Comparison of Achievable Contrast Features in Computed Tomography Observing the Growth of a 4H-SiC Bulk Crystal

Abstract

:1. Introduction

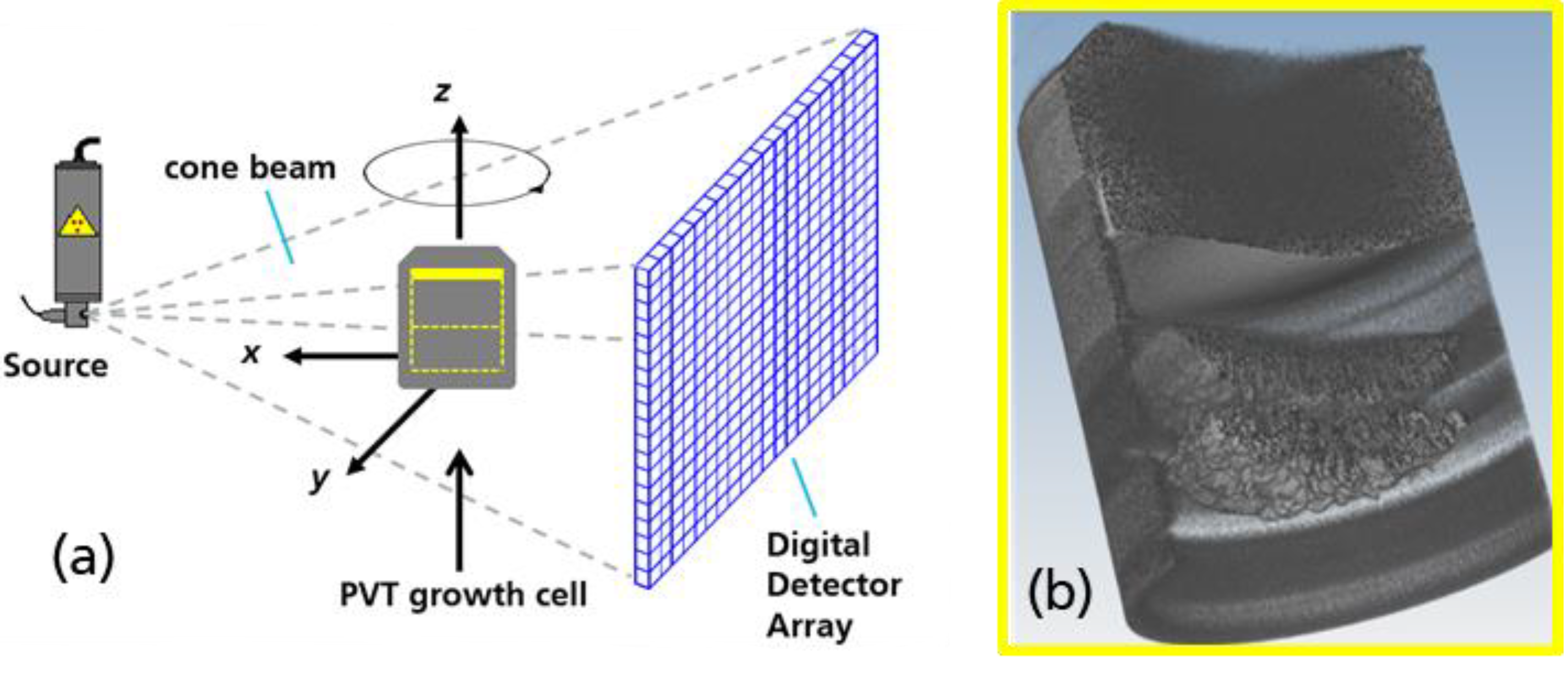

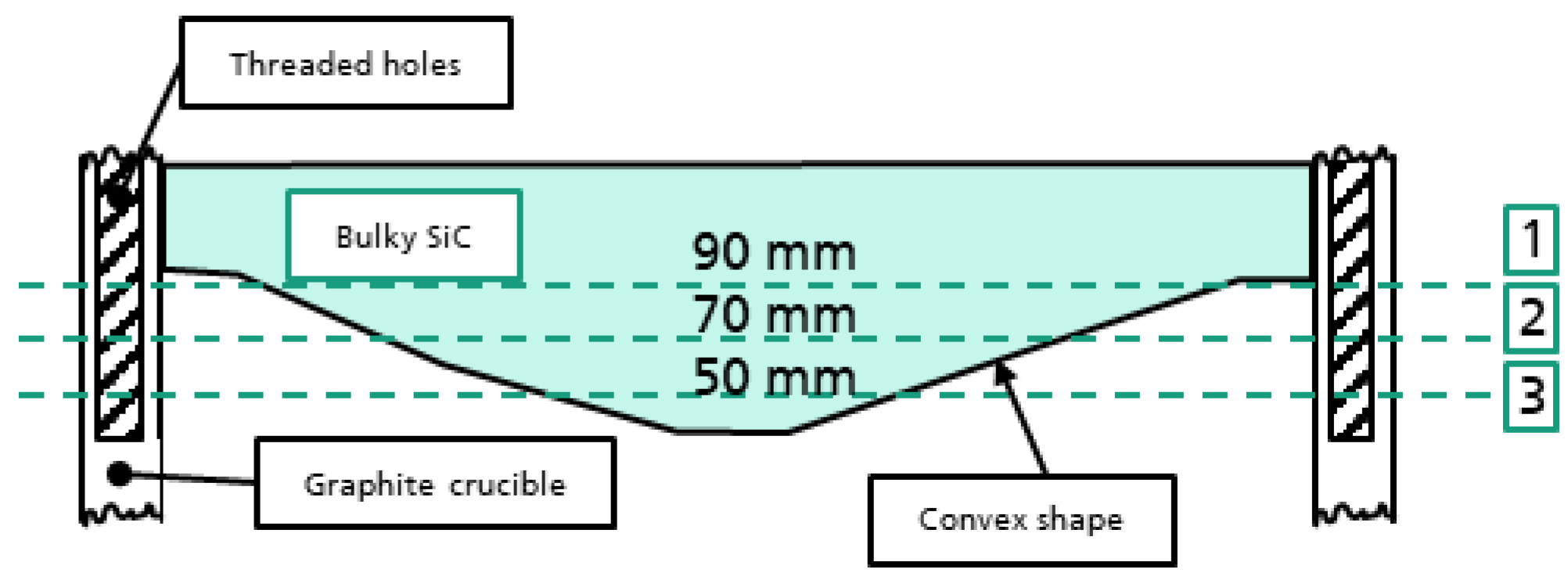

2. Materials and Methods

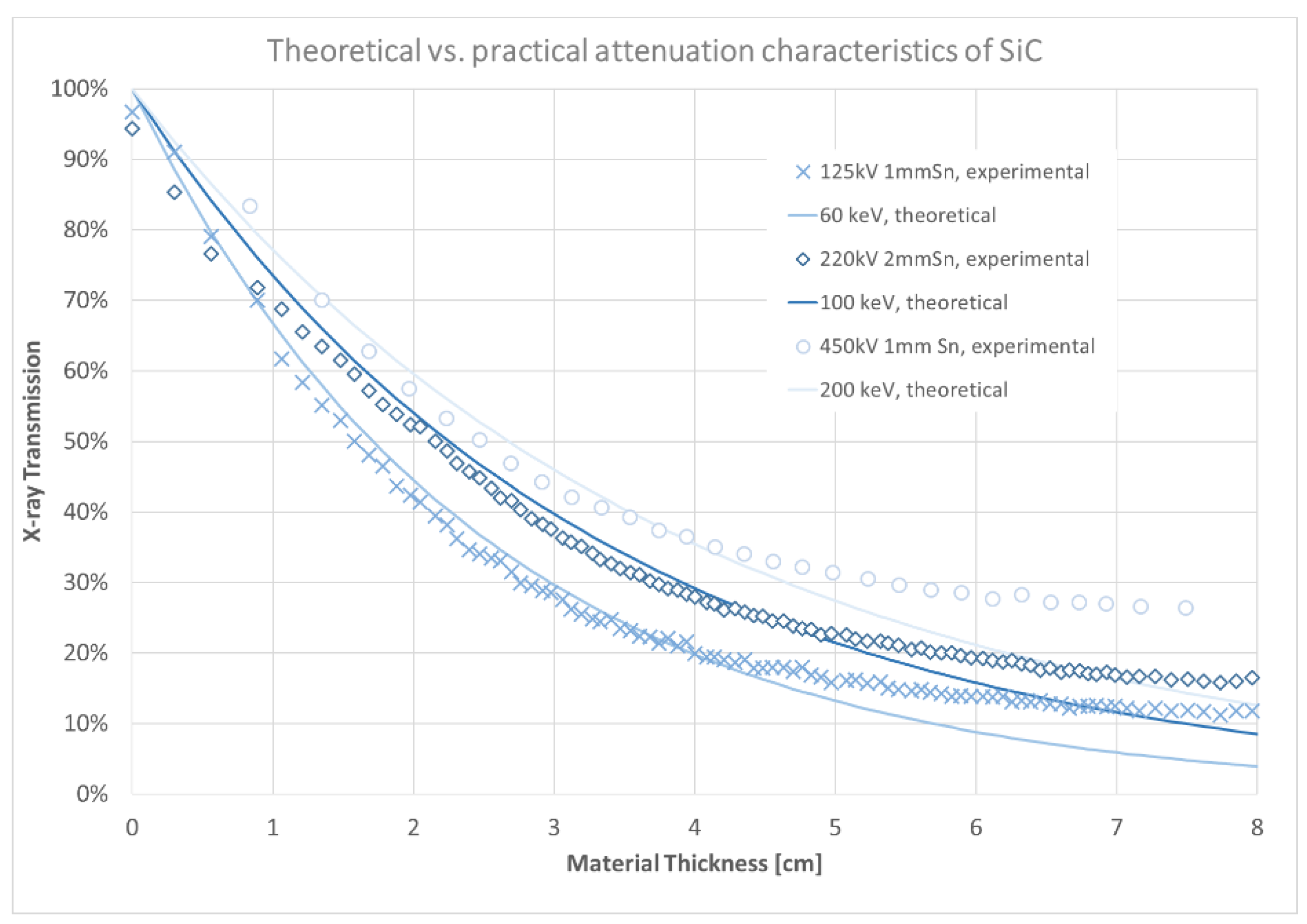

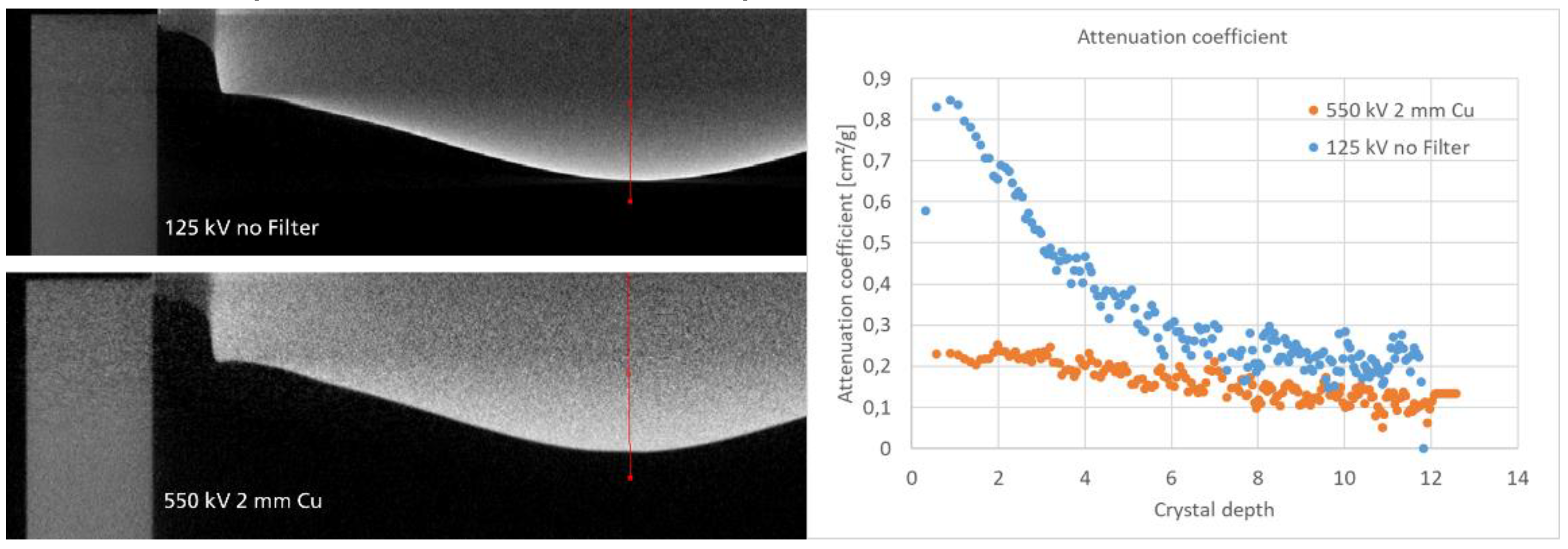

2.1. Attenuation Properties and Influence on the Density Fidelity in CT

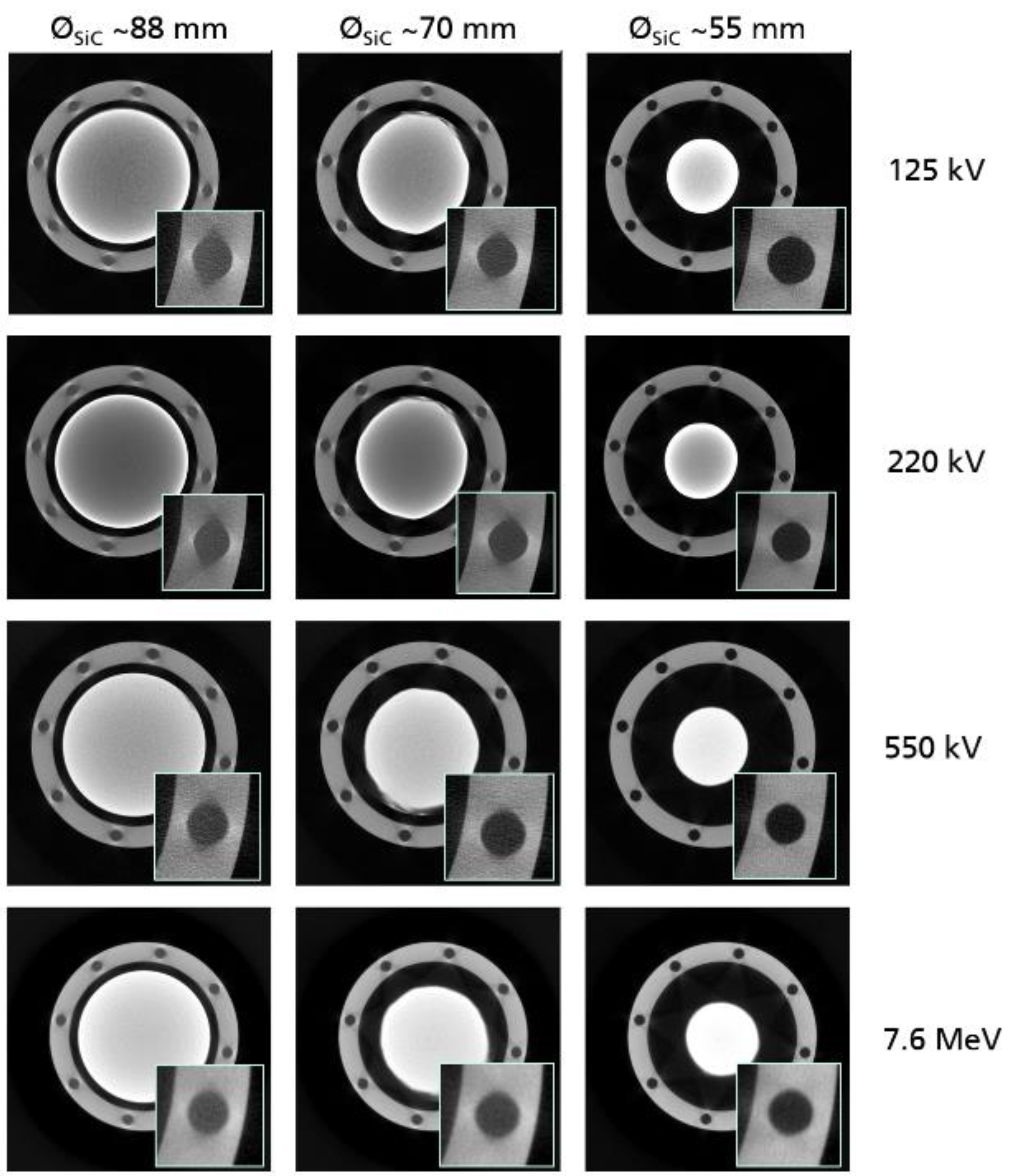

2.2. Contrast Properties in Ex Situ CT Scan

