Long-Term Bonding and Tensile Strengths of Carbon Textile Reinforced Mortar

Abstract

1. Introduction

2. Test Program for Bonding Performance

2.1. Materials

2.2. Aging and Testing Methods

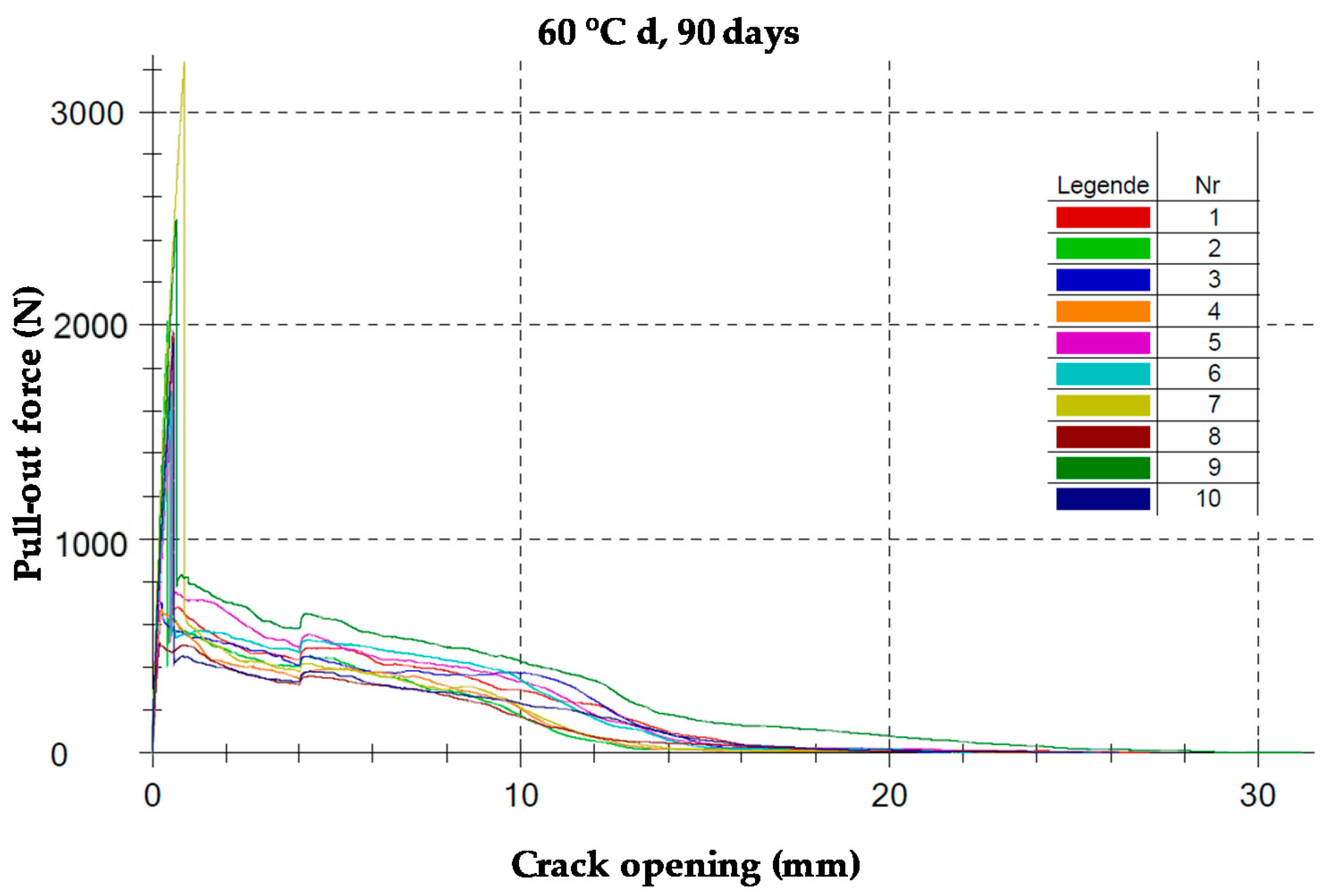

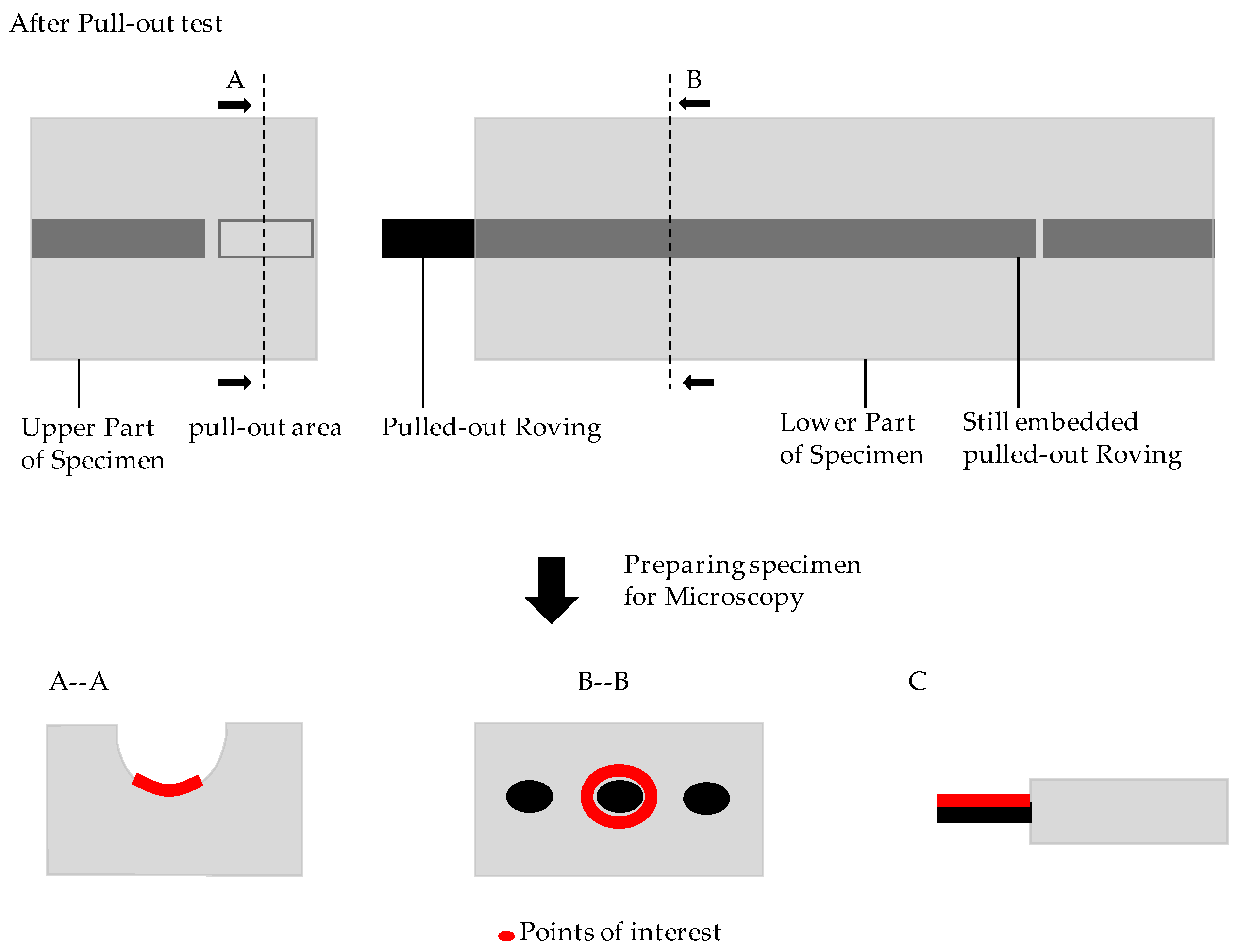

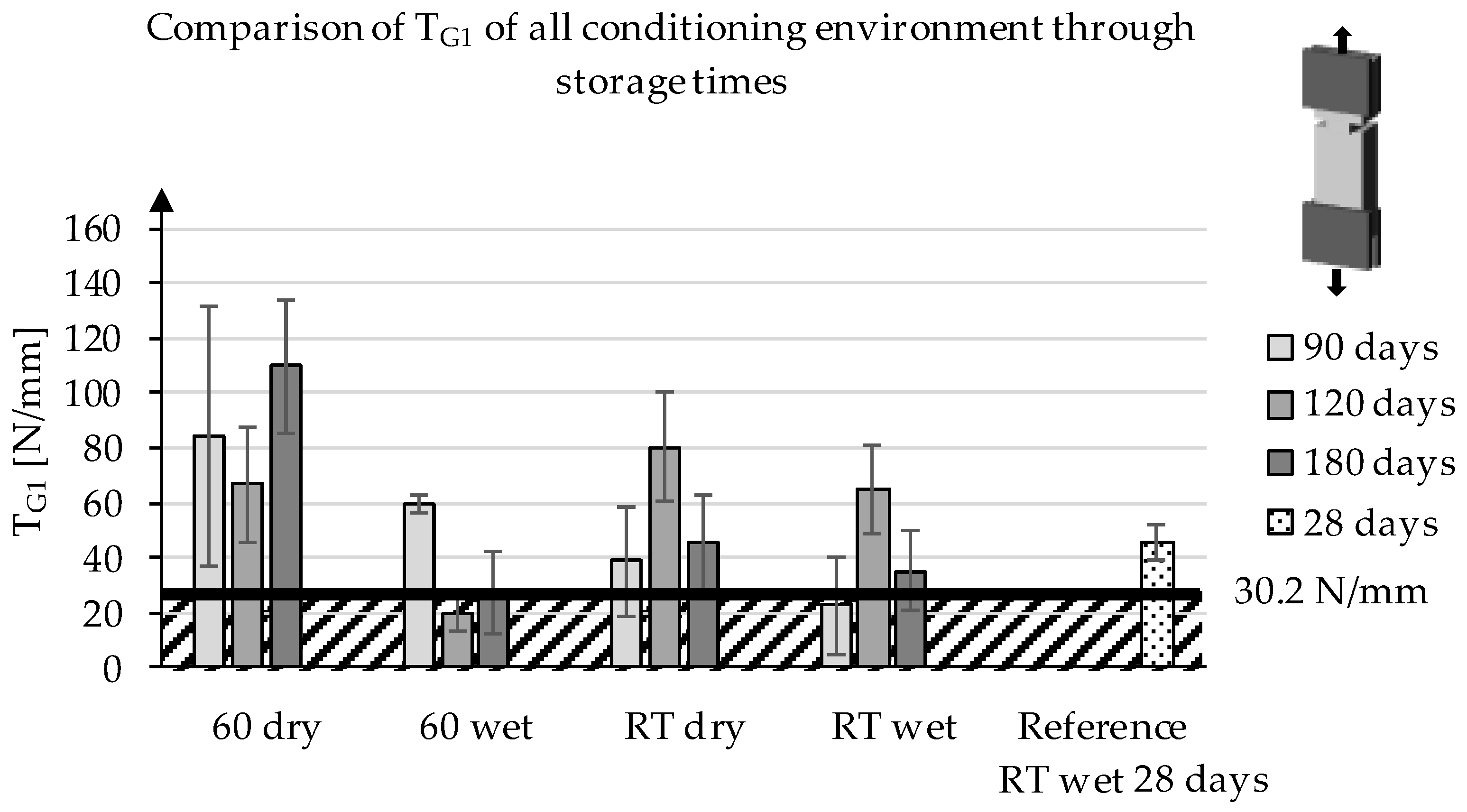

