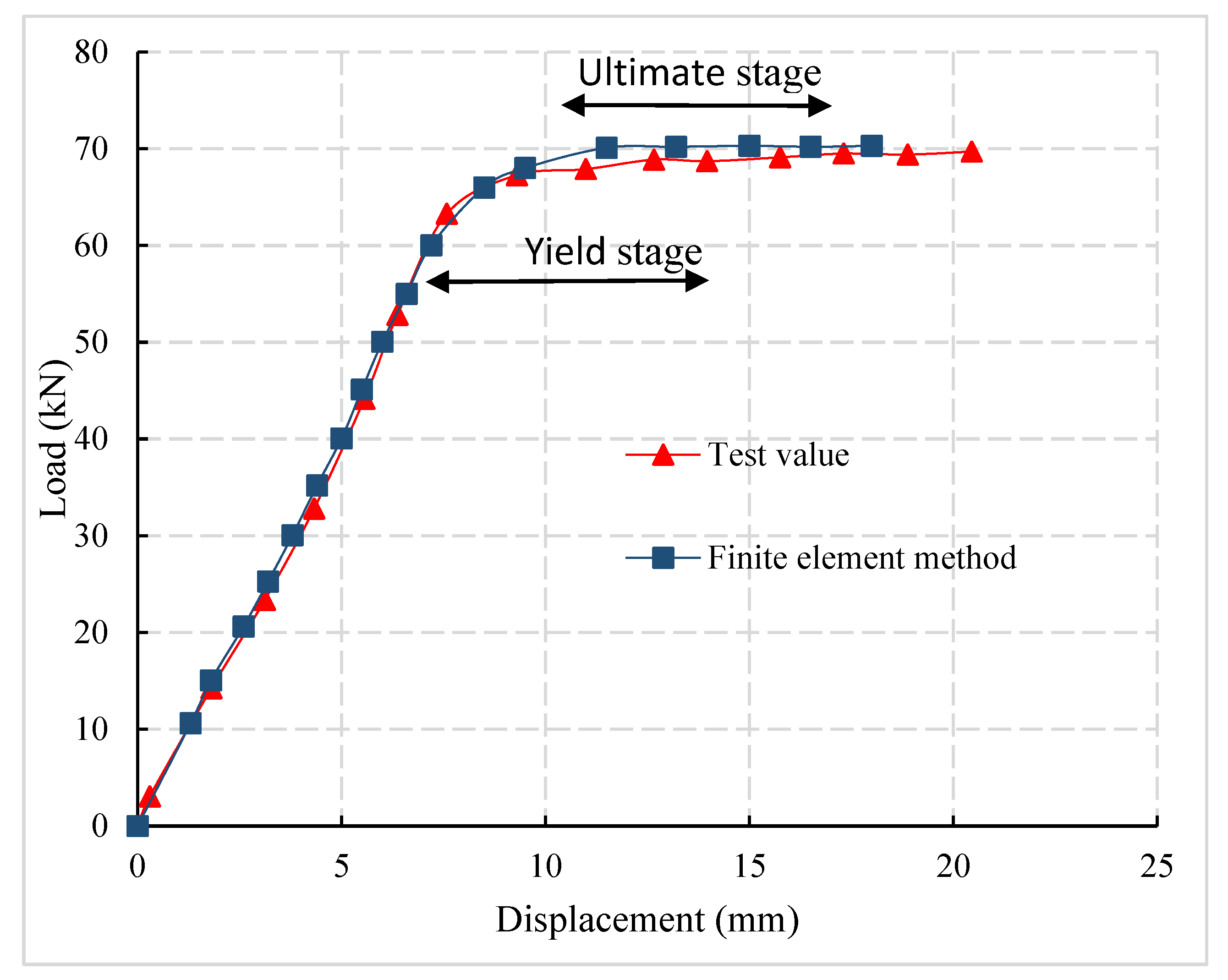

3.7. Load-Displacement Curve

4. Parametric Study

4.1. Scope of Investigation

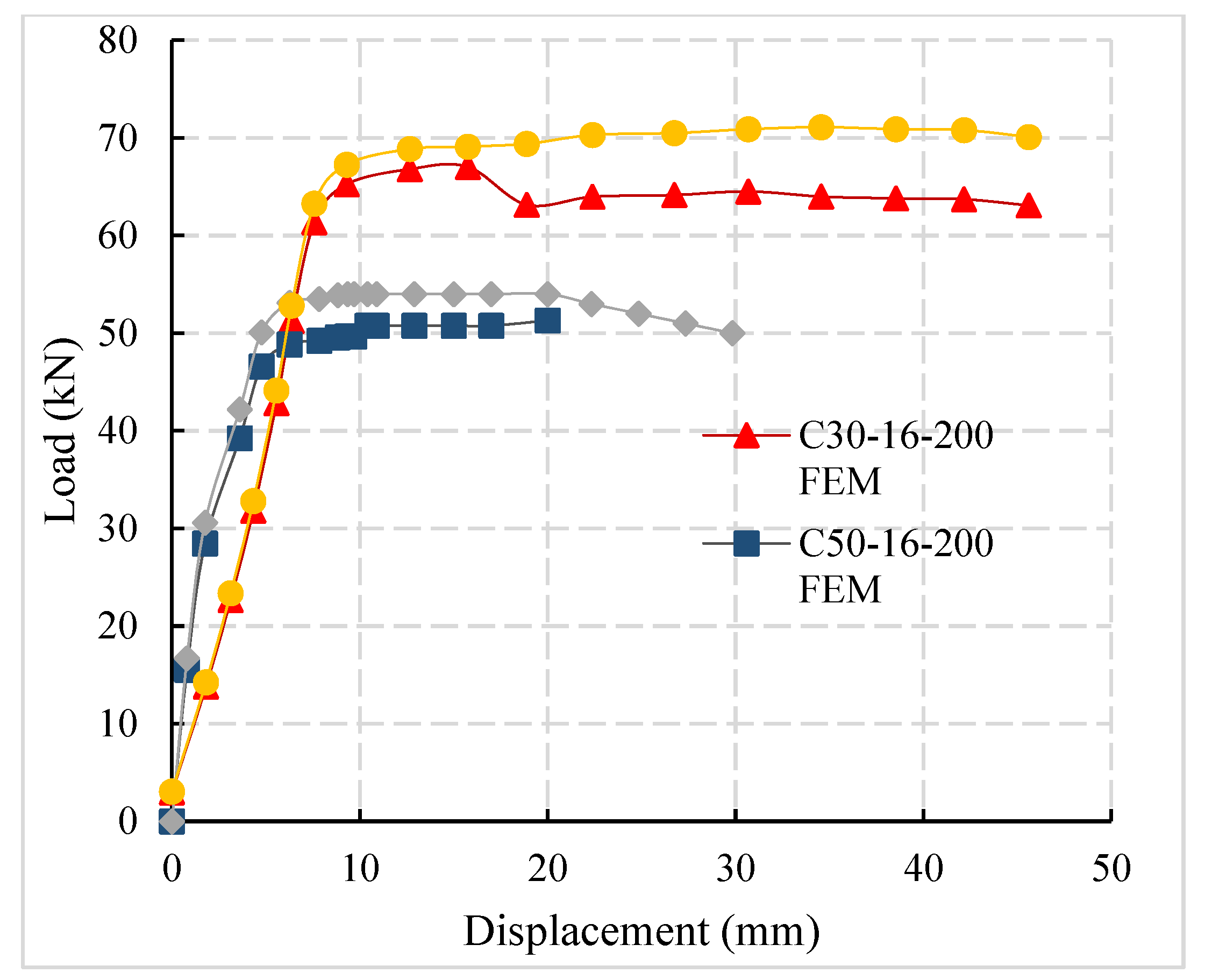

4.2. Comparison of Load-Displacement Curves of FEM and Test Result

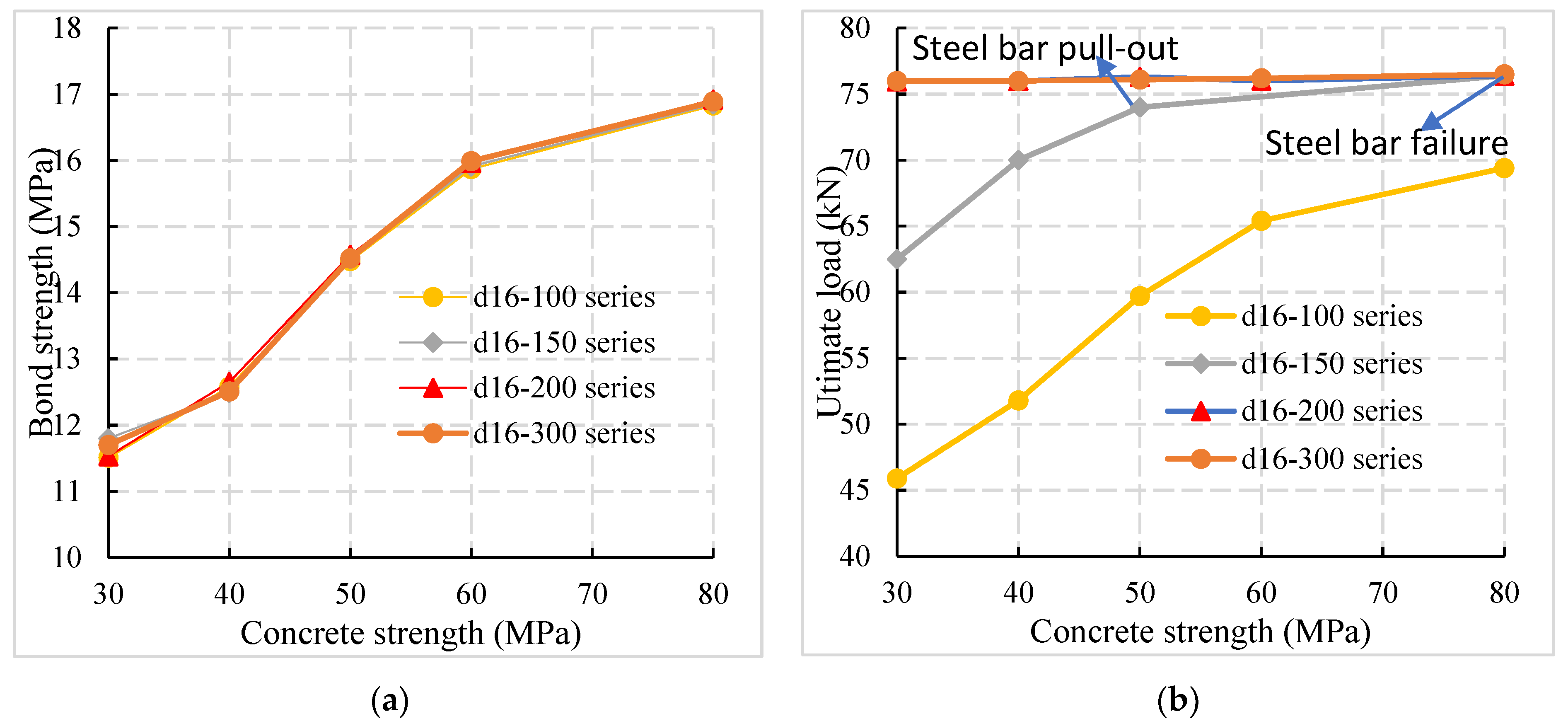

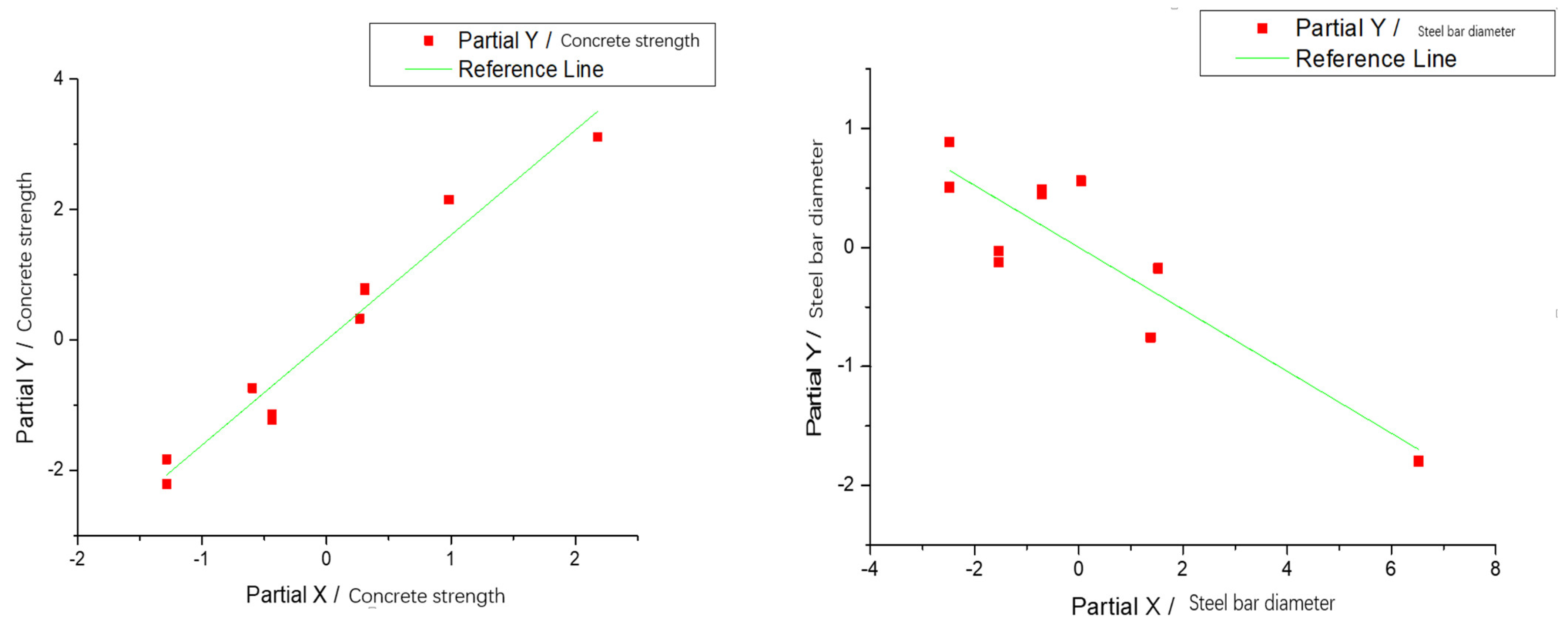

