Probabilistic Fatigue/Creep Optimization of Turbine Bladed Disk with Fuzzy Multi-Extremum Response Surface Method

Abstract

:1. Introduction

2. Methods and Models

2.1. FMERSM Modeling

2.2. Fatigue/Creep Modeling for Probabilistic Optimization of Bladed Disks

2.3. Miner Linear Accumulation Damage Law

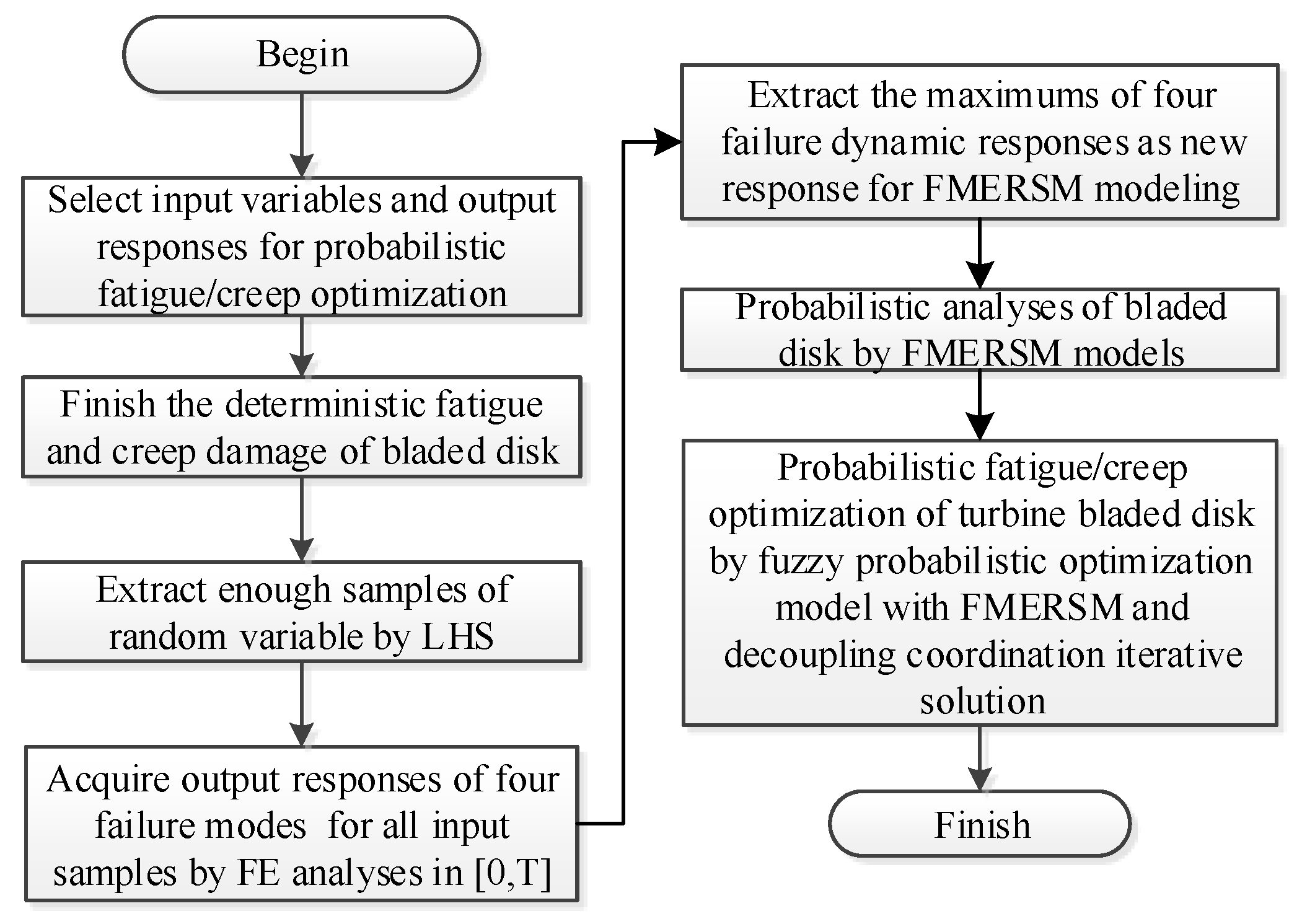

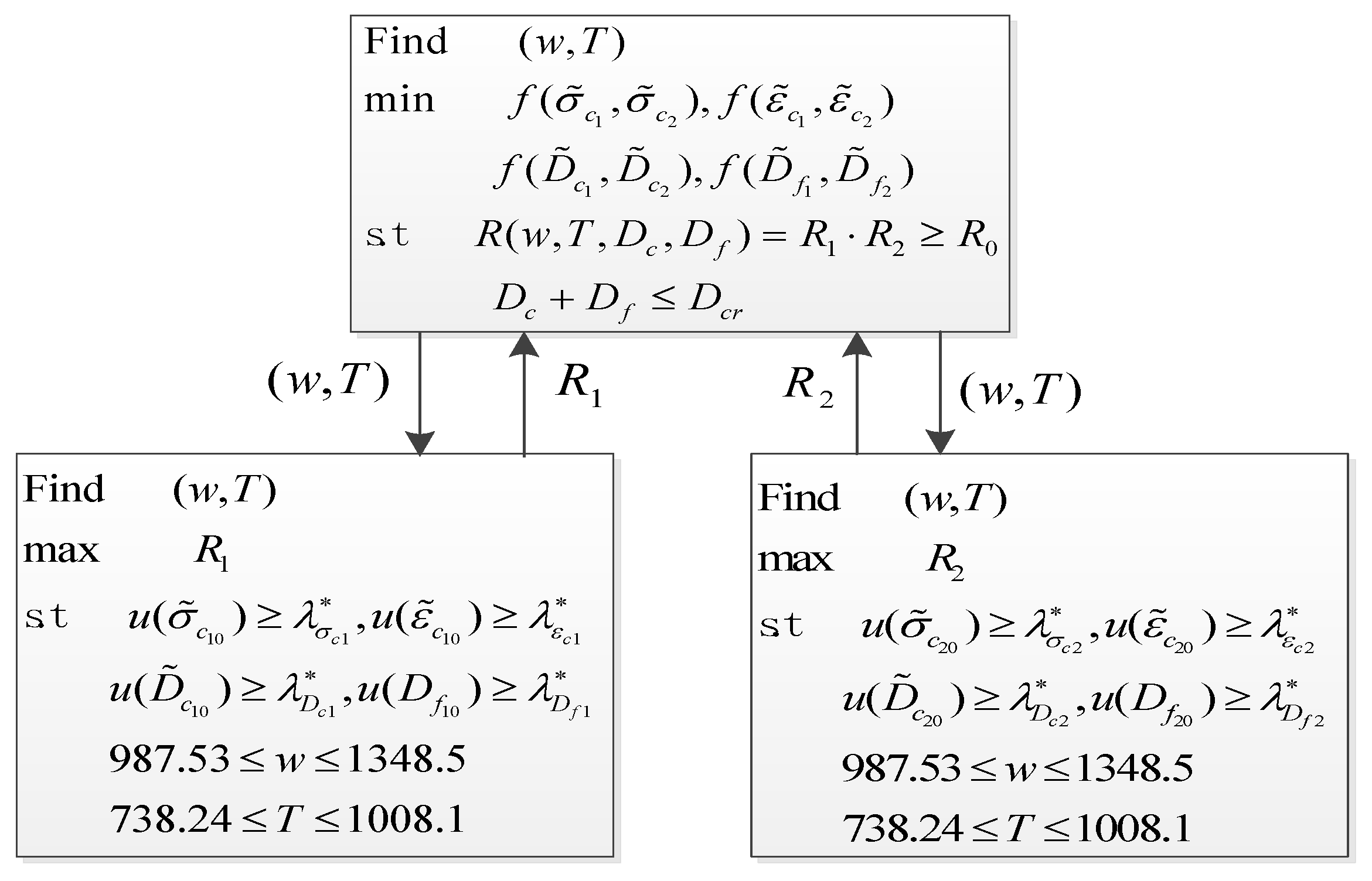

2.4. Basic Thought of Probabilistic Fatigue/Creep Optimization with FMERSM

3. Fuzzy Probabilistic Fatigue/Creep Optimization of Turbine Bladed Disk

3.1. Parameters Preparation

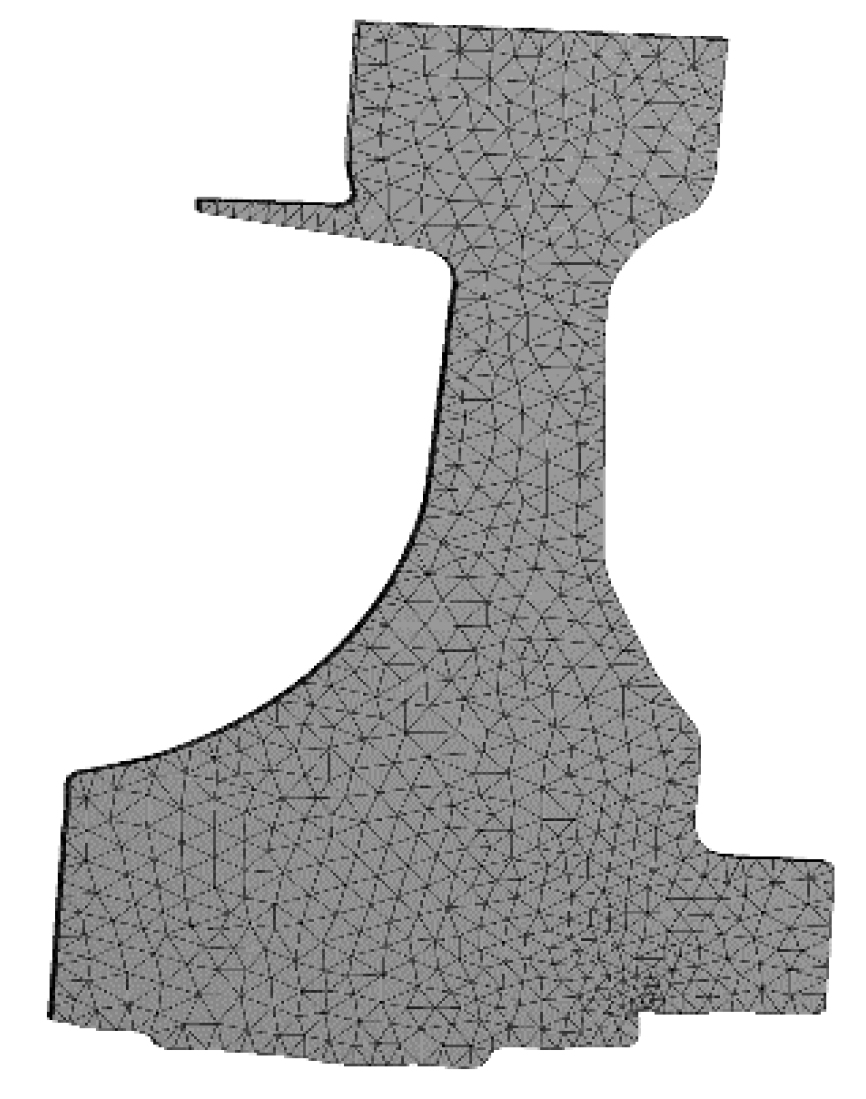

