Experimental Study of the Mechanical Properties and Microstructures of Lightweight Toughness Cement-Based Composites

Abstract

1. Introduction

2. Experimental Program

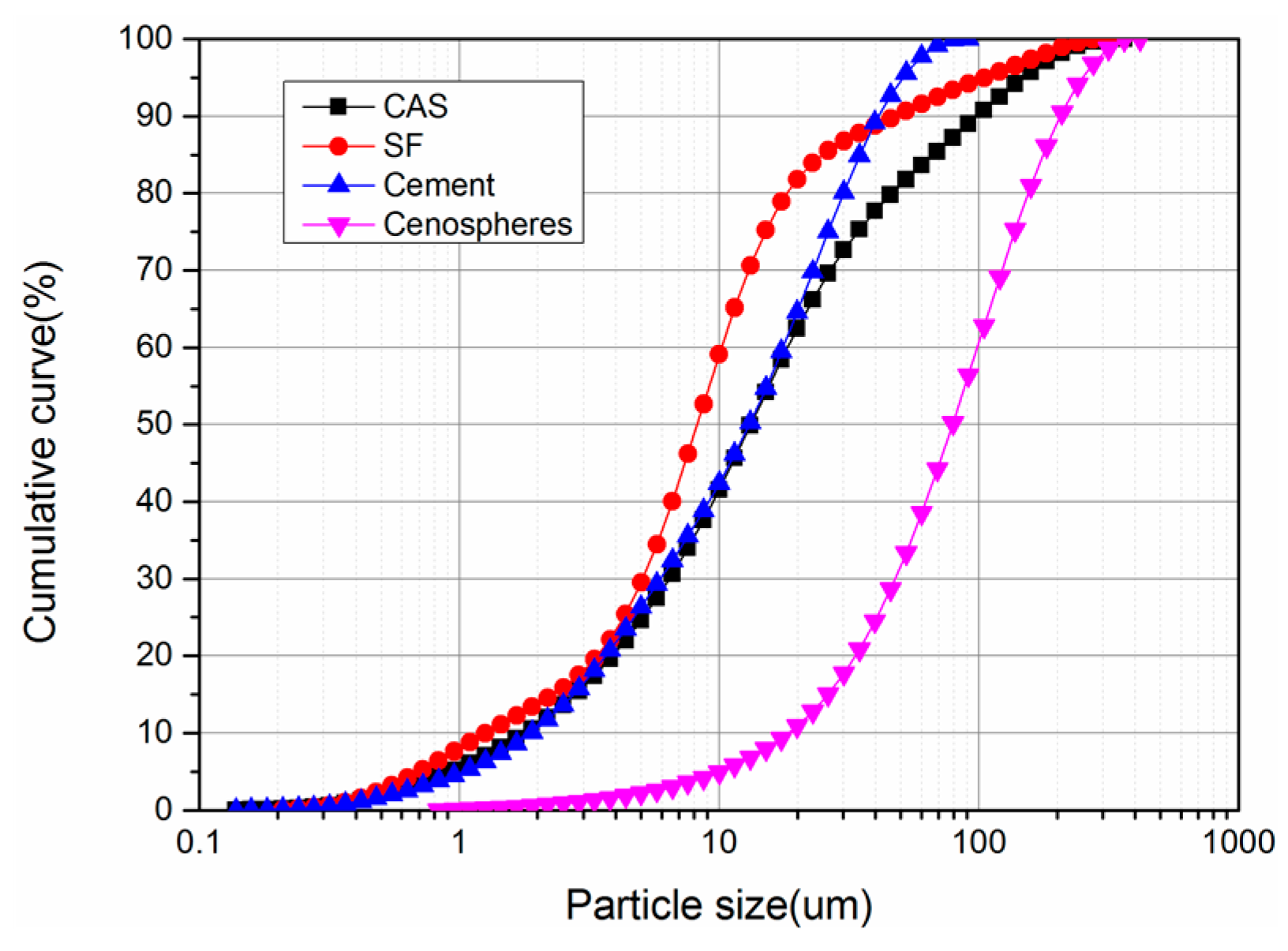

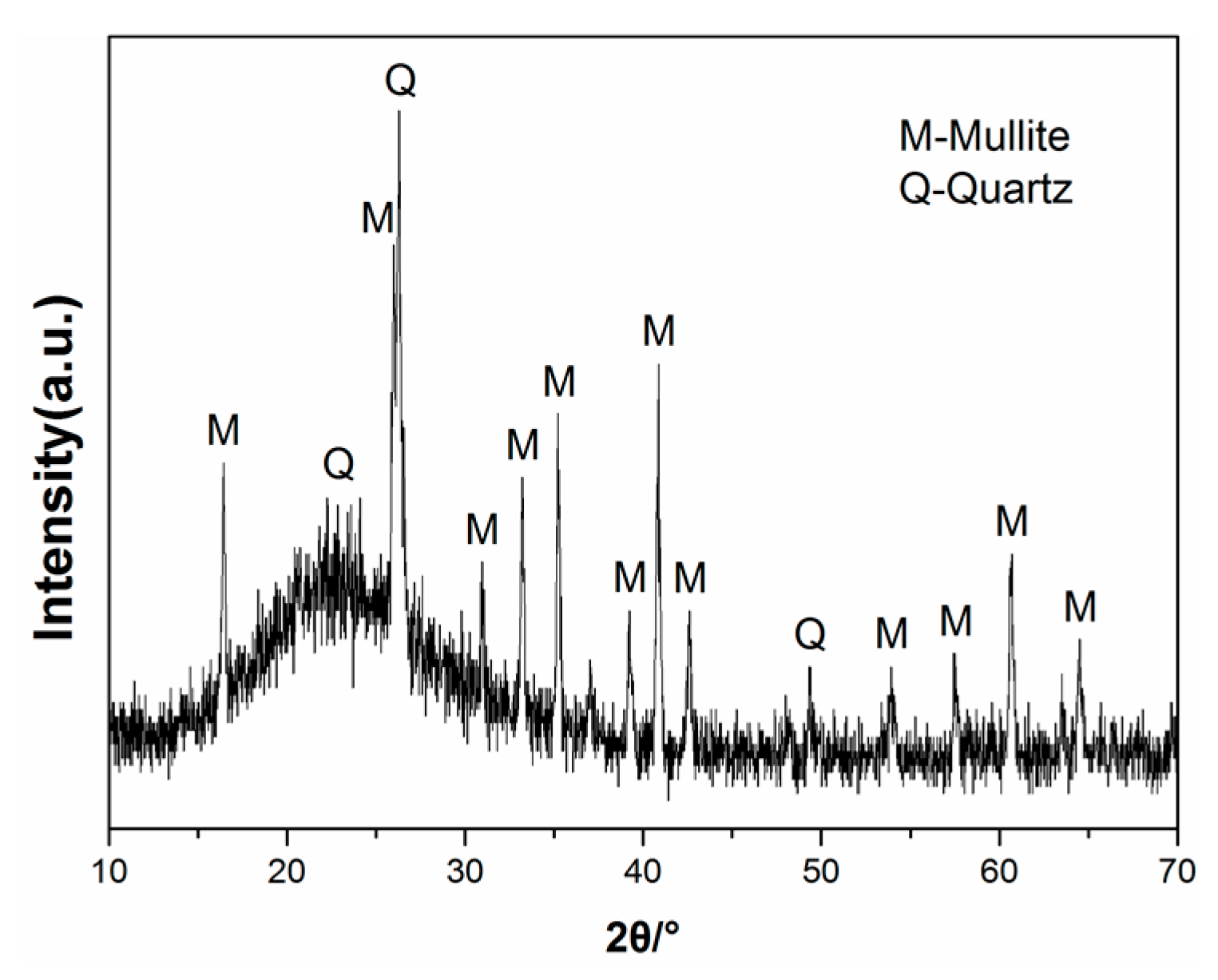

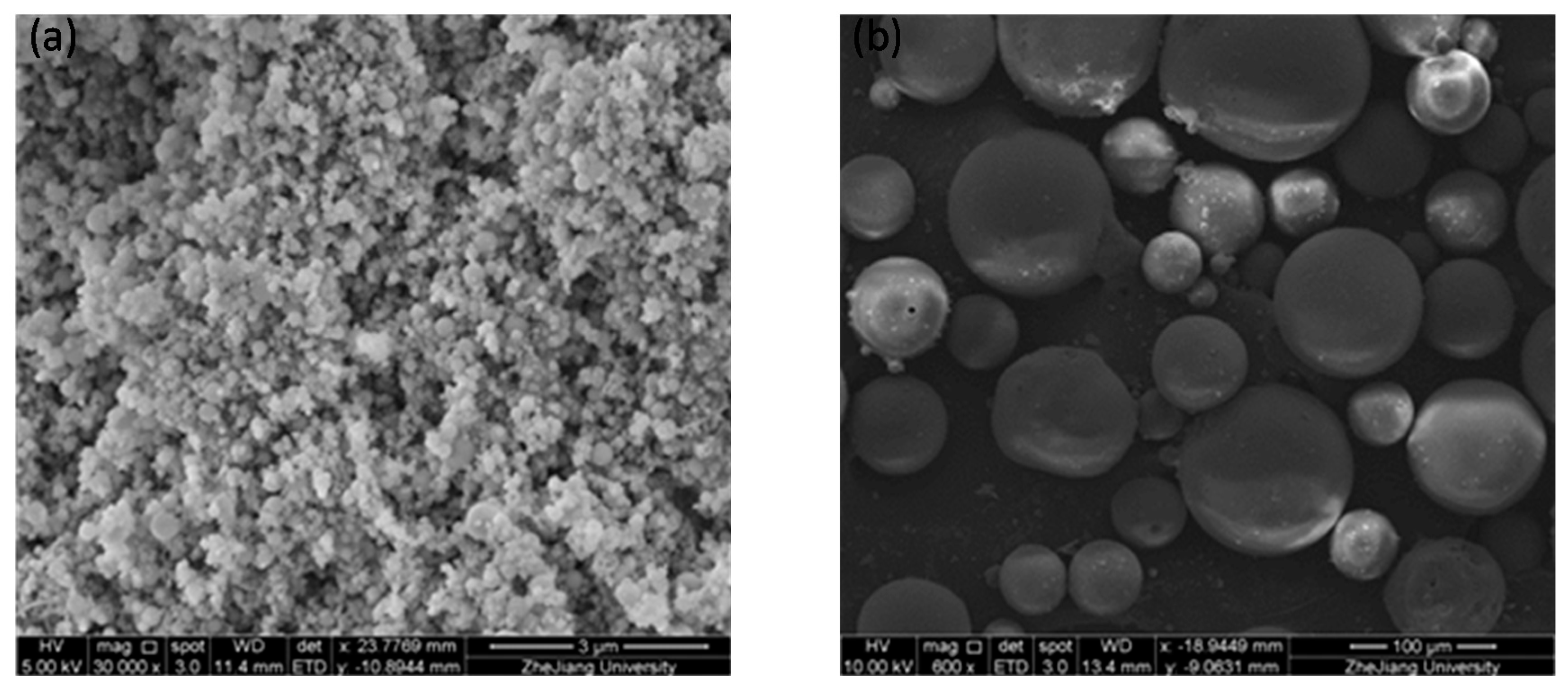

2.1. Materials

2.2. Mix Design and Specimen Preparations

2.3. Tests Methods

2.3.1. Compressive and Flexural Strength of LTCCs

