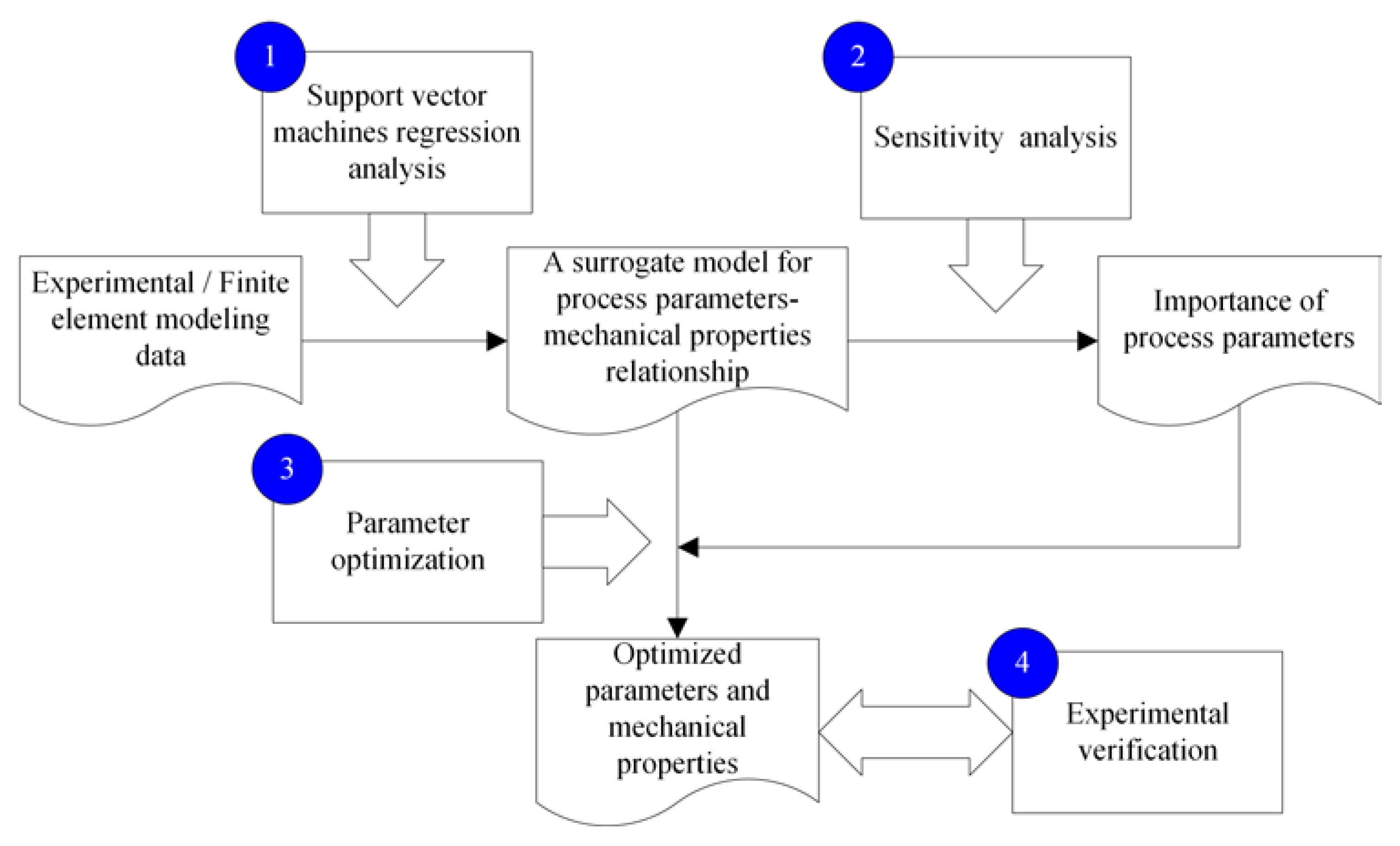

A Sensitivity Analysis-Based Parameter Optimization Framework for 3D Printing of Continuous Carbon Fiber/Epoxy Composites

