Towards Optimization of Surface Roughness and Productivity Aspects during High-Speed Machining of Ti–6Al–4V

Abstract

:1. Introduction

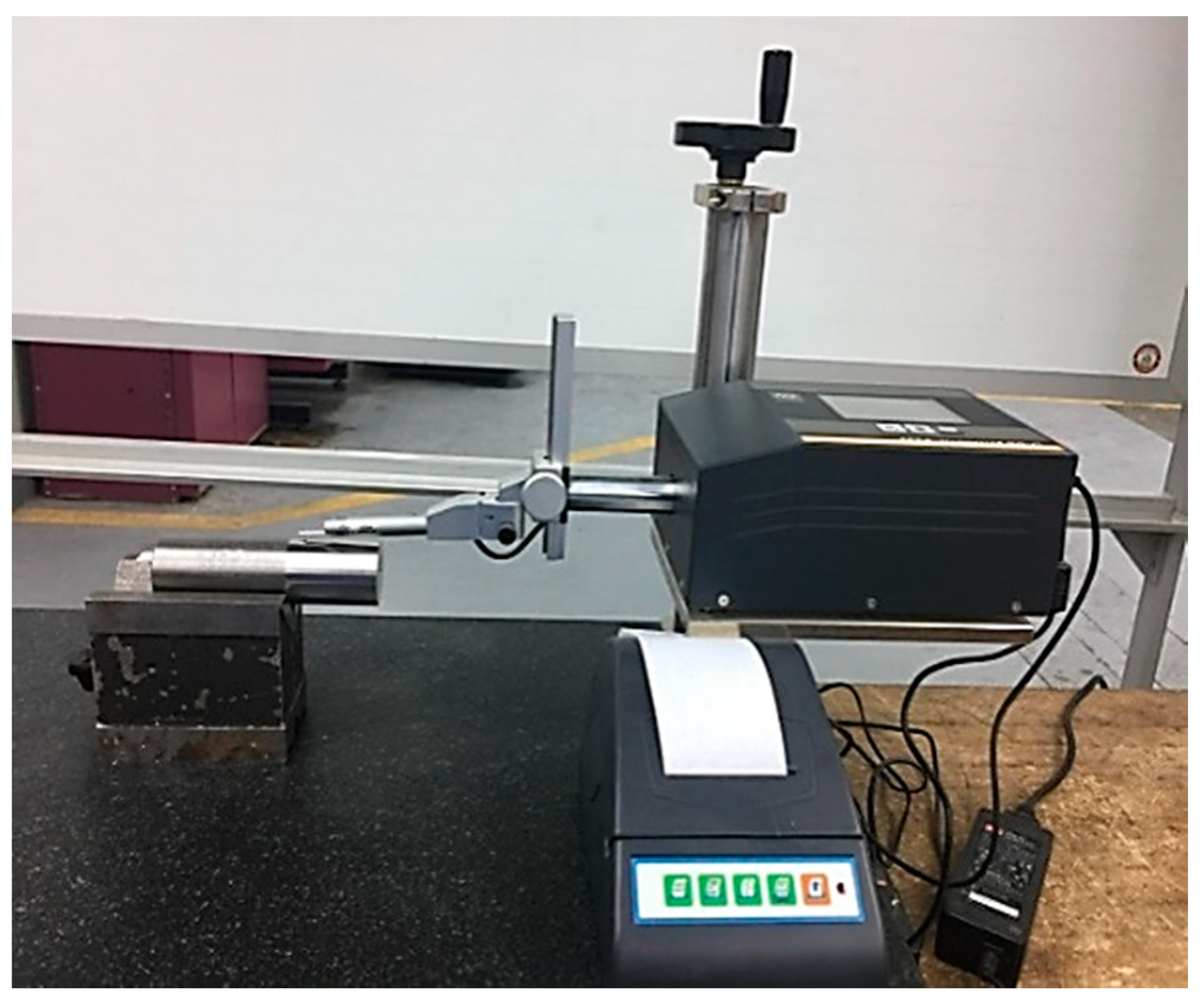

2. Experimentation and Optimization Approach

- Step 1: Initially, the input parameters and performance characteristics were defined.

- Step 2: The data should be transformed into a matrix form (decision matrix) as provided by Equation (1):where m and n are the number of alternatives and number of attributes, respectively. In the newly developed ratio system, the comparison is made for the denominator and the performance of the alternative on the attribute. The denominator used in this step is the characteristic of all alternatives for an attribute.

- Step 3: The ratio can be investigated using Equation (2). The square root of the sum of square for each alternative is to be the best choice for the denominator.

- Step 1: In the first step, the data obtained from the experiments were analyzed.

- Step 2: In the second step, the response characteristics were normalized to investigate the performance indices using MOORA.

