InAs/GaAs Quantum Dot Microlasers Formed on Silicon Using Monolithic and Hybrid Integration Methods

Abstract

1. Introduction

2. Monolithically Integrated III–V Quantum-Dot Microdisk Lasers

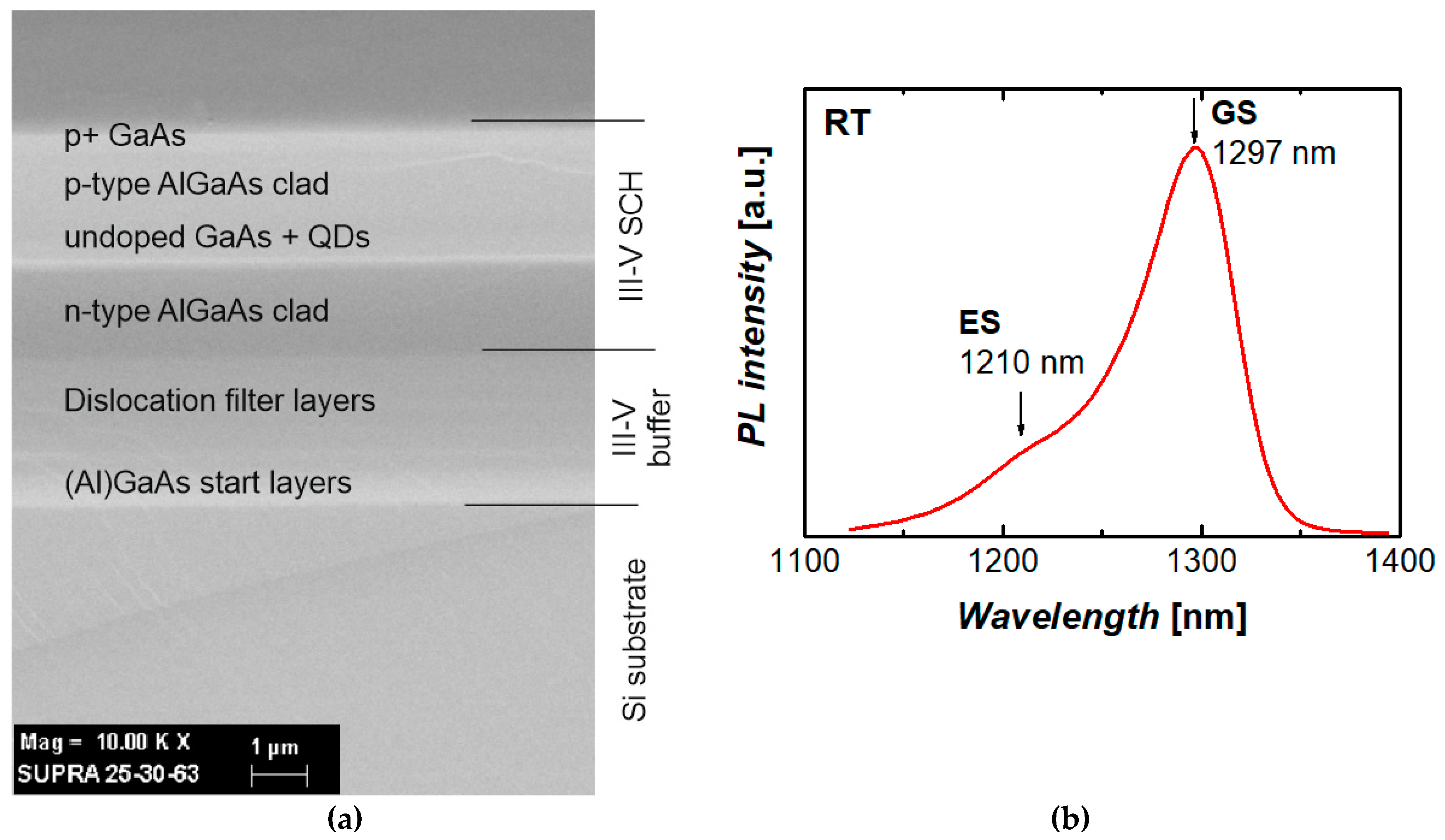

2.1. Epitaxial QD Heterostructure Grown on Si Substrate

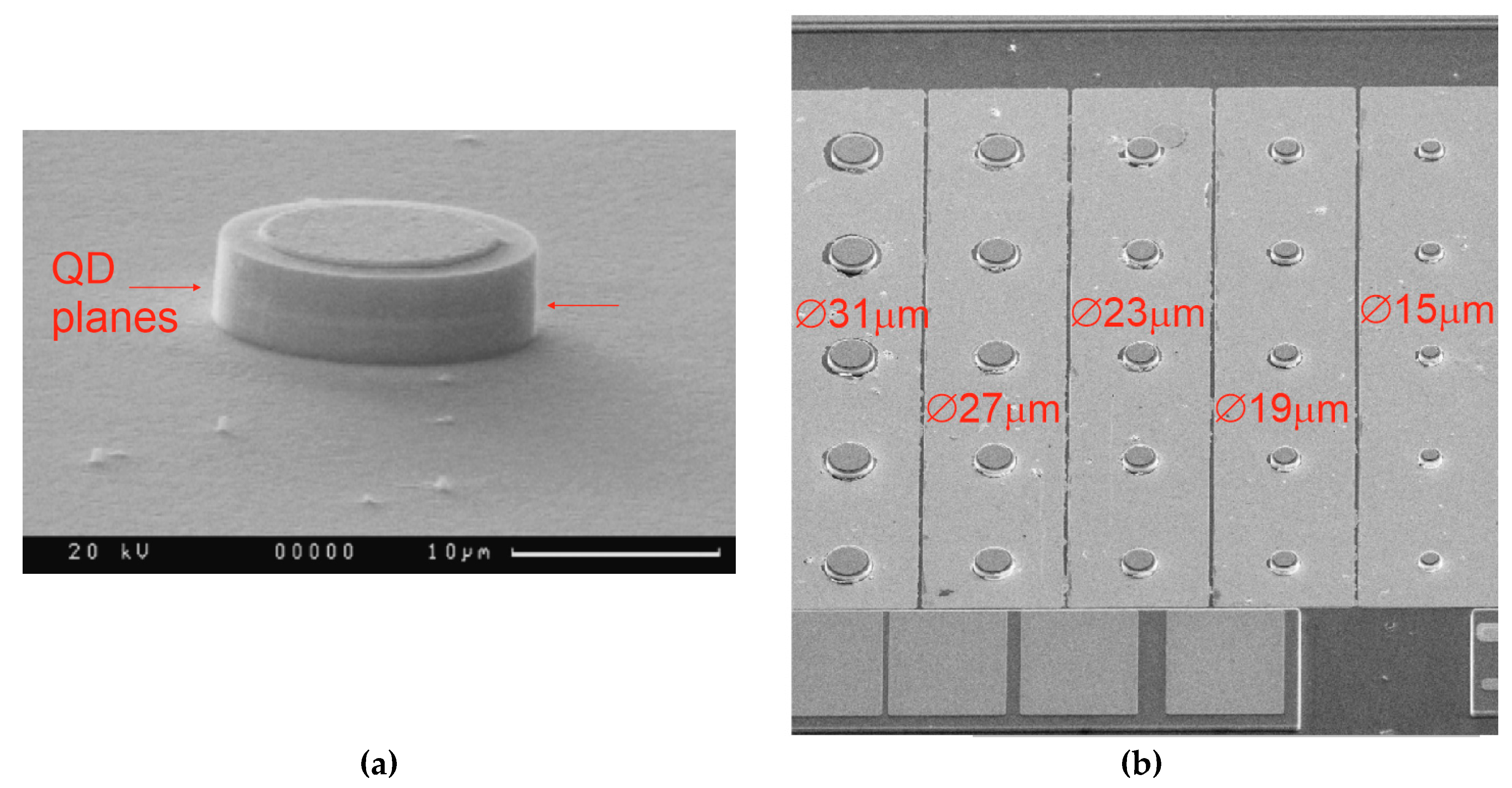

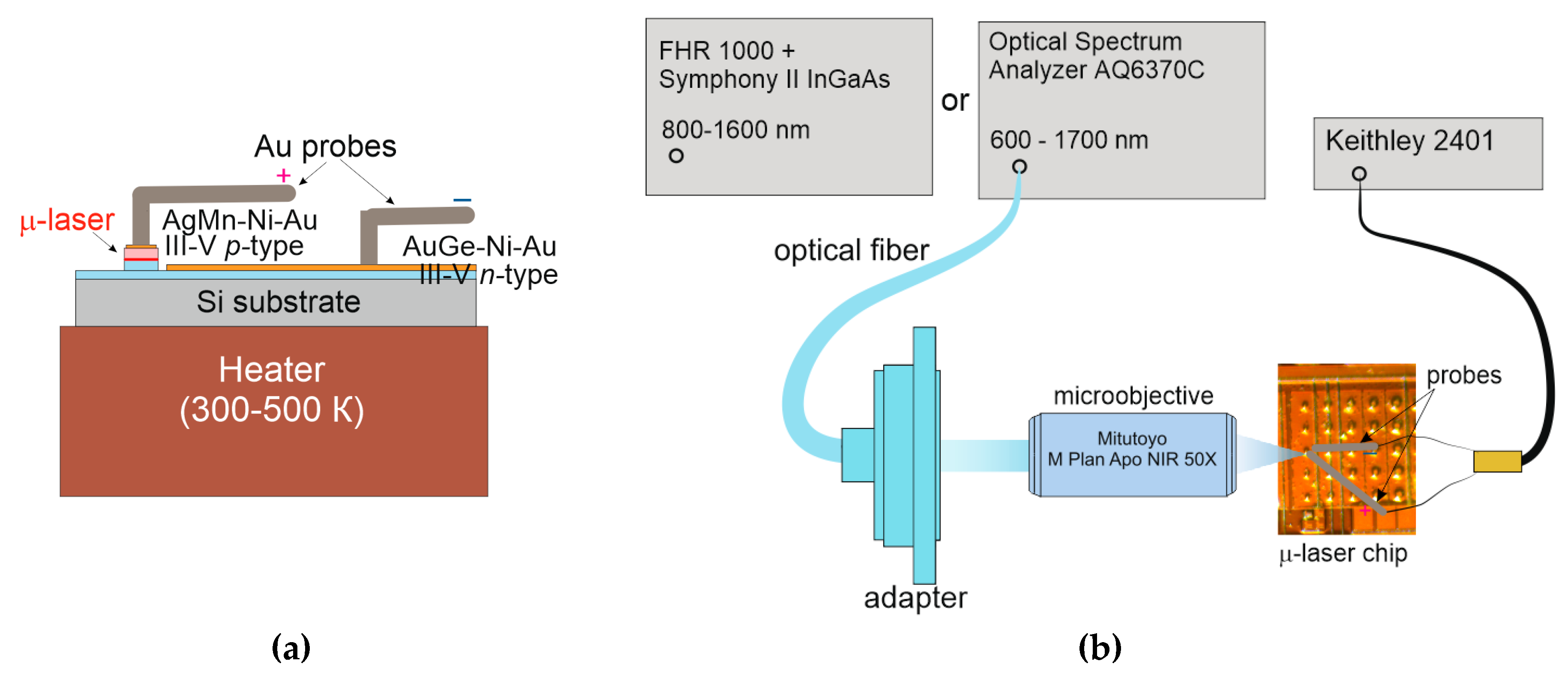

