Femtosecond-Laser Nanostructuring of Black Diamond Films under Different Gas Environments

Abstract

1. Introduction

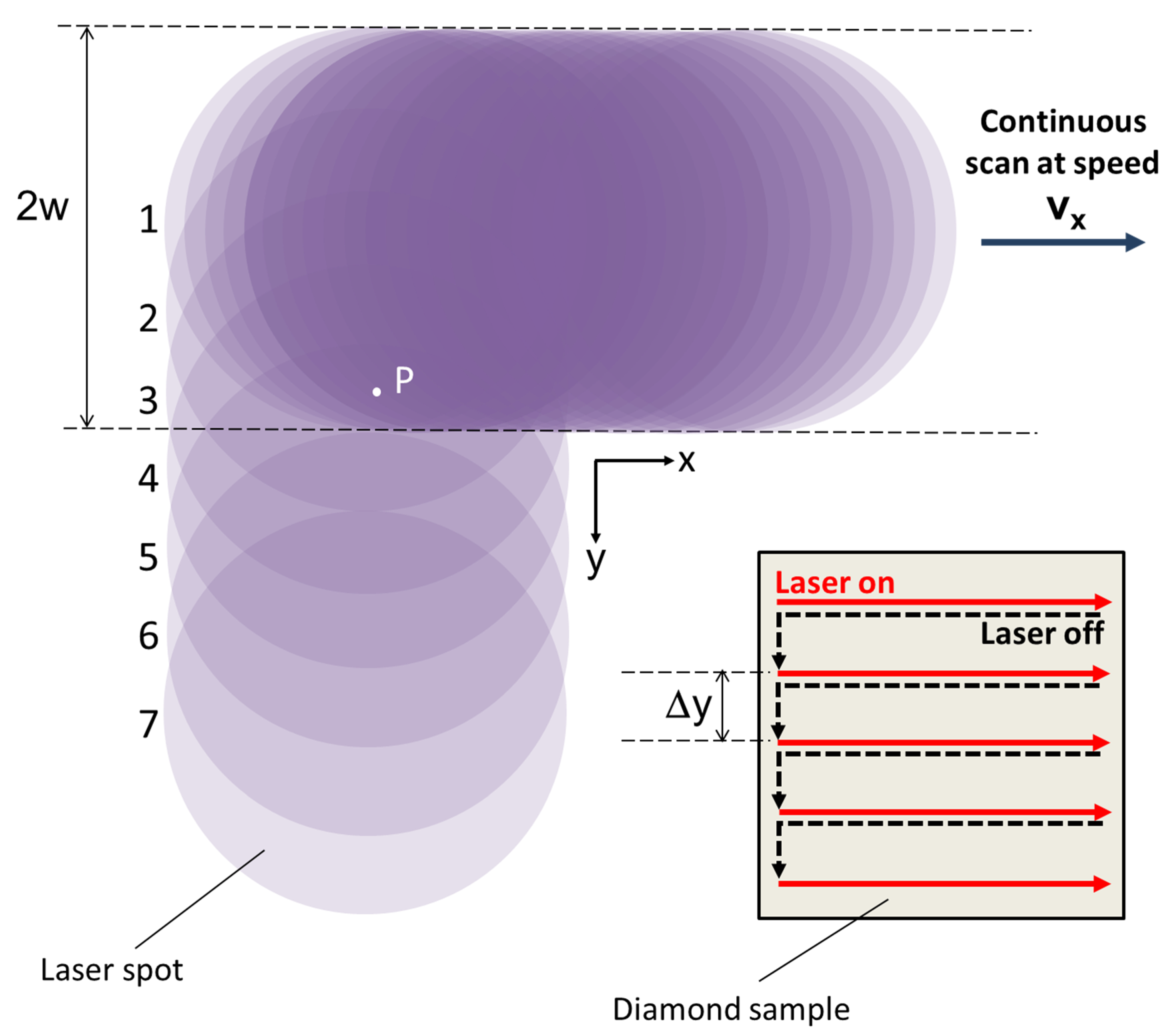

2. Materials and Methods

3. Results

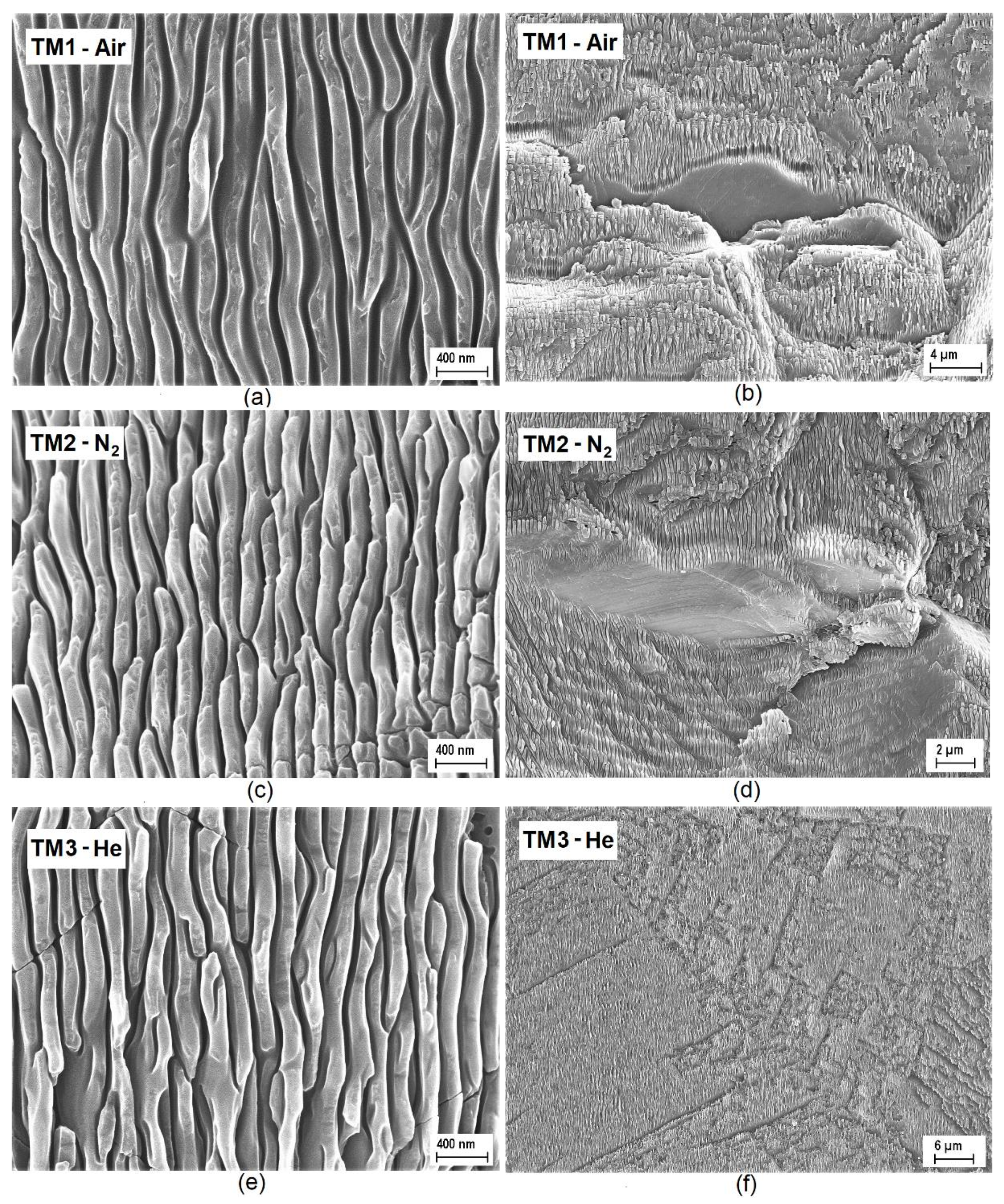

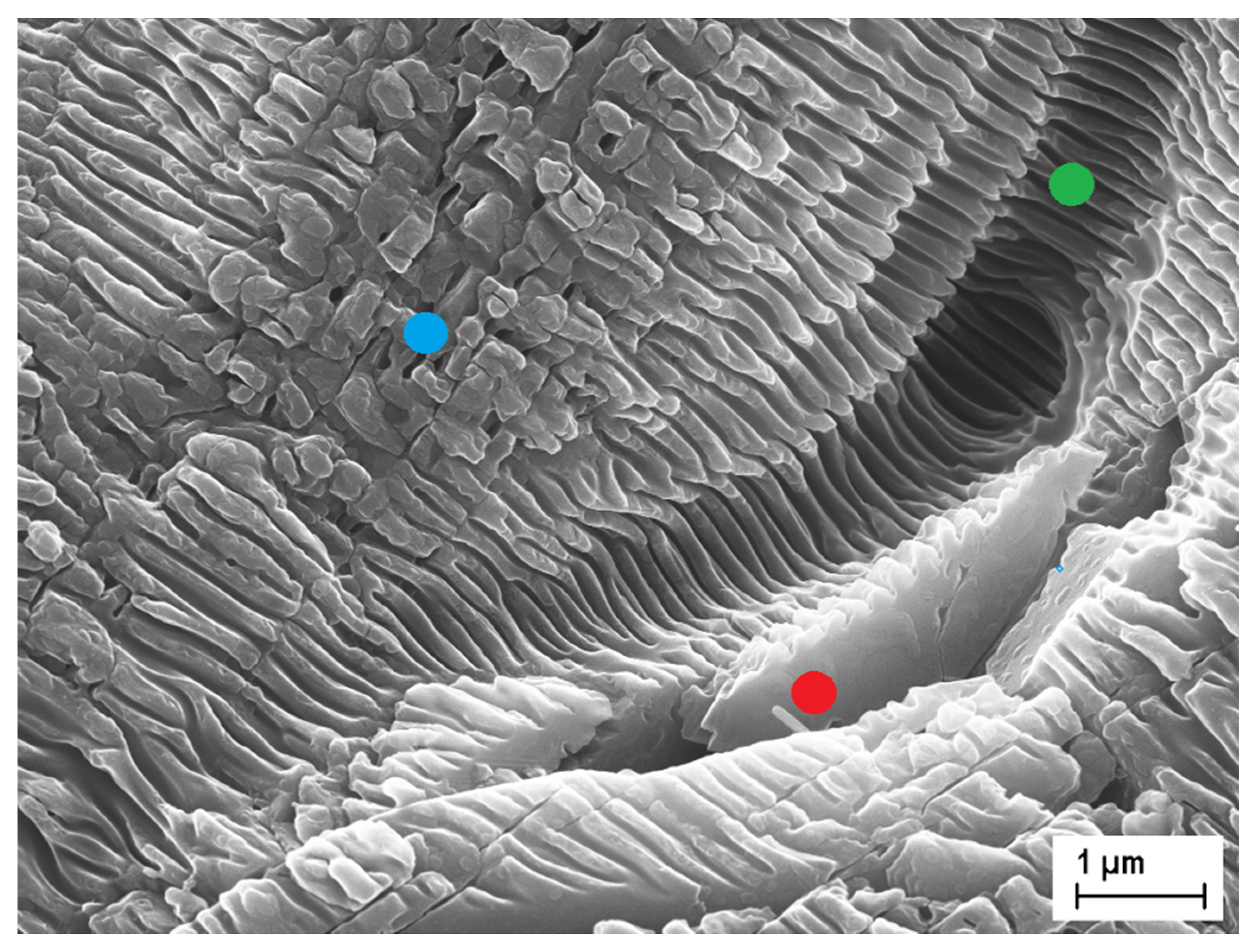