4.3. Influence of the Concrete Strength Grade

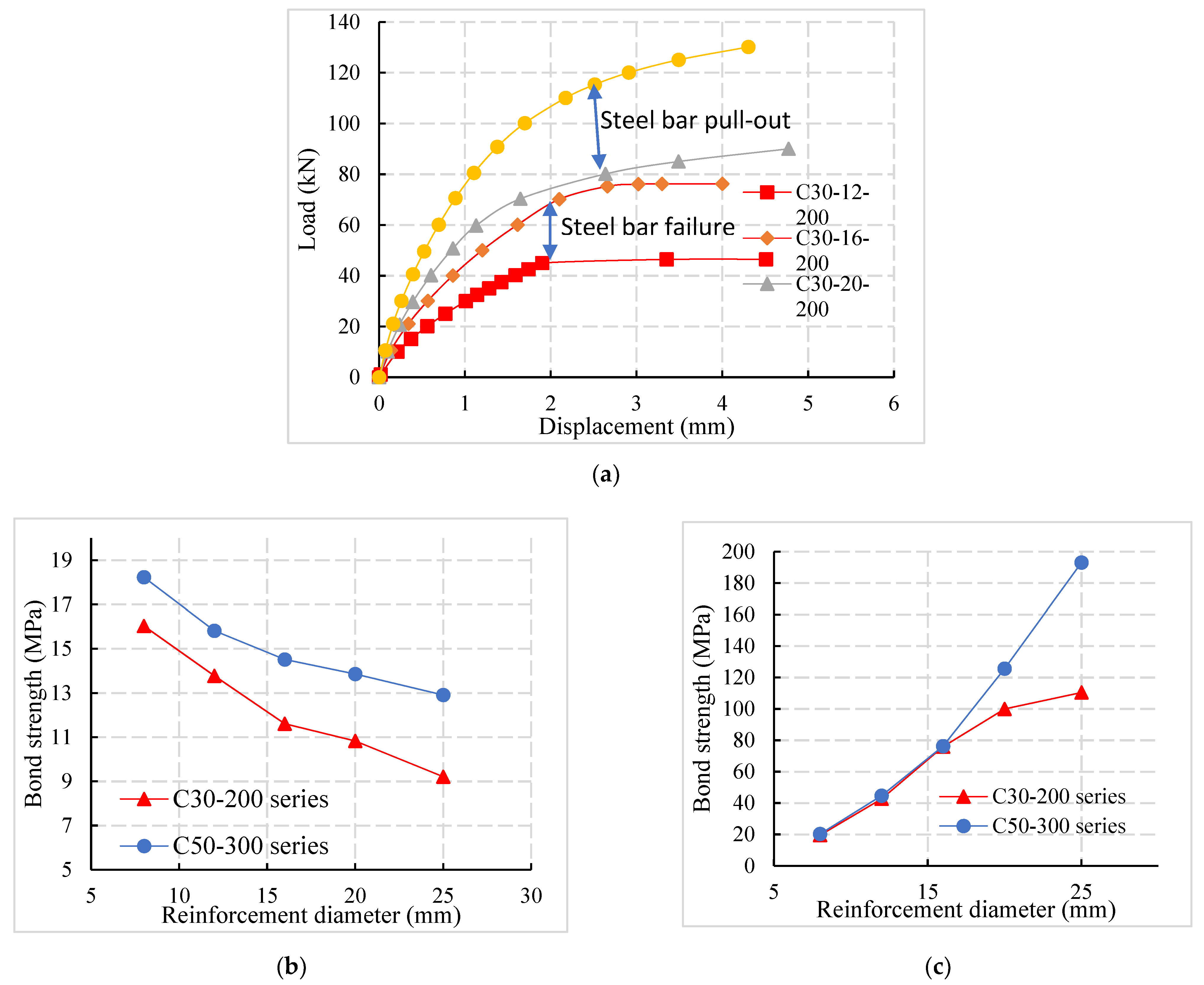

4.4. Influence of the Reinforcement Diameter

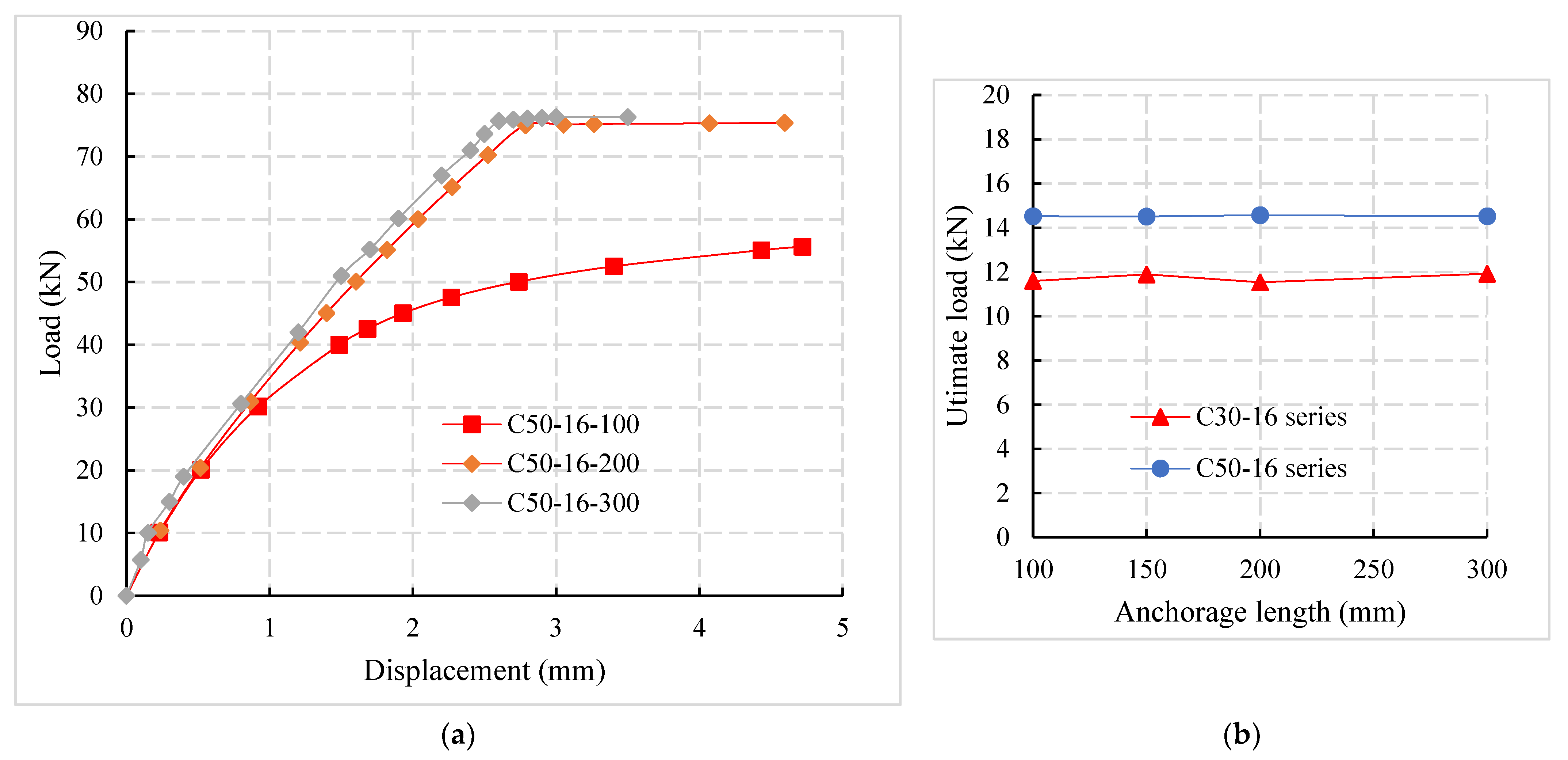

4.5. Influence of Anchorage Length

5. Simplified Calculation Formula

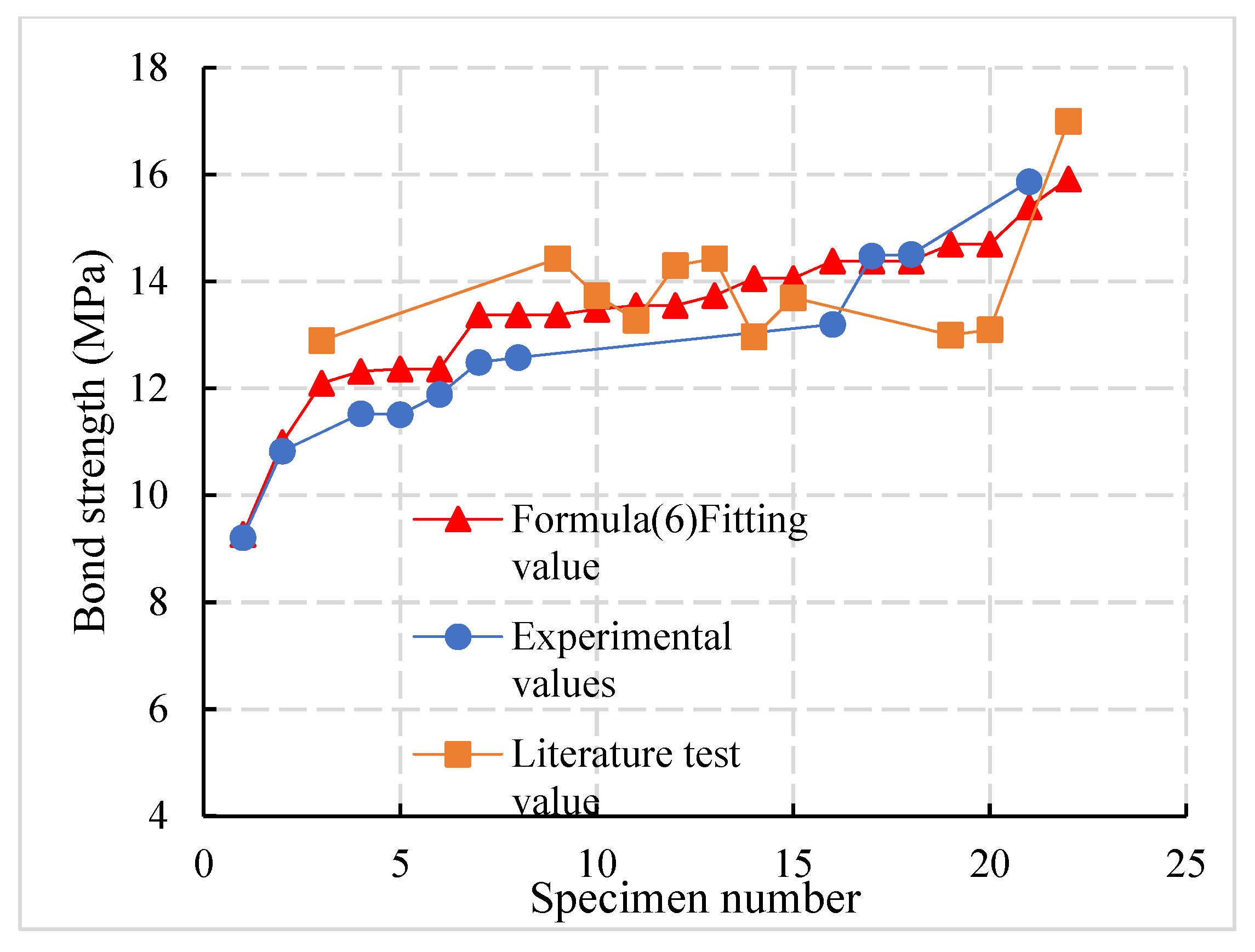

