Prediction of Stress–Strain Curves Based on Hydric Non-Destructive Tests on Sandstones

Abstract

1. Introduction

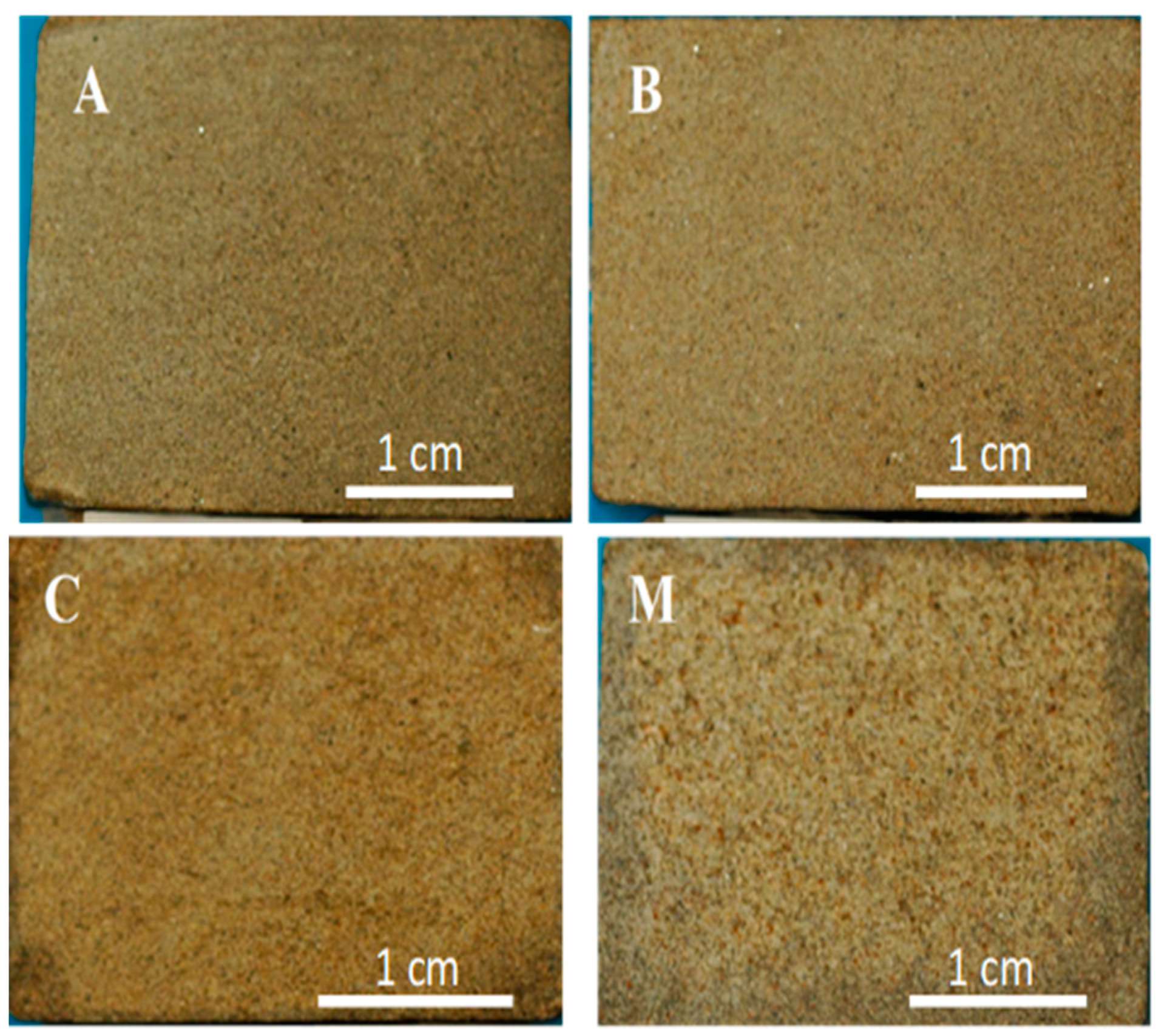

2. Selection of Rock Materials

3. Experimental Methodology and Results

3.1. Introduction

3.2. Preparation of Samples

3.3. Evaluation Tests on Physical Properties

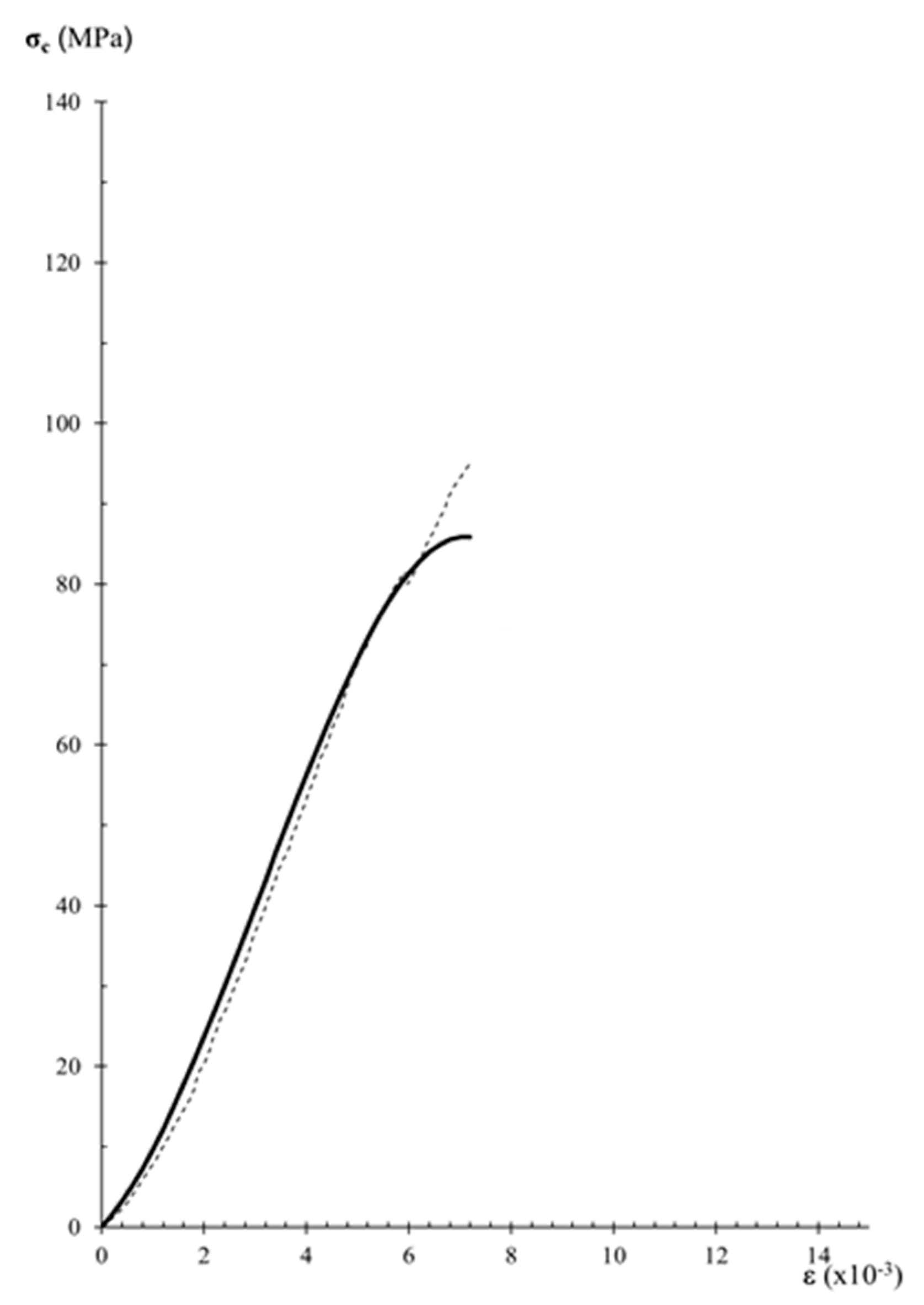

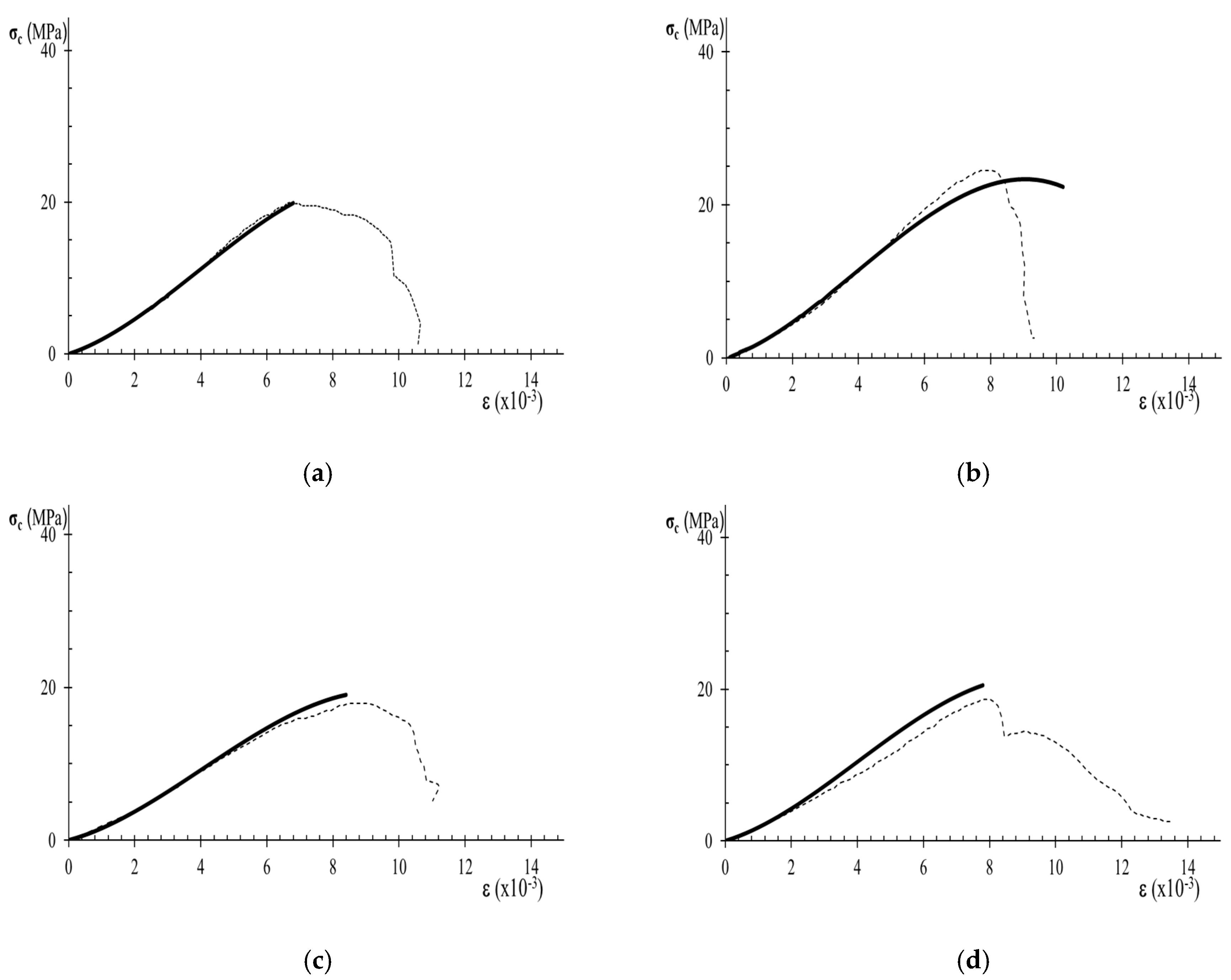

3.4. Monotonic Compression Tests

4. Modeling of Compression Behavior

4.1. Ludovico-Marques Global Model Used on Sandstones

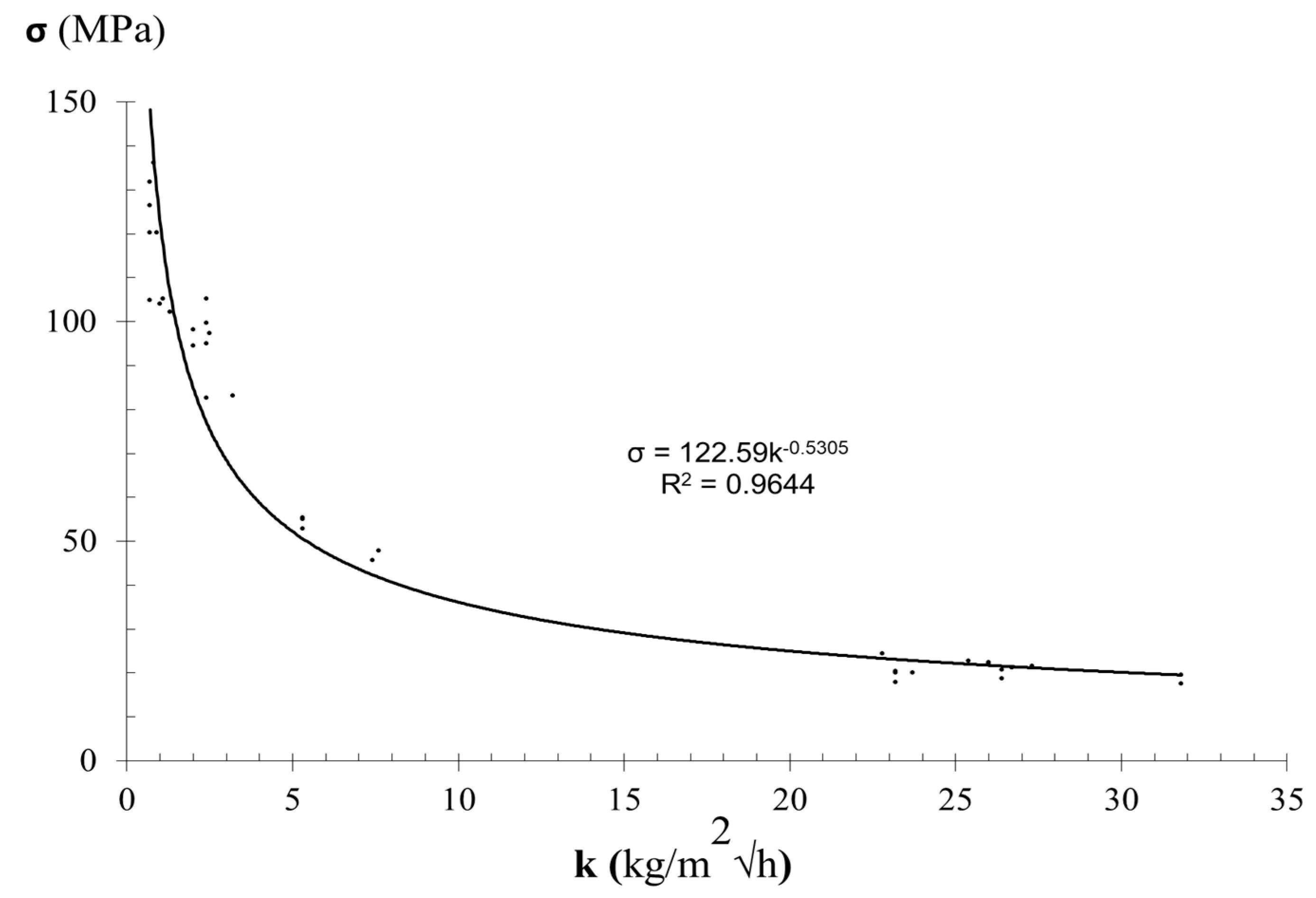

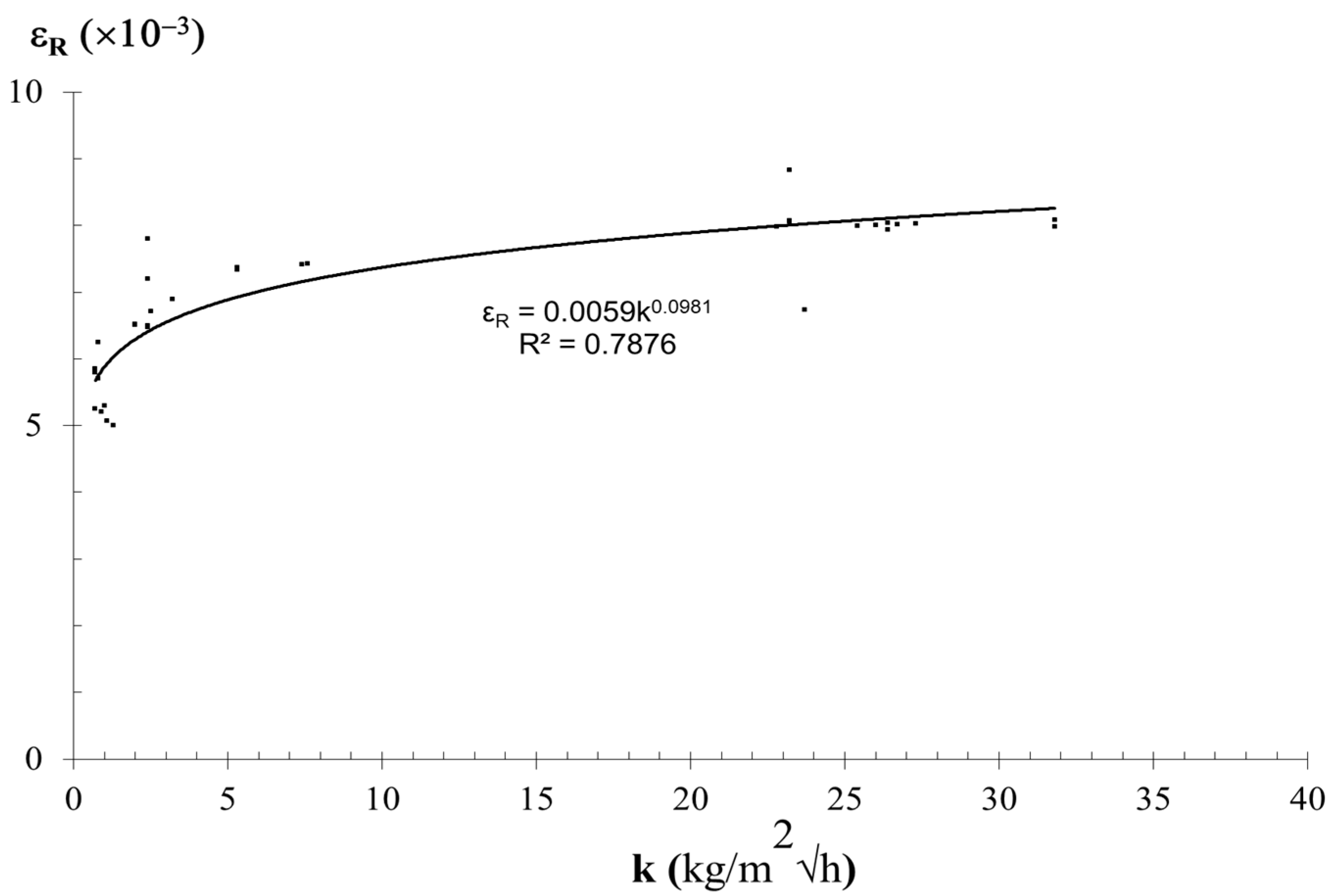

4.2. Correlations Between Compressive Strength, Strain at Failure, and Coefficient of Water Absorption Under Low Pressure

4.3. Analysis of Experimental and Predicted Results

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ludovico-Marques, M. Contribution to the Knowledge of the Effect of Crystallization of Salts in the Weathering of Sandstones. Application to the Built Heritage of Atouguia da Baleia. Ph.D. Thesis, Universidade Nova de Lisboa, Lisbon, Portugal, 2008; p. 314. (In Portuguese). [Google Scholar]

