Dynamic Pullout Behavior of Multiple Steel Fibers in UHPC: Effects of Fiber Geometry, Inclination Angle, and Loading Rate

Abstract

:1. Introduction

2. A Review on Dynamic Pullout Behavior of Steel Fibers in UHPC

3. Research Significance

4. Experimental Program

4.1. Specimen Manufacturing Process

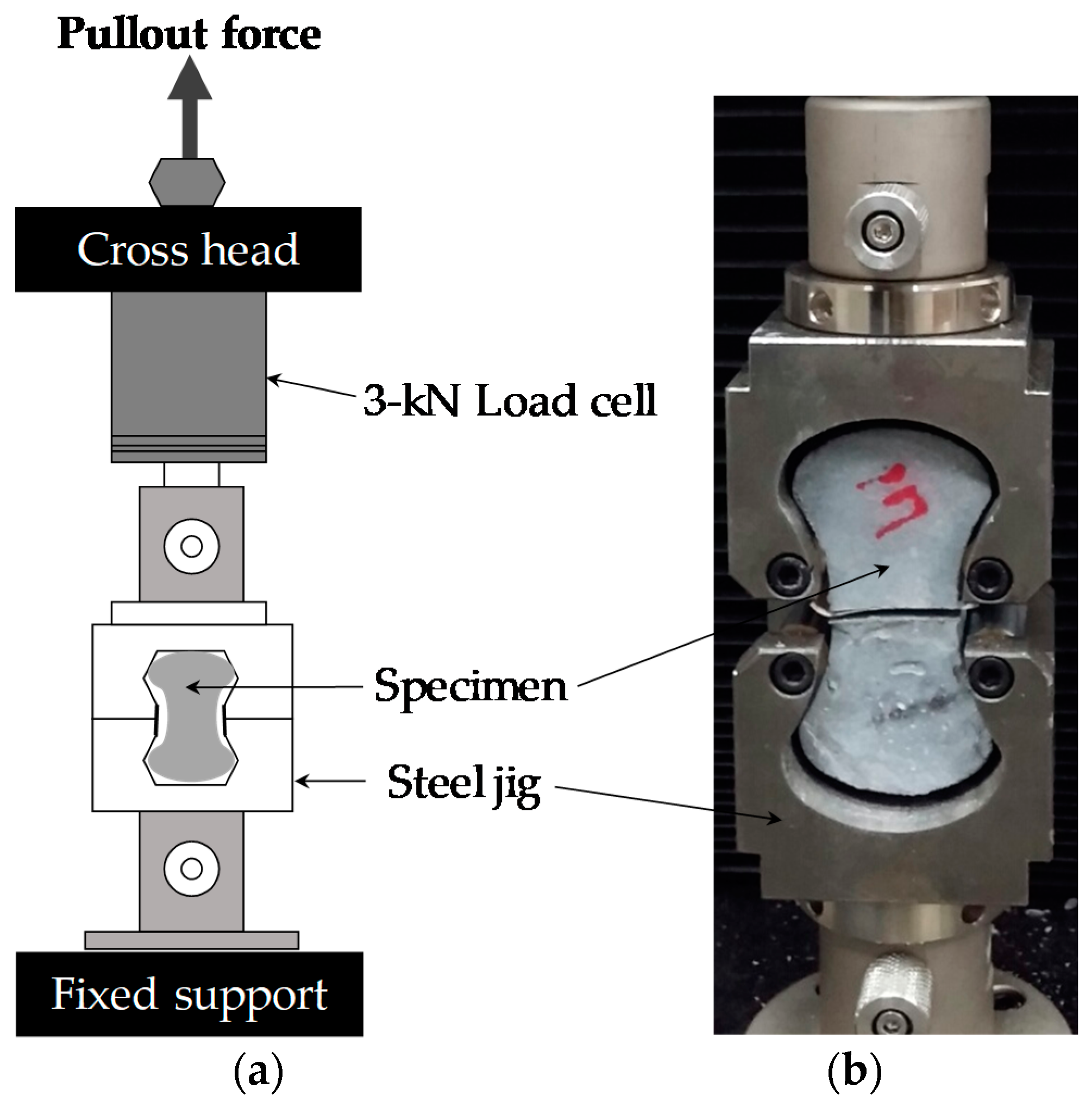

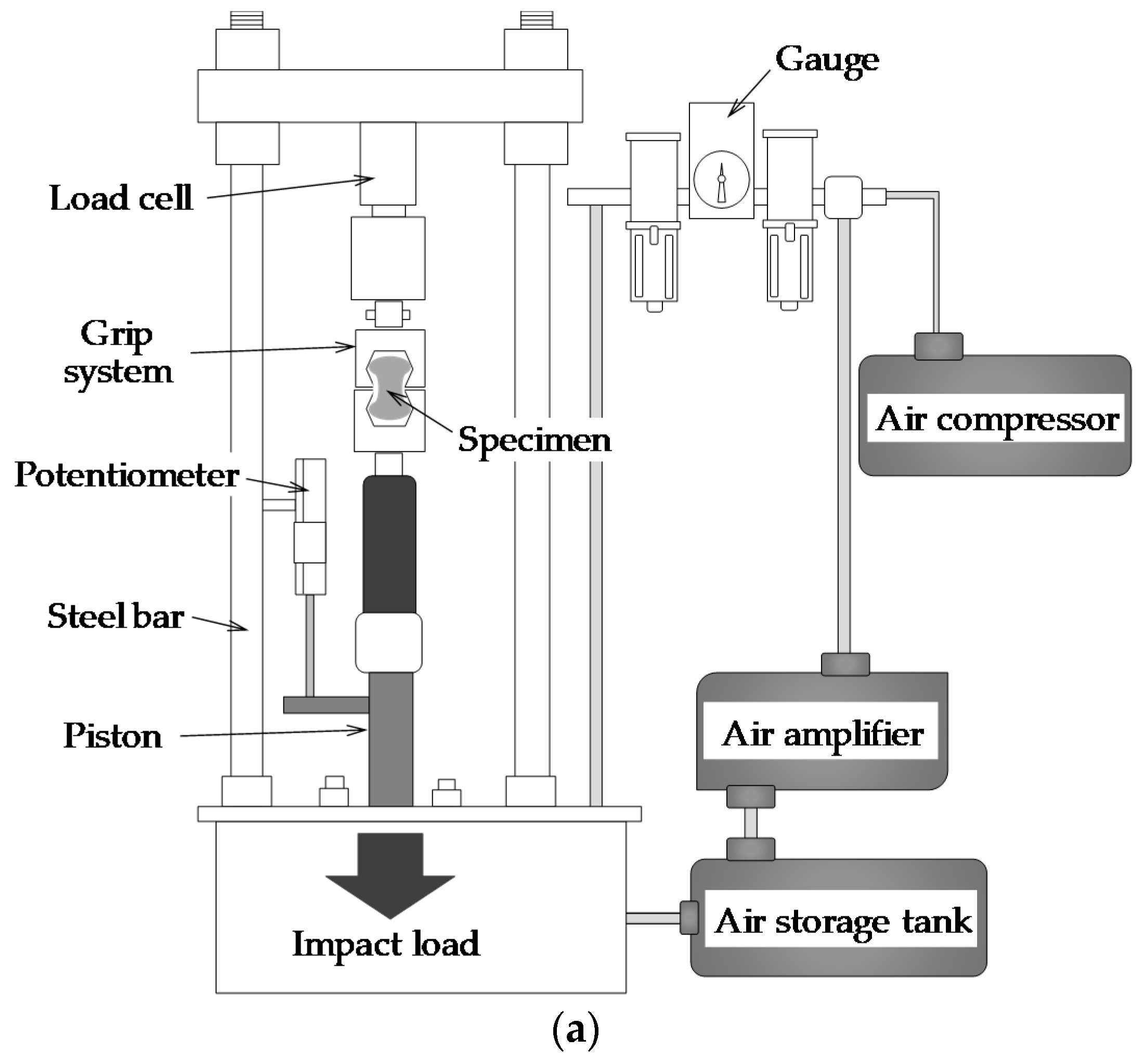

4.2. Test Setup and Instruments

5. Experimental Results and Discussion

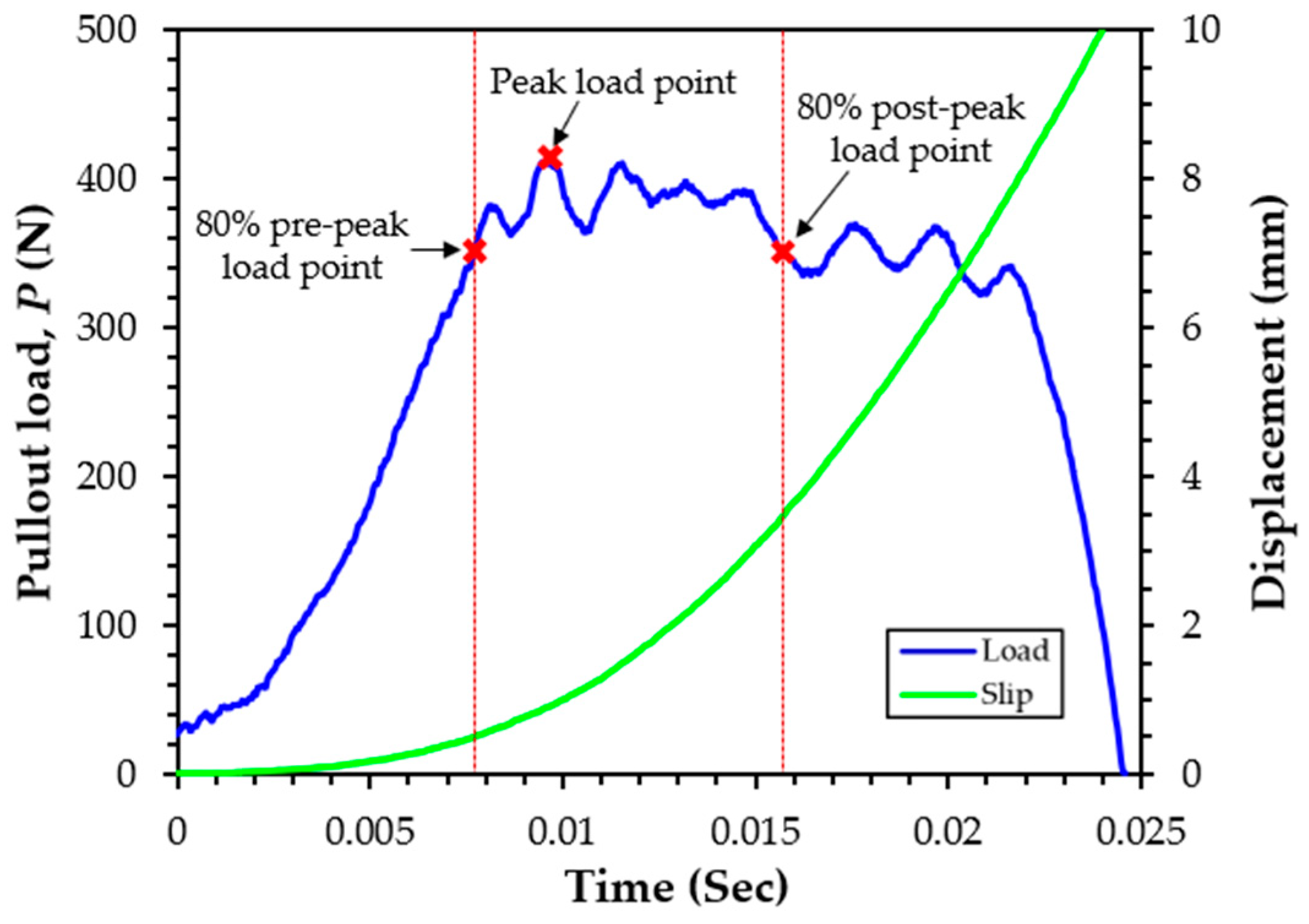

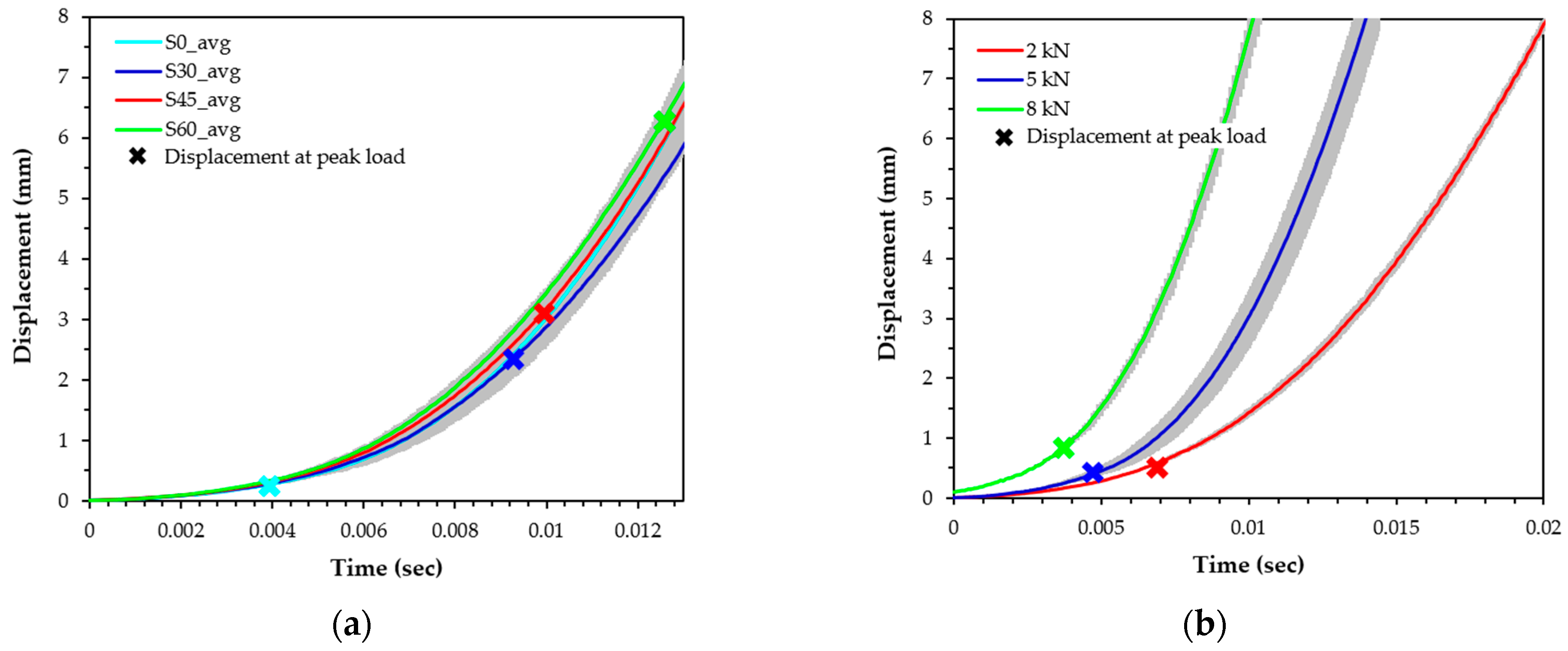

5.1. Determination of Loading Rate