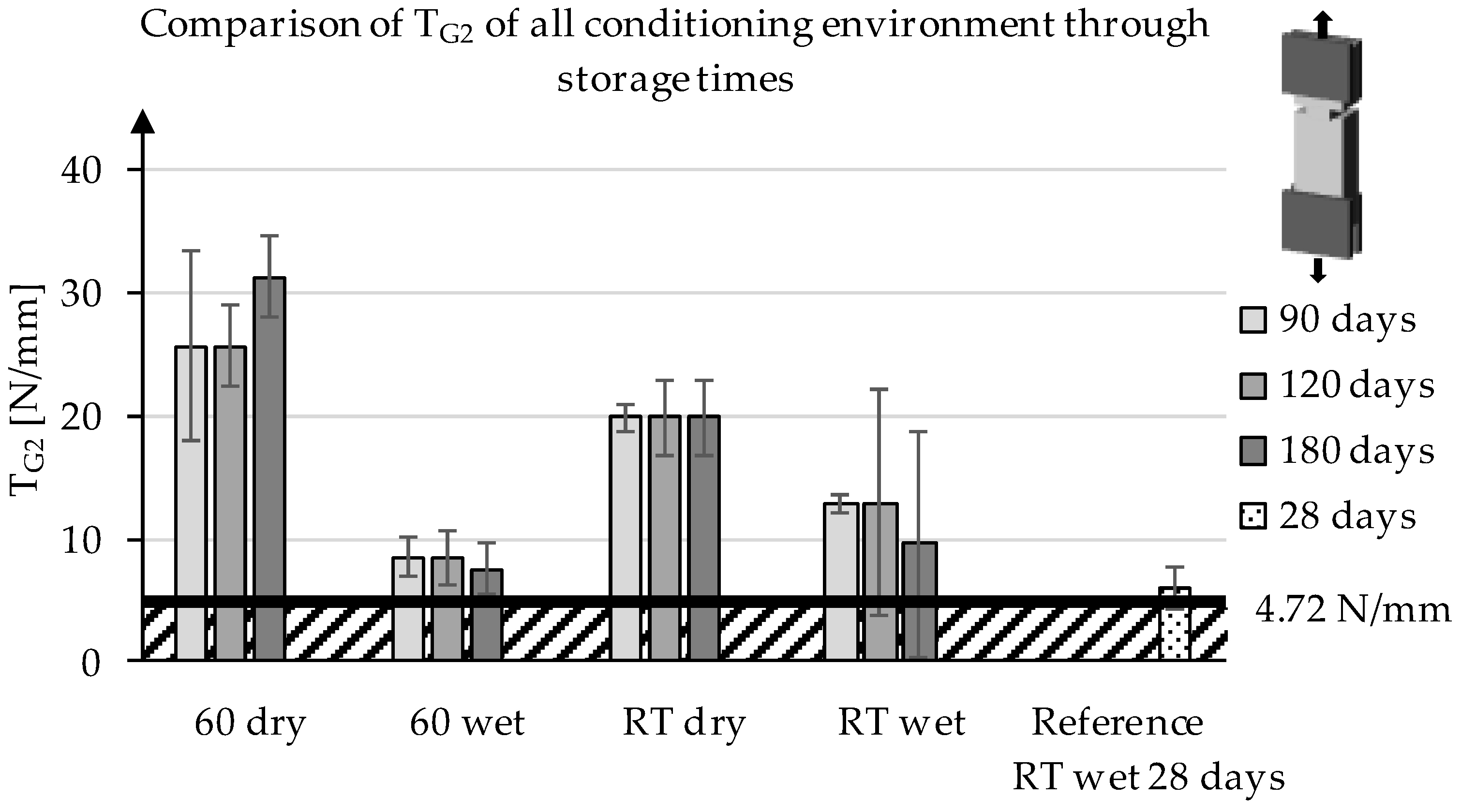

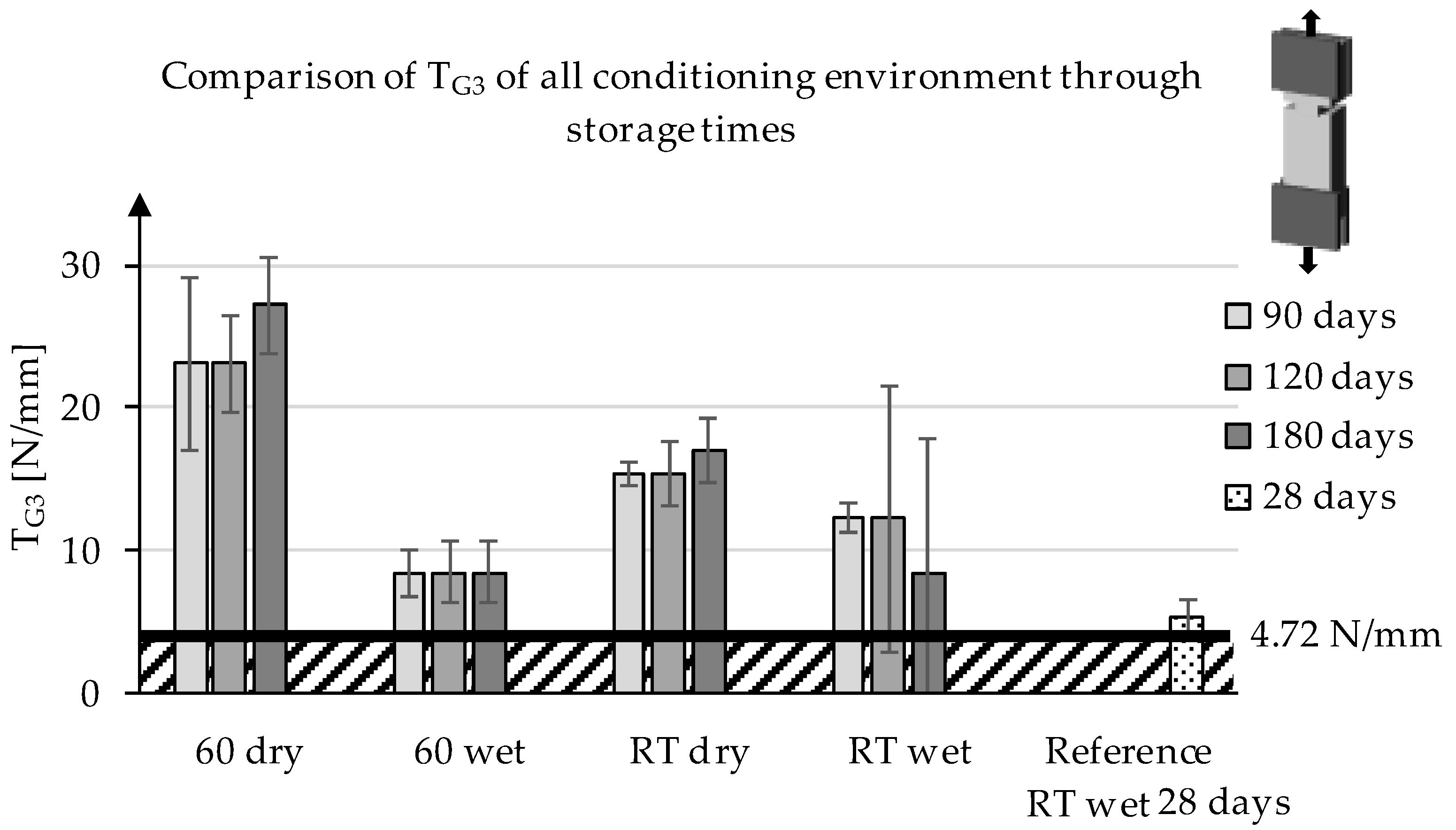

2.3. Results of Bonding Test

2.4. Discussion

3. Test Program for Tensile Performance