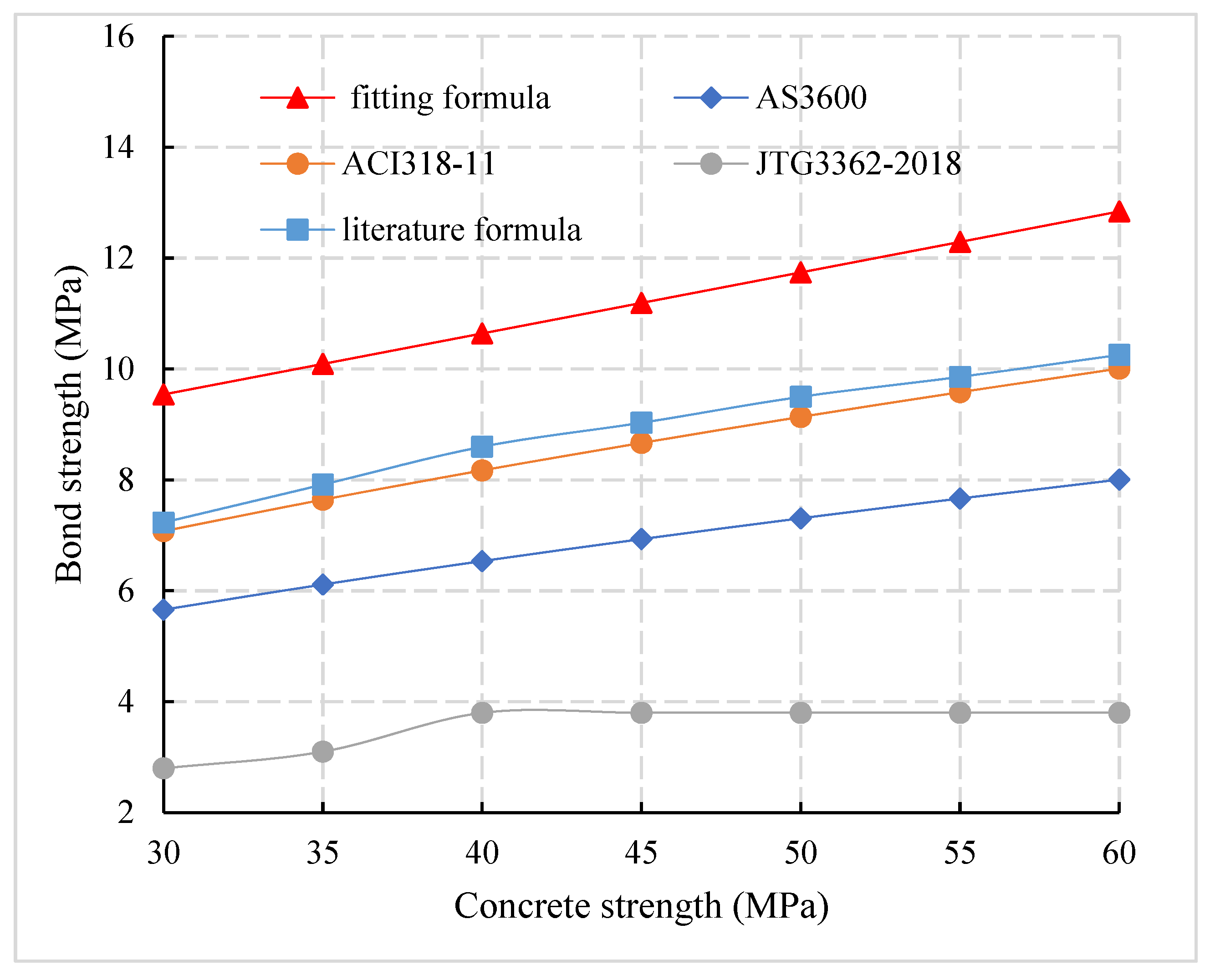

5.1. Calculation Formula for the Bond Strength

5.2. Calculation Formula for the Anchorage Length

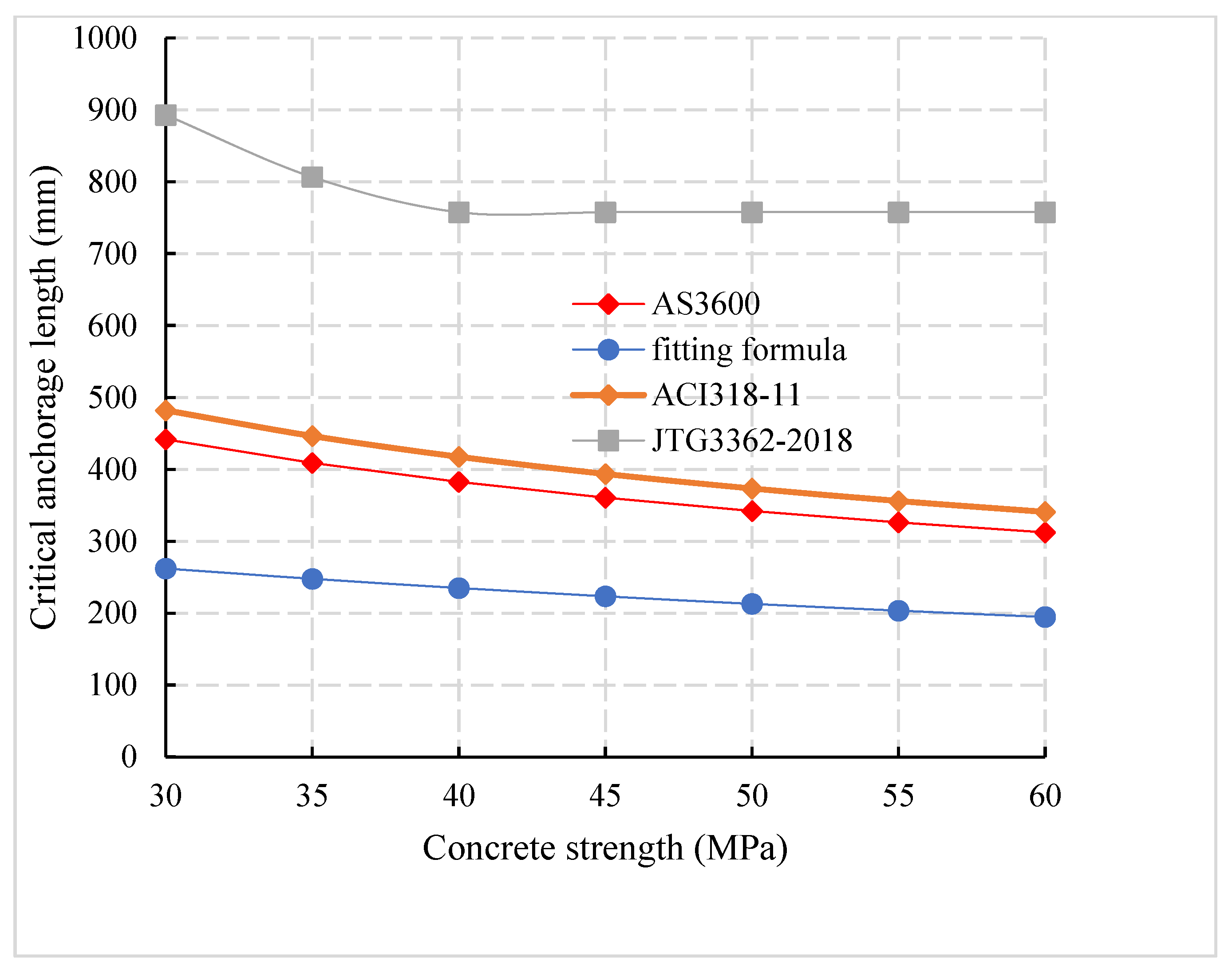

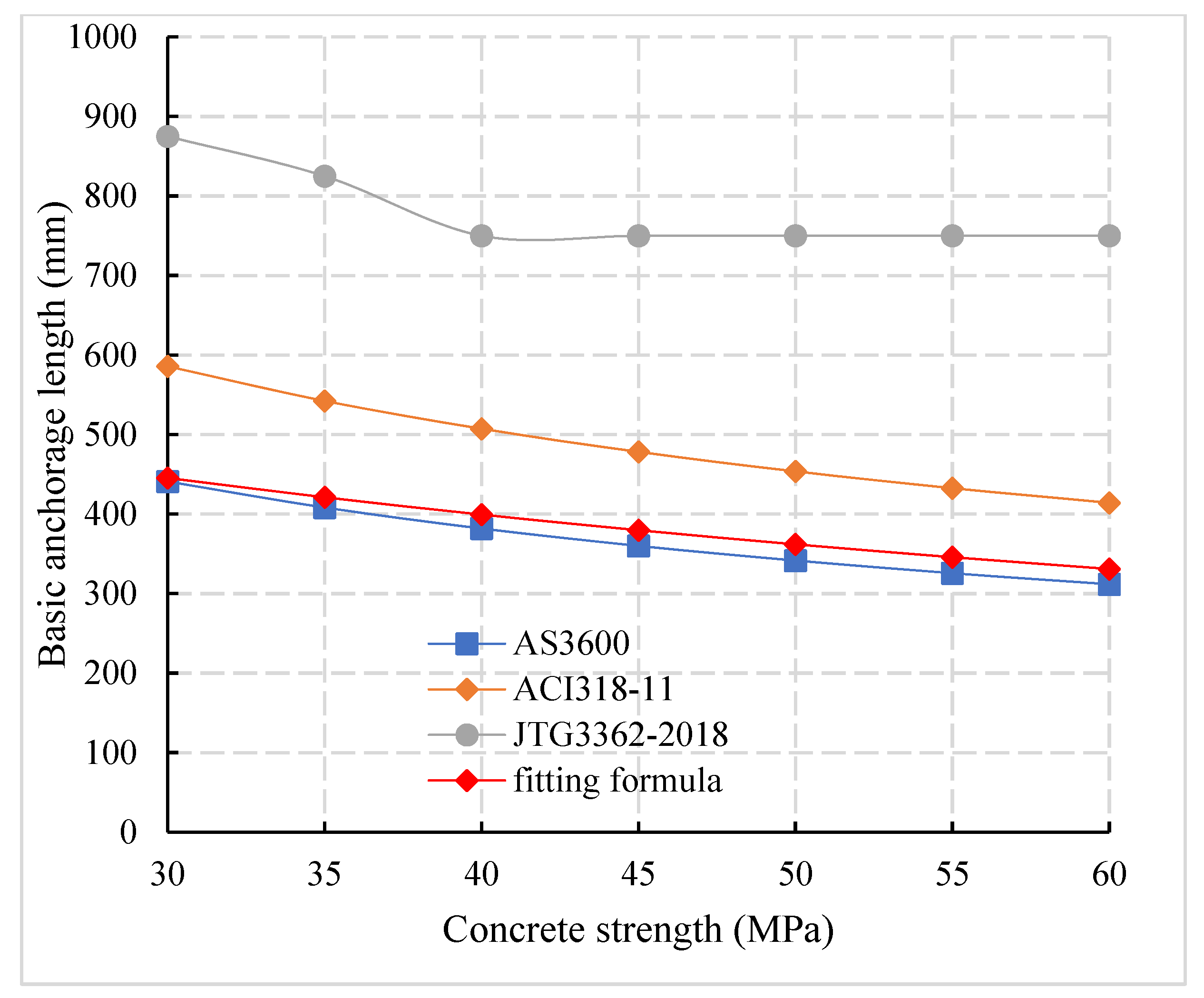

6. Discussion

7. Conclusions

- It is concluded that the effect of cover thickness of the surrounding concrete is negligible for calculating interface bond strength within prefabricated structures.

- Compared with C50-12-300 and C50-12-400, the ultimate load of C50-16-300 and C50-16-400 increased by 85.7% and 49.9%, respectively, and 19.8% and 20.8%, respectively, when compared with C30-16-300 and C30-16-400, which indicates that for precast concrete members with larger cover thicknesses, the concrete strength grade and reinforcement diameter possess a significant influence on the ultimate load of the bond interface between reinforcement and concrete.

- The ultimate load of the ribbed steel bar specimen C50-20-300 is 8.5 times higher than that of the plain steel bar specimen C50-G20-300. It is estimated that the mechanical interlocking force accounts for about 88% of the bond strength between deformed steel bars and concrete.

