Mechanical and Tribological Characteristics of Cladded AISI 1045 Carbon Steel

Abstract

1. Introduction

2. Materials and Experimental Methods

2.1. Test Material

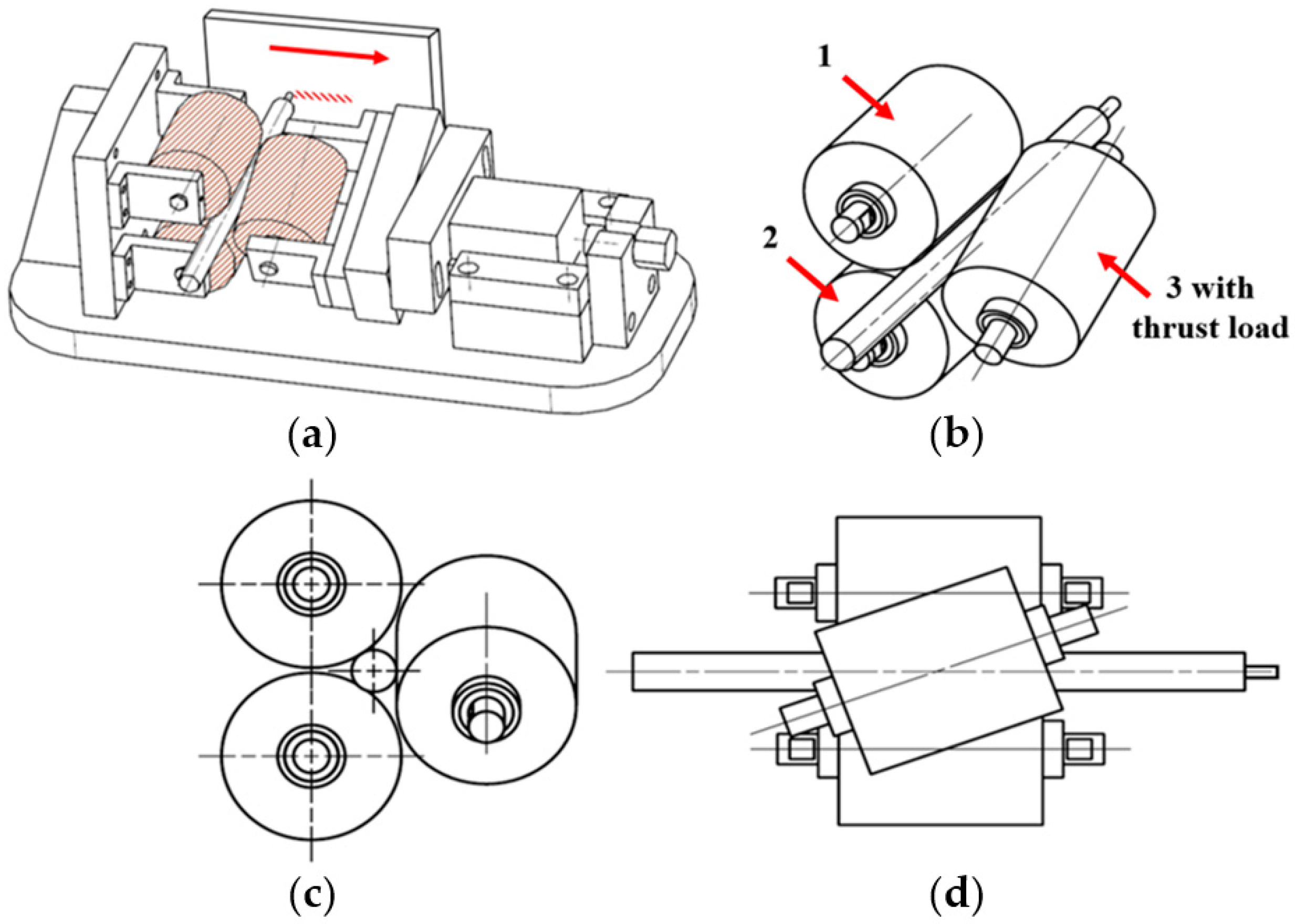

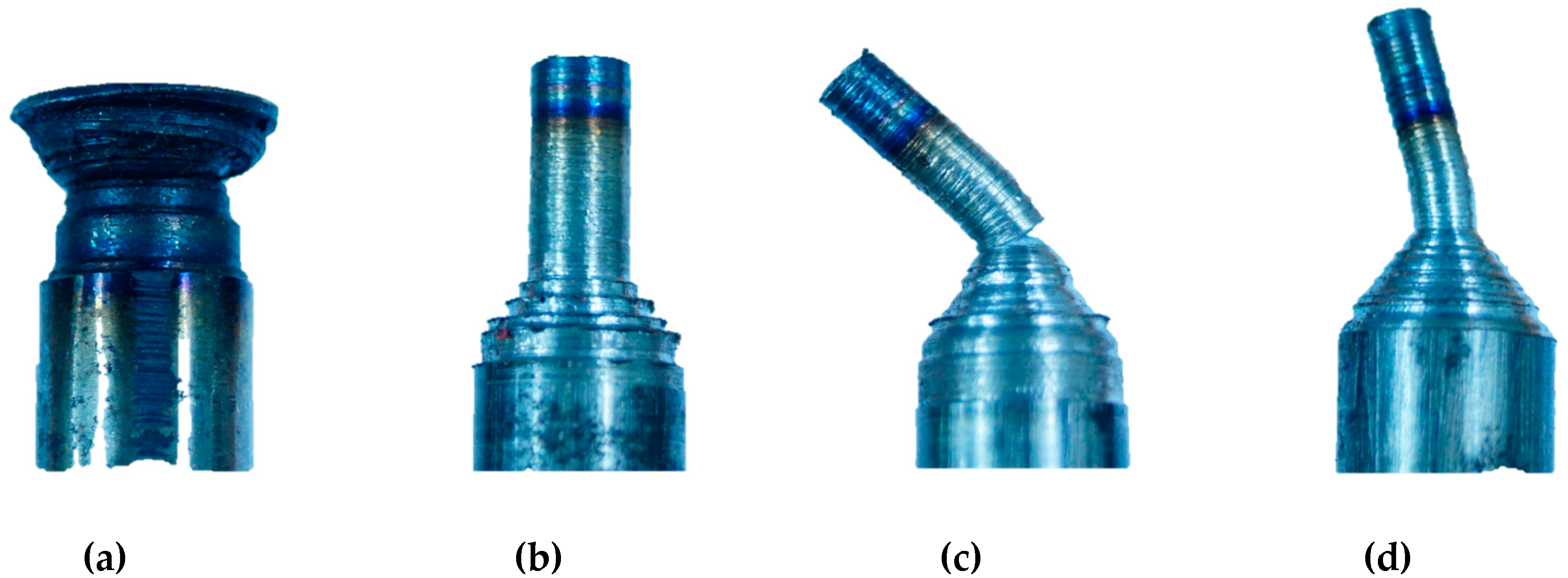

2.2. Cladding Device

2.3. UNSM Treatment

2.4. Tribological Test

2.5. Characterizations

3. Results and Discussions

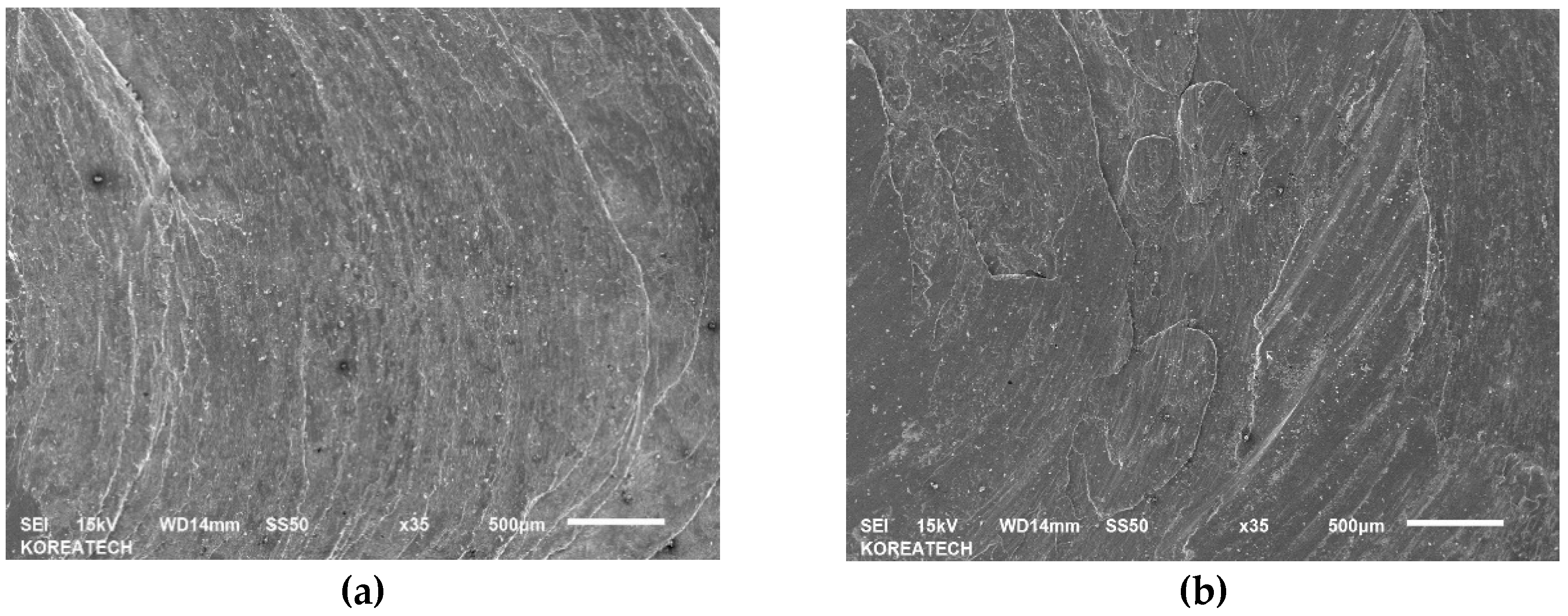

3.1. Microstructure