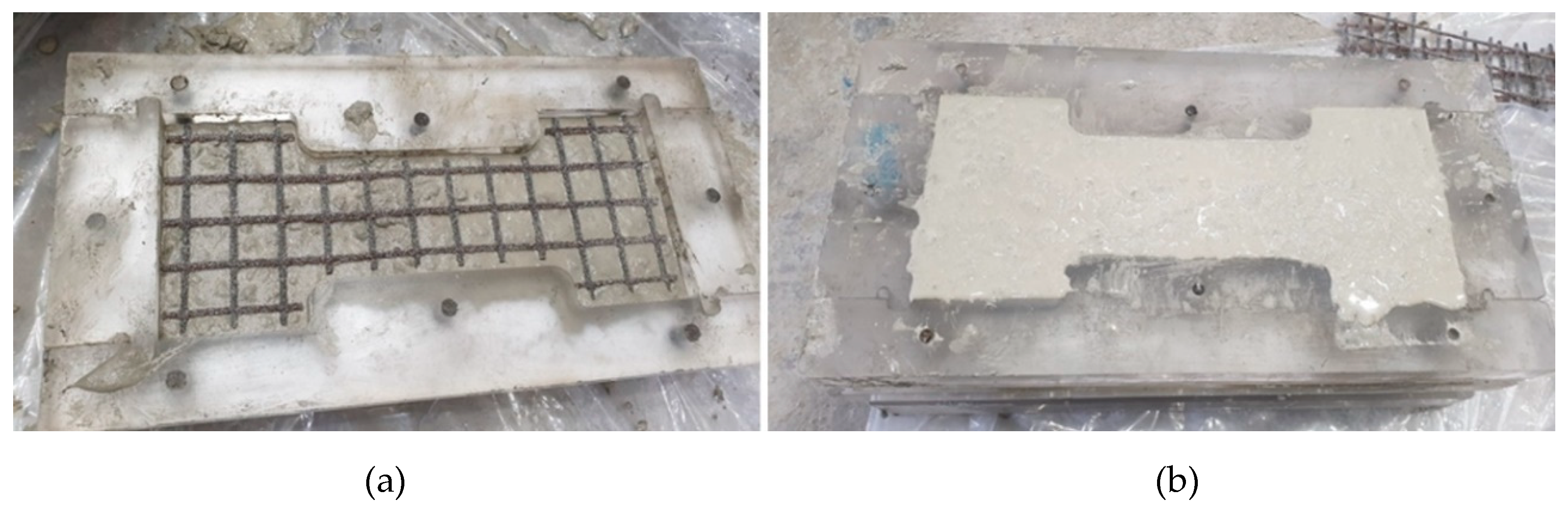

3.1. Specimen Fabrication

3.2. Conditioning and Testing Methods

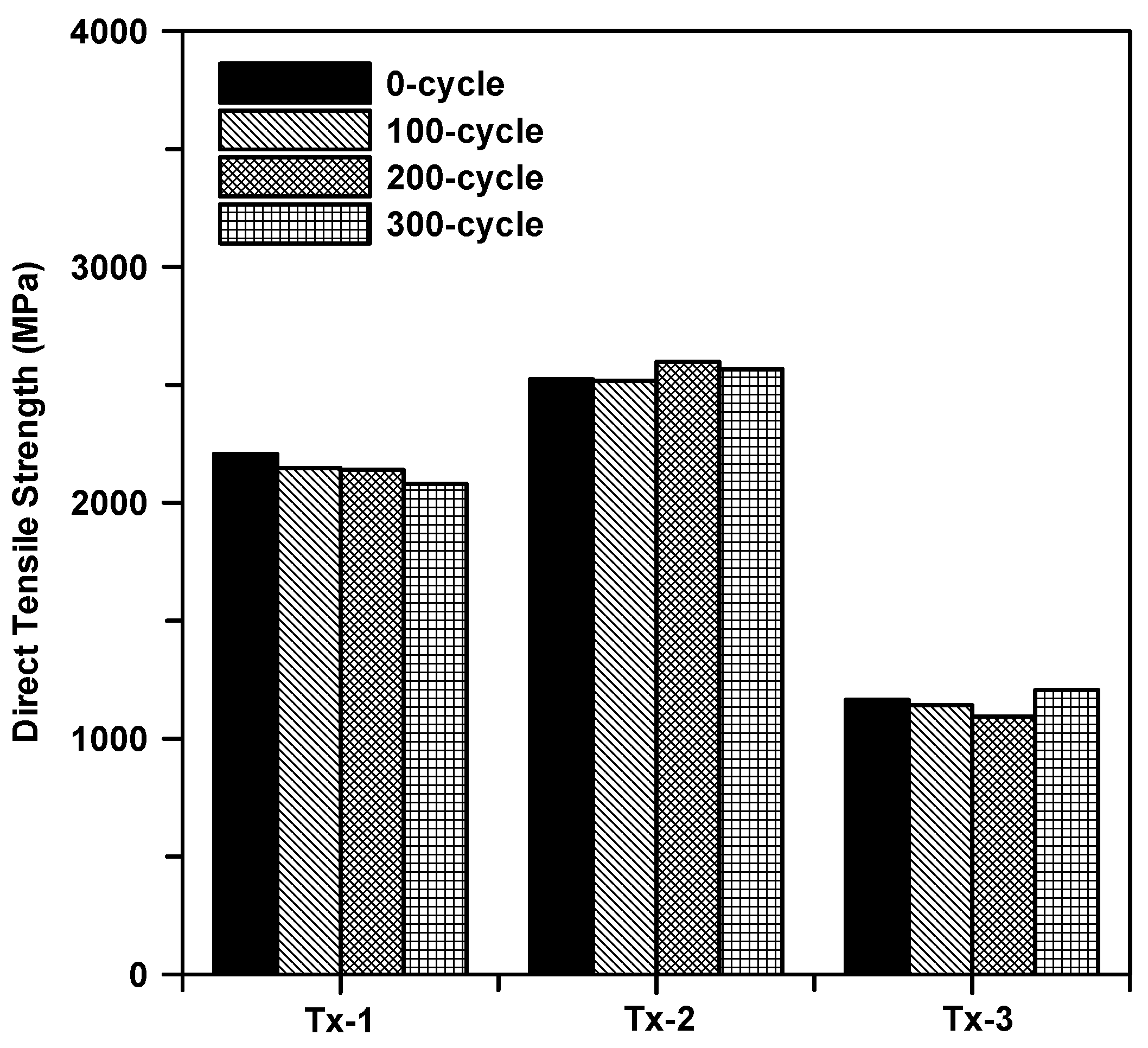

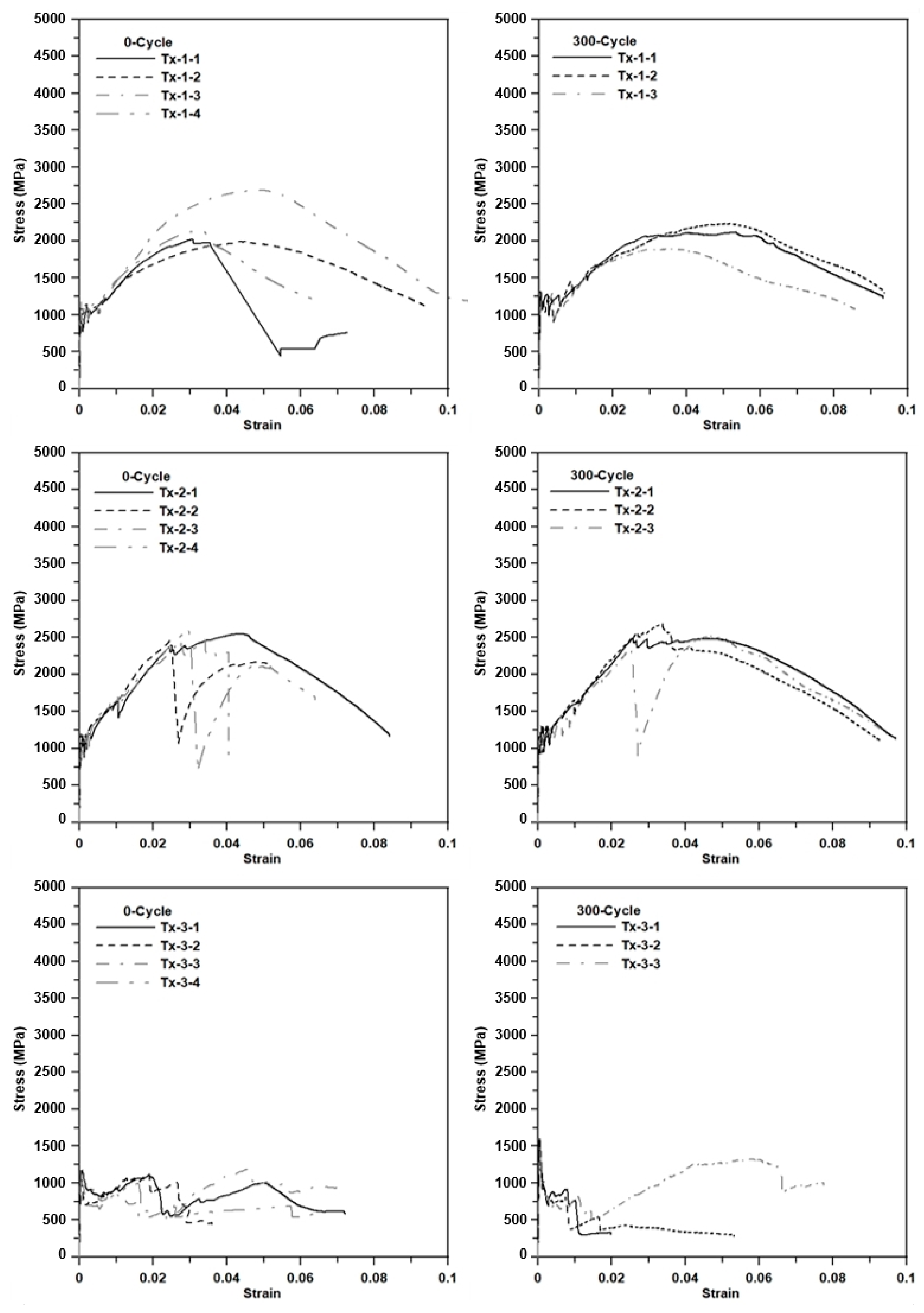

