Isokinetic Analysis of Fe41Co7Cr15Mo14Y2C15B6 Bulk Metallic Glass: Effect of Minor Copper Addition

Abstract

1. Introduction

2. Materials and Methods

3. Results

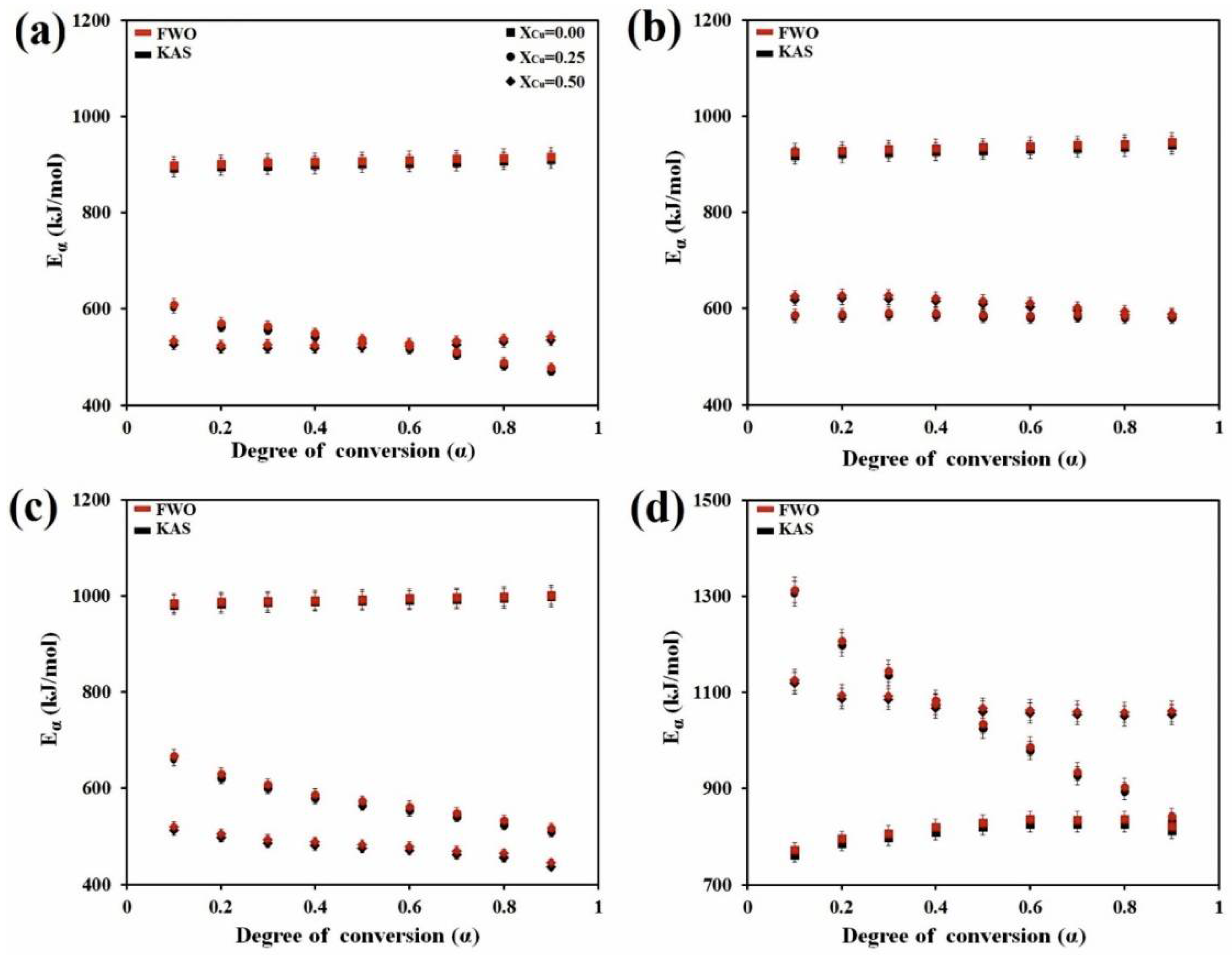

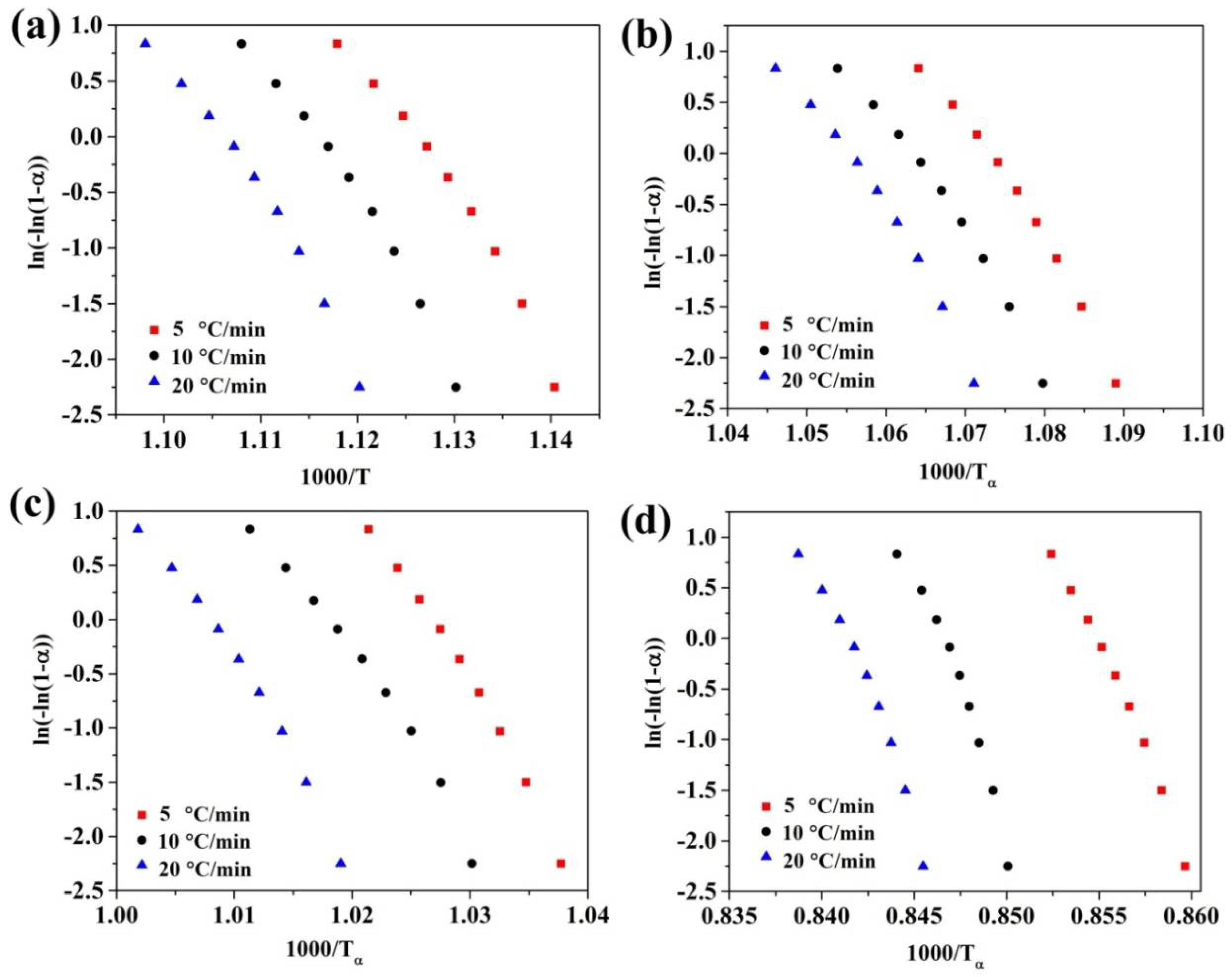

3.1. Isoconversional Methods

3.1.1. Local Activation Energy

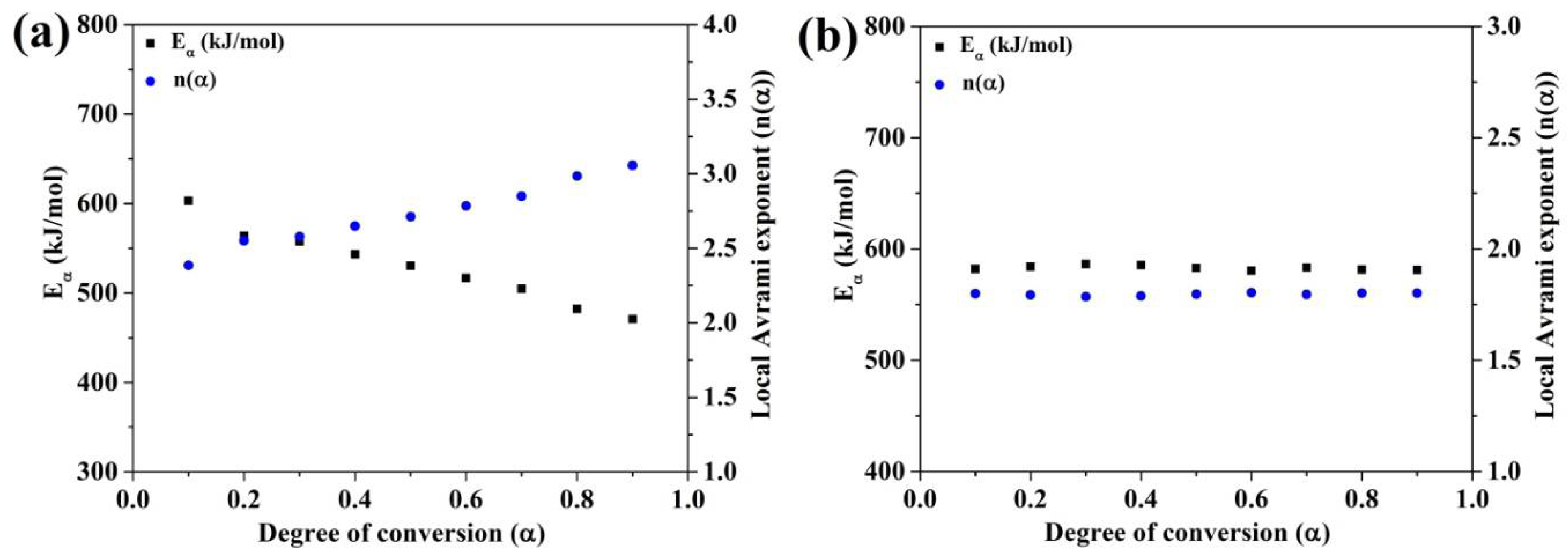

3.1.2. Apparent Activation Energy

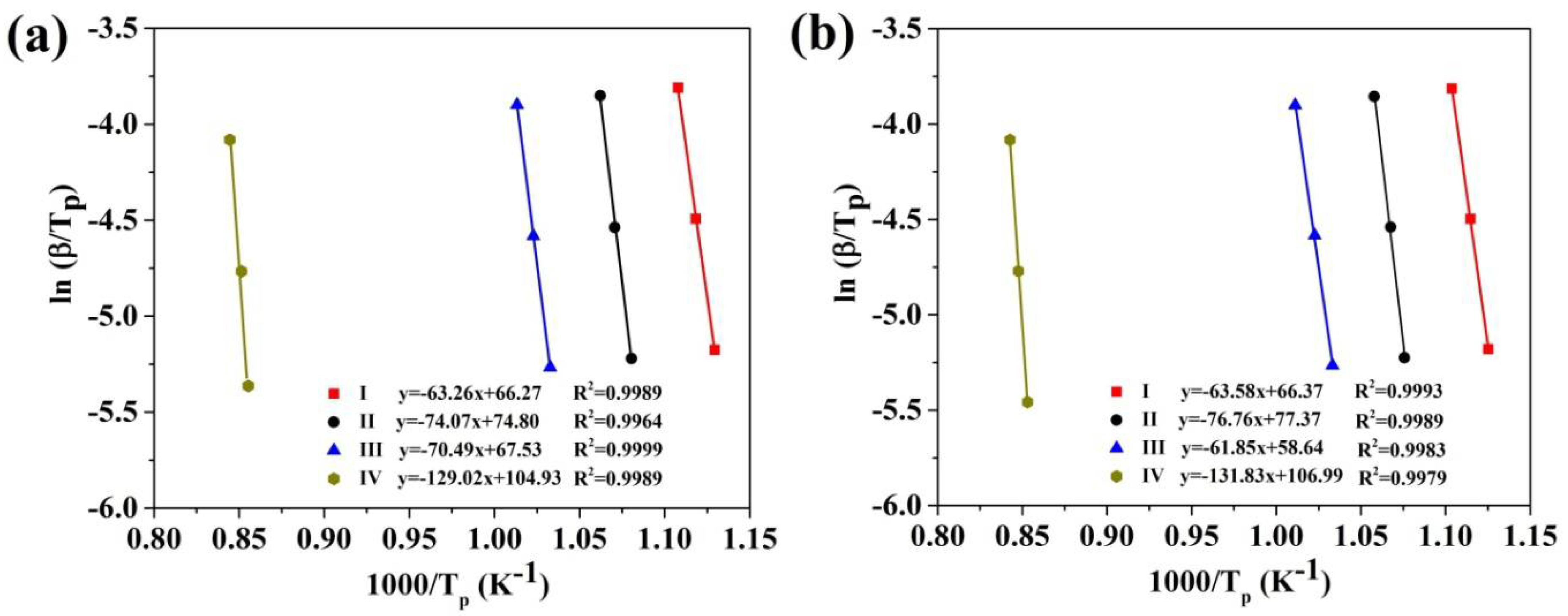

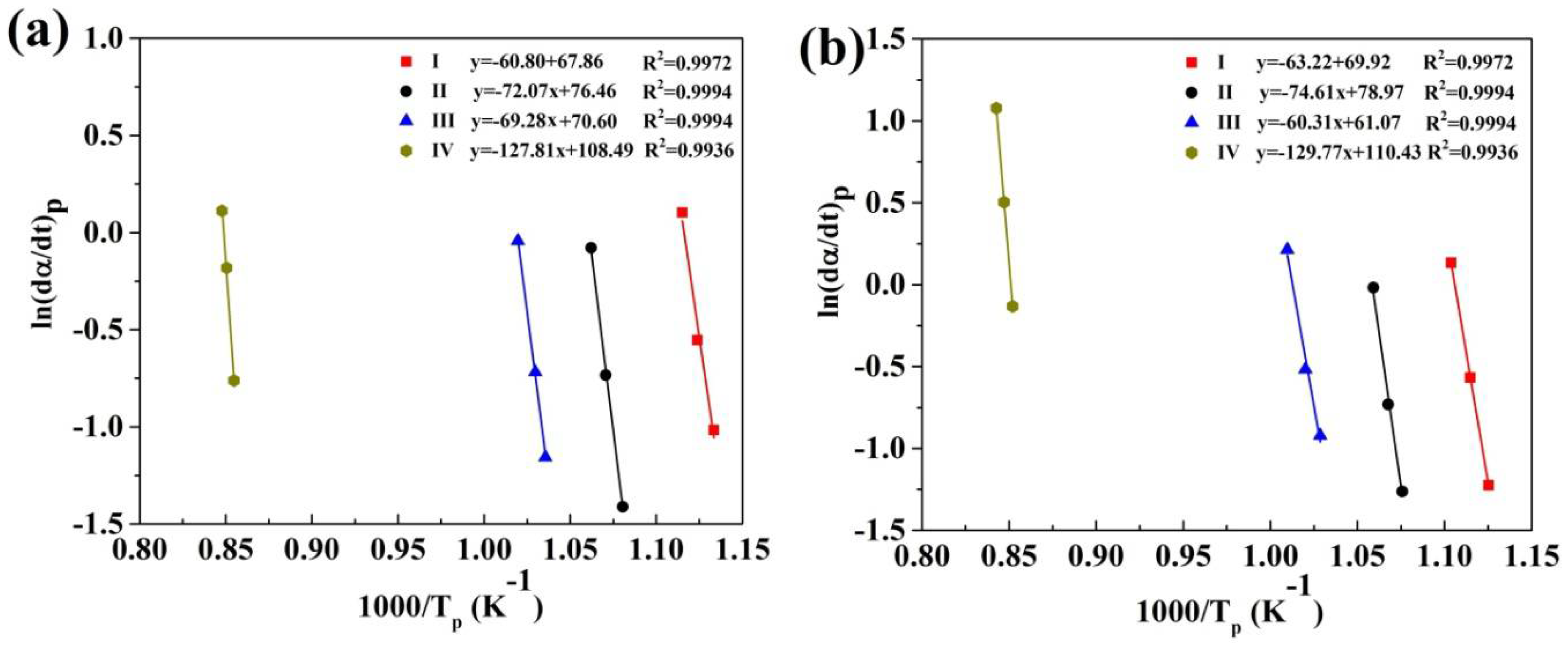

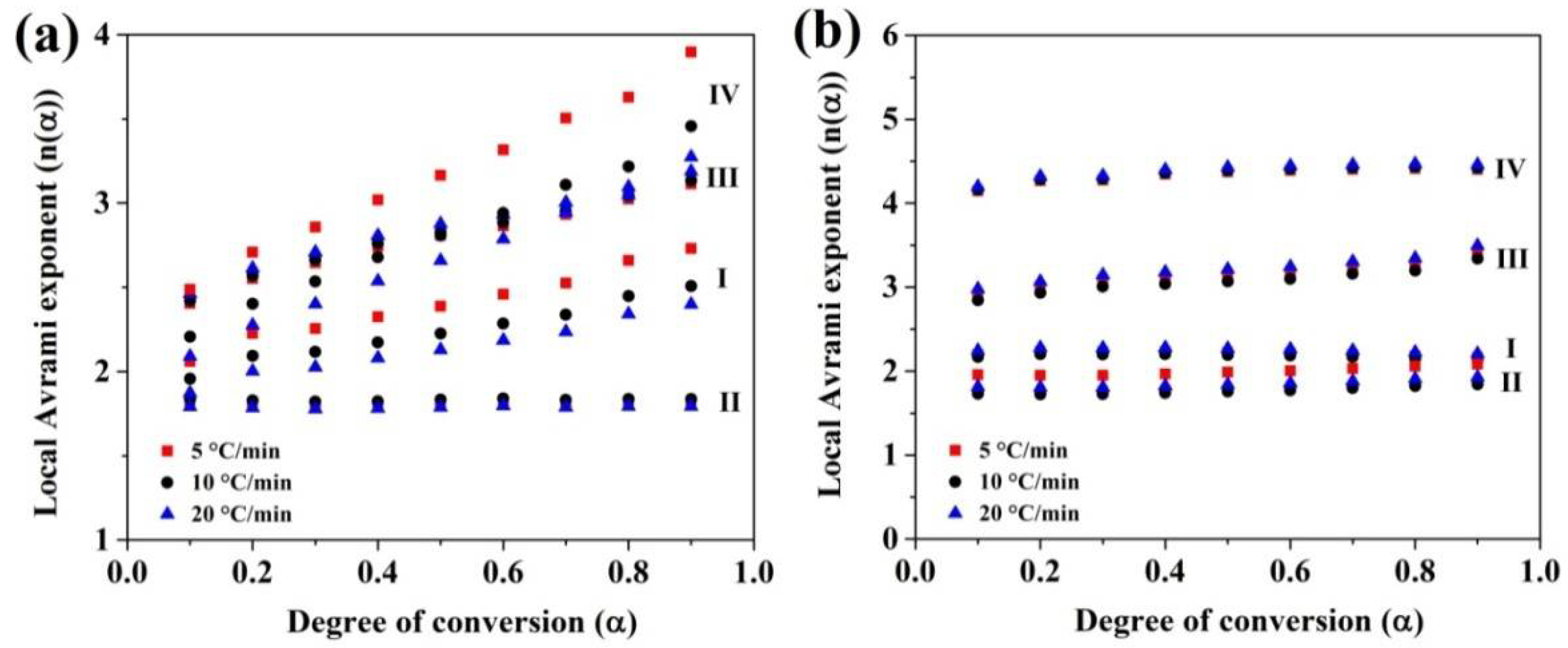

3.2. Nucleation and Growth Mechanisms

3.2.1. Avrami Exponent and the Rate Constant

3.2.2. Relationship between n & m Parameters

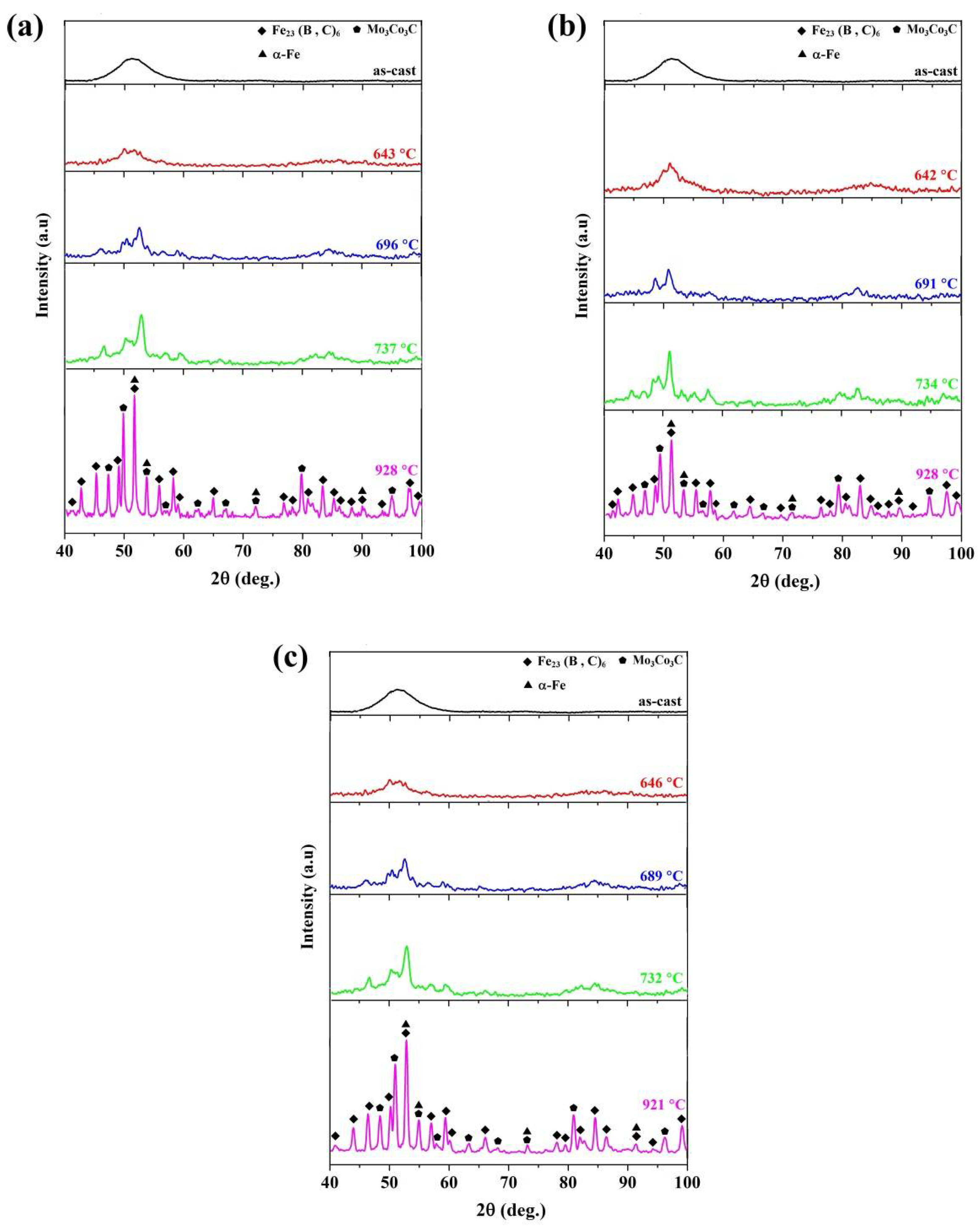

3.3. Microstructural Observations

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Collocott, S.J. Magnetic Materials: Domestic Applications. In The Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar] [CrossRef]