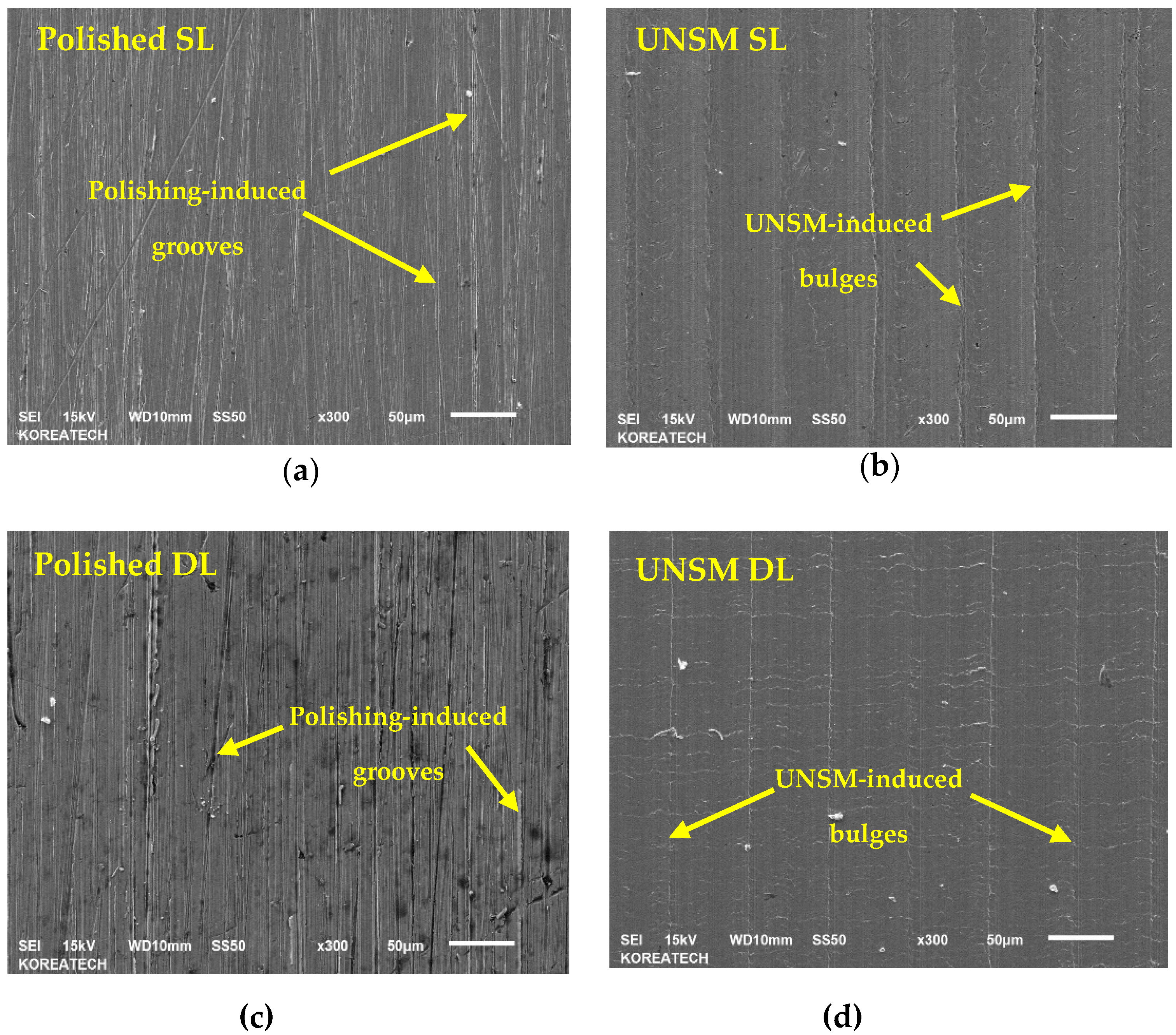

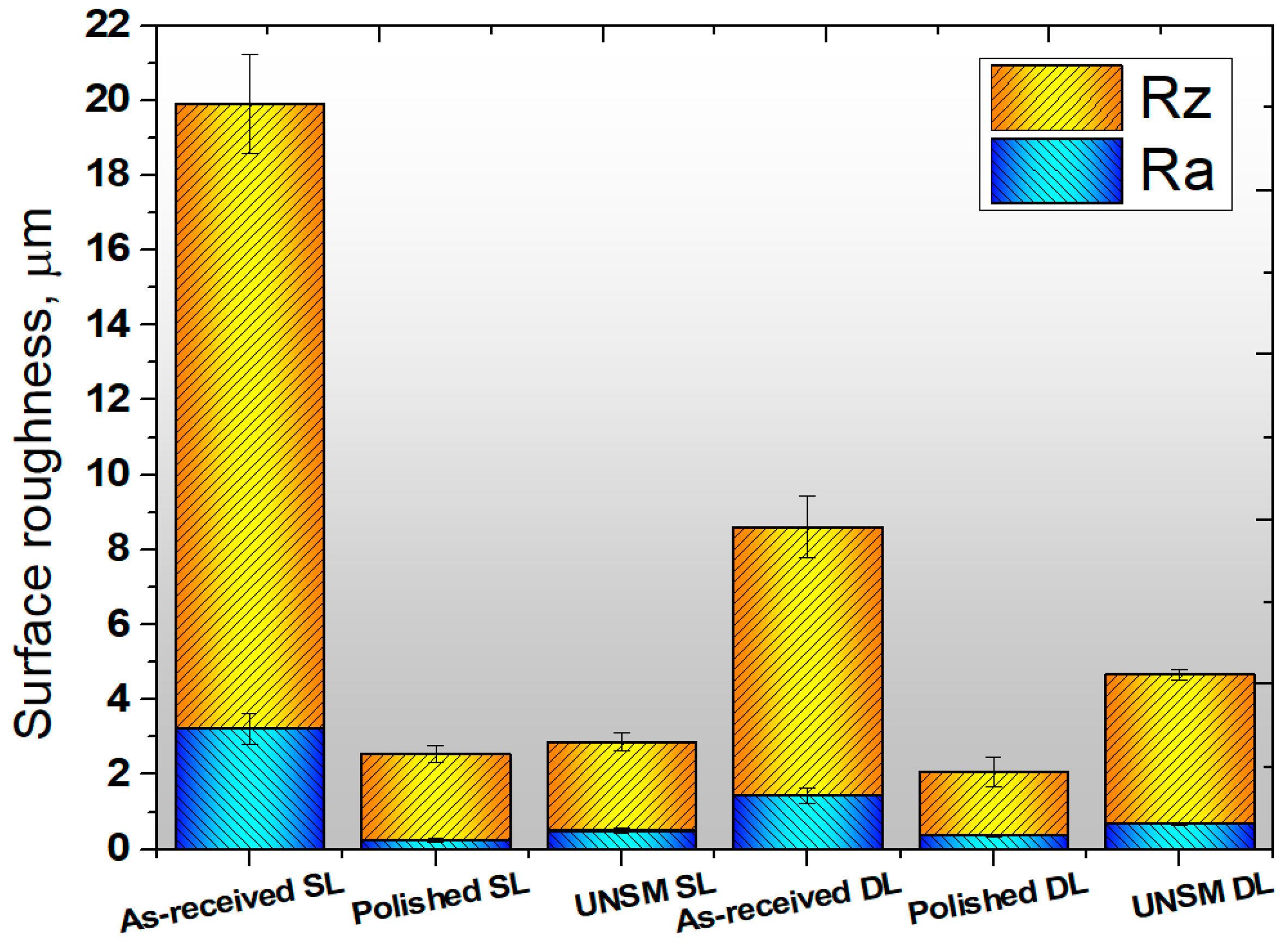

3.2. Surface Roughness

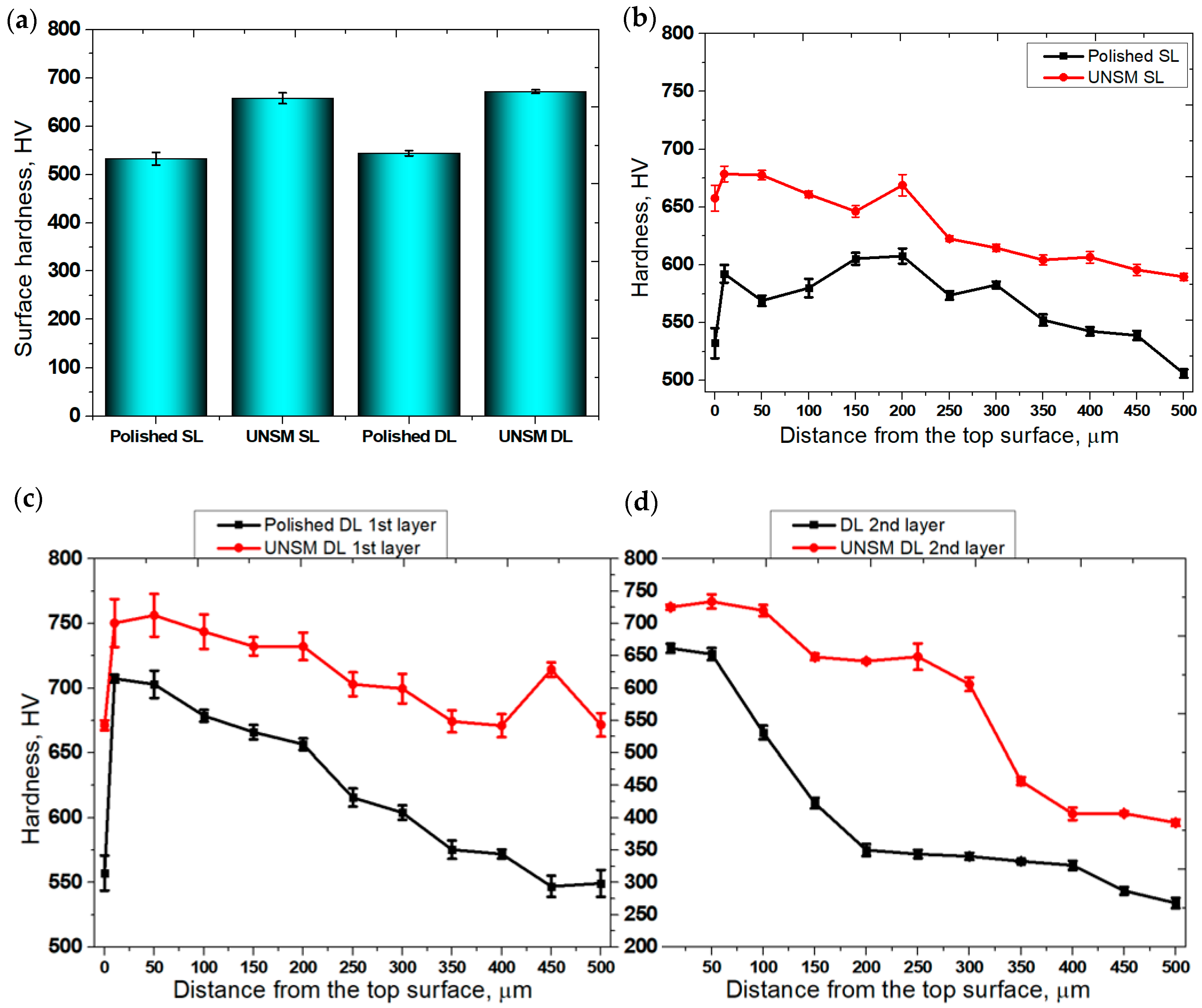

3.3. Hardness Test

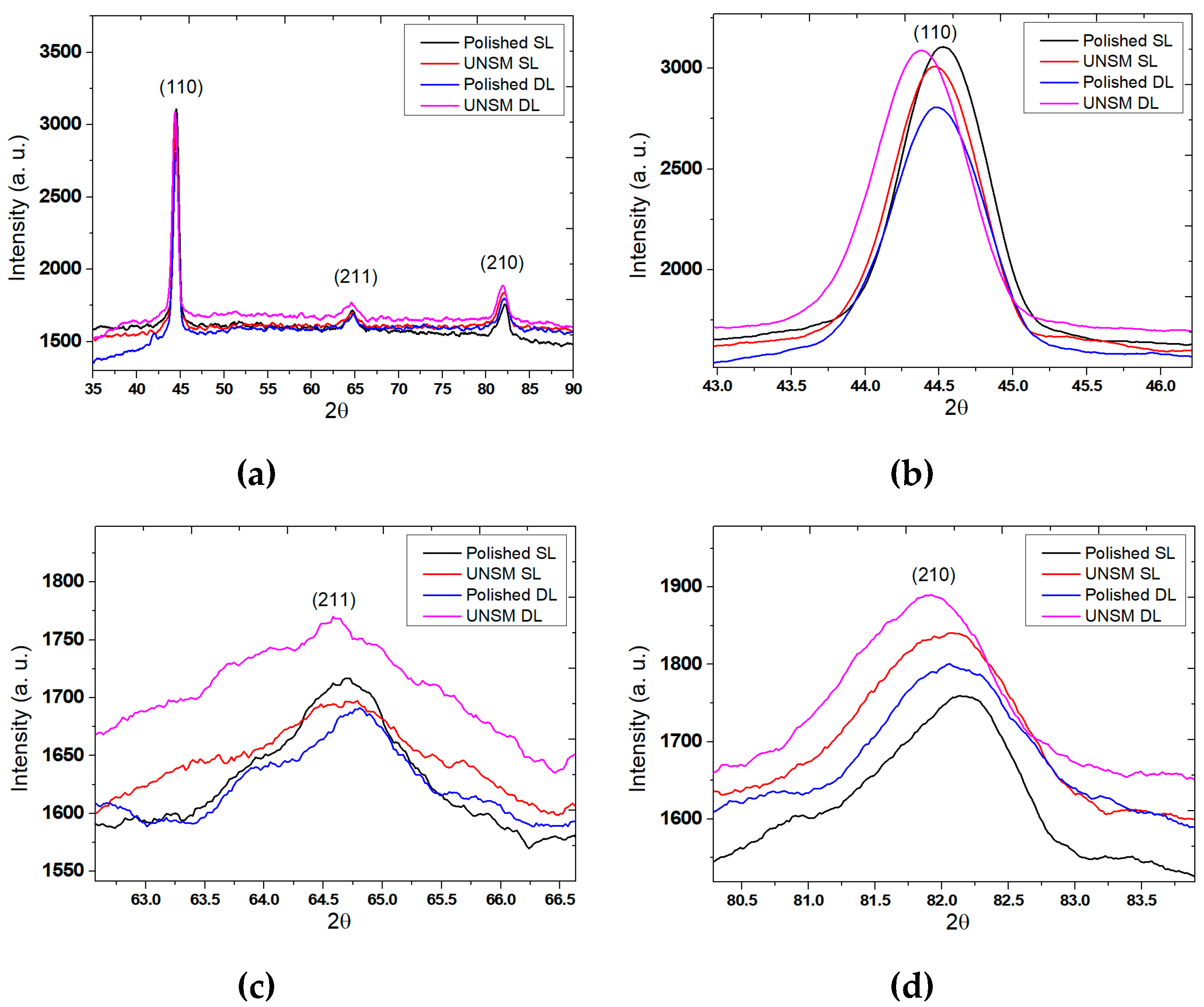

3.4. XRD Results

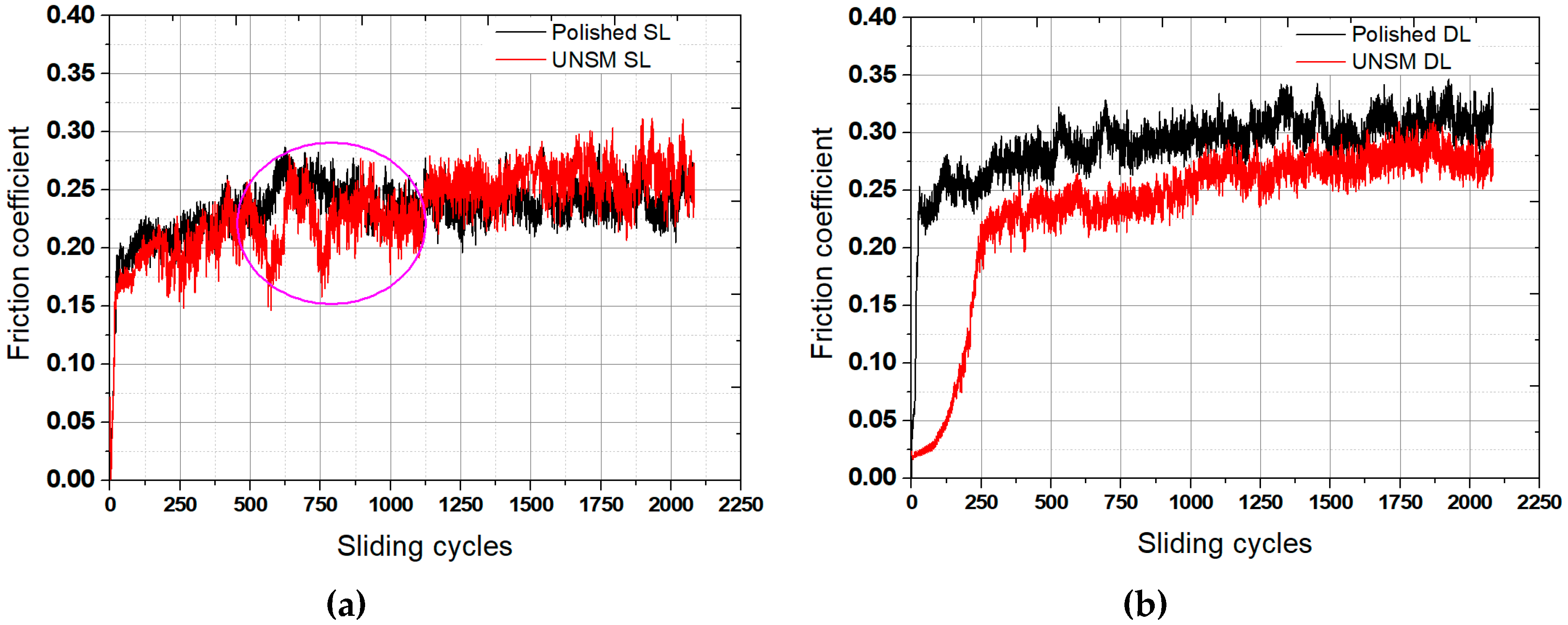

3.5. Variation in Tribological Characteristics

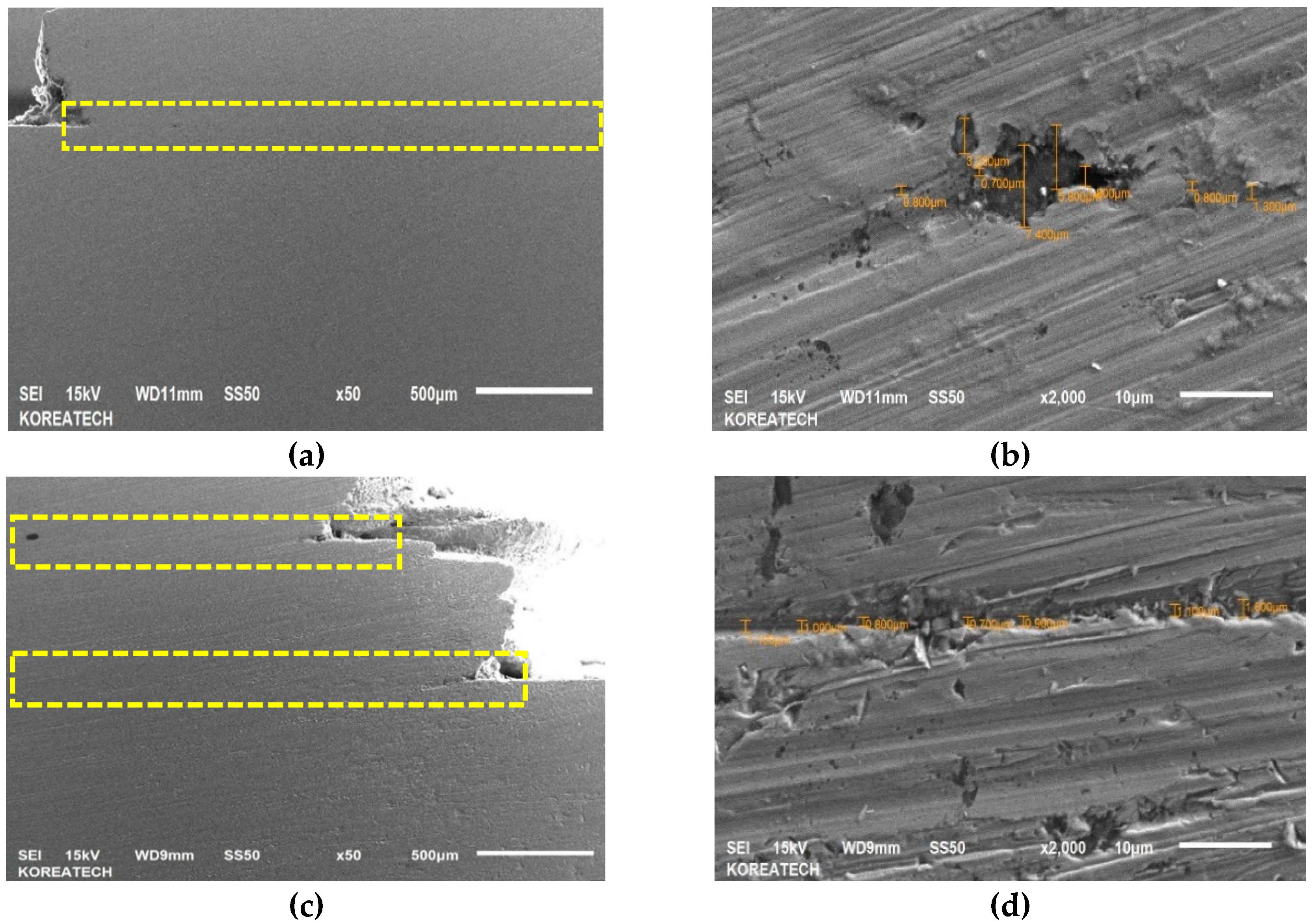

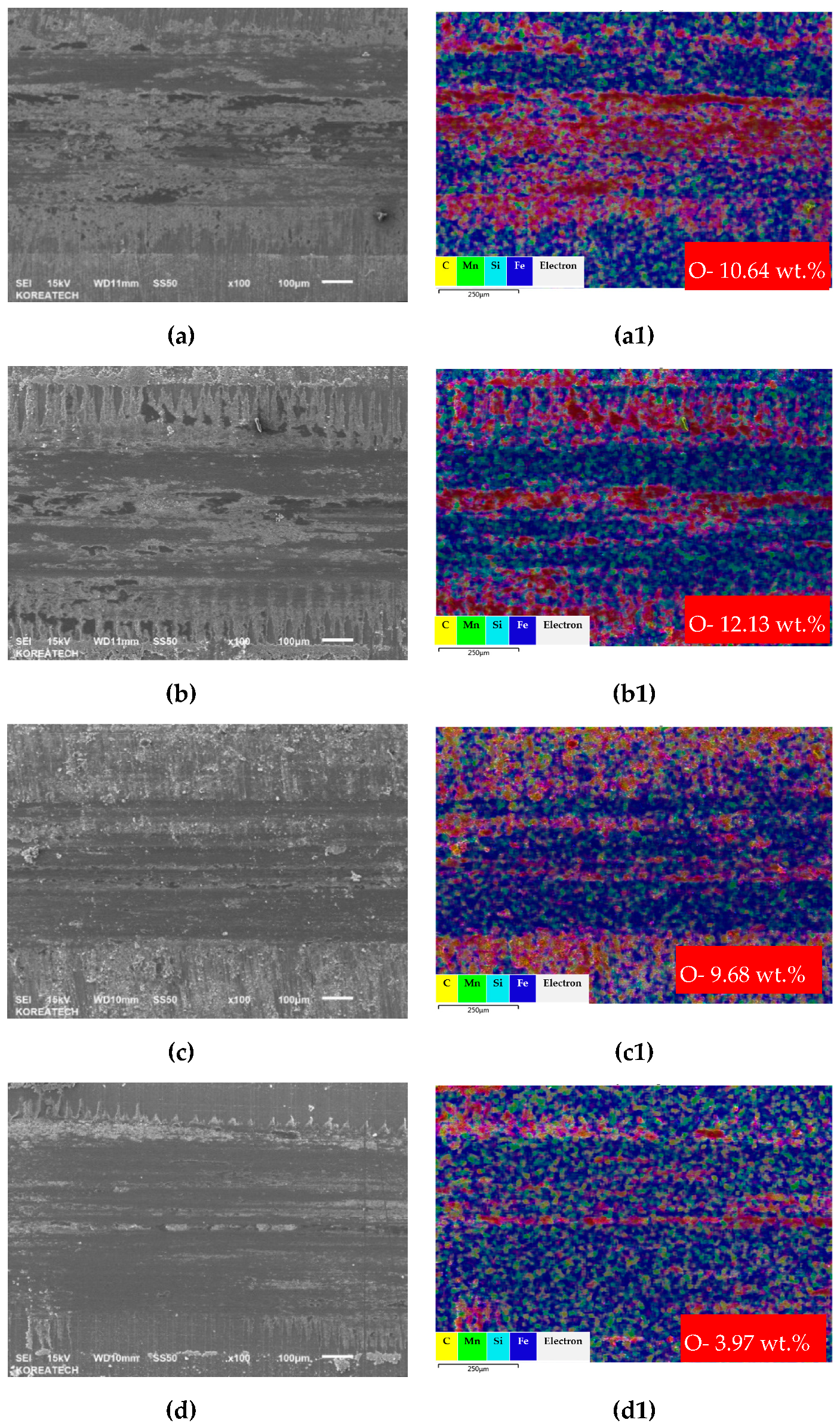

3.6. Wear Track Analysis

