Investigation of the Prediction Accuracy of a Finite Element Analysis Model for the Coating Thickness in Cross-Wedge Rolled Coaxial Hybrid Parts

Abstract

:1. Introduction

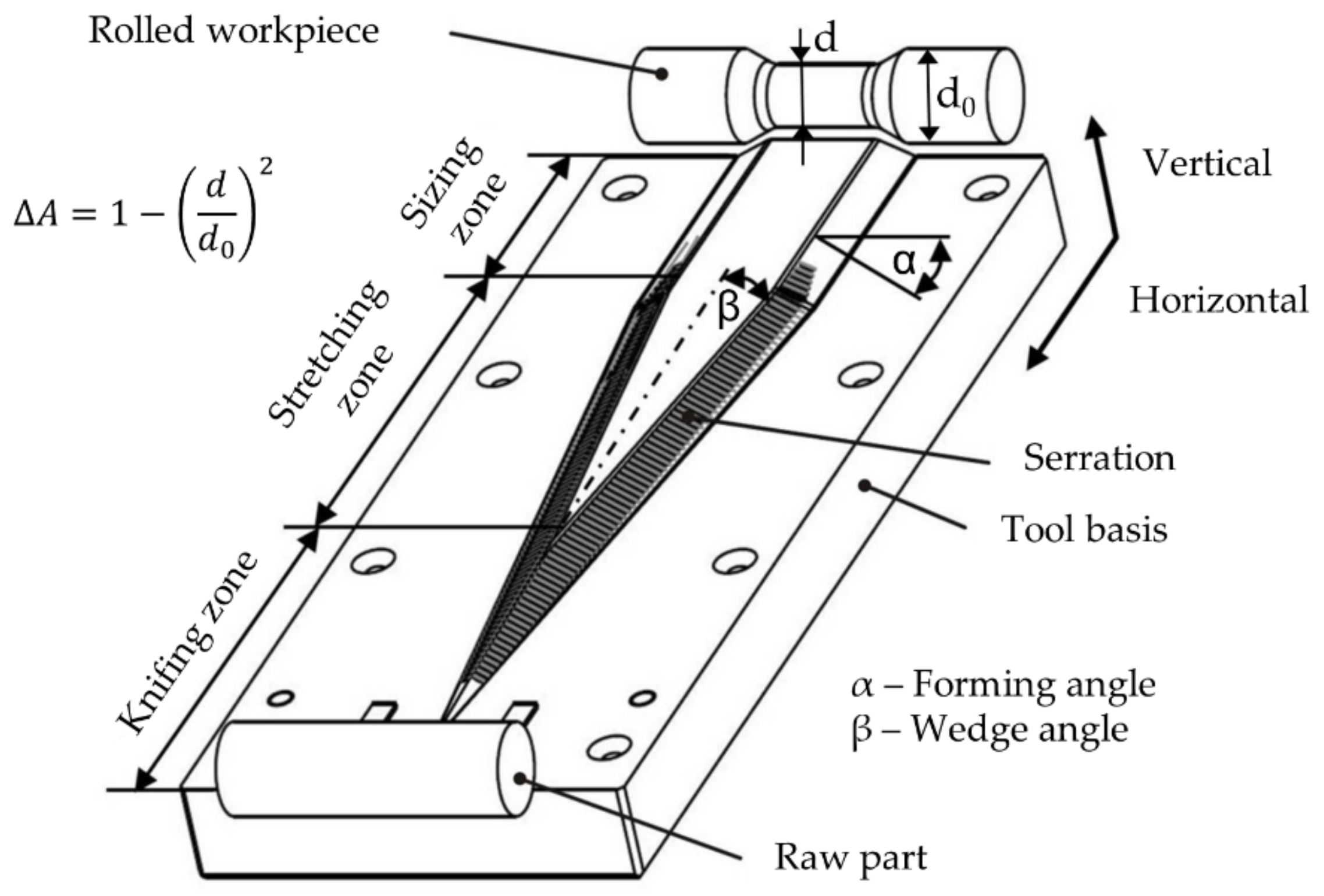

1.1. Cross-Wedge Rolling