- Berradja, A. Metallic Glasses for Triboelectrochemistry Systems. In Metallic Glasses: Properties and Processing; InTech: London, UK, 2018. [Google Scholar] [CrossRef]

- Wang, C.; Li, M.; Zhu, M.; Wang, H.; Qin, C.; Zhao, W.; Wang, Z. Controlling the Mechanical Properties of Bulk Metallic Glasses by Superficial Dealloyed Layer. Nanomaterials 2017, 7, 352. [Google Scholar] [CrossRef] [PubMed]

- Pan, X.F.; Zhang, H.; Zhang, Z.F.; Stoica, M.; He, G.; Eckert, J. Vickers hardness and compressive properties of bulk metallic glasses and nanostructure-dendrite composites. J. Mater. Res. 2005, 20, 2632–2638. [Google Scholar] [CrossRef]

- Jafary-Zadeh, M.; Praveen Kumar, G.; Branicio, P.; Seifi, M.; Lewandowski, J.; Cui, F. A Critical Review on Metallic Glasses as Structural Materials for Cardiovascular Stent Applications. J. Funct. Biomater. 2018, 20, 19. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.H. Correlations between elastic moduli and properties in bulk metallic glasses. J. Appl. Phys. 2006, 99, 093506. [Google Scholar] [CrossRef]

