Corrosion-Fatigue Failure of Gas-Turbine Blades in an Oil and Gas Production Plant

Abstract

1. Introduction

2. Experimental

3. Case Background

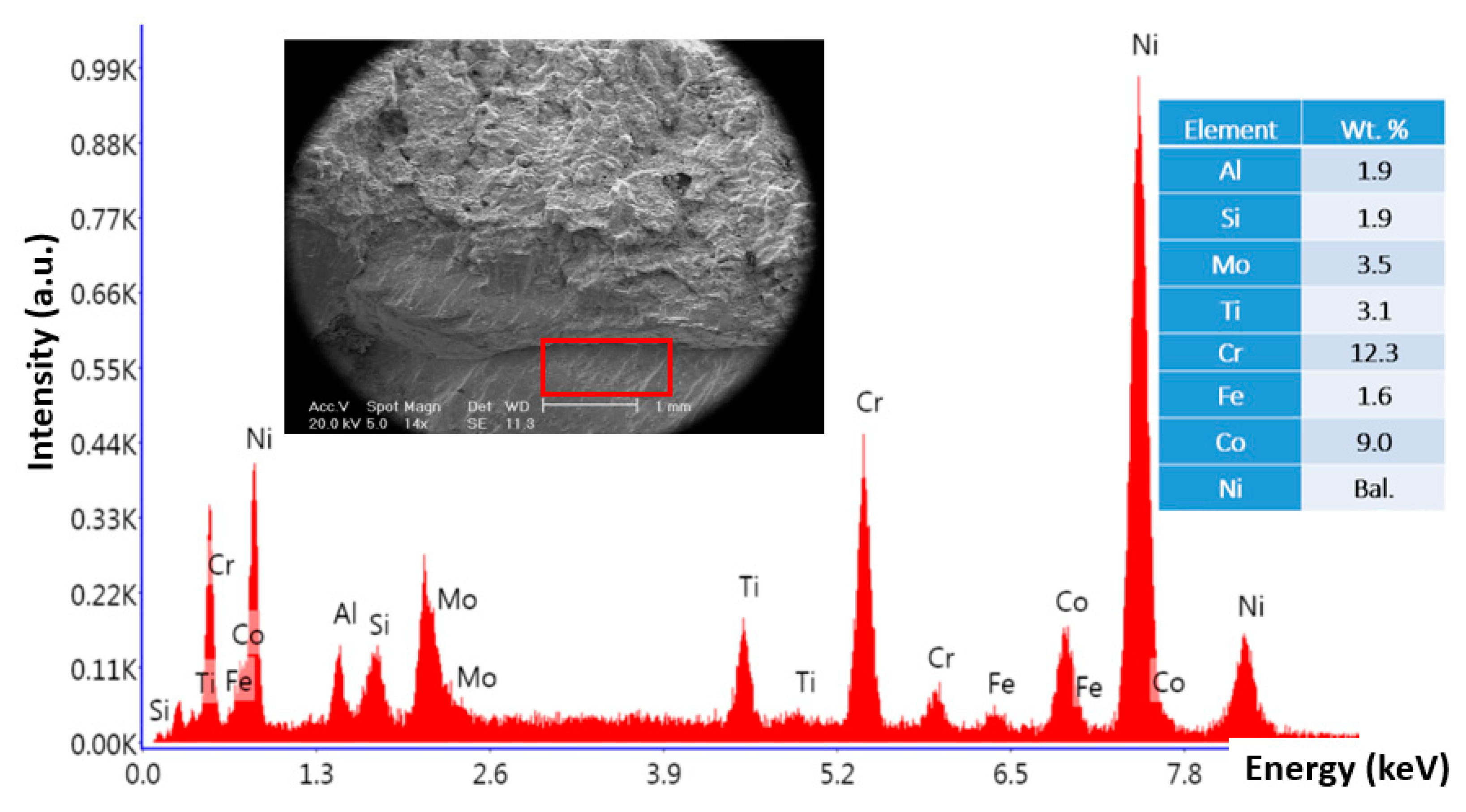

4. Results and Discussion

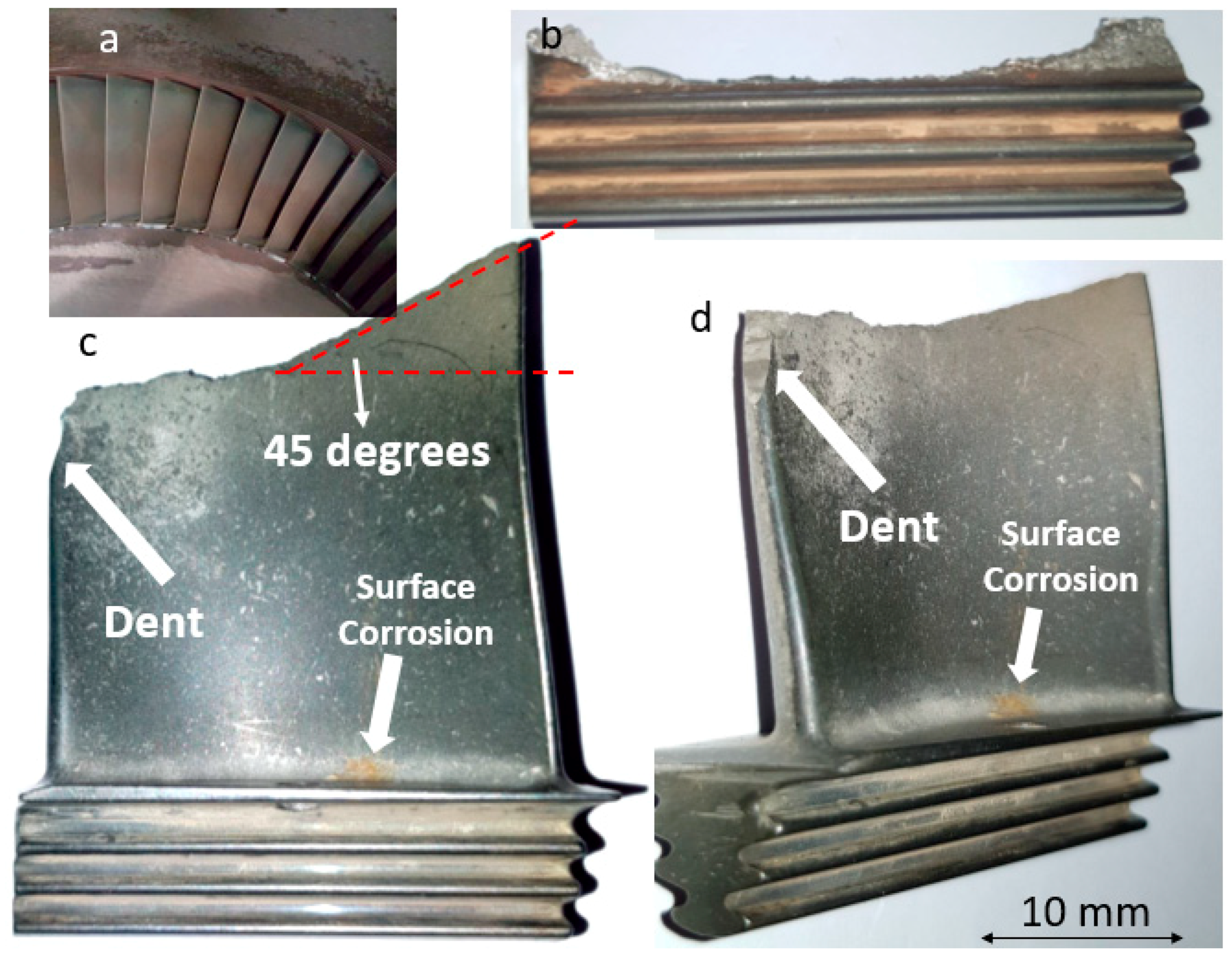