3.1. SEM Characterization

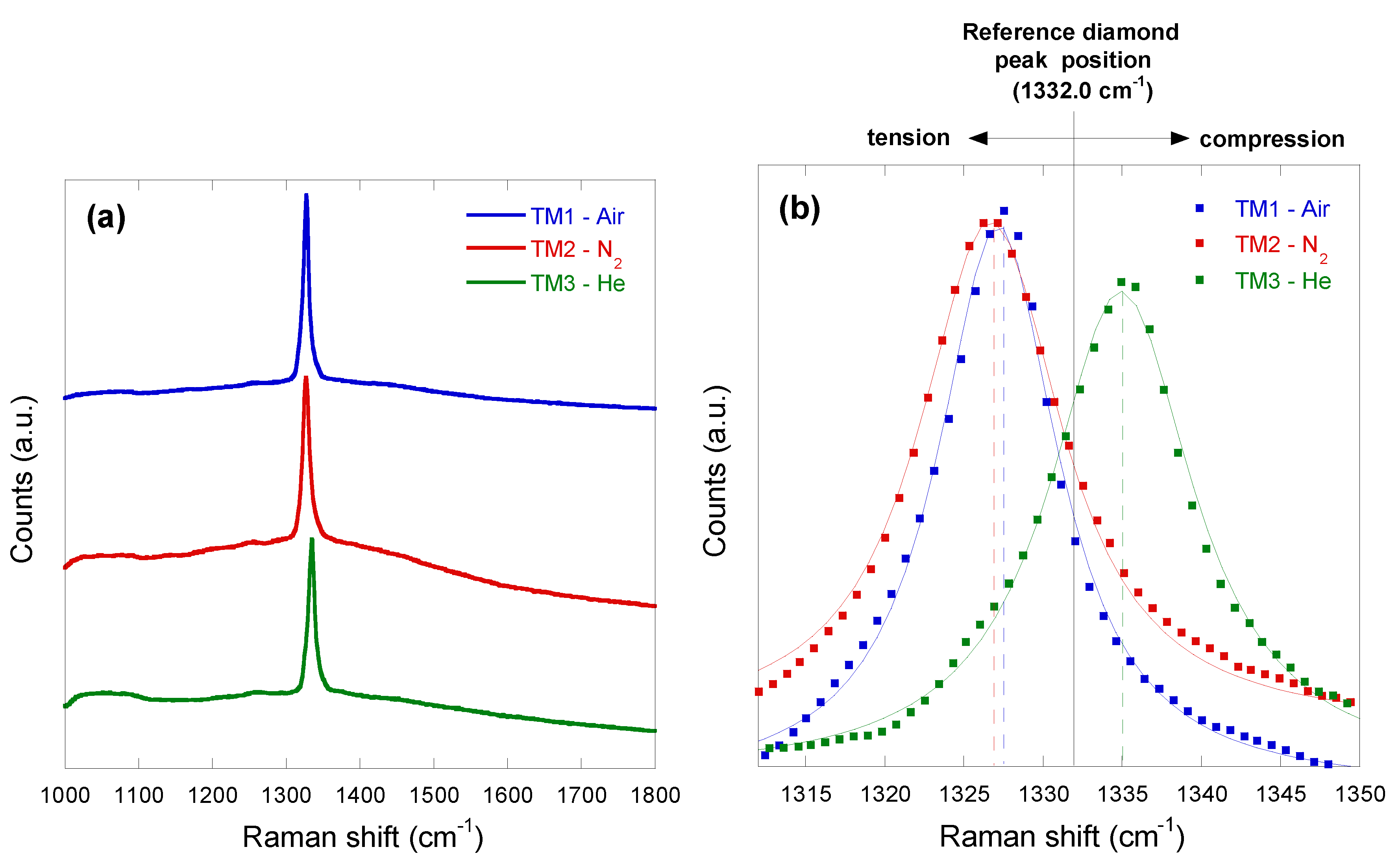

3.2. Raman Characterization

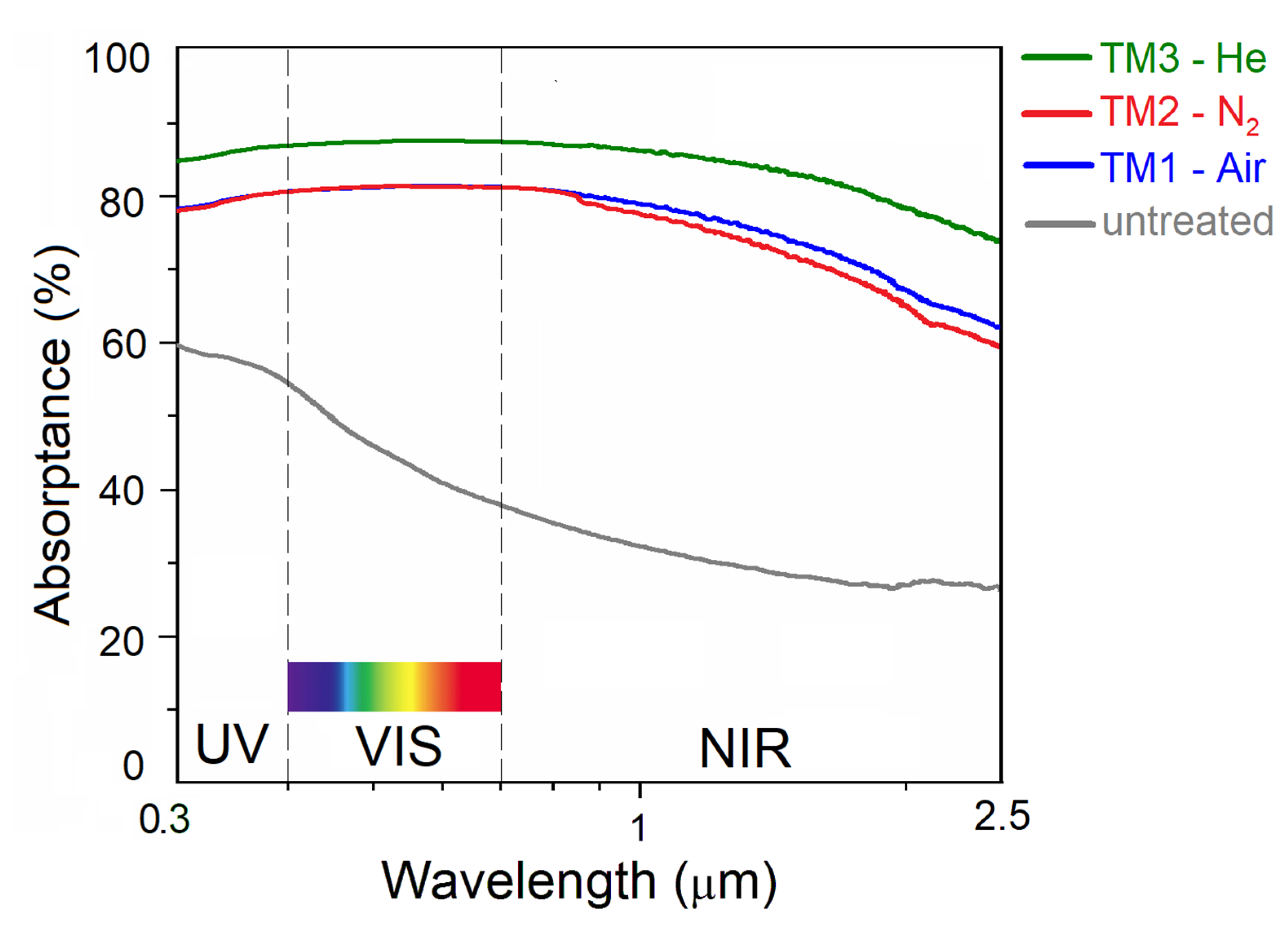

3.3. Spectrophotometric Analysis

4. Discussion

Author Contributions

Funding

Conflicts of Interest

References

- Trucchi, D.M.; Bellucci, A.; Girolami, M.; Mastellone, M.; Orlando, S. Surface texturing of CVD diamond assisted by ultrashort laser pulses. Coatings 2017, 7, 185. [Google Scholar] [CrossRef]

- Calvani, P.; Bellucci, A.; Girolami, M.; Orlando, S.; Valentini, V.; Polini, R.; Trucchi, D.M. Absorptance enhancement in fs-laser-treated CVD diamond. Phys. Status Solidi A 2015, 212, 2463–2467. [Google Scholar] [CrossRef]

- Calvani, P.; Bellucci, A.; Girolami, M.; Orlando, S.; Valentini, V.; Polini, R.; Mezzetti, A.; di Fonzo, F.; Trucchi, D.M. Infrared absorption of fs-laser textured CVD diamond. Appl. Phys. A Mater. Sci. Process. 2016, 122, 211. [Google Scholar] [CrossRef]

- Bellucci, A.; Calvani, P.; Girolami, M.; Orlando, S.; Polini, R.; Trucchi, D.M. Optimization of black diamond films for solar energy conversion. Appl. Surf. Sci. 2016, 380, 8–11. [Google Scholar] [CrossRef]

