Influence of Oxygen–Plasma Treatment on In-Situ SiN/AlGaN/GaN MOSHEMT with PECVD SiO2 Gate Insulator

Abstract

:1. Introduction

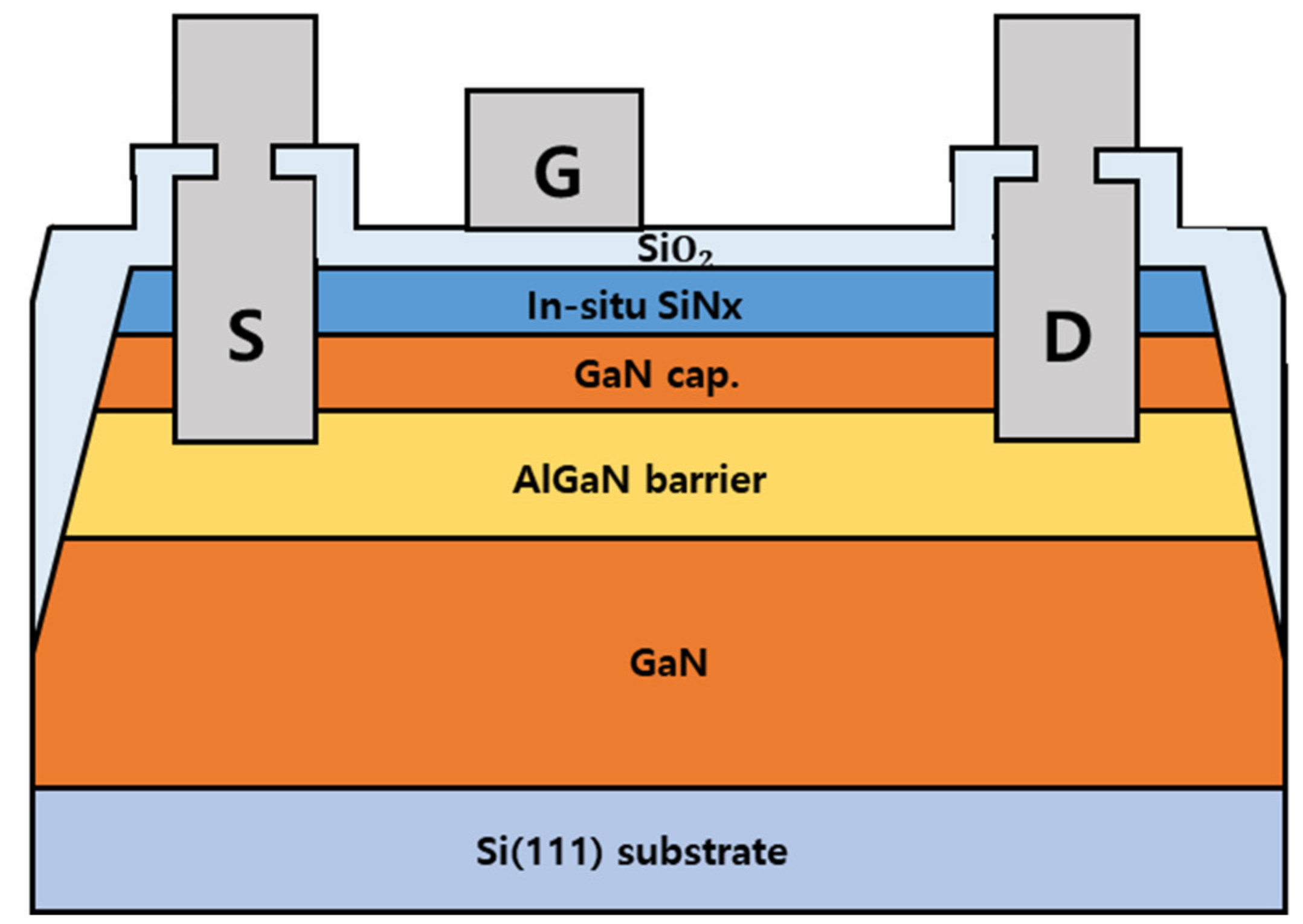

2. Materials and Methods

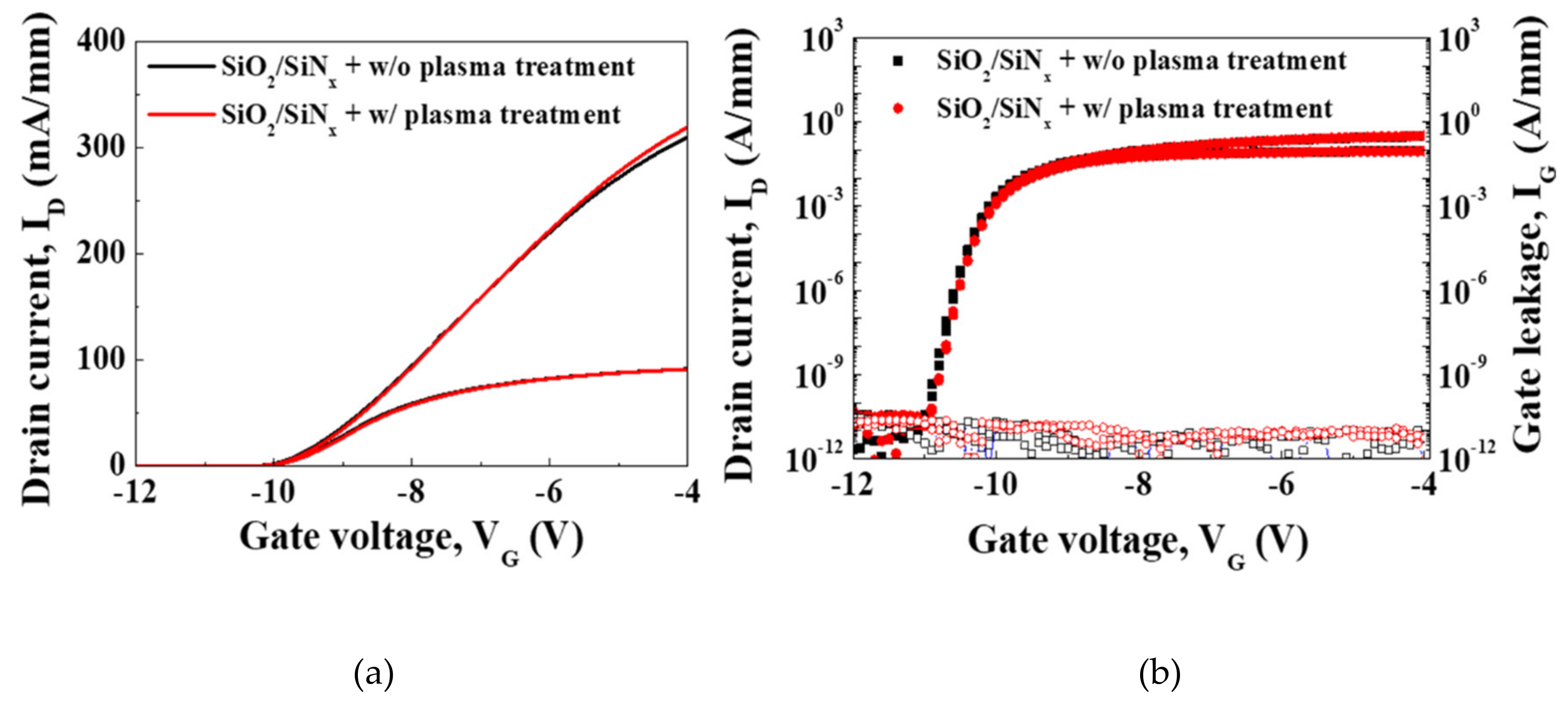

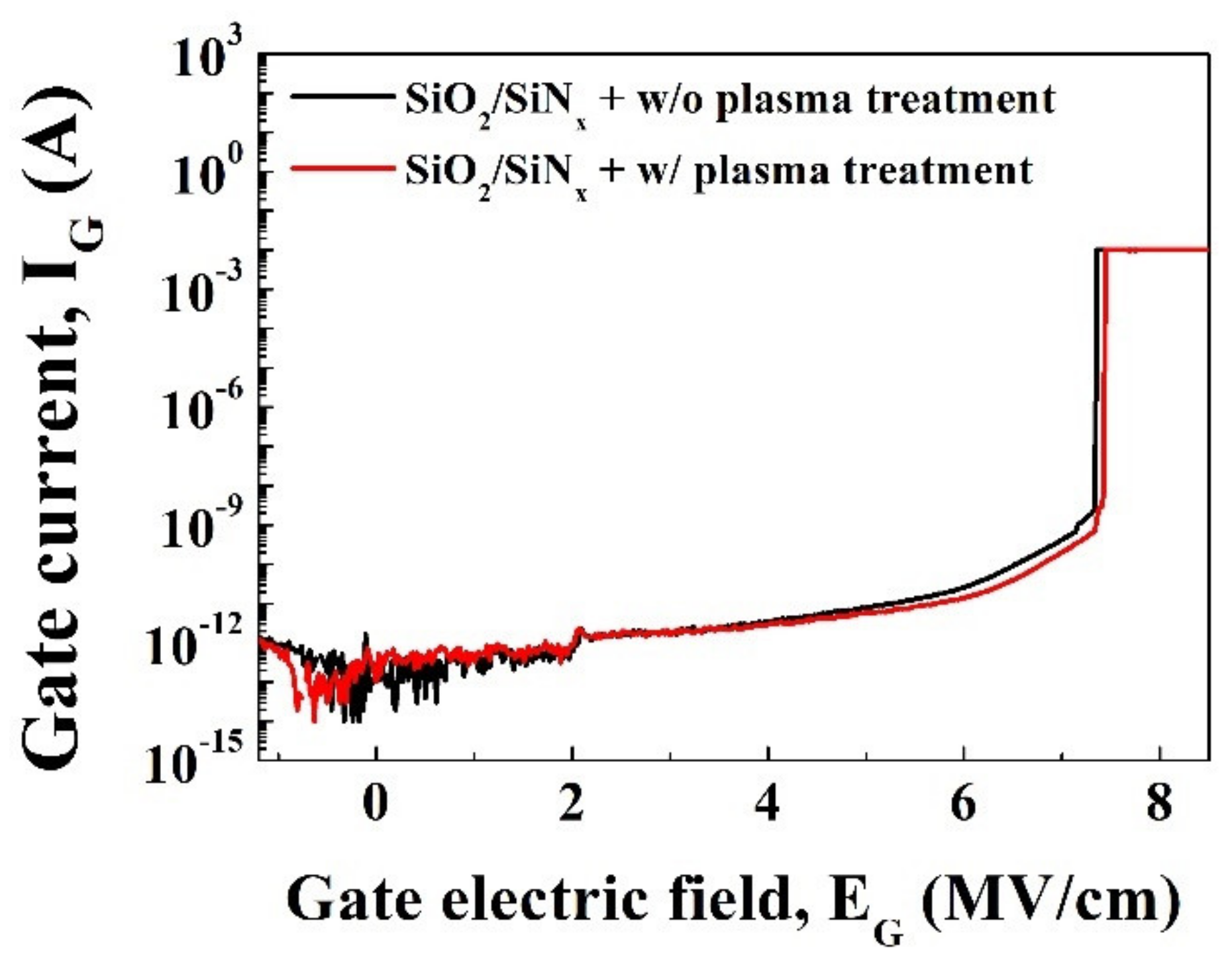

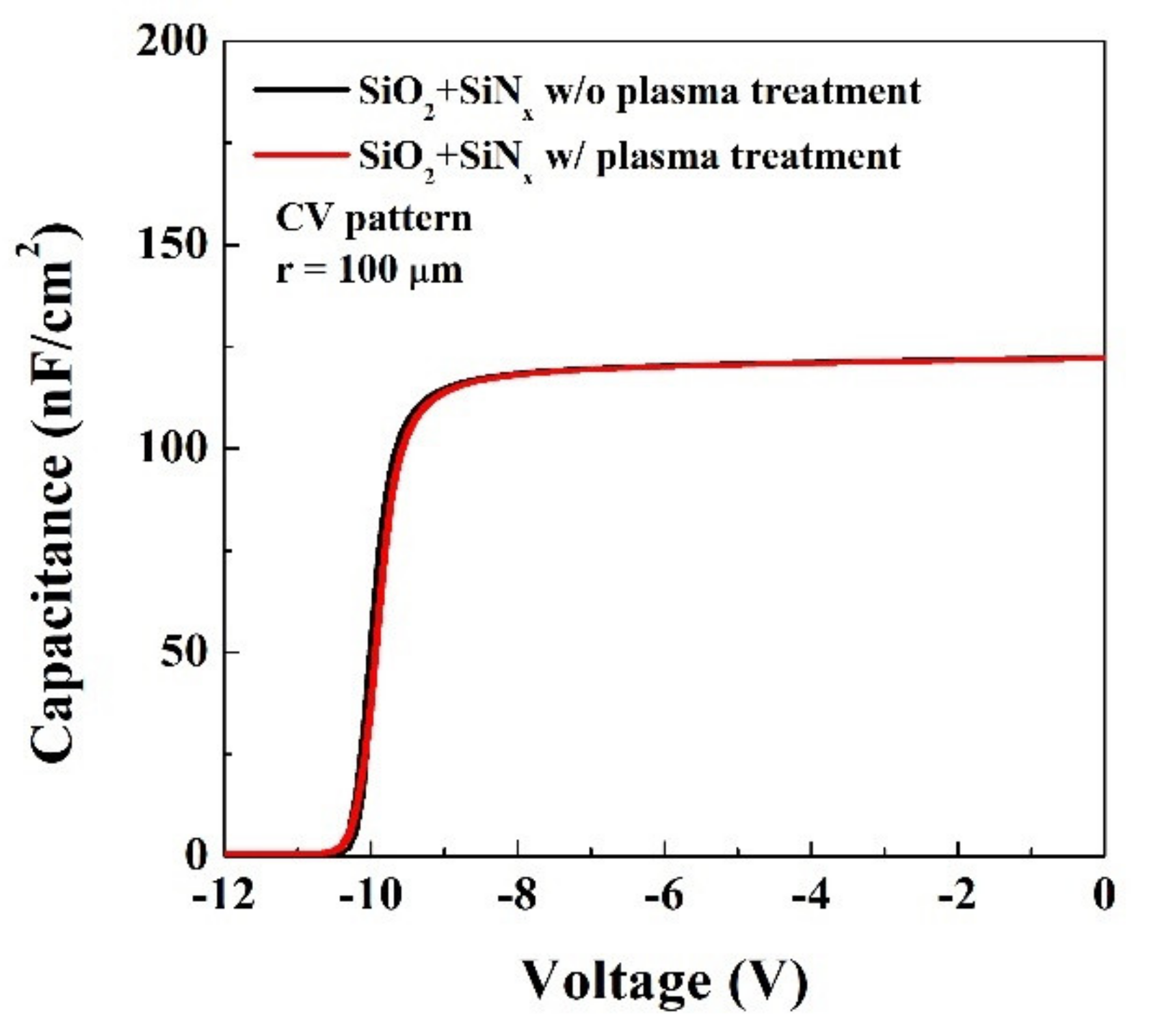

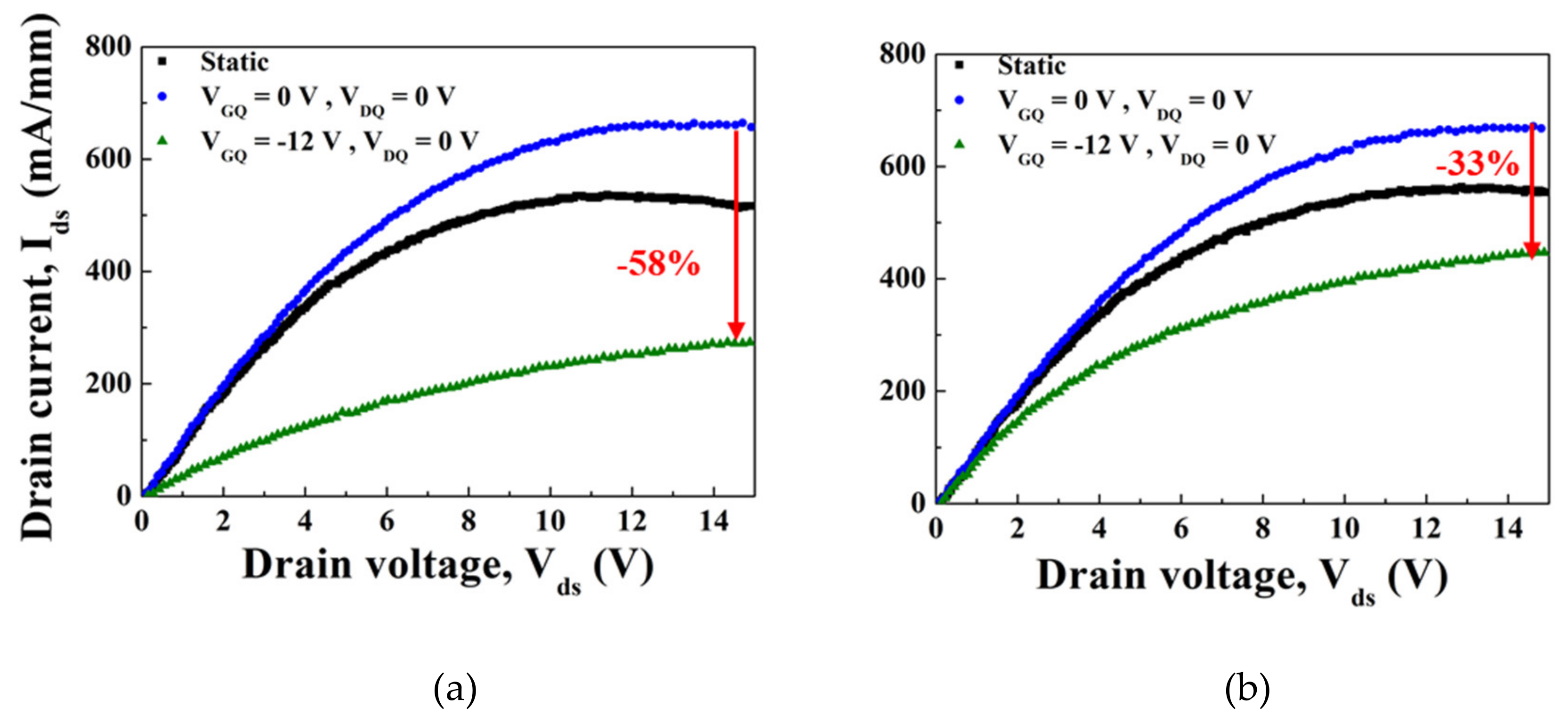

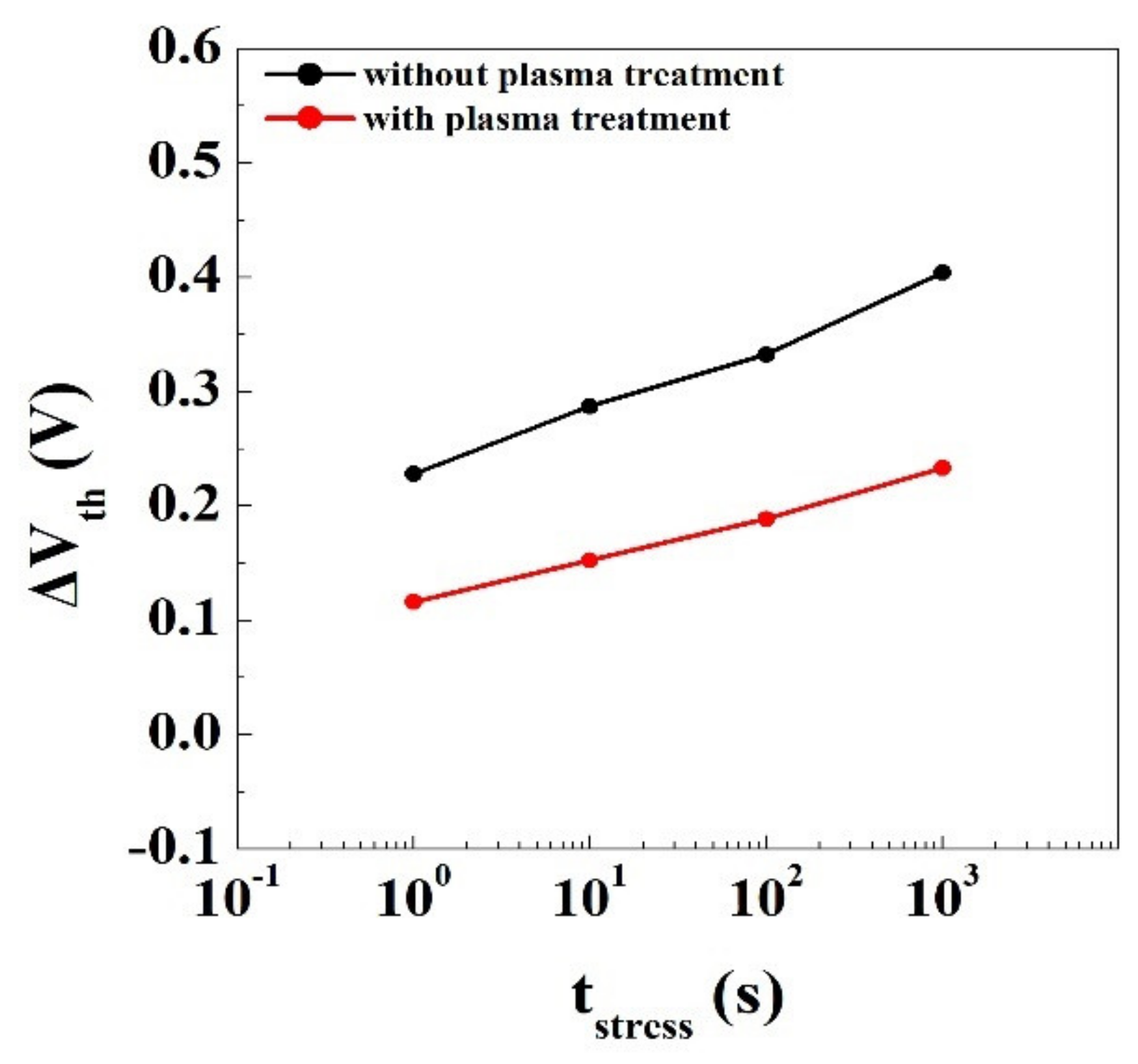

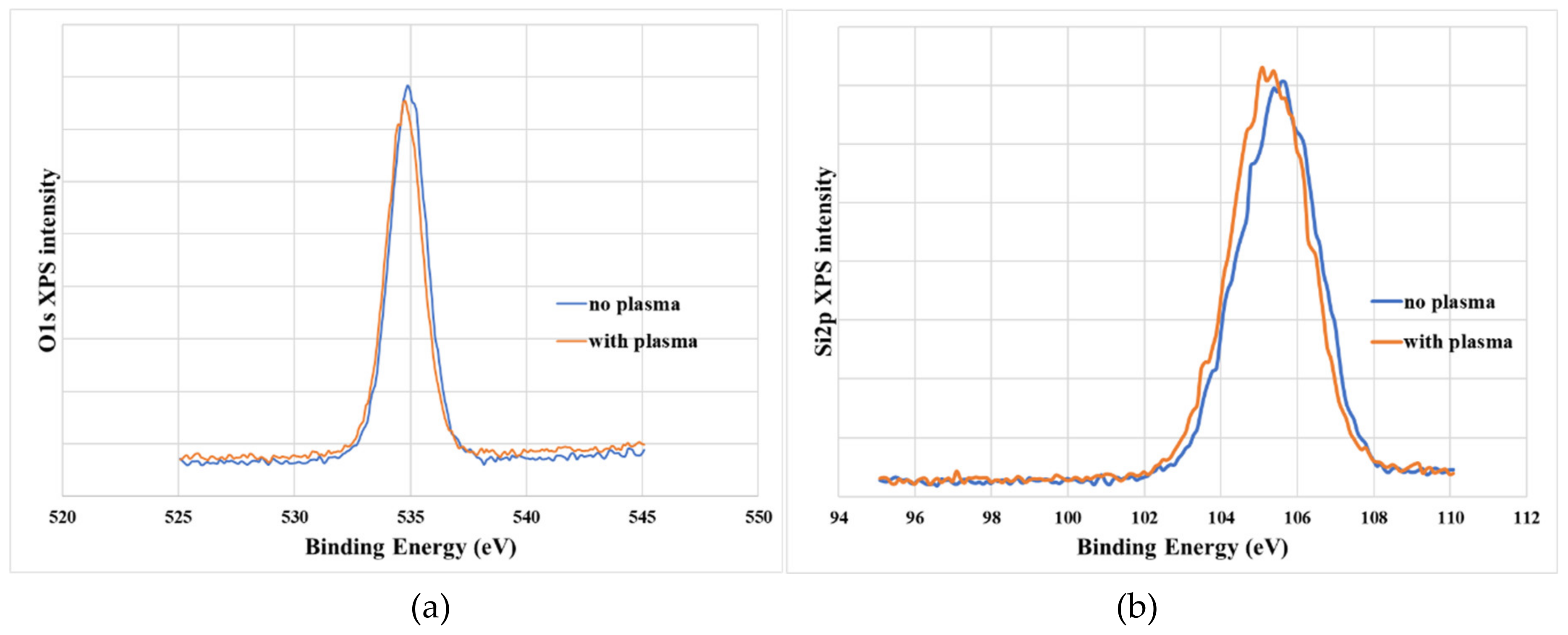