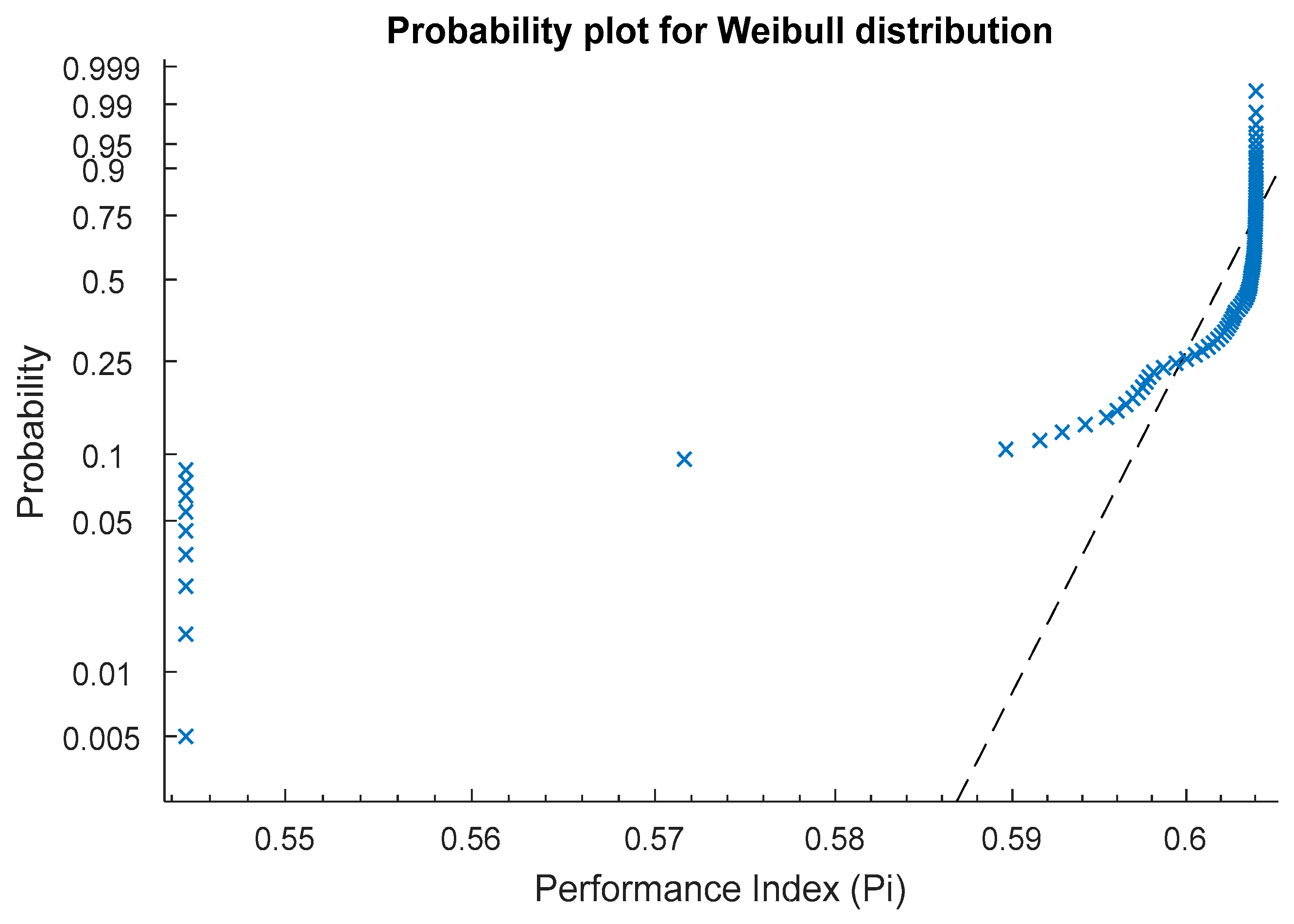

- Step 3: The statistical analysis of the performance index was made by MiniTab statistical software.

- Step 4: In the next step, the regression coefficients with empirical models were investigated. The empirical model of Pi varies the Pi with the input process variables.