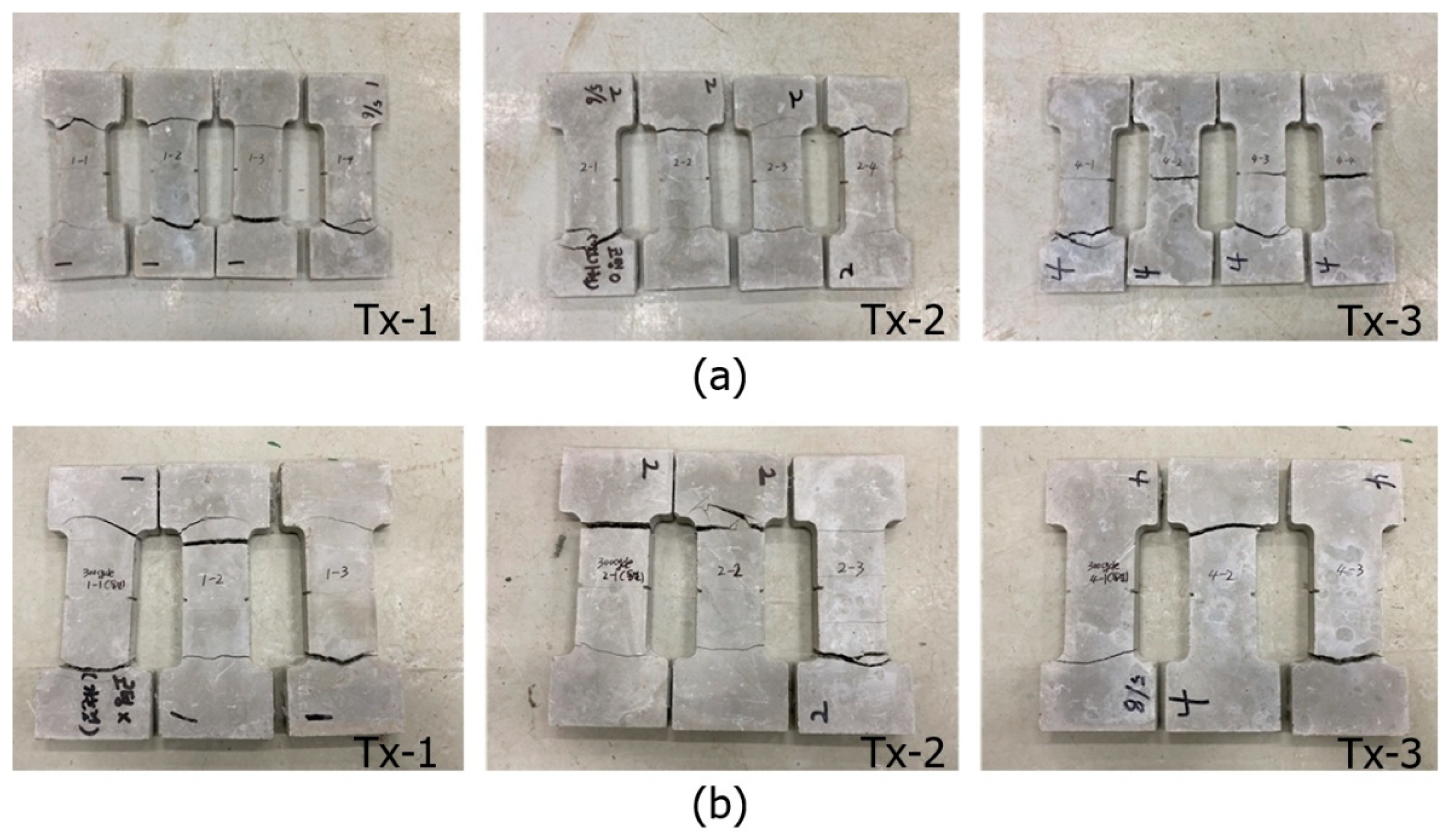

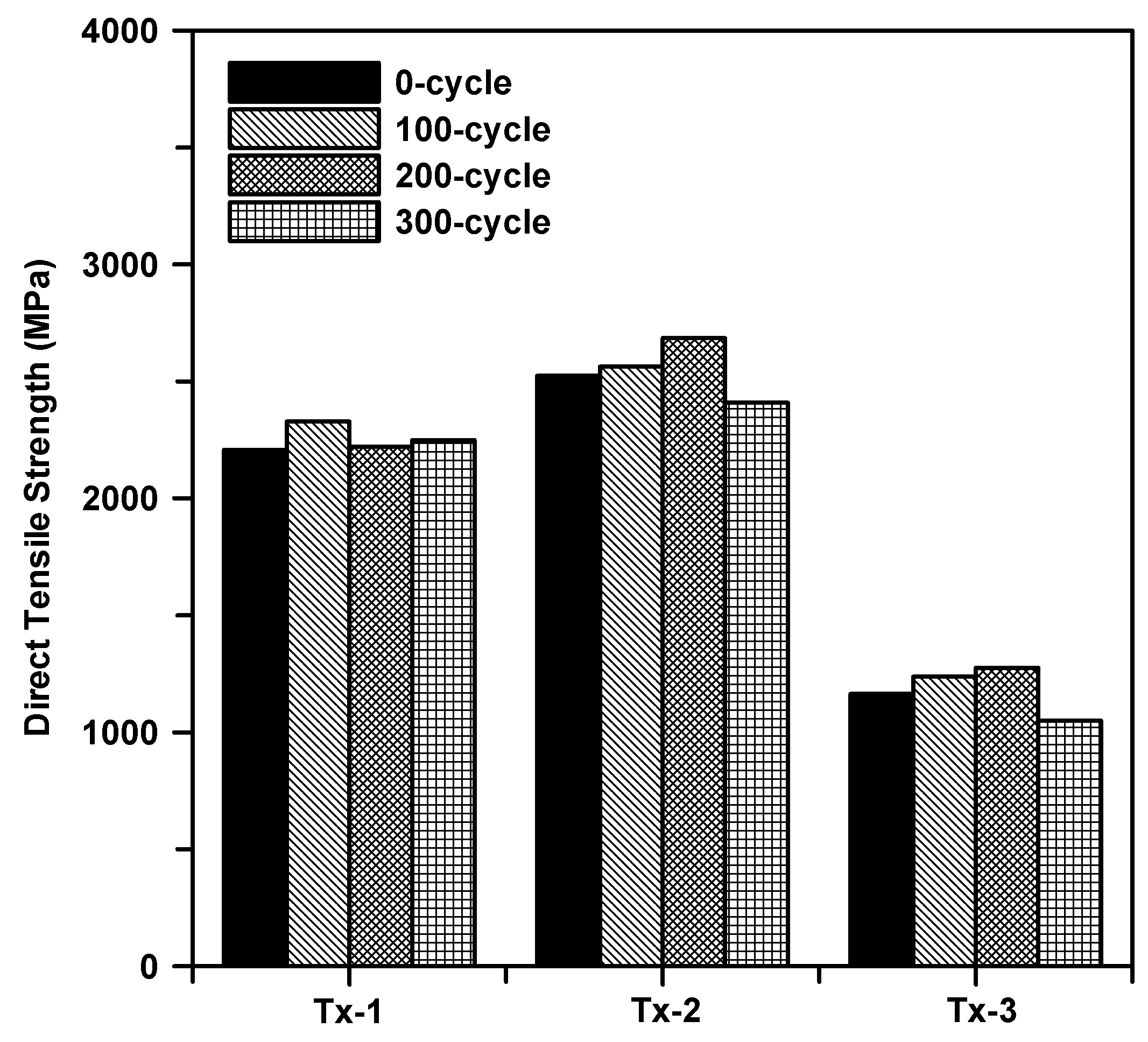

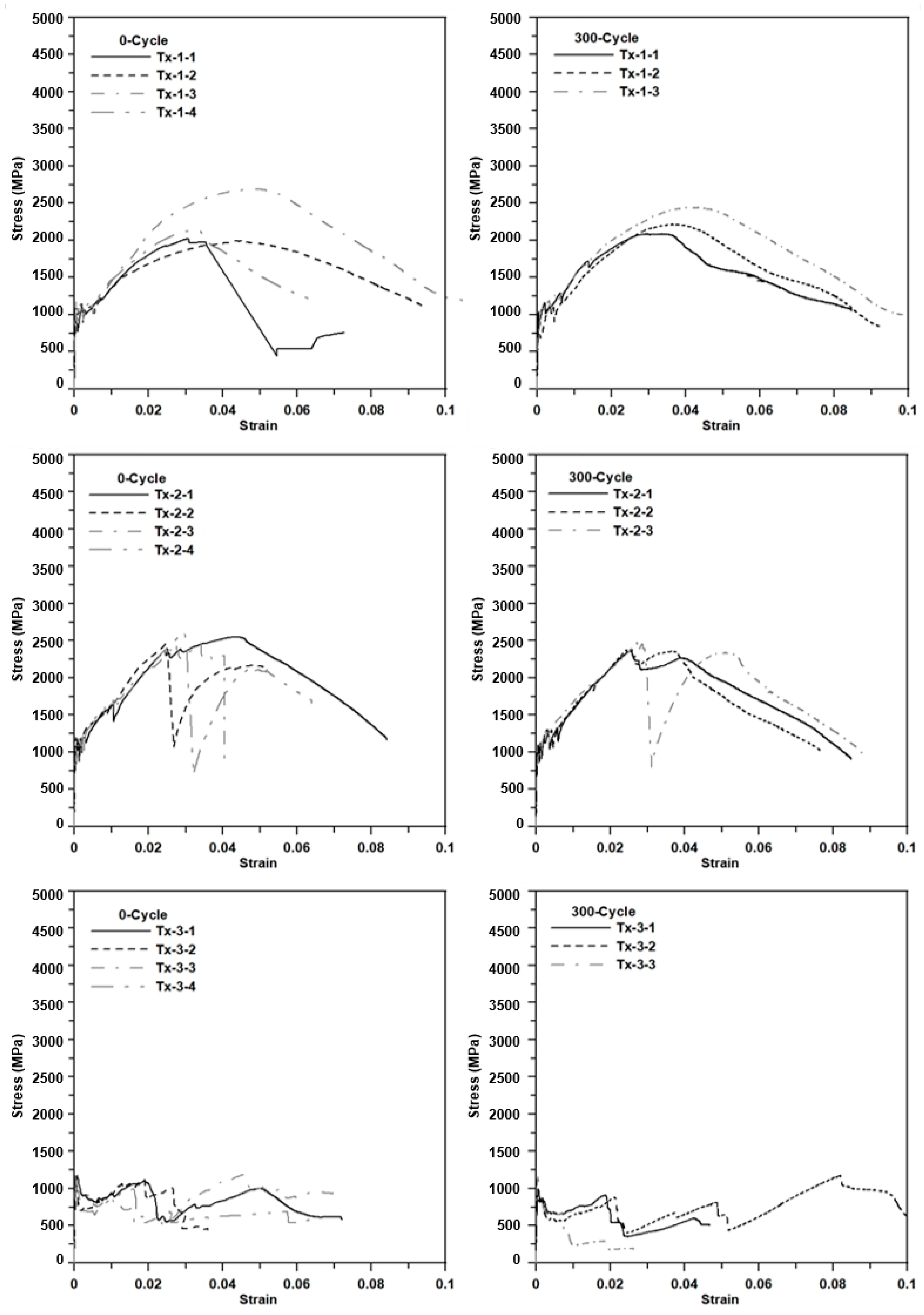

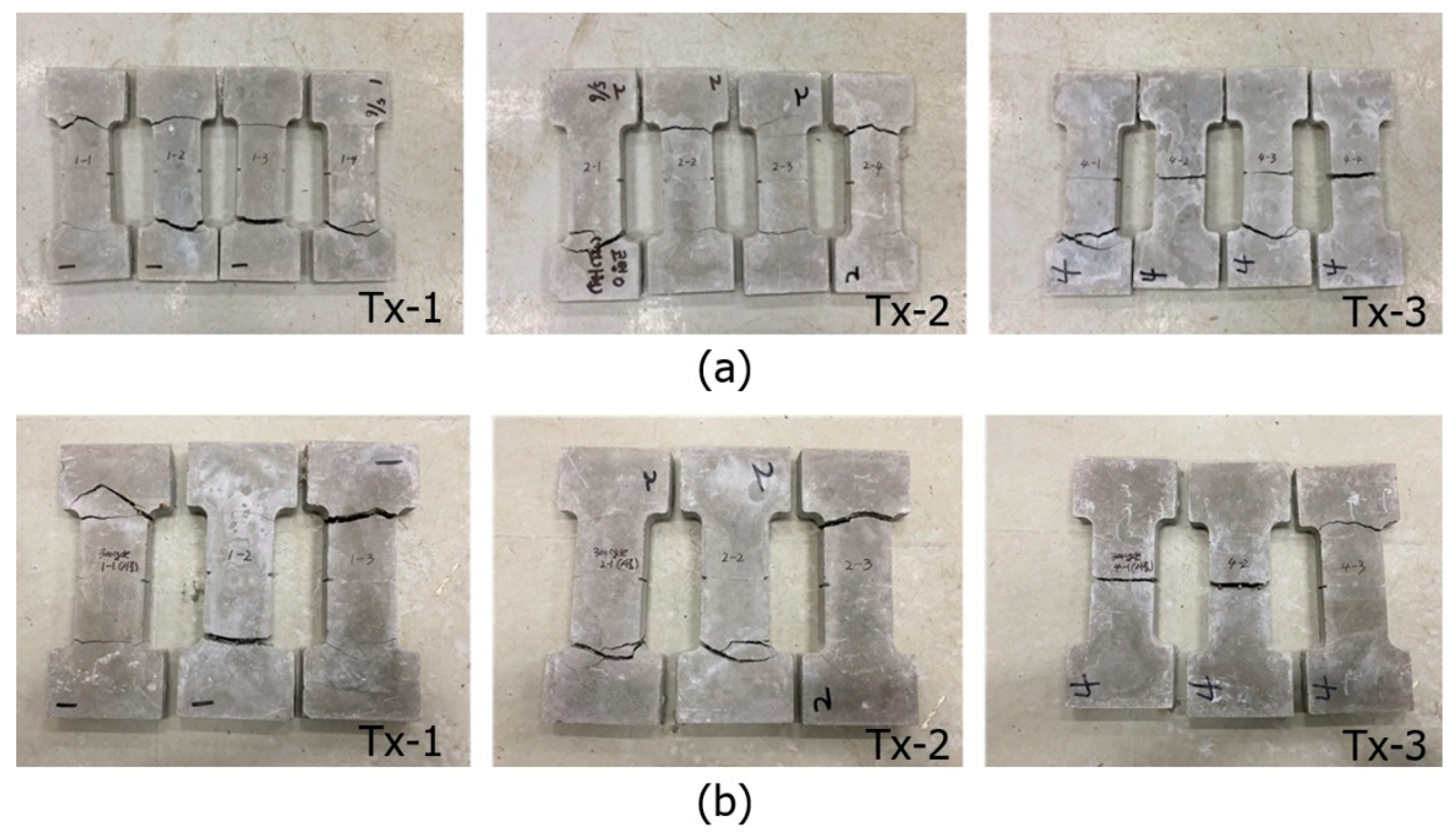

3.3. Results for Durability Test

3.4. Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| AbZ | Allgemeine Bauaufsichtliche Zulassung (General technical approval) |

