Durability of Hydrophobic/Icephobic Coatings in Protection of Lightweight Concrete with Waste Aggregate

Abstract

1. Introduction

2. Materials and Method

2.1. Materials

2.2. Method

3. Results and Discussion

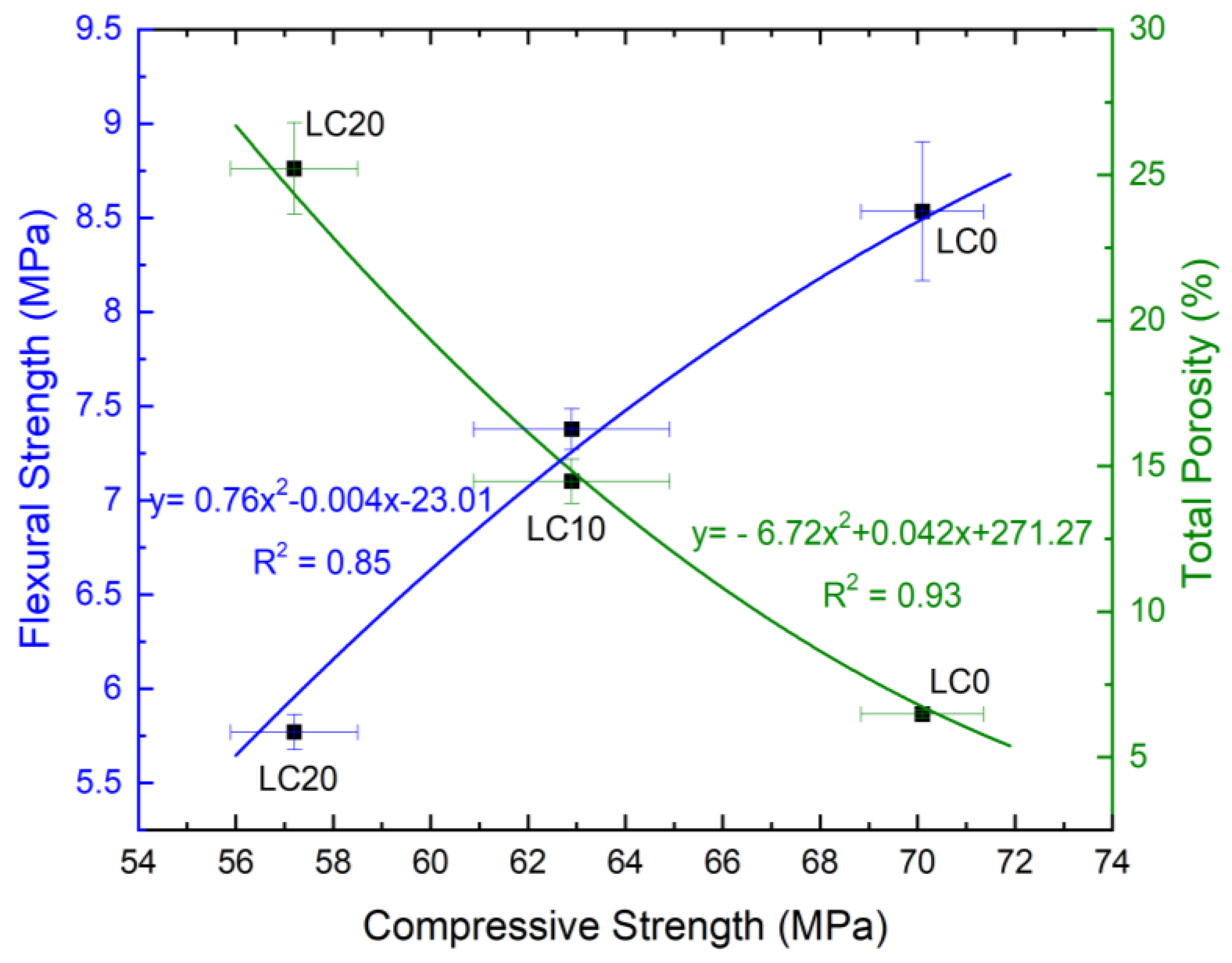

3.1. Basic Properties of Lightweight Concrete