Abstract

:1. Introduction

2. Experimental Setup and Data Validation

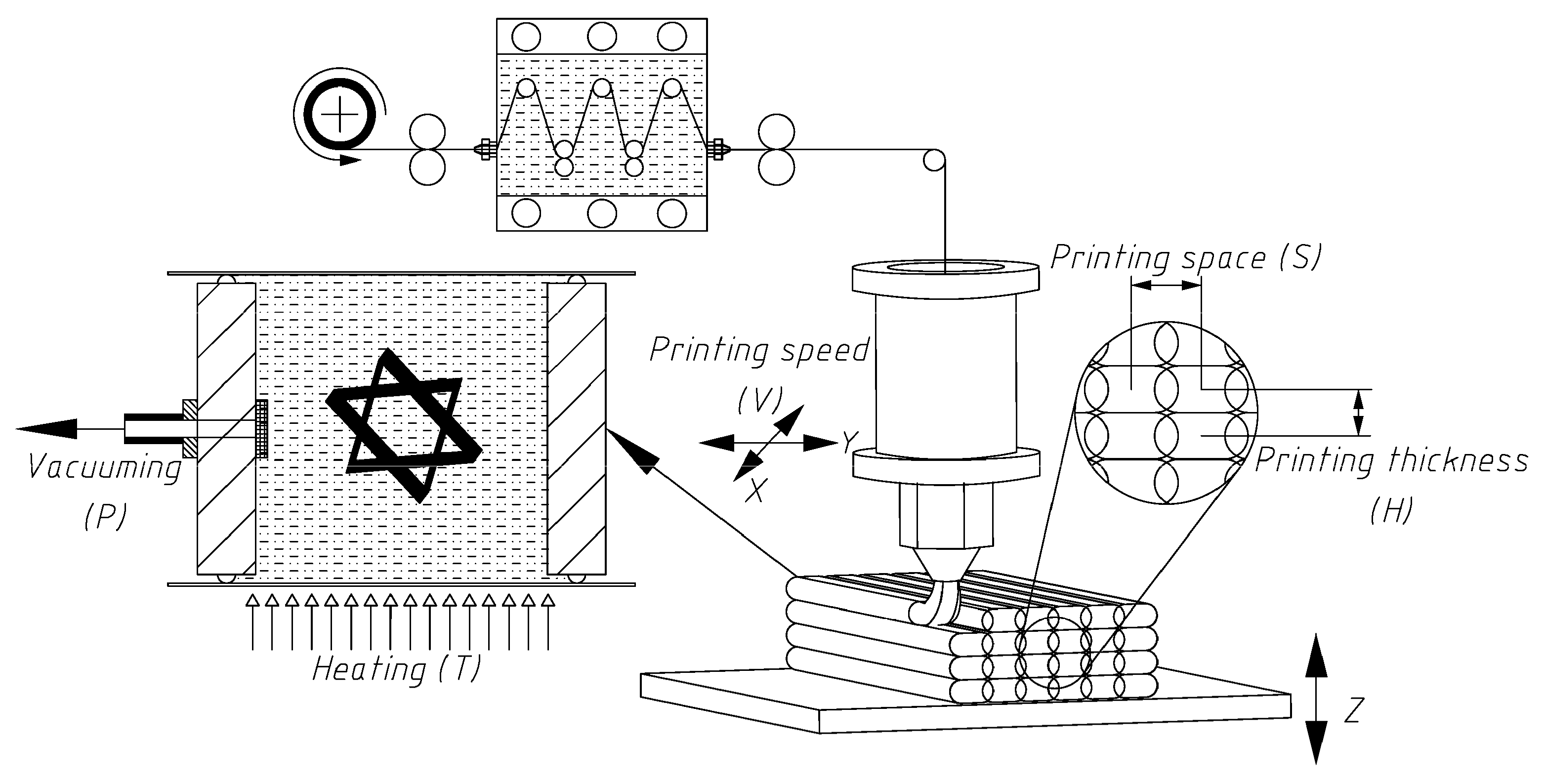

2.1. Experimental Setup

2.1.1. Raw Materials for 3D Printing

2.1.2. 3D Printing Process and Mechanical Property Test

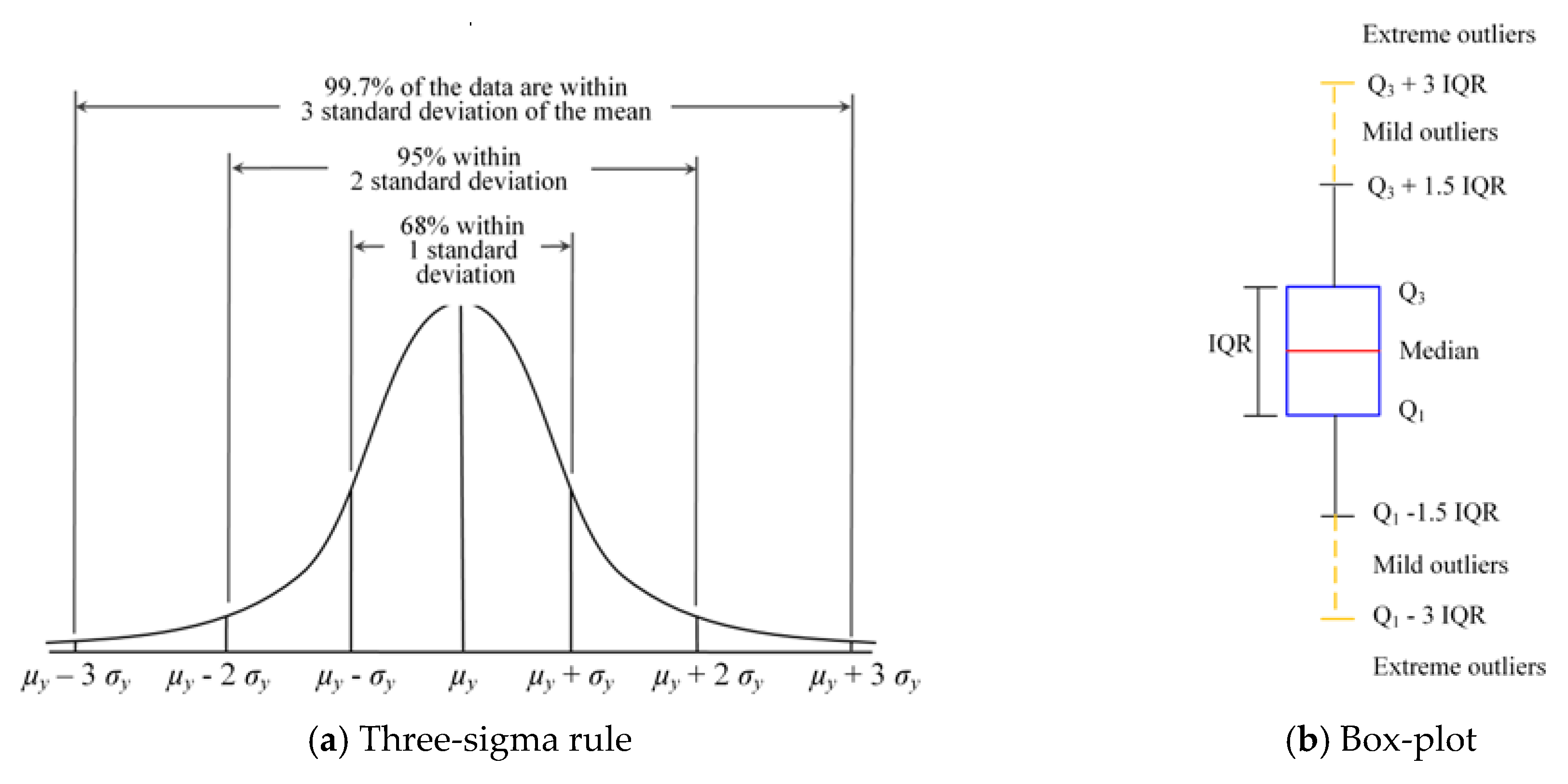

2.2. Experimental Data Validation

2.2.1. Three-Sigma Rule

2.2.2. Box-Plot

3. Regression Analysis for a Surrogate Model of a Process Parameter–Mechanical Property Relationship

- Step 1: Randomly divide the experimental and the corresponding predicted data into k groups;

- Step 2: Leave one group of the data for the validation of the surrogate model accuracy, and train the surrogate model with the data of the remaining k − 1 groups;

- Step 3: Repeatedly perform Step 2 k times until each group of the data has been used for model validation. Choose the model with the minimum RSME as the final model. The final accuracy of the surrogate model is measured by the mean of all the RSME of the k-trained surrogate model.