- Ludovico-Marques, M.; Chastre, C. Effect of artificial accelerated salt weathering on physical and mechanical behaviour of sandstone samples from surface reservoirs. In Handbook of Materials Failure Analysis with Case Studies from the Oil and Gas Industry; Makhlouf, H., Aliofkhazraei, M., Eds.; Butterworth Heinemann (Elsevier): Oxford, UK, 2016; pp. 215–233. [Google Scholar]

- International Charter for the Conservation and Restoration of Monuments and Sites (the Venice Charter 1964); International Council on Monuments and Sites (ICOMOS): Charenton-le-Pont, France, 1965.

- Charter, K. Magazine Trieste Contemporanea; Trieste Contemporanea: Trieste, Italy, 2000. [Google Scholar]

- Recommendations for the Analysis, Conservation and Structural Restoration of Architectural Heritage; International Council on Monuments and Sites (ICOMOS): Charenton-le-Pont, France, 2004.

- Foraboschi, P. The central role played by structural design in enabling the construction of buildings that advanced and revolutionized architecture. Constr. Build. Mater. 2016, 114, 956–976. [Google Scholar] [CrossRef]

- Goodman, R. Introduction to Rock Mechanics, 2nd ed.; John Wiley & Sons: New York, NY, USA, 1989. [Google Scholar]

- Palchik, V. Influence of the porosity and elastic modulus on uniaxial compressive strength in soft brittle porous sandstones. Rock Mech. Rock Eng. 1999, 32, 303–309. [Google Scholar] [CrossRef]