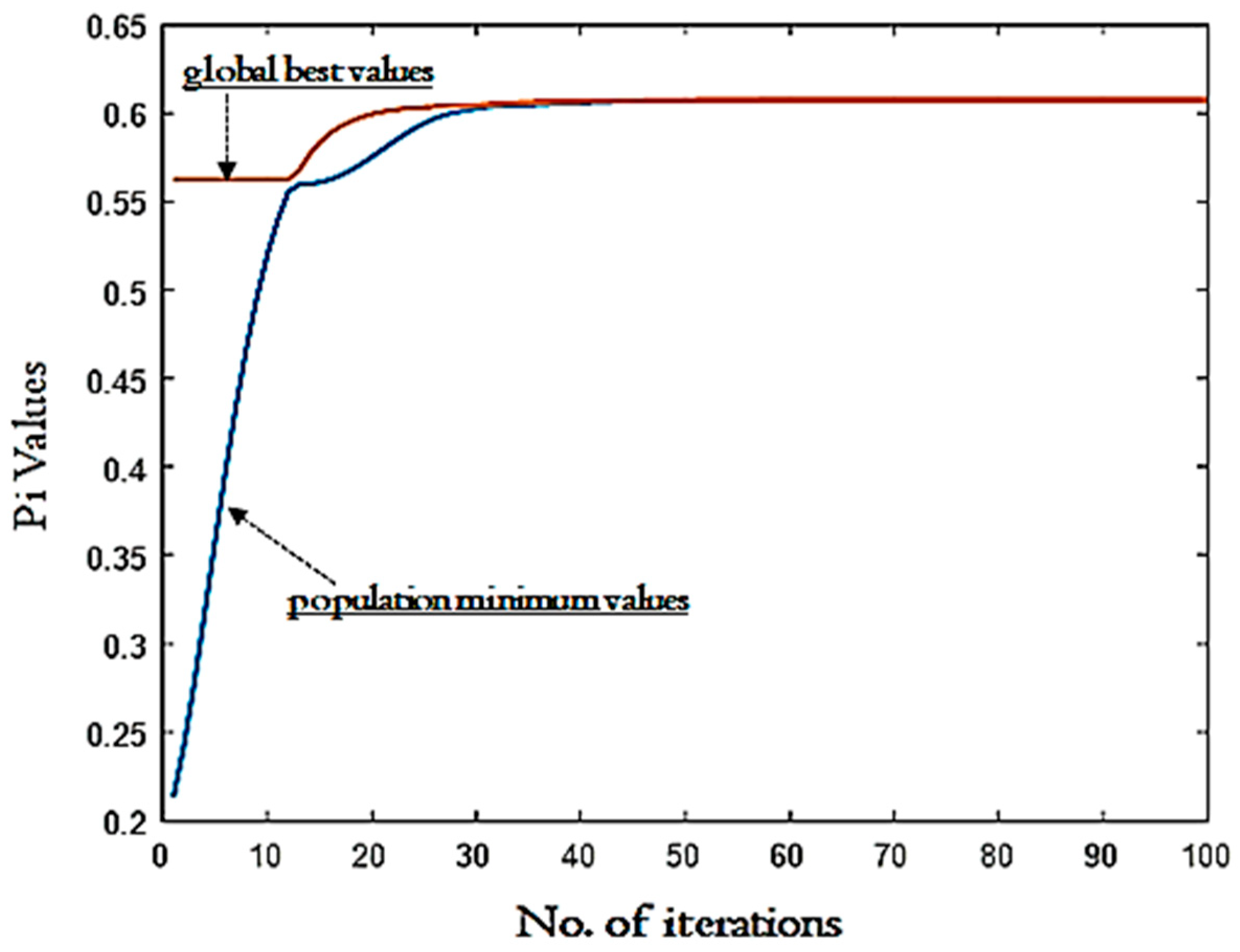

- Step 5: In the fifth step, the empirical model was solved varying the population and generation using PSO. With the implementation of PSO, the global best velocity and positions were determined.

- Step 6: Finally, confirmation experiments were performed at the machining setting suggested by the MCDM approach to analyze the performance characteristics of machining for titanium.