- Girolami, M.; Criante, L.; Di Fonzo, F.; Lo Turco, S.; Mezzetti, A.; Notargiacomo, A.; Bellucci, A.; Calvani, P.; Valentini, V.; Trucchi, D.M.; et al. Graphite distributed electrodes for diamond-based photon-enhanced thermionic emission solar cells. Carbon 2017, 111, 48–53. [Google Scholar] [CrossRef]

- Calvani, P.; Bellucci, A.; Girolami, M.; Orlando, S.; Valentini, V.; Polini, R.; Trucchi, D.M. Black diamond for solar energy conversion. Carbon 2016, 105, 401–407. [Google Scholar] [CrossRef]

- Bonse, J.; Krüger, J. Femtosecond laser-induced periodic surface structures. J. Laser Appl. 2012, 24, 042006. [Google Scholar] [CrossRef]

- Reyes-Contreras, A.; Camacho-López, M.; Camacho-López, S.; Olea-Mejía, O.; Esparza-García, A.; Bañuelos-Muñetón, J.G.; Camacho-López, M.A. Laser-induced periodic surface structures on bismuth thin films with ns laser pulses below ablation threshold. Opt. Mater. Express 2017, 7, 1777–1786. [Google Scholar] [CrossRef]

- Yin, K.; Chu, D.; Dong, X.; Wang, C.; Duan, J.-A.; He, J. Femtosecond laser induced robust periodic nanoripple structured mesh for highly efficient oil–water separation. Nanoscale 2017, 9, 14229–14235. [Google Scholar] [CrossRef]

- San-Blas, A.; Martinez-Calderon, M.; Buencuerpo, J.; Sanchez-Brea, L.M.; del Hoyo, J.; Gómez-Aranzadi, M.; Rodríguez, A.; Olaizola, S.M. Femtosecond laser fabrication of LIPSS-based waveplates on metallic surfaces. Appl. Surf. Sci. 2020, 520, 146328. [Google Scholar] [CrossRef]

- Wang, T.; Bian, J.; Li, X.; Kong, H.; Wang, L.; Wang, X.; Sun, X. Enhanced absorptance of 45# steel by laser-induced periodic surface structures (LIPSS). Metals 2020, 10, 1237. [Google Scholar] [CrossRef]

- Gnilitskyi, I.; Derrien, T.J.-Y.; Levy, Y.; Bulgakova, N.M.; Mocek, T.; Orazi, L. High-speed manufacturing of highly regular femtosecond laser-induced periodic surface structures: Physical origin of regularity. Sci. Rep. 2017, 7, 8485. [Google Scholar] [CrossRef] [PubMed]

- Fraggelakis, F.; Mincuzzi, G.; Manek-Hönninger, I.; Lopez, J.; Kling, R. Generation of micro- and nano-morphologies on a stainless steel surface irradiated with 257 nm femtosecond laser pulses. RSC Adv. 2018, 8, 16082–16087. [Google Scholar] [CrossRef]

- Rebollar, E.; Vázquez de Aldana, J.R.; Martín-Fabiani, I.; Hernández, M.; Rueda, D.R.; Ezquerra, T.A.; Domingo, C.; Moreno, P.; Castillejo, M. Assessment of femtosecond laser induced periodic surface structures on polymer films. Phys. Chem. Chem. Phys. 2013, 15, 11287–11298. [Google Scholar] [CrossRef]

- Xu, S.-Z.; Sun, K.; Yao, C.-Z.; Liu, H.; Miao, X.-X.; Jiang, Y.-L.; Wang, H.-J.; Jiang, X.; Yuan, X.; Zu, X. Periodic surface structures on dielectrics upon femtosecond laser pulses irradiation. Opt. Express 2019, 27, 8983–8993. [Google Scholar] [CrossRef]

- Gräf, S.; Kunz, C.; Engel, S.; Derrien, T.J.-Y.; Müller, F.A. Femtosecond laser-induced periodic surface structures on fused silica: The impact of the initial substrate temperature. Materials 2018, 11, 1340. [Google Scholar] [CrossRef]

- Le Harzic, R.; Dörr, D.; Sauer, D.; Neumeier, M.; Epple, M.; Zimmermann, H.; Stracke, F. Formation of periodic nanoripples on silicon and germanium induced by femtosecond laser pulses. Phys. Procedia 2011, 12, 29–36. [Google Scholar] [CrossRef]