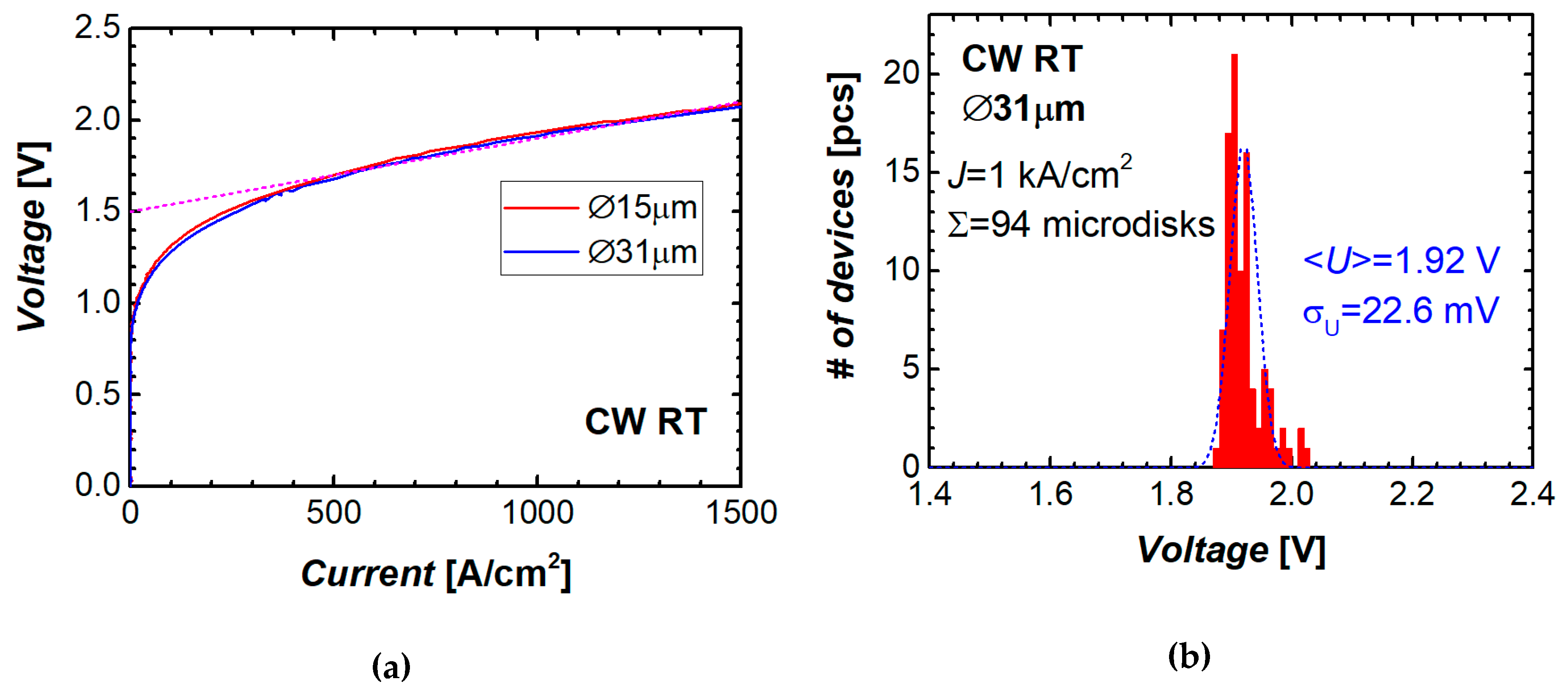

2.2. Formation of Microdisk Laser Resonators and Experimental Details

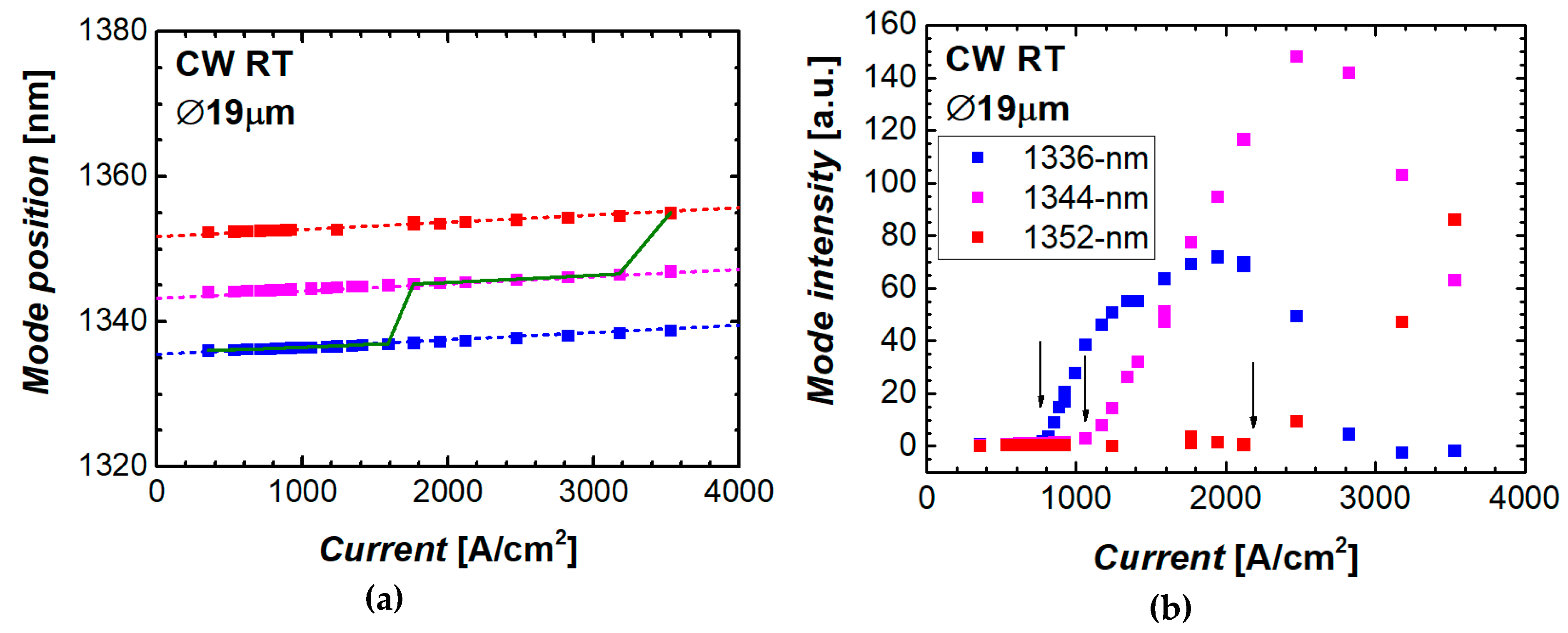

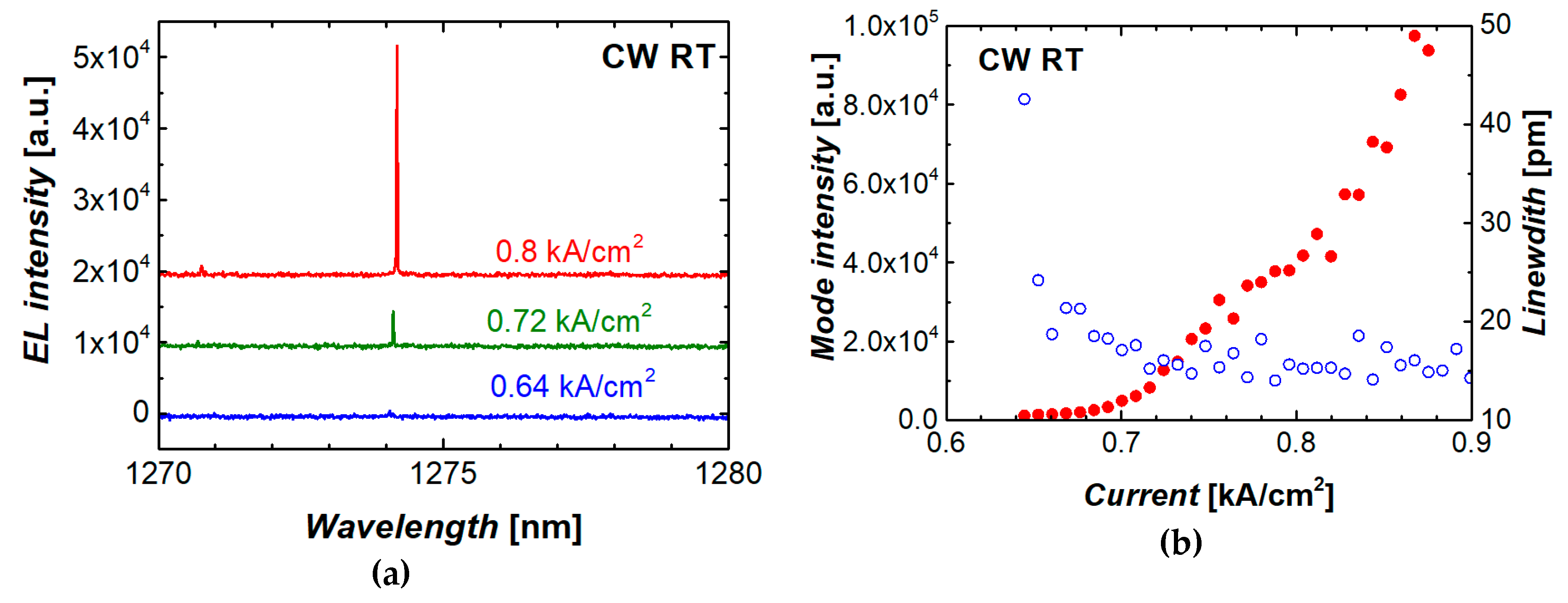

2.3. Spectral Characteristics of Microdisks

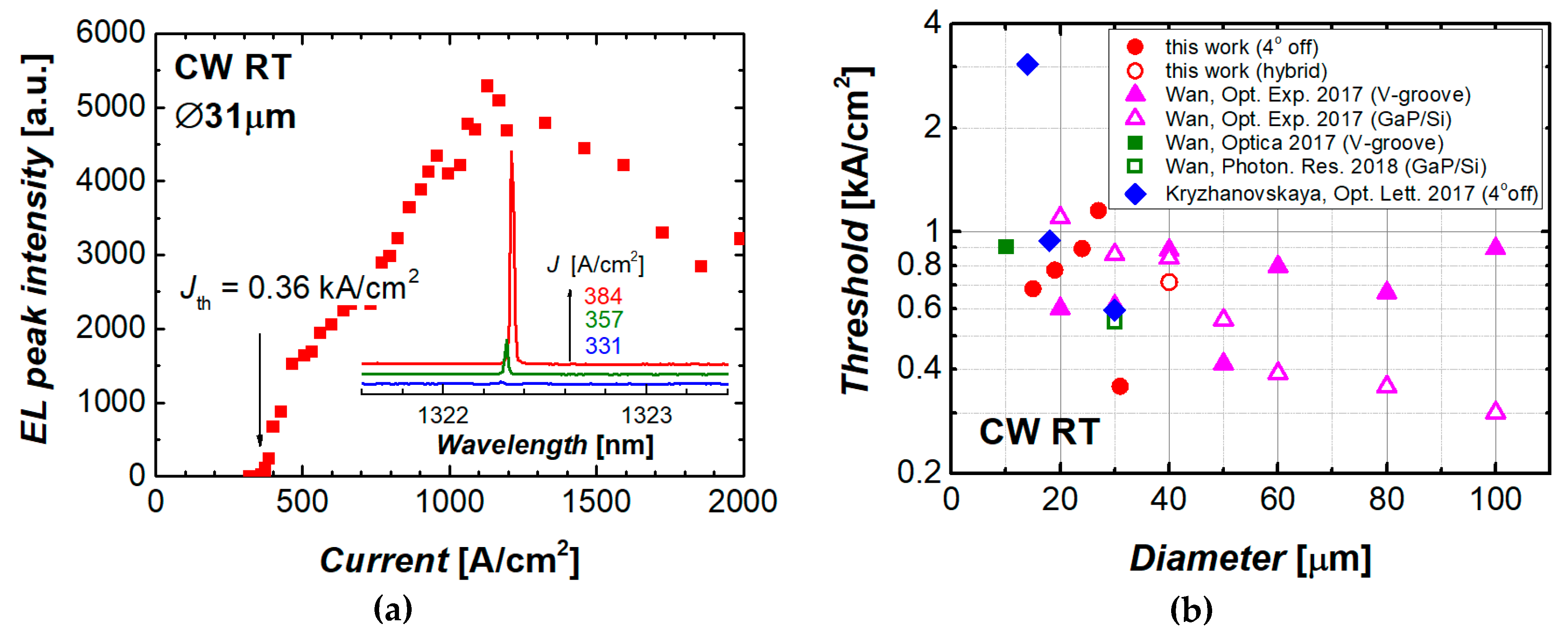

2.4. Threshold Current Density of Microdisk Lasers