4. Sensitivity Analysis of the Process Parameters

5. Optimization of the 3D Printing Parameters of CCF/EPCs

6. Results and Discussion

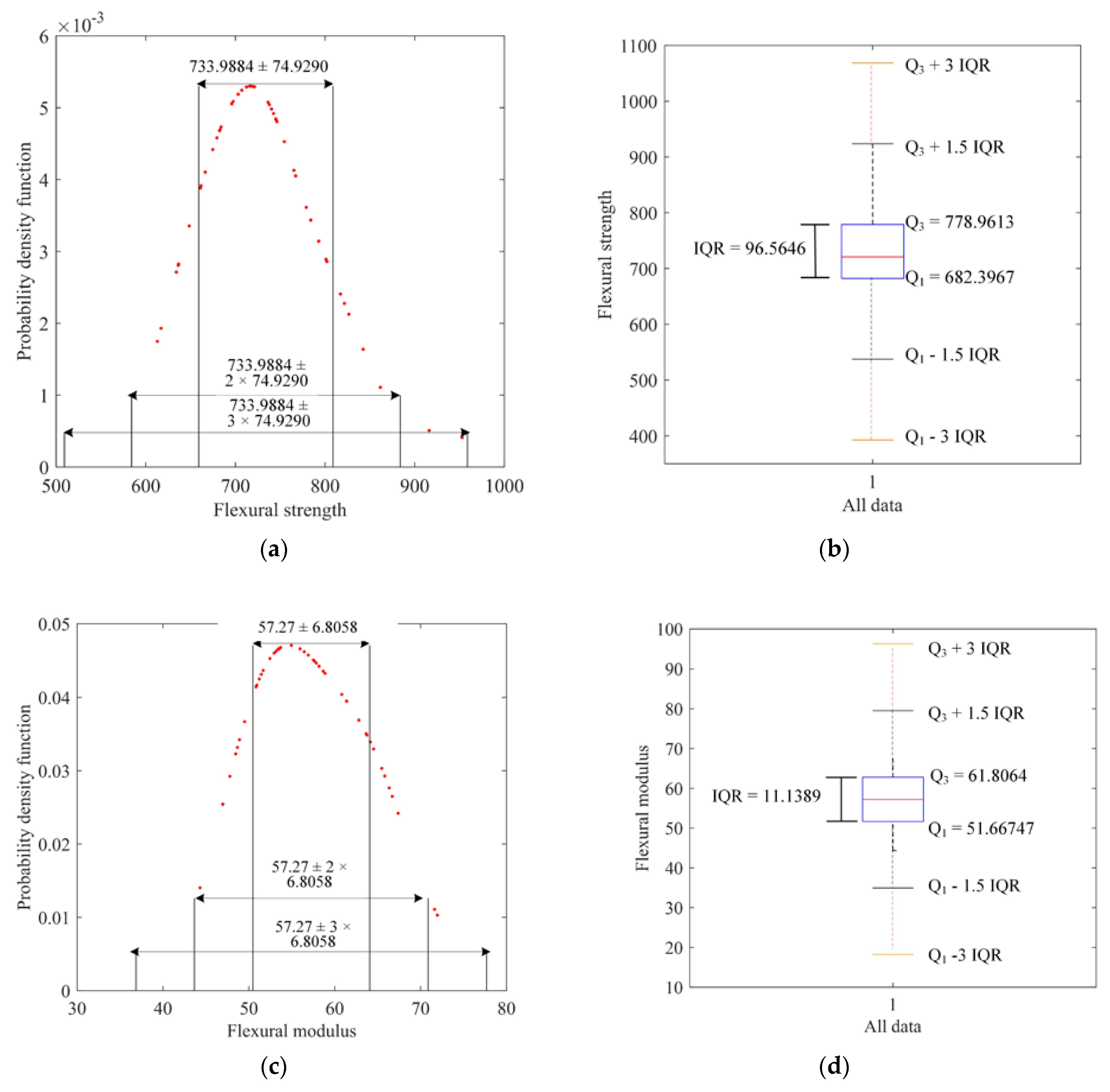

6.1. Experimental Data Validation

6.2. Construction of the SVR Surrogate Model

6.3. SVR Model-Based SA of the 3D Printing Parameters of CCF/EPCs

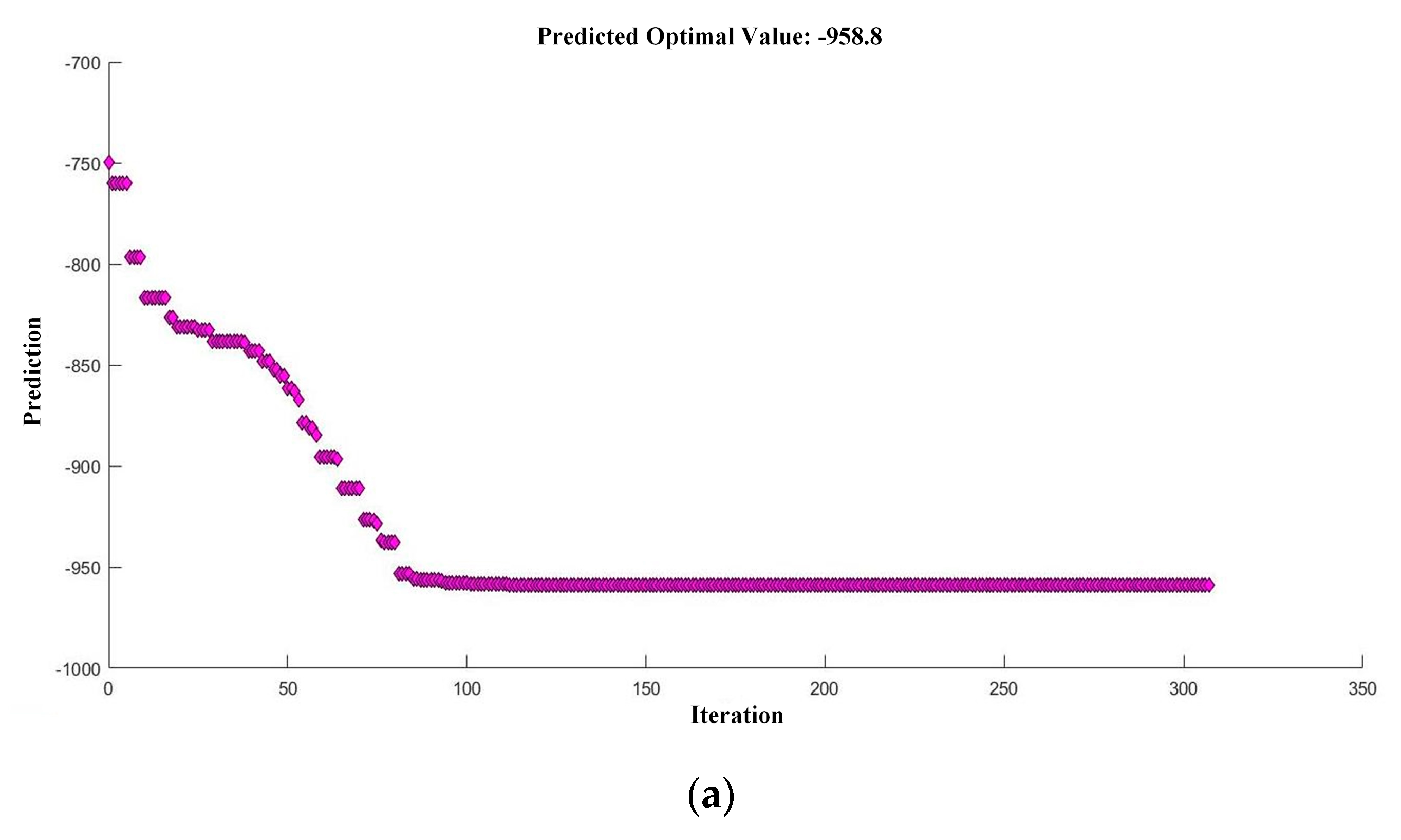

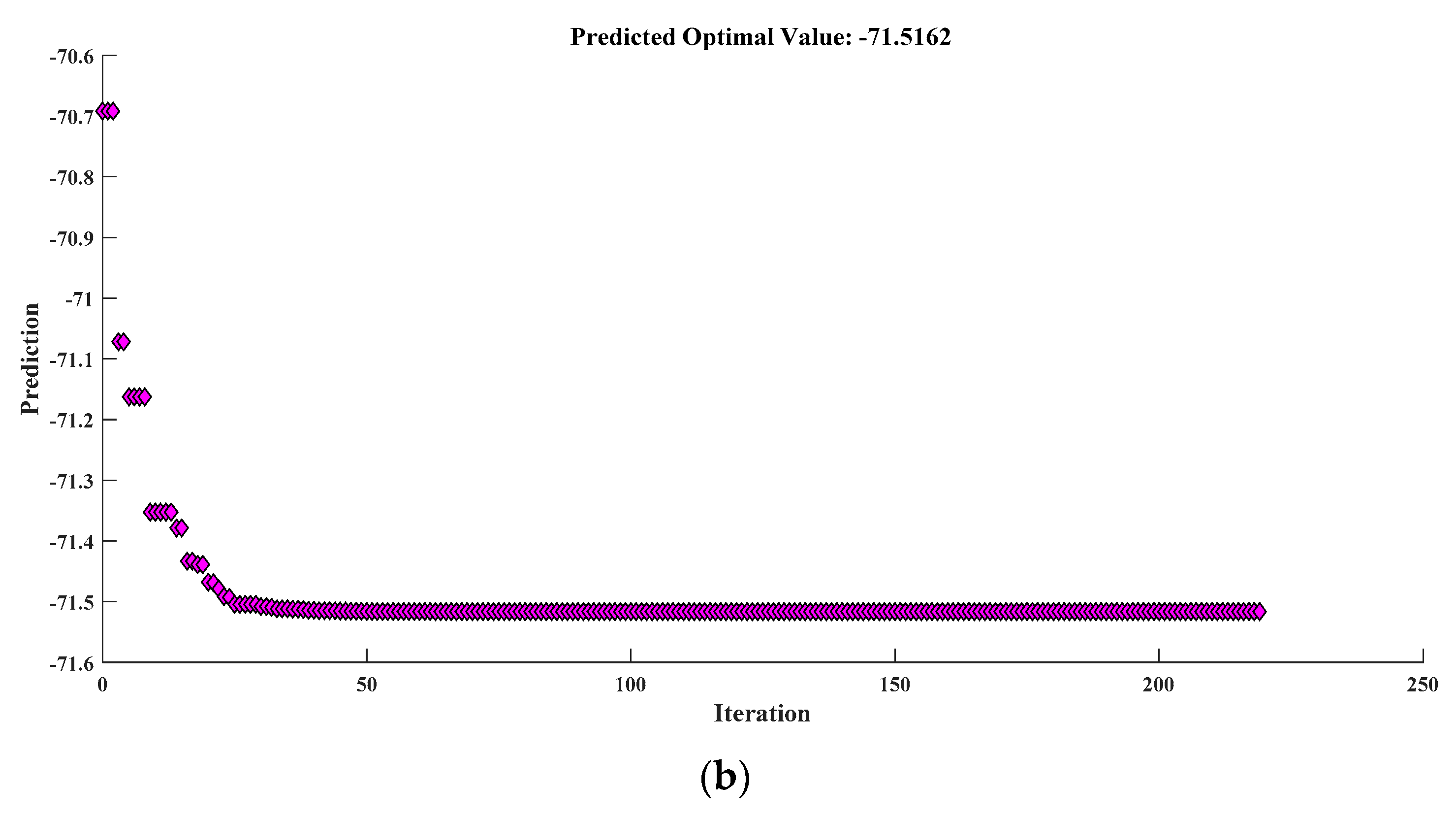

6.4. 3D Printing Parameter Optimization of CCF/EPCs

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Bakis, C.E.; Bank, L.C.; Brown, V.; Cosenza, E.; Davalos, J.; Lesko, J.; Machida, A.; Rizkalla, S.; Triantafillou, T. Fiber-reinforced polymer composites for construction—State-of-the-art review. J. Compos. Constr. 2002, 6, 73–87. [Google Scholar] [CrossRef]

- Mallick, P.K. Fiber-Reinforced Composites: Materials, Manufacturing, and Design; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Peters, S.T.; Humphrey, W.D.; Foral, R.F. Filament Winding-Composite Structure Fabrication; SAMPE International Business Office: Diamond Bar, CA, USA, 1991. [Google Scholar]

- Rouison, D.; Sain, M.; Couturier, M. Resin transfer molding of natural fiber reinforced composites: Cure simulation. Compos. Sci. Technol. 2004, 64, 629–644. [Google Scholar] [CrossRef]

- Compton, B.G.; Lewis, J.A. 3D-printing of lightweight cellular composites. Adv. Mater. 2014, 26, 5930–5935. [Google Scholar] [CrossRef] [PubMed]