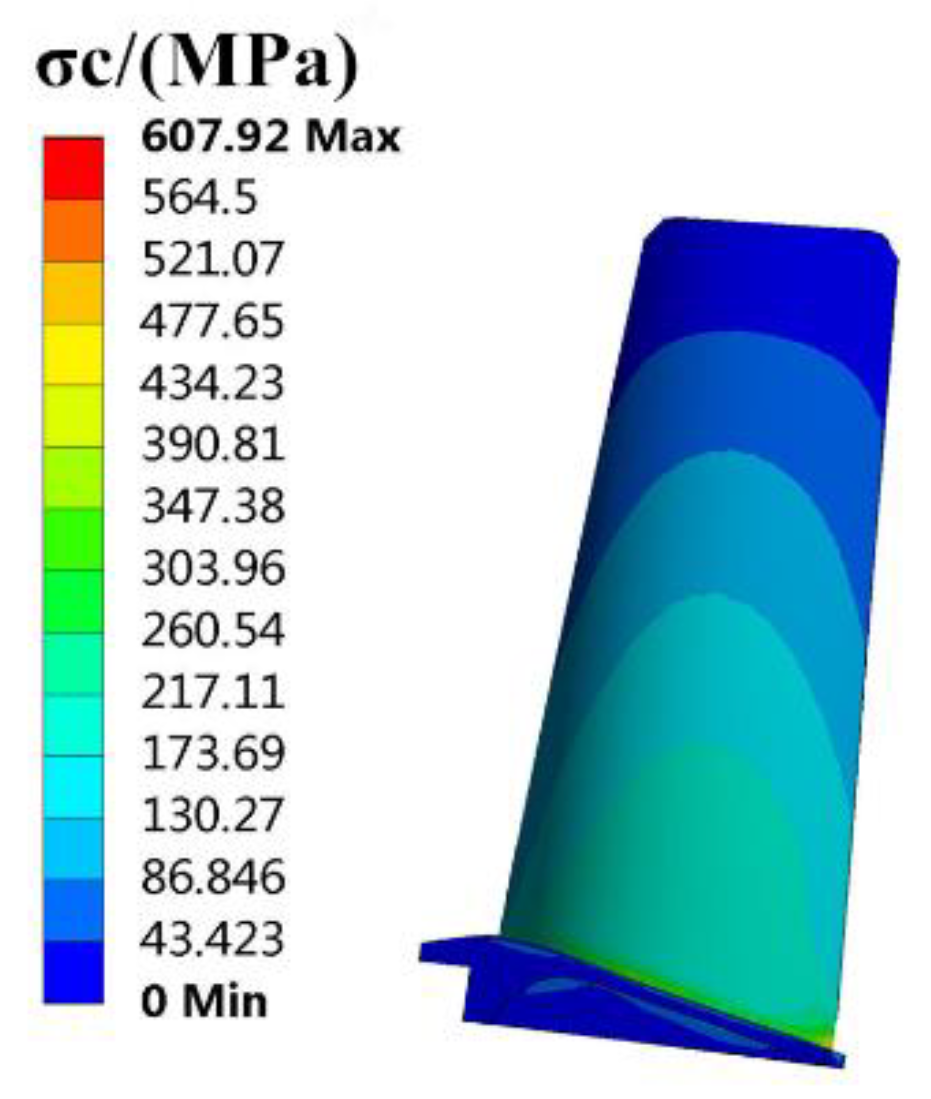

3.2. Deterministic Analysis of Bladed Disk

3.3. FMERSM Modeling

3.4. Probabilistic Fatigue/Creep Optimization of Bladed Disk

3.5. FMERSM Validation

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zhang, C.Y.; Lu, C.; Fei, C.W.; Jing, H.Z.; Li, C.W. Dynamic probabilistic design technique for multi-component system with multi-failure modes. J. Cent. South Univ. 2018, 25, 2688–2700. [Google Scholar] [CrossRef]

- Fei, C.W.; Choy, Y.S.; Hu, D.Y.; Bai, G.C.; Tang, W.Z. Transient probabilistic analysis for turbine blade-tip radial