| CoV | Coefficient of Variation |

| ITA | Institut für Textiltechnik (Institute for Textile Technology) |

| KICT | Korea Institute of Civil Engineering and Building Technology |

| RWTH | Rheinisch-Westfälische Technische Hochschule |

| STD | Standard Deviation |

| TRM | Textile Reinforced Mortar |

| TU | Technische Universität (Technical University) |

References

- Peled, A.; Bentur, A.; Mobasher, B. Textile Reinforced Concrete; CRC Press: Boca Ranton, FL, USA, 2017. [Google Scholar]

- Sonderforschungsbereich 532. In Textilbewehrter Beton - Grundlagen für die Entwicklung einer Neuartigen Technologie Abschlussbericht SFB 532; Sonderforschungsbereich 532: Aachen, Germany, 2011. [Google Scholar]

- Triantafillou, T. (Ed.) Textile Fibre Composites in Civil Engineering; Woodhead Publishing: Duxford, UK, 2016. [Google Scholar]

- Brameshuber, W. (Ed.) Textile Reinforced Concrete, State-of-the-Art Report of RILEM Technical Committee 201-TRC; RILEM Report 36; RILEM Publications: Bagneux, France, 2006. [Google Scholar]

- ACI Committee 549. Guide to Design and Construction of Externally Bonded Fabric-Reinforced Cementitious Matrix (FRCM) Systems for Repair and Strengthening Concrete and Masonry Structures; American Concrete Institute: Farmington Hills, MI, USA, 2013. [Google Scholar]

- Faleschini, F.; Zanini, M.A.; Hofer, L.; Toska, K.; De Domenico, D.; Pellegrino, C. Confinement of reinforced concrete columns with glass fiber reinforced cementitious matrix jackets. Eng. Struct. 2020, 218, 110847. [Google Scholar] [CrossRef]

- Zanini, M.A.; Toska, K.; Faleschini, F.; Pellegrino, C. Seismic reliability of reinforced concrete bridges subject to environmental deterioration and strengthened with FRCM composites. Soil Dyn. Earthq. Eng. 2020, 136, 106224. [Google Scholar] [CrossRef]

- Kim, H.-Y.; You, Y.-J.; Ryu, G.-S.; Koh, K.-T.; Ahn, G.-H.; Kang, S.-H. Flexural strengthening of concrete slab-type elements with textile reinforced concrete. Materials 2020, 13, 2246. [Google Scholar] [CrossRef] [PubMed]

- You, Y.-J.; Kim, H.-Y.; Ryu, G.-S.; Koh, K.-T.; Ahn, G.-H.; Kang, S.-H. Strengthening of Concrete Element with Precast Textile Reinforced Concrete Panel and Grouting Material. Materials 2020, 13, 3856. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.-Y.; Koh, K.-T.; You, Y.-J.; Ryu, G.-S.; Seo, D.-W.; Jin, S.-S.; Ahn, G.-H.; Nam, J.-H. Load-deflection behaviour of concrete slab-type elements casted on stay-in-place TRC formwork. Compos. Struct. 2020, 244, 112310. [Google Scholar] [CrossRef]

- Ray, B.C. Temperature effect during humid ageing on interfaces of glass and carbon fibers reinforced epoxy composites. J. Colloid Interface Sci. 2006, 298, 111–117. [Google Scholar] [CrossRef]

- Al-Lami, K.; D’Antino, T.; Colombi, P. Durability of Fabric-Reinforced Cementitious Matrix (FRCM) Composites. Appl. Sci. 2020, 10, 1714. [Google Scholar] [CrossRef]

- Spelter, A.; Bergmann, S.; Bielak, J.; Hegger, J. Long-Term Durability of Carbon-Reinforced Concrete: An Overview and Experimental Investigations. Appl. Sci. 2019, 9, 1651. [Google Scholar] [CrossRef]

- Colombo, I.G.; Colombo, M.; di Prisco, M. Tensile behavior of textile reinforced concrete subjected to freezing–thawing cycles in un-cracked and cracked regimes. Cem. Concr. Res. 2015, 169–183. [Google Scholar] [CrossRef]

- Rambo, D.; Silva, F.; Filho, R.; Gomes, O. Effect of elevated temperatures on the mechanical behavior of basalt textile reinforced refractory concrete. Mater. Des. 2015, 65, 24–33. [Google Scholar] [CrossRef]

- Yin, S.; Jing, L.; Yin, M.; Wang, B. Mechanical properties of textile reinforced concrete under chloride wet-dry and freeze-thaw cycle environments. Cem. Concr. Compos. 2019, 96, 118–127. [Google Scholar] [CrossRef]

- De Munck, M.; El Kadi, M.; Tsangouri, E.; Vervloet, J.; Verbruggen, S.; Wastiels, J.; Tysmans, T.; Remy, O. Influence of environmental loading on the tensile and cracking behaviour of textile reinforced cementitious composites. Constr. Build. Mater. 2018, 181, 325–334. [Google Scholar] [CrossRef]

- Yin, S.-P.; Li, Y.; Jin, Z.-y.; Li, P.-H. Interfacial Properties of Textile-Reinforced Concrete and Concrete in Chloride Freezing-and-Thawing Cycle. ACI Mater. J. 2018, 115, 197–208. [Google Scholar] [CrossRef]

- Pekmezci, B.Y.; Arabaci, E.; Ustundag, C. Freeze-Thaw Durability of Lime Based FRCM Systems for Strengthening Historical Masonry. Key Eng. Mater. 2019, 817, 174–181. [Google Scholar] [CrossRef]

- Diana, A.; Saman, B.; Carol, D.H.; Antonio, N. Durability of Fabric Reinforced Cementitious Matrix (FRCM) composites. In Proceedings of the 7th International Conference on FRP Composites in Civil Engineering, CICE 2014, Vancouver, BC, Canada, 20–22 August 2014. [Google Scholar]

- ITA Technologietransfer GmbH. Investigation of Long-term Bonding Strength of Textile Reinforcement in Concrete; Final report submitted to KICT. Report No. K5118-A03-01; ITA Technologietransfer GmbH: Aachen, Germany, 2020. [Google Scholar]

- International Code Council Evaluation Service (ICC-ES). Masonry and Concrete Strengthening Using Fabric-Reinforced Cementitious Matrix (FRCM) and Steel Reinforced Grout (SRG) Composite Systems AC434; International Code Council Evaluation Service: Whittier, CA, USA, 2018. [Google Scholar]

- CSLLPP—Servizio Tecnico Centrale. Linee Guida per la Identificazione, la Qualificazione ed il Controllo di Accettazione di Compositi Fibrorinforzati a Matrice Inorganica (FRCM) da Utilizzarsi per il Consolidamento Strutturale di Costruzioni Esistenti; CSLLPP: Rome, Italy, 2019. [Google Scholar]