- Dostovalov, A.; Bronnikov, K.; Korolkov, V.; Babin, S.; Mitsai, E.; Mironenko, A.; Tutov, M.; Zhang, D.; Sugioka, K.; Maksimovic, J.; et al. Hierarchical anti-reflective laser-induced periodic surface structures (LIPSSs) on amorphous si films for sensing applications. Nanoscale 2020, 12, 13431–13441. [Google Scholar] [CrossRef]

- Kafka, K.; Austin, D.; Cheng, J.; Trendafilov, S.; Shvets, G.; Li, H.; Yi, A.; Blaga, C.I.; DiMauro, L.F.; Chowdhury, E. Laser induced periodic surface structure formation in germanium above laser damage fluence by mid IR femtosecond laser irradiation. Proc. Spie 2014, 9237, 92371S. [Google Scholar] [CrossRef]

- Bonse, J.; Kirner, S.V.; Höhm, S.; Epperlein, N.; Spaltmann, D.; Rosenfeld, A.; Krüger, J. Applications of laser-induced periodic surface structures (LIPSS). Proc. Spie 2017, 10092, 100920N. [Google Scholar] [CrossRef]

- Zhang, R.; Huang, C.; Wang, J.; Feng, S.; Zhu, H. Evolution of micro/nano-structural arrays on crystalline silicon carbide by femtosecond laser ablation. Mater. Sci. Semicond. Process. 2020, 121, 105299. [Google Scholar] [CrossRef]

- Mastellone, M.; Bellucci, A.; Girolami, M.; Montereali, R.M.; Orlando, S.; Polini, R.; Sani, E.; Valentini, V.; Vincenti, M.A.; Trucchi, D.M.; et al. Enhanced selective solar absorption of surface nanotextured semi-insulating 6H–SiC. Opt. Mater. 2020, 107, 109967. [Google Scholar] [CrossRef]

- Amalathas, A.P.; Alkaisi, M.M. Nanostructures for light trapping in thin film solar cells. Micromachines 2019, 10, 619. [Google Scholar] [CrossRef] [PubMed]

- Girolami, M.; Bellucci, A.; Mastellone, M.; Orlando, S.; Valentini, V.; Montereali, R.M.; Vincenti, M.A.; Polini, R.; Trucchi, D.M. Impact of laser wavelength on the optical and electronic properties of black diamond. Phys. Status Solidi A 2017, 214, 1700250. [Google Scholar] [CrossRef]

- Martínez-Calderon, M.; Azkona, J.J.; Casquero, N.; Rodríguez, A.; Domke, M.; Gómez-Aranzadi, M.; Olaizola, S.M.; Granados, E. Tailoring diamond’s optical properties via direct femtosecond laser nanostructuring. Sci. Rep. 2018, 8, 14262. [Google Scholar] [CrossRef]

- Komlenok, M.S.; Kononenko, V.V.; Ralchenko, V.G.; Pimenov, S.M.; Konov, V.I. Laser induced nanoablation of diamond materials. Phys. Procedia 2011, 12, 37–45. [Google Scholar] [CrossRef]

- Standard ISO 8573-1:2010. Compressed Air—Part 1: Contaminants and Purity Classes; International Organization for Standardization (ISO): Geneva, Switzerland, 2010. [Google Scholar]

- Nishijima, Y.; Komatsu, R.; Ota, S.; Seniutinas, G.; Balčytis, A.; Juodkazis, S. Anti-reflective surfaces: Cascading nano/microstructuring. APL Photon. 2016, 1, 076104. [Google Scholar] [CrossRef]

- Huang, M.; Zhao, F.; Cheng, Y.; Xu, N.; Xu, Z. Origin of laser-induced near-subwavelength ripples: Interference between surface plasmons and incident laser. ACS Nano 2009, 3, 4062–4070. [Google Scholar] [CrossRef]

- Balmer, R.S.; Brandon, J.R.; Clewes, S.L.; Dhillon, H.K.; Dodson, J.M.; Friel, I.; Inglis, P.N.; Madgwick, T.D.; Markham, M.L.; Mollart, T.P.; et al. Chemical vapour deposition synthetic diamond: Materials, technology and applications. J. Phys. Condens. Matter 2009, 21, 364221. [Google Scholar] [CrossRef]