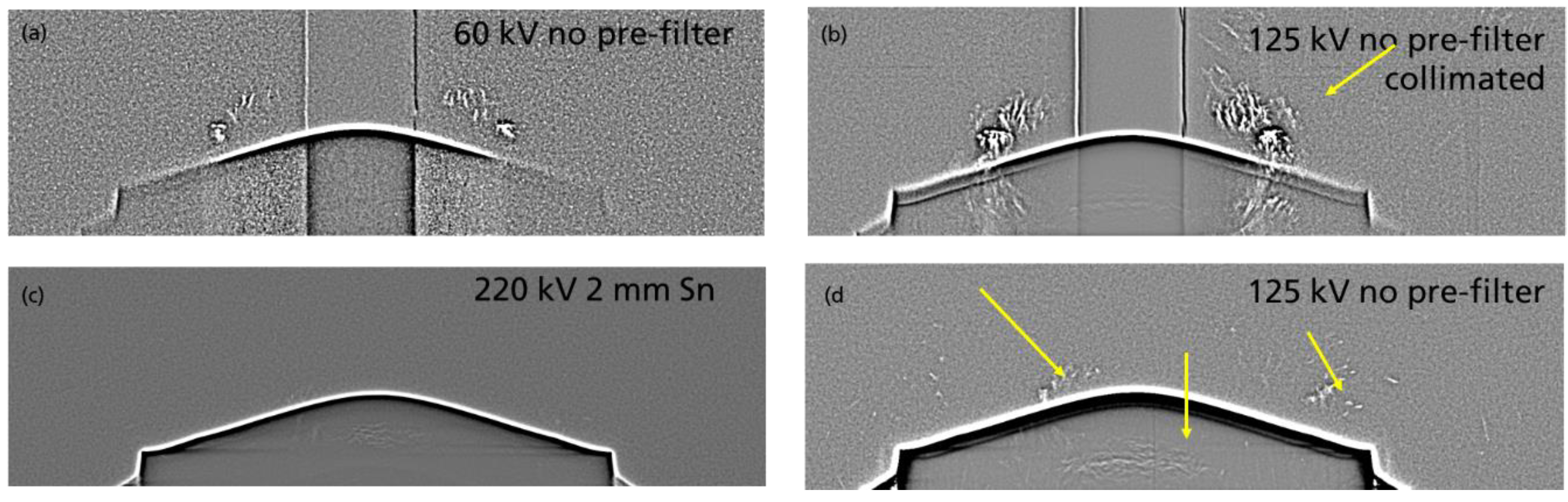

2.3. Side Effects of X-ray Diffraction

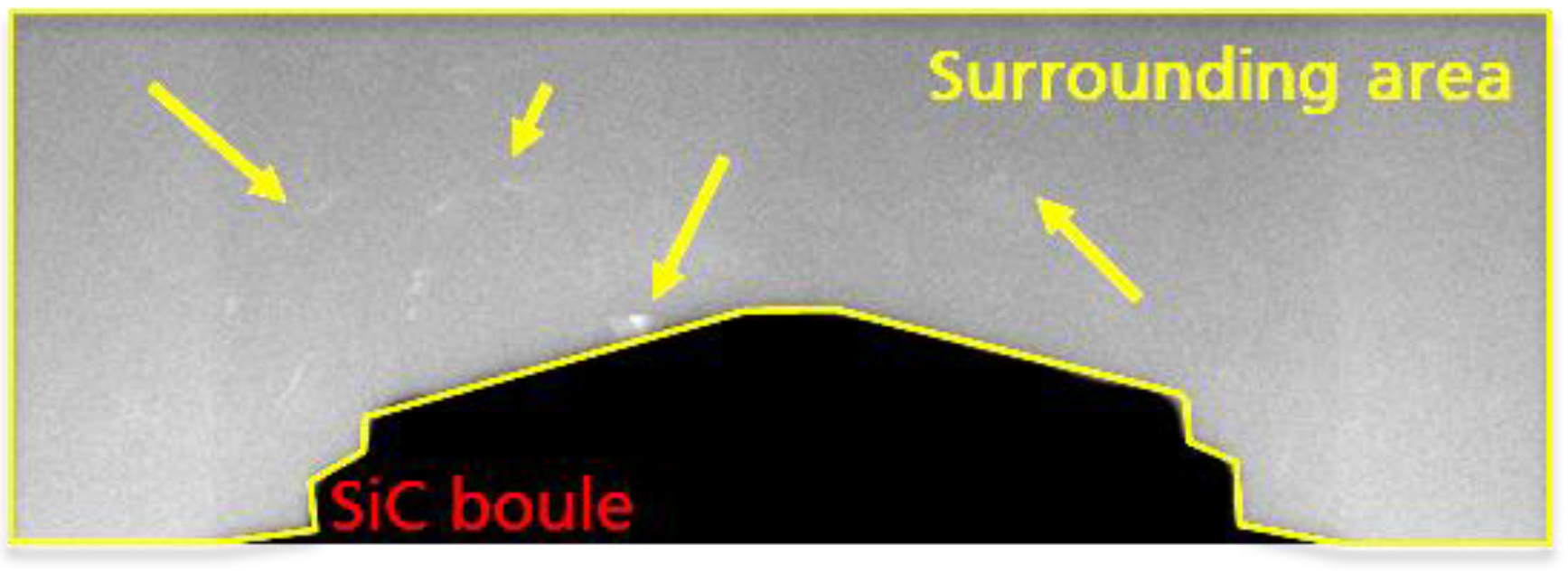

3. Results

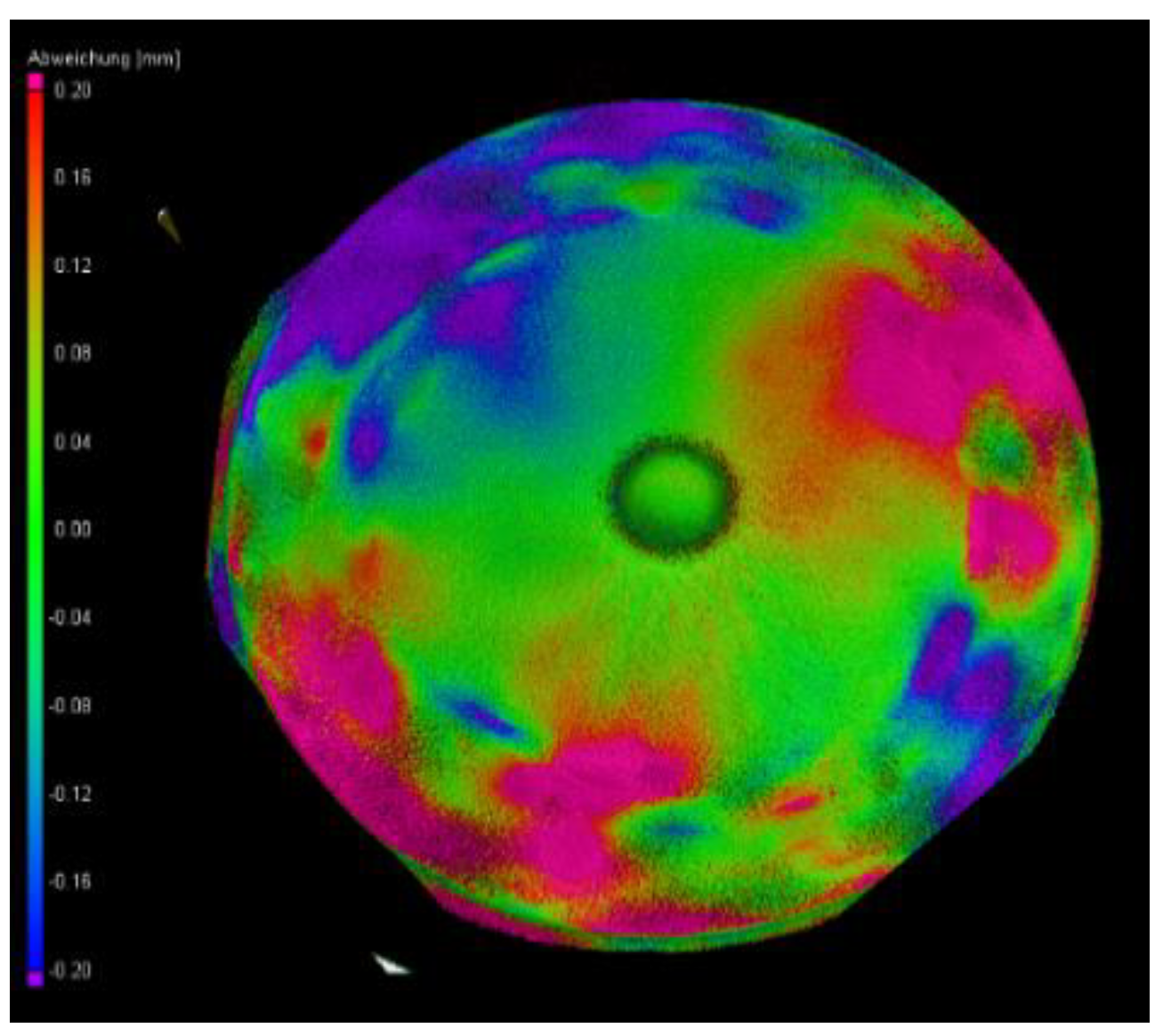

3.1. Attenuation Properties and Influence on the Density Fidelity in CT

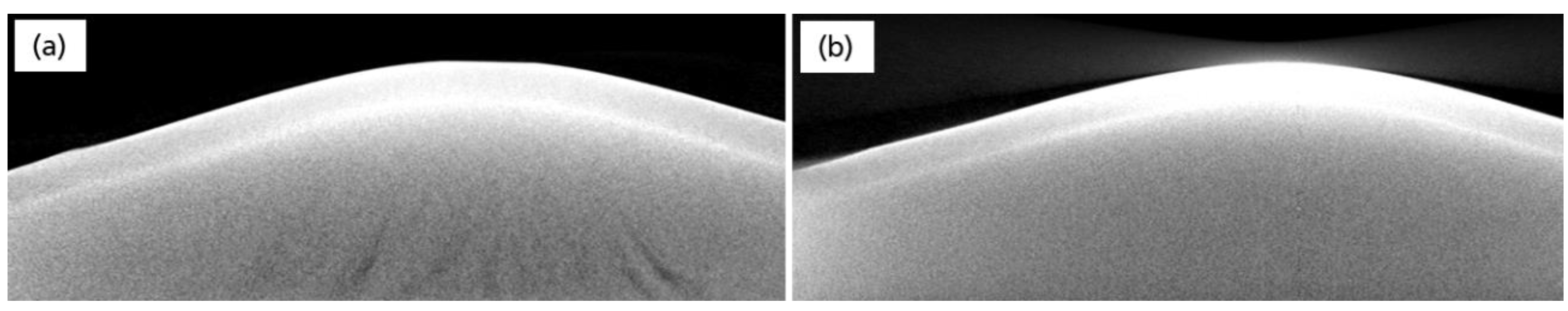

3.2. Contrast Properties in Ex Situ CT Scan

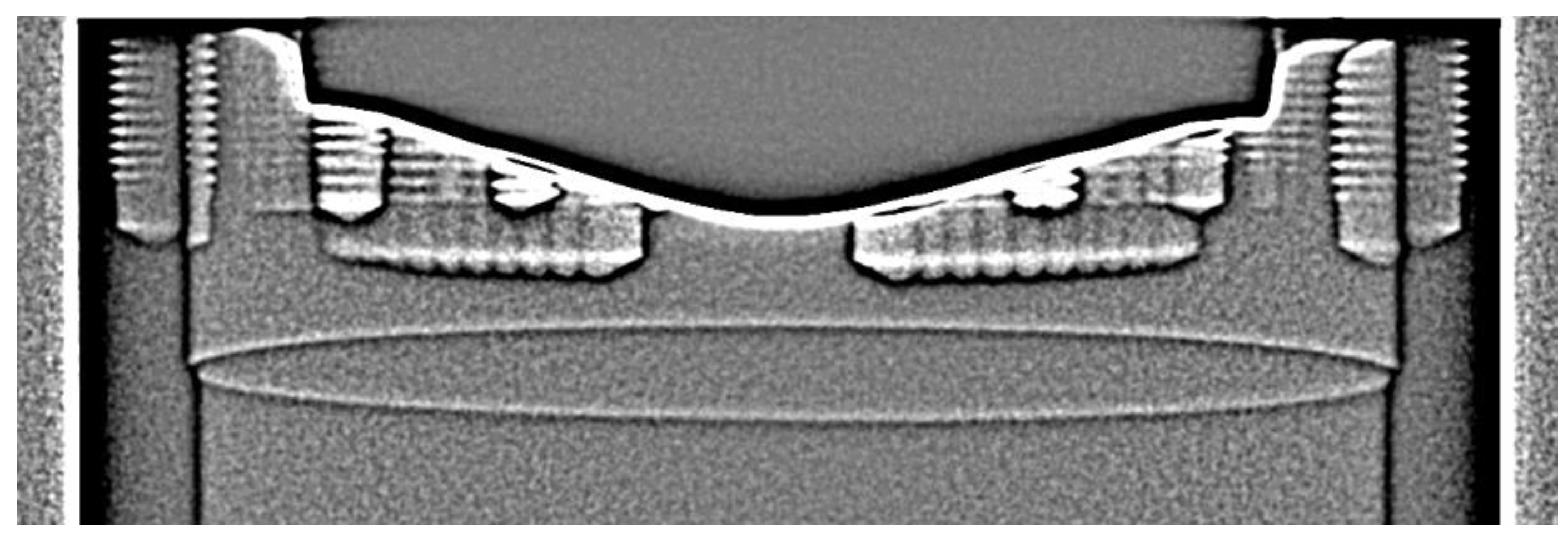

3.3. Side Effects of X-ray Diffraction