- Hasani, S.; Rezaei-Shahreza, P.; Seifoddini, A. Effect of Cu presence on the evolution of mechanical and magnetic properties in a novel Fe-based BMGs during partial annealing process. Metall. Mater. Trans. A 2018, 50, 63–71. [Google Scholar] [CrossRef]

- Wang, S. Corrosion Resistance and Electrocatalytic Properties of Metallic Glasses. In Metallic Glasses-Formation and Properties; InTech: London, UK, 2016. [Google Scholar] [CrossRef][Green Version]

- Li, M.-X.; Zhao, S.-F.; Lu, Z.; Hirata, A.; Wen, P.; Bai, H.-Y.; Chen, M.; Schroers, J.; Liu, Y.; Wang, W.-H. High-temperature bulk metallic glasses developed by combinatorial methods. Nature 2019, 569, 99–103. [Google Scholar] [CrossRef]

- Wang, W. Roles of minor additions in formation and properties of bulk metallic glasses. Prog. Mater. Sci. 2007, 52, 540–596. [Google Scholar] [CrossRef]

- Olszewski, J.; Zbroszczyk, J.; Hasiak, M.; Kaleta, J.; Nabiałek, M.; Brągiel, P.; Sobczyk, K.; Ciurzyńska, W.; Świerczek, J.; Łukiewska, A. Microstructure and magnetic properties of Fe-Co-Nd-Y-B alloys obtained by suction casting method. J. Rare Earths. 2009, 27, 680–683. [Google Scholar] [CrossRef]

- Rezaei-Shahreza, P.; Seifoddini, A.; Hasani, S. Microstructural and phase evolutions: Their dependent mechanical and magnetic properties in a Fe-based amorphous alloy during annealing process. J. Alloys Compd. 2018, 738, 197–205. [Google Scholar] [CrossRef]

- Gondro, J.; Świerczek, J.; Olszewski, J.; Zbroszczyk, J.; Sobczyk, K.; Ciurzyńska, W.H.; Rzącki, J.; NabiaŁek, M. Magnetization behavior and magnetocaloric effect in bulk amorphous Fe60Co5Zr8Mo5W2B20 alloy. J. Magn. Magn. Mater. 2012, 324, 1360–1364. [Google Scholar] [CrossRef]

