Mechanical Behavior of Bi-Layer and Dispersion Coatings Composed of Several Nanostructures on Ti13Nb13Zr Alloy

Abstract

1. Introduction

2. Materials and Methods

2.1. Surface Preparation

2.2. Preparation of MWCNTs/TiO2 Bi-Layer and MWCNTs_Cu Dispersion Coatings

2.3. Structure and Morphology

2.4. Nanoindentation Studies

3. Results and Discussion

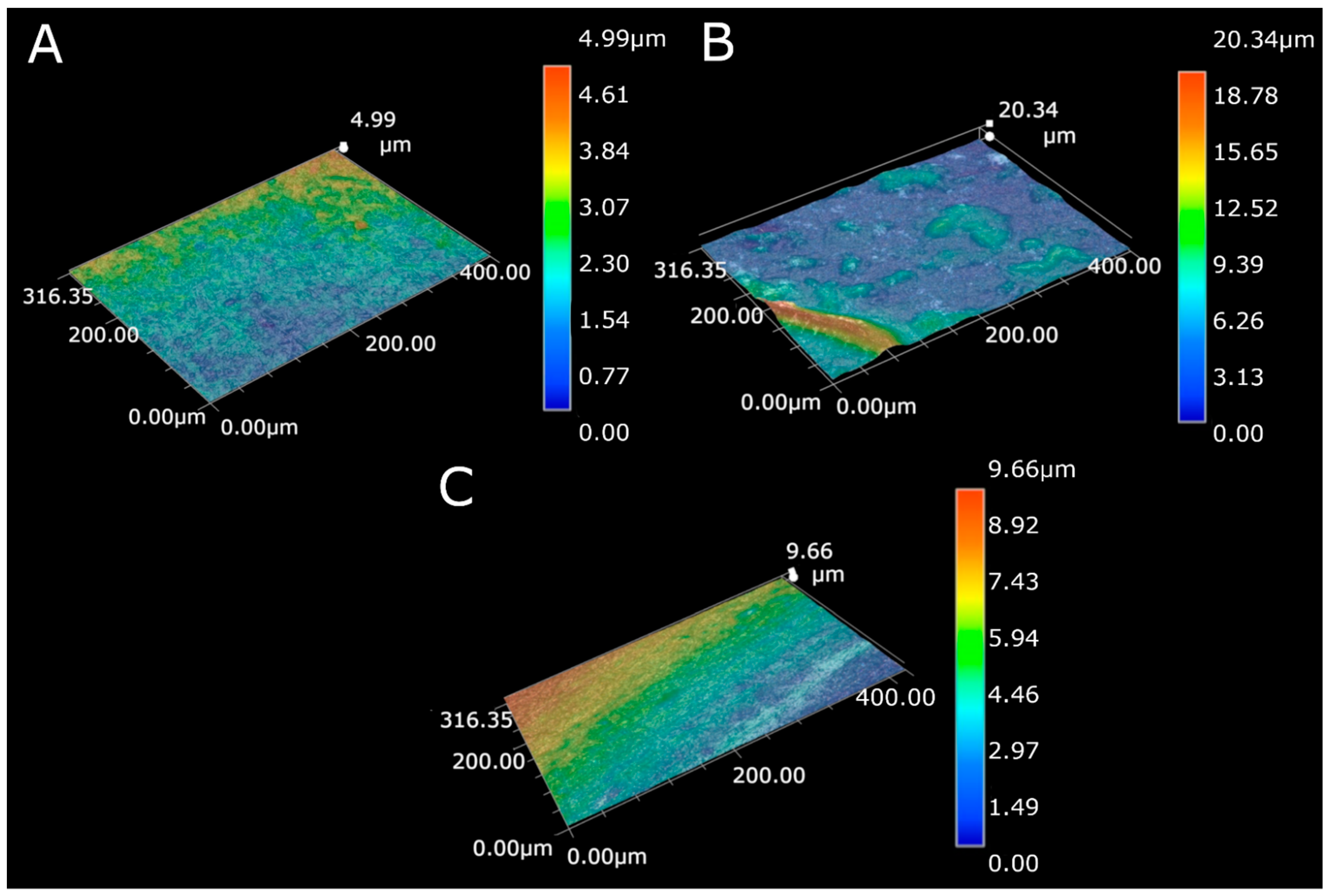

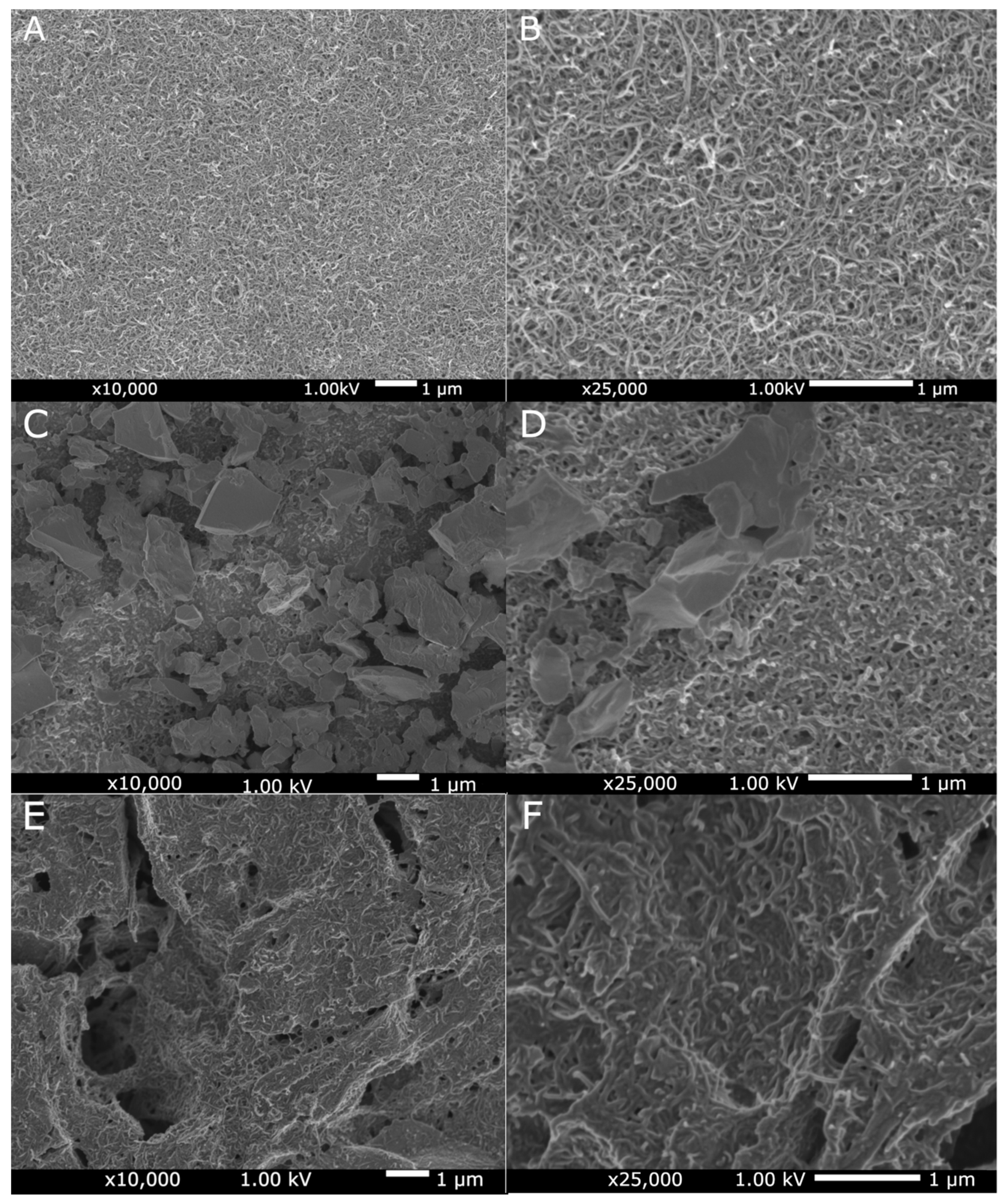

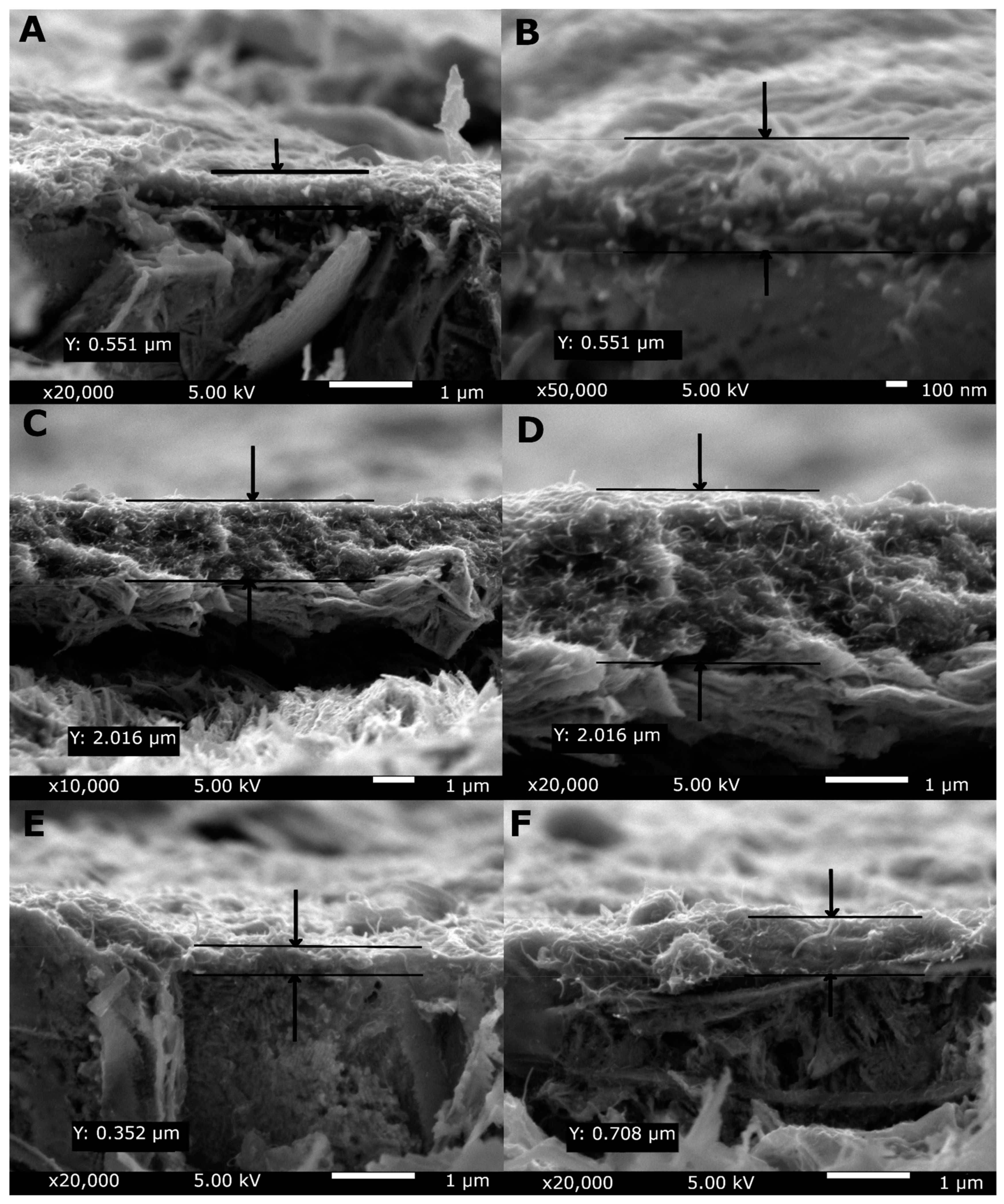

3.1. Structure and Morphology

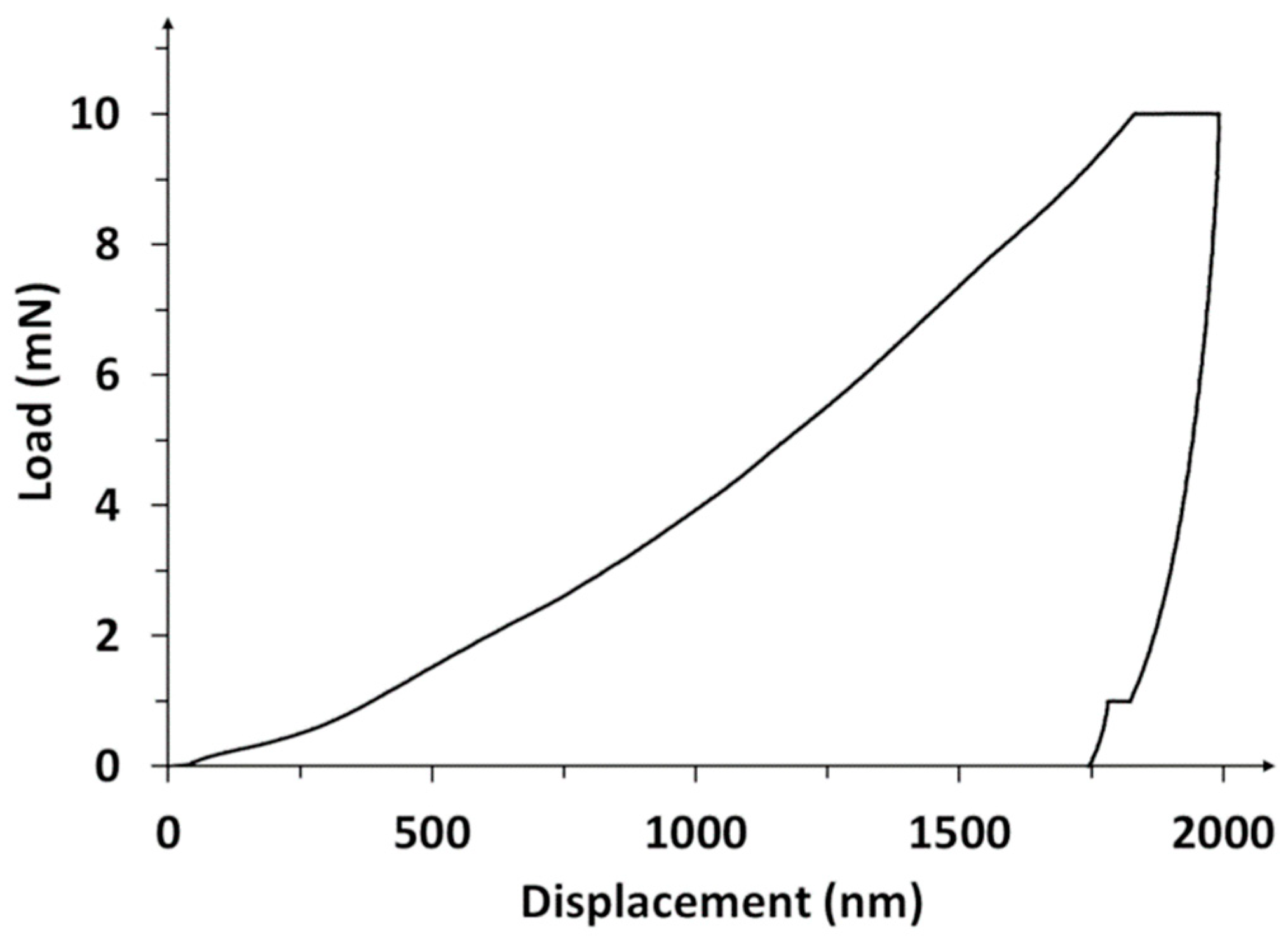

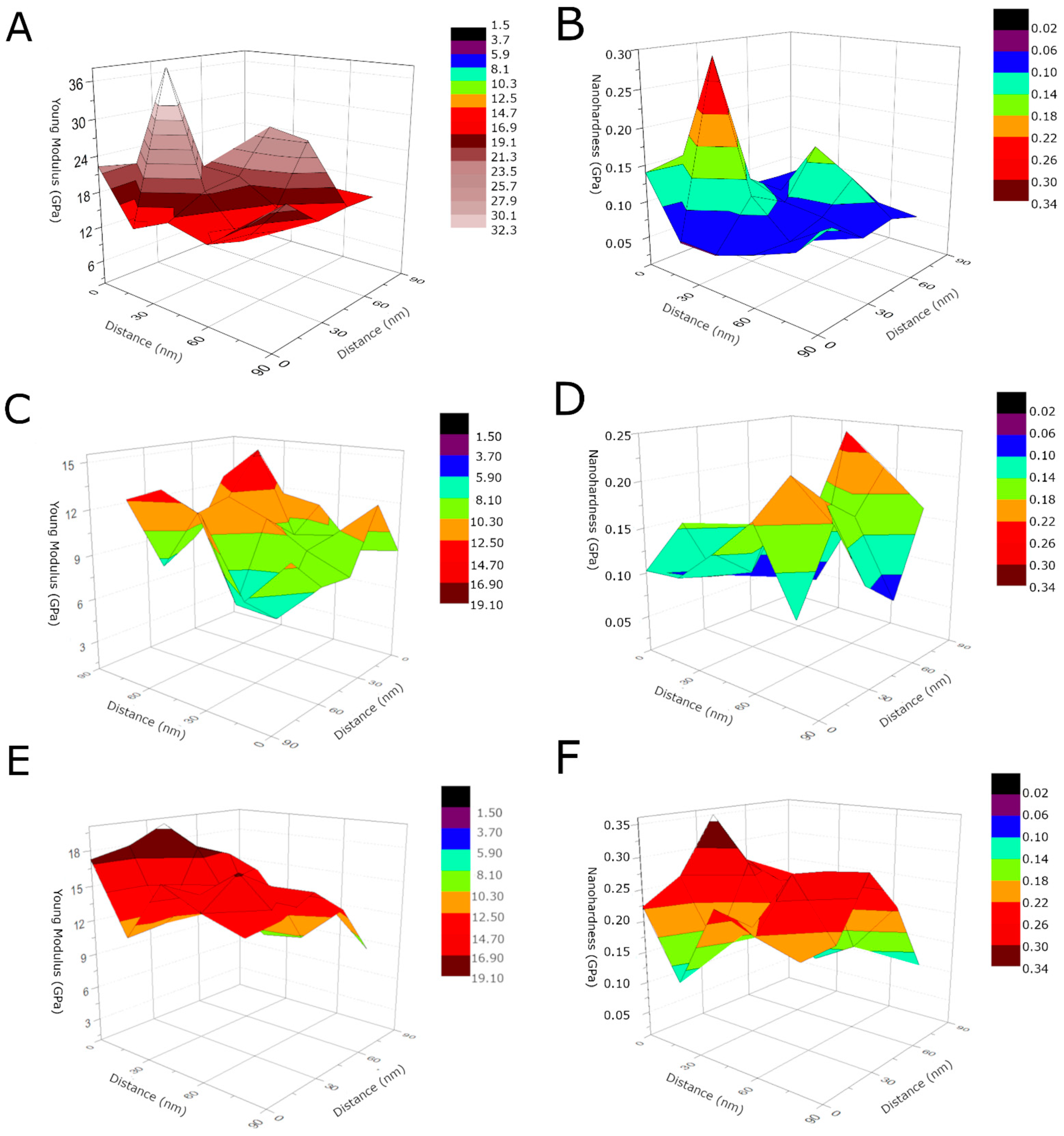

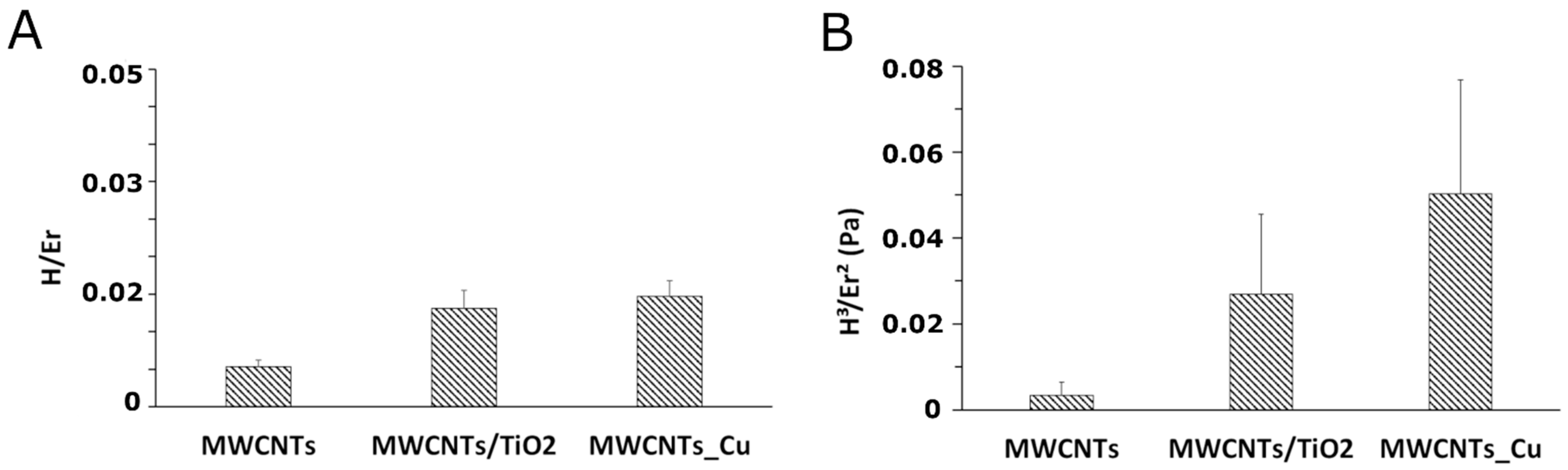

3.2. Nanoindentation Studies

4. Conclusions

- (1)

- The results show Young’s modulus value tends to decrease with rising nanohardness, which is a positive effect resulting from the structure of composite coatings, i.e., a simultaneous presence of elastic carbon nanotubes and tough nanoparticles of copper or rutile.