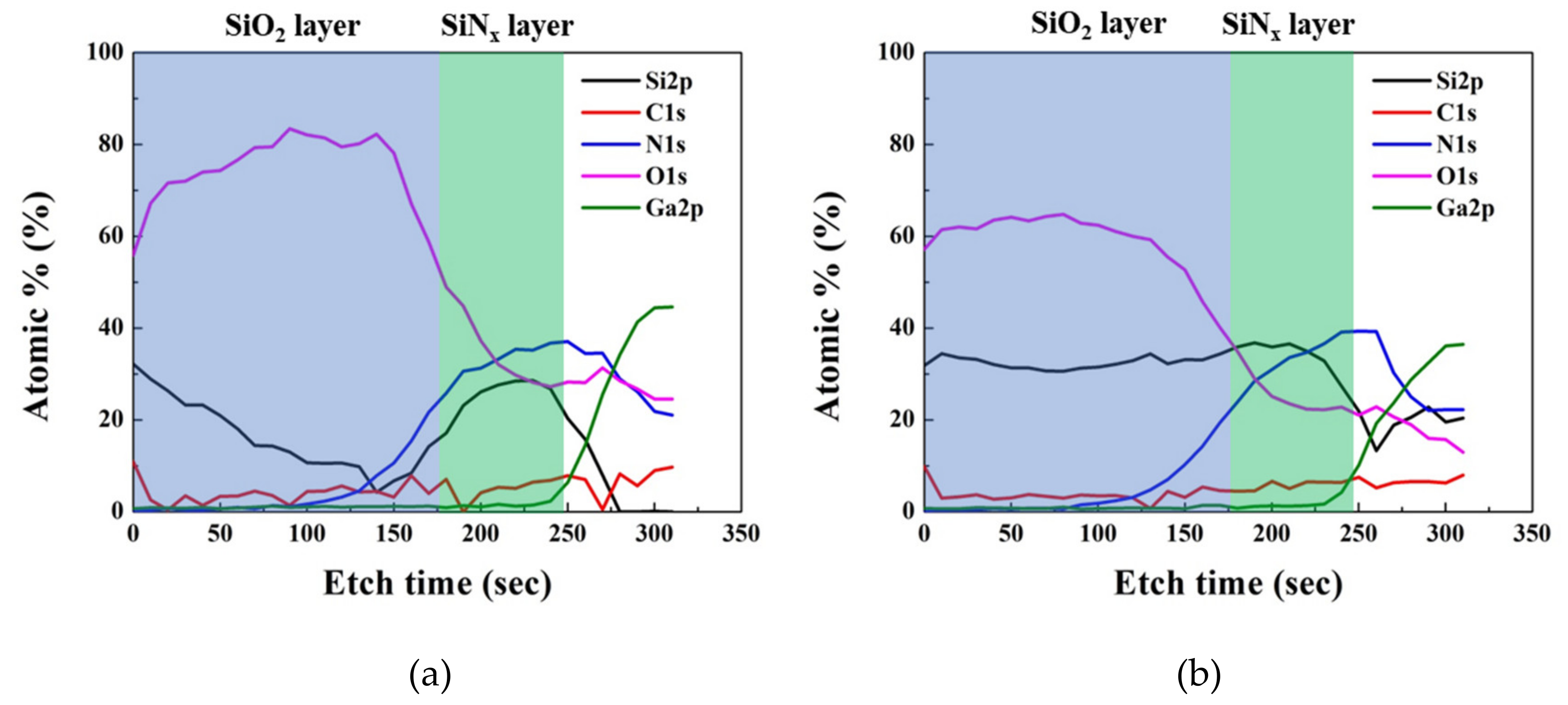

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Chen, K.J.; Zhou, C. Enhancement-mode AlGaN/GaN HEMT and MIS-HEMT technology. Phys. Status Solidi A 2011, 208, 434–438. [Google Scholar] [CrossRef]

- Choi, W.; Ryu, H.; Jeon, N.; Lee, M.; Cha, H.-Y.; Seo, K.-S. Improvement of Vth instability in normally-off GaN MIS-HEMTs employing PEALD-SiNx as an interfacial layer. IEEE