- Hatzor, Y.H.; Palchick, V. The influence of the grain size and porosity on the crack initiation stress and critical flaw length in dolomites. Int. J. Rock Mech. Min. Sci. 1997, 34, 805–816. [Google Scholar] [CrossRef]

- Tugrul, A.; Zarif, I.H. Correlation of mineralogical and textural characteristics with engineering properties of selected granitic rocks from Turkey. Eng. Geol. 1999, 51, 303–317. [Google Scholar] [CrossRef]

- Palchick, V.; Hatzor, Y.H. Crack damage stress as a composite function of porosity and elastic stiffness in dolomites and limestones. Eng. Geol. 2002, 63, 233–245. [Google Scholar] [CrossRef]

- Palchick, V.; Hatzor, Y.H. The influence of porosity on tensile and compressive strength of porous chalks. Rock Mech. Rock Eng. 2004, 37, 331–341. [Google Scholar] [CrossRef]

- Vasarhelyi, B.; Van, P. Influence of water content on the strength of rock. Eng. Geol. 2006, 84, 70–74. [Google Scholar] [CrossRef]

- Yilmaz, I. Influence of water content on the strength and deformability of gypsum. Int. J. Rock Mech. Min. Sci. 2010, 47, 342–347. [Google Scholar] [CrossRef]