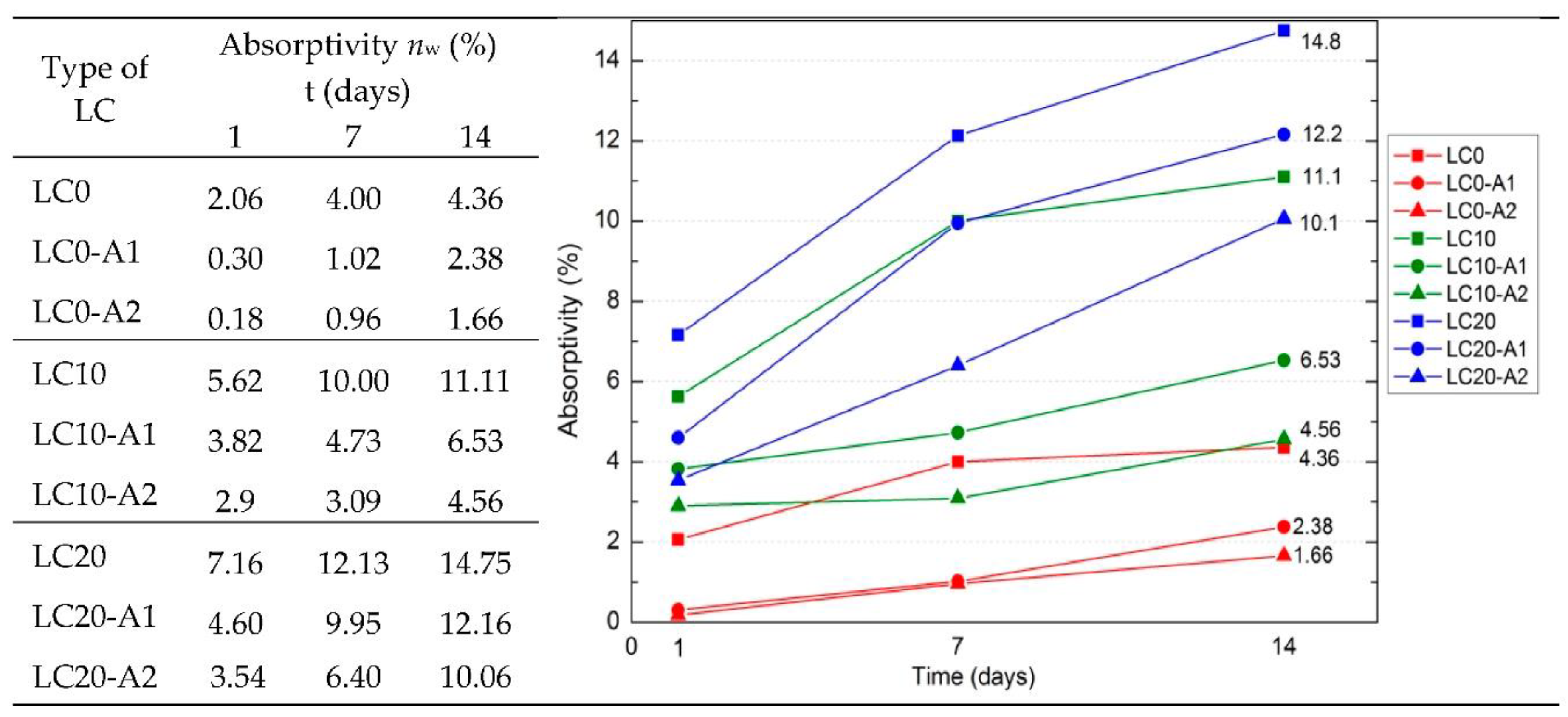

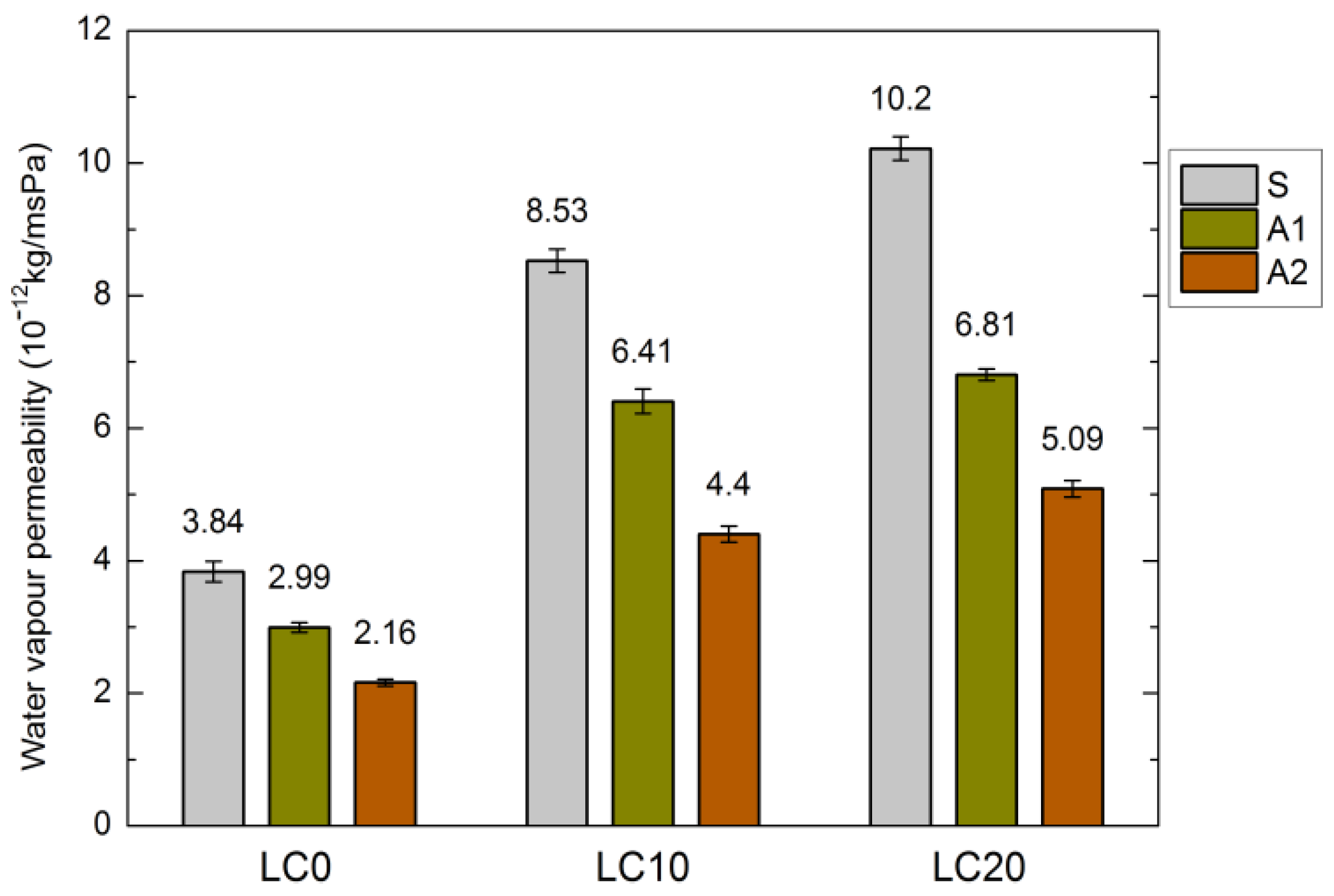

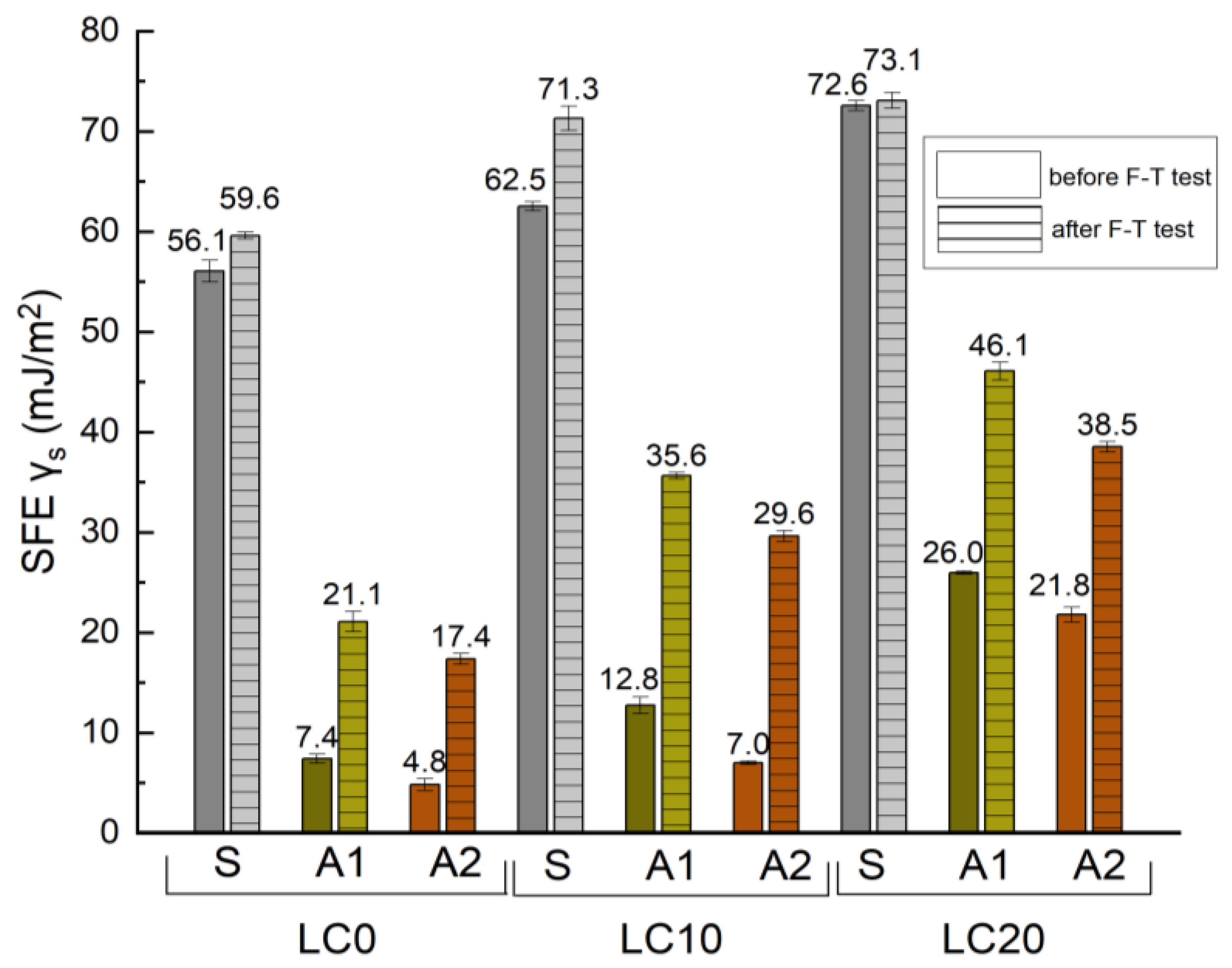

3.2. Properties of Lightweight Concrete after Surface Hydrophobization

4. Conclusions

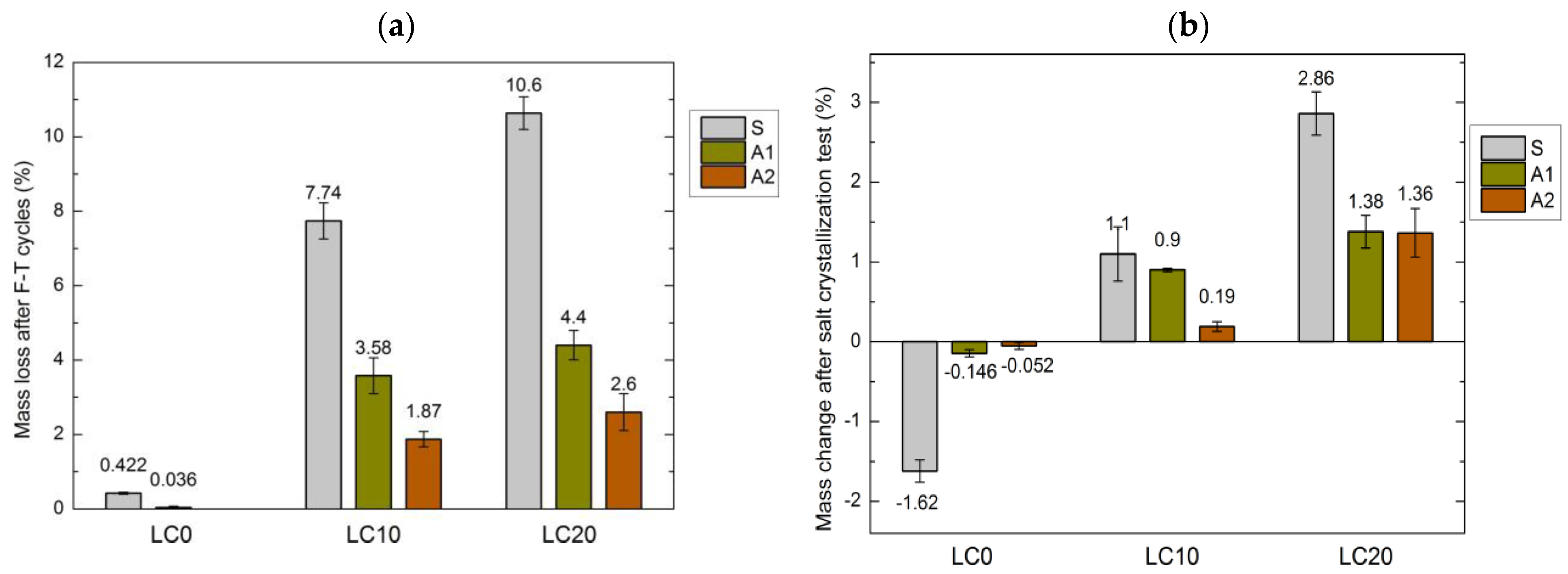

- The EPS addition to concrete influences the properties of the tested concrete samples. Application of EPS reduces strength characteristics, density, and frost resistance. The frost resistance of LC10 and LC20 after 50 F–T cycles decreases by 18 and 25 times compared to reference concrete. The EPS also increases porosity, absorbability, and water vapor permeability.