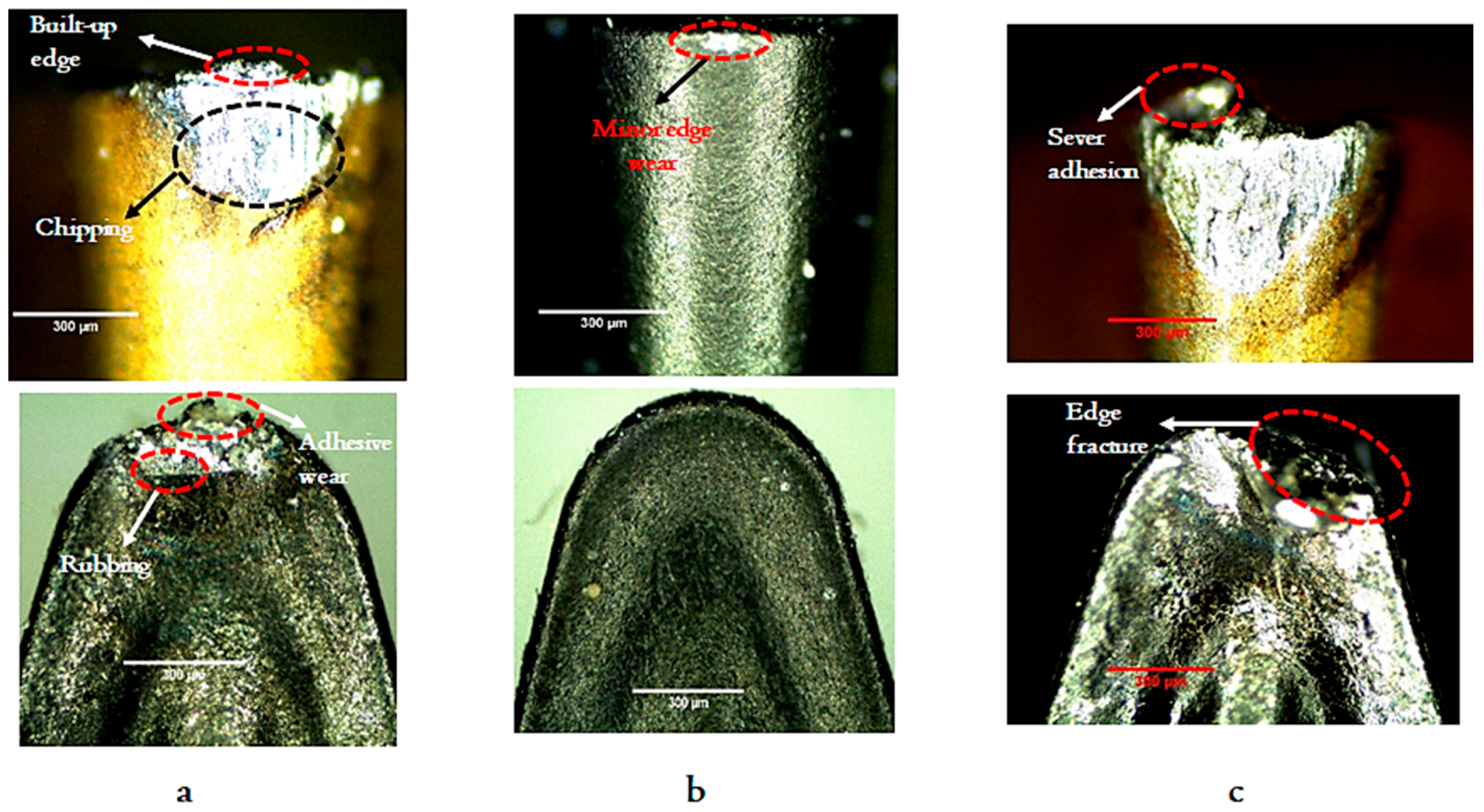

3. Results and Discussions: Analysis, Optimization and Validation

0.1 ≤ DoC ≤ 0.3

0.05 ≤ Feed≤ 0.15

5 ≤ Cutting Length ≤ 120

Performance Index = 0.12 − 0.0005 × speed − 0.79 × DoC + 3.218 × F + 0.0012 × Cutting Length + 0.0026 × speed × DoC + 0.0046 × speed × F

- Minimizing Ra and Rq

- Maximizing MRR

- Multi-objective optimization between Ra, Rq and MRR

4. Conclusions and Future Work

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Jamil, M.; Khan, A.M.; Hegab, H.; Gong, L.; Mia, M.; Gupta, M.K.; He, N. Effects of hybrid Al2O3-CNT nanofluids and cryogenic cooling on machining of Ti–6Al–4V. Int. J. Adv. Manuf. Technol. 2019, 102, 3895–3909. [Google Scholar] [CrossRef]

- Mia, M.; Dhar, N.R. Effects of duplex jets high-pressure coolant on machining temperature and machinability of Ti-6Al-4V superalloy. J. Mater. Process. Technol. 2018, 252, 688–696. [Google Scholar] [CrossRef]

- Arrazola, P.J.; Garay, A.; Iriarte, L.M.; Armendia, M.; Marya, S.; Le Maître, F. Machinability of titanium alloys (Ti6Al4V and Ti555.3). J. Mater. Process. Technol. 2009, 209, 2223–2230. [Google Scholar] [CrossRef]

- Komanduri, R. Some clarifications on the mechanics of chip formation when machining titanium alloys. Wear 1982, 76, 15–34. [Google Scholar] [CrossRef]

- Sun, J.; Guo, Y. A comprehensive experimental study on surface integrity by end milling Ti–6Al–4V. J. Mater. Process. Technol. 2009, 209, 4036–4042. [Google Scholar] [CrossRef]

- Ginting, A.; Nouari, M. Surface integrity of dry machined titanium alloys. Int. J. Mach. Tools Manuf. 2009, 49, 325–332. [Google Scholar] [CrossRef]

- Selvakumar, S.; Ravikumar, R.; Raja, K. Implementation of response surface methodology in finish turning on titanium alloy Gr. 2. Eur. J. Sci. Res. 2012, 81, 436–445. [Google Scholar]

- Pervaiz, S.; Deiab, I.; Rashid, A.; Nicolescu, M.; Kishawy, H. Energy consumption and surface finish analysis of machining Ti6Al4V. World Acad. Sci. Eng. Technol. 2013, 76, 113–118. [Google Scholar]

- Fang, N.; Wu, Q. A comparative study of the cutting forces in high speed machining of Ti–6Al–4V and Inconel 718 with a round cutting edge tool. J. Mater. Process. Technol. 2009, 209, 4385–4389. [Google Scholar] [CrossRef]