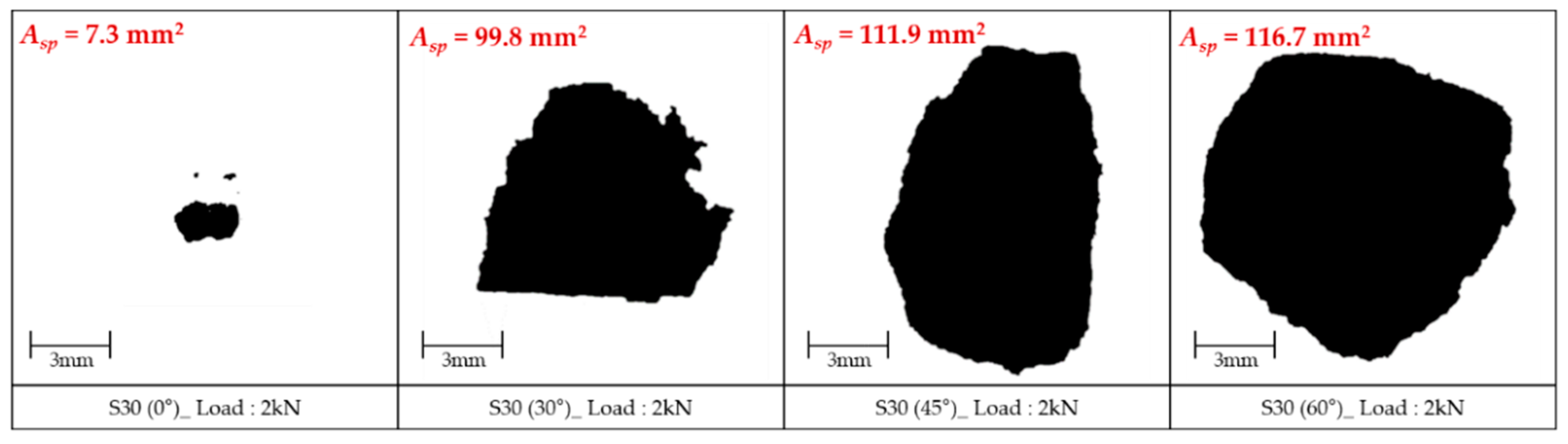

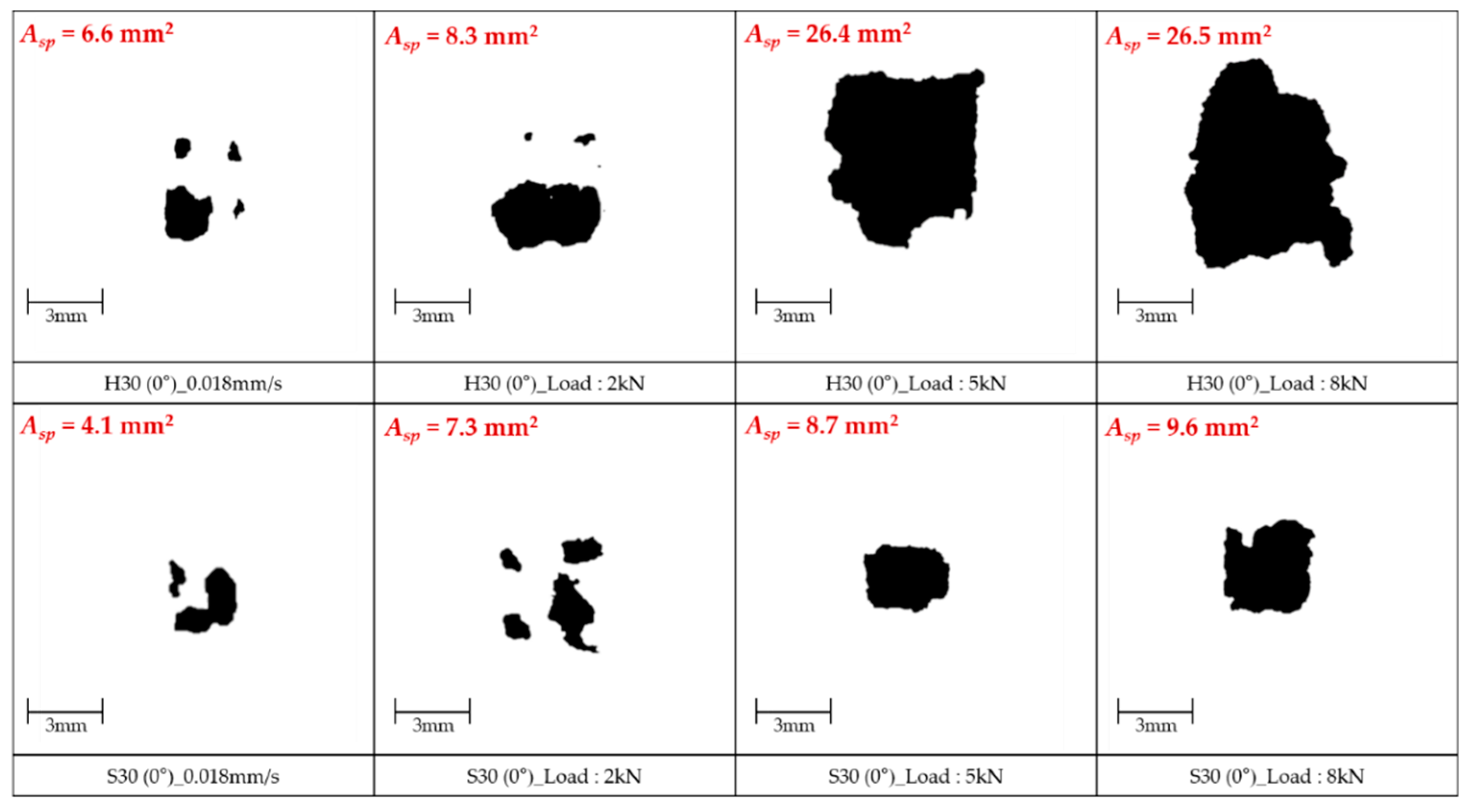

5.2. Pullout Behavior of S-Fibers According to Inclination Angle and Loading Rate

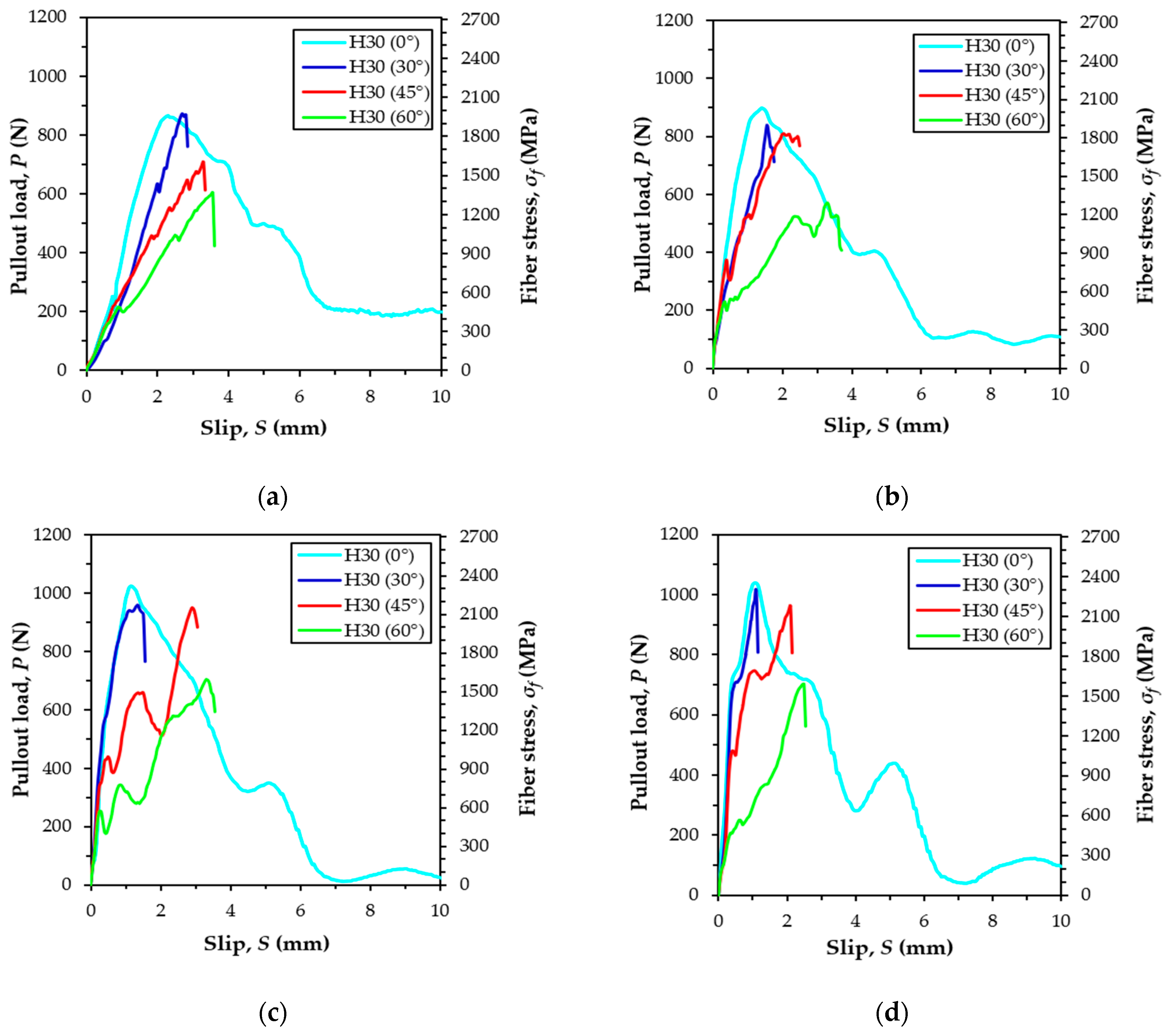

5.3. Pullout Behavior of H-fiber According to Inclination Angle and Loading Rate

5.4. Comparisons between Pullout Parameters of S- and H-fibers in UHPC

5.4.1. Discussion on Bond Strengths and Pullout Work

5.4.2. Relationship between DIF and Loading Rate

6. Discussion on the Comparative Dynamic Pullout Behaviors of Single and Multiple Steel Fibers in UHPC

7. Conclusions

- (1)