- Keryvin, V.; Hoang, V.H.; Shen, J. Hardness, toughness, brittleness and cracking systems in an iron-based bulk metallic glass by indentation. Intermetallics 2009, 17, 211–217. [Google Scholar] [CrossRef]

- Hin, S.; Bernard, C.; Doquet, V.; Yokoyama, Y.; Magueresse, A.; Keryvin, V. Influence of as-cast spherulites on the fracture toughness of a Zr 55 Cu 30 Al 10 Ni 5 bulk metallic glass. Mater. Sci. Eng. A 2019, 740–741, 137–147. [Google Scholar] [CrossRef]

- Hua, N.; Pang, S.; Li, Y.; Wang, J.; Li, R.; Georgarakis, K.; Yavari, A.R.; Vaughan, G.; Zhang, T. Ni- and Cu-free Zr–Al–Co–Ag bulk metallic glasses with superior glass-forming ability. J. Mater. Res. 2011, 26, 539–546. [Google Scholar] [CrossRef]

- Hasani, S.; Rezaei-Shahreza, P.; Seifoddini, A.; Hakimi, M. Enhanced glass forming ability, mechanical, and magnetic properties of Fe41Co7Cr15Mo14Y2C15B6 bulk metallic glass with minor addition of Cu. J. Non. Cryst. Solids 2018, 497, 40–47. [Google Scholar] [CrossRef]

- Zhang, G.; Zhang, H.; Yue, S.; Wang, A.; He, A.; Cheng, R.; Dong, Y.; Ni, H.; Liu, C.-T. Ultra-low cost and energy-efficient production of FePCSi amorphous alloys with pretreated molten iron from a blast furnace. J. Non. Cryst. Solids 2019, 514, 108–115. [Google Scholar] [CrossRef]

- Yang, W.; Wang, Q.; Li, W.; Xue, L.; Liu, H.; Zhou, J.; Mo, J.; Shen, B. A novel thermal-tuning Fe-based amorphous alloy for automatically recycled methylene blue degradation. Mater. Des. 2019, 161, 136–146. [Google Scholar] [CrossRef]

- Liu, L.; Zhang, C. Fe-based amorphous coatings: Structures and properties. Thin Solid Films 2014, 561, 70–86. [Google Scholar] [CrossRef]

- Hasani, S.; Ansariniya, M.; Seifoddini, A. Enhancement of mechanical properties of a soft magnetic Fe-based metallic glass. Mater. Sci. Technol. 2019, 35, 865–871. [Google Scholar] [CrossRef]

- Ansariniya, M.; Seifoddini, A.; Hasani, S. (Fe0.9Ni0.1)77Mo5P9C7.5B1.5 bulk metallic glass matrix composite produced by partial crystallization: The non-isothermal kinetic analysis. J. Alloys Compd. 2018, 763, 606–612. [Google Scholar] [CrossRef]

- Li, F.C.; Liu, T.; Zhang, J.Y.; Shuang, S.; Wang, Q.; Wang, A.D.; Wang, J.G.; Yang, Y. Amorphous–nanocrystalline alloys: Fabrication, properties, and applications. Mater. Today Adv. 2019, 4, 100027. [Google Scholar] [CrossRef]

- Luborsky, F.E.; Liebermann, H.H. Crystallization kinetics of Fe-B amorphous alloys. Appl. Phys. Lett. 1978, 33, 233–234. [Google Scholar] [CrossRef]

- Abrosimova, G.; Aronin, A. Amorphous and Nanocrystalline Metallic Alloys. In Progress in Metallic Alloys; InTech: London, UK, 2016. [Google Scholar] [CrossRef]

- Rho, I.C.; Yoon, C.S.; Kim, C.K.; Byun, T.Y.; Hong, K.S. Microstructure and crystallization kinetics of amorphous metallic alloy: Fe54Co26Si6B14. J. Non. Cryst. Solids 2003, 316, 289–296. [Google Scholar] [CrossRef]

- Perepezko, J.H.; Hebert, R.J.; Wu, R.I.; Wilde, G. Primary crystallization in amorphous Al-based alloys. J. Non. Cryst. Solids 2003, 317, 52–61. [Google Scholar] [CrossRef]

- Liu, L.; Wu, Z.F.; Zhang, J. Crystallization kinetics of Zr55Cu30Al10Ni5 bulk amorphous alloy. J. Alloys Compd. 2002, 339, 90–95. [Google Scholar] [CrossRef]

- Egami, T. Structural relaxation in amorphous alloys—Compositional short range ordering. Mater. Res. Bull. 1978, 13, 557–562. [Google Scholar] [CrossRef]

- Suryanarayana, C.; Inoue, A. Iron-based bulk metallic glasses. Int. Mater. Rev. 2013, 58, 131–166. [Google Scholar] [CrossRef]

- Chen, N.; Martin, L.; Luzguine-Luzgin, D.V.; Inoue, A. Role of Alloying Additions in Glass Formation and Properties of Bulk Metallic Glasses. Materials (Basel) 2010, 3, 5320–5339. [Google Scholar] [CrossRef]

- Lesz, S.; Kwapuliński, P.; Nabiałek, M.; Zackiewicz, P.; Hawelek, L. Thermal stability, crystallization and magnetic properties of Fe-Co-based metallic glasses. J. Therm. Anal. Calorim. 2016, 125, 1143–1149. [Google Scholar] [CrossRef]

- Ribeiro, R.M.; dos Santos, D.S. Crystallization Kinetics of Fe-Based Amorphous Alloys with Addition of Ag-Y. J. Metastable Nanocrystalline Mater. 2004, 20–21, 535–540. [Google Scholar] [CrossRef]

- Fan, C.; Yue, X.; Inoue, A.; Liu, C.-T.; Shen, X.; Liaw, P.K. Recent Topics on the Structure and Crystallization of Al-based Glassy Alloys. Mater. Res. 2019, 22, e20180619. [Google Scholar] [CrossRef]

- Louzguine-Luzgin, D.V.; Bazlov, A.I.; Ketov, S.V.; Inoue, A. Crystallization behavior of Fe- and Co-based bulk metallic glasses and their glass-forming ability. Mater. Chem. Phys. 2015, 162, 197–206. [Google Scholar] [CrossRef]

- Tan, J.; Pan, F.S.; Li, C.J.; Wang, J.F.; Eckert, J. Effect of Fe on Crystallization Process of Zr-Co-Al-(Fe) Bulk Metallic Glasses. Mater. Sci. Forum 2013, 745–746, 734–739. [Google Scholar] [CrossRef]

- Rezaei-Shahreza, P.; Seifoddini, A.; Hasani, S. Thermal stability and crystallization process in a Fe-based bulk amorphous alloy: The kinetic analysis. J. Non. Cryst. Solids 2017, 471, 286–294. [Google Scholar] [CrossRef]