- Ludovico-Marques, M.; Chastre, C.; Vasconcelos, G. Modelling the compressive mechanical behaviour of granite and sandstone historical building stones. Constr. Build. Mater. 2012, 28, 372–381. [Google Scholar] [CrossRef]

- Heidari, M.; Torabi-Kaveh, M.; Chastre, C.; Ludovico-Marques, M.; Mohseni, H.; Akefi, H. Determination of weathering degree of the Persepolis stone under laboratory and natural conditions using fuzzy inference system. Constr. Build. Mater. 2017, 145, 28–41. [Google Scholar] [CrossRef]

- Heidari, M.; Chastre, C.; Torabi-Kaveh, M.; Ludovico-Marques, M.; Mohseni, H. Application of fuzzy inference system for determining weathering degree of some monument stones in Iran. J. Cult. Herit. 2017, 25, 41–55. [Google Scholar] [CrossRef]

- Chastre, C.; Ludovico-Marques, M. Nondestructive testing methodology to assess the conservation of historic stone buildings and monuments. In Handbook of Materials Failure Analysis with Case Studies from the Construction Industries; Makhlouf, H., Aliofkhazraei, M., Eds.; Butterworth Heinemann (Elsevier): Oxford, UK, 2018; pp. 255–294. [Google Scholar]

- Tan, X.; Chen, W.; Yang, J.; Cao, J. Laboratory investigations on the mechanical properties degradation of granite under freeze-thaw cycles. Cold Reg. Sci. Technol. 2011, 68, 130–138. [Google Scholar] [CrossRef]