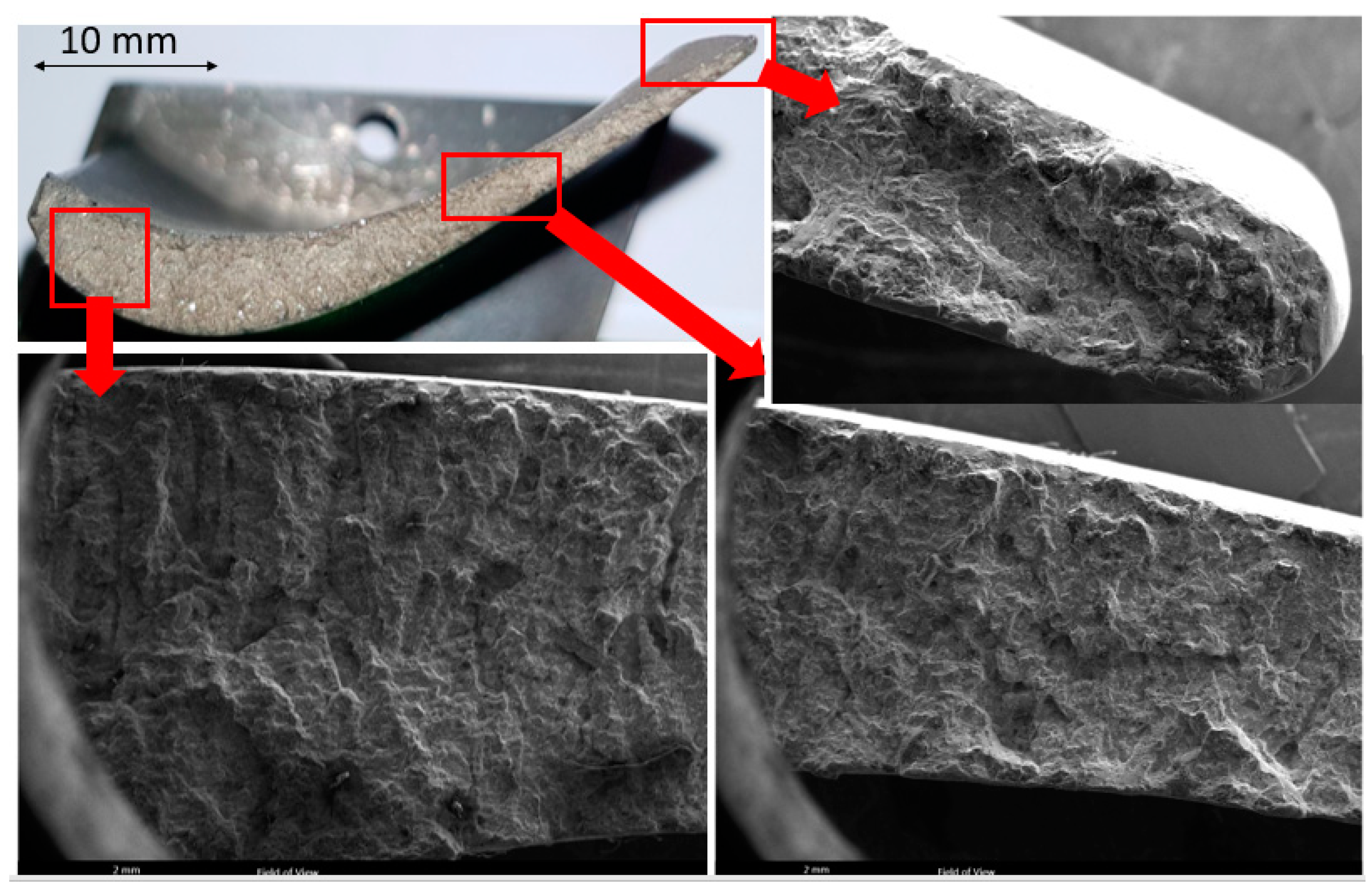

4.1. Visual Observations

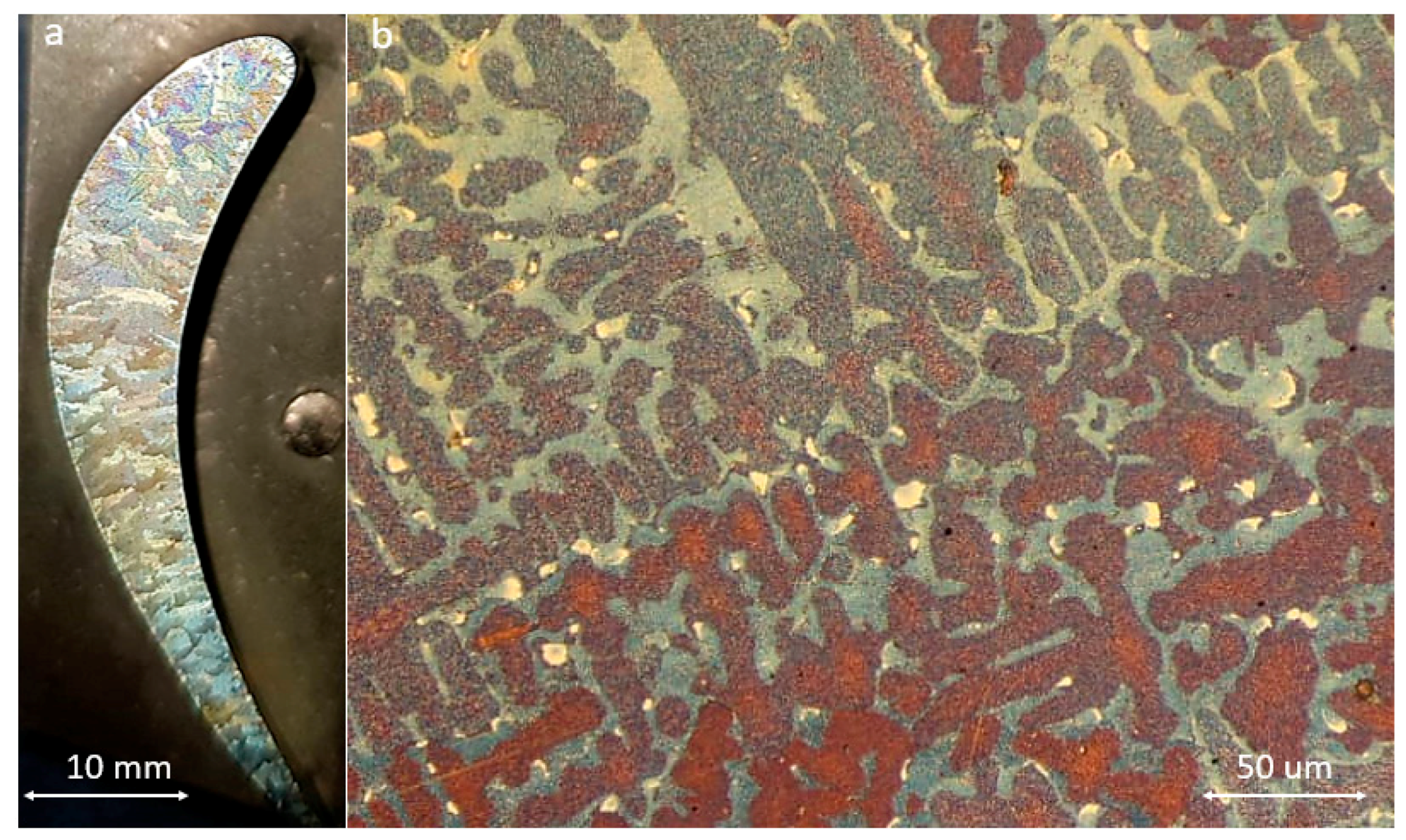

4.2. Microstructure of Failed Blades