- It is concluded that domestic codes design the anchorage length of prefabricated members, leads to a large size, and increases the construction cost and construction difficulty. It is suggested to take it as 0.5 times the design value of the existing JTG3362-2018 [27] by considering the safety factor of 1.7 times.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Khaleghi, B.; Schultz, E.; Seguirant, S.; Marsh, L.; Haraldsson, O.; Eberhard, M.; Stanton, J. Accelerated bridge construction in Washington State: From research to practice. PCI J. 2012, 57, 34–49. [Google Scholar] [CrossRef]

- Baghchesaraei, O.R.; Hossein, H.L.; Alireza, B. Behavior of prefabricated structures in developed and developing countries. Bull. Soc. Sci. Liège 2016, 85, 1229–1234. [Google Scholar]

- Culmo, M.P. Accelerated Bridge. Construction: Experience in Design, Fabrication, and Erection of Prefabricated Bridge. Elements and Systems: Final Manual. No. FHWA-HIF-12-The United States. Federal Highway Administration; Office of Bridge Technology: Washington, DC, USA, 2011. [Google Scholar]

- Baran, E.; Tolga, A.; Seda, Y. Pull-out behavior of prestressing strands in steel fibre reinforced concrete. Constr. Build. Mater. 2012, 28, 362–371. [Google Scholar] [CrossRef]

- Li, S.; Song, C. Experimental research on bond anchorage performance of 1860-grade high-strength steel strands and lightweight aggregate concrete. Constr. Build. Mater. 2020, 235, 117482. [Google Scholar] [CrossRef]

- Li, H.-T.; Deeks, A.J.; Su, X.-Z. Experimental Study on Compressive Bond Anchorage Properties of 500 MPa Steel Bars in Concrete. J. Struct. Eng. 2013, 139, 04013005. [Google Scholar] [CrossRef]

- Saeed, Y.M.; Al-Obaidi, S.M.; Al-Hasany, E.G.; Rad, F.N. Evaluation of a new bond-type anchorage system with expansive grout for a single FRP rod. Constr. Build. Mater. 2020, 261, 120004. [Google Scholar] [CrossRef]

- Dang, C.N.W.; Micah, H.; José, R.M.-V. Quantification of bond performance of 18-mm prestressing steel. Construct. Build. Mater. 2018, 159, 451–462. [Google Scholar] [CrossRef]

- Hayashi, D.; Nagai, K.; Eddy, L. Mesoscale Analysis of RC Anchorage Performance in Multidirectional Reinforcement Using a Three-Dimensional Discrete Model. J. Struct. Eng. 2017, 143, 04017059. [Google Scholar] [CrossRef]

- Zhang, B.; Zhu, H.; Chen, J.; Yang, O. Evaluation of bond performance of corroded steel bars in concrete after high temperature exposure. Eng. Struct. 2019, 198, 109–479. [Google Scholar] [CrossRef]

- Cairns, J. Bond and anchorage of embedded steel reinforcement in fib Model Code. Struct. Concr. 2015, 16, 45–55. [Google Scholar] [CrossRef]

- Saatcioglu, M.; Alsiwat, J.M.; Ozcebe, G. Hysteretic Behavior of Anchorage Slip in R/C Members. J. Struct. Eng. 1992, 118, 2439–2458. [Google Scholar] [CrossRef]

- Abdallah, S.; Fan, M. Anchorage mechanisms of novel geometrical hooked-end steel fibres. Mater. Struct. 2017, 50, 139. [Google Scholar] [CrossRef] [Green Version]

- Sulaiman, M.F.; Ma, C.-K.; Apandi, N.M.; Chin, S.; Awang, A.Z.; Mansur, S.A.; Omar, W. A Review on Bond and Anchorage of Confined High-strength Concrete. Structures 2017, 11, 97–109. [Google Scholar] [CrossRef]

- Ogura, N.; Bolander, J.E.; Ichinose, T. Analysis of bond splitting failure of deformed bars within structural concrete. Eng. Struct. 2008, 30, 428–435. [Google Scholar] [CrossRef]

- Sucharda, O.; Mateckova, P.; Bilek, V. Non-Linear Analysis of an RC Beam without Shear Reinforcement with a Sensitivity Study of the Material Properties of Concrete. Slovak J. Civ. Eng. 2020, 28, 33–43. [Google Scholar] [CrossRef]

- Yu, Q.; Chen, Z.; Yang, J.; Rong, K. Numerical Study of Concrete Dynamic Splitting Based on 3D Realistic Aggregate Mesoscopic Model. Materials 2021, 14, 1948. [Google Scholar] [CrossRef] [PubMed]

- Jonak, J.; Siegmund, M.; Karpiński, R.; Wójcik, A. Three-Dimensional Finite Element Analysis of the Undercut Anchor Group Effect in Rock Cone Failure. Materials 2020, 13, 1332. [Google Scholar] [CrossRef] [Green Version]

- Jonak, J.; Karpiński, R.; Wójcik, A.; Siegmund, M. The Influence of the Physical-Mechanical Parameters of Rock on the Extent of the Initial Failure Zone under the Action of an Undercut Anchor. Materials 2021, 14, 1841. [Google Scholar] [CrossRef]

- Falkowicz, K.; Ferdynus, M.; Rozylo, P. Experimental and numerical analysis of stability and failure of compressed composite plates. Compos. Struct. 2021, 263, 113657. [Google Scholar] [CrossRef]

- Ombres, L.; Verre, S. Experimental and Numerical Investigation on the Steel Reinforced Grout (SRG) Composite-to-Concrete Bond. J. Compos. Sci. 2020, 4, 182. [Google Scholar] [CrossRef]

- Funari, M.F.; Spadea, S.; Fabbrocino, F.; Luciano, R. A Moving Interface Finite Element Formulation to Predict Dynamic Edge Debonding in FRP-Strengthened Concrete Beams in Service Conditions. Fibers 2020, 8, 42. [Google Scholar] [CrossRef]

- JGJ 145-2004 Technical Specification for Post Anchorage of Concrete Structures; Ministry of construction of the People’s Republic of China: Beijing, China, 2004.

- Ministry of Housing and Urban.-Rural Development of the People’s Republic of China. Code for Design of Concrete Structures (GB 50010-2010); Construction Industry: Beijing, China, 2010.