- (2)

- Both composite coatings demonstrate the mechanical properties better than the MWCNTs coating on Ti alloy. The additions of nanocopper or titanium dioxide to the MWCNTs coating-based Ti13Nb13Zr alloy substrate improve plastic and elastic recovery index, wear resistance to surface deflection, and to plastic deformation under applied load.

- (3)

- Comparing composite coatings to each other, the dispersion coating with nanocopper has distinctly higher hardness, slightly higher yield pressure and Young’s modulus, comparable endurance capability and elasticity recovery index, and substantially lower plasticity index. On the other side, the bi-layer coating has the greatest thickness combined with a satisfactory ability to accommodate the substrate under applied load, and the highest plasticity index, which indicates its best resistance to plastic deformation.

- (4)

- The yield pressure parameter is strictly related to the plasticity index, which shows the endurance of material to plastic deformation.

- (5)

- The observed stiffening effect can be attributed to dislocation strengthening under a load of the nanoindenter tip in presence of tough and hard nanoparticles.

- (6)

- The noticed decreasing Young’s modulus in both composite coatings compared to the MWCNTs coating may be explained by an appearance of porosity of coatings.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Park, J.E.; Jang, Y.S.; Bae, T.S.; Lee, M.H. Biocompatibility characteristics of titanium coated with multiwalled carbon nanotubes-hydroxyapatite nanocomposites. Materials 2019, 12, 224. [Google Scholar] [CrossRef]

- Ji, X.; Li, X.; Yu, H.; Zhang, W.; Dong, H. Study on the carbon nanotubes reinforced nanocomposite coatings. Diam. Relat. Mater. 2019, 91, 247–254. [Google Scholar] [CrossRef]

- Curtin, W.A.; Sheldon, B.W. CNT-reinforced ceramics and metals. Mater. Today 2004, 7, 44–49. [Google Scholar] [CrossRef]

- Maleki-Ghaleh, H.; Khalil-Alla, J. Characterization, mechanical and in vitro biological behavior of hydroxyapatite-titanium-carbon nanotube composite coatings deposited on NiTi alloy by electrophoretic deposition. Surf. Coat. Technol. 2019, 363, 179–190. [Google Scholar] [CrossRef]

- Cho, J.; Schaab, S.; Roether, J.A.; Boccaccini, A.R. Nanostructured carbon nanotube/TiO2 composite coatings using electrophoretic deposition (EPD). J. Nanopart. Res. 2008, 10, 99–105. [Google Scholar] [CrossRef]

- Priyadershini, S.; Rahman, O.S.A.; Pandey, K.K.; Keshri, A.K. Remarkable improvement in tribological behavior of plasma sprayed carbon nanotube and graphene nanoplatelates hybrid reinforced alumina nanocomposite coating. Ceram. Int. 2019, 45, 5768–5778. [Google Scholar] [CrossRef]

- Ahmad, I.; Kennedy, A.; Zhu, Y.Q. Wear resistant properties of multi-walled carbon nanotubes reinforced Al2O3 nanocomposites. Wear 2010, 269, 71–78. [Google Scholar] [CrossRef]

- Jambagi, S.C. Scratch adhesion strength of plasma sprayed carbon nanotube reinforced ceramic coatings. J. Alloys Compd. 2017, 728, 126–137. [Google Scholar] [CrossRef]

- Lahiri, D.; Singh, V.; Keshri, A.K.; Seal, S.; Agarwal, A. Carbon nanotube toughened hydroxyapatite by spark plasma sintering: Microstructural evolution and multiscale tribological properties. Carbon 2010, 48, 3103–3120. [Google Scholar] [CrossRef]

- Rajesh, R.; Senthilkumar, N.; Hariharasubramanian, A.; Ravichandran, Y.D. Review on hydroxyapatite-carbon nanotube composites and some of their applications. Int. J. Pharm. Pharm. Sci. 2012, 4, 2–6. [Google Scholar]

- Singh, I.; Allan, P.; London, W. Nano-mechanical testing of novel bioactive carbon nanotubes/HAP nano particles composite coating. NSTI Nanotechol. 2007, 4, 145–148. [Google Scholar]

- Farrokhi-rad, M.; Shahrabi, T.; Mahmoodi, S.; Khanmohammadi, S. Electrophoretic deposition of hydroxyapatite-chitosan-CNTs nanocomposite coatings. Ceram. Int. 2017, 43, 4663–4669. [Google Scholar] [CrossRef]

- Kaya, C.; Singh, I.; Boccaccini, A.R. Multi-walled carbon nanotube-reinforced hydroxyapatite layers on Ti6Al4V medical implants by electrophoretic deposition (EPD). Adv. Eng. Mater. 2008, 10, 131–138. [Google Scholar] [CrossRef]

- Wang, H.; He, P.; Ma, G.; Xu, B.; Xing, Z.; Chen, S.; Liu, Z.; Wang, Y. Tribological behavior of plasma sprayed carbon nanotubes reinforced TiO2 coatings. J. Eur. Ceram. Soc. 2018, 38, 3660–3672. [Google Scholar] [CrossRef]

- Jarernboon, W.; Pimanpang, S.; Maensiri, S.; Swatsitang, E.; Amornkitbamrung, V. Effects of multiwall carbon nanotubes in reducing microcrack formation on electrophoretically deposited TiO2 film. J. Alloys Compd. 2009, 476, 840–846. [Google Scholar] [CrossRef]

- Jażdżewska, M.; Bartmański, M. Nanotubular Oxide Layer Formed on Helix Surfaces of Dental Screw Implants. Coatings 2021, 11, 115. [Google Scholar] [CrossRef]

- Golchin, A.; Wikner, A.; Emami, N. An investigation into tribological behaviour of multi-walled carbon nanotube/graphene oxide reinforced UHMWPE in water lubricated contacts. Tribiol. Int. 2016, 95, 156–161. [Google Scholar] [CrossRef]

- Samad, M.A.; Sinha, S.K. Mechanical, thermal and tribological characterization of a UHMWPE film reinforced with carbon nanotubes coated on steel. Tribiol. Int. 2011, 44, 1932–1941. [Google Scholar] [CrossRef]

- Lee, C.K. Wear and corrosion behavior of electrodeposited nickel–carbon nanotube composite coatings on Ti–6Al–4V alloy in Hanks’ solution. Tribiol. Int. 2012, 55, 7–14. [Google Scholar] [CrossRef]

- Chen, X.H.; Chen, C.S.; Xiao, H.N.; Liu, H.B.; Zhou, L.P.; Li, S.L.; Zhang, G. Dry friction and wear characteristics of nickel/carbon nanotube electroless composite deposits. Tribiol. Int. 2006, 39, 22–28. [Google Scholar] [CrossRef]

- Zhen-Qiang, M.; Xi-Bin, L.I.; Yong-Jun, X.; Jing, Z. Preparation and tribological performances of Ni − P − multi-walled carbon nanotubes composite coatings. Trans. Nonferrous Met. Soc. China 2012, 22, 2719–2725. [Google Scholar] [CrossRef]