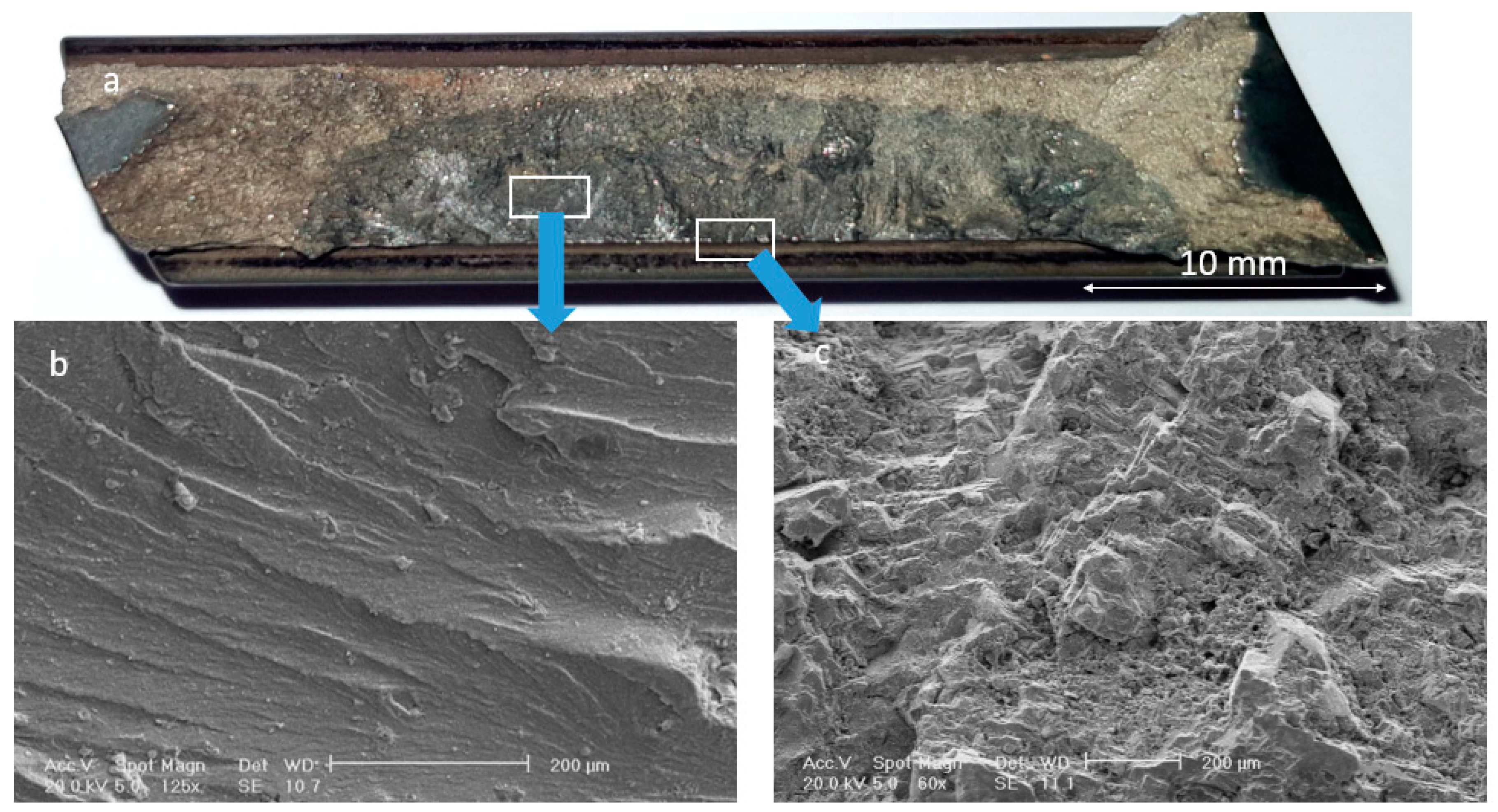

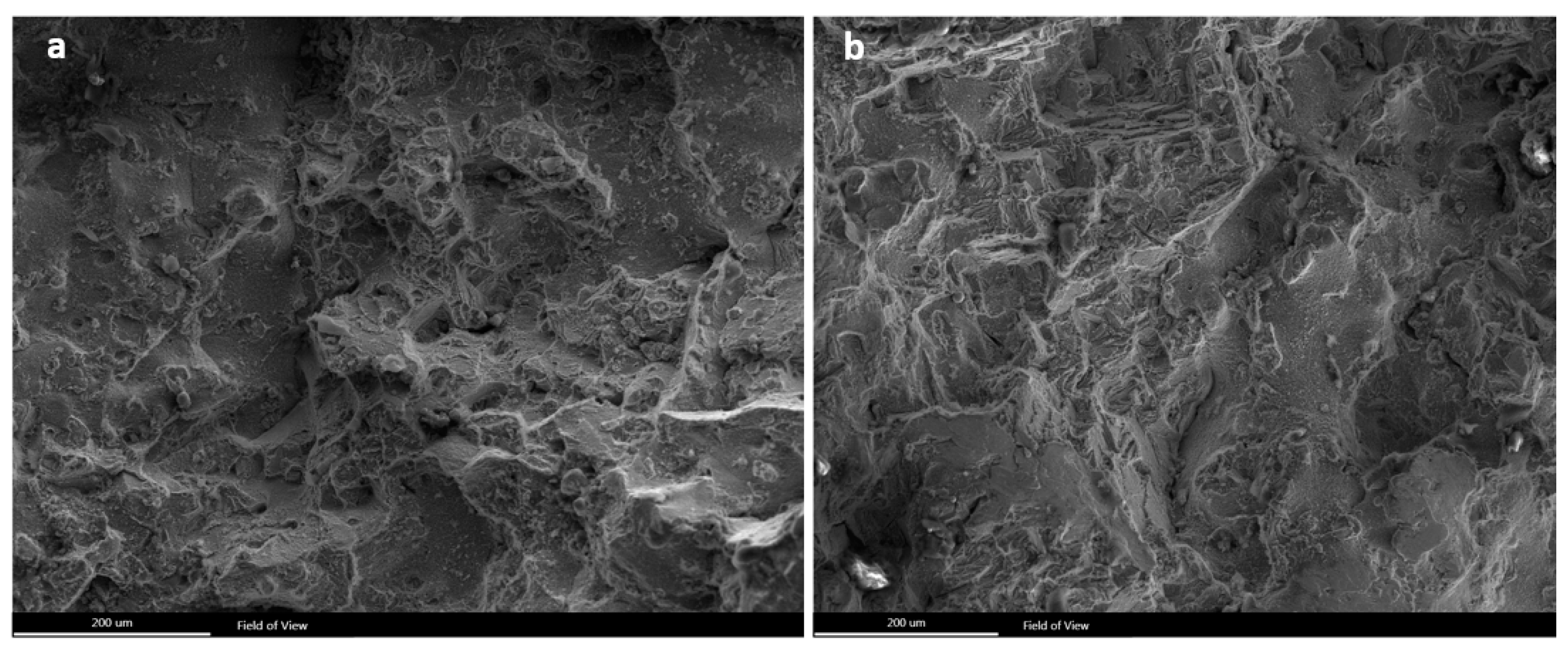

4.3. Fractography of Failed Blades

5. Concluding Remarks

- −

- Nimonic-105 superalloy in this case had a typical dendritic cast structure, with dendrites growing from the edges towards the center.