Electron Device Lett. 2014, 35, 30–32. [Google Scholar] [CrossRef]

- Scott, M.J.; Fu, L.; Zhang, X.; Li, J.; Yao, C.; Sievers, M.; Wang, J. Merits of gallium nitride based power conversion. Semicond. Sci. Technol. 2013, 28, 074013. [Google Scholar] [CrossRef]

- Freedsman, J.J. Normally-OFF Al2O3/AlGaN/GaN MOS-HEMT on 8 in. Si with low leakage current and high breakdown voltage (825 V). Appl. Phys. Exp. 2014, 7, 041003. [Google Scholar] [CrossRef]

- Huang, T.; Zhu, X.; Wong, K.M.; Lau, K.M. Low-leakage current AlN/GaN MOSHFETs using Al2O3 for increased 2DEG. IEEE Electron Device Lett. 2012, 33, 212–214. [Google Scholar] [CrossRef]

- Wu, T.-L. Time dependent dielectric breakdown (TDDB) evaluation of PE-ALD SiN gate dielectrics on AlGaN/GaN recessed gate D-mode MIS-HEMTs and E-mode MIS-FETs. In Proceedings of the IEEE International Reliability Physics Symposium, Monterey, CA, USA, 19–23 April 2015. [Google Scholar]

- Derluym, J.; Boeykens, S.; Cheng, K.; Vandersmissen, R.; Das, J.; Ruythooren, W.; Degroote, S.; Leys, M.R.; Germain, M.; Borghs, G. Improvement of AlGaN/GaN high electron mobility transistor structures by in situ deposition of a Si3N4 surface layer. J. Appl. Phys. 2005, 98, 054501. [Google Scholar] [CrossRef]

- Lu, X.; Ma, J.; Jiang, H.; Liu, C.; Lau, K.M. Low trap states in situ SiNx/AlN/GaN metal-insulator-semiconductor structures grown by metal-organic chemical vapor deposition. Appl. Phys. Lett. 2014, 105, 102911–102913. [Google Scholar] [CrossRef]

- Tadjer, M.J.; Anderson, T.J.; Hobart, K.D.; Mastro, M.A.; Hite, J.K.; Caldwell, J.D.; Picard, Y.N.; Kub, F.J.; Eddy, C.R. Electrical and Optical Characterization of AlGaN/GaN HEMTs with In Situ and Ex-situ Deposited SiN x Layers. J. Electron. Mater. 2010, 39, 2452–2458. [Google Scholar] [CrossRef]

- Kambayashi, H.; Nomura, T.; Kato, S.; Ueda, H.; Teramoto, A.; Sugawa, S.; Ohmi, T. High integrity SiO2 gate insulator formed by microwave excited plasma enhanced chemical vapor deposition for AlGaN/GaN hybrid metal–oxide–semiconductor heterojunction field-effect transistor on Si substrate. Jpn. J. Appl. Phys. 2012, 51, 04DF03. [Google Scholar] [CrossRef]