- Hasani, S.; Rezaei-Shahreza, P.; Seifoddini, A. The effect of Cu minor addition on the non-isothermal kinetic of nano-crystallites formation in Fe41Co7Cr15Mo14Y2C15B6 BMG. J. Therm. Anal. Calorim 2020, 1–11. [Google Scholar] [CrossRef]

- Augis, J.A.; Bennett, J.E. Calculation of the Avrami parameters for heterogeneous solid state reactions using a modification of the Kissinger method. J. Therm. Anal. 1978, 13, 283–292. [Google Scholar] [CrossRef]

- Gao, J.; Wang, Q. Existence of nonoscillatory solutions to second-order nonlinear neutral dynamic equations on time scales. Rocky Mt. J. Math. 2013, 43, 1521–1535. [Google Scholar] [CrossRef]

- Kissinger, H.E. Reaction Kinetics in Differential Thermal Analysis. Anal. Chem. 1957, 29, 1702–1706. [Google Scholar] [CrossRef]

- Ozawa, T. A New Method of Analyzing Thermogravimetric Data. Bull. Chem. Soc. Jpn. 1965, 38, 1881–1886. [Google Scholar] [CrossRef]

- Flynn, J.H.; Wall, L.A. General treatment of the thermogravimetry of polymers. J. Res. Natl. Bur. Stand. Sect. A Phys. Chem. 1966, 70A, 487. [Google Scholar] [CrossRef]

- Todinov, M.T. On some limitations of the Johnson–Mehl–Avrami–Kolmogorov equation. Acta Mater. 2000, 48, 4217–4224. [Google Scholar] [CrossRef]

- Fanfoni, M.; Tomellini, M. The Johnson-Mehl- Avrami-Kohnogorov model: A brief review. Nuovo Cim. D 1998, 20, 1171–1182. [Google Scholar] [CrossRef]

- Avrami, M. Kinetics of phase change. II Transformation-time relations for random distribution of nuclei. J. Chem. Phys. 1940, 8, 212–224. [Google Scholar] [CrossRef]

- Hasani, S.; Panjepour, M.; Shamanian, M. Effect of atmosphere and heating rate on mechanism of MoSi2 formation during self-propagating high-temperature synthesis. J. Therm. Anal. Calorim. 2012, 107, 1073–1081. [Google Scholar] [CrossRef]

- Hasani, S.; Panjepour, M.; Shamanian, M. A study of the effect of aluminum on MoSi2 formation by self-propagation high-temperature synthesis. J. Alloys Compd. 2010, 502, 80–86. [Google Scholar] [CrossRef]

- Rezaei-Shahreza, P.; Seifoddini, A.; Hasani, S. Non-isothermal kinetic analysis of nano-crystallization process in (Fe41Co7Cr15Mo14Y2C15)94B6 amorphous alloy. Thermochim. Acta 2017, 652, 119–125. [Google Scholar] [CrossRef]

- Zhu, S.L.; Wang, X.M.; Qin, F.X.; Yoshimura, M.; Inoue, A. New TiZrCuPd Quaternary Bulk Glassy Alloys with Potential of Biomedical Applications. Mater. Trans. 2007, 48, 2445–2448. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, D.Q.; Wang, R.J.; Wang, W.H. Formation and properties of Zr48Nb8Cu14Ni12Be18 bulk metallic glass. Acta Mater. 2003, 51, 1971–1979. [Google Scholar] [CrossRef]

- Kosiba, K.; Pauly, S. Inductive flash-annealing of bulk metallic glasses. Sci. Rep. 2017, 7, 2151. [Google Scholar] [CrossRef]

- Wang, Z.X.; Zhao, D.Q.; Pan, M.X.; Wang, W.H.; Okada, T.; Utsumi, W. Formation and crystallization of CuZrHfTi bulk metallic glass under ambient and high pressures. J. Phys. Condens. Matter. 2003, 15, 5923–5932. [Google Scholar] [CrossRef]

- Kasap, S.; Málek, J.; Svoboda, R. Thermal Properties and Thermal Analysis: Fundamentals, Experimental Techniques and Applications. In Springer Handbook of Electronic and Photonic Materials; Springer International Publishing: Cham, Switzerland, 2017; p. 1. [Google Scholar] [CrossRef]

- Marseglia, E.A. Kinetic theory of crystallization of amorphous materials. J. Non. Cryst. Solids 1980, 41, 31–36. [Google Scholar] [CrossRef]

- Celikbilek, M.; Erin, A.; Ayd, S. Crystallization Kinetics of Amorphous Materials in Advances in Crystallization Processes; InTech: London, UK, 2012; pp. 127–162. [Google Scholar] [CrossRef][Green Version]

- Šimon, P. Isoconversional methods. J. Therm. Anal. Calorim. 2004, 76, 123–132. [Google Scholar] [CrossRef]

- Sbirrazzuoli, N. Advanced Isoconversional Kinetic Analysis for the Elucidation of Complex Reaction Mechanisms: A New Method for the Identification of Rate-Limiting Steps. Molecules 2019, 24, 1683. [Google Scholar] [CrossRef] [PubMed]

- Kaloshkin, S.D.; Tomilin, I.A. The crystallization kinetics of amorphous alloys. Thermochim. Acta 1996, 280–281, 303–317. [Google Scholar] [CrossRef]

- Liu, F.; Wang, H.F.; Chen, Z.; Yang, W.; Yang, G.C. Determination of activation energy for crystallization in amorphous alloys. Mater. Lett. 2006, 60, 3916–3921. [Google Scholar] [CrossRef]

- Lu, K.; Wang, J.T. Activation energies for crystal nucleation and growth in amorphous alloys. Mater. Sci. Eng. A 1991, 133, 500–503. [Google Scholar] [CrossRef]

- Lu, W.; Yan, B.; Huang, W. Complex primary crystallization kinetics of amorphous Finemet alloy. J. Non. Cryst. Solids 2005, 351, 3320–3324. [Google Scholar] [CrossRef]

- Korkmaz, S.; Kariper, İ.A. Glass formation, production and superior properties of Zr-based thin film metallic glasses (TFMGs): A status review. J. Non. Cryst. Solids 2020, 527, 119753. [Google Scholar] [CrossRef]

- Xing, L.Q.; Hufnagel, T.C.; Eckert, J.; Löser, W.; Schultz, L. Relation between short-range order and crystallization behavior in Zr-based amorphous alloys. Appl. Phys. Lett. 2000, 77, 1970–1972. [Google Scholar] [CrossRef]

- Egami, T.; Iwashita, T.; Dmowski, W. Mechanical Properties of Metallic Glasses. Metals (Basel) 2013, 3, 77–113. [Google Scholar] [CrossRef]

- Telford, M. The case for bulk metallic glass. Mater. Today 2004, 7, 36–43. [Google Scholar] [CrossRef]

- Ma, Y.-B.; Wang, B.-Z.; Zhang, Q.-D.; Jiang, Y.; Hou, D.-W.; Cui, X.; Zu, F.-Q. Change dynamic behaviors by heightening its stored energy of monolithic bulk metallic glass. Mater. Des. 2019, 181, 107971. [Google Scholar] [CrossRef]