- −

- There were no surface irregularities, excessive deformation, buckling, or surface cracking observed on the surface of the blades, except for a dent on the edge of one of the broken blades.

- −

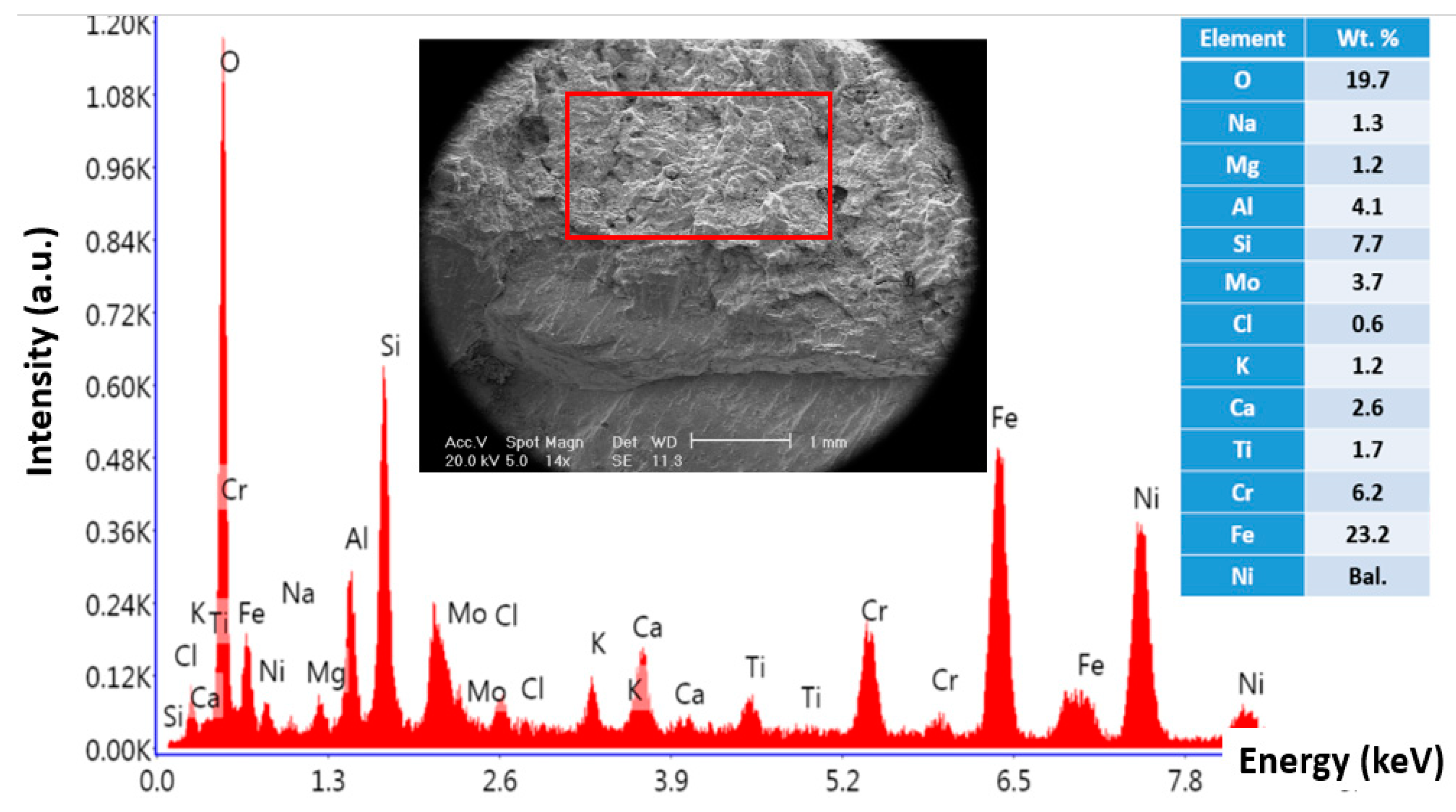

- Results showed that corrosion fatigue is the governing failure mechanism in the blade that failed from the root. In this case, there are corrosion deposits at the edge of the blade, rich in Cl, Ca, O, Na, and K. Fatigue cracks have initiated from corroded spots at the edge of the blade.

- −

- Fractography of the blade that failed from the airfoil showed that, contrary to the former case, there is hardly any fatigue involved in the failure of this blade.