- Noor-E-Khuda, S.; Albermani, F.; Veidt, M. Flexural strength of weathered granites: Influence of freeze and thaw cycles. Constr. Build. Mater. 2017, 156, 891–901. [Google Scholar] [CrossRef]

- Foraboschi, P.; Vanin, A. Experimental investigation on bricks from historical Venetian buildings subjected to moisture and salt crystallization. Eng. Fail. Anal. 2014, 45, 185–203. [Google Scholar] [CrossRef]

- Ludovico-Marques, M.; Chastre, C. Effect of salt crystallization ageing on the compressive behavior of sandstone blocks in historical buildings. Eng. Fail. Anal. 2012, 26, 247–257. [Google Scholar] [CrossRef]

- Malesani, P.; Vannuci, S. Decay of Pietra Serena and Pietraforte, Florentine building stones: Petrographic observations. Stud. Conserv. 1974, 19, 36–50. [Google Scholar]

- Felix, C. Molasses et grès de Villarlod (Fribourg). Inventaire des Carrièrs Suisses de Pierre de Taille; École Polytechnique Fédérale de Lausanne-Laboratoire des Matériaux Pierreux: Lausanne, Switzerland, 1977; p. 18. [Google Scholar]

- Sorace, S. Long-term tensile and bending strength of natural building stones. Mater. Struct. 1996, 29, 426–435. [Google Scholar] [CrossRef]

- Banchelli, A.; Fratini, F.; Germani, M.; Malesani, P.; Manganelli Del Fa, C. The sandstones of Florentine historic buildings: Individuation of the marker and determination of the supply quarries of the rocks used in some Florentine monuments. Sci. Technol. Cult. Herit. 1997, 6, 12–22. [Google Scholar]

- Uchida, E.; Ogawa, Y.; Maeda, N.; Nakagawa, T. Deterioration of stone materials in the Angkor monuments, Cambodia. Eng. Geol. 1999, 55, 101–112. [Google Scholar] [CrossRef]

- Tiano, P.; Valentini, E.; Exadaktylos, G.; Garrod, E.; Snethlage, R.; Wendler, E.; Singer, B.; Delgado Rodrigues, J.; Cadot-Leroux, L.; De Witte, E.; et al. Technical Annex. In Proceedings of the Workshop Drillmore—Drilling Methodologies for Monuments Restoration, Munich, Germany, 16–17 March 2000; Centro Stampa Toscana Nuova: Firenze, Italy, 2000. [Google Scholar]

- Fitzner, B.; Heinrichs, K.; La Bouchardiere, D. Weathering damage on Pharaonic sandstone monuments in Luxor—Egipt. Build. Environ. 2003, 38, 1089–1103. [Google Scholar] [CrossRef]

- Zoghlami, K.; Gomez-Graz, D.; Alvarez, A. Petrophysical characterization and durability of Miocenic sandstones used in Roman aqueduct of Zaghouan—Cartaghe building. In Lectures and Proceedings of 6th International Symposium on the Conservation of Monuments in the Mediterranean Basin; Aires-Barros, L., Zezza, F., Eds.; IST: Lisboa, Portugal, 2004; pp. 385–389. [Google Scholar]

- Heinrichs, K. Diagnose der Verwitterungsschaden an den Felsmonumenten der Antiken Stadt Petra/Jordanien. Ph.D. Thesis, Geologisches Institut/RWTH Aachen, Aachen, Germany, 2005. [Google Scholar]

- Ehrenberg, S.; Nadeau, P. Sandstone versus carbonate petroleum reservoirs: A global perspective on porosity-depth and porosity-permeability relationships. AAPG Bull. 2005, 89, 435–445. [Google Scholar] [CrossRef]

- Jizba, D. Mechanical and Acoustical Properties of Sandstones and Shales. Ph.D. Thesis, Stanford University, Stanford, CA, USA, 1991. [Google Scholar]

- Folk, R. Petrology of Sedimentary Rocks; Hemphill Publishing: Austin, TX, USA, 1974; p. 184. [Google Scholar]

- Vernik, L.; Bruno, M.; Bovberg, C. Empirical relations between compressive strength and porosity of siliciclastic rocks. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1993, 30, 677–681. [Google Scholar] [CrossRef]

- Moos, D.; Zoback, M.; Bailey, L. Feasibility study of the stability of open hole multilaterals, Cook Inlet, Alaska. In SPE Mid-Continent Operations Symposium 1999; Society of Petroleum Engineers: Oklahoma City, OK, USA, 2001. [Google Scholar]

- Cnudde, V. Exploring the Potencial of X ray Tomography as a Non-Destructive Research Tool in Conservation Studies of Natural Building Stones. Ph.D. Thesis, University of Gent, Gent, Belgium, 2005. [Google Scholar]

- Hasnikova, H.; Zima, P. Comparative testing of natural stones used as a building material. In Experimental Methods and Numerical Simulation in Engineering Sciences, Proceedings of XIIIth Bilateral Czech/German Symposium, Telč, Czech Republic, 5–8 June 2012; Jirousek, O., Kyty, D., Eds.; University Centre Telč: Telč, Czech Republic, 2012. [Google Scholar]

- Ludovico-Marques, M. A fast and less expensive test to determine permeability-related parameters on well’s drilled cuttings. In Advances in Petroleum Engineering and Petroleum Geochemistry, Advances in Science, Technology & Innovation; Springer Nature Switzerland AG: Cham, Switzerland, 2019; pp. 13–16. [Google Scholar]

- Fener, M.; Kahraman, K.; Bilgil, A.; Gunaydin, O. A comparative evaluation of indirect methods to estimate the compressive strength of rocks. Rock Mech. Rock Eng. 2005, 38, 329–343. [Google Scholar] [CrossRef]

- Chang, C. Empirical rock strength logging in boreholes penetrating sedimentary formations. Geol. Earth Environ. Sci. 2004, 7, 174–183. [Google Scholar]

- Vasconcelos, G.; Lourenço, P.B.; Alves, C.A.; Pamplona, J. Ultrasonic evaluation of the physical and mechanical properties of granites. Ultrason 2008, 48, 453–466. [Google Scholar] [CrossRef]