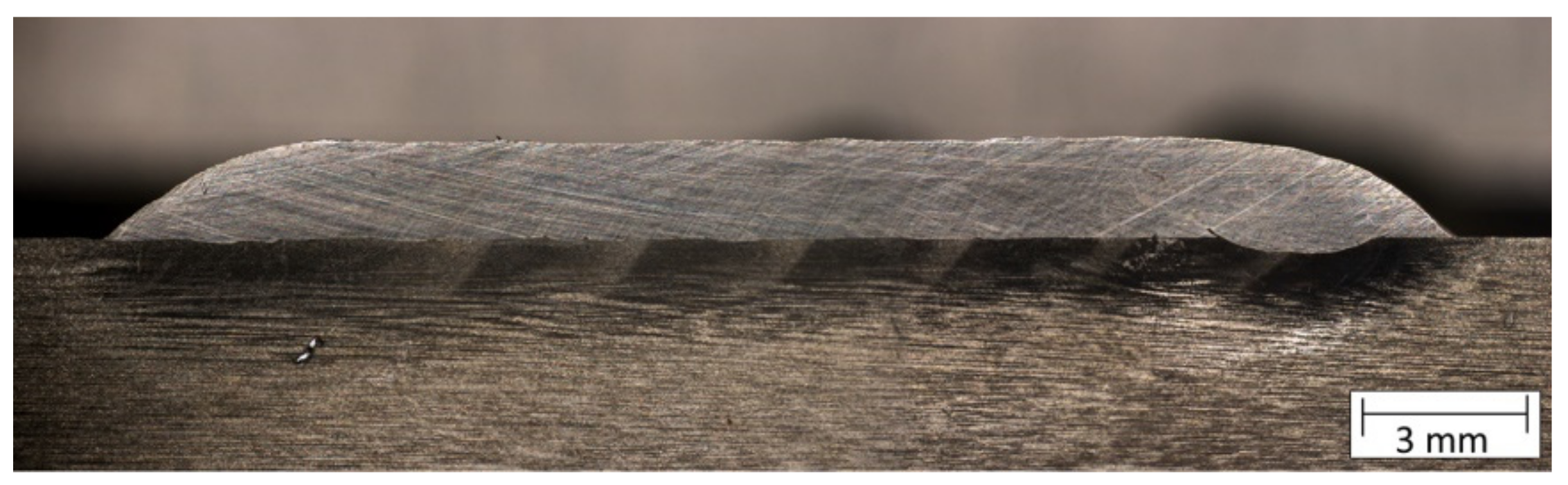

1.2. Hybrid Parts

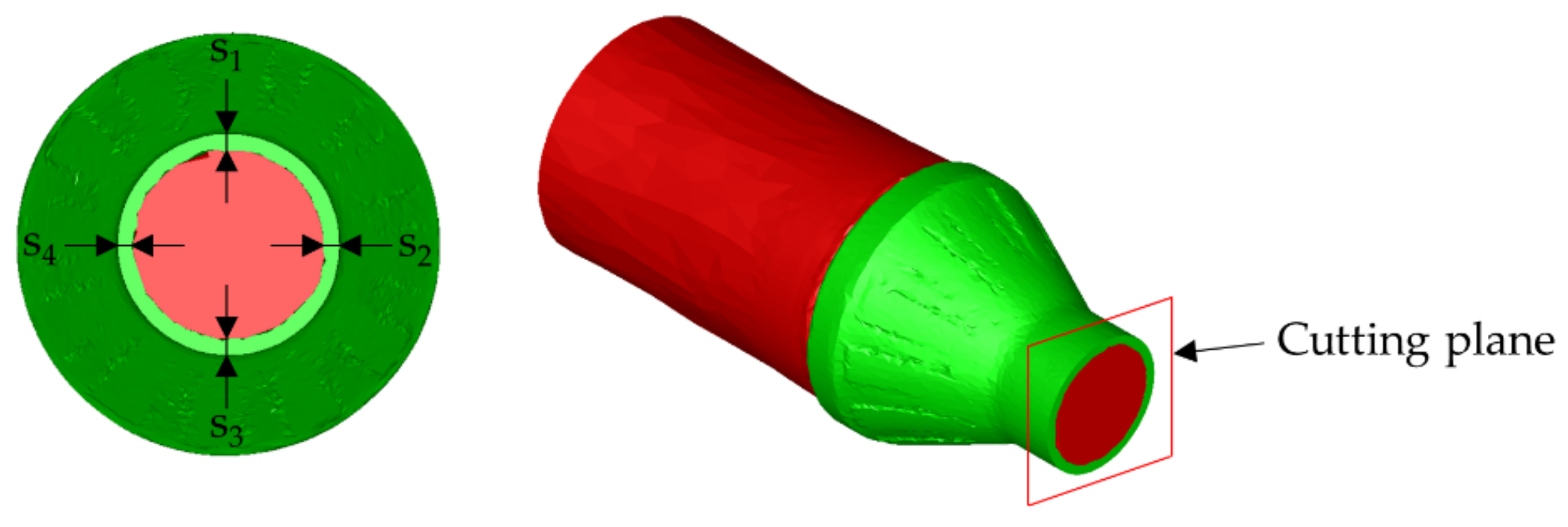