4. Conclusions

5. Patents

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- He, X.; Gu, F.; Ball, A. A review of numerical analysis of friction stir welding. Prog. Mater. Sci. 2014, 65, 1–66. [Google Scholar] [CrossRef]

- Silva-Magalhães, A.; Cederqvist, L.; De Backer, J.; Håkansson, E.; Ossiansson, B.; Bolmsjö, G. A Friction Stir Welding case study using Temperature Controlled Robotics with a HPDC Cylinder Block and dissimilar materials joining. J. Manuf. Process. 2019, 46, 177–184. [Google Scholar] [CrossRef]

- Kar, A.; Suwas, S.; Kailas, S.V. Two-pass friction stir welding of aluminum alloy to titanium alloy: A simultaneous improvement in mechanical properties. Mater. Sci. Eng. A 2018, 733, 199–210. [Google Scholar] [CrossRef]

- Jenarthanan, M.P.; Varma, C.V.; Manohar, V.K. Impact of friction stir welding (FSW) process parameters on tensile strength during dissimilar welds of AA2014 and AA606. Mater. Today Proceed. 2018, 5, 14384–14391. [Google Scholar] [CrossRef]

- Lauro, A. Friction stir welding of titanium alloys. Weld. Int. 2012, 26, 8–21. [Google Scholar] [CrossRef]

- Rouhi, S.; Mostafapour, A.; Ashjari, M. Effects of welding environment on microstructure and mechanical properties of friction stir welded AZ91C magnesium alloy joints. Sci. Technol. Weld. Join. 2016, 21, 41–47. [Google Scholar] [CrossRef]

- Lee, W.-B.; Jung, S.-B. The joint properties of copper by friction stir welding. Mater. Lett. 2004, 58, 1041–1046. [Google Scholar] [CrossRef]

- Wu, B.; Zhang, L.; Zhang, J.; Murakami, R.-I.; Pyoun, Y.-S. An investigation of ultrasonic nanocrystal surface modification machining process by numerical simulation. Adv. Eng. Softw. 2015, 83, 59–69. [Google Scholar] [CrossRef]