- National Standard of the People’s Republic of China, Steel for Reinforced Concrete Part. 2: Hot Rolled Ribbed Steel Bar: GB1499.2-Beijing: China; Quality Inspection Press: Beijing, China, 2018.

- State Administration of Market. Supervision and Administration. GB / T50082-Standard for Test. Methods of Long-Term Performance and Durability of Ordinary Concrete; Construction Industry Press: Beijing, China, 2010.

- JTG 3362—2018 Specifications for Design of Highway Reinforced Concrete and Prestressed Concrete Bridges and Culverts; Ministry of Transport of the People’s Republic of China: Beijing, China, 2018.

- Code for Design of Highway Reinforced Concrete and Prestressed Concrete Bridges and Culverts; People’s Communications Press: Beijing, China, 2018.

- Wang, C.; Wei, H.; Wu, J. Experimental research and numerical simulation on bond behavior between recycled concrete and rebar. J. Guangxi Uni. Nat. Sci. Ed. 2013, 4, 218–224. [Google Scholar]

- Liu, W.; Xu, M.; Chen, Z. Parameter calibration and verification of abaqus concrete damage plasticity model. Ind. Build. 2014, S1, 167. [Google Scholar]

- Zhao, W.; Xiao, J. On bond-slip Constitutive model between ribbed steel bars and concrete. Eng. Mech. 2011, 28, 164–171. [Google Scholar]

- Xu, Y.; Shao, Z.; Shen, W. Bonding and Anchor Strength of Reinforcement and Concrete. Architect. Sci. 1988, 04, 10–16. [Google Scholar]

- AS-3600. Standard Concrete Structures; Standards Australia International: Sydney, Australia, 2001. [Google Scholar]

- ACI Committee. ACI318-11 Building Code Requirements for Structural Concrete; American Concrete Institute: Farmington Hills, MI, USA, 2011. [Google Scholar]

- Yu, Q.; Xu, X.; You, G. Experimental study on bond behavior for ribbed steel bars and grout. J. Harbin Instit. Technol. 2017, 49, 91–101. [Google Scholar]

- Shan, X. Experimental Study on Bonding and Anchorage Properties between Deformed Steel Bar and Self-Compacting Concrete; Harbin Institute of Technology: Harbin, China, 2008. [Google Scholar]

| C30 | Mix Ratio | C50 | Mix Ratio | ||

|---|---|---|---|---|---|

| Cement | 440 | 1 | Cement | 450 | 1 |

| Sand | 532 | 1.209 | Sand | 682 | 1.515 |

| Aggregate | 1243 | 2.82 | Aggregate | 1113 | 2.47 |

| Water | 185 | 0.420 | Water | 155 | 0.344 |

| - | - | - | Fly ash | 50 | 0.111 |

| Specimen | Average of Elastic Modulus (MPa) | Compressive Strength (MPa) |

|---|---|---|

| C50 | 34,429 | 53.8 |

| C30 | 32,521 | 31.2 |

| Steel bar | Yield strength (MPa) | Ultimate strength (MPa) |

| HRB400Φ12 | 525 | 645 |

| HRB400Φ16 | 605 | 705 |

| Specimen Number | Failure Mode | Ultimate Load (kN) | Specimen Number | Failure Mode | Ultimate Load (kN) |

|---|---|---|---|---|---|

| C30-12-200 | Reinforcement failure | 59.5 | C50-12-200 | Reinforcement failure | 72.5 |

| C30-12-300 | Reinforcement failure | 64.75 | C50-12-300 | Reinforcement failure | 68.9 |

| C30-16-200 | Reinforcement failure | 60 | C50-16-200 | Reinforcement failure | 125.1 |

| C30-16-300 | Reinforcement failure | 106.82 | C50-16-300 | Reinforcement failure | 128 |

| C50-ø8-300 | Pull-out of a plain bar | 11.48 | C50-16-400 | Reinforcement failure | 119.7 |

| C50-ø20-300 | Pull-out of a plain bar | 18.1 | C50-20-300 | Reinforcement failure | 153.77 |

| Specimen | Poisson’s Ratio | Young’s Modulus (MPa) | Compressive Strength (MPa) |

|---|---|---|---|

| C50 | 0.2 | 34429 | 53.8 |

| C30 | 0.2 | 32521 | 31.2 |

| Steel bar | / | / | Ultimate strength (MPa) |

| HRB400Φ12 | 0.3 | 206000 | 645 |

| HRB400Φ16 | 0.3 | 206000 | 705 |

| Scheme | Failure Mode | Ultimate Load [kN] | Bond Strength /MPa | Specimen Number | Failure Mode | Ultimate Load [kN] | Bond Strength /MPa |

|---|---|---|---|---|---|---|---|

| C30-12-200 | Reinforcement failure | 42.71 | 14.78 | C50-16-300 | Reinforcement failure | 76.3 | 14.52 |

| C30-16-200 | Reinforcement failure | 75.96 | 11.53 | C50-12-300 | Reinforcement failure | 44.71 | 15.82 |

| C30-20-200 | Reinforcement pull-out | 99.97 | 10.83 | C50-20-200 | Reinforcement failure | 124.27 | 13.86 |

| C30-16-300 | Reinforcement failure | 74.4 | 11.81 | C50-16-200 | Reinforcement failure | 75.74 | 14.57 |

| Standard | Calculation Formula of Bond Strength |

|---|---|

| Australia AS3600 [33] | |

| America ACI318-11 [34] | |

| Literature [35] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, Z.; Shah, Y.I.; Yao, P. Experimental and Numerical Study on Interface Bond Strength and Anchorage Performance of Steel Bars within Prefabricated Concrete. Materials 2021, 14, 3713. https://doi.org/10.3390/ma14133713

Hu Z, Shah YI, Yao P. Experimental and Numerical Study on Interface Bond Strength and Anchorage Performance of Steel Bars within Prefabricated Concrete. Materials. 2021; 14(13):3713. https://doi.org/10.3390/ma14133713

Chicago/Turabian StyleHu, Zhijian, Yasir Ibrahim Shah, and Pengfei Yao. 2021. "Experimental and Numerical Study on Interface Bond Strength and Anchorage Performance of Steel Bars within Prefabricated Concrete" Materials 14, no. 13: 3713. https://doi.org/10.3390/ma14133713

APA StyleHu, Z., Shah, Y. I., & Yao, P. (2021). Experimental and Numerical Study on Interface Bond Strength and Anchorage Performance of Steel Bars within Prefabricated Concrete. Materials, 14(13), 3713. https://doi.org/10.3390/ma14133713