- Hydrophobization allows the effective protection of all tested types of concrete, using both silane and tetramethoxysilane.

- Application of EPS and organosilicon affects the wettability and adhesive properties of concrete, defined by SFE and CA. The lowest value of SFE, thus the weakest adhesive characteristics, is determined for LC hydrophobized by tetramethoxysilane.

- A significant decrease in wettability and adhesive properties (SFE) is observed after surface hydrophobization of concrete, which indicates the high efficiency of the hydrophobization process.

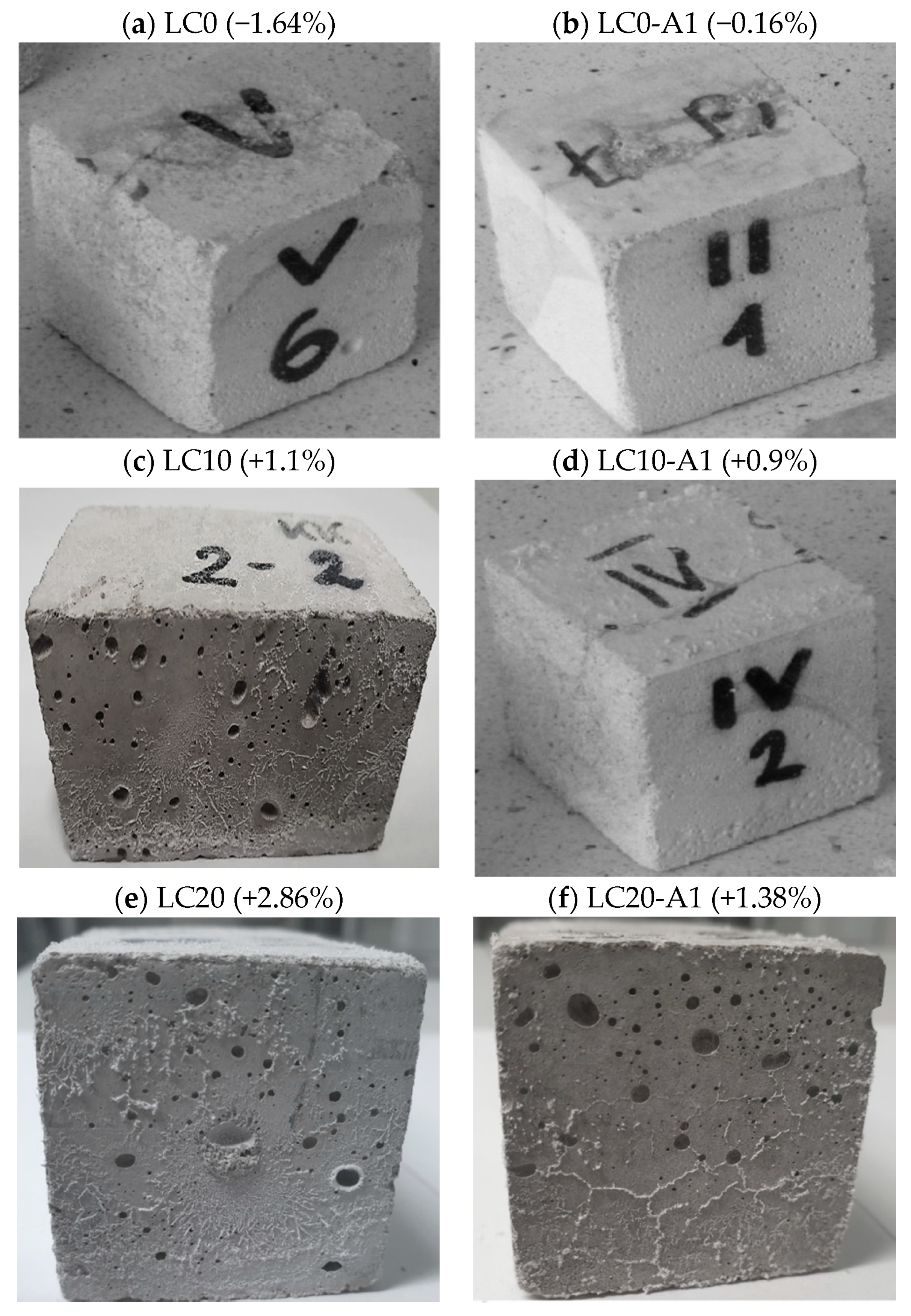

- Hydrophobization by silane agent results in significantly higher mass loss than after the application of tetramethoxysilane, after tests of reference concrete resistance against salt crystallization. These specimens contain porous additions in which pore crystallization of salt occurred. No visible damages of EPS concrete were observed.