- Ammara, S.; Shamaila, S.; Bokhari, A.; Sabah, A. Nonenzymatic glucose sensor with high performance electrodeposited nickel/copper/carbon nanotubes nanocomposite electrode. J. Phys. Chem. Solids 2018, 120, 12–19. [Google Scholar] [CrossRef]

- Bakshi, S.R.; Lahiri, D.; Patel, R.R.; Agarwal, A. Nanoscratch behavior of carbon nanotube reinforced aluminum coatings. Thin Solid Films 2010, 518, 1703–1711. [Google Scholar] [CrossRef]

- Bakshi, S.R.; Keshri, A.K.; Agarwal, A. A comparison of mechanical and wear properties of plasma sprayed carbon nanotube reinforced aluminum composites at nano and macro scale. Mater. Sci. Eng. A 2011, 528, 3375–3384. [Google Scholar] [CrossRef]

- Maiti, A.; Laha, T. Study of distribution of Carbon nanotube in Al-CNT nanocomposite synthesized via Spark-Plasma sintering. IOP Conf. Ser. Mater. Sci. Eng. 2018, 338, 012014. [Google Scholar] [CrossRef]

- Zeng, Z.; Lin, Y. Mechanical properties of hard Cr—MWNT composite coatings. Surf. Coat. Technol. 2009, 203, 3610–3613. [Google Scholar] [CrossRef]

- Zanello, L.P.; Zhao, B.; Hu, H.; Haddon, R.C. Bone Cell Proliferation on Carbon Nanotubes. Nano Lett. 2006, 6, 562–567. [Google Scholar] [CrossRef]

- Sasani, N.; Vahdati Khaki, J.; Mojtaba Zebarjad, S. Characterization and nanomechanical properties of novel dental implant coatings containing copper decorated-carbon nanotubes. J. Mech. Behav. Biomed. Mater. 2014, 37, 125–132. [Google Scholar] [CrossRef] [PubMed]

- Benko, A.; Wiecheć, A.; Rajchel, B.; Długoń, E.; Błażewicz, M. Titanium surface modification with carbon nanotubes. Towards improved biocompatibility. Acta Phys. Pol. A 2016, 129, 176–178. [Google Scholar] [CrossRef]

- Zhao, X.; Chang, S.; Long, J.; Li, J.; Li, X.; Cao, Y. The toxicity of multi-walled carbon nanotubes (MWCNTs) to human endothelial cells: The influence of diameters of MWCNTs. Food Chem. Toxicol. 2019, 126, 169–177. [Google Scholar] [CrossRef]

- Li, Y.; Cao, J. The impact of multi-walled carbon nanotubes (MWCNTs) on macrophages: Contribution of MWCNT characteristics. Sci. China Life Sci. 2018, 61, 1333–1351. [Google Scholar] [CrossRef] [PubMed]

- Louro, H. Relevance of physicochemical characterization of nanomaterials for understanding nano-cellular interactions. Adv. Exp. Med. Biol. 2018, 1048, 123–142. [Google Scholar] [CrossRef] [PubMed]

- Portan, D.V.; Deligianni, D.D.; Deligianni, K.; Kroustalli, A.A.; Tyllianakis, M.; Papanicolaou, G.C. Modeling of the interaction between osteoblasts and biocompatible substrates as a function of adhesion strength. J. Biomed. Mater. Res. Part A 2018, 106, 621–628. [Google Scholar] [CrossRef] [PubMed]

- Kumar, P. Nano-TiO2 doped chitosan scaffold for the bone tissue engineering applications. Int. J. Biomater. 2018, 2018, 1–7. [Google Scholar] [CrossRef]

- Fathi-Achachelouei, M.; Knopf-Marques, H.; Ribeiro da Silva, C.E.; Barthès, J.; Bat, E.; Tezcaner, A.; Vrana, N.E. Use of nanoparticles in tissue engineering and regenerative medicine. Front. Bioeng. Biotechnol. 2019, 7, 1–22. [Google Scholar] [CrossRef] [PubMed]

- Park, H.; Yeo, M. Effects of TiO2 nanoparticles and nanotubes on zebrafish caudal fin regeneration. Mol. Cell. Toxicol. 2013, 9, 375–383. [Google Scholar] [CrossRef]

- Kumar, S.; Rani, R.; Dilbaghi, N.; Tankeshwar, K.; Kim, K.-H. Carbon nanotubes: A novel material for multifaceted applications in human healthcare. Chem. Soc. Rev. 2017, 46, 158–196. [Google Scholar] [CrossRef]

- Vargas, M.A.; Rodríguez-Páez, J.E. Amorphous TiO2 nanoparticles: Synthesis and antibacterial capacity. J. Non. Cryst. Solids 2017, 459, 192–205. [Google Scholar] [CrossRef]

- Raddaha, N.; Cordero-Arias, L.; Cabanas-Polo, S.; Virtanen, S.; Roether, J.; Boccaccini, A. Electrophoretic deposition of chitosan/h-BN and chitosan/h-BN/TiO2 composite coatings on stainless steel (316L) substrates. Materials 2014, 7, 1814–1829. [Google Scholar] [CrossRef] [PubMed]

- Ikono, R.; Li, N.; Pratama, N.H.; Vibriani, A.; Yuniarni, D.R.; Luthfansyah, M.; Bachtiar, B.M.; Bachtiar, E.W.; Mulia, K.; Nasikin, M.; et al. Enhanced bone regeneration capability of chitosan sponge coated with TiO2 nanoparticles. Biotechnol. Rep. 2019, 24, e00350. [Google Scholar] [CrossRef]

- Hsiao, I.-L.; Huang, Y.-J. Effects of various physicochemical characteristics on the toxicities of ZnO and TiO2 nanoparticles toward human lung epithelial cells. Sci. Total Environ. 2011, 409, 1219–1228. [Google Scholar] [CrossRef] [PubMed]

- Uboldi, C.; Urbán, P.; Gilliland, D.; Bajak, E.; Valsami-Jones, E.; Ponti, J.; Rossi, F. Role of the crystalline form of titanium dioxide nanoparticles: Rutile, and not anatase, induces toxic effects in Balb/3T3 mouse fibroblasts. Toxicol. Vitr. 2016, 31, 137–145. [Google Scholar] [CrossRef]

- Boccaccini, A.R.; Cho, J.; Roether, J.A.; Thomas, B.J.C.; Minay, E.J.; Shaffer, M.S.P. Electrophoretic deposition of carbon nanotubes. Carbon 2006, 44, 3149–3160. [Google Scholar] [CrossRef]

- Mohammed Thalib Basha, G.; Srikanth, A.; Venkateshwarlu, B. Effect of reinforcement of carbon nanotubes on air plasma sprayed conventional Al2O3-3%TiO2 ceramic coatings. Mater. Today Proc. 2020, 20, 191–194. [Google Scholar] [CrossRef]

- Kolmas, J.; Groszyk, E.; Kwiatkowska-Różycka, D. Substituted hydroxyapatites with antibacterial properties. Biomed. Res. Int. 2014, 2014, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Hidalgo-Robatto, B.M.; López-Álvarez, M.; Azevedo, A.S.; Dorado, J.; Serra, J.; Azevedo, N.F.; González, P. Pulsed laser deposition of copper and zinc doped hydroxyapatite coatings for biomedical applications. Surf. Coat. Technol. 2018, 333, 168–177. [Google Scholar] [CrossRef]