- Lipson, H.; Kurman, M. Fabricated: The New World of 3D Printing; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Dawoud, M.; Taha, I.; Ebeid, S.J. Mechanical behaviour of ABS: An experimental study using FDM and injection moulding techniques. J. Manuf. Process. 2016, 21, 39–45. [Google Scholar] [CrossRef]

- Brenken, B.; Barocio, E.; Favaloro, A.; Kunc, V.; Pipes, R.B. Fused filament fabrication of fiber-reinforced polymers: A review. Addit. Manuf. 2018, 21, 1–16. [Google Scholar] [CrossRef]

- Blok, L.G.; Longana, M.L.; Yu, H.; Woods, B.K.S. An investigation into 3D printing of fibre reinforced thermoplastic composites. Addit. Manuf. 2018, 22, 176–186. [Google Scholar] [CrossRef]

- Goh, G.D.; Yap, Y.L.; Agarwala, S.; Yeong, W.Y. Recent Progress in Additive Manufacturing of Fiber Reinforced Polymer Composite. Adv. Mater. Technol. 2019, 4, 1800271. [Google Scholar] [CrossRef]

- Yang, C.; Tian, X.; Liu, T.; Cao, Y.; Li, D. 3D printing for continuous fiber reinforced thermoplastic composites: Mechanism and performance. Rapid Prototyp. J. 2017, 23, 209–215. [Google Scholar] [CrossRef]

- Dickson, A.N.; Barry, J.N.; McDonnell, K.A.; Dowling, D.P. Fabrication of continuous carbon, glass and Kevlar fibre reinforced polymer composites using additive manufacturing. Addit. Manuf. 2017, 16, 146–152. [Google Scholar] [CrossRef]

- Ming, Y.; Duan, Y.; Wang, B.; Xiao, H.; Zhang, X. A Novel Route to Fabricate High-Performance 3D Printed Continuous Fiber-Reinforced Thermosetting Polymer Composites. Materials 2019, 12, 1369. [Google Scholar] [CrossRef]

- Zhong, W.; Fan, L.; Zhang, Z.; Song, L.; Li, Z. Short fiber reinforced composites for fused deposition modeling. Mater. Sci. Eng. A 2001, 301, 125–130. [Google Scholar] [CrossRef]

- Tekinalp, H.L.; Kunc, V.; Velez-Garcia, G.M.; Duty, C.E.; Love, L.J.; Naskar, A.K.; Blue, C.A.; Ozcan, S.; Tekinalp, H.L.; Duty, C.E. Highly oriented carbon fiber–polymer composites via additive manufacturing. Compos. Sci. Technol. 2014, 105, 144–150. [Google Scholar] [CrossRef]

- Ning, F.; Cong, W.; Qiu, J.; Wei, J.; Wang, S. Additive manufacturing of carbon fiber reinforced thermoplastic composites using fused deposition modeling. Compos. Part B Eng. 2015, 80, 369–378. [Google Scholar] [CrossRef]

- Der Klift, F.V.; Koga, Y.; Todoroki, A.; Ueda, M.; Hirano, Y.; Matsuzaki, R. 3D Printing of Continuous Carbon Fibre Reinforced Thermo-Plastic (CFRTP) Tensile Test Specimens. Open J. Compos. Mater. 2016, 6, 18–27. [Google Scholar] [CrossRef]

- Justo, J.; Távara, L.; García-Guzmán, L.; París, F. Characterization of 3D printed long fibre reinforced composites. Compos. Struct. 2018, 185, 537–548. [Google Scholar] [CrossRef]

- Matsuzaki, R.; Ueda, M.; Namiki, M.; Jeong, T.K.; Asahara, H.; Horiguchi, K.; Nakamura, T.; Todoroki, A.; Hirano, Y. Three-dimensional printing of continuous-fiber composites by in-nozzle impregnation. Sci. Rep. 2016, 6, 23058. [Google Scholar] [CrossRef]

- Tian, X.; Liu, T.; Yang, C.; Wang, Q.; Li, D. Interface and performance of 3D printed continuous carbon fiber reinforced PLA composites. Compos. Part A Appl. Sci. Manuf. 2016, 88, 198–205. [Google Scholar] [CrossRef]

- Hao, W.; Liu, Y.; Zhou, H.; Chen, H.; Fang, D. Preparation and characterization of 3D printed continuous carbon fiber reinforced thermosetting composites. Polym. Test. 2018, 65, 29–34. [Google Scholar] [CrossRef]

- Mohan, N.; Senthil, P.; Vinodh, S.; Jayanth, N. A review on composite materials and process parameters optimisation for the fused deposition modelling process. Virtual Phys. Prototyp. 2017, 12, 47–59. [Google Scholar] [CrossRef]

- Crosetto, M.; Tarantola, S. Uncertainty and sensitivity analysis: Tools for GIS-based model implementation. Int. J. Geogr. Inf. Sci. 2001, 15, 415–437. [Google Scholar] [CrossRef]

- Lurette, A.; Touzeau, S.; Lamboni, M.; Monod, H. Sensitivity analysis to identify key parameters influencing Salmonella infection dynamics in a pig batch. J. Theor. Biol. 2009, 258, 43–52. [Google Scholar] [CrossRef] [PubMed]