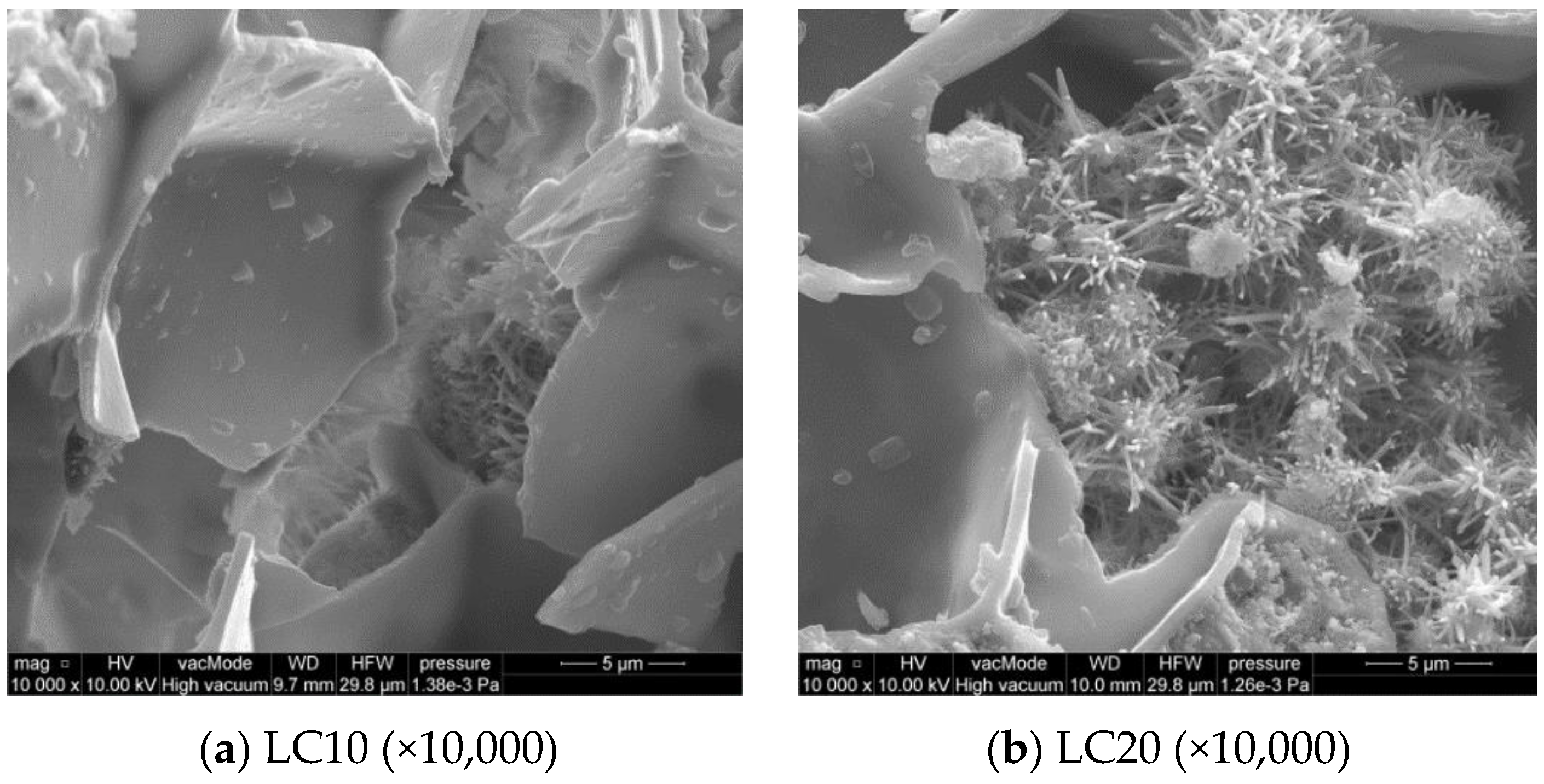

- Very good distribution of hydrophobic coatings inside the concrete structure was observed in SEM pictures. The size of particle generated from tetramethoxysilanes is greater than that from silane, and varies between 2 μm and 14 μm. However, particles of gel generated from silane (A1) have dimensions in the range 0.4–3 μm. Such arrangements and sizes of hydrophobic coating sufficiently protect LCs with EPS from frost and chemical corrosion.

- The highest efficiency of EPS concrete hydrophobization was obtained after tetramethoxysilane application, while the performance of silane coating was weaker.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| SFE | Surface free energy |

| CA | Contact angle |

| F–T | Freezing and thawing |

| LC | Lightweight concrete |

| EPS | Expanded polystyrene |

| SEM | Scanning electron microscope technique |

| LC0 | Reference concrete without recycled polystyrene |

| LC10 or LC20 | Concrete with 10% or 20% addition by volume of EPS |

| A1 | Agent 1—silane |

| A2 | Agent 2—tetramethoxysilane |

| w/c | Water/cement ratio |

| SD | Standard deviation |

| CV | Coefficient of variation |

| LC0-A1 | Reference concrete coated with silane A1 |

| LC0-A2 | Reference concrete coated with tetramethoxysilane A2 |

| AAS | Alkyl-alkoxy-silane |

| ITZ | Interphase transition zone |

References

- Barnat-Hunek, D.; Grzegorczyk, M.; Łagód, G. Influence of Temperature Difference on Thermal Conductivity of Lightweight Mortars with Waste Aggregate. AIP Conf. Proc. 2019, 2170, 020003. [Google Scholar] [CrossRef]

- Duan, P.; Song, L.; Yan, C.; Ren, D.; Li, Z. Novel thermal insulating and lightweight composites from metakaolin geopolymer and polystyrene particles. Ceram. Int. 2016, 5115–5120. [Google Scholar] [CrossRef]

- Alshihri, M.M.; Azmy, A.M.; El-Bisy, M.S. Neural networks for predicting compressive strength of structural light weight concrete. Constr. Build. Mater. 2009, 23, 2214–2219. [Google Scholar] [CrossRef]

- Babu, D.S.; Babu, K.G.; Wee, T.H. Effect of polystyrene aggregate size on strength and moisture migration characteristics of lightweight concrete. Cem. Concr. Compos. 2006, 28, 520–527. [Google Scholar] [CrossRef]

- Xuan, D.; Poon, C.S.; Zheng, W. Management and sustainable utilization of processing wastes from ready-mixed concrete plants in construction: A review. Resour. Conserv. Recycl. 2018, 136, 238–247. [Google Scholar] [CrossRef]

- Petrounias, P.; Giannakopoulou, P.P.; Rogkala, A.; Lampropoulou, P.; Tsikouras, B.; Rigopoulos, I.; Hatzipanagiotou, K. Petrographic and mechanical characteristics of concrete produced by different type of recycled materials. Geosciences 2019, 9, 264. [Google Scholar] [CrossRef]

- Solikin, M.; Zaini, A.N.; Setiawan, B.; Asroni, A. Flexural strength analysis of Styrofoam concrete hollow panel walls incorporated with high volume fly ash. Civ. Eng. Archit. 2020, 8, 320–325. [Google Scholar] [CrossRef]

- Suchorab, Z.; Barnat-Hunek, D.; Franus, M.; Łagód, G. Mechanical and physical properties of hydrophobized lightweight aggregate concrete with sewage sludge. Materials 2016, 317, 317. [Google Scholar] [CrossRef] [PubMed]

- Habib, U.; Remzi, S.; Ramazan, D.; Rüstem, G. The effects of different cement dosages, slumps, and pumice aggregate eratios on the thermal conductivity and density of concrete. Cem. Concr. Res. 2004, 34, 845–848. [Google Scholar] [CrossRef]