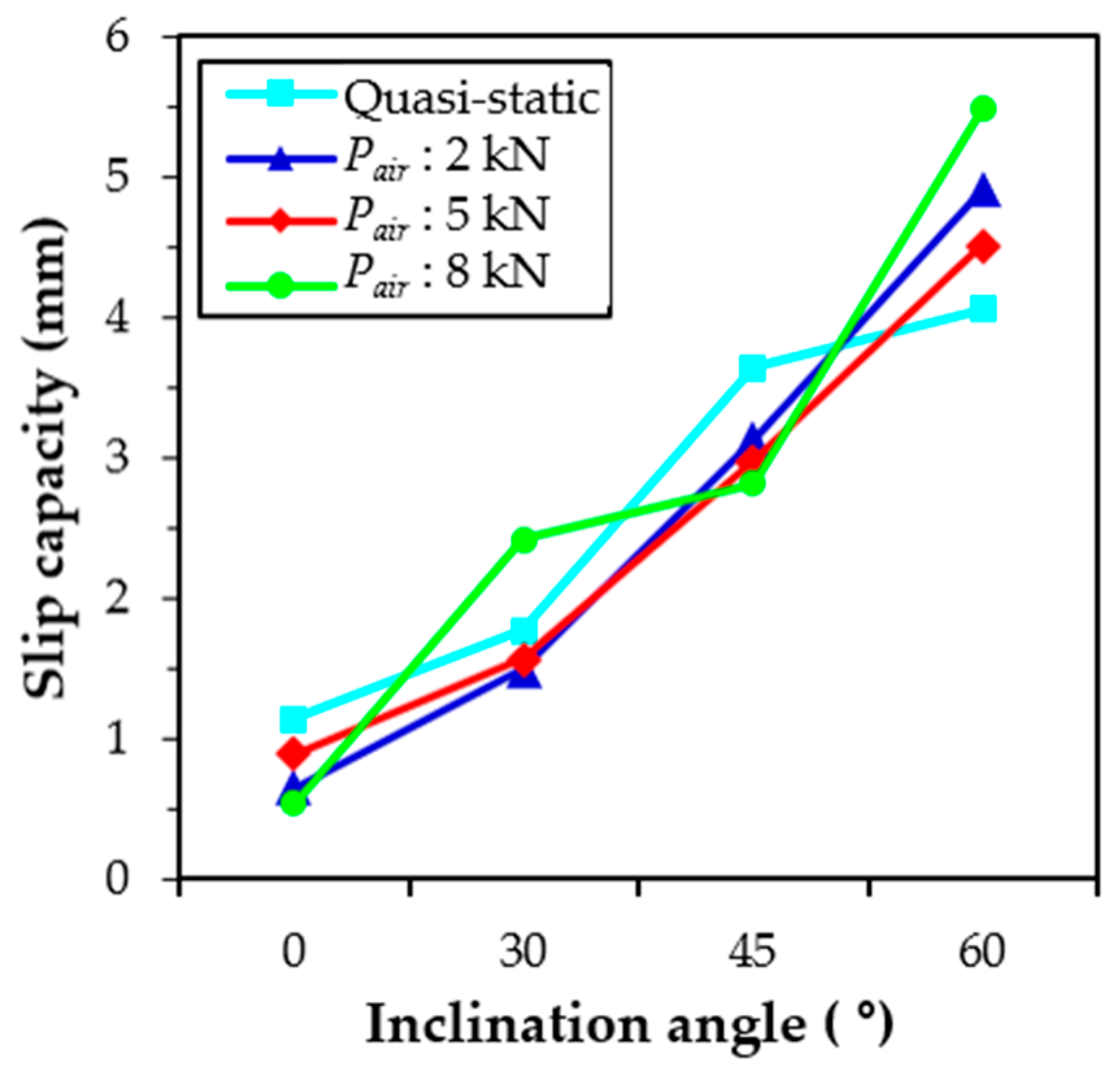

- The maximum pullout loads of S-fibers increased with increasing loading rate, but no clear trend was elicited on the rate sensitivity of the DIF of bond strength according to their inclination angle. The slip capacity of S-fibers increased at increasing inclination angles but was not influenced by the loading rate.

- (2)

- The pullout work and equivalent bond strength of S-fibers increased with increases in the loading rate. However, the aligned S-fiber was more sensitive to the loading rate than the inclined ones due to the more severe matrix spalling phenomenon in the latter cases.

- (3)

- The maximum pullout loads of H-fibers in UHPC generally increased with increasing the loading rate. The H-fibers at the inclination angle of 45° exhibited the highest sensitivity to the loading rate, while the H-fibers at the angle of 30° were the least sensitive. Furthermore, the slip capacity of H-fibers increased with an increasing inclination angle but decreased with the loading rate.

- (4)

- Given the identical failure mode, the pullout work of the H-fibers in UHPC was insensitive to the loading rate, but became sensitive to the loading rate as the failure mode was changed from matrix fracture to fiber rupture.

- (5)

- The H-fibers generally exhibited higher average bond strengths than the S-fibers at all loading rates and inclination angles. However, similar equivalent bond strengths of aligned S-fibers and even higher pullout work of inclined S-fibers were observed at the impact as respectively compared to the aligned and inclined H-fibers.

- (6)

- The DIF of aligned S-fibers in UHPC was most sensitive to the loading rate. The rate sensitivity became moderate at increasing inclination angle of S-fibers. The aligned S-fibers are recommended to be used to achieve excellent pullout energy and interfacial bond strength at impact loading.