- Adivarahan, V.; Rai, S.; Tipirneni, N.; Koudymov, A.; Yang, J.; Simin, G.; Khan, M.A. Digital oxide deposition of SiO2 layers for III-nitride metal–oxide–semiconductor heterostructure field-effect transistors. Appl. Phys. Lett. 2006, 88, 182507. [Google Scholar] [CrossRef]

- Park, B.-R.; Lee, J.-G.; Choi, W.; Kim, H.; Seo, K.-S.; Cha, H.-Y. High Quality ICPCVD SiO2 for Normally-off AlGaN/GaN-on-Si Recessed MOSHFETs. IEEE Electron Dev. Lett. 2013, 34, 354–356. [Google Scholar] [CrossRef]

- Binari, S.C.; Ikossi, K.; Roussos, J.A.; Kruppa, W.; Park, D.; Dietrich, H.B.; Koleske, D.D.; Wichenden, A.E.; Henry, R.L. Trapping Effects and Microwave Power Performance in AlGaN/GaN HEMTs. IEEE Trans. Electron Devices 2001, 48, 465–471. [Google Scholar] [CrossRef]

- Green, B.M.; Chu, K.K.; Chumbes, J.A.; Smart, J.A.; Shealy, J.R.; Eastman, L.E. The effect of surface passivation on the microwave characteristics of undoped AlGaN/GaN HEMTs. IEEE Electron. Dev. Lett. 2000, 21, 268–270. [Google Scholar] [CrossRef]

- Vetury, R.; Zhang, N.Q.; Keller, S.; Mishra, U.K. The impact of surface states on the DC and RF characteristics of AlGaN/GaN HFETs. IEEE Trans. Electron Devices 2001, 48, 560–566. [Google Scholar] [CrossRef]

- Lagger, P.; Ostermaier, C.; Pobegen, G.; Pogany, D. Towards understanding the origin of threshold voltage instability of AlGaN/GaN MISHEMTs. In Proceedings of the International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 10–13 December 2012. [Google Scholar]

- Goswami, R.; Butcher, J.B.; Ginige, R.; Zhang, J.F.; Taylor, S.; Eccleston, W. Low temperature gate dielectrics formed by plasma anodization of silicon nitride. Electron. Lett. 1988, 24, 129–1270. [Google Scholar] [CrossRef]

- Kennedy, G.P.; Taylor, S.; Eccleston, W.; Arnoldbik, W.M.; Habraken, F.H.P.M. Physical and electrical characterisation of oxynitride films produced by plasma oxidation of deposited silicon nitride. Microelectron. Eng. 1995, 28, 141–144. [Google Scholar] [CrossRef]

- Usenko, A.; Senawiratne, J. Silicon nitride surface conversion into oxide to enable hydrophilic bonding. ECS Trans. 2010, 33, 475–483. [Google Scholar]

- Buiu, O.; Kennedy, G.P.; Gartner, M.; Taylor, S. Structural analysis of silicon dioxide and silicon oxynitride films produced using an oxygen plasma. IEEE Trans. Plasma Sci. 1998, 26, 1700–1712. [Google Scholar] [CrossRef]

- Jiminez, C.; Perriere, J.; Vickridge, I.; Enard, J.P.; Albella, J.M. Transformation of silicon nitride in oxygen plasma. Surf. Coat. Tech. 1991, 45, 147–154. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cho, G.; Cha, H.-y.; Kim, H. Influence of Oxygen–Plasma Treatment on In-Situ SiN/AlGaN/GaN MOSHEMT with PECVD SiO2 Gate Insulator. Materials 2019, 12, 3968. https://doi.org/10.3390/ma12233968

Cho G, Cha H-y, Kim H. Influence of Oxygen–Plasma Treatment on In-Situ SiN/AlGaN/GaN MOSHEMT with PECVD SiO2 Gate Insulator. Materials. 2019; 12(23):3968. https://doi.org/10.3390/ma12233968

Chicago/Turabian StyleCho, Geunho, Ho-young Cha, and Hyungtak Kim. 2019. "Influence of Oxygen–Plasma Treatment on In-Situ SiN/AlGaN/GaN MOSHEMT with PECVD SiO2 Gate Insulator" Materials 12, no. 23: 3968. https://doi.org/10.3390/ma12233968

APA StyleCho, G., Cha, H.-y., & Kim, H. (2019). Influence of Oxygen–Plasma Treatment on In-Situ SiN/AlGaN/GaN MOSHEMT with PECVD SiO2 Gate Insulator. Materials, 12(23), 3968. https://doi.org/10.3390/ma12233968