clearance with multi-component and multi-physics fields based on DCERSM. Aerosp. Sci. Technol. 2016, 50, 62–70. [Google Scholar] [CrossRef]

- Li, X.; Qiu, H.; Chen, Z.; Gao, L.; Shao, X. A local Kriging approximation method using MPP for reliability-based design optimization. Comput. Struct. 2016, 162, 102–115. [Google Scholar] [CrossRef]

- Majumdar, R.; Ghosh, A.; Das, A.K.; Raha, S.; Laha, K.; Das, S.; Abraham, A. Artificial Weed Colonies with Neighbourhood Crowding Scheme for Multimodal Optimization; Springer: New York, NY, USA, 2013. [Google Scholar]

- Song, L.K.; Bai, G.C.; Fei, C.W.; Tang, W.Z. Multi-failure probabilistic design for turbine bladed disks using neural network regression with distributed collaborative strategy. Aerosp. Sci. Technol. 2019, 92, 464–477. [Google Scholar] [CrossRef]

- Zhang, C.Y.; Bai, G.C. Extremum response surface method of reliability analysis on two-link flexible robot manipulator. J. Cent. South Univ. 2012, 19, 101–107. [Google Scholar] [CrossRef]

- Fei, C.W.; Bai, G.C.; Tang, W.Z.; Choy, Y.S. Transient reliability optimization for turbine disk radial deformation. J. Cent. South Univ. 2016, 23, 344–352. [Google Scholar] [CrossRef]