- Pilarczyk, W. Structure and Properties of Zr-Based Bulk Metallic Glasses in As-Cast State and After Laser Welding. Materials (Basel) 2018, 11, 1117. [Google Scholar] [CrossRef] [PubMed]

- Hu, Q.; Wang, J.M.; Yan, Y.H.; Guo, S.; Chen, S.S.; Lu, D.P.; Zou, J.Z.; Zeng, X.R. Invar effect of Fe-based bulk metallic glasses. Intermetallics 2018, 93, 318–322. [Google Scholar] [CrossRef]

- Su, C.; Chen, Y.; Yu, P.; Song, M.; Chen, W.; Guo, S.F. Linking the thermal characteristics and mechanical properties of Fe-based bulk metallic glasses. J. Alloys Compd. 2016, 663, 867–871. [Google Scholar] [CrossRef]

- Wang, G.; Feng, L.; Shen, W.; Liu, Z. Effect of Mo content on glass forming ability and crystallization behavior of Fe-based alloy prepared by atmospheric plasma spraying. Results Phys. 2019, 14, 102512. [Google Scholar] [CrossRef]

- Yang, W.; Liu, H.; Zhao, Y.; Inoue, A.; Jiang, K.; Huo, J.; Ling, H.; Li, Q.; Shen, B. Mechanical properties and structural features of novel Fe-based bulk metallic glasses with unprecedented plasticity. Sci. Rep. 2015, 4, 6233. [Google Scholar] [CrossRef]

- Jaafari, Z.; Seifoddini, A.; Hasani, S.; Rezaei-Shahreza, P. Kinetic analysis of crystallization process in [(Fe0.9Ni0.1)77Mo5P9C7.5B1.5]100−xCux (x = 0.1 at.%) BMG. J. Therm. Anal. Calorim. 2018, 134, 1565–1574. [Google Scholar] [CrossRef]

- Nguyen, V.H.; Nguyen, O.T.H.; Dudina, D.V.; Le, V.V.; Kim, J.-S. Crystallization Kinetics of Al-Fe and Al-Fe-Y Amorphous Alloys Produced by Mechanical Milling. J. Nanomater. 2016, 2016, 1–9. [Google Scholar] [CrossRef]

- Browne, D.J.; Kovacs, Z.; Mirihanage, W.U. Comparison of nucleation and growth mechanisms in alloy solidification to those in metallic glass crystallisation—Relevance to modeling. Trans. Indian Inst. Met. 2009, 62, 409–412. [Google Scholar] [CrossRef]

- Malizia, F.; Ronconi, F. Nucleation-and-growth process in Fe 80 B 20 amorphous alloys. Philos. Mag. B 1993, 68, 869–875. [Google Scholar] [CrossRef]

- An, S.; Li, J.; Li, Y.; Li, S.; Wang, Q.; Liu, B. Two-step crystal growth mechanism during crystallization of an undercooled Ni50Al50 alloy. Sci. Rep. 2016, 6, 31062. [Google Scholar] [CrossRef] [PubMed]

- Zhu, M.; Li, J.; Yao, L.; Jian, Z.; Chang, F.; Yang, G. Non-isothermal crystallization kinetics and fragility of (Cu46Zr47Al7)97Ti3 bulk metallic glass investigated by differential scanning calorimetry. Thermochim. Acta. 2013, 565, 132–136. [Google Scholar] [CrossRef]

- Matusita, K.; Sakka, S. Kinetic study of crystallization of glass by differential thermal analysis—Criterion on application of Kissinger plot. J. Non. Cryst. Solids 1980, 38–39, 741–746. [Google Scholar] [CrossRef]

- Matusita, K.; Komatsu, T.; Yokota, R. Kinetics of non-isothermal crystallization process and activation energy for crystal growth in amorphous materials. J. Mater. Sci. 1984, 19, 291–296. [Google Scholar] [CrossRef]

- Gong, P.; Yao, K.F.; Ding, H.Y. Crystallization kinetics of TiZrHfCuNiBe high entropy bulk metallic glass. Mater. Lett. 2015, 156, 146–149. [Google Scholar] [CrossRef]

- Yan, Z.; Dang, S.; Wang, X.; Lian, P. Applicability of Johnson-Mehl-Avrami model to crystallization kinetics of Zr60Al15Ni25 bulk amorphous alloy. Trans. Nonferrous Met. Soc. China 2008, 18, 138–144. [Google Scholar] [CrossRef]

- Wang, T.; Yang, X.; Li, Q. Effect of Cu and Nb additions on crystallization kinetics of Fe80P13C7 bulk metallic glasses. Thermochim. Acta 2014, 579, 9–14. [Google Scholar] [CrossRef]

- Pratap, A.; Raval, K.G.; Gupta, A.; Kulkarni, S.K. Nucleation and growth of a multicomponent metallic glass. Bull. Mater. Sci. 2000, 23, 185–188. [Google Scholar] [CrossRef]

| X (at.%) | Heating Rate (°C/min) | Tg (°C) | Tx (°C) | Tm (°C) | Tl (°C) | Reference |

|---|---|---|---|---|---|---|

| 0.00 | 5 | 472 | 595 | 1105 | 1156 | This work |

| 10 | 499 | 601 | 1108 | 1159 | This work | |

| 20 | 516 | 610 | 1112 | 1165 | [17] | |

| 0.25 | 5 | 507 | 597 | 1108 | 1153 | This work |

| 10 | 530 | 604 | 1111 | 1157 | This work | |

| 20 | 545 | 609 | 1114 | 1162 | [17] | |

| 0.50 | 5 | 512 | 601 | 1107 | 1154 | This work |

| 10 | 533 | 605 | 1109 | 1159 | This work | |

| 20 | 552 | 612 | 1113 | 1163 | [17] |

| Peak Number | X(at.%) | E (kJ/mol) | Heating Rate (°C/min) | Kp | n | Reference | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| FWO | KAS | Augis and Bennet | Gao–Wang | Gao–Wang | Gao–Wang | JMAK | Augis and Bennet | ||||

| I | 0.00 | 546.0 ± 11.0 | 559.3 ± 11.5 | 578.3 ± 2.4 | 583.2 ± 2.4 | 5 | 0.449 | 1.66 | 1.88 ± 0.03 | 1.71 | [37] |

| 10 | 0.882 | 1.67 | 1.92 ± 0.03 | 1.82 | [37] | ||||||

| 20 | 1.735 | 1.72 | 1.95 ± 0.04 | 1.90 | [37] | ||||||

| 0.25 | – | – | 525.9 ± 3.7 | 505.5 ± 4.3 | 5 | 0.451 | 1.98 | – | 2.09 | This work | |

| 10 | 0.768 | 2.02 | – | 2.14 | This work | ||||||

| 20 | 1.512 | 2.17 | – | 2.23 | This work | ||||||

| 0.50 | 512.5 ± 3.4 | 524.1 ± 3.5 | 528.6 ± 5.2 | 525.6 ± 7.2 | 5 | 0.413 | 1.99 | 2.18 ± 0.02 | 1.88 | This work | |