Author Contributions

Funding

Conflicts of Interest

References

- Banthia, N.; Troitter, J.F. Concrete reinforced with deformed steel fibers, Part 1: Bond-slip mechanisms. ACI Mater. J. 1995, 91, 435–446. [Google Scholar]

- Wu, H.C.; Victor, C. Snubbing and bundling effects on multiple crack spacing of discontinuous random fiber-reinforced brittle matrix composites. J. Am. Ceram. Soc. 1992, 75, 3487–3489. [Google Scholar] [CrossRef]

- Fantilli, A.P.; Vallini, P. A cohesive Interface model for the pullout of inclined steel fibers in cementitious matrixes. J. Adv. Concr. Technol. 2007, 5, 247–258. [Google Scholar] [CrossRef]

- Alnaki, A.A.; Weigan, F.M.; Abdalghaffar, M.A.; Alotabi, F.A.; Al-Temeemi, A.A.; Alkhamis, M.T. Behavior of high-performance pull-out bond strength of fibers reinforced concrete structures. Jordan J. Civ. Eng. 2013, 7, 93–100. [Google Scholar]

- Naaman, A.E.; Namur, G.G.; Alwan, J.M.; Najm, H.S. Fiber pullout and bond slip I: Analytical study. J. Struct. Eng. 1991, 117, 2769–2790. [Google Scholar] [CrossRef]

- Richard, P.; Cheyrezy, M. Composition of reactive powder concretes. Cem. Concr. Res. 1995, 25, 1501–1511. [Google Scholar] [CrossRef]

- AFGC. Ultra High Performance Fibre-Reinforced Concretes; Interim Recommendations; AFGC Publication: Bagneux, France, 2013. [Google Scholar]

- Li, J.; Wu, C.; Hao, H. An experimental and numerical study of reinforced ultra-high performance concrete slabs under blast loads. Mater. Des. 2015, 82, 64–76. [Google Scholar] [CrossRef]

- Aoude, H.; Dagenais, F.P.; Burrell, R.P.; Saatcioglu, M. Behavior of ultra-high performance fiber reinforced concrete columns under blast loading. Int. J. Impact Eng. 2015, 80, 185–202. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Banthia, N.; Yoon, Y.S. Impact resistance of reinforced ultra-high-performance concrete beams with different steel fibers. ACI Struct. J. 2017, 114, 113–124. [Google Scholar] [CrossRef]

- Shehab El-Din, H.K.; Mohamed, H.A.; El-Hak Khater, M.A.; Ahmed, S. Effect of steel fibers on behavior of ultra high-performance concrete. In Proceedings of the First International Interactive Symposium on UHPC, Des Moines, IA, USA, 18–20 July 2016. [Google Scholar]

- Isla, F.; Ruano, F.; Luccioni, B. Analysis of steel fibers pull-out. Experimental study. Constr. Build. Mater. 2015, 100, 183–193. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Park, J.J.; Kim, S.W. Fiber pullout behavior of HPFRCC: Effects of matrix strength and fiber type. Compos. Struct. 2017, 174, 263–276. [Google Scholar] [CrossRef]

- Wille, K.; Naaman, A.E. Effect of ultra-high-performance concrete on pullout behavior of high-strength brass-coated straight steel fibers. ACI Mater. J. 2013, 110, 451–462. [Google Scholar]

- Chan, Y.W.; Chu, S.H. Effect of silica fume on steel fiber bond characteristics in reactive powder concrete. Cem. Concr. Res. 2004, 34, 1167–1172. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Kang, S.T.; Lee, J.H.; Yoon, Y.S. Effect of shrinkage reducing admixture on tensile and flexural behaviors of UHPFRC considering fiber distribution characteristics. Cem. Concr. Res. 2013, 54, 180–190. [Google Scholar] [CrossRef]

- Kim, J.J.; Yoo, D.Y. Effects of fiber shape and distance on the pullout behavior of steel fibers embedded in ultra-high-performance concrete. Cem. Concr. Compos. 2019, 103, 213–223. [Google Scholar] [CrossRef]

- Armelin, H.S.; Banthia, N. Predicting the flexural postcracking performance of steel fiber reinforced concrete from the pullout of single fibers. ACI Mater. J. 1997, 94, 18–31. [Google Scholar]

- Wang, Y.J.; Li, V.C.; Backer, S. Analysis of synthetic fiber pull-out from a cement matrix. MRS Online Proc. Libr. Arch. 1987, 114, 159–165. [Google Scholar] [CrossRef]

- Naaman, A.E.; Namur, G.; Najm, H.; Alwan, J. Bond Mechanisms in Fiber-Reinforced Cement-Based Composites (No. UMCE-89-9); Final Report; Department of Civil Engineering, University of Michigan: Ann Arbor, MI, USA, 1989. [Google Scholar]

- Yoo, D.Y.; Banthia, N.; Kang, S.T.; Yoon, Y.S. Size effect in ultra-high-performance concrete beams. Eng. Fract. Mech. 2016, 157, 86–106. [Google Scholar] [CrossRef]

- Kwon, S.H.; Kang, S.T.; Lee, B.Y.; Kim, J.K. The variation of flow-dependent tensile behavior in radial flow dominant placing of Ultra High Performance Fiber Reinforced Cementitious Composites (UHPFRCC). Constr. Build. Mater. 2012, 33, 109–121. [Google Scholar] [CrossRef]

- Lee, Y.; Kang, S.T.; Kim, J.K. Pullout behavior of inclined steel fiber in an ultra-high strength cementitious matrix. Constr. Build. Mater. 2010, 24, 2030–2041. [Google Scholar] [CrossRef]

- Tai, Y.S.; Tawil, S.E. High loading-rate pullout behavior of inclined deformed steel fibers embedded in ultra-high performance concrete. Constr. Build. Mater. 2017, 148, 204–218. [Google Scholar] [CrossRef]

- Tai, Y.S.; Tawil, S.E.; Chung, T.H. Performance of deformed steel fibers embedded in ultra-high performance concrete subjected to various pullout rates. Cem. Concr. Res. 2016, 89, 1–13. [Google Scholar] [CrossRef]

- Kim, D.J.; Tawil, S.E.; Naaman, A.E. Loading rate effect on pullout behavior of deformed steel fibers. ACI Mater. J. 2008, 105, 576–584. [Google Scholar]

- Xu, M.; Hallinan, B.; Wille, K. Effect of loading rates on pullout behavior of high strength steel fibers embedded in ultra-high performance concrete. Cem. Concr. Compos. 2016, 70, 98–109. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Kim, S.H.; Park, G.J.; Park, J.J.; Kim, S.W. Effects of fiber shape, aspect ratio, and volume fraction on flexural behavior of ultra-high-performance fiber-reinforced cement composites. Compos. Struct. 2017, 174, 375–388. [Google Scholar] [CrossRef]