- Selcuk, L.; Nar, A. Prediction of uniaxial compressive strength of intact rocks using ultrasonic pulse velocity and rebound-hammer number. Q. J. Eng. Geol. Hydrogeol. 2015, 49, 67–75. [Google Scholar] [CrossRef]

- Yasar, E.; Erdogan, Y. Estimation of rock physicomechanical properties using hardness methods. Eng. Geol. 2004, 71, 281–288. [Google Scholar] [CrossRef]

- RILEM. Recommended tests to measure the deterioration of stone and to assess the effectiveness of treatment methods. Mat. Const. Bourdais Dunoud 1980, 13, 175–253. [Google Scholar]

- EN 1936. Natural Stone Test Method-Determination of Real Density and Apparent Density, and of Total and Open Porosity; European Committee for Standardization: Brussels, Belgium, 1999. [Google Scholar]

- Pellerin, F. La porosimetrie au mercure apliquee a l’ estude geotechnique des sols et des roches. Bull. Lias. Ponts Chaussés 1980, 106, 105–116. [Google Scholar]

- Fairhurst, C.; Hudson, J. Draft ISRM suggested method for the complete stress–strain curve for intact rock in uniaxial compression. International Society for Rock Mechanics Commission on Testing Methods. Int. J. Rock Mech. Min. Sci. 1999, 36, 279–289. [Google Scholar]

- ASTM D7012. Standard Test Method for Compressive Strength and Elastic Moduli of Intact Rock Core Specimens under Varying States of Stress and Temperatures; ASTM Standards: West Conshohocken, PA, USA, 2010. [Google Scholar]

- Eberhardt, E.; Stead, D.; Stimpson, B. Quantifying progressive pre-peak brittle fracture damage in rock during uniaxial compression. Int. J. Rock Mech. Min. Sci. 1999, 36, 361–380. [Google Scholar] [CrossRef]

- Rocha, M. Mecânica das Rochas; Laboratório Nacional de Engenharia Civil: Lisboa, Portugal, 1981. (In Portuguese) [Google Scholar]

- Zoback, M.; Byerlee, J. The effect of Microcrack Dilatancy on the Permeability of Westerly Granite. J. Geophys. Res. 1975, 80, 752–755. [Google Scholar] [CrossRef]

- Keaney, G.; Meredith, P.; Murrell, S. Laboratory study of permeability evolution in a ‘tight’ sandstone under non-hydrostatic stress conditions. Rock Mech. Pet. Eng. 1998, 1, 329–335. [Google Scholar]

- Heiland, J.; Raab, S. Experimental investigation of the influence of differential stress on permeability of a lower permian (Rotliegend) sandstone deformed in the brittle deformation field. Phys. Chem. Earth Part A 2001, 26, 33–38. [Google Scholar] [CrossRef]

- Popp, T.; Kern, H.; Schulze, O. Evolution of dilatancy and permeability in rock salt during hydrostatic compaction and triaxial deformation. J. Geophys. Res. 2001, 106, 4061–4078. [Google Scholar] [CrossRef]

- Heiland, J. Laboratory testing of coupled hydro-mechanical processes during rock deformation. Hydrogeol. J. 2003, 11, 122–141. [Google Scholar] [CrossRef]

| Countries | Tunisia | Egypt | Jordan | Switzerland | Germany | Italy | Cambodja | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Origin | Aqueduct (Zoghlami et al., 2004) | Gebel Silsila (Fitzner et al., 2003) | Petra tombs (Heinrichs, 2005) | Fribourg (“Suisse plateau”) (Félix, 1977) | Birkenfeld Monastery (Tiano et al., 2000) | Strozzi Palace (Malesani and Vannucci, 1974) (Banchelli et al., 1997) | Angkor (Uchida et al., 1999) | ||||||

| Lithology | Medium to fine grained sandstones | Fine grained sandstones (white to yellow brown) | Medium to fine grained sandstones (several colors, including white) | Blue molasse | Yellow molasse | Villarlod sandstone | Sandstones with rock fragments (green to gray) | Lithic arenites with carbonate cement (Pietraforte) | Grey yellow sandstone | Red sandstone | Green grauwacke | ||

| Stratigraphy | Miocene Fortuna Formation. | Cretaceous Qoseir Formation. | Cambrian Umm Ishrin, Formation | Ordovician Disi Formation. | Extra Alpin sea molasse. | Triassic, middle Keuper (Schilfsandstein) | Upper Cretaceous (External Ligurides) | - | - | - | |||

| Composition (%) | Quartz | 69–84 | 65–90 | Matrix-rich sandstone | quartz. sandstone | 60–70 | 89 | Major | + | ++ | + | ||

| Feldspars | 0–1 | 0–8 | 10–15 | 9 | Major k-feldspar and plagioclases | + | + | ||||||

| Micas | 0–0.5 | + | 1 | + | - | + | |||||||

| Clays | 0–10 | 0–10; *25 | - | ++ | Illite and chlorite-vermiculite | - | - | - | |||||

| Calcite | 0–3 | 20–30 | - | Major calcite and dolomite | - | - | - | ||||||

| others | 1–5 | 3–5 (glauconite) | 1 (chlorite) | chlorite | + (goeth.) | + (hemat., goeth) | - | ||||||

| Grain size analysis | Average size (mm) | 0.15–0.42 | 0.1–0.2 | 0.17 | 0.31 | 0.4–0.5 | 0.3–0.4 | 0.1–0.2 0.2–0.3 | 0.3 (0.1–0.5) | 0.08 (max. 0.25) | 0.2–0.3 | 0.1–-0.2 | - |

| Distribution | Slight to poor graded | Slight to poor graded | - | - | graded | Slight graded | Slight graded | Slight graded | Poor graded | graded | |||

| Origin | Aqueduct (Zoghlami et al., 2004) | Gebel Silsila (Fitzner et al., 2003) | Petra Tombs (Heinrichs, 2005) | Fribourg (“Suisse Plateau”) (Félix, 1977) | Birkenfeld Monastery (Tiano et al., 2000) | Strozzi Palace (Malesani and Vannucci, 1974) (Sorace, 1996) | Angkor (Uchida et al., 1999) | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Median pore radius (µm) | 20–50 (Mode) | 75–110 10 clayey sandstone | 13 | 115 | - | - | - | 100–200 (average) | - | - | - | - |