- D’Mello, G.; Pai, P.S.; Puneet, N.; Fang, N. Surface roughness evaluation using cutting vibrations in high speed turning of Ti-6Al-4V-an experimental approach. Int. J. Mach. Mach. Mater. 2016, 18, 288–312. [Google Scholar]

- Ezugwu, E.O.; Bonney, J.; Da Silva, R.B.; Cakir, O. Surface integrity of finished turned Ti–6Al–4V alloy with PCD tools using conventional and high pressure coolant supplies. Int. J. Mach. Tools Manuf. 2007, 47, 884–891. [Google Scholar] [CrossRef]

- Yigit, R.; Celik, E.; Findik, F.; Koksal, S. Effect of cutting speed on the performance of coated and uncoated cutting tools in turning nodular cast iron. J. Mater. Process. Technol. 2008, 204, 80–88. [Google Scholar] [CrossRef]

- Haron, C.C.; Ginting, A.; Goh, J. Wear of coated and uncoated carbides in turning tool steel. J. Mater. Process. Technol. 2001, 116, 49–54. [Google Scholar] [CrossRef]

- Sun, S.; Brandt, M.; Mo, J.P. Evolution of tool wear and its effect on cutting forces during dry machining of Ti-6Al-4V alloy. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2014, 228, 191–202. [Google Scholar] [CrossRef]

- Ezugwu, E.; Da Silva, R.; Bonney, J.; Machado, A. Evaluation of the performance of CBN tools when turning Ti–6Al–4V alloy with high pressure coolant supplies. Int. J. Mach. Tools Manuf. 2005, 45, 1009–1014. [Google Scholar] [CrossRef]

- Mello, G.D.; Pai, P.S. Surface Roughness Modeling in High Speed Turning of Ti-6Al-4V Using Response Surface Methodology. Mater. Today Proc. 2018, 5, 11686–11696. [Google Scholar] [CrossRef]

- Ramesh, S.; Karunamoorthy, L.; Palanikumar, K. Measurement and analysis of surface roughness in turning of aerospace titanium alloy (gr5). Measurement 2012, 45, 1266–1276. [Google Scholar] [CrossRef]

- Sen, B.; Hussain, S.A.I.; Mia, M.; Mandal, U.K.; Mondal, S.P. Selection of an ideal MQL-assisted milling condition: An NSGA-II-coupled TOPSIS approach for improving machinability of Inconel 690. Int. J. Adv. Manuf. Technol. 2019, 103, 1811–1829. [Google Scholar] [CrossRef]

- Bhowmik, S.; Paul, A.; Panua, R.; Ghosh, S.K.; Debroy, D. Performance-exhaust emission prediction of diesosenol fueled diesel engine: An ANN coupled MORSM based optimization. Energy 2018, 153, 212–222. [Google Scholar] [CrossRef]

- Ranganathan, S.; Senthilvelan, T.; Sriram, G. Evaluation of machining parameters of hot turning of stainless steel (Type 316) by applying ANN and RSM. Mater. Manuf. Process. 2010, 25, 1131–1141. [Google Scholar] [CrossRef]

- Brauers, W.K. Optimization Methods for a Stakeholder Society: A Revolution in Economic Thinking by Multi-Objective Optimization; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013; Volume 73. [Google Scholar]

- Abbas, A.T.; Benyahia, F.; El Rayes, M.M.; Pruncu, C.; Taha, M.A.; Hegab, H. Towards optimization of machining performance and sustainability aspects when turning AISI 1045 Steel under different cooling and lubrication strategies. Materials 2019, 12, 3023. [Google Scholar] [CrossRef] [PubMed]

- Hegab, H.; Kishawy, H.A.; Umer, U.; Mohany, A. A model for machining with nano-additives based minimum quantity lubrication. Int. J. Adv. Manuf. Technol. 2019, 102, 1–16. [Google Scholar] [CrossRef]

| N | C | H | Fe | O | Al | V | Ti |

|---|---|---|---|---|---|---|---|

| 0.05% | 0.1% | 0.012% | 0.4% | 0.2% | 6% | 4% | Balance |

| Tensile Strength (MPa) | Yield Strength, 0.2% Offset (MPa) | Elongation (%) | Reduction of Area (%) | Hardness |

|---|---|---|---|---|

| 895 | 825 | 10 | 25 | HRC 36 |

| Test # | Speed (m/min) | Depth of Cut (mm) | Feed (mm/rev) | Cutting Length (mm) | Ra (µm) | Rq (μm) | MRR (mm3/min) |