| 10 | 0.782 | 1.95 | 2.21 ± 0.02 | 1.97 | This work | ||||||

| 20 | 1.540 | 2.00 | 2.25 ± 0.03 | 2.12 | This work | ||||||

| II | 0.00 | 616.2 ± 4.5 | 632.3 ± 4.7 | 627.6 ± 3.3 | 636.6 ± 3.3 | 5 | 0.445 | 1.43 | 1.48 ± 0.08 | 1.45 | [37] |

| 10 | 0.875 | 1.45 | 1.49 ± 0.06 | 1.47 | [37] | ||||||

| 20 | 1.724 | 1.49 | 1.53 ± 0.08 | 1.49 | [37] | ||||||

| 0.25 | 578.0 ± 3.4 | 582.0 ± 3.7 | 615.8 ± 4.2 | 599.2 ± 5.1 | 5 | 0.355 | 1.82 | 1.79 ± 0.05 | 1.78 | This work | |

| 10 | 0.712 | 1.84 | 1.80 ± 0.07 | 1.82 | This work | ||||||

| 20 | 1.354 | 1.86 | 1.83 ± 0.06 | 1.89 | This work | ||||||

| 0.50 | 601.6 ± 3.5 | 605.9 ± 3.5 | 638.2 ± 8.3 | 620.3 ± 3.8 | 5 | 0.432 | 1.77 | 1.82 ± 0.08 | 1.74 | This work | |

| 10 | 0.723 | 1.83 | 1.95 ± 0.07 | 1.79 | This work | ||||||

| 20 | 1.421 | 1.88 | 2.01 ± 0.08 | 1.82 | This work | ||||||

| III | 0.00 | 513.5 ± 2.3 | 591.6 ± 2.4 | 588.7 ± 5.1 | 592.7 ± 5.1 | 5 | 0.378 | 1.98 | 1.88 ± 0.13 | 1.78 | [37] |

| 10 | 0.745 | 2.10 | 1.92 ± 0.12 | 1.82 | [37] | ||||||

| 20 | 1.460 | 2.30 | 1.90 ± 0.11 | 1.89 | [37] | ||||||

| 0.25 | – | – | 586.0 ± 7.2 | 575.9 ± 6.7 | 5 | 0.295 | 2.71 | – | 2.84 | This work | |

| 10 | 0.462 | 2.83 | – | 2.88 | This work | ||||||

| 20 | 0.955 | 3.21 | – | 3.12 | This work | ||||||

| 0.50 | 467.4 ± 4.6 | 474.8 ± 4.6 | 514.2 ± 6.5 | 501.4 ± 5.1 | 5 | 0.319 | 2.91 | 3.08 ± 0.12 | 2.79 | This work | |

| 10 | 0.55 | 2.93 | 3.16 ± 0.12 | 2.87 | This work | ||||||

| 20 | 1.492 | 3.37 | 3.22 ± 0.13 | 3.12 | This work | ||||||

| IV | 0.00 | 826.5 ± 9.5 | 808.0 ± 9.5 | 929.2 ± 6.3 | 935.2 ± 6.3 | 5 | 0.412 | 3.31 | 3.71 ± 0.07 | 3.61 | [37] |

| 10 | 0.810 | 3.85 | 3.85 ± 0.07 | 3.74 | [37] | ||||||

| 20 | 1.600 | 4.20 | 3.91 ± 0.06 | 3.82 | [37] | ||||||

| 0.25 | – | – | 1072.7 ± 8.2 | 1062.6 ± 7.3 | 5 | 0.565 | 2.83 | – | 2.97 | This work | |

| 10 | 0.954 | 2.93 | – | 3.07 | This work | ||||||

| 20 | 1.566 | 4.09 | – | 3.12 | This work | ||||||

| 0.50 | 1063.9 ± 5.7 | 1068.7 ± 3.4 | 1096.0 ± 3.8 | 1078.9 ± 6.9 | 5 | 0.552 | 3.98 | 4.29 ± 0.06 | 3.85 | This work | |

| 10 | 1.091 | 4.01 | 4.35 ± 0.08 | 4.12 | This work | ||||||

| 20 | 1.576 | 4.22 | 4.39 ± 0.08 | 4.15 | This work | ||||||

| Peak Number | X (at.%) | Avrami Exponent (n) | Dimensionality of Growth (m) | Growth Index (p) | Nucleation Index (b) | Reference |

|---|---|---|---|---|---|---|

| I | 0.00 | 2 | 2 | 1 | 0 | [37] |

| 0.25 | 2 | 2 | 1 | 0 | This work | |

| 0.50 | 2 | 2 | 1 | 0 | This work | |

| II | 0.00 | 1.5 | 1 | 1 | 0 | [37] |

| 0.25 | 2 | 2 | 1 | 0 | This work | |

| 0.50 | 2 | 2 | 1 | 0 | This work | |

| III | 0.00 | 2 | 2 | 1 | 0 | [37] |

| 0.25 | 3 | 3 | 1 | 0 | This work | |

| 0.50 | 3 | 3 | 1 | 0 | This work | |

| IV | 0.00 | 4 | 3 | 1 | 1 | [37] |

| 0.25 | 3 | 2 | 1 | 1 | This work | |

| 0.50 | 4 | 3 | 1 | 1 | This work |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rezaei-Shahreza, P.; Seifoddini, A.; Hasani, S.; Jaafari, Z.; Śliwa, A.; Nabiałek, M. Isokinetic Analysis of Fe41Co7Cr15Mo14Y2C15B6 Bulk Metallic Glass: Effect of Minor Copper Addition. Materials 2020, 13, 3704. https://doi.org/10.3390/ma13173704

Rezaei-Shahreza P, Seifoddini A, Hasani S, Jaafari Z, Śliwa A, Nabiałek M. Isokinetic Analysis of Fe41Co7Cr15Mo14Y2C15B6 Bulk Metallic Glass: Effect of Minor Copper Addition. Materials. 2020; 13(17):3704. https://doi.org/10.3390/ma13173704

Chicago/Turabian StyleRezaei-Shahreza, Parisa, Amir Seifoddini, Saeed Hasani, Zahra Jaafari, Agata Śliwa, and Marcin Nabiałek. 2020. "Isokinetic Analysis of Fe41Co7Cr15Mo14Y2C15B6 Bulk Metallic Glass: Effect of Minor Copper Addition" Materials 13, no. 17: 3704. https://doi.org/10.3390/ma13173704

APA StyleRezaei-Shahreza, P., Seifoddini, A., Hasani, S., Jaafari, Z., Śliwa, A., & Nabiałek, M. (2020). Isokinetic Analysis of Fe41Co7Cr15Mo14Y2C15B6 Bulk Metallic Glass: Effect of Minor Copper Addition. Materials, 13(17), 3704. https://doi.org/10.3390/ma13173704