- Cuncha, V.M.C.G.; Barros, J.A.O.; Sena-Cruz, J.M. Pullout Behavior of steel fibers in self-compacting concrete. J. Mater. Civil Eng. 2010, 22, 1–9. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, M.H.; Zakaria, M.H. Effect of high strain rate loading on compressive behavior of fibre-reinforced high-strength concrete. Mag. Concr. Res. 2011, 63, 813–827. [Google Scholar] [CrossRef]

- Kanda, T.; Li, V.C. Interface property and apparent strength of high-strength hydrophilic fiber in cement matrix. J. Mater. Civ. Eng. 1980, 10, 5–13. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Kang, S.T.; Banthia, N.; Yoon, Y.S. Nonlinear finite element analysis of ultra-high-performance fiber-reinforced concrete beams. Int. J. Damage Mech. 2017, 26, 735–757. [Google Scholar] [CrossRef]

- Gokoz, U.; Naaman, A.E. Effect of strain-rate on the pull-out behavior of fibers in mortar. Int. J. Cem. Compos. 1981, 3, 187–202. [Google Scholar]

- Bindiganavile, V.; Banthia, N. Polymer and steel fiber-reinforced cementitious composites under impact loading—Part 1: Bond-slip response. ACI Mater. J. 2001, 98, 10–16. [Google Scholar]

- Yoo, D.Y.; Banthia, N.; Kang, S.T.; Yoon, Y.S. Effect of fiber orientation on the rate-dependent flexural behavior of ultra-high-performance fiber-reinforced concrete. Compos. Struct. 2016, 157, 62–70. [Google Scholar] [CrossRef]

- Robins, P.; Austin, S.; Jones, P. Pull-out behaviour of hooked steel fibres. Mater. Struct. 2002, 35, 434–442. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Banthia, N.; Lee, J.Y.; Yoon, Y.S. Effect of fiber geometric property on rate dependent flexural behavior of ultra-high-performance cementitious composite. Cem. Concr. Compos. 2018, 86, 57–71. [Google Scholar] [CrossRef]

- Bindiganavile, V.; Banthia, N. Impact response of the fiber-matrix bond in concrete. Can. J. Civ. Eng. 2005, 32, 924–933. [Google Scholar] [CrossRef]

- Wille, K.; Xu, M.; El-Tawil, S.; Naaman, A.E. Dynamic impact factors of strain hardening UHP-FRC under direct tensile loading at low strain rates. Mater. Struct. 2016, 49, 1351–1365. [Google Scholar] [CrossRef]

- Park, S.H.; Kim, D.J.; Kim, S.W. Investigating the impact resistance of ultra-high-performance fiber-reinforced concrete using an improved strain energy impact test machine. Constr. Build. Mater. 2016, 125, 145–159. [Google Scholar] [CrossRef]

- Fujikake, K.; Uebayashi, K.; Ohno, T.; Mizuno, J.; Suzuki, A. Formulation of orthotropic constitutive model for concrete materials under high strain-rates and tri-axial stress states. J. Mater. Concr. Struct. Pavement 2001, 50, 109–123. [Google Scholar]

- Salloum, Y.A.; Almusallam, T.; Ibrahim, S.M.; Abbas, H.; Alsayed, S. Rate dependent behavior and modeling of concrete based on SHPB experiments. Cem. Concr. Compos. 2015, 55, 34–44. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Kim, S.; Kim, J.J.; Chun, B. An experimental study on pullout and tensile behavior of ultra-high-performance concrete reinforced with various steel fibers. Constr. Build. Mater. 2019, 206, 46–61. [Google Scholar] [CrossRef]

| Composition % (Mass) | Type I Portland Cement | Silica Fume |

|---|---|---|

| CaO | 61.33 | 0.38 |

| Al2O3 | 6.40 | 0.25 |

| SiO2 | 21.01 | 96.00 |

| Fe2O3 | 3.12 | 0.12 |

| MgO | 3.02 | 0.10 |

| SO3 | 2.30 | - |

| Specific surface area (cm2/g) | 3413 | 200,000 |

| Density (g/cm3) | 3.15 | 2.10 |

| lg. loss (%) | 1.40 | 1.50 |

| W/B | Unit Weight (kg/m3) | |||||

|---|---|---|---|---|---|---|

| Water | Cement | Silica Fume | Silica Sand | Silica Flour | Superplasticizer | |

| 0.2 | 160.3 | 788.5 | 197.1 | 867.4 | 236.6 | 52.6 |

| Type of Fiber | df (mm) | lf (mm) | Aspect Ratio (lf/df) | Density (g/cm3) | ft (MPa) | Ef (GPa) |

|---|---|---|---|---|---|---|

| S30 | 0.300 | 30.0 | 100.0 | 7.9 | 2580 | 200 |

| H30 | 0.375 | 30.0 | 80.0 | 7.9 | 2630 | 200 |

| Fiber Type | Inclination Angle | Quasi-Static | Pair: 2 kN | Pair: 5 kN | Pair: 8 kN | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pmax (N) | DIF | Slipu (mm) | Rate (mm/s) | Pmax (N) | DIF | Slipu (mm) | Rate (mm/s) | Pmax (N) | DIF | Slipu (mm) | Rate (mm/s) | Pmax (N) | DIF | Slipu (mm) | Rate (mm/s) | ||

| S30 | 0° | 278.5 | 1.00 | 1.14 | 0.018 | 406.7 | 1.46 | 0.65 | 262.5 | 458.9 | 1.65 | 0.54 | 268.7 | 537.7 | 1.93 | 0.89 | 499.0 |

| 30° | 363.0 | 1.00 | 1.77 | 0.018 | 503.9 | 1.39 | 1.49 | 410.6 | 612.2 | 1.69 | 2.41 | 648.4 | 596.3 | 1.64 | 1.56 | 662.6 | |

| 45° | 375.7 | 1.00 | 3.63 | 0.018 | 554.2 | 1.48 | 3.13 | 568.7 | 576.5 | 1.53 | 2.82 | 708.9 | 646.6 | 1.72 | 2.98 | 999.5 | |

| 60° | 338.0 | 1.00 | 4.06 | 0.018 | 507.7 | 1.50 | 4.90 | 736.6 | 581.9 | 1.72 | 5.48 | 1170.7 | 563.2 | 1.67 | 4.51 | 1293.9 | |