- Fei, C.W.; Tang, W.Z.; Bai, G.C. Novel method and model for dynamic reliability optimal design of turbine blade deformation. Aerosp. Sci. Technol. 2014, 39, 588–595. [Google Scholar] [CrossRef]

- Fei, C.W.; Tang, W.Z.; Bai, G.C. Study on the theory, method and model for mechanical dynamic assembly reliability optimization. Proc. IME Part C J. Mech. Eng. Sci. 2014, 228, 3019–3038. [Google Scholar] [CrossRef]

- Song, L.K.; Fei, C.W.; Wen, J.; Bai, G.C. Multi-objective reliability-based design optimization approach of complex structure with multi-failure modes. Aerosp. Sci. Technol. 2017, 64, 52–62. [Google Scholar] [CrossRef]

- Hamzaoui, Y.E.; Rodríguez, J.A.; Hernández, J.A.; Salazar, V. Optimization of operating conditions for steam turbine using an artificial neural network inverse. Appl. Therm. Eng. 2015, 75, 648–657. [Google Scholar] [CrossRef]

- Rodríguez, J.A.; Garcia, J.C.; Alonso, E.; Hamzaoui, Y.E.; Rodríguez, J.M.; Urquiza, G. Failure probability estimation of steam turbine blades by enhanced Monte Carlo Method. Eng. Fail. Anal. 2015, 56, 80–88. [Google Scholar] [CrossRef]

- Wang, C.; Matthies, H.G. Epistemic uncertainty-based reliability analysis for engineering system with hybrid evidence and fuzzy variables. Comput. Methods Appl. Mech. Eng. 2019, 355, 438–455. [Google Scholar] [CrossRef]

- Gao, H.F.; Wang, A.J.; Bai, G.C.; Wei, C.M.; Fei, C.W. Substructure-based distributed collaborative probabilistic analysis method for low-cycle fatigue damage assessment of turbine blade–disk. Aerosp. Sci. Technol. 2018, 79, 636–646. [Google Scholar] [CrossRef]

- Ai, Y.; Zhu, S.P.; Liao, D.; Cirreia, J.A.F.O.; Souto, C.; De Jesus, A.M.P.; Keshtegar, B. Probabilistic modeling of fatigue life distribution and size effect of components with random defects. Int. J. Fatigue 2019, 126, 165–173. [Google Scholar] [CrossRef]

- Song, L.K.; Bai, G.C.; Fei, C.W.; Wen, J. Probabilistic LCF life assessment of turbine discs using DC-based wavelet neural network regression. Int. J. Fatigue 2019, 119, 204–219. [Google Scholar] [CrossRef]

- Cano, S.; Rodríguez, J.A.; Rodríguez, J.M.; García, J.C.; Sierra, F.Z.; Casolco, S.R.; Herrera, M. Detection of damage in steam turbine blades caused by low cycle and strain cycling fatigue. Eng. Fail. Anal. 2019, 97, 579–588. [Google Scholar] [CrossRef]

- Fei, C.W.; Lu, C.; Liem, R.P. Decomposed-coordinated surrogate modelling strategy for compound function approximation and a turbine blisk reliability evaluation. Aerosp. Sci. Technol. 2019, 105466. [Google Scholar] [CrossRef]

- Zhang, C.Y.; Wei, J.S.; Jing, H.Z.; Fei, C.W.; Tang, W.Z. Reliability analysis of blisk low fatigue life with generalized regression extreme neural network method. Materials 2019, 12, 1545. [Google Scholar] [CrossRef]

- Lu, C.; Feng, Y.W.; Liem, R.P.; Fei, C.W. Improved kriging with extremum response surface method for structural dynamic reliability and sensitivity analyses. Aerosp. Sci. Technol. 2018, 76, 164–175. [Google Scholar] [CrossRef]

- Gao, H.F.; Fei, C.W.; Bai, G.C. Reliability-based low-cycle fatigue life analysis of turbine blade with thermo- structural interaction. Aerosp. Sci. Technol. 2016, 49, 289–300. [Google Scholar] [CrossRef]

- Fei, C.W.; Bai, G.C.; Tian, C. Extremum response surface method for casing radial deformation probabilistic analysis. J. Aerosp. Inf. Syst. 2013, 10, 47–52. [Google Scholar]