- Shanmugam, S.; Gopal, B. Copper substituted hydroxyapatite and fluorapatite: Synthesis, characterization and antimicrobial properties. Ceram. Int. 2014, 40, 15655–15662. [Google Scholar] [CrossRef]

- Rau, J.V.; Wu, V.M.; Graziani, V.; Fadeeva, I.V.; Fomin, A.S.; Fosca, M.; Uskoković, V. The bone building blues: Self-hardening copper-doped calcium phosphate cement and its in vitro assessment against mammalian cells and bacteria. Mater. Sci. Eng. C 2017, 79, 270–279. [Google Scholar] [CrossRef]

- Chen, Z.; Meng, H.; Xing, G.; Chen, C.; Zhao, Y.; Jia, G.; Wang, T.; Yuan, H.; Ye, C.; Zhao, F.; et al. Acute toxicological effects of copper nanoparticles in vivo. Toxicol. Lett. 2006, 163, 109–120. [Google Scholar] [CrossRef]

- Radovanović, Ž.; Jokić, B.; Veljović, D.; Dimitrijević, S.; Kojić, V.; Petrović, R.; Janaćković, D. Antimicrobial activity and biocompatibility of Ag+- and Cu2+-doped biphasic hydroxyapatite/α-tricalcium phosphate obtained from hydrothermally synthesized Ag+- and Cu2+-doped hydroxyapatite. Appl. Surf. Sci. 2014, 307, 513–519. [Google Scholar] [CrossRef]

- Karthika, A. Biocompatible iron and copper incorporated nanohydroxyapatite coating for biomedical implant applications. Mater. Today Proc. 2021, in press. [Google Scholar] [CrossRef]

- Rivera, L.R.; Cochis, A.; Biser, S.; Canciani, E.; Ferraris, S.; Rimondini, L.; Boccaccini, A.R. Antibacterial, pro-angiogenic and pro-osteointegrative zein-bioactive glass/copper based coatings for implantable stainless steel aimed at bone healing. Bioact. Mater. 2021, 6, 1479–1490. [Google Scholar] [CrossRef]

- Liang, T.; Wang, Y.; Zeng, L.; Liu, Y.; Qiao, L.; Zhang, S.; Zhao, R.; Li, G.; Zhang, R.; Xiang, J.; et al. Copper-doped 3D porous coating developed on Ti-6Al-4V alloys and its in vitro long-term antibacterial ability. Appl. Surf. Sci. 2020, 509, 144717. [Google Scholar] [CrossRef]

- Fraczek-Szczypta, A.; Wedel-Grzenda, A.; Benko, A.; Grzonka, J.; Mizera, J. Interaction of carbon nanotubes coatings with titanium substrate. Appl. Phys. A 2017, 123, 120. [Google Scholar] [CrossRef]

- Cho, J.; Konopka, K.; Rożniatowski, K.; García-Lecina, E.; Shaffer, M.S.P.; Boccaccini, A.R. Characterisation of carbon nanotube films deposited by electrophoretic deposition. Carbon 2009, 47, 58–67. [Google Scholar] [CrossRef]

- Zhong, Z.; Qian, L.; Tan, Y.; Wang, G.; Yang, L.; Hou, C.; Liu, A. A high-performance glucose/oxygen biofuel cell based on multi-walled carbon nanotube films with electrophoretic deposition. J. Electroanal. Chem. 2018, 823, 723–729. [Google Scholar] [CrossRef]

- Fraczek-Szczypta, A.; Dlugon, E.; Weselucha-Birczynska, A.; Nocun, M.; Blazewicz, M. Multi walled carbon nanotubes deposited on metal substrate using EPD technique. A spectroscopic study. J. Mol. Struct. 2013, 1040, 238–245. [Google Scholar] [CrossRef]

- Benko, A.; Przekora, A.; Wesełucha-Birczyńska, A.; Nocuń, M.; Ginalska, G.; Błażewicz, M. Fabrication of multi-walled carbon nanotube layers with selected properties via electrophoretic deposition: Physicochemical and biological characterization. Appl. Phys. A 2016, 122, 447. [Google Scholar] [CrossRef]

- Zhong, Z.; Qin, J.; Ma, J. Electrophoretic deposition of biomimetic zinc substituted hydroxyapatite coatings with chitosan and carbon nanotubes on titanium. Ceram. Int. 2015, 41, 8878–8884. [Google Scholar] [CrossRef]

- Wedel-Grzenda, K.; Tran, A.F.-S. The influence different types of carbon nanomaterial on the properties of coatings obtained by EPD process. Eng. Biomater. 2016, 135, 13–20. [Google Scholar]

- Dlugon, E.; Simka, W.; Fraczek-Szczypta, A.; Niemiec, W.; Markowski, J.; Szymanska, M.; Blazewicz, M. Carbon nanotube-based coatings on titanium. Bull. Mater. Sci. 2015, 38, 1339–1344. [Google Scholar] [CrossRef]

- Singh, I.; Kaya, C.; Shaffer, M.S.P.; Thomas, B.C.; Boccaccini, A.R. Bioactive ceramic coatings containing carbon nanotubes on metallic substrates by electrophoretic deposition. J. Mater. Sci. 2006, 41, 8144–8151. [Google Scholar] [CrossRef]

- Fraczek-Szczypta, A.; Jantas, D.; Ciepiela, F.; Grzonka, J.; Bernasik, A.; Marzec, M. Carbon nanomaterials coatings–Properties and influence on nerve cells response. Diam. Relat. Mater. 2018, 84, 127–140. [Google Scholar] [CrossRef]

- Ibrahim, M.Z.; Sarhan, A.A.D.; Yusuf, F.; Hamdi, M. Biomedical materials and techniques to improve the tribological, mechanical and biomedical properties of orthopedic implants—A review article. J. Alloys Compd. 2017, 714, 636–667. [Google Scholar] [CrossRef]

- Feizi Mohazzab, B.; Jaleh, B.; Kakuee, O.; Fattah-alhosseini, A. Formation of titanium carbide on the titanium surface using laser ablation in n-heptane and investigating its corrosion resistance. Appl. Surf. Sci. 2019, 478, 623–635. [Google Scholar] [CrossRef]

- Bartmanski, M.; Cieslik, B.; Glodowska, J.; Kalka, P.; Pawlowski, L.; Pieper, M.; Zielinski, A. Electrophoretic deposition (EPD) of nanohydroxyapatite—nanosilver coatings on Ti13Zr13Nb alloy. Ceram. Int. 2017, 43, 11820–11829. [Google Scholar] [CrossRef]

- Majkowska-Marzec, B.; Rogala-Wielgus, D.; Bartmański, M.; Bartosewicz, B.; Zieliński, A. Comparison of properties of the hybrid and bilayer MWCNTs—hydroxyapatite coatings on Ti alloy. Coatings 2019, 9, 643. [Google Scholar] [CrossRef]

- Borgese, L.; Gelfi, M.; Bontempi, E.; Goudeau, P.; Geandier, G.; Thiaudière, D.; Depero, L.E. Young modulus and Poisson ratio measurements of TiO2 thin films deposited with Atomic Layer Deposition. Surf. Coat. Technol. 2012, 206, 2459–2463. [Google Scholar] [CrossRef]