2.3.2. Bending Toughness of LTCCs

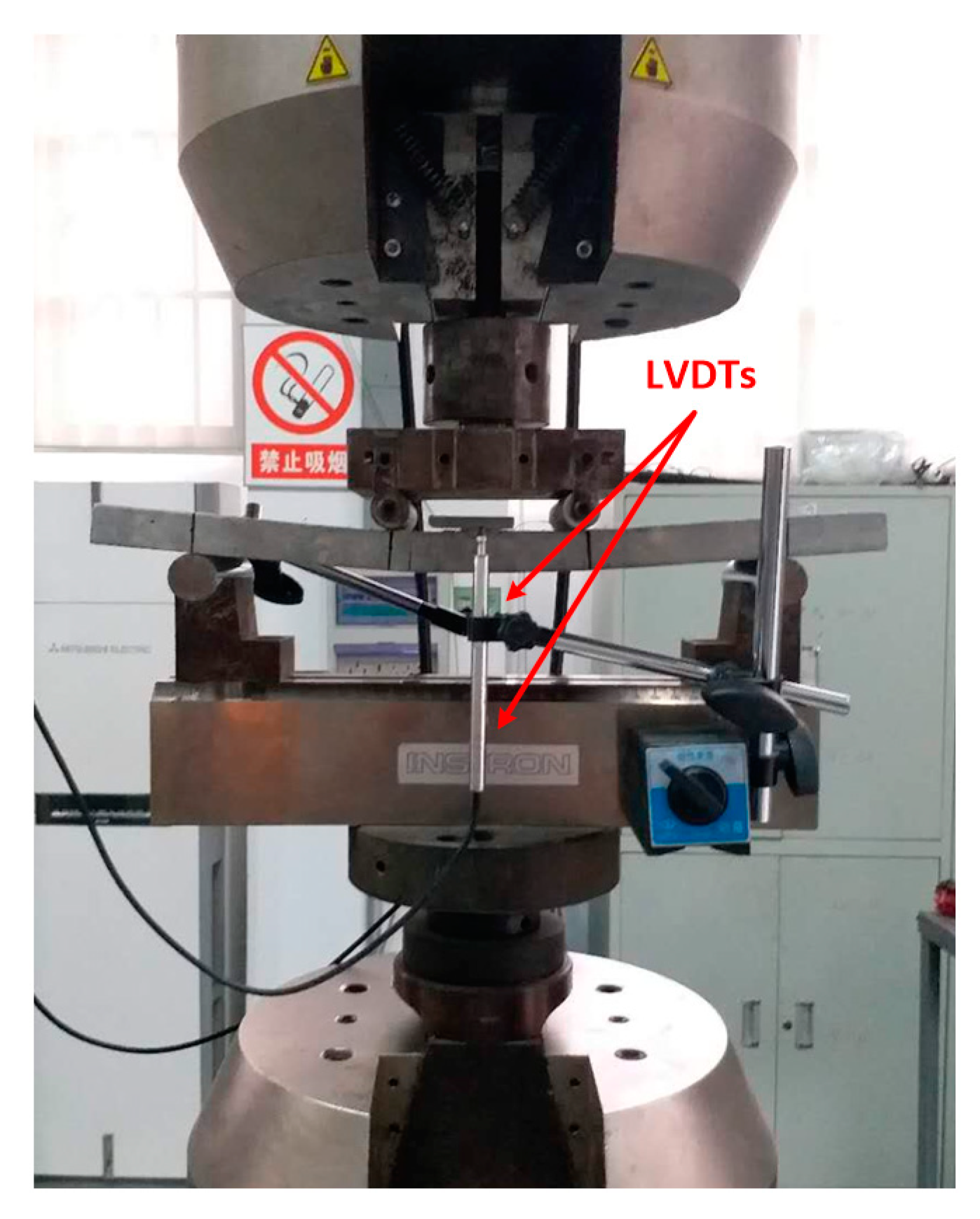

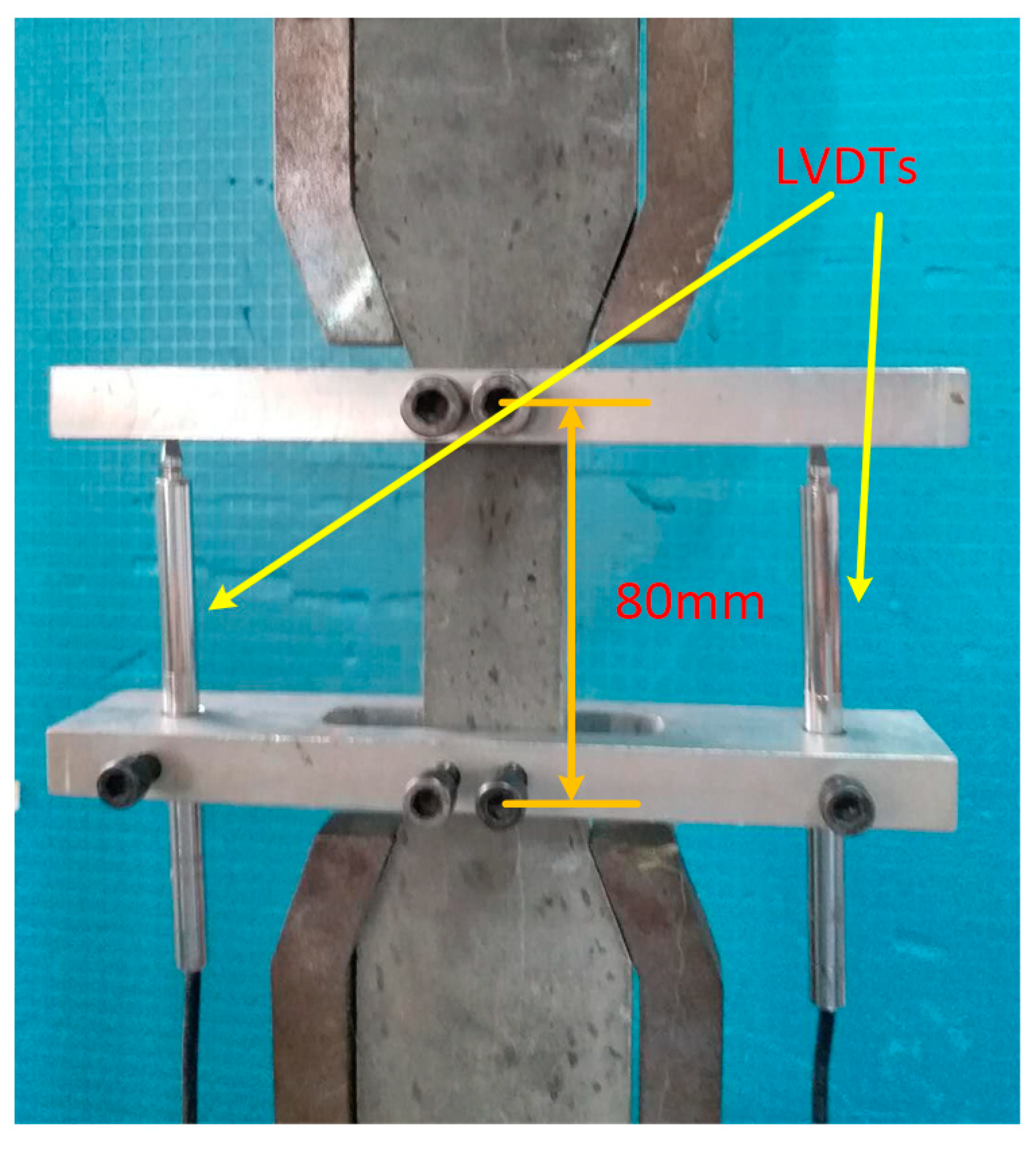

2.3.3. Uniaxial Tensile Properties of LTCCs

2.3.4. Chemical Composition of LTCCs

2.3.5. LTCC Microstructure

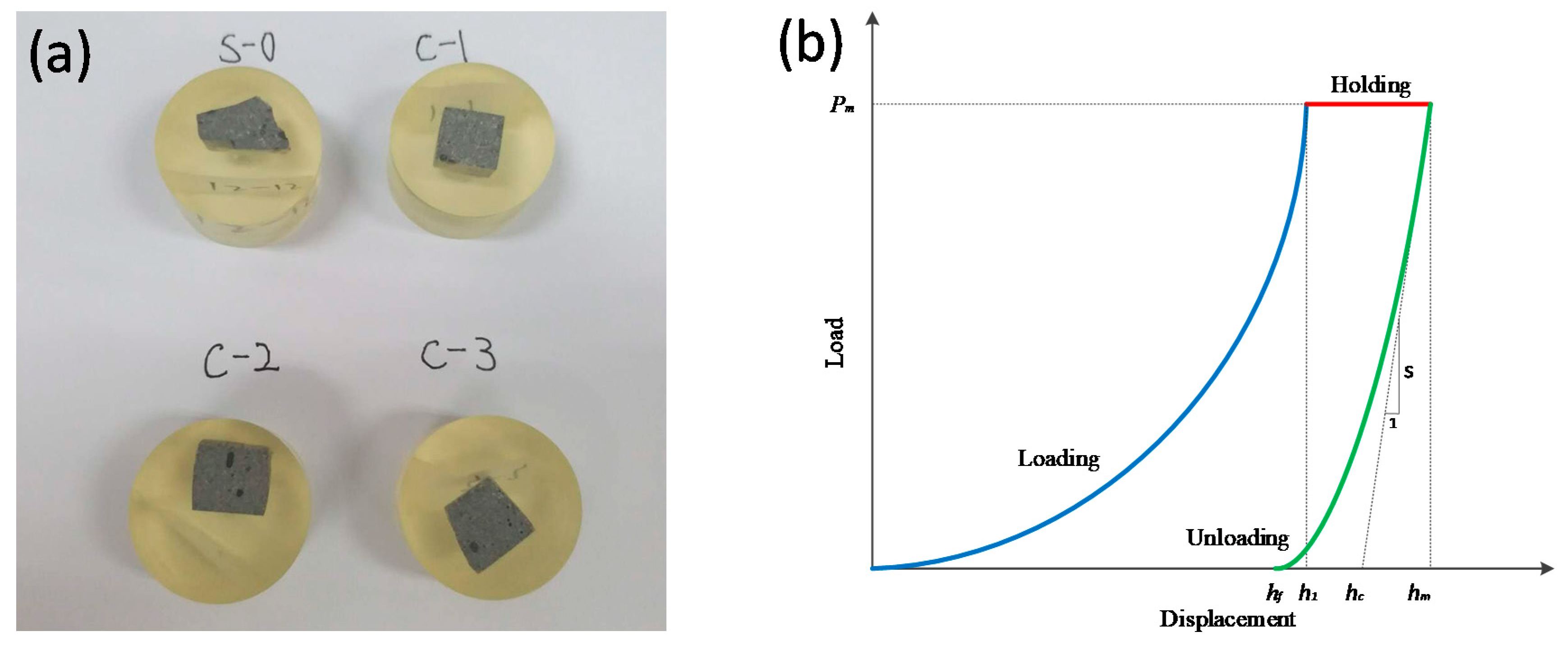

2.3.6. Nano-Indentation of LTCC

3. Results and Discussion

3.1. Mechanical Properties