- Wiora, N.; Mertens, M.; Brühne, K.; Fecht, H.-J.; Tran, I.C.; Willey, T.; van Buuren, A.; Biener, J.; Lee, J. Grain boundary dominated electrical conductivity in ultrananocrystalline diamond. J. Appl. Phys. 2017, 122, 145102. [Google Scholar] [CrossRef]

- Cuenca, J.A.; Sankaran, K.J.; Pobedinskas, P.; Panda, K.; Lin, I.-N.; Porch, A.; Haenen, K.; Williams, O.A. Microwave cavity perturbation of nitrogen doped nano-crystalline diamond films. Carbon 2019, 145, 740–750. [Google Scholar] [CrossRef]

- Baranauskas, V.; Li, B.B.; Peterlevitz, A.; Tosin, M.C.; Durrant, S.F. Nitrogen-doped diamond films. J. Appl. Phys. 1999, 85, 7455–7458. [Google Scholar] [CrossRef][Green Version]

- Boerner, P.; Hajri, M.; Ackerl, N.; Wegener, K. Experimental and theoretical investigation of ultrashort pulsed laser ablation of diamond. J. Laser Appl. 2019, 31, 022202. [Google Scholar] [CrossRef]

- Boerner, P. Ultra-Short Pulsed Laser Ablation of Diamond. Ph.D. Thesis, ETH, Zürich, Switzerland, 2019. [Google Scholar] [CrossRef]

- Bellucci, A.; Calvani, P.; Girolami, M.; Trucchi, D.M. Defect engineering of diamond cathodes for high temperature solar cells. In Proceedings of the 2015 IEEE 15th International Conference on Environment and Electrical Engineering (EEEIC), Rome, Italy, 10–13 June 2015; pp. 1616–1619. [Google Scholar] [CrossRef]

- Trucchi, D.M.; Bellucci, A.; Girolami, M.; Calvani, P.; Cappelli, E.; Orlando, S.; Polini, R.; Silvestroni, L.; Sciti, D.; Kribus, A. Solar thermionic-thermoelectric generator (ST2G): Concept, materials engineering, and prototype demonstration. Adv. Energy Mater. 2018, 8, 1802310. [Google Scholar] [CrossRef]

- Girolami, M.; Bellucci, A.; Mastellone, M.; Orlando, S.; Valentini, V.; Montereali, R.M.; Vincenti, M.A.; Polini, R.; Trucchi, D.M. Optical characterization of double-nanotextured black diamond films. Carbon 2018, 138, 384–389. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Girolami, M.; Bellucci, A.; Mastellone, M.; Orlando, S.; Serpente, V.; Valentini, V.; Polini, R.; Sani, E.; De Caro, T.; Trucchi, D.M. Femtosecond-Laser Nanostructuring of Black Diamond Films under Different Gas Environments. Materials 2020, 13, 5761. https://doi.org/10.3390/ma13245761

Girolami M, Bellucci A, Mastellone M, Orlando S, Serpente V, Valentini V, Polini R, Sani E, De Caro T, Trucchi DM. Femtosecond-Laser Nanostructuring of Black Diamond Films under Different Gas Environments. Materials. 2020; 13(24):5761. https://doi.org/10.3390/ma13245761

Chicago/Turabian StyleGirolami, Marco, Alessandro Bellucci, Matteo Mastellone, Stefano Orlando, Valerio Serpente, Veronica Valentini, Riccardo Polini, Elisa Sani, Tilde De Caro, and Daniele M. Trucchi. 2020. "Femtosecond-Laser Nanostructuring of Black Diamond Films under Different Gas Environments" Materials 13, no. 24: 5761. https://doi.org/10.3390/ma13245761

APA StyleGirolami, M., Bellucci, A., Mastellone, M., Orlando, S., Serpente, V., Valentini, V., Polini, R., Sani, E., De Caro, T., & Trucchi, D. M. (2020). Femtosecond-Laser Nanostructuring of Black Diamond Films under Different Gas Environments. Materials, 13(24), 5761. https://doi.org/10.3390/ma13245761