| Unimodal/multimodal | Unimodal | Unimodal | - | - | - | - | - | - | - | - | - | - |

| Porosity (%) | 17.5–26; 23 (open) | 25–35 | 17.4 | 21.3 | 15 | 18.2 | 14.9 | 19.2 ± 0.7 (open) | 1.8–5.5 (open) | 13–19 (open) | 11–15 (open) | 2 (open) |

| Densities: bulk 1, real 2 (kg/m3) | 1950–2150 1 2550–2600 2 | 1800–2000 1 2600–2750 2 | - | - | 2260–2280 1 2670 2 | 2180–2190 1 2660–2670 2 | 2240–2270 1 2640–2660 2 | 2160 ± 20 1 2670 ± 10 2 | 2580–2610 2 | 2100–2400 1 | 2100–2400 1 | 2600–2700 1 |

| Maximum water absorption (%) | 11 ± 1.7 | - | - | - | - | - | - | 1–2.5 | - | - | - | |

| Water absorption coefficient/ /capillarity (kg/m2h1/2) or permeability (mD) | 3.1 ± 1.6 (0.51 ± 0.27 kg/m2s1/2) | - | - | - | 3.2–3.4 (┴) 3.3–3.5 (║) | 5.3–5.4 (┴) 6.2–6.5 (║) | 2.2–2.4 (┴) 3.6–3.7 (║) | - | < 1 mD | - | - | - |

| Expansion (mm/m) | None | - | - | - | 1.63–1.74 (┴) 1.58–1.68 (║) | 2.5–2.76 (┴) 1.71–2.10 (║) | 2.27–2.28 (┴) 1.35–1.44 (║) | - | - | - | - | - |

| Compressive strength (MPa) | 15.6 ± 7.9 | - | - | - | 46.3–55.4 (┴) 46.7–51.7 (║) | 30.6–40.4 (┴) | 62.4–71.0 (┴) 51.6–57.3 (║) | 52.3 ± 10.9 | 121.2-140 | 32–44 estimated | 43 estimated | 80 estimated |

| Dynamic elastic modulus (GPa) | - | - | - | - | 7.2–8.4 (║) | 17.5–18.1 (║) | 10.3–12.1 (║) | - | 38.3 | - | - | - |

| Bending strength (MPa) | - | - | - | - | 2.55–2.70 (┴) | 2.49–3.65 (┴) | 9.60–9.90 (┴) | - | 9.4 | - | - | - |

| Tensile strength (MPa) | - | - | - | - | 1.17–1.28 (║) | 0.6–0.7 (║) | 2.24–2.74 (║) | - | 3.9 | - | - | - |

| UPV of P waves (km/s) | - | 1.2–2.2 (┴) 1.3–2.6 (║) | - | - | 1.7 (┴) 1.9 (║) | 1.2–1.4 (┴) 1.7–1.8 (║) | 1.7–2.1 (┴) 2.3–2.5 (║) | - | - | 1.9–3.2 (║) | 3.9–4.0 (║) | 4.4 (║) |

| Rebound number | - | - | - | - | 45 (┴) | 31 (┴) & 29 (║) | 47 (┴) & 42 (║) | - | - | 45–54 | 53 | 64 |

| Drilling strength | - | 0.5–1.2 (┴) | 4.5 | 2.0 | - | - | - | 15 N | - | - | - | - |

| Variety | Specimens | σc (MPa) | εr (×10−3) | k (kg/m2/√h) |

|---|---|---|---|---|

| A | AP38 | 126.4 | 5.7900 | 0.7 |

| AP39 | 131.8 | 5.7931 | 0.7 | |

| AP53 | 148.2 | 5.6968 | 0.8 | |

| AP96 | 104.9 | 5.8542 | 0.7 | |

| AP1 | 102.3 | 5.0000 | 1.3 | |

| AP5 | 105.2 | 5.1000 | 1.1 | |

| AP6 | 104.0 | 5.3000 | 1.0 | |

| AP9 | 120.3 | 5.2000 | 0.9 | |

| AP11 (N) | 136.2 | 6.2500 | 0.8 | |

| AP13 (X) | 135.7 | 6.6300 | 0.9 | |

| B | BP6 | 99.7 | 6.4725 | 2.4 |

| BP27 | 82.6 | 6.4932 | 2.4 | |

| BP32 | 83.1 | 6.8965 | 3.2 | |

| BP45 | 97.3 | 6.7059 | 2.5 | |

| BP72 | 98.2 | 6.5136 | 2.0 | |

| BP3 | 95.0 | 7.2000 | 2.4 | |

| BP13 | 105.3 | 7.8000 | 2.4 | |

| BP | 94.5 | 6.5136 | 2.0 | |

| C | CP18 | 47.8 | 7.4265 | 7.6 |

| CP24 | 45.7 | 7.4139 | 7.4 | |

| CP50 | 52.8 | 7.3366 | 5.3 | |

| CP40 | 55.1 | 7.3497 | 5.3 | |

| CP87 | 55.3 | 7.3627 | 5.3 | |

| M | MP12 | 20.0 | 8.0615 | 23.2 |

| MP13 | 20.4 | 8.0708 | 23.2 | |

| MP9 | 22.0 | 8.0048 | 26.0 | |

| MP10 | 22.7 | 7.9953 | 25.4 | |

| MP11 | 20.7 | 8.0333 | 26.4 | |

| MP12M | 22.3 | 8.0048 | 26.0 | |

| MP92 | 21.3 | 8.0144 | 26.7 | |

| MP109 | 19.6 | 8.0800 | 31.8 | |

| MP110 | 22.4 | 8.0048 | 26.0 | |

| MP111 | 21.6 | 8.0239 | 27.3 | |

| MP112 | 21.3 | 8.0144 | 26.7 | |

| MP113 | 22.2 | 8.0048 | 26.0 | |

| MP1 | 18.7 | 7.9000 | 26.4 | |

| MP2 | 20.0 | 6.7300 | 23.7 | |

| MP3 | 24.5 | 7.9800 | 22.8 | |

| MP5 | 17.9 | 8.8300 | 23.2 | |

| MP6 | 17.6 | 7.9800 | 31.8 |

| Variety | Specimens | σc (MPa) | εr (×10−3) | Predicted εr (×10−3) | Predicted and Experimental Absolute Difference εr (%) | Predicted σc (MPa) | Predicted and Experimental Absolute Difference σc (%) |