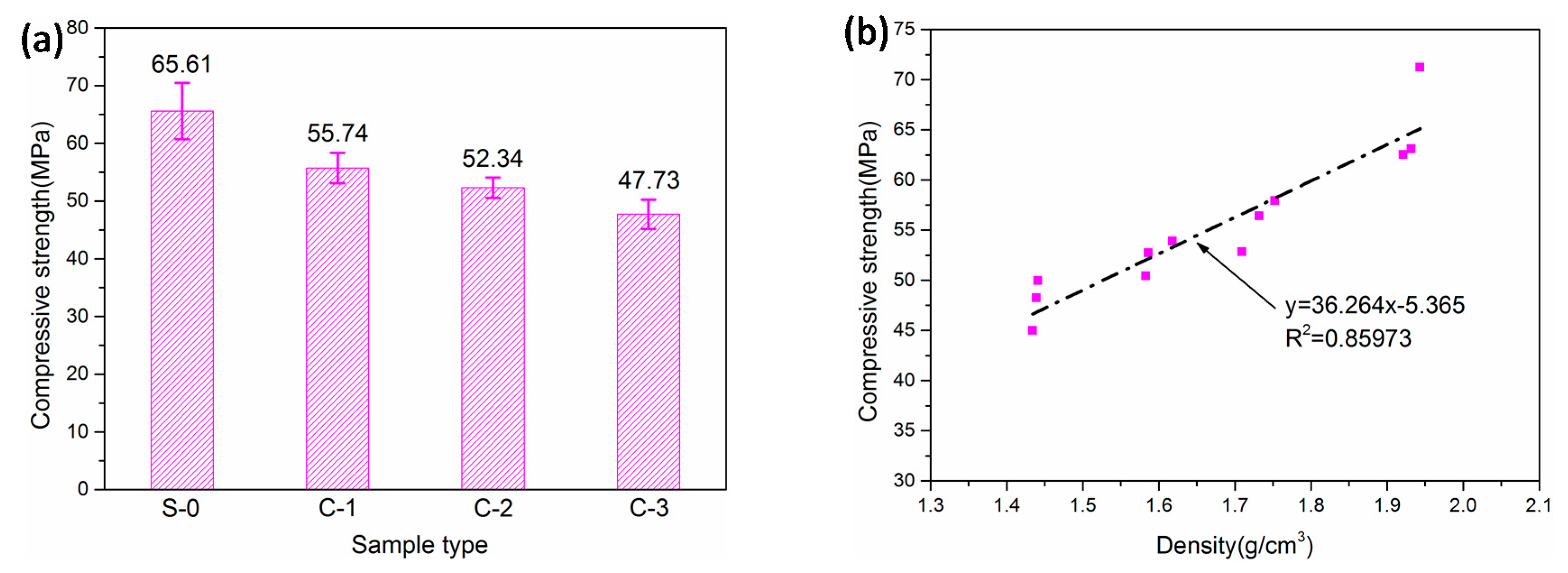

3.1.1. Compressive and Flexural Strength

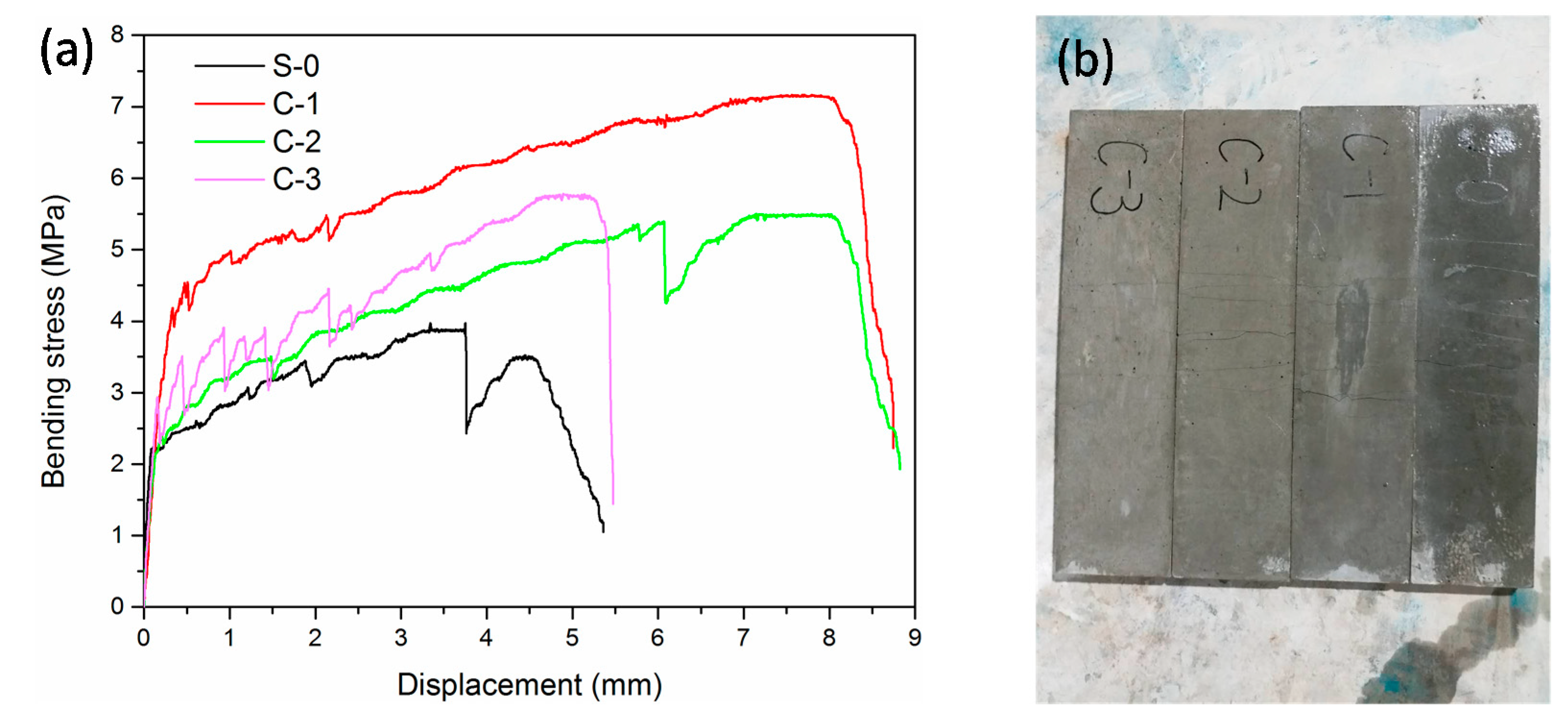

3.1.2. Toughness Performance

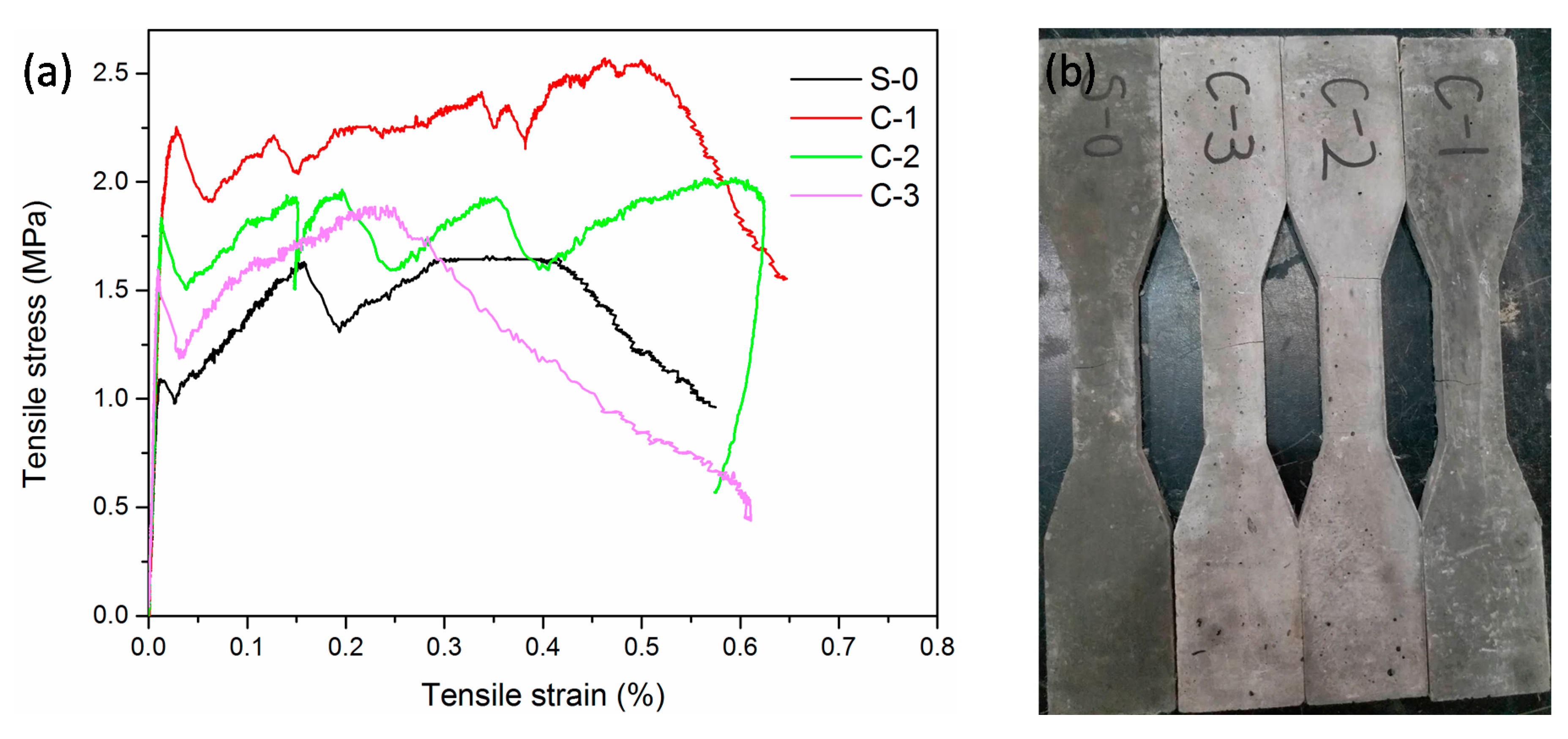

3.1.3. Tensile Performance

3.2. Chemical Components

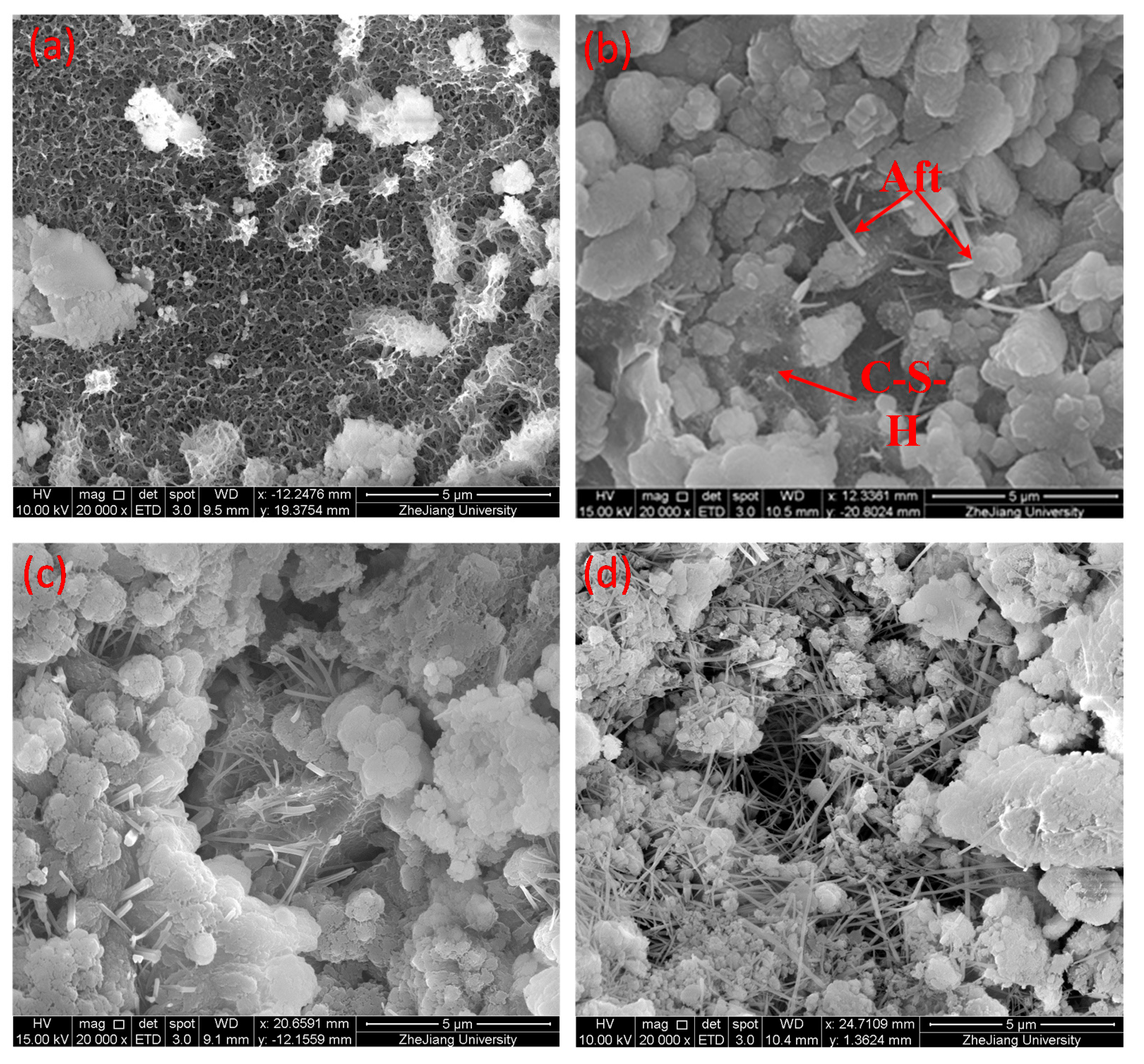

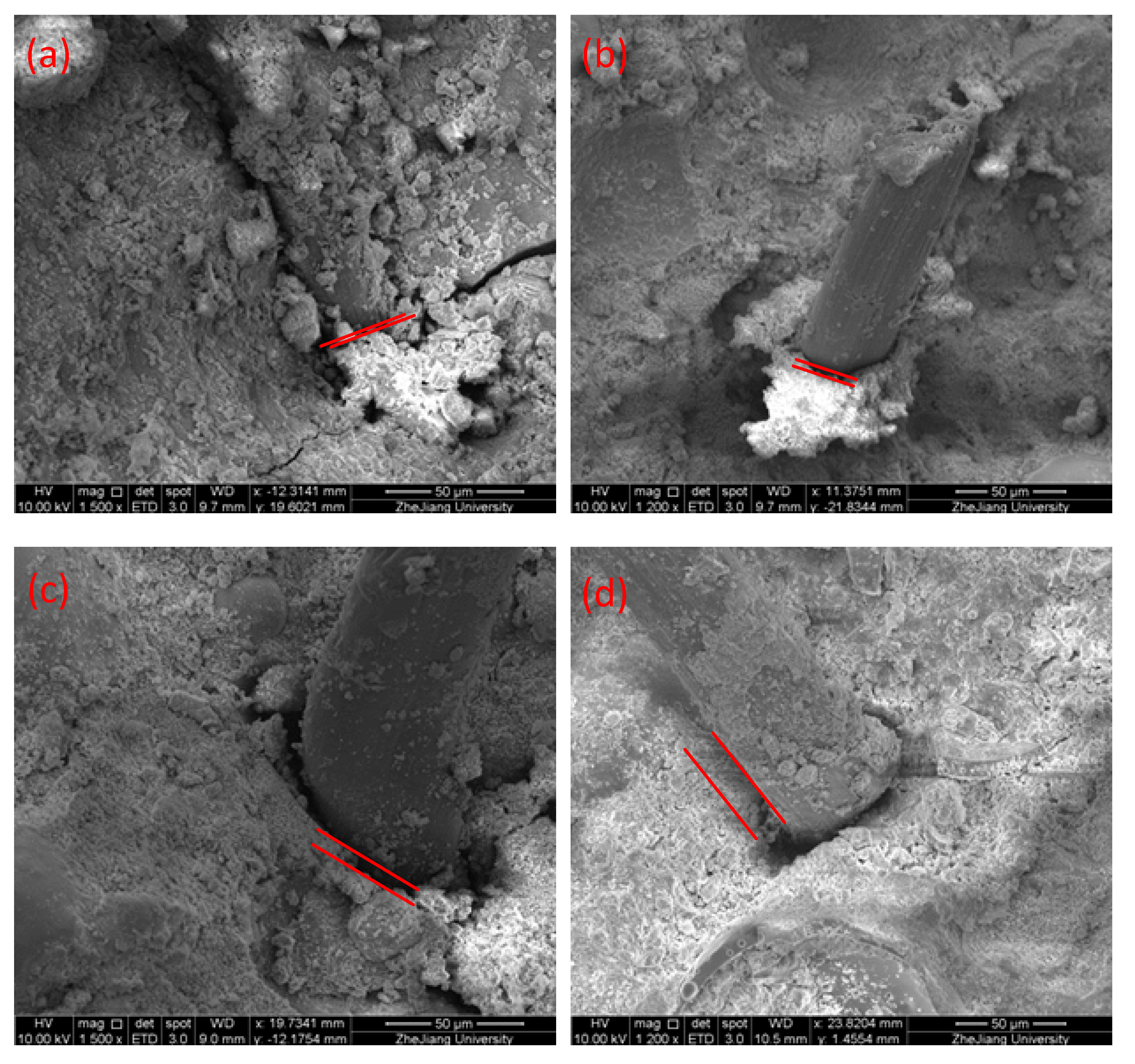

3.3. Microstructures

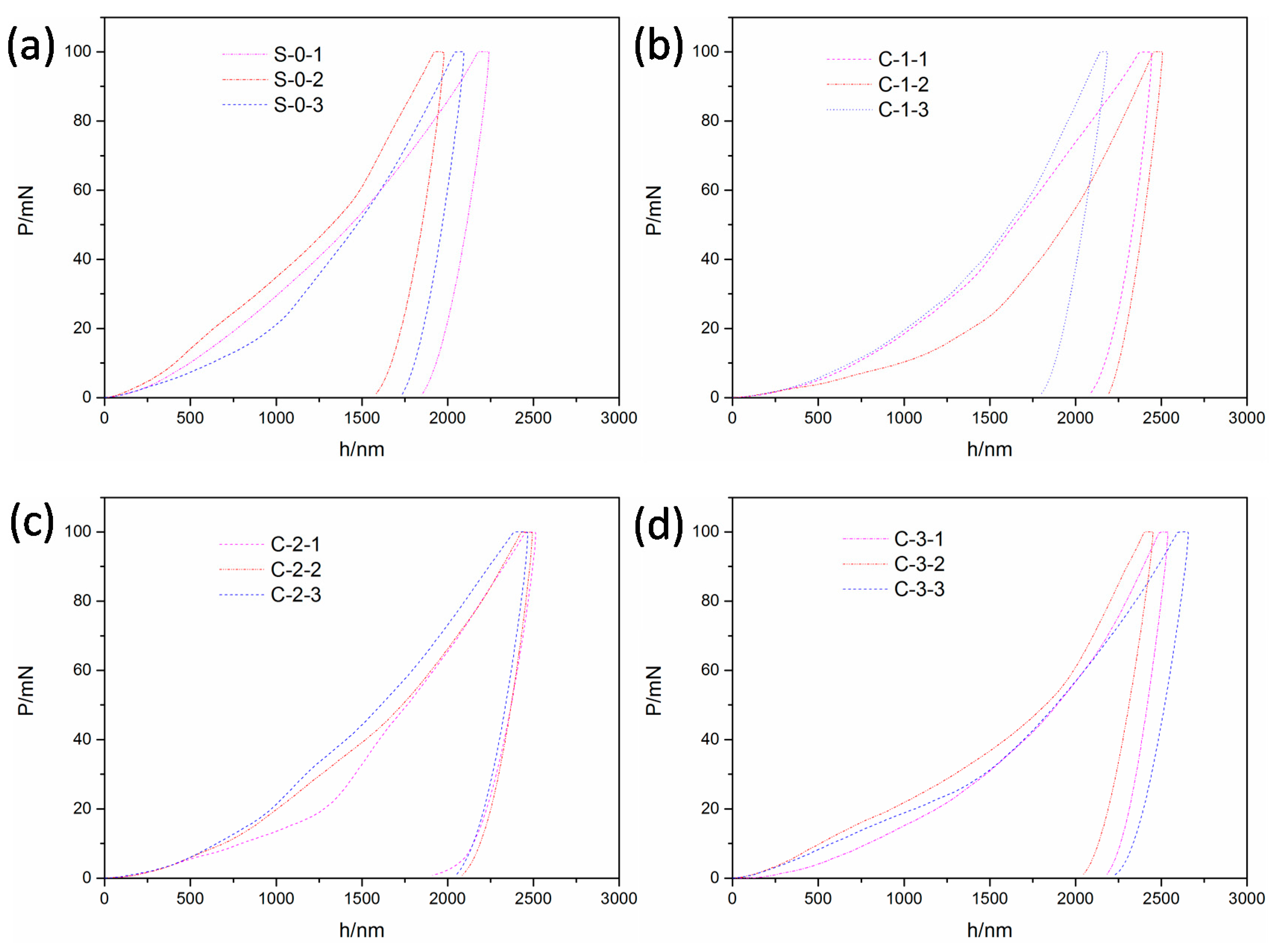

3.4. Micromechanics

4. Conclusions

- (a)

- The compressive and flexural strength of LTCCs decrease with increasing cenosphere content, and the compressive strength decreases linearly with the decrease in density. However, the specific strength of LTCCs increases with increasing cenosphere content. LTCCs have proven to be lightweight and high-strength green cement-based composites.

- (b)

- Both the bending and tensile behavior of LTCCs show significant strain hardening according to the four-point bending and uniaxial tensile curves. The LTCCs with 20% cenosphere content (the ratio of cenospheres to cementitious materials) has excellent toughness and ductility.

- (c)

- The incorporation of cenospheres contributes to the hydration reaction of the LTCC and the production of more C-S-H gel by hydration reaction due to its high pozzolanic activity.

- (d)

- The incorporation of cenospheres causes the microstructure of the LTCCs to become looser and more ettringite to appear. The bonding strength between fiber and cement paste decreases with increasing cenosphere content. A suitable amount of cenospheres is beneficial for fiber slipping to produce large bending deformation and good ductility.

- (e)