- Zhao, J.-H.; Du, Y.; Morgen, M.; Ho, P.S. Simultaneous measurement of Young’s modulus, Poisson ratio, and coefficient of thermal expansion of thin films on substrates. J. Appl. Phys. 2000, 87, 1575–1577. [Google Scholar] [CrossRef]

- Mahmun, A.; Kirtania, S. Evaluation of elastic properties of graphene nanoplatelet/epoxy nanocomposites. Mater. Today Proc. 2021, 44, 1531–1535. [Google Scholar] [CrossRef]

- Goyal, R.K.; Tiwari, A.N.; Negi, Y.S. Microhardness of PEEK/ceramic micro- and nanocomposites: Correlation with Halpin–Tsai model. Mater. Sci. Eng. A 2008, 491, 230–236. [Google Scholar] [CrossRef]

- Adegbenjo, A.O.; Obadele, B.A.; Olubambi, P.A. Densification, hardness and tribological characteristics of MWCNTs reinforced Ti6Al4V compacts consolidated by spark plasma sintering. J. Alloys Compd. 2018, 749, 818–833. [Google Scholar] [CrossRef]

- Ramganesh, V.; Ananth Kumar, M.; Mini, K.; Vignesh, V.; Karthikeyan, R. Effect of nano TiO2-epoxy composite in bond strength and corrosion resistance of rebar embedded in micro-silica modified concrete. J. Phys. Conf. Ser. 2020, 1706, 012122. [Google Scholar] [CrossRef]

- Kaczmar, J.W.; Granat, K.; Kurzawa, A.; Grodzka, E. Physical Properties of Copper Based MMC Strengthened with Alumina. Arch. Foundry Eng. 2014, 14, 85–90. [Google Scholar] [CrossRef]

- Lee, W.; Lee, S.-B.; Choi, O.; Yi, J.-W.; Um, M.-K.; Byun, J.-H.; Thostenson, E.T.; Chou, T.-W. Formicary-like carbon nanotube/copper hybrid nanostructures for carbon fiber-reinforced composites by electrophoretic deposition. J. Mater. Sci. 2011, 46, 2359–2364. [Google Scholar] [CrossRef]

- Chen, Y.; Jiang, H.; Li, D.; Song, H.; Li, Z.; Sun, X.; Miao, G.; Zhao, H. Improved field emission performance of carbon nanotube by introducing copper metallic particles. Nanoscale Res. Lett. 2011, 6, 537. [Google Scholar] [CrossRef]

- Byrne, D.P.; Lacroix, D.; Planell, J.A.; Kelly, D.J.; Prendergast, P.J. Simulation of tissue differentiation in a scaffold as a function of porosity, Young’s modulus and dissolution rate: Application of mechanobiological models in tissue engineering. Biomaterials 2007, 28, 5544–5554. [Google Scholar] [CrossRef]

- Javaid, F.; Pouriayevali, H.; Durst, K. Dislocation–grain boundary interactions: Recent advances on the underlying mechanisms studied via nanoindentation testing. J. Mater. Res. 2021. [Google Scholar] [CrossRef]

- Zheng, C.; Chen, W.; Ye, X. Study on Au nanoparticles, TiO2 nanoclusters, and SiO2 nanoshells coated multi-wall carbon nanotubes/silica gel-glass. Opt. Mater. 2012, 34, 1042–1047. [Google Scholar] [CrossRef]

- Jämting, Å.K.; Bell, J.M.; Swain, M.V.; Wielunski, L.S.; Clissold, R. Measurement of the micro mechanical properties of sol-gel TiO2 films. Thin Solid Films 1998, 332, 189–194. [Google Scholar] [CrossRef]

- Pavithra, C.L.P.; Sarada, B.V.; Rajulapati, K.V.; Rao, T.N.; Sundararajan, G. A new electrochemical approach for the synthesis of copper-graphene nanocomposite foils with high hardness. Sci. Rep. 2015, 4, 4049. [Google Scholar] [CrossRef]

- Zhang, X.C.; Xu, B.S.; Xuan, F.Z.; Tu, S.T.; Wang, H.D.; Wu, Y.X. Porosity and effective mechanical properties of plasma-sprayed Ni-based alloy coatings. Appl. Surf. Sci. 2009, 255, 4362–4371. [Google Scholar] [CrossRef]

- Ahn, S.; Lee, J.; Kim, H.; Kim, J. A study on the quantitative determination of through-coating porosity in PVD-grown coatings. Appl. Surf. Sci. 2004, 233, 105–114. [Google Scholar] [CrossRef]

- Zhang, S.D.; Zhang, W.L.; Wang, S.G.; Gu, X.J.; Wang, J.Q. Characterisation of three-dimensional porosity in an Fe-based amorphous coating and its correlation with corrosion behaviour. Corros. Sci. 2015, 93, 211–221. [Google Scholar] [CrossRef]

- Praveen, B.M.; Venkatesha, T.V.; Arthoba Naik, Y.; Prashantha, K. Corrosion studies of carbon nanotubes–Zn composite coating. Surf. Coat. Technol. 2007, 201, 5836–5842. [Google Scholar] [CrossRef]

- Ehtemam-Haghighi, S.; Cao, G.; Zhang, L. Nanoindentation study of mechanical properties of Ti based alloys with Fe and Ta additions. J. Alloys Compd. 2017, 692, 892–897. [Google Scholar] [CrossRef]

- Okoro, A.M.; Machaka, R.; Lephuthing, S.S.; Oke, S.R.; Awotunde, M.A.; Olubambi, P.A. Nanoindentation studies of the mechanical behaviours of spark plasma sintered multiwall carbon nanotubes reinforced Ti6Al4V nanocomposites. Mater. Sci. Eng. A 2019, 765, 138320. [Google Scholar] [CrossRef]

- Feng, G.; Li, H.; Yao, X.; Liu, T.; Jia, Y.; Yang, L.; Li, B. Mechanical properties and ablation resistance of La2O3-modified HfC-SiC coating for SiC-coated C/C composites. Corros. Sci. 2021, 182, 109259. [Google Scholar] [CrossRef]

- Thakare, J.G.; Pandey, C.; Mulik, R.S.; Mahapatra, M.M. Mechanical property evaluation of carbon nanotubes reinforced plasma sprayed YSZ-alumina composite coating. Ceram. Int. 2018, 44, 6980–6989. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, T.; Chen, L.; Yu, T.; Sun, J.; Guan, C. Microstructure and mechanical properties of Ti–C–TiN-reinforced Ni204-based laser-cladding composite coating. Ceram. Int. 2021, 47, 5918–5928. [Google Scholar] [CrossRef]

- Kumar, V.; Kempaiah, U.N.; Shivasharanayyaswamy; Bopanna, S.B. Nanoindentation studies on multiwalled carbon nanotubes/graphene reinforced aluminium alloy 6061 nanocomposites. Mater. Today Proc. 2020, 45, 202–206. [Google Scholar] [CrossRef]

- Lu, X.-J.; Wang, X.; Xiao, P. Nanoindentation and residual stress measurements of yttria-stablized zirconia composite coatings produced by electrophoretic deposition. Thin Solid Films 2006, 494, 223–227. [Google Scholar] [CrossRef]

- Hahn, B.; Lee, J.-M.; Park, D.; Choi, J.; Ryu, J.; Yoon, W.; Lee, B.; Shin, D.; Kim, H. Mechanical and in vitro biological performances of hydroxyapatite–carbon nanotube composite coatings deposited on Ti by aerosol deposition. Acta Biomater. 2009, 5, 3205–3214. [Google Scholar] [CrossRef]