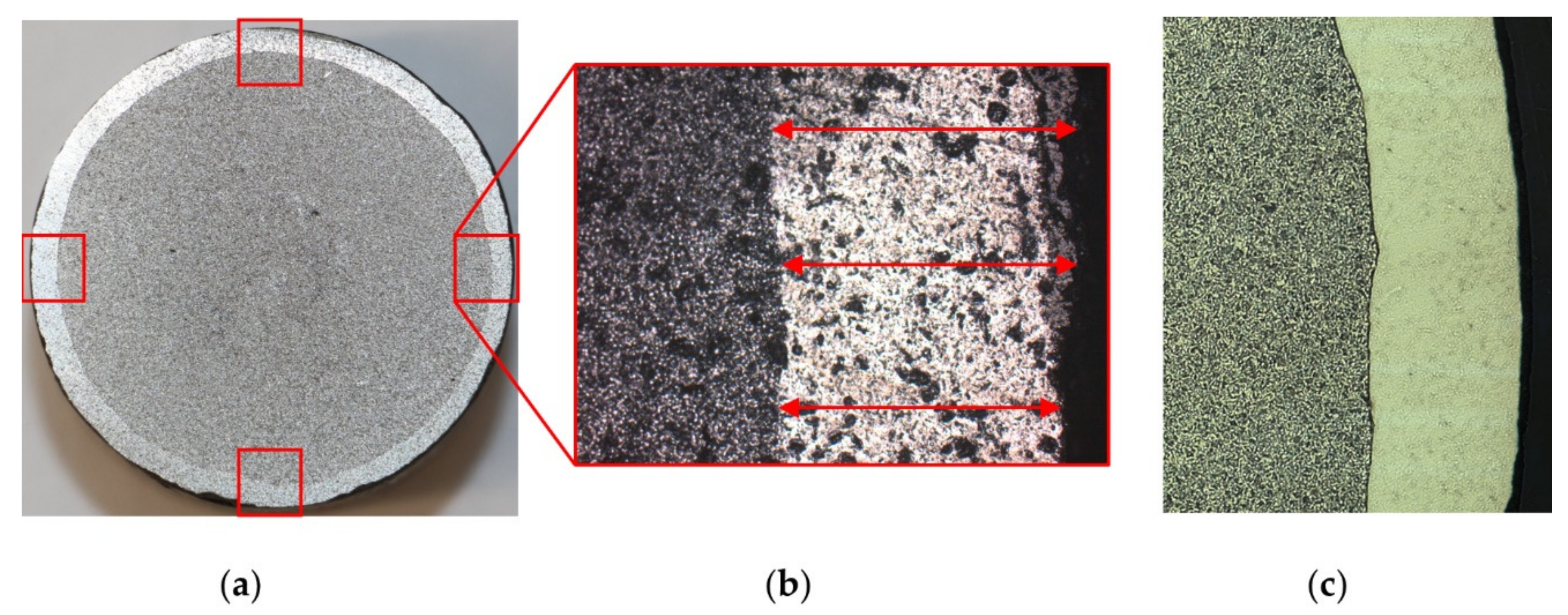

2. Investigations of the Coating Thickness

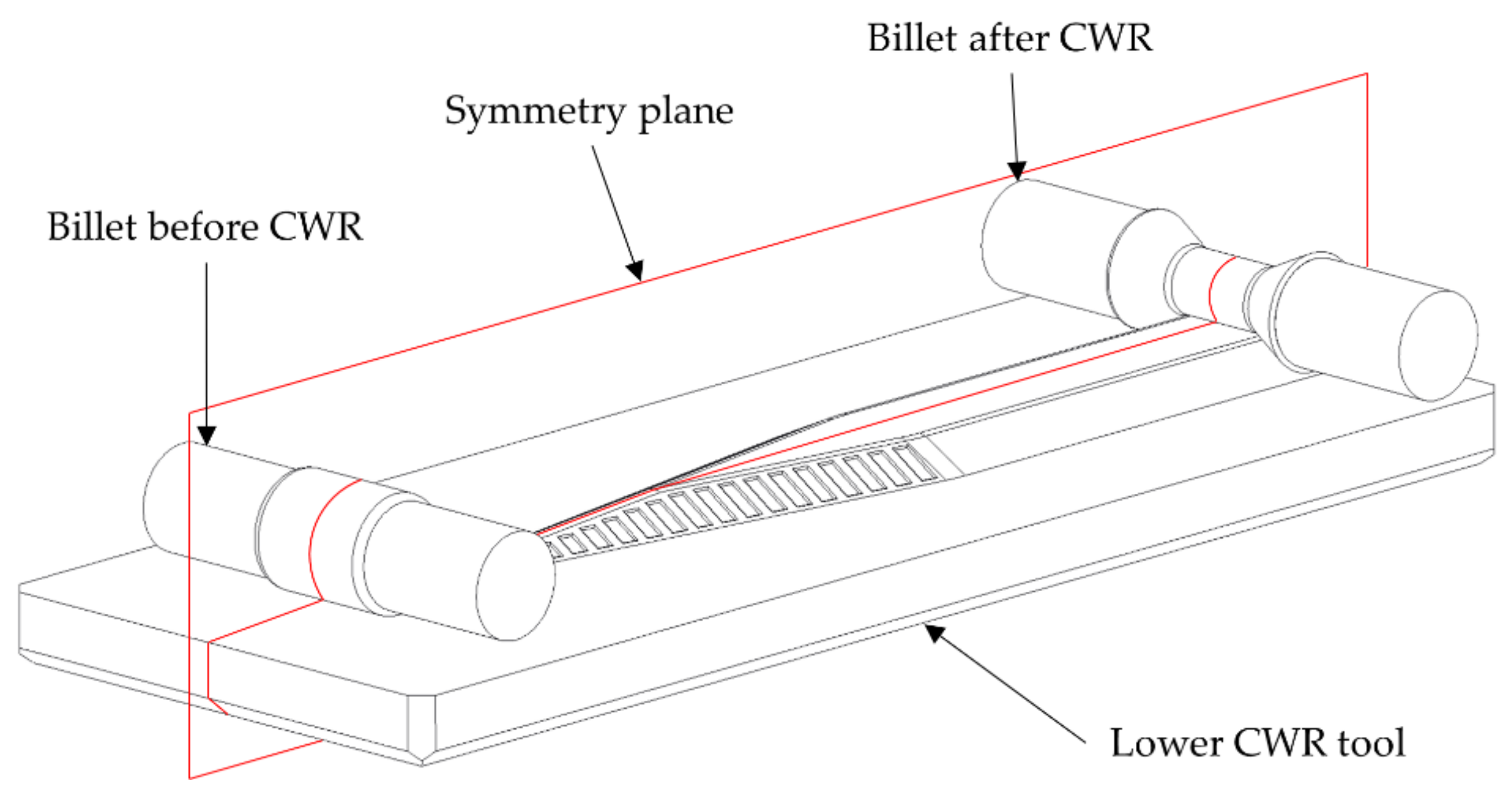