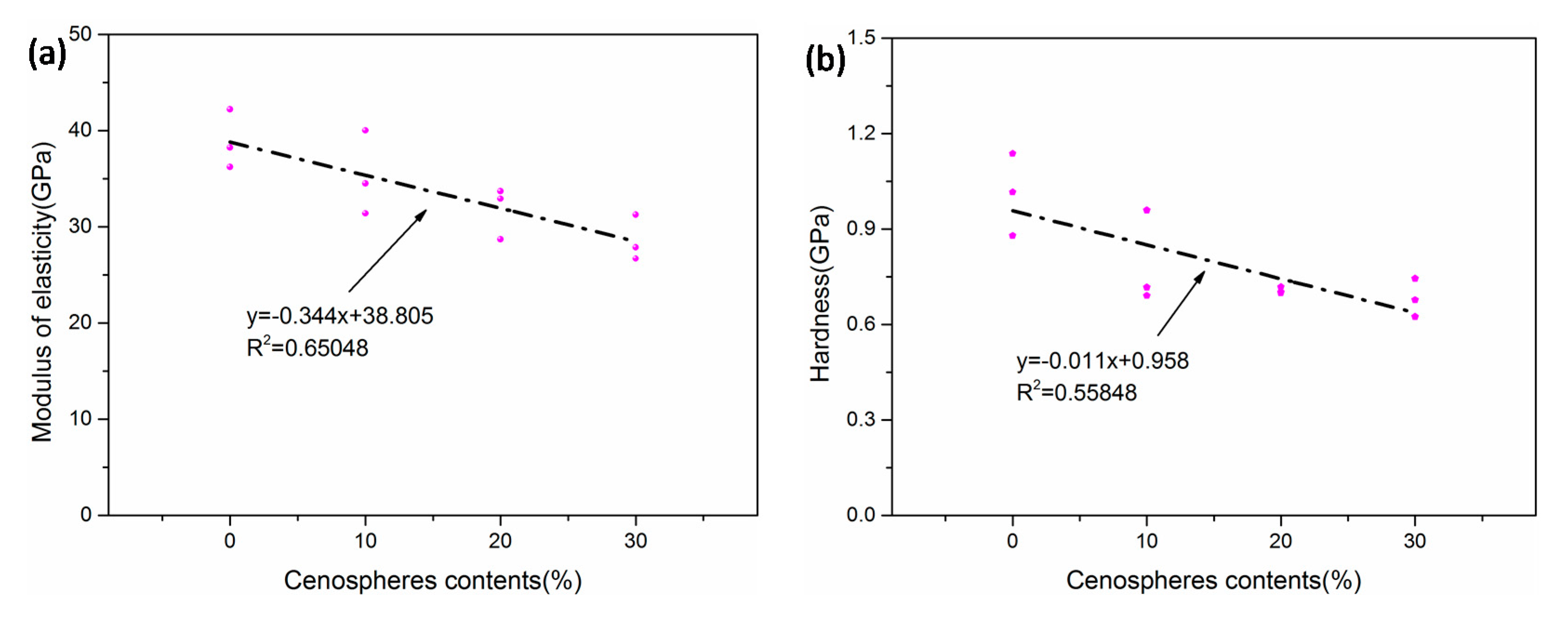

- The incorporation of cenospheres decreases the elastic modulus and hardness of the LTCC cement paste; these decreases are linear with the amount of cenospheres. Cenospheres act as a reinforcing phase, and the reason for the decrease in the compressive strength of the LTCCs is the weak interfacial transition zone between the cenospheres and the cement matrix.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Nikbin, I.M.; Aliaghazadeh, M.; Charkhtab, S.; Fathollahpour, A. Environmental impacts and mechanical properties of lightweight concrete containing bauxite residue (red mud). J. Clean. Prod. 2018, 172, 2683–2694. [Google Scholar] [CrossRef]

- Zhang, B.; Poon, C. Sound insulation properties of rubberized lightweight aggregate Concrete. J. Clean. Prod. 2018, 172, 3176–3185. [Google Scholar] [CrossRef]

- Ahmed, W.; Khushnood, R.A.; Memon, S.A.; Ahmad, S.; Baloch, W.L.; Usman, M. Effective use of sawdust for the production of eco-friendly and thermal-energy efficient normal weight and lightweight concretes with tailored fracture properties. J. Clean. Prod. 2018, 184, 1016–1027. [Google Scholar] [CrossRef]

- Aslam, M.; Shafigh, P.; Jumaat, M.Z.; Lachemi, M. Benefits of using blended waste coarse lightweight aggregates in structural lightweight aggregate concrete. J. Clean. Prod. 2016, 119, 108–117. [Google Scholar] [CrossRef]

- Bogas, J.A.; Brito, J.; Figueiredo, J.M. Mechanical characterization of concrete produced with recycled lightweight expanded clay aggregate concrete. J. Clean. Prod. 2015, 89, 187–195. [Google Scholar] [CrossRef]

- Ma, X.; Liu, J.; Shi, C. A review on the use of LWA as an internal curing agent of high performance cement-based materials. Constr. Build. Mater. 2019, 218, 385–393. [Google Scholar] [CrossRef]

- Hanif, A.; Lu, Z.; Li, Z. Utilization of fly ash cenosphere as lightweight filler in cement-based composites—A review. Constr. Build. Mater. 2017, 144, 373–384. [Google Scholar] [CrossRef]

- BS EN 206-1. Concrete e Part 1: Speciation, Performance, Production and Conformity; British Standards Institution: London, UK, 2001. [Google Scholar]

- Zhuang, Y.; Chen, C.; Ji, T. Effect of shale ceramsite type on the tensile creep of lightweight aggregate concrete. Constr. Build. Mater. 2013, 46, 13–18. [Google Scholar] [CrossRef]

- Ismail, M.K.; Hassan, A.A. Use of metakaolin on enhancing the mechanical properties of self-consolidating concrete containing high percentages of crumb rubber. J. Clean. Prod. 2016, 125, 282–295. [Google Scholar] [CrossRef]

- Yap, S.P.; Chen, P.Z.C.; Goh, Y.; Ibrahim, H.A.; Mo, K.H.; Yuen, C.W. Characterization of pervious concrete with blended natural aggregate and recycled concrete aggregates. J. Clean. Prod. 2018, 181, 155–165. [Google Scholar] [CrossRef]

- Yu, R.; van Onna, D.V.; Spiesz, P.; Yu, Q.L.; Brouwers, H.J.H. Development of Ultra-Lightweight Fibre Reinforced Concrete applying expanded waste glass. J. Clean. Prod. 2016, 112, 690–701. [Google Scholar] [CrossRef]

- Turner, L.K.; Collins, F.G. Carbon dioxide equivalent (CO2-e) emissions: A comparison between geopolymer and OPC cement concrete. Constr. Build. Mater. 2013, 43, 125–130. [Google Scholar] [CrossRef]

- Pastor, J.L.; Ortega, J.M.; Flor, M.; López, M.P.; Sánchez, I.; Climent, M.A. Microstructure and durability of fly ash cement grouts for micropiles. Constr. Build. Mater. 2016, 117, 47–57. [Google Scholar] [CrossRef]

- Ramezanianpour, A.A.; Malhotra, V.M. Effect of curing on the compressive strength, resistance to chloride-ion penetration and porosity of concretes incorporating slag, fly ash or silica fume. Cem. Concr. Compos. 1995, 17, 125–133. [Google Scholar] [CrossRef]

- Ortega, J.; Esteban, M.; Rodríguez, R.; Pastor, J.; Ibanco, F.; Sánchez, I.; Climent, M. Long-term behaviour of fly ash and slag cement grouts for micropiles exposed to a sulphate aggressive medium. Materials 2017, 10, 598. [Google Scholar] [CrossRef]

- Joshaghani, A.; Balapour, M.; Ramezanianpour, A.A. Effect of controlled environmental conditions on mechanical, microstructural and durability properties of cement mortar. Constr. Build. Mater. 2018, 164, 134–149. [Google Scholar] [CrossRef]

- Montgomery, D.; Diamond, S. The influence of fly ash cenospheres on the details of cracking in fly ash-bearing cement pastes. Cem. Concr. Res. 1984, 14, 767–775. [Google Scholar] [CrossRef]

- Ranjbar, N.; Kuenzel, C. Cenospheres: A review. Fuel 2017, 207, 1–12. [Google Scholar] [CrossRef]

- Żyrkowski, M.; Neto, R.C.; Santos, L.F.; Witkowski, K. Characterization of fly-ash cenospheres from coal-fired power plant unit. Fuel 2016, 174, 49–53. [Google Scholar] [CrossRef]

- Blanco, F.; García, P.; Mateos, P.; Ayala, J. Characteristics and properties of lightweight concrete manufactured with cenospheres. Cem. Concr. Res. 2000, 30, 1715–1722. [Google Scholar] [CrossRef]

- Huang, X.; Ranade, R.; Zhang, Q.; Ni, W.; Li, V.C. Mechanical and thermal properties of green lightweight engineered cementitious composites. Constr. Build. Mater. 2013, 48, 954–960. [Google Scholar] [CrossRef]

- Wang, J.; Chia, K.; Liew, J.; Zhang, M. Flexural performance of fiber reinforced ultra-lightweight cement composites with low fiber content. Cem. Concr. Compos. 2013, 43, 39–47. [Google Scholar] [CrossRef]

- Liu, X.; Chia, K.; Zhang, M. Development of lightweight concrete with high resistance to water and chloride-ion penetration. Cem. Concr. Compos. 2010, 32, 757–766. [Google Scholar] [CrossRef]

- Du, H. Properties of ultra-lightweight cement composites with nano-silica. Constr. Build. Mater. 2019, 199, 696–704. [Google Scholar] [CrossRef]

- Huang, Z.; Padmaja, K.; Li, S.; Richard Liew, J.Y. Mechanical properties and microstructure of ultra-lightweight cement composites with fly ash cenospheres after exposure to high temperatures. Constr. Build. Mater. 2018, 164, 760–774. [Google Scholar] [CrossRef]

- Wang, J.; Gao, X.; Yan, J. Developments and mechanical behaviors of steel fiber reinforced ultra-lightweight cement composite with different densities. Constr. Build. Mater. 2018, 171, 643–653. [Google Scholar] [CrossRef]