|---|---|---|---|---|---|---|---|

| 1 | 300 | 0.1 | 0.05 | 5 | 0.590 | 0.707 | 1500 |

| 2 | 300 | 0.1 | 0.05 | 40 | 0.767 | 0.866 | 1500 |

| 3 | 300 | 0.1 | 0.05 | 80 | 1.048 | 1.210 | 1500 |

| 4 | 300 | 0.1 | 0.05 | 120 | 1.183 | 1.335 | 1500 |

| 5 | 300 | 0.1 | 0.15 | 5 | 2.001 | 2.459 | 4500 |

| 6 | 300 | 0.1 | 0.15 | 40 | 2.539 | 3.062 | 4500 |

| 7 | 300 | 0.1 | 0.15 | 80 | 2.917 | 3.553 | 4500 |

| 8 | 300 | 0.1 | 0.15 | 120 | 4.326 | 5.213 | 4500 |

| 9 | 200 | 0.1 | 0.05 | 5 | 0.470 | 0.598 | 1000 |

| 10 | 200 | 0.1 | 0.05 | 40 | 0.486 | 0.603 | 1000 |

| 11 | 200 | 0.1 | 0.05 | 80 | 0.601 | 0.758 | 1000 |

| 12 | 200 | 0.1 | 0.05 | 120 | 0.689 | 0.916 | 1000 |

| 13 | 200 | 0.1 | 0.15 | 5 | 1.497 | 1.762 | 3000 |

| 14 | 200 | 0.1 | 0.15 | 40 | 1.539 | 1.883 | 3000 |

| 15 | 200 | 0.1 | 0.15 | 80 | 1.808 | 2.064 | 3000 |

| 16 | 200 | 0.1 | 0.15 | 120 | 2.262 | 2.520 | 3000 |

| 17 | 100 | 0.1 | 0.05 | 5 | 0.244 | 0.310 | 500 |

| 18 | 100 | 0.1 | 0.05 | 40 | 0.295 | 0.392 | 500 |

| 19 | 100 | 0.1 | 0.05 | 80 | 0.302 | 0.384 | 500 |

| 20 | 100 | 0.1 | 0.05 | 120 | 0.370 | 0.455 | 500 |

| 21 | 100 | 0.1 | 0.15 | 5 | 1.747 | 2.264 | 1500 |

| 22 | 100 | 0.1 | 0.15 | 40 | 1.869 | 2.254 | 1500 |

| 23 | 100 | 0.1 | 0.15 | 80 | 1.910 | 2.447 | 1500 |

| 24 | 100 | 0.1 | 0.15 | 120 | 2.146 | 2.502 | 1500 |

| 25 | 300 | 0.3 | 0.05 | 5 | 0.687 | 0.813 | 4500 |

| 26 | 300 | 0.3 | 0.05 | 40 | 0.722 | 0.818 | 4500 |

| 27 | 300 | 0.3 | 0.05 | 80 | 0.810 | 0.935 | 4500 |

| 28 | 300 | 0.3 | 0.05 | 120 | 1.031 | 1.212 | 4500 |

| 29 | 300 | 0.3 | 0.15 | 5 | 1.701 | 1.997 | 13,500 |

| 30 | 300 | 0.3 | 0.15 | 40 | 1.877 | 2.213 | 13,500 |

| 31 | 300 | 0.3 | 0.15 | 80 | 4.700 | 5.352 | 13,500 |

| 32 | 300 | 0.3 | 0.15 | 120 | 4.956 | 6.240 | 13,500 |

| 33 | 200 | 0.3 | 0.05 | 5 | 1.008 | 1.482 | 3000 |

| 34 | 200 | 0.3 | 0.05 | 40 | 1.104 | 1.529 | 3000 |

| 35 | 200 | 0.3 | 0.05 | 80 | 1.430 | 1.728 | 3000 |

| 36 | 200 | 0.3 | 0.05 | 120 | 1.533 | 1.901 | 3000 |

| 37 | 200 | 0.3 | 0.15 | 5 | 1.821 | 2.300 | 9000 |

| 38 | 200 | 0.3 | 0.15 | 40 | 1.891 | 2.355 | 9000 |

| 39 | 200 | 0.3 | 0.15 | 80 | 2.002 | 2.235 | 9000 |

| 40 | 200 | 0.3 | 0.15 | 120 | 2.576 | 2.808 | 9000 |

| 41 | 100 | 0.3 | 0.05 | 5 | 0.440 | 0.533 | 1500 |

| 42 | 100 | 0.3 | 0.05 | 40 | 0.633 | 0.761 | 1500 |

| 43 | 100 | 0.3 | 0.05 | 80 | 0.923 | 1.183 | 1500 |

| 44 | 100 | 0.3 | 0.05 | 120 | 0.993 | 1.218 | 1500 |

| 45 | 100 | 0.3 | 0.15 | 5 | 1.452 | 1.802 | 4500 |

| 46 | 100 | 0.3 | 0.15 | 40 | 1.633 | 1.911 | 4500 |

| 47 | 100 | 0.3 | 0.15 | 80 | 1.727 | 1.999 | 4500 |

| 48 | 100 | 0.3 | 0.15 | 120 | 1.788 | 2.110 | 4500 |

| Test # | Ra2 | Rq2 | MRR2 | Normalized Ra | Normalized Rq | Normalized MRR | Performance Index (Pi) |