- Björn, B.; Brockmann, T.; Brameshuber, W. Material and bonding characteristics for dimensioning and modelling of textile reinforced concrete (TRC) elements. Mater. Struct. 2006, 39, 749. [Google Scholar] [CrossRef]

- Allgemeine Bauaufsichtliche Zulassung (General Technical Approval). Zulassungsnummer AbZ-31.10-182. Antragsteller TUDAG 8TU Dresden Aktiengesellschaft; Deutsches Institut für Bautechnik, Zulassungsstelle für Bauprodukte und Bauarten: Dresden, Germany, 2016. [Google Scholar]

- Lorenz, E.; Schütze, E.; Weiland, S. Textilbeton—Eigenschaften des Verbundwerkstoffs. Beton Stahlbeton Suppl. Verstärken Text. 2015, 110, 29–41. [Google Scholar] [CrossRef]

- Lorenz, E. Endverankerung und Übergreifung Textiler Bewehrungen in Betonmatrices. Ph.D. Thesis, Fakultät Bauingenieurwesen der Technischen Universität Dresden, Dresden, Germany, 2014. [Google Scholar]

- Donnini, J.; Corinaldesi, V.; Nanni, A. Mechanical properties of FRCM using carbon fabrics with different coating treatments. Compos. Part B Eng. 2016, 88, 220–228. [Google Scholar] [CrossRef]

- Colombo, I.G.; Magri, A.; Zani, G.; Colombo, M.; Di Prisco, M. Textile Reinforced Concrete: Experimental investigation on design parameters. Mater. Struct. 2013, 46, 1933–1951. [Google Scholar] [CrossRef]

- Brameshuber, W. Recommendation of RILEM TC 232-TDT: Test methods and design of textile reinforced concrete. Mater. Struct. 2016, 49, 4923–4927. [Google Scholar] [CrossRef]

- D’Antino, T.; Papanicolaou, C. Mechanical characterization of textile reinforced inorganic-matrix composites. Compos. Part B Eng. 2017, 127, 78–91. [Google Scholar] [CrossRef]

- Li, B.; Xiong, H.; Jiang, J.; Dou, X. Tensile behavior of basalt textile grid reinforced Engineering Cementitious Composite. Compos. Part B Eng. 2019, 156, 185–200. [Google Scholar] [CrossRef]

- ASTM International. ASTM C666. In Standard Test Method for Resistance of Concrete to Rapid Freezing and Thawing; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

| Constituent | Amount (kg/m³) |

|---|---|

| Cement CEM I 52.5 | 490 |

| Fly ash f | 175 |

| Silica fume s | 35 |

| Quartz flour (grain size 0–0.125 mm) | 500 |

| Sand (grain size 0.2–0.6 mm) | 713 |

| Water | 280 |

| Plasticizer | 7–8 |

| Aging Method ID | Temperature (°C) | Moisture Condition | Duration (days) |

|---|---|---|---|

| RT w, 90 days | 20 | wet | 90 days |

| RT w, 90 days | 20 | dry | 90 days |

| 60 °C w, 90 days | 60 | wet | 90 days |

| 60 °C d, 90 days | 60 | dry | 90 days |

| RT w, 120 days | 20 | wet | 120 days |

| RT w, 120 days | 20 | dry | 120 days |

| 60 °C w, 120 days | 60 | wet | 120 days |

| 60 °C d, 120 days | 60 | dry | 120 days |

| RT w, 180 days | 20 | wet | 180 days |

| RT w, 180 days | 20 | dry | 180 days |

| 60 °C w, 180 days | 60 | wet | 180 days |

| 60 °C d, 180 days | 60 | dry | 180 days |

| Textile ID | Resin | Mesh Size (mm × mm) | Cross-Sectional Area of Yarn (mm2) | Tensile Strength (MPa) | Elastic Modulus (GPa) | Surface Coating |

|---|---|---|---|---|---|---|

| Tx-1 | Polystyrene | 25 × 25 | 1.808 | 1700 | 200 | Uncoated |

| Tx-2 | Polystyrene | 25 × 25 | 1.808 | 1700 | 200 | Coated |

| Tx-3 | Acrylate | 21 × 21 | 1.808 | 2531 | 229 | Uncoated |

| Cement | Granulated Blast-Furnace Slag | Sand | Water | Superplasticizer | PVA Fibers |

|---|---|---|---|---|---|

| 466 | 466 | 1024 | 278 | 7 | 1% |

| Conditioning Method | Temperature (°C) | No. of Cycles | No. of Specimens |

|---|---|---|---|

| Freezing–thaw | −18–+4 | 0, 100, 200, 300 | 48 |

| Hot weather | +30–+70 | 0, 100, 200, 300 | 48 |

| Textile | No. of Cycles | Tensile Strength (MPa) | Standard Deviation |

|---|---|---|---|

| Tx-1 | 0 | 2207 | 280 |

| 100 | 2147 | 186 | |

| 200 | 2139 | 88 | |

| 300 | 2081 | 145 | |

| Tx-2 | 0 | 2524 | 67 |

| 100 | 2518 | 63 | |

| 200 | 2598 | 133 | |

| 300 | 2567 | 84 | |

| Tx-3 | 0 | 1164 | 23 |

| 100 | 1142 | 59 | |

| 200 | 1094 | 58 | |

| 300 | 1205 | 147 |

| Textile | No. of Cycles | Tensile Strength (MPa) | Standard Deviation |

|---|---|---|---|

| Tx-1 | 0 | 2208 | 280 |

| 100 | 2329 | 43 | |

| 200 | 2222 | 339 | |

| 300 | 2249 | 146 | |

| Tx-2 | 0 | 2524 | 67 |

| 100 | 2563 | 70 | |

| 200 | 2685 | 17 | |

| 300 | 2409 | 47 | |

| Tx-3 | 0 | 1164 | 23 |

| 100 | 1238 | 73 | |

| 200 | 1275 | 65 | |

| 300 | 1048 | 75 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Heins, K.; Kimm, M.; Olbrueck, L.; May, M.; Gries, T.; Kolkmann, A.; Ryu, G.-S.; Ahn, G.-H.; Kim, H.-Y. Long-Term Bonding and Tensile Strengths of Carbon Textile Reinforced Mortar. Materials 2020, 13, 4485. https://doi.org/10.3390/ma13204485

Heins K, Kimm M, Olbrueck L, May M, Gries T, Kolkmann A, Ryu G-S, Ahn G-H, Kim H-Y. Long-Term Bonding and Tensile Strengths of Carbon Textile Reinforced Mortar. Materials. 2020; 13(20):4485. https://doi.org/10.3390/ma13204485

Chicago/Turabian StyleHeins, Kira, Magdalena Kimm, Lea Olbrueck, Matthias May, Thomas Gries, Annette Kolkmann, Gum-Sung Ryu, Gi-Hong Ahn, and Hyeong-Yeol Kim. 2020. "Long-Term Bonding and Tensile Strengths of Carbon Textile Reinforced Mortar" Materials 13, no. 20: 4485. https://doi.org/10.3390/ma13204485

APA StyleHeins, K., Kimm, M., Olbrueck, L., May, M., Gries, T., Kolkmann, A., Ryu, G.-S., Ahn, G.-H., & Kim, H.-Y. (2020). Long-Term Bonding and Tensile Strengths of Carbon Textile Reinforced Mortar. Materials, 13(20), 4485. https://doi.org/10.3390/ma13204485