- Jin, Q.; Li, V.C. Development of lightweight engineered cementitious composite for durability enhancement of tall concrete wind towers. Cem. Concr. Compos. 2019, 96, 87–94. [Google Scholar] [CrossRef]

- Yan, J.; Wang, J.; Liew, J.; Qian, X. Applications of ultra-lightweight cement composite in flat slabs and double skin composite structures. Constr. Build. Mater. 2016, 111, 774–793. [Google Scholar] [CrossRef]

- Collepardi, M.; Borsoi, A.; Collepardi, S.; Olagot, J.J.O.; Troli, R. Effects of shrinkage reducing admixture in shrinkage compensating concrete under non-wet curing conditions. Cem. Concr. Compos. 2005, 27, 704–708. [Google Scholar] [CrossRef]

- Bentz, D.P.; Geiker, M.R.; Hansen, K.K. Shrinkage-reducing admixtures and early-age desiccation in cement pastes and mortars. Cem. Concr. Res. 2001, 31, 1075–1085. [Google Scholar] [CrossRef]

- China National Standards GBT 17671-1999. Method of Testing Cements Determination of Strength; CSBTS: Beijing, China, 1999. (In Chinese) [Google Scholar]

- JSCE, 1-16. Recommendations for Design and Construction of High Performance Fiber Reinforced Cement Composites with Multiple Fine Cracks; Japan Society of Civil Engineers: Tokyo, Japan, 2008. [Google Scholar]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, J.; Monteiro, P.J.M.; Zhang, M. Development of ultra-lightweight cement composites with low thermal conductivity and high specific strength for energy efficient buildings. Constr. Build. Mater. 2015, 87, 100–112. [Google Scholar] [CrossRef]

- Challis, V.J.; Xu, X.; Zhang, L.C.; Roberts, A.P.; Grotowski, J.F.; Sercombe, T.B. High specific strength and stiffness structures produced using selective laser melting. Mater. Des. 2014, 63, 783–788. [Google Scholar] [CrossRef]

- Banfill, P.F.G.; Starrs, G.; Derruau, G.; McCarter, W.J.; Chrisp, T.M. Rheology of low carbon fibre content reinforced cement mortar. Cem. Concr. Compos. 2006, 28, 773–780. [Google Scholar] [CrossRef]

- Luo, S.; Liu, M.; Yang, L.; Chang, J. Effects of drying techniques on the crystal structure and morphology of Ettringite. Constr. Build. Mater. 2019, 195, 305–311. [Google Scholar] [CrossRef]

- Colombo, A.; Geiker, M.; Justnes, H. The effect of calcium lignosulfonate on ettringite formation in cement paste. Cem. Concr. Res. 2018, 107, 188–205. [Google Scholar] [CrossRef]

- Pavoine, A.; Brunetaud, X.; Divet, L. The impact of cement parameters on Delayed Ettringite Formation. Cem. Concr. Compos. 2012, 34, 521–528. [Google Scholar] [CrossRef]

- Teixeira, R.S.; Tonoli, G.H.D.; Santos, S.F.D.; Rayon, E.; Amigo, V.; Savastano, H., Jr.; Lahr, F.R. Nanoindentation study of the interfacial zone between cellulose fiber and cement matrix in extruded composites. Cem. Concr. Compos. 2018, 85, 1–8. [Google Scholar] [CrossRef]

- Wu, C.; Leunga, C.K.Y.; Li, V.C. Derivation of crack bridging stresses in engineered cementitious composites under combined opening and shear displacements. Cem. Concr. Res. 2018, 107, 253–263. [Google Scholar] [CrossRef]

- Zhao, S.; Sun, W. Nano-mechanical behavior of a green ultra-high performance concrete. Constr. Build. Mater. 2014, 63, 150–160. [Google Scholar] [CrossRef]

- Mondal, P.; Shah, S.P.; Marks, L. A reliable technique to determine the local mechanical properties at the nanoscale for cementitious materials. Cem. Concr. Res. 2007, 37, 1440–1444. [Google Scholar] [CrossRef]

- Scrivener, K.L.; Crumbie, A.K.; Laugesen, P. The Interfacial Transition Zone (ITZ) Between Cement Paste and Aggregate in Concrete. Interface Sci. 2004, 12, 411–421. [Google Scholar] [CrossRef]

| Description | SiO2 | Al2O3 | MgO | SO3 | K2O | CaO | Fe2O3 | CaCO3 | Na2O |

|---|---|---|---|---|---|---|---|---|---|

| Cement | 13.23 | 4.28 | 1.69 | 2.24 | 1.59 | 63.95 | 4.02 | 8.23 | - |

| Cenosphere | 60.10 | 28.40 | 1.50 | 0.03 | 3.50 | 0.80 | 4.80 | - | 0.90 |

| Silica fume | 92.26 | 0.89 | 0.96 | 0.33 | 1.31 | 0.49 | 1.97 | - | 0.42 |

| Mix ID | Weight Ratio of Matrix | Fiber (%) | |||||

|---|---|---|---|---|---|---|---|

| Cementitious Binders | Cenosphere | PSP | SRA | CSA | Water | PVA (by Volume) | |

| S-0 | 1 | 0 | 0.002 | 0.002 | 0.05 | 0.32 | 1 |

| C-1 | 1 | 0.1 | 0.002 | 0.002 | 0.05 | 0.32 | 1 |

| C-2 | 1 | 0.2 | 0.002 | 0.002 | 0.05 | 0.32 | 1 |

| C-3 | 1 | 0.3 | 0.002 | 0.002 | 0.05 | 0.32 | 1 |

| Mix ID | Density (g/cm3) | Compressive Strength | Flexural Strength | Specific Strength | Ratio of Flexural to Compressive Strength |

|---|---|---|---|---|---|

| (MPa) | (MPa) | (kPa/kgm−3) | |||

| S-0 | 1.870 | 58.87 | 10.80 | 31.49 | 0.184 |

| C-1 | 1.724 | 56.35 | 16.00 | 32.69 | 0.284 |

| C-2 | 1.592 | 53.86 | 13.61 | 33.83 | 0.253 |

| C-3 | 1.477 | 50.06 | 11.59 | 33.89 | 0.232 |

| Mix ID | Ultimate Bending Strength (MPa) | Ultimate Bending Deflection (mm) | Initial Cracking Stress (MPa) | Ultimate Tensile Stress (MPa) | Ultimate Tensile Strain (%) |

|---|---|---|---|---|---|

| S-0 | 3.85 | 4.57 | 1.10 | 1.64 | 0.40 |

| C-1 | 6.60 | 7.17 | 2.25 | 2.56 | 0.50 |

| C-2 | 5.15 | 7.37 | 1.83 | 2.00 | 0.61 |

| C-3 | 5.50 | 5.38 | 1.56 | 1.88 | 0.25 |

| Mix ID | S-0 | C-1 | C-2 | C-3 | Cenospheres | ITZ |

|---|---|---|---|---|---|---|

| Modulus of elasticity (GPa) | 38.90 | 35.31 | 31.78 | 28.61 | 61.81 | 22.48 |

| Hardness (GPa) | 0.940 | 0.789 | 0.695 | 0.682 | 8.009 | 0.465 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, W.; Huang, Z. Experimental Study of the Mechanical Properties and Microstructures of Lightweight Toughness Cement-Based Composites. Materials 2019, 12, 3891. https://doi.org/10.3390/ma12233891

Chen W, Huang Z. Experimental Study of the Mechanical Properties and Microstructures of Lightweight Toughness Cement-Based Composites. Materials. 2019; 12(23):3891. https://doi.org/10.3390/ma12233891

Chicago/Turabian StyleChen, Wenhua, and Zhiyi Huang. 2019. "Experimental Study of the Mechanical Properties and Microstructures of Lightweight Toughness Cement-Based Composites" Materials 12, no. 23: 3891. https://doi.org/10.3390/ma12233891

APA StyleChen, W., & Huang, Z. (2019). Experimental Study of the Mechanical Properties and Microstructures of Lightweight Toughness Cement-Based Composites. Materials, 12(23), 3891. https://doi.org/10.3390/ma12233891