|---|---|---|---|---|---|---|---|

| A | AP38 | 126.4 | 5.7900 | 5.6971 | 1.6 | 146.0 | 15.5 |

| AP39 | 131.8 | 5.7931 | 5.6971 | 1.7 | 146.1 | 10.9 | |

| AP53 | 148.2 | 5.6968 | 5.7723 | 1.3 | 132.1 | 10.9 | |

| AP96 | 104.9 | 5.8542 | 5.6971 | 2.7 | 147.6 | 40.7 | |

| AP1 | 102.3 | 5.0000 | 6.0538 | 21.1 | 85.5 | 16.5 | |

| AP5 | 105.2 | 5.1000 | 5.9554 | 16.8 | 96.8 | 8.0 | |

| AP6 | 104.0 | 5.3000 | 5.9000 | 11.3 | 106.8 | 2.7 | |

| AP9 | 120.3 | 5.2000 | 5.8393 | 12.3 | 112.0 | 6.9 | |

| AP11 (N) | 136.2 | 6.2500 | 5.7723 | 7.6 | 144.9 | 6.4 | |

| AP13 (X) | 135.7 | 6.6300 | 5.8393 | 11.9 | 142.8 | 5.2 | |

| B | BP6 | 99.7 | 6.4725 | 6.4291 | 0.7 | 75.2 | 24.5 |

| BP27 | 82.6 | 6.4932 | 6.4291 | 1.0 | 75.5 | 8.6 | |

| BP32 | 83.1 | 6.8965 | 6.6131 | 4.1 | 66.9 | 19.5 | |

| BP45 | 97.3 | 6.7059 | 6.4549 | 3.7 | 76.0 | 21.9 | |

| BP72 | 98.2 | 6.5136 | 6.3151 | 3.0 | 84.9 | 13.5 | |

| BP3 | 95.0 | 7.2000 | 6.4291 | 10.7 | 83.7 | 11.9 | |

| BP13 | 105.3 | 7.8000 | 6.4291 | 17.6 | 90.7 | 13.9 | |

| BP | 94.5 | 6.5136 | 6.3151 | 3.0 | 84.9 | 10.1 | |

| C | CP18 | 47.8 | 7.4265 | 7.1988 | 3.1 | 41.8 | 12.5 |

| CP24 | 45.7 | 7.4139 | 7.1800 | 3.2 | 42.5 | 7.1 | |

| CP50 | 52.8 | 7.3366 | 6.9487 | 5.3 | 51.8 | 1.8 | |

| CP40 | 55.1 | 7.3497 | 6.9487 | 5.5 | 51.9 | 5.8 | |

| CP87 | 55.3 | 7.3627 | 6.9487 | 5.6 | 52.0 | 5.9 | |

| M | MP12 | 20.0 | 8.0615 | 8.0317 | 0.4 | 22.5 | 12.6 |

| MP13 | 20.4 | 8.0708 | 8.0317 | 0.5 | 22.5 | 10.5 | |

| MP9 | 22.0 | 8.0048 | 8.1220 | 1.5 | 20.8 | 5.4 | |

| MP10 | 22.7 | 7.9953 | 8.1034 | 1.4 | 21.1 | 7.1 | |

| MP11 | 20.7 | 8.0333 | 8.1341 | 1.3 | 20.7 | 0.1 | |

| MP12M | 22.3 | 8.0048 | 8.1220 | 1.5 | 20.8 | 6.7 | |

| MP92 | 21.3 | 8.0144 | 8.1432 | 1.6 | 20.5 | 3.8 | |

| MP109 | 19.6 | 8.0800 | 8.2840 | 2.5 | 18.5 | 5.6 | |

| MP110 | 22.4 | 8.0048 | 8.1220 | 1.5 | 20.8 | 7.1 | |

| MP111 | 21.6 | 8.0239 | 8.1609 | 1.7 | 20.2 | 6.3 | |

| MP112 | 21.3 | 8.0144 | 8.1432 | 1.6 | 20.5 | 3.8 | |

| MP113 | 22.2 | 8.0048 | 8.1220 | 1.5 | 20.8 | 6.3 | |

| MP1 | 18.7 | 7.9000 | 8.1341 | 3.0 | 20.3 | 8.8 | |

| MP2 | 20.0 | 6.7300 | 8.0485 | 19.6 | 18.5 | 7.3 | |

| MP3 | 24.5 | 7.9800 | 8.0180 | 0.5 | 22.5 | 8.0 | |

| MP5 | 17.9 | 8.8300 | 8.0317 | 9.0 | 24.7 | 37.8 | |

| MP6 | 17.6 | 7.9800 | 8.2840 | 3.8 | 18.3 | 3.9 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ludovico-Marques, M.; Chastre, C. Prediction of Stress–Strain Curves Based on Hydric Non-Destructive Tests on Sandstones. Materials 2019, 12, 3366. https://doi.org/10.3390/ma12203366

Ludovico-Marques M, Chastre C. Prediction of Stress–Strain Curves Based on Hydric Non-Destructive Tests on Sandstones. Materials. 2019; 12(20):3366. https://doi.org/10.3390/ma12203366

Chicago/Turabian StyleLudovico-Marques, Marco, and Carlos Chastre. 2019. "Prediction of Stress–Strain Curves Based on Hydric Non-Destructive Tests on Sandstones" Materials 12, no. 20: 3366. https://doi.org/10.3390/ma12203366

APA StyleLudovico-Marques, M., & Chastre, C. (2019). Prediction of Stress–Strain Curves Based on Hydric Non-Destructive Tests on Sandstones. Materials, 12(20), 3366. https://doi.org/10.3390/ma12203366