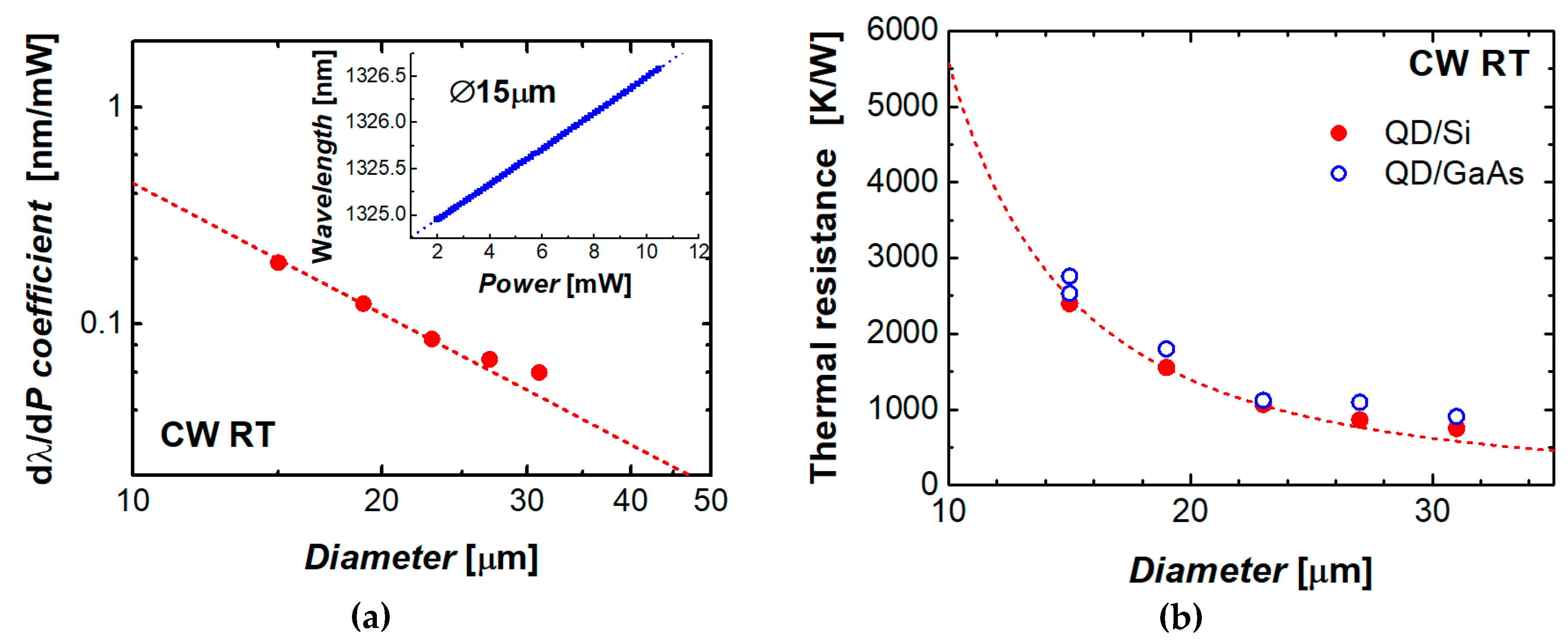

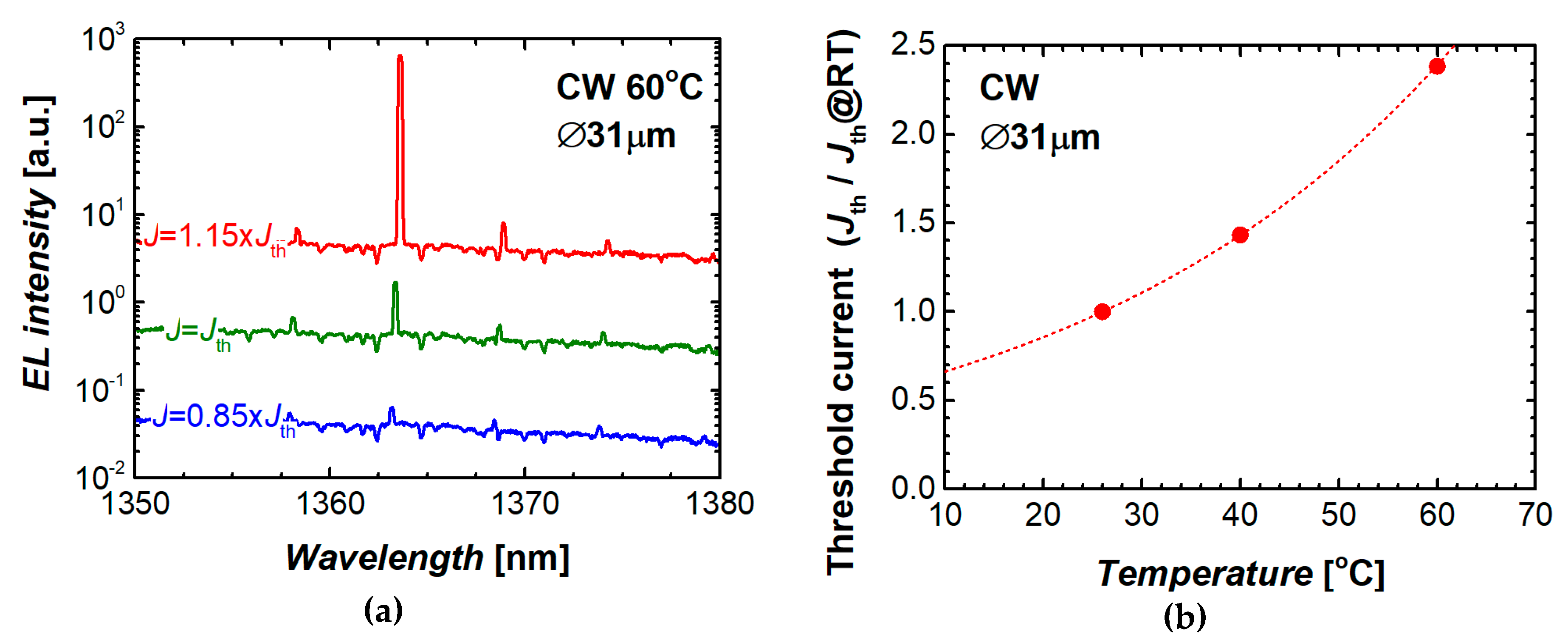

2.5. Thermal Resistancе of Microdisk Lasers and Lasing at Elevated Temperatures

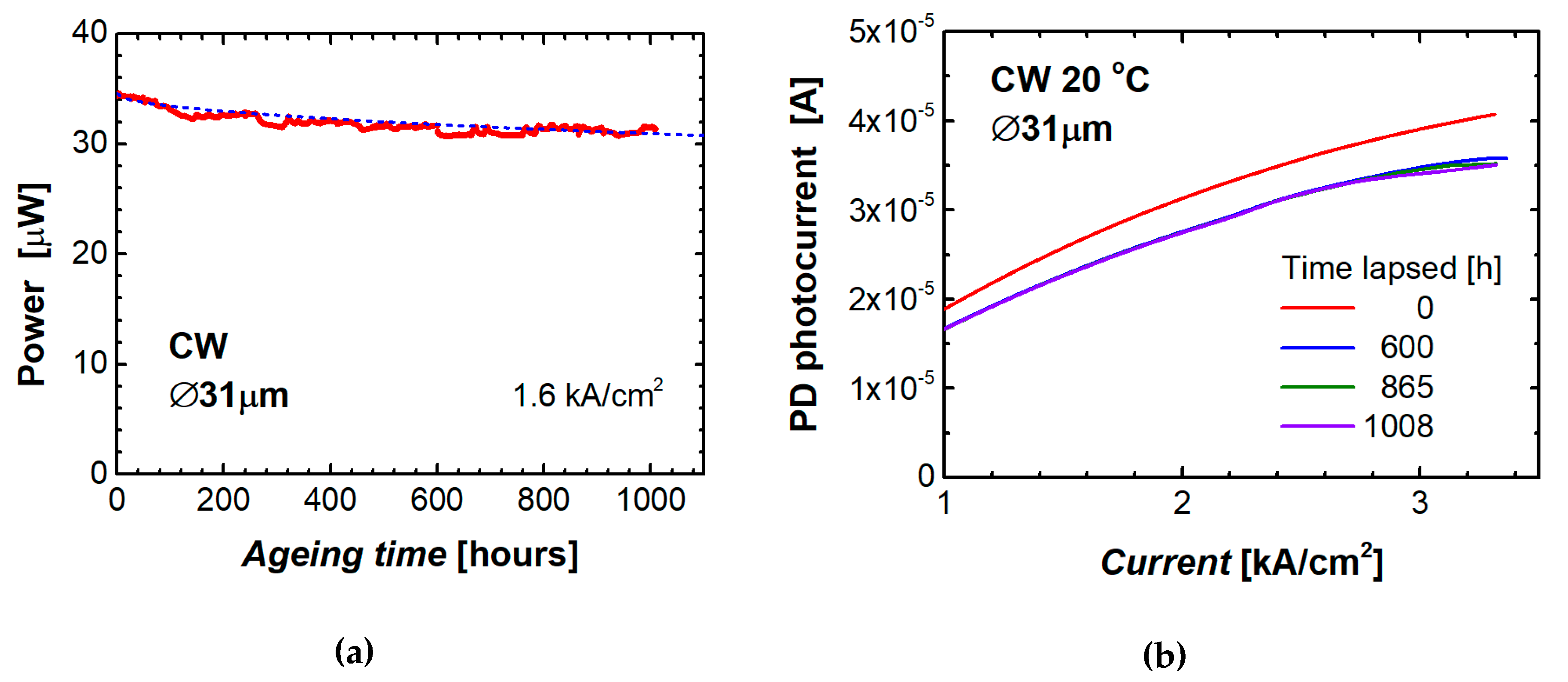

2.6. Ageing Test of Microdisk Lasers

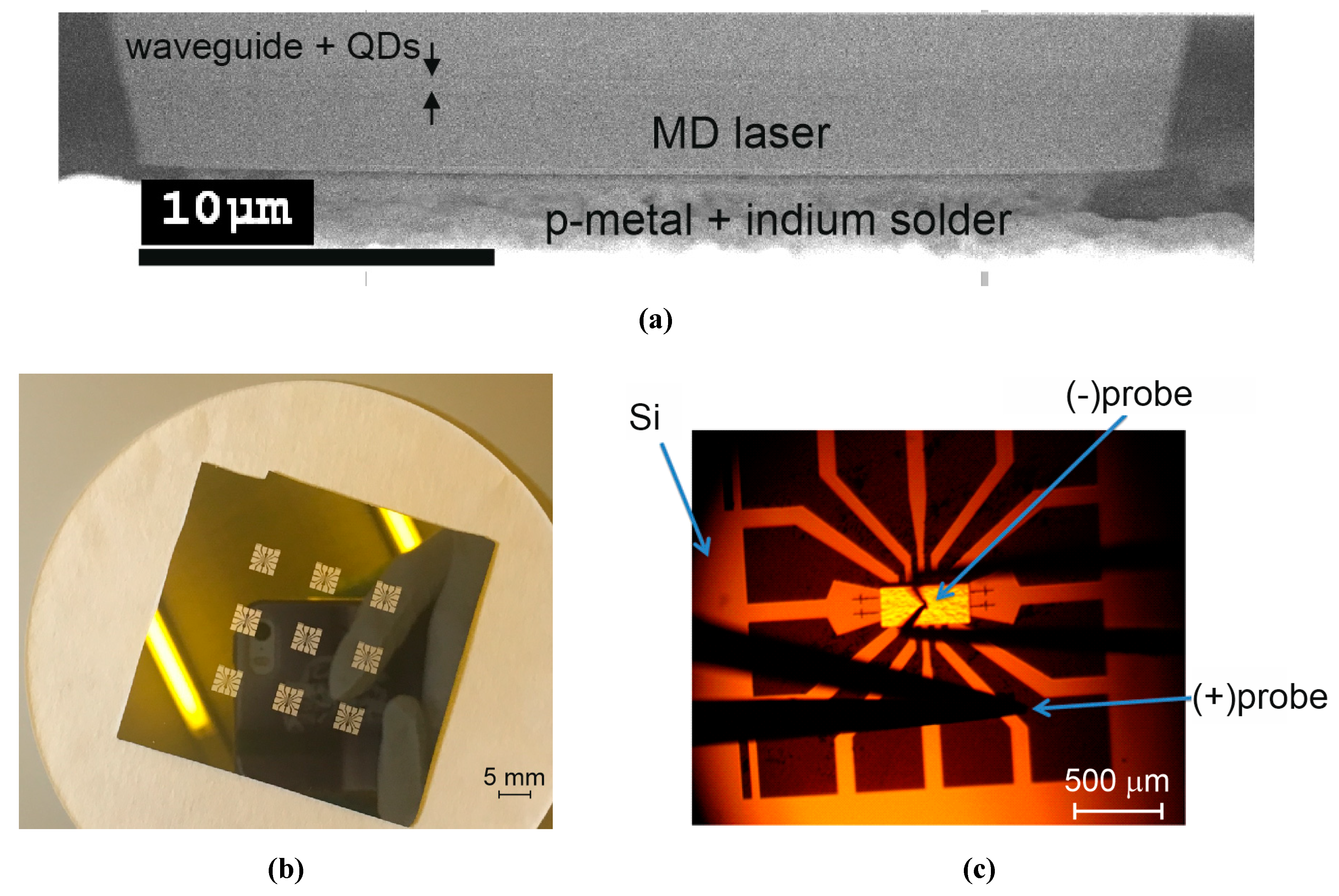

3. Quantum Dot Microdisk Lasers Transferred onto Silicon Wafer

3.1. Sample Description