- Leong, G.W.; Mo, K.H.; Loh, Z.P.; Ibrahim, Z. Mechanical properties and drying shrinkage of lightweight cementitious composite incorporating perlite microspheres and polypropylene fibers. Constr. Build. Mater. 2020, 246, 118410. [Google Scholar] [CrossRef]

- Barnat-Hunek, D.; Góra, J.; Andrzejuk, W.; Łagód, G. The Microstructure-Mechanical Properties of Hybrid Fibres-Reinforced Self-Compacting Lightweight Concrete with Perlite Aggregate. Materials 2018, 11, 1093. [Google Scholar] [CrossRef] [PubMed]

- Celik, A.G. Expanded perlite aggregate characterization for use as a lightweight construction raw material. Physicochem. Prob. Miner. Process. 2013, 49, 689–700. [Google Scholar] [CrossRef]

- Setyowati, E. Eco-building material of Styrofoam waste and sugar industry fly-ash based on nano-technology. Procedia Environ. Sci. 2014, 20, 245–253. [Google Scholar] [CrossRef]

- Kaya, A.; Kar, F. Properties of concrete containing waste expanded polystyrene and natural resin. Constr. Build. Mater. 2016, 105, 572–578. [Google Scholar] [CrossRef]

- Koksal, F.; Mutluay, E.; Gencel, O. Characteristics of isolation mortars produced with expanded vermiculite and waste expanded polystyrene. Constr. Build. Mater. 2020, 236, 117789. [Google Scholar] [CrossRef]

- Barnat-Hunek, D.; Siddique, R.; Klimek, B.; Franus, M. The use of zeolite, lightweight aggregate and boiler slag in restoration renders. Constr. Build. Mater. 2017, 142, 162–174. [Google Scholar] [CrossRef]

- Arroyo, R.; Horgnies, M.; Junco, C.; Rodríguez, A.; Calderón, V. Lightweight structural eco-mortars made with polyurethane wastes and non-ionic surfactants. Constr. Build. Mater. 2019, 197, 157–163. [Google Scholar] [CrossRef]

- Barnat-Hunek, D.; Widomski, M.K.; Szafraniec, M.; Łagód, G. Impact of Different Binders on the Roughness, Adhesion Strength and Other Properties of Mortars with Expanded Cork. Materials 2018, 11, 364. [Google Scholar] [CrossRef]

- Degirmenci, N.; Yilmaz, A. Use of pumice fine aggregate as an alternative to standard sand in production of lightweight cement mortar. Indian J. Eng. Mater. Sci. 2011, 18, 61–68. [Google Scholar]

- Miled, K.; Roy, R.L.; Sab, K. Compressive behavior of an idealized EPS lightweight concrete: Size effects and failure mode. Mech. Mater. 2004, 36, 1031–1046. [Google Scholar] [CrossRef]

- Barnat-Hunek, D.; Łagód, G.; Klimek, B. Evaluation of the contact angle and frost resistance of hydrophobised heat-insulating mortars with polystyrene. AIP Conf. Proc. 2017, 1866, 040004-1–040004-5. [Google Scholar] [CrossRef]

- Roy, R.L.; Parant, E.; Boulay, C. Taking into account the inclusions’size inlightweight concrete compressive strength prediction. Cem. Concr. Res. 2005, 35, 770–775. [Google Scholar] [CrossRef]

- Chen, B.; Liu, J. Mechanical properties of polymer-modified concretes containing expanded polystyrene beads. Constr. Build. Mater. 2007, 21, 7–11. [Google Scholar] [CrossRef]

- Al-Kheetan, M.J.; Rahman, M.M.; Chamberlain, D.A. Fundamental interaction of hydrophobic materials in concrete with different moisture contents in saline environment. Constr. Build. Mater. 2019, 207, 122–135. [Google Scholar] [CrossRef]

- Al-Kheetan, M.J.; Rahman, M.; Muniswamappa, B.N.; Chamberlain, D. Performance enhancement of self-compacting concrete in saline environment by hydrophobic surface protection. Can. J. Civ. Eng. 2019, 46, 677–686. [Google Scholar] [CrossRef]

- Arabzadeh, A.; Ceylan, H.; Kim, S.; Gopalakrishnan, K.; Sassani, A.; Sundararajan, S.; Taylor, P.C. Superhydrophobic coatings on Portland cement concrete surfaces. Constr. Build. Mater. 2017, 141, 393–401. [Google Scholar] [CrossRef]

- Li, S.; Zhang, W.; Liu, J.; Hou, D.; Geng, Y.; Chen, X.; Gao, Y.; Jin, Z.; Yin, B. Protective Mechanism of Silane on Concrete upon Marine Exposure. Coatings 2019, 9, 558. [Google Scholar] [CrossRef]

- Barnat-Hunek, D.; Smarzewski, P.; Suchorab, Z. Effect of hydrophobisation on durability related properties of ceramic brick. Constr. Build. Mater. 2016, 111, 275–285. [Google Scholar] [CrossRef]

- Ramachandran, R.; Sobolev, K.; Nosonovsky, M. Dynamics of Droplet Impact on Hydrophobic/Icephobic Concrete with the Potential for Superhydrophobicity. Langmuir 2015, 31, 1437–1444. [Google Scholar] [CrossRef]

- Szafraniec, M.; Barnat-Hunek, D.; Grzegorczyk-Frańczak, M.; Trochonowicz, M. Surface Modification of Lightweight Mortars by Nanopolymers to Improve Their Water-Repellency and Durability. Materials 2020, 13, 1350. [Google Scholar] [CrossRef]

- Liu, Z.; Hansen, W. Efect of hydrophobic surface treatment on freeze-thaw durability of concrete. Cem. Concr. Compos. 2016, 69, 49–60. [Google Scholar] [CrossRef]

- Barnat-Hunek, D.; Grzegorczyk-Frańczak, M.; Suchorab, Z. Surface hydrophobisation of mortars with waste aggregate by nanopolymer trietoxi-isobutyl-silane and methyl silicon resin. Constr. Build. Mater. 2020, 264, 120175. [Google Scholar] [CrossRef]