4. Final Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wellmann, P.; Neubauer, G.; Fahlbusch, L.; Salamon, M.; Uhlmann, N. Growth of SiC bulk crystals for application in power electronic devices—process design, 2D and 3D X-ray in situ visualization and advanced doping. Cryst. Res. Technol. 2015, 50, 2–9. [Google Scholar] [CrossRef]

- Salamon, M.; Arzig, M.; Uhlmann, N.; Wellmann, P. Advances in In Situ SiC growth analysis using cone beam computed tomography. Mater. Sci. Forum 2019, 963, 5–9. [Google Scholar] [CrossRef]

- Salamon, M.; Arzig, M.; Wellmann, P.J.; Uhlmann, N. Three-dimensional in-situ growth surveillance of bulky SiC crystals. International Symposium on Digital Industrial Radiology and Computed Tomography—DIR2019. Available online: http://www.dir2019.com/Programme#We.2.A.1 (accessed on 5 November 2019).

- Hubbell, J.H.; Coursey, J.S.; Hwang, J.; Zucker, D.S. Bibliography of Photon Total Cross Section (Attenuation Coefficient) Measurements (version 2.3). National Institute of Standards and Technology, Gaithersburg, MD. 2003. Available online: http://physics.nist.gov/photoncs (accessed on 23 September 2019).

- Feldkamp, L.A.; Davis, L.C.; Kress, J.W. Practical cone-beam algorithm. J. Opt. Soc. Am. A 1984, 1, 612–619. [Google Scholar] [CrossRef]

- Bragg, W.H.; Bragg, W.L. The reaction of x-rays by crystals. Proc. R. Soc. Lond. A Math. Phys. Eng. Sci. 1913, 88, 428–438. [Google Scholar] [CrossRef]