3.2. Results on Hybridly Integrated Microdisks

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Srinivasan, K.; Borselli, M.; Painter, O.; Stintz, A.; Krishna, S. Cavity Q, mode volume, and lasing threshold in small diameter AlGaAs microdisks with embedded quantum dots. Opt. Express 2006, 14, 1094–1105. [Google Scholar] [CrossRef] [PubMed]

- Kryzhanovskaya, N.V.; Zhukov, A.E.; Maximov, M.V.; Moiseev, E.I.; Shostak, I.I.; Nadtochiy, A.M.; Kudashova, Y.V.; Lipovskii, A.A.; Kulagina, M.M.; Troshkov, S.I. Room temperature lasing in 1-μm microdisk quantum dot lasers. IEEE J. Sel. Top. Quantum Electron. 2015, 21, 709–713. [Google Scholar] [CrossRef]

- Watanabe, H.; Baba, T. High-efficiency photonic crystal microlaser integrated with a passive waveguide. Opt. Express 2008, 16, 2694–2698. [Google Scholar] [CrossRef] [PubMed]

- Albert, F.; Braun, T.; Heindel, T.; Schneider, C.; Reitzenstein, S.; Höfling, S.; Worschech, L.; Forchel, A. Whispering gallery mode lasing in electrically driven quantum dot micropillars. Appl. Phys. Lett. 2010, 97, 101108. [Google Scholar] [CrossRef]