- Lu, C.; Feng, Y.W.; Fei, C.W. Weighted regression-based extremum response surface method for structural dynamic fuzzy reliability analysis. Energies 2019, 12, 1588. [Google Scholar] [CrossRef]

- Zhang, C.Y.; Song, L.K.; Fei, C.W.; Lu, C.; Xie, Y.M. Advanced multiple response surface method for reliability sensitivity analysis of turbine blisk with multi-physics coupling. Chin. J. Aeronaut. 2016, 29, 962–971. [Google Scholar] [CrossRef]

- Titli, A.; Lefevre, T.; Richetin, M. Multilevel optimization methods for non-separable problems and application. Int. J. Syst. Sci. 1973, 4, 865–880. [Google Scholar] [CrossRef]

- Kemp, A.W. Convolutions Involving binomial pseudo-variables. Sankhyā Indian J. Stat. Ser. A 1979, 41, 232–243. [Google Scholar]

- Chakraborty, S.; Sam, P.C. Probabilistic safety analysis of structures under hybrid uncertainty. Int. J. Numer. Methods Eng. 2007, 70, 405–422. [Google Scholar] [CrossRef]

- Hwang, W.; Han, K.S. Cumulative damage models and multi-stress fatigue life prediction. J. Compos. Mater. 1986, 20, 125–153. [Google Scholar] [CrossRef]

- Mahler, M.; Özkan, F.; Aktaa, J. ANSYS creep-fatigue assessment tool for EUROFER97 components. Nucl. Mater. Energy 2016, 9, 535–538. [Google Scholar] [CrossRef]

- Zhai, X.; Fei, C.W.; Wang, J.J.; Choy, Y.S. A stochastic model updating strategy-based improved response surface model and advanced Monte Carlo simulation. Mech. Syst. Signal Process. 2017, 82, 323–338. [Google Scholar] [CrossRef]

- Zhao, R.G.; Li, Q.B.; Jiang, Y.Z.; Luo, X.Y.; Liu, Y.F.; Cai, P.; Chen, Y. Research on transition from short to long fatigue crack propagation of GH4133B superalloy used in turbine disk of aeroengine. Key Eng. Mater. 2016, 697, 664–669. [Google Scholar] [CrossRef]

- Liao, D.; Zhu, S.P.; Correia, J.A.F.O.; De Jesus, A.M.P.; Calçada, R. Computational framework for multiaxial fatigue life prediction of compressor discs considering notch effects. Eng. Fract. Mech. 2018, 202, 423–435. [Google Scholar] [CrossRef]

- Zhu, Z.Z.; Feng, Y.W.; Lu, C.; Fei, C.W. Efficient driving plan and validation of aircraft NLG emergency extension system via mixture of reliability models and test bench. Appl. Sci. 2019, 9, 3578. [Google Scholar] [CrossRef]

- Devloo, P.R.B.; Rylo, E.C. Systematic and generic construction of shape functions for p-adaptive meshes of multidimensional finite elements. Comput. Methods Appl. Mech. Eng. 2009, 198, 1716–1725. [Google Scholar] [CrossRef]

- Hashiguchi, K. A basic formulation of elastoplastic constitutive equations. Mod. Approaches Plast. 1993, 1993, 39–57. [Google Scholar]

- Zhang, C.Y.; Lu, C.; Fei, C.W.; Liu, L.J.; Choy, Y.S.; Su, X.G. Multiobject reliability analysis of turbine blisk with multidiscipline under multiphysical field interaction. Adv. Mater. Sci. Eng. 2015, 2015, 519–520. [Google Scholar] [CrossRef]

- Asraff, A.K.; Sunil, S.; Muthukumar, R.; Ramanathan, T.J. Stress analysis & life prediction of a cryogenic rocket engine thrust chamber considering low cycle fatigue, creep and thermal ratchetting. Trans. Indian Inst. Met. 2010, 63, 601–606. [Google Scholar]

- Zhu, S.P.; Liu, Q.; Peng, W.; Zhang, X.C. Computational-experimental approaches for fatigue reliability assessment of turbine bladed disks. Int. J. Mech. Sci. 2018, 142, 502–517. [Google Scholar] [CrossRef]