- −

- It was concluded that the blade that failed from the root first underwent a corrosion-fatigue failure, finally ending up in the breakage of the airfoil from the root. The broken piece then hit the adjacent blade in its trajectory, causing the fracture of the adjacent blade from the airfoil. The dent observed at the edge of the airfoil possibly formed as a result of the collision between the flying broken piece and the airfoil.

- −

- Given that both corrosion and fatigue mechanisms were involved in this failure, it is important to minimize mechanical vibrations and to reduce contaminants in the system. The latter necessitates further investigation on the origins of the Cl, Na, and Ca-containing residues and how they can be controlled/eliminated from the system.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Maktouf, W.; Saï, K. An investigation of premature fatigue failures of gas turbine blade. Eng. Fail. Anal. 2015, 47, 89–101. [Google Scholar] [CrossRef]

- Carter, T. Common failures in gas turbine blades. Eng. Fail. Anal. 2005, 12, 237–247. [Google Scholar] [CrossRef]

- Wang, W.; Xuan, F. Failure analysis of the final stage blade in steam turbine. Eng. Fail. Anal. 2007, 14, 632–641. [Google Scholar] [CrossRef]

- Vardar, N.; Ekerim, A. Failure analysis of gas turbine blades in a thermal power plant. Eng. Fail. Anal. 2007, 14, 743–749. [Google Scholar] [CrossRef]

- Bhaumik, S.K.; Sujata, M. Failure of a low pressure turbine rotor blade of an aero engine. Eng. Fail. Anal. 2006, 13, 1202–1219. [Google Scholar] [CrossRef]

- Kargarnejad, S.; Djavanroodi, F. Failure assessment of Nimonic 80 A gas turbine blade. Eng. Fail. Anal. 2012, 26, 211–219. [Google Scholar] [CrossRef]

- Qu, S.; Fu, C.; Dong, C.; Tian, J.; Zhang, Z. Failure analysis of the 1st stage blades in gas turbine engine. Eng. Fail. Anal. 2013, 32, 292–303. [Google Scholar] [CrossRef]

- Poursaeidi, E.; Babaei, A.; Mohammadi Arhani, M.; Arablu, M. Effects of natural frequencies on the failure of R1 compressor blades. Eng. Fail. Anal. 2012, 25, 304–315. [Google Scholar] [CrossRef]

- Rama Rao, A.; Dutta, B. Vibration analysis for detecting failure of compressor blade. Eng. Fail. Anal. 2012, 25, 211–218. [Google Scholar] [CrossRef]

- Witek, L. Experimental crack propagation and failure analysis of the first stage compressor blade subjected to vibration. Eng. Fail. Anal. 2009, 16, 2163–2170. [Google Scholar] [CrossRef]

- Mazur, Z.; Garcia-Illescas, R.; Porcayo-Calderon, J. Last stage blades failure analysis of a 28 MW geothermal turbine. Eng. Fail. Anal. 2009, 16, 1020–1032. [Google Scholar] [CrossRef]

- Witek, L. Numerical stress and crack initiation analysis of the compressor blades after foreign object damage subjected to high-cycle fatigue. Eng. Fail. Anal. 2011, 18, 2111–2125. [Google Scholar] [CrossRef]

- Silveira, E.; Atxaga, G.; Irisarri, A. Failure analysis of a set of compressor blades. Eng. Fail. Anal. 2008, 15, 666–674. [Google Scholar] [CrossRef]

- Lourenço, N.; Graça, M.; Franco, L.A.L.; Silva, O. Fatigue failure of a compressor blade. Eng. Fail. Anal. 2008, 15, 1150–1154. [Google Scholar] [CrossRef]

- Bhagi, L.; Gupta, P.; Rastogi, V. Fractographic investigations of the failure of L-1 low pressure steam turbine blade. Case Stud. Eng. Fail. Anal. 2013, 1, 72–78. [Google Scholar] [CrossRef][Green Version]

- Ziegler, D.; Puccinelli, M.; Bergallo, B.; Picasso, A. Investigation of turbine blade failure in a thermal power plant. Case Stud. Eng. Fail. Anal. 2013, 1, 192–199. [Google Scholar] [CrossRef]

- Kolagar, A.M.; Tabrizi, N.; Cheraghzadeh, M.; Shahriari, M.S. Failure analysis of gas turbine first stage blade made of nickel-based superalloy. Case Stud. Eng. Fail. Anal. 2017, 8, 61–68. [Google Scholar] [CrossRef]

- Mousavi Anijdan, S.H.; Bahrami, A. A new method in prediction of TCP phases formation in superalloys. Mater. Sci. Eng. A 2005, 396, 138–142. [Google Scholar] [CrossRef]