| Name | Max X-ray Energy | Applied X-ray Energy | Pre-Filtration (mm) |

|---|---|---|---|

| PVT-CT | 125 kV | 125 kV | PVT Reactor 1 |

| Micro CT | 225 kV | 125 kV | 1 Al |

| Micro CT | 225 kV | 125 kV | 1 Sn |

| Micro CT | 225 kV | 220 kV | 2 Sn |

| Micro CT | 225 kV | 220 kV | 0.5 Cu |

| Macro CT | 600 kV | 450 kV | 1 Sn |

| Macro CT | 600 kV | 550 kV | 2 Cu |

| Linac CT | 9 MV | 7.6 MV | 2 Al |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salamon, M.; Arzig, M.; Wellmann, P.J.; Uhlmann, N. Comparison of Achievable Contrast Features in Computed Tomography Observing the Growth of a 4H-SiC Bulk Crystal. Materials 2019, 12, 3652. https://doi.org/10.3390/ma12223652

Salamon M, Arzig M, Wellmann PJ, Uhlmann N. Comparison of Achievable Contrast Features in Computed Tomography Observing the Growth of a 4H-SiC Bulk Crystal. Materials. 2019; 12(22):3652. https://doi.org/10.3390/ma12223652

Chicago/Turabian StyleSalamon, Michael, Matthias Arzig, Peter J. Wellmann, and Norman Uhlmann. 2019. "Comparison of Achievable Contrast Features in Computed Tomography Observing the Growth of a 4H-SiC Bulk Crystal" Materials 12, no. 22: 3652. https://doi.org/10.3390/ma12223652

APA StyleSalamon, M., Arzig, M., Wellmann, P. J., & Uhlmann, N. (2019). Comparison of Achievable Contrast Features in Computed Tomography Observing the Growth of a 4H-SiC Bulk Crystal. Materials, 12(22), 3652. https://doi.org/10.3390/ma12223652