- Lu, C.Y.; Chang, S.W.; Chuang, S.L.; Germann, T.D.; Bimberg, D. Metal-cavity surface-emitting microlaser at room temperature. Appl. Phys. Lett. 2010, 96, 251101–251103. [Google Scholar] [CrossRef]

- Moser, P.; Wolf, P.; Mutig, A.; Larisch, G.; Unrau, W.; Hofmann, W.; Bimberg, D. 85 °C error-free operation at 38 Gb/s of oxide-confined 980-nm vertical-cavity surface-emitting lasers. Appl. Phys. Lett. 2012, 100, 081103. [Google Scholar] [CrossRef]

- Ouyang, D.; Ledentsov, N.N.; Bimberg, D.; Kovsh, A.R.; Zhukov, A.E.; Mikhrin, S.S.; Ustinov, V.M. High performance narrow stripe quantum-dot lasers with etched waveguide. Semicond. Sci. Technol. 2003, 18, L53–L54. [Google Scholar] [CrossRef]

- Chung, H.U.; Kim, B.H.; Lee, J.Y.; Lee, J.; Xie, Z.; Ibler, E.M.; Lee, K.H.; Jeong, J.Y.; Kim, J.; Ogle, C.; et al. Binodal, wireless epidermal electronic systems with in-sensor analytics for neonatal intensive care. Science 2010, 363, eaau0780. [Google Scholar] [CrossRef]

- Ghaffari, R.; Choi, J.; Raj, M.S.; Chen, S.; Lee, S.P.; Reeder, J.T.; Aranyosi, A.J.; Leech, A.; Li, W.; Schon, S.; et al. Soft wearable systems for colorimetric and electrochemical analysis of biofluids. Adv. Funct. Mater. 2020, 30. [Google Scholar] [CrossRef]

- Jeong, Y.-C.; Lee, H.E.; Shin, A.; Kim, D.-G.; Lee, K.J.; Kim, D. Progress in brain-compatible interfaces with soft nanomaterials. Adv. Mater. 2020, 32. [Google Scholar] [CrossRef]

- Liu, A.Y.; Zhang, C.; Norman, J.; Snyder, A.; Lubyshev, D.; Fastenau, J.M.; Liu, A.W.K.; Gossard, A.C.; Bowers, J.E. High performance continuous wave 1.3 μm quantum dot lasers on silicon. Appl. Phys. Lett. 2014, 104, 041104. [Google Scholar] [CrossRef]

- Chen, S.; Li, W.; Wu, J.; Jiang, Q.; Tang, M.; Shutts, S.; Elliott, S.N.; Sobiesierski, A.; Seeds, A.J.; Ross, I.; et al. Electrically pumped continuous-wave III–V quantum dot lasers on silicon. Nat. Photonics 2016, 10, 307–311. [Google Scholar] [CrossRef]

- Wan, Y.; Norman, J.; Li, Q.; Kennedy, M.J.; Liang, D.; Zhang, C.; Huang, D.; Zhang, Z.; Liu, A.Y.; Torres, A.; et al. 1.3 μm submilliamp threshold quantum dot micro-lasers on Si. Optica 2017, 4, 940–944. [Google Scholar] [CrossRef]

- Kryzhanovskaya, N.; Moiseev, E.; Polubavkina, Y.; Maximov, M.; Kulagina, M.; Troshkov, S.; Zadiranov, Y.; Guseva, Y.; Lipovskii, A.; Tang, M.; et al. Heatsink-free CW operation of injection microdisk lasers grown on Si substrate with emission wavelength beyond 1.3 µm. Opt. Lett. 2017, 42, 3319–3322. [Google Scholar] [CrossRef] [PubMed]

- Wan, Y.; Jung, D.; Norman, J.; Shang, C.; Macfarlane, I.; Li, Q.; Kennedy, M.J.; Gossard, A.C.; Lau, L.M.; Bowers, J.E. O-band electrically injected quantum dot micro-ring lasers on on-axis (001) GaP/Si and V-groove Si. Opt. Express 2017, 25, 26853–26860. [Google Scholar] [CrossRef] [PubMed]

- Wan, Y.; Inoue, D.; Jung, D.; Norman, J.C.; Shang, C.; Gossard, A.C.; Bowers, J.E. Directly modulated quantum dot lasers on silicon with a milliampere threshold and high temperature stability. Photonics Res. 2018, 6, 776–781. [Google Scholar] [CrossRef]

- Coldren, L.A.; Corzine, S.W.; Masanovic, M.L. Diode Lasers and Photonic Integrated Circuits, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2012; pp. 247–275. [Google Scholar]

- McCall, S.L.; Levi, A.F.J.; Slusher, R.E.; Pearton, S.J.; Logan, R.A. Whispering gallery mode microdisk lasers. Appl. Phys. Lett. 1992, 60, 289–291. [Google Scholar] [CrossRef]

- Liu, A.Y.; Herrick, R.W.; Ueda, O.; Petroff, P.M.; Gossard, A.C.; Bowers, J.E. Reliability of InAs/GaAs quantum dot lasers epitaxially grown on silicon. IEEE J. Sel. Top. Quantum Electron. 2015, 21, 1900708. [Google Scholar] [CrossRef]

- Krestnikov, I.; Livshits, D.; Mikhrin, S.; Kozhukhov, A.; Kovsh, A.; Ledentsov, N.; Zhukov, A. Reliability study of InAs/InGaAs quantum-dot diode lasers. Electron. Lett. 2005, 41, 1330–1331. [Google Scholar] [CrossRef]

- Ohlsson, B.J.; Malm, J.-O.; Gustafsson, A.; Samuelson, L. Anti-domain-free GaP, grown in atomically flat (001) Si sub-µm-sized openings. Appl. Phys. Lett. 2002, 80, 4546–4548. [Google Scholar] [CrossRef]

- McCaulley, J.A.; Donnelly, V.M.; Vernon, M.; Taha, I. Temperature dependence of the near-infrared refractive index of silicon, gallium arsenide, and indium phosphide. Phys. Rev. B 1994, 49, 7408–7417. [Google Scholar] [CrossRef] [PubMed]

- Mandorlo, F.; Rojo-Romeo, P.; Ferrier, L. Full CMOS compatible III-V microdisk tunable CW lasers for on chip optical interconnects. In Proceedings of the 1st International Symposium on Access Spaces (IEEE-ISAS), Yokohama, Japan, 17–19 June 2011; pp. 299–303. [Google Scholar]

- Tanabe, K.; Watanabe, K.; Arakawa, Y. III-V/Si hybrid photonic devices by direct fusion bonding. Sci. Rep. 2012, 2, 349. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Liang, D.; Kurczveil, G.; Bowers, J.E.; Beausoleil, R.G. Thermal management of hybrid silicon ring lasers for high temperature operation. IEEE J. Sel. Top. Quantum Electron. 2015, 21, 1502607. [Google Scholar] [CrossRef]