| H30 | 0° | 837.3 | 1.00 | 2.33 | 0.018 | 922.8 | 1.10 | 1.33 | 247.5 | 1026.8 | 1.23 | 1.14 | 438.6 | 1041.5 | 1.24 | 1.01 | 476.6 |

| 30° | 962.8 † | 1.00 | 3.15 | 0.018 | 887.7 † | 0.92 | 2.34 | 371.3 | 917.0 † | 0.95 | 1.72 | 468.1 | 1050.3 † | 1.09 | 1.22 | 507.1 | |

| 45° | 763.4 ‡ | 1.00 | 3.71 | 0.018 | 938.5 † | 1.23 | 2.66 | 416.0 | 981.5 † | 1.29 | 3.60 | 897.1 | 1054.7 † | 1.38 | 2.51 | 828.9 | |

| 60° | 628.0 ‡ | 1.00 | 3.89 | 0.018 | 679.2 † | 1.08 | 4.62 | 624.1 | 741.5 † | 1.18 | 3.38 | 898.6 | 771.9 † | 1.23 | 3.63 | 1104.2 | |

| Fiber Type | Incli. Angle | Parameters | Quasi-Static | Pair: 2 kN | Pair: 5 kN | Pair: 8 kN | |

|---|---|---|---|---|---|---|---|

| S30 | 0° | τeq | MPa | 6.84 | 14.22 | 13.92 | 16.49 |

| DIF | 1 | 2.08 | 2.04 | 2.41 | |||

| τav | MPa | 6.63 | 10.79 | 11.33 | 12.33 | ||

| DIF | 1 | 1.63 | 1.71 | 1.86 | |||

| WP | N·mm | 1626.08 | 2680.72 | 3043.54 | 4154.05 | ||

| DIF | 1 | 1.65 | 1.87 | 2.55 | |||

| 30° | τeq | MPa | 13.49 | 17.56 | 16.30 | 21.32 | |

| DIF | 1 | 1.30 | 1.21 | 1.58 | |||

| τav | MPa | 9.63 | 13.37 | 16.24 | 16.36 | ||

| DIF | 1 | 1.39 | 1.69 | 1.70 | |||

| WP | N·mm | 2542.21 | 3310.51 | 3071.96 | 4018.84 | ||

| DIF | 1 | 1.30 | 1.21 | 1.58 | |||

| 45° | τeq | MPa | 13.14 | 17.48 | 14.72 | 14.16 | |

| DIF | 1 | 1.33 | 1.12 | 1.08 | |||

| τav | MPa | 9.96 | 14.70 | 15.29 | 17.39 | ||

| DIF | 1 | 1.48 | 1.54 | 1.75 | |||

| WP | N·mm | 2477.02 | 3294.46 | 2774.65 | 2669.41 | ||

| DIF | 1 | 1.33 | 1.12 | 1.08 | |||

| 60° | τeq | MPa | 9.85 | 13.98 | 14.69 | 17.12 | |

| DIF | 1 | 1.42 | 1.49 | 1.74 | |||

| τav | MPa | 8.97 | 13.47 | 15.44 | 14.99 | ||

| DIF | 1 | 1.50 | 1.72 | 1.67 | |||

| WP | N·mm | 1856.11 | 2635.05 | 2769.01 | 3227.95 | ||

| DIF | 1 | 1.42 | 1.49 | 1.74 | |||

| H30 | 0° | τeq | MPa | 15.53 | 14.62 | 16.24 | 16.14 |

| DIF | 1 | 0.94 | 1.05 | 1.04 | |||

| τav | MPa | 15.96 | 19.59 | 21.79 | 22.10 | ||

| DIF | 1 | 1.23 | 1.37 | 1.38 | |||

| WP | N·mm | 4713.62 | 3444.82 | 3826.48 | 3801.96 | ||

| DIF | 1 | 0.73 | 0.81 | 0.81 | |||

| 30° | τav | MPa | 20.43 † | 18.84 † | 20.98 † | 22.29 † | |

| DIF | 1 | 0.92 | 1.03 | 1.09 | |||

| WP* | N·mm | 1468.17 † | 1153.24 † | 931.54 † | 837.65 † | ||

| DIF | 1 | 0.79 | 0.63 | 0.57 | |||

| 45° | τav | MPa | 16.21 ‡ | 19.92 † | 20.83 † | 22.38 † | |

| DIF | 1 | 1.23 | 1.29 | 1.38 | |||

| WP* | N·mm | 1376.87 ‡ | 1543.61 † | 1920.76 † | 1665.36 † | ||

| DIF | 1 | 1.12 | 1.40 | 1.21 | |||

| 60° | τav | MPa | 13.33 ‡ | 14.41 † | 15.74 † | 16.38 † | |

| DIF | 1 | 1.08 | 1.18 | 1.23 | |||

| WP* | N·mm | 1191.64 ‡ | 1686.90 † | 1448.57 † | 1571.32 † | ||

| DIF | 1 | 1.42 | 1.22 | 1.32 | |||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jang, E.-Y.; Kim, J.J.; Yoo, D.-Y. Dynamic Pullout Behavior of Multiple Steel Fibers in UHPC: Effects of Fiber Geometry, Inclination Angle, and Loading Rate. Materials 2019, 12, 3365. https://doi.org/10.3390/ma12203365

Jang E-Y, Kim JJ, Yoo D-Y. Dynamic Pullout Behavior of Multiple Steel Fibers in UHPC: Effects of Fiber Geometry, Inclination Angle, and Loading Rate. Materials. 2019; 12(20):3365. https://doi.org/10.3390/ma12203365

Chicago/Turabian StyleJang, Eun-Yoo, Jung J. Kim, and Doo-Yeol Yoo. 2019. "Dynamic Pullout Behavior of Multiple Steel Fibers in UHPC: Effects of Fiber Geometry, Inclination Angle, and Loading Rate" Materials 12, no. 20: 3365. https://doi.org/10.3390/ma12203365

APA StyleJang, E.-Y., Kim, J. J., & Yoo, D.-Y. (2019). Dynamic Pullout Behavior of Multiple Steel Fibers in UHPC: Effects of Fiber Geometry, Inclination Angle, and Loading Rate. Materials, 12(20), 3365. https://doi.org/10.3390/ma12203365