- He, Y.; Li, K.; Pyoun, Y.-S.; Cho, I.-S.; Lee, C.-S.; Park, I.-G.; Song, J.-I.; Yang, C.-W.; Lee, J.-H.; Shin, K. Characterization of the Nano-Scale Surface Layer of a Tempered Martensitic Steel Synthesized by Ultrasonic Nanocrystalline Surface Modification Treatment. Sci. Adv. Mater. 2014, 6, 2260–2268. [Google Scholar] [CrossRef]

- Kondavalasa, S.R.; Prakash, A.; Jagtap, R.; Shanmugam, S.; Samajdar, I.; Vasudevan, V.K.; Wilde, G.; Rajeshwari, K.S.; Sankaran, S. On the comparison of graded microstructures developed through High Reduction (per pass) Cold Rolling (HRCR) and Ultrasonic Nanocrystal Surface Modification (UNSM) in nickel-base Alloy 602CA. Mater. Charact. 2019, 153, 328–338. [Google Scholar] [CrossRef]

- Cho, I.; Amanov, A.; Kim, J. The effects of AlCrN coating, surface modification and their combination on the tribological properties of high speed steel under dry conditions. Tribol. Int. 2015, 81, 61–72. [Google Scholar] [CrossRef]

- Amanov, A.; Pyun, Y.-S.; Sasaki, S. Effects of ultrasonic nanocrystalline surface modification (UNSM) technique on the tribological behavior of sintered Cu-based alloy. Tribol. Int. 2014, 72, 187–197. [Google Scholar] [CrossRef]

- Ma, C.; Dong, Y.; Ye, C. Improving Surface Finish of 3D-printed Metals by Ultrasonic Nanocrystal Surface Modification. Procedia CIRP 2016, 45, 319–322. [Google Scholar] [CrossRef]

- Zhao, W.; Liu, D.; Qin, H.; Zhang, X.; Zhang, H.; Zhang, R.; Ren, Z.; Ma, C.; Amanov, A.; Pyun, Y.-S.; et al. The effect of ultrasonic nanocrystal surface modification on low temperature nitriding of ultra-high strength steel. Surf. Coatings Technol. 2019, 375, 205–214. [Google Scholar] [CrossRef]

- Cao, X.; Pyoun, Y.; Murakami, R. Fatigue properties of a S45C steel subjected to ultrasonic nanocrystal surface modification. Appl. Surf. Sci. 2010, 256, 6297–6303. [Google Scholar] [CrossRef]

- Ma, C.; Andani, M.T.; Qin, H.; Moghaddam, N.S.; Ibrahim, H.; Jahadakbar, A.; Amerinatanzi, A.; Ren, Z.; Zhang, H.; Doll, G.L.; et al. Improving surface finish and wear resistance of additive manufactured nickel-titanium by ultrasonic nano-crystal surface modification. J. Mater. Process. Technol. 2017, 249, 433–440. [Google Scholar] [CrossRef]

- Zhang, H.; Chiang, R.; Qin, H.; Ren, Z.; Hou, X.; Lin, D.; Doll, G.L.; Vasudevan, V.K.; Dong, Y.; Ye, C. The effects of ultrasonic nanocrystal surface modification on the fatigue performance of 3D-printed Ti64. Int. J. Fatigue 2017, 103, 136–146. [Google Scholar] [CrossRef]

- Martinez, I.; Tanaka, R.; Yamane, Y.; Sekiya, K.; Yamada, K.; Yamada, S.; Hasegawa, M. Effect of coating layer loss on the wear rate change of coated carbide tools in turning process. Precis. Eng. 2017, 50, 1–7. [Google Scholar] [CrossRef]

- Song, Y.; Tane, M.; Nakajima, H. Dynamic and quasi-static compression of porous carbon steel S30C and S45C with directional pores. Mater. Sci. Eng. A 2012, 534, 504–513. [Google Scholar] [CrossRef]

- Shin, H.; Yoo, Y.; Ahn, D.; Im, K. Laser surface hardening of S45C medium carbon steel using ND: YAG laser with a continuous wave. J. Mater. Process. Technol. 2007, 187, 467–470. [Google Scholar] [CrossRef]

- Li, X.; Li, W.; Yang, S.; Shi, H. Experimental investigation into the surface integrity and tribological property of AISI 1045 steel specimen for barrel finishing. Procedia CIRP 2018, 71, 47–52. [Google Scholar] [CrossRef]

- ASTM Steel. OTAI Special Steel Co. Ltd. Available online: http://www.astmsteel.com (accessed on 8 February 2020).

- Amanov, A.; Cho, I.; Pyoun, Y.; Lee, C.; Park, I. Micro-dimpled surface by ultrasonic nanocrystal surface modification and its tribological effects. Wear 2012, 286, 136–144. [Google Scholar] [CrossRef]

- Amanov, A.; Karimbaev, R.; Maleki, E.; Unal, O.; Pyun, Y.-S.; Amanov, T. Effect of combined shot peening and ultrasonic nanocrystal surface modification processes on the fatigue performance of AISI 304. Surf. Coatings Technol. 2019, 358, 695–705. [Google Scholar] [CrossRef]

- Vakis, A.; Yastrebov, V.; Scheibert, J.; Nicola, L.; Dini, D.; Minfray, C.; Almqvist, A.; Paggi, M.; Lee, S.; Limbert, G.; et al. Modeling and simulation in tribology across scales: An overview. Tribol. Int. 2018, 125, 169–199. [Google Scholar] [CrossRef]

- Amanov, A.; Sembiring, J.P.B.A.; Amanov, T. Experimental Investigation on Friction and Wear Behavior of the Vertical Spindle and V-belt of a Cotton Picker. Materials 2019, 12, 773. [Google Scholar] [CrossRef] [PubMed]

- Amanov, A. Wear resistance and adhesive failure of thermal spray ceramic coatings deposited onto graphite in response to ultrasonic nanocrystal surface modification technique. Appl. Surf. Sci. 2019, 477, 184–197. [Google Scholar] [CrossRef]

- Zhang, H.; Zhao, J.; Liu, J.; Qin, H.; Ren, Z.; Doll, G.; Dong, Y.; Ye, C. The effects of electrically-assisted ultrasonic nanocrystal surface modification on 3D-printed Ti-6Al-4V alloy. Addit. Manuf. 2018, 22, 60–68. [Google Scholar] [CrossRef]