- Thakur, A.; Gangopadhyay, S. State-of-the-art in surface integrity in machining of nickel-based super alloys. Int. J. Machine Tools Manuf. 2016, 100, 25–54. [Google Scholar] [CrossRef]

- Wright, P.K.; Chow, J.G. Deformation characteristics of nickel alloys during machining. J. Eng. Mater. Tech. ASME 1982, 104, 85–93. [Google Scholar] [CrossRef]

- Schönbauer, B.; Tschegg, S.; Perlega, A.; Salzman, R.; Rieger, N.; Zhou, S.; Turnbull, A.; Gandy, D. Fatigue life estimation of pitted 12% Cr turbine blade steel in different environments and at different stress ratios. Int. J. Fatigue 2014, 65, 33–43. [Google Scholar] [CrossRef]

- Larrosa, N.O.; Akid, R.; Ainsworth, R.A. Corrosion-fatigue: A review of damage tolerance models. Int. Mater. Rev. 2017, 63, 283–308. [Google Scholar] [CrossRef]

- Kiani Khouzani, M.; Bahrami, A.; Hosseini-Abari, A.; Khandouzi, M.; Taheri, P. Microbiologically Influenced Corrosion of a Pipeline in a Petrochemical Plant. Metals 2019, 9, 459. [Google Scholar] [CrossRef]

- Kiani Khouzani, M.; Bahrami, A.; Eslami, A. Metallurgical aspects of failure in a broken femoral HIP prosthesis. Eng. Fail. Anal. 2018, 90, 168–178. [Google Scholar] [CrossRef]

- Hadizadeh, B.; Bahrami, A.; Eslami, A.; Abdian, K.; Younes Araghi, M.; Etezazi, M. Establishing the cause of failure in continuous casting rolls. Eng. Fail. Anal. 2020, 108, 104346. [Google Scholar] [CrossRef]

- Bahrami, A.; Taheri, P. Creep failure of reformer tubes in a petrochemical plant. Metals 2019, 9, 1026. [Google Scholar] [CrossRef]

- Bahrami, A.; Kiani Khouzani, M.; Mokhtari, S.A.; Zareh, S.; Yazdan Mehr, M. Root cause analysis of surface cracks in heavy steel plates during the hot rolling process. Metals 2019, 9, 801. [Google Scholar] [CrossRef]

- Abdali Varnosfaderani, M.; Eslami, A.; Saiedi, N.; Bahrami, A. Metallurgical aspects of a blowdown pipe failure in a petrochemical plant. Eng. Fail. Anal. 2019, 98, 141–149. [Google Scholar] [CrossRef]

- Bahrami, A.; Mousavi Anijdan, S.H.; Taheri, P.; Yazdan Mehr, M. Failure of AISI 304H stainless steel elbows in a heat exchanger. Eng. Fail. Anal. 2018, 90, 397–403. [Google Scholar] [CrossRef]

- Bahrami, A.; Taheri, P. A Study on the failure of AISI 304 stainless steel tubes in a gas heater unit. Metals 2019, 9, 969. [Google Scholar] [CrossRef]

| Element | C | Si | Cu | Fe | >Mn | Cr | Ti | Al | Co | Mo | Zr | Ni |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| wt. % | 0.1 | 0.5 | 0.1 | 0.5 | 0.6 | 15.0 | 1.0 | 4.5 | 19.0 | 5.0 | 0.1 | Bal. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rajabinezhad, M.; Bahrami, A.; Mousavinia, M.; Seyedi, S.J.; Taheri, P. Corrosion-Fatigue Failure of Gas-Turbine Blades in an Oil and Gas Production Plant. Materials 2020, 13, 900. https://doi.org/10.3390/ma13040900

Rajabinezhad M, Bahrami A, Mousavinia M, Seyedi SJ, Taheri P. Corrosion-Fatigue Failure of Gas-Turbine Blades in an Oil and Gas Production Plant. Materials. 2020; 13(4):900. https://doi.org/10.3390/ma13040900

Chicago/Turabian StyleRajabinezhad, Mojtaba, Abbas Bahrami, Mohammad Mousavinia, Seyed Jalil Seyedi, and Peyman Taheri. 2020. "Corrosion-Fatigue Failure of Gas-Turbine Blades in an Oil and Gas Production Plant" Materials 13, no. 4: 900. https://doi.org/10.3390/ma13040900

APA StyleRajabinezhad, M., Bahrami, A., Mousavinia, M., Seyedi, S. J., & Taheri, P. (2020). Corrosion-Fatigue Failure of Gas-Turbine Blades in an Oil and Gas Production Plant. Materials, 13(4), 900. https://doi.org/10.3390/ma13040900