- Wang, Y.; Li, Y.; Liu, W.; Gao, Y. Assessing operational ocean observing equipment (OOOE) based on the fuzzy comprehensive evaluation method. Ocean Eng. 2015, 107, 54–59. [Google Scholar] [CrossRef]

| Random Variables | Mean | Length of Fuzzy Zone | Distribution |

|---|---|---|---|

| Density, ρ, kg·m−3 | 8210 | 410.5 | Normal |

| Rotor speed, ω, rad·s−1 | 1168 | 58.4 | Normal |

| Temperature T, K | 873.15 | 43.658 | Normal |

| Pneumatic pressure p, MPa | 0.1 | 0.005 | Normal |

| Elastic modulus E, MPa | 163,000 | 8150 | Normal |

| Thermal expansion coefficient α, ×10−6 °C−1 | 9.4 | 0.47 | Normal |

| Fatigue Damage Df | Creep Damage Dc | |

|---|---|---|

| Blade | 0.36363 | 0.0039 |

| Disk | 0.40859 | 0.0041 |

| Blade | Disk | ||||

|---|---|---|---|---|---|

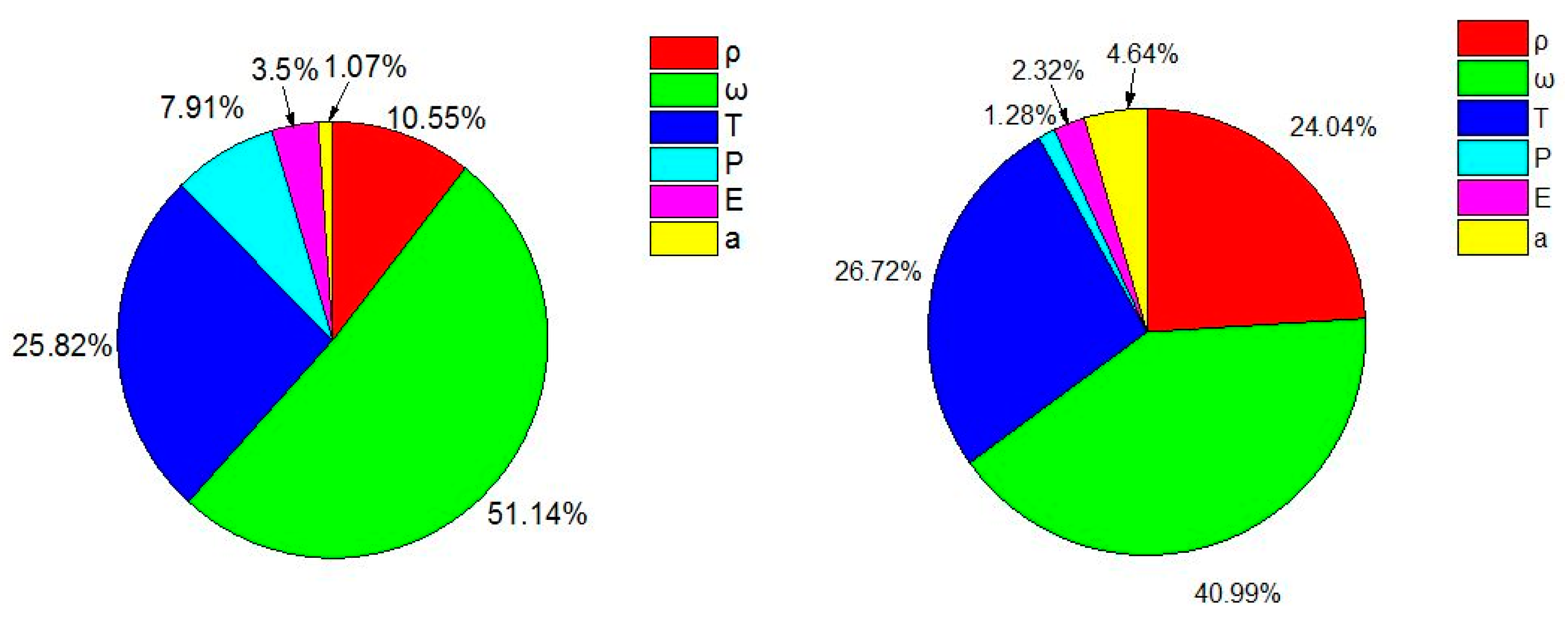

| Variables | Sensitivity | Effect Probability % | Variable | Sensitivity | Effect Probability % |