- Huang, Z.; Zhao, W. Coupling hybrid of HBN nanosheets and TiO2 to enhance the mechanical and tribological properties of composite coatings. Prog. Org. Coat. 2020, 148, 105881. [Google Scholar] [CrossRef]

- Chmielewski, M.; Nosewicz, S.; Wyszkowska, E.; Kurpaska, Ł.; Strojny-Nedza, A.; Pi, A.; Bazarnik, P.; Pietrzak, K. Analysis of the micromechanical properties of copper-silicon carbide composites using nanoindentation measurements. Ceram. Int. 2019, 45, 9164–9173. [Google Scholar] [CrossRef]

- Bull, S.J. Nanoindentation of coatings. J. Phys. D Appl. Phys. 2005, 38, R393–R413. [Google Scholar] [CrossRef]

- Epshtein, S.A.; Borodich, F.M.; Bull, S.J. Evaluation of elastic modulus and hardness of highly inhomogeneous materials by nanoindentation. Appl. Phys. A 2015, 119, 325–335. [Google Scholar] [CrossRef]

- Balak, Z.; Zakeri, M.; Rahimipur, M.R.; Salahi, E.; Nasiri, H. Effect of open porosity on flexural strength and hardness of ZrB2-based composites. Ceram. Int. 2015, 41, 8312–8319. [Google Scholar] [CrossRef]

- Zhang, L.; Gao, K.; Elias, A.; Dong, Z.; Chen, W. Porosity dependence of elastic modulus of porous Cr3C2 ceramics. Ceram. Int. 2014, 40, 191–198. [Google Scholar] [CrossRef]

- Karthikeyan, S.; Balasubramanian, V.; Rajendran, R. Developing empirical relationships to estimate porosity and Young’s modulus of plasma sprayed YSZ coatings. Appl. Surf. Sci. 2014, 296, 31–46. [Google Scholar] [CrossRef]

- Garcia-Prieto, A.; Hornez, J.C.; Leriche, A.; Pena, P.; Baudín, C. Influence of porosity on the mechanical behaviour of single phase β-TCP ceramics. Ceram. Int. 2017, 43, 6048–6053. [Google Scholar] [CrossRef]

- Jang, B.; Matsubara, H. Influence of porosity on hardness and Young’s modulus of nanoporous EB-PVD TBCs by nanoindentation. Mater. Lett. 2005, 59, 3462–3466. [Google Scholar] [CrossRef]

- Musil, J.; Kunc, F.; Zeman, H.; Poláková, H. Relationships between hardness, Young’s modulus and elastic recovery in hard nanocomposite coatings. Surf. Coat. Technol. 2002, 154, 304–313. [Google Scholar] [CrossRef]

| Element | Nb | Zr | Fe | C | H | O | S | Hf | Ti |

|---|---|---|---|---|---|---|---|---|---|

| wt. pct. | 13.18 | 13.49 | 0.085 | 0.035 | 0.004 | 0.078 | <0.001 | 0.055 | rem. |

| Coating | Substrate | Deposited Materials | Content of Component in a Bath (wt. pct.) | EPD Time (min) | EPD Voltage (V) |

|---|---|---|---|---|---|

| MWCNTs | Ti13Nb13Zr | MWCNTs | 0.25 | 0.5 | 20 |

| MWCNTs/TiO2 | Ti13Nb13Zr | (I) MWCNTs | 0.25 | 0.5 | 20 |

| (II) TiO2 | 0.30 | 4 | 50 | ||

| MWCNTs_Cu | Ti13Zr13Nb | MWCNTs + nanoCu | 0.25 0.0125 | 4 | 50 |

| Sample | Roughness Sa (µm) |

|---|---|

| MWCNTs | 0.34 |

| MWCNTs/TiO2 | 0.65 |

| MWCNTs_Cu | 0.41 |

| Material | Weight Fraction of MWCNTs | Weight Fraction of TiO2 | Weight Fraction of nanoCu | Calculated H (GPa) | Calculated E (GPa) | Real H (GPa) | Real E (GPa) |

|---|---|---|---|---|---|---|---|

| Ti13Zr13Nb alloy | 0 | 0 | 0 | - | - | 3.760 [67] | 83.32 [67] |

| MWCNTs | 1 | 0 | 0 | - | - | 0.204 [79] | 2.659 [79] |

| TiO2 | 0 | 1 | 0 | - | - | 1.000 [80] | 68.00 [80] |

| nanoCu | 0 | 0 | 1 | - | - | 1.200 [81] | 104.20 [69] |

| MWCNTs coating | 1 | 0 | 0 | - | - | 0.101 | 14.17 |

| MWCNTs/TiO2 coating | 0.4 | 0.6 | 0 | 0.485 | 37.15 | 0.137 | 7.69 |

| MWCNTs_Cu coating | 0.952 | 0 | 0.048 | 0.114 | 15.22 | 0.213 | 10.83 |

| Sample | Nanohardness H (GPa) | Reduced Young’s Modulus Er (GPa) | Young’s Modulus E (GPa) | Maximum Indent Depth (µm) | Plasticity Index PI (nJ) | Elastic Recovery Index EI (nJ) |

|---|---|---|---|---|---|---|

| MWCNTs | 0.101 ± 0.049 | 18.59 ± 5.66 | 14.17 ± 4.32 | 2.07 ± 0.35 | 3.88 ± 0.85 | 0.378 ± 0.056 |

| MWCNTs/TiO2 | 0.137 ± 0.048 | 10.22 ± 2.33 | 7.69 ± 1.75 | 1.81 ± 0.33 | 5.87 ± 1.08 | 0.722 ± 0.084 |

| MWCNTs_Cu | 0.213 ± 0.061 | 14.28 ± 2.80 | 10.83 ± 2.12 | 1.43 ± 0.23 | 3.53 ± 0.53 | 0.688 ± 0.065 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rogala-Wielgus, D.; Majkowska-Marzec, B.; Zieliński, A.; Bartmański, M.; Bartosewicz, B. Mechanical Behavior of Bi-Layer and Dispersion Coatings Composed of Several Nanostructures on Ti13Nb13Zr Alloy. Materials 2021, 14, 2905. https://doi.org/10.3390/ma14112905

Rogala-Wielgus D, Majkowska-Marzec B, Zieliński A, Bartmański M, Bartosewicz B. Mechanical Behavior of Bi-Layer and Dispersion Coatings Composed of Several Nanostructures on Ti13Nb13Zr Alloy. Materials. 2021; 14(11):2905. https://doi.org/10.3390/ma14112905

Chicago/Turabian StyleRogala-Wielgus, Dorota, Beata Majkowska-Marzec, Andrzej Zieliński, Michał Bartmański, and Bartosz Bartosewicz. 2021. "Mechanical Behavior of Bi-Layer and Dispersion Coatings Composed of Several Nanostructures on Ti13Nb13Zr Alloy" Materials 14, no. 11: 2905. https://doi.org/10.3390/ma14112905

APA StyleRogala-Wielgus, D., Majkowska-Marzec, B., Zieliński, A., Bartmański, M., & Bartosewicz, B. (2021). Mechanical Behavior of Bi-Layer and Dispersion Coatings Composed of Several Nanostructures on Ti13Nb13Zr Alloy. Materials, 14(11), 2905. https://doi.org/10.3390/ma14112905