|---|---|---|---|---|---|---|---|

| 1 | 0.3481 | 0.4998 | 2,250,000 | 0.0461 | 0.0460 | 0.0401 | 0.1322 |

| 2 | 0.5883 | 0.7500 | 2,250,000 | 0.0599 | 0.0563 | 0.0401 | 0.1563 |

| 3 | 1.0983 | 1.4641 | 2,250,000 | 0.0819 | 0.0787 | 0.0401 | 0.2007 |

| 4 | 1.3995 | 1.7822 | 2,250,000 | 0.0924 | 0.0869 | 0.0401 | 0.2193 |

| 5 | 4.0040 | 6.0467 | 20,250,000 | 0.1563 | 0.1600 | 0.1203 | 0.4365 |

| 6 | 6.4465 | 9.3758 | 20,250,000 | 0.1983 | 0.1992 | 0.1203 | 0.5178 |

| 7 | 8.5089 | 12.6238 | 20,250,000 | 0.2278 | 0.2312 | 0.1203 | 0.5793 |

| 8 | 18.7143 | 27.1754 | 20,250,000 | 0.3379 | 0.3392 | 0.1203 | 0.7973 |

| 9 | 0.2209 | 0.3576 | 1,000,000 | 0.0367 | 0.0389 | 0.0267 | 0.1023 |

| 10 | 0.2362 | 0.3636 | 1,000,000 | 0.0380 | 0.0392 | 0.0267 | 0.1039 |

| 11 | 0.3612 | 0.5746 | 1,000,000 | 0.0469 | 0.0493 | 0.0267 | 0.1230 |

| 12 | 0.4747 | 0.8391 | 1,000,000 | 0.0538 | 0.0596 | 0.0267 | 0.1401 |

| 13 | 2.2410 | 3.1046 | 9,000,000 | 0.1169 | 0.1146 | 0.0802 | 0.3117 |

| 14 | 2.3685 | 3.5457 | 9,000,000 | 0.1202 | 0.1225 | 0.0802 | 0.3229 |

| 15 | 3.2689 | 4.2601 | 9,000,000 | 0.1412 | 0.1343 | 0.0802 | 0.3557 |

| 16 | 5.1166 | 6.3504 | 9,000,000 | 0.1767 | 0.1639 | 0.0802 | 0.4208 |

| 17 | 0.0595 | 0.0961 | 250,000 | 0.0191 | 0.0202 | 0.0134 | 0.0526 |

| 18 | 0.0870 | 0.1537 | 250,000 | 0.0230 | 0.0255 | 0.0134 | 0.0619 |

| 19 | 0.0912 | 0.1475 | 250,000 | 0.0236 | 0.0250 | 0.0134 | 0.0619 |

| 20 | 0.1369 | 0.2070 | 250,000 | 0.0289 | 0.0296 | 0.0134 | 0.0719 |

| 21 | 3.0520 | 5.1257 | 2,250,000 | 0.1365 | 0.1473 | 0.0401 | 0.3238 |

| 22 | 3.4932 | 5.0805 | 2,250,000 | 0.1460 | 0.1466 | 0.0401 | 0.3327 |

| 23 | 3.6481 | 5.9878 | 2,250,000 | 0.1492 | 0.1592 | 0.0401 | 0.3485 |

| 24 | 4.6053 | 6.2600 | 2,250,000 | 0.1676 | 0.1628 | 0.0401 | 0.3705 |

| 25 | 0.4720 | 0.6610 | 20,250,000 | 0.0537 | 0.0529 | 0.1203 | 0.2268 |

| 26 | 0.5213 | 0.6691 | 20,250,000 | 0.0564 | 0.0532 | 0.1203 | 0.2299 |

| 27 | 0.6561 | 0.8742 | 20,250,000 | 0.0633 | 0.0608 | 0.1203 | 0.2444 |

| 28 | 1.0630 | 1.4689 | 20,250,000 | 0.0805 | 0.0789 | 0.1203 | 0.2797 |

| 29 | 2.8934 | 3.9880 | 182,250,000 | 0.1329 | 0.1299 | 0.3608 | 0.6236 |

| 30 | 3.5231 | 4.8974 | 182,250,000 | 0.1466 | 0.1440 | 0.3608 | 0.6514 |

| 31 | 22.0900 | 28.6439 | 182,250,000 | 0.3671 | 0.3482 | 0.3608 | 1.0761 |

| 32 | 24.5619 | 38.9376 | 182,250,000 | 0.3871 | 0.4060 | 0.3608 | 1.1539 |

| 33 | 1.0161 | 2.1963 | 9,000,000 | 0.0787 | 0.0964 | 0.0802 | 0.2553 |

| 34 | 1.2188 | 2.3378 | 9,000,000 | 0.0862 | 0.0995 | 0.0802 | 0.2659 |

| 35 | 2.0449 | 2.9860 | 9,000,000 | 0.1117 | 0.1124 | 0.0802 | 0.3043 |

| 36 | 2.3501 | 3.6138 | 9,000,000 | 0.1197 | 0.1237 | 0.0802 | 0.3236 |

| 37 | 3.3160 | 5.2900 | 81,000,000 | 0.1422 | 0.1496 | 0.2405 | 0.5324 |

| 38 | 3.5759 | 5.5460 | 81,000,000 | 0.1477 | 0.1532 | 0.2405 | 0.5415 |