- Moiseev, E.I.; Kryzhanovskaya, N.V.; Nadtochiy, A.M.; Maximov, M.V.; Zhukov, A.E.; Shostak, I.I.; Kulagina, M.M.; Savelyev, A.V.; Vashanova, K.A.; Lipovskii, A.A. Lasing in microdisc resonators with InAs/InGaAs quantum dots transferred on a silicon substrate. J. Phys. Conf. Ser. 2014, 541, 012049. [Google Scholar] [CrossRef]

- Zou, L.-X.; Huang, Y.-Z.; Liu, B.-W.; Lv, X.-M.; Ma, X.-W.; Yang, Y.-D.; Xiao, J.-L.; Du, Y. Thermal and high speed modulation characteristics for AlGaInAs/InP microdisk lasers. Opt. Express 2015, 23, 2879–2888. [Google Scholar] [CrossRef] [PubMed]

- Kryzhanovskaya, N.V.; Moiseev, E.I.; Kudashova, Y.V.; Zubov, F.I.; Lipovskii, A.A.; Kulagina, M.M.; Troshkov, S.I.; Zadiranov, Y.M.; Livshits, D.A.; Maximov, M.V.; et al. Continuous-wave lasing at 100 °C in 1.3 µm quantum dot microdisk diode laser. Electron. Lett. 2015, 51, 1354–1355. [Google Scholar] [CrossRef]

- Tang, M.; Chen, S.; Wu, J.; Jiang, Q.; Kennedy, K.; Jurczak, P.; Liao, M.; Beanland, R.; Seeds, A.J.; Liu, H. Optimizations of defect filter layers for 1.3-μm InAs/GaAs quantum-dot lasers monolithically grown on Si substrates. IEEE J. Sel. Top. Quantum Electron. 2016, 22, 1900207. [Google Scholar] [CrossRef]

- Chen, S.M.; Tang, M.C.; Wu, J.; Jiang, Q.; Dorogan, V.G.; Benamara, M.; Mazur, Y.I.; Salamo, G.J.; Seeds, A.J.; Liu, H. 1.3 μm InAs/GaAs quantum-dot laser monolithically grown on Si substrates operating over 100 °C. Electron. Lett. 2014, 50, 1467–1468. [Google Scholar] [CrossRef]

- Liu, H.Y.; Sellers, I.R.; Badcock, T.J.; Mowbray, D.J.; Skolnick, M.S.; Groom, K.M.; Gutiérrez, M.; Hopkinson, M.; Ng, J.S.; David, J.P.R.; et al. Improved performance of 1.3 μm multilayer InAs quantum-dot lasers using a high-growth-temperature GaAs spacer layer. Appl. Phys. Lett. 2004, 85, 704–706. [Google Scholar] [CrossRef]

- Ustinov, V.M.; Maleev, N.A.; Zhukov, A.E.; Kovsh, A.R.; Egorov, A.Y.; Lunev, A.V.; Volovik, B.V.; Krestnikov, I.L.; Musikhin, Y.G.; Bert, N.A.; et al. InAs/InGaAs quantum dot structures on GaAs substrates emitting at 1.3 μm. Appl. Phys. Lett. 1999, 74, 2815–2817. [Google Scholar] [CrossRef]

- Moiseev, E.; Kryzhanovskaya, N.; Maximov, M.; Zubov, F.; Nadtochiy, A.; Kulagina, M.; Zadiranov, Y.; Kalyuzhnyy, N.; Mintairov, S.; Zhukov, A. Highly efficient injection microdisk lasers based on quantum well-dots. Opt. Lett. 2018, 43, 4554–4557. [Google Scholar] [CrossRef] [PubMed]

- Moiseev, E.I.; Kryzhanovskaya, N.V.; Zubov, F.I.; Mikhailovskii, M.S.; Abramov, A.N.; Maximov, M.V.; Kulagina, M.M.; Guseva, Y.A.; Livshits, D.A.; Zhukov, A.E. Record low threshold current density in quantum dot microdisk laser. Semiconductors 2019, 53, 1888–1890. [Google Scholar] [CrossRef]

- Kryzhanovskaya, N.V.; Maximov, M.V.; Blokhin, S.A.; Bobrov, M.A.; Kulagina, M.M.; Troshkov, S.I.; Zadiranov, Y.M.; Lipovskii, A.A.; Moiseev, E.I.; Kudashova, Y.V.; et al. Microdisk injection lasers for the 1.27-μm spectral range. Semiconductors 2016, 50, 390–393. [Google Scholar] [CrossRef]

- Huang, J.S. Temperature and current dependences of reliability degradation of buried heterostructure semiconductor lasers. IEEE Trans. Device Mater. Rel. 2005, 5, 150–154. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhukov, A.E.; Kryzhanovskaya, N.V.; Moiseev, E.I.; Dragunova, A.S.; Tang, M.; Chen, S.; Liu, H.; Kulagina, M.M.; Kadinskaya, S.A.; Zubov, F.I.; et al. InAs/GaAs Quantum Dot Microlasers Formed on Silicon Using Monolithic and Hybrid Integration Methods. Materials 2020, 13, 2315. https://doi.org/10.3390/ma13102315

Zhukov AE, Kryzhanovskaya NV, Moiseev EI, Dragunova AS, Tang M, Chen S, Liu H, Kulagina MM, Kadinskaya SA, Zubov FI, et al. InAs/GaAs Quantum Dot Microlasers Formed on Silicon Using Monolithic and Hybrid Integration Methods. Materials. 2020; 13(10):2315. https://doi.org/10.3390/ma13102315

Chicago/Turabian StyleZhukov, Alexey E., Natalia V. Kryzhanovskaya, Eduard I. Moiseev, Anna S. Dragunova, Mingchu Tang, Siming Chen, Huiyun Liu, Marina M. Kulagina, Svetlana A. Kadinskaya, Fedor I. Zubov, and et al. 2020. "InAs/GaAs Quantum Dot Microlasers Formed on Silicon Using Monolithic and Hybrid Integration Methods" Materials 13, no. 10: 2315. https://doi.org/10.3390/ma13102315

APA StyleZhukov, A. E., Kryzhanovskaya, N. V., Moiseev, E. I., Dragunova, A. S., Tang, M., Chen, S., Liu, H., Kulagina, M. M., Kadinskaya, S. A., Zubov, F. I., Mozharov, A. M., & Maximov, M. V. (2020). InAs/GaAs Quantum Dot Microlasers Formed on Silicon Using Monolithic and Hybrid Integration Methods. Materials, 13(10), 2315. https://doi.org/10.3390/ma13102315