- Kim, M.; Oh, W.; Baek, G.; Jo, Y.; Lee, K.; Park, S.; Shim, D. Ultrasonic nanocrystal surface modification of high-speed tool steel (AISI M4) layered via direct energy deposition. J. Mater. Process. Technol. 2020, 277, 116420. [Google Scholar] [CrossRef]

- Wu, B.; Wang, P.; Pyoun, Y.-S.; Zhang, J.; Murakami, R. Study on the fatigue properties of plasma nitriding S45C with a pre-ultrasonic nanocrystal surface modification process. Surf. Coatings Technol. 2013, 216, 191–198. [Google Scholar] [CrossRef]

- Wu, B.; Wang, P.; Pyoun, Y.-S.; Zhang, J.; Murakami, R.-I. Effect of ultrasonic nanocrystal surface modification on the fatigue behaviors of plasma-nitrided S45C steel. Surf. Coatings Technol. 2012, 213, 271–277. [Google Scholar] [CrossRef]

- Mishchenko, A.; Wu, L.; Silva, V.K.; Scotti, A. Analysis of residual stresses resulting from the surface preparation for X-ray diffraction measurement. J Braz. Soc. Mech. Sci. Eng. 2018, 40, 94. [Google Scholar] [CrossRef]

- Kumar, D.; Idapalapati, S.; Wang, W.; Narasimalu, S. Effect of Surface Mechanical Treatments on the Microstructure-Property-Performance of Engineering Alloys. Materials 2019, 12, 2503. [Google Scholar] [CrossRef]

- Du Plessis, A.; Yadroitsava, I.; Yadroitsev, I. Effects of defects on mechanical properties in metal additive manufacturing: A review focusing on X-ray tomography insights. Mater. Des. 2020, 187, 108385. [Google Scholar] [CrossRef]

- Chae, J.-M.; Lee, K.-O.; Amanov, A. Gradient Nanostructured Tantalum by Thermal-Mechanical Ultrasonic Impact Energy. Materials 2018, 11, 452. [Google Scholar] [CrossRef]

- Gill, A.; Telang, A.; Mannava, S.; Qian, D.; Pyoun, Y.-S.; Soyama, H.; Vasudevan, V.K. Comparison of mechanisms of advanced mechanical surface treatments in nickel-based superalloy. Mater. Sci. Eng. A 2013, 576, 346–355. [Google Scholar] [CrossRef]

- Amanov, A.; Cho, I.-S.; Pyun, Y.-S. Microstructural evolution and surface properties of nanostructured Cu-based alloy by ultrasonic nanocrystalline surface modification technique. Appl. Surf. Sci. 2016, 388, 185–195. [Google Scholar] [CrossRef]

- Pei, X.; Pu, W.; Zhang, Y.; Huang, L. Surface topography and friction coefficient evolution during sliding wear in a mixed lubricated rolling-sliding contact. Tribol. Int. 2019, 137, 303–312. [Google Scholar] [CrossRef]

- Thakare, M.; Mason, J.; Owen, A.; Gillespie, D.; Wilkinson, A.; Franceschini, G. Effect of sliding speed and counterface properties on the tribo-oxidation of brush seal material under dry sliding conditions. Tribol. Int. 2016, 96, 373–381. [Google Scholar] [CrossRef]

| Materials | C | Mn | P | S | Si | Cr | V | Mo |

|---|---|---|---|---|---|---|---|---|

| AISI 1045 | 0.50 | 0.80 | 0.035 | 0.035 | 0.27 | 0.25 | - | - |

| ASTM H13 | 0.45 | 0.6 | 0.03 | 0.03 | 1.25 | 5.5 | 1.2 | 1.75 |

| Materials | Tensile Strength, MPa | Yield Strength, MPa | Elastic Modules, GPa | Hardness, HV |

|---|---|---|---|---|

| AISI 1045 | 569 | 343 | 80 | 260 |

| ASTM H13 | 1590 | 1380 | 215 | 205 |

| Roller Diameter, mm | Speed of Roller, rpm | Speed of Filler, rpm |

|---|---|---|

| 40 | 5190 | 20760 |

| Frequency, kHz | Amplitude, μm | Speed, mm/min | Static Load, N | Interval, μm | Ball Diam., mm | Ball Material |

|---|---|---|---|---|---|---|

| 20 | 30 | 2000 | 50 | 0.03 | 2.38 | WC |

| Load, N | Frequency, Hz | Sliding Distance, m | Time, min | Temperature, °C |

|---|---|---|---|---|

| 10 | 1.33 | 25 | 26 | RT |

| Single Layer (SL) | |||

| Diffraction Peaks | Specimens | 2θ Degree | FWHM |

| (110) | Polished | 44.53 | 0.5562 |

| UNSM-treated | 44.47 | 0.6720 | |

| (211) | Polished | 64.61 | 1.2822 |

| UNSM-treated | 64.56 | 2.0780 | |

| (210) | Polished | 82.03 | 1.0892 |

| UNSM-treated | 81.95 | 1.3206 | |

| Double Layer (DL) | |||

| (110) | Polished | 44.48 | 0.7288 |

| UNSM-treated | 44.37 | 0.7293 | |

| (211) | Polished | 64.69 | 1.3933 |

| UNSM-treated | 64.43 | 2.8394 | |

| (210) | Polished | 82.06 | 1.1465 |

| UNSM-treated | 81.83 | 1.2285 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karimbaev, R.; Choi, S.; Pyun, Y.-S.; Amanov, A. Mechanical and Tribological Characteristics of Cladded AISI 1045 Carbon Steel. Materials 2020, 13, 859. https://doi.org/10.3390/ma13040859

Karimbaev R, Choi S, Pyun Y-S, Amanov A. Mechanical and Tribological Characteristics of Cladded AISI 1045 Carbon Steel. Materials. 2020; 13(4):859. https://doi.org/10.3390/ma13040859

Chicago/Turabian StyleKarimbaev, Ruslan, Seimi Choi, Young-Sik Pyun, and Auezhan Amanov. 2020. "Mechanical and Tribological Characteristics of Cladded AISI 1045 Carbon Steel" Materials 13, no. 4: 859. https://doi.org/10.3390/ma13040859

APA StyleKarimbaev, R., Choi, S., Pyun, Y.-S., & Amanov, A. (2020). Mechanical and Tribological Characteristics of Cladded AISI 1045 Carbon Steel. Materials, 13(4), 859. https://doi.org/10.3390/ma13040859