| ρ | 0.09855 | 10.55 | ρ | 0.22067 | 24.04 |

| ω | 0.477722 | 51.14 | ω | 0.386637 | 40.99 |

| T | 0.241222 | 25.82 | T | 0.252026 | 26.72 |

| p | 0.073895 | 7.91 | p | –0.0121 | 1.28 |

| E | 0.032676 | 3 | 0.02191 | 2.32 | |

| α | −0.01 | 1.07 | α | 0.043787 | 4.64 |

| Blade | Disk | ||||||

|---|---|---|---|---|---|---|---|

| Optimal Level Threshold | Allowable Mean | Optimal Level Threshold | Allowable Mean | ||||

| 0.3558 | 677.92 | 0.6008 | 654.94 | ||||

| 0.8051 | 2.010824 | 0.8516 | 1.0076991 | ||||

| 0.6720 | 0.2039 | 0.1608 | 0.2041 | ||||

| 0.0260 | 0.96363 | 0.8392 | 0.90895 | ||||

| Design Variable | Original Data | Optimization Results |

|---|---|---|

| ω, rad·s−1 | 1168 | 1055.1 |

| T, K | 873.15 | 788.15 |

| Number of Samples | Computational Time, s | Reliability Degree % | Precision of FMERSM | ||

|---|---|---|---|---|---|

| MC Method | FMERSM | MC Method | FMERSM | ||

| 102 | 32400 | 0.203 | 99 | 98.6 | 0.996 |

| 103 | 72000 | 0.279 | 99.7 | 99.5 | 0.998 |

| 104 | 432000 | 0.437 | 99.83 | 99.60 | 0.9977 |

| 105 | - | 4.43 | - | 99.962 | - |

| Objective Function | Before Optimization | MCM | FMERSM | ||

|---|---|---|---|---|---|

| After Optimization | Reduction | After Optimization | Reduction | ||

| , MPa | 607.92 | 548.66 | 9.8% | 487.08 | 19.9% |

| , MPa | 454.94 | 423.03 | 7% | 368.8 | 18.93% |

| , m/m | 0.010824 | 0.001298 | 88% | 0.0073988 | 31.64% |

| , m/m | 0.0076991 | 0.0076629 | 0.47% | 0.0065652 | 14.77% |

| Df1 | 0.36363 | 0.30452 | 16.25% | 0.24822 | 31.74% |

| Df2 | 0.40859 | 0.39375 | 4.52% | 0.29315 | 28.3% |

| 0.0039 | 0.0036 | 7.69% | 0.0025 | 35.9% | |

| 0.0041 | 0.00409 | 0.24% | 0.0032 | 21.95% | |

| R | 95 | 99.515 | - | 99.635 | - |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.-Y.; Yuan, Z.-S.; Wang, Z.; Fei, C.-W.; Lu, C. Probabilistic Fatigue/Creep Optimization of Turbine Bladed Disk with Fuzzy Multi-Extremum Response Surface Method. Materials 2019, 12, 3367. https://doi.org/10.3390/ma12203367

Zhang C-Y, Yuan Z-S, Wang Z, Fei C-W, Lu C. Probabilistic Fatigue/Creep Optimization of Turbine Bladed Disk with Fuzzy Multi-Extremum Response Surface Method. Materials. 2019; 12(20):3367. https://doi.org/10.3390/ma12203367

Chicago/Turabian StyleZhang, Chun-Yi, Zhe-Shan Yuan, Ze Wang, Cheng-Wei Fei, and Cheng Lu. 2019. "Probabilistic Fatigue/Creep Optimization of Turbine Bladed Disk with Fuzzy Multi-Extremum Response Surface Method" Materials 12, no. 20: 3367. https://doi.org/10.3390/ma12203367

APA StyleZhang, C.-Y., Yuan, Z.-S., Wang, Z., Fei, C.-W., & Lu, C. (2019). Probabilistic Fatigue/Creep Optimization of Turbine Bladed Disk with Fuzzy Multi-Extremum Response Surface Method. Materials, 12(20), 3367. https://doi.org/10.3390/ma12203367