- Makowski, D.; Naud, C.; Jeuffroy, M.-H.; Barbottin, A.; Monod, H. Global sensitivity analysis for calculating the contribution of genetic parameters to the variance of crop model prediction. Reliab. Eng. Syst. Saf. 2006, 91, 1142–1147. [Google Scholar] [CrossRef]

- Saltelli, A.; Ratto, M.; Tarantola, S.; Campolongo, F. Sensitivity analysis for chemical models. Chem. Rev. 2005, 105, 2811–2828. [Google Scholar] [CrossRef] [PubMed]

- Kiébré, R.; Anstett-Collin, F.; Basset, M. Sensitivity analysis for the study of influential parameters in tyre models. Int. J. Veh. Syst. Model. Test. 2011, 1–19. [Google Scholar]

- Campolongo, F.; Saltelli, A. Sensitivity analysis of an environmental model: An application of different analysis methods. Reliab. Eng. Syst. Saf. 1997, 57, 49–69. [Google Scholar] [CrossRef]

- Ruan, D.; Chen, G.; Kerre, E.E.; Wets, G. Intelligent Data Mining: Techniques and Applications; Springer Science & Business Media: Berlin, Germany, 2005; Volume 5. [Google Scholar]

- Tukey, J.W. Exploratory data analysis. Methods 1977, 2, 131–160. [Google Scholar]

- Basudhar, A.; Dribusch, C.; Lacaze, S.; Missoum, S. Constrained efficient global optimization with support vector machines. Struct. Multidiscip. Optim. 2012, 46, 201–221. [Google Scholar] [CrossRef]

- Smola, A.J.; Scholkopf, B. A tutorial on support vector regression. Stat. Comput. 2004, 14, 199–222. [Google Scholar] [CrossRef]

- Ma, J.; Theiler, J.; Perkins, S. Accurate On-line Support Vector Regression. Neural Comput. 2003, 15, 2683–2703. [Google Scholar] [CrossRef]

- Rodriguez, J.D.; Perez, A.; Lozano, J.A. Sensitivity analysis of k-fold cross validation in prediction error estimation. IEEE Trans. Pattern Anal. Mach. Intell. 2009, 32, 569–575. [Google Scholar] [CrossRef]

- Haaker, M.; Verheijen, P. Local and global sensitivity analysis for a reactor design with parameter uncertainty. Chem. Eng. Res. Des. 2004, 82, 591–598. [Google Scholar] [CrossRef]

- Sobol, I.M. Global sensitivity indices for nonlinear mathematical models and their Monte Carlo estimates. Math. Comput. Simul. 2001, 55, 271–280. [Google Scholar] [CrossRef]

- Saltelli, A.; Tarantola, S.; Campolongo, F.; Ratto, M. Sensitivity Analysis in Practice: A Guide to Assessing Scientific Models; John Wiley & Sons: Chichester, UK, 2004. [Google Scholar]

| Process Parameters | Values |

|---|---|

| Printing speed (mm·min−1) | 200~1400 |

| Printing space (mm) | 1.0~1.4 |

| Printing thickness (mm) | 0.25~0.45 |

| Curing temperature (°C) | 150~190 |

| Curing pressure (MPa) | −0.02~−0.1 |

| # | Printing Speed (mm·min−1) | Printing Space (mm) | Printing Thickness (mm) | Curing Temperature (°C) | Curing Pressure (MPa) | Flexural Strength (MPa) | Flexural Modulus (GPa) |