| 39 | 4.0080 | 4.9952 | 81,000,000 | 0.1564 | 0.1454 | 0.2405 | 0.5423 |

| 40 | 6.6358 | 7.8849 | 81,000,000 | 0.2012 | 0.1827 | 0.2405 | 0.6244 |

| 41 | 0.1936 | 0.2841 | 2,250,000 | 0.0344 | 0.0347 | 0.0401 | 0.1091 |

| 42 | 0.4007 | 0.5791 | 2,250,000 | 0.0494 | 0.0495 | 0.0401 | 0.1390 |

| 43 | 0.8519 | 1.3995 | 2,250,000 | 0.0721 | 0.0770 | 0.0401 | 0.1891 |

| 44 | 0.9860 | 1.4835 | 2,250,000 | 0.0776 | 0.0792 | 0.0401 | 0.1969 |

| 45 | 2.1083 | 3.2472 | 20,250,000 | 0.1134 | 0.1172 | 0.1203 | 0.3509 |

| 46 | 2.6667 | 3.6519 | 20,250,000 | 0.1276 | 0.1243 | 0.1203 | 0.3721 |

| 47 | 2.9825 | 3.9960 | 20,250,000 | 0.1349 | 0.1301 | 0.1203 | 0.3852 |

| 48 | 3.1969 | 4.4521 | 20,250,000 | 0.1397 | 0.1373 | 0.1203 | 0.3972 |

| Source | Degree of Freedom (DF) | Statistical Summation (SS) | Contribution Percentage (%) | Mean Square (MS) | F-Value | P-Value |

|---|---|---|---|---|---|---|

| Model | 11 | 2.34519 | 0.21320 | 20.98 | 0.000 | |

| Speed | 2 | 0.04423 | 1.63 | 0.02211 | 2.18 | 0.128 |

| DoC* | 1 | 0.00427 | 0.16 | 0.00427 | 0.42 | 0.521 |

| F* | 1 | 1.39348 | 51.4 | 1.39348 | 137.11 | 0.000 |

| Cutting Length | 3 | 0.12240 | 4.51 | 0.04080 | 4.01 | 0.015 |

| Speed*DoC | 2 | 0.68923 | 25.42 | 0.34462 | 33.91 | 0.000 |

| Speed*F | 2 | 0.09158 | 3.38 | 0.04579 | 4.51 | 0.018 |

| Error | 36 | 0.36586 | 13.5 | 0.01016 | ||

| Total | 47 | 2.71106 |

| Cutting Conditions | Initial Machining Parameter | Predicted | Experimental | |

|---|---|---|---|---|

| Ra and Rq | MRR | |||

| (S)100(DoC)0.1(F)0.05(CL)5 | (S)300(DoC)0.3(F)0.15(CL)120 | (S)190(DoC)0.1(F)0.15(CL)120 | (S)190(DoC)0.1(F)0.15(CL)120 | |

| Ra | 0.244 | 4.956 | 2.262 | 2.19 |

| Rq | 0.31 | 6.240 | 2.52 | 2.43 |

| MRR | 500 | 13,500 | 3000 | 2850 |

| Pi | - | - | 0.6074 | - |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abbas, A.T.; Sharma, N.; Anwar, S.; Hashmi, F.H.; Jamil, M.; Hegab, H. Towards Optimization of Surface Roughness and Productivity Aspects during High-Speed Machining of Ti–6Al–4V. Materials 2019, 12, 3749. https://doi.org/10.3390/ma12223749

Abbas AT, Sharma N, Anwar S, Hashmi FH, Jamil M, Hegab H. Towards Optimization of Surface Roughness and Productivity Aspects during High-Speed Machining of Ti–6Al–4V. Materials. 2019; 12(22):3749. https://doi.org/10.3390/ma12223749

Chicago/Turabian StyleAbbas, Adel T., Neeraj Sharma, Saqib Anwar, Faraz H. Hashmi, Muhammad Jamil, and Hussien Hegab. 2019. "Towards Optimization of Surface Roughness and Productivity Aspects during High-Speed Machining of Ti–6Al–4V" Materials 12, no. 22: 3749. https://doi.org/10.3390/ma12223749

APA StyleAbbas, A. T., Sharma, N., Anwar, S., Hashmi, F. H., Jamil, M., & Hegab, H. (2019). Towards Optimization of Surface Roughness and Productivity Aspects during High-Speed Machining of Ti–6Al–4V. Materials, 12(22), 3749. https://doi.org/10.3390/ma12223749