- Sadowski, Ł.; Stefaniuk, D. The effect of surface treatment on the microstructure of the skin of concrete. Appl. Surf. Sci. 2017, 427, 1–16. [Google Scholar] [CrossRef]

- Barnat-Hunek, D.; Duda, S.; Łagód, G.; Garbacz, M. Hydrophobisation of mortars containing waste polyurethane foam. MATEC Web Conf. 2018, 163, 04006. [Google Scholar] [CrossRef]

- Barnat-Hunek, D. Surface, Free Energy as a Factor Affecting Effectiveness of Hydrophobisation in Protection of Building Construction; Politechnika Lubelska: Lublin, Poland, 2016; ISBN 978-83-7947-216-1. (In Polish) [Google Scholar]

- EN 206:2016. Concrete—Specification, Performance, Production and Conformity; BSI: London, UK, 2016. [Google Scholar]

- EN 12390-7:2019. Testing Hardened Concrete—Part 7: Density of Hardened Concrete; BSI: London, UK, 2019. [Google Scholar]

- EN 12390-3:2019. Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens; BSI: London, UK, 2019. [Google Scholar]

- EN 12390-5:2019. Testing Hardened Concrete—Part 5: Flexural Strength of Test Specimens; BSI: London, UK, 2019. [Google Scholar]

- PN-B-06250:1988. Ordinary Concrete; PKN: Warsaw, Poland, 1988. (In Polish) [Google Scholar]

- EN ISO 7783:2011. Paints and Varnishes—Determination of Water-Vapour Transmission Properties—Cup Method; BSI: London, UK, 2011. [Google Scholar]

- Neumann, A.; Good, R.; Hope, C.; Sejpal, M. An equation-of-state approach to determine surface tensions of low-energy solids from contact angles. J. Colloid Interf. Sci. 1974, 49, 291–304. [Google Scholar] [CrossRef]

- EN 12370:2020-08. Natural Stone Test Methods—Determination of Resistance to Salt Crystallization; BSI: London, UK, 2020. [Google Scholar]

- Cadere, C.A.; Barbuta, M.; Rosca, B.; Serbanoiu, A.A.; Burlacu, A.; Oancea, I. Engineering properties of concrete with polystyrene granules. Procedia Manuf. 2018, 22, 288–293. [Google Scholar] [CrossRef]

- Ranjbar, M.M.; Mousavi, S.Y. Strength and durability assessment of self-compacted lightweight concrete containing expanded polystyrene. Mater. Struct. 2013, 48, 1–11. [Google Scholar] [CrossRef]

- Sussman, V.; Baumann, G.H. Expanded polystyrene beads lighten the load. Soc. Plastic Eng. J. 1972, 28, 18–21. [Google Scholar]

- Błaszczyński, T.; Osesek, M.; Gwozdowski, B.; Ilski, M. Performance of Hydrophobisation Techniques in Case of Reinforced Concrete Structures. IOP Conf. Ser. Mater. Sci. Eng. 2017, 245, 22059. [Google Scholar] [CrossRef]

- Sabatini, V.; Pargoletti, E.; Longoni, M.; Ortenzi, M.A.; Cappelletti, G. Stearyl methacrylate co-polymers: Towards new polymer coatings for mortars protection. Appl. Surf. Sci. 2019, 488, 213–220. [Google Scholar] [CrossRef]

- Barnat-Hunek, D.; Siddique, R.; Łagód, G. Properties of hydrophobized lightweight mortars with expanded cork. Constr. Build. Mater. 2017, 155, 15–25. [Google Scholar] [CrossRef]

- Carmeliet, J. Water Transport-Liquid and Vapour. In Porous Materials: Understanding Physical Mechanisms and Effects from Hydrophobic Treatments. In Proceedings of the Hydrophobe III—3rd International Conference on Surface Technology with Water Repellent Agents, Hanover, Germany, 25–26 September 2001; Aedificatio Publishers: Freiburg, Germany, 2001; Volume 178, pp. 171–178. [Google Scholar]

- Barnat-Hunek, D.; Łagód, G.; Fic, S.; Jarosz-Hadam, M. Effect of Polysiloxanes on Roughness and Durabilityof Basalt Fibres–Reinforced Cement Mortar. Polymers 2018, 10, 420. [Google Scholar] [CrossRef] [PubMed]

- Najduchowska, M.; Pichniarczyk, P. Effect of hydrophobic compounds on the properties of cement and gypsum mortars. Cem. Lime Concr. 2010, 15, 141–148. [Google Scholar]

- Król, P.; Lechowicz, J.B.; Król, B. Modelling the surface free energy parameters of polyurethane coats—Part 1.Solvent-based coats obtained from linear polyure-thane elastomers. Colloid Polym. Sci. 2013, 291, 1031–1047. [Google Scholar] [CrossRef]

- Fagerlund, G. The critical degree of saturation method of assessing the freeze/thaw resistance of concrete. Mat. Constr. 1977, 10, 217–229. [Google Scholar] [CrossRef]

- Pigeon, M.; Pleau, R. Durability of Concrete in Cold Climates; E&FN Spon: London, UK, 2010. [Google Scholar]

- Richardson, A.; Coventry, K.; Bacon, J. Freeze/thaw durability of concrete with recycled demolition aggregate compared to virgin aggregate concrete. J. Clean. Prod. 2011, 19, 272–277. [Google Scholar] [CrossRef]

- Shang, H.S.; Zhao, T.J.; Cao, W.Q. Bond behavior between steel bar and recycled aggregate concrete after freeze–thaw cycles. Cold. Reg. Sci. Technol. 2015, 118, 38–44. [Google Scholar] [CrossRef]

- Yildirim, S.T.; Meyer, C.; Herfellner, S. Effects of internal curing on the strength, drying shrinkage and freeze-thaw resistance of concrete containing recycled concrete aggregates. Constr. Build. Mater. 2015, 91, 288–296. [Google Scholar] [CrossRef]

- Afroughsabet, V.; Ozbakkaloglu, T. Mechanical and durability properties of high-strength concrete containing steel and polypropylene fibers. Constr. Build. Mater. 2015, 94, 73–82. [Google Scholar] [CrossRef]

- Mancigotti, S.; Hamilton, A. Salt crystallization in pores: The effect of crystal growth rate on damage. WIT Trans. Built Environ. 2017, 171, 207–214. [Google Scholar] [CrossRef]

- Scherer, G.W. Crystallization in pores. Cem. Concr. Res. 1999, 29, 1347–1358. [Google Scholar] [CrossRef]

- Suleiman, A.R.; Soliman, A.M.; Nehdi, M.L. Effect of surface treatment on durability of concrete exposed to physical sulfate attack. Constr. Build. Mater. 2014, 73, 674–681. [Google Scholar] [CrossRef]

| Property | Agent A1 (Silane) | Agent A2 (Tetramethoxysilane) |

|---|---|---|

| Density (20 °C), kg/dm3 | ~0.94 | ~0.96 |

| Appearance | White liquid | Clear, colorless, or slightly yellow liquid |

| Viscosity (20 °C), mPa·s | ~15 | ~17 |

| Active components, % | 50 | 55 |

| pH value (20 °C) | 6–8 | >13 |

| Compound | CaO | SiO2 | Al2O3 | Fe2O3 | MgO | Na2O | K2O | Na2Oe |

|---|---|---|---|---|---|---|---|---|

| Content | 63.65 | 20.89 | 4.29 | 3.55 | 1.33 | 0.23 | 0.47 | 0.61 |

| Le Chatelier, mm | Specific Surface, cm2/g | Specific Gravity, kg/dm3 | Initial Setting Time, min | Heat of Hydration, J/g ** | 2-Day Compressive Strength, MPa | 28-Day Compressive Strength, MPa |

|---|---|---|---|---|---|---|

| 0.7 | 3821 | 3.07 | 158 | 305 | 28.9 | 55.6 |

| Sieve Size, mm | Sand 0–2 mm | EPS 0–2 mm | Gravel Aggregate 2–16 mm |

|---|---|---|---|

| 16 | 100 | 100 | 100 |

| 8 | 100 | 100 | 53.2 |

| 4 | 100 | 100 | 28.2 |

| 2 | 95.2 | 100 | 6.8 |

| 1 | 79.7 | – | – |

| 0.5 | 41.1 | – | – |

| 0.25 | 9.1 | – | – |

| 0.125 | 1.0 | – | – |

| Concrete Constituents | Unit | LC0 | LC10 | LC20 |

|---|---|---|---|---|

| Portland cement CEM I 42.5 R | kg/m3 | 374 | ||

| Sand 0–2 mm | kg/m3 | 772 | 696 | 618 |

| EPS 0–2 mm | kg/m3 | 0 | 0.52 | 1.05 |

| Total waste replacement ratio (by volume) | % | 0 | 10 | 20 |

| Gravel 2–16 mm | kg/m3 | 1154 | ||

| Superplasticizer | kg/m3 | 3.6 | ||

| Water | L/m3 | 148 | ||

| Type of LC/Descriptive Statistics | Volumetric Density | Total Porosity | Compressive Strength fc,cube#150 | Flexural Tensile Strength fct,flex | |

|---|---|---|---|---|---|

| kg/m3 | % | MPa | MPa | ||

| LC0 | Mean | 2250 | 6.48 | 70.1 | 8.53 |

| SD | 3.67 | 0.13 | 1.26 | 0.37 | |

| CV (%) | 0.16 | 1.96 | 1.79 | 4.32 | |

| LC10 | Mean | 1960 | 14.48 | 62.9 | 7.38 |

| SD | 2.92 | 0.76 | 2.01 | 0.11 | |

| CV (%) | 0.14 | 5.25 | 3.20 | 1.47 | |

| LC20 | Mean | 2080 | 25.22 | 57.2 | 5.77 |

| SD | 2.74 | 1.57 | 1.30 | 0.09 | |

| CV (%) | 0.13 | 6.21 | 2.28 | 1.64 | |

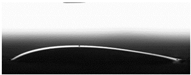

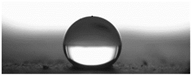

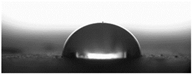

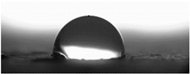

| Type of LC | Water Contact Angle (°) | |

|---|---|---|

| before F–T Tests | after F–T Tests | |

| LC0 |  |  |

| CA = 44° SD = 0.72 | CA = 40° SD = 0.82 | |

| LC0-A1 | CA = 129° SD = 1.17 | CA = 103° SD = 0.69 |

| LC0-A2 |  |  |

| CA = 136° SD = 0.61 | CA = 110° SD = 1.58 | |

| LC10 |  |  |

| CA = 34° SD = 0.79 | CA = 11° SD = 0.78 | |

| LC10-A1 | CA = 118° SD = 1.58 | CA = 80° SD = 0.76 |

| LC10-A2 |  |  |

| CA = 130° SD = 0.82 | CA = 89° SD = 0.99 | |

| LC20 |  |  |

| CA = approx. 3° SD = 0.33 | CA = approx. 2° SD = 0.12 | |

| LC20-A1 | CA = 95° SD = 0.84 | CA = 63° SD = 1.37 |

| LC20-A2 |  |  |

| CA = 102° SD = 0.65 | CA = 75° SD = 1.09 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barnat-Hunek, D.; Góra, J.; Widomski, M.K. Durability of Hydrophobic/Icephobic Coatings in Protection of Lightweight Concrete with Waste Aggregate. Materials 2021, 14, 101. https://doi.org/10.3390/ma14010101

Barnat-Hunek D, Góra J, Widomski MK. Durability of Hydrophobic/Icephobic Coatings in Protection of Lightweight Concrete with Waste Aggregate. Materials. 2021; 14(1):101. https://doi.org/10.3390/ma14010101

Chicago/Turabian StyleBarnat-Hunek, Danuta, Jacek Góra, and Marcin K. Widomski. 2021. "Durability of Hydrophobic/Icephobic Coatings in Protection of Lightweight Concrete with Waste Aggregate" Materials 14, no. 1: 101. https://doi.org/10.3390/ma14010101

APA StyleBarnat-Hunek, D., Góra, J., & Widomski, M. K. (2021). Durability of Hydrophobic/Icephobic Coatings in Protection of Lightweight Concrete with Waste Aggregate. Materials, 14(1), 101. https://doi.org/10.3390/ma14010101