|---|---|---|---|---|---|---|---|

| 1 | 200 | 1.0 | 0.25 | 150 | −0.02 | 660.8699 | 57.5127 |

| 2 | 200 | 1.1 | 0.30 | 160 | −0.04 | 717.4586 | 61.3590 |

| 3 | 200 | 1.2 | 0.35 | 170 | −0.06 | 801.9369 | 65.4731 |

| 4 | 200 | 1.3 | 0.40 | 180 | −0.08 | 767.1566 | 58.6598 |

| 5 | 200 | 1.4 | 0.45 | 190 | −0.10 | 666.3564 | 54.9489 |

| 6 | 500 | 1.1 | 0.25 | 170 | −0.08 | 861.6027 | 71.6292 |

| 7 | 500 | 1.2 | 0.30 | 180 | −0.10 | 712.3392 | 58.8811 |

| 8 | 500 | 1.3 | 0.35 | 190 | −0.02 | 695.9950 | 65.8205 |

| 9 | 500 | 1.4 | 0.40 | 150 | −0.04 | 740.2541 | 57.6429 |

| 10 | 500 | 1.0 | 0.45 | 160 | −0.06 | 842.4707 | 67.3847 |

| 11 | 800 | 1.2 | 0.25 | 190 | −0.04 | 616.9910 | 44.3187 |

| 12 | 800 | 1.3 | 0.30 | 150 | −0.06 | 636.2180 | 48.6564 |

| 13 | 800 | 1.4 | 0.35 | 160 | −0.08 | 792.8516 | 63.6566 |

| 14 | 800 | 1.0 | 0.40 | 170 | −0.10 | 697.4975 | 57.5773 |

| 15 | 800 | 1.1 | 0.45 | 180 | −0.02 | 674.6801 | 53.1469 |

| 16 | 1100 | 1.3 | 0.25 | 160 | −0.10 | 682.3967 | 51.4495 |

| 17 | 1100 | 1.4 | 0.30 | 170 | −0.02 | 636.5848 | 48.9007 |

| 18 | 1100 | 1.0 | 0.35 | 180 | −0.04 | 679.3136 | 50.8338 |

| 19 | 1100 | 1.1 | 0.40 | 190 | −0.06 | 783.9741 | 60.8011 |

| 20 | 1100 | 1.2 | 0.45 | 150 | −0.08 | 817.1150 | 66.3398 |

| 21 | 1400 | 1.4 | 0.25 | 180 | −0.06 | 778.9613 | 63.7432 |

| 22 | 1400 | 1.0 | 0.30 | 190 | −0.08 | 721.1591 | 57.8544 |

| 23 | 1400 | 1.1 | 0.35 | 150 | −0.10 | 702.9702 | 53.3820 |

| 24 | 1400 | 1.2 | 0.40 | 160 | −0.02 | 707.0509 | 53.7000 |

| 25 | 1400 | 1.3 | 0.45 | 170 | −0.04 | 745.8622 | 52.9382 |

| 26 | 200 | 1.2 | 0.35 | 150 | −0.10 | 765.1427 | 53.63408 |

| 27 | 500 | 1.2 | 0.35 | 150 | −0.10 | 736.4206 | 53.44402 |

| 28 | 800 | 1.2 | 0.35 | 150 | −0.10 | 746.3091 | 56.4504 |

| 29 | 1100 | 1.2 | 0.35 | 150 | −0.10 | 682.7215 | 51.20623 |

| 30 | 1400 | 1.2 | 0.35 | 150 | −0.10 | 634.1206 | 46.95916 |

| 31 | 800 | 1.2 | 0.25 | 150 | −0.10 | 612.8753 | 50.9161 |

| 32 | 800 | 1.2 | 0.30 | 150 | −0.10 | 715.8942 | 56.92083 |

| 33 | 800 | 1.2 | 0.40 | 150 | −0.10 | 737.8536 | 52.44632 |

| 34 | 800 | 1.2 | 0.45 | 150 | −0.10 | 742.5152 | 55.96409 |

| 35 | 800 | 1.0 | 0.35 | 150 | −0.10 | 661.6145 | 49.49135 |

| 36 | 800 | 1.1 | 0.35 | 150 | −0.10 | 683.9867 | 48.4565 |

| 37 | 800 | 1.3 | 0.35 | 150 | −0.10 | 745.0633 | 58.17614 |

| 38 | 800 | 1.4 | 0.35 | 150 | −0.10 | 821.5221 | 64.13514 |

| 39 | 800 | 1.2 | 0.35 | 150 | −0.08 | 826.4611 | 64.51862 |

| 40 | 800 | 1.2 | 0.35 | 150 | −0.06 | 800.9212 | 62.79963 |

| 41 | 800 | 1.2 | 0.35 | 150 | −0.04 | 717.5753 | 62.80635 |

| 42 | 800 | 1.2 | 0.35 | 150 | −0.02 | 648.4216 | 47.78122 |

| 43 | 800 | 1.2 | 0.35 | 160 | −0.10 | 916.0076 | 66.69733 |

| 44 | 800 | 1.2 | 0.35 | 170 | −0.10 | 952.8868 | 71.95371 |

| 45 | 800 | 1.2 | 0.35 | 180 | −0.10 | 754.4841 | 61.38528 |

| 46 | 800 | 1.2 | 0.35 | 190 | −0.10 | 720.601 | 51.66744 |

| # | Flexural Strength (MPa) | Flexural Modulus (GPa) |

|---|---|---|

| 1 | 897.33 | 69.20 |

| 2 | 886.15 | 66.70 |

| 3 | 952.89 | 71.95 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, H.; Han, W.; Ming, Y.; Ding, Z.; Duan, Y. A Sensitivity Analysis-Based Parameter Optimization Framework for 3D Printing of Continuous Carbon Fiber/Epoxy Composites. Materials 2019, 12, 3961. https://doi.org/10.3390/ma12233961

Xiao H, Han W, Ming Y, Ding Z, Duan Y. A Sensitivity Analysis-Based Parameter Optimization Framework for 3D Printing of Continuous Carbon Fiber/Epoxy Composites. Materials. 2019; 12(23):3961. https://doi.org/10.3390/ma12233961

Chicago/Turabian StyleXiao, Hong, Wei Han, Yueke Ming, Zhongqiu Ding, and Yugang Duan. 2019. "A Sensitivity Analysis-Based Parameter Optimization Framework for 3D Printing of Continuous Carbon Fiber/Epoxy Composites" Materials 12, no. 23: 3961. https://doi.org/10.3390/ma12233961

APA StyleXiao, H., Han, W., Ming, Y., Ding, Z., & Duan, Y. (2019). A Sensitivity Analysis-Based Parameter Optimization Framework for 3D Printing of Continuous Carbon Fiber/Epoxy Composites. Materials, 12(23), 3961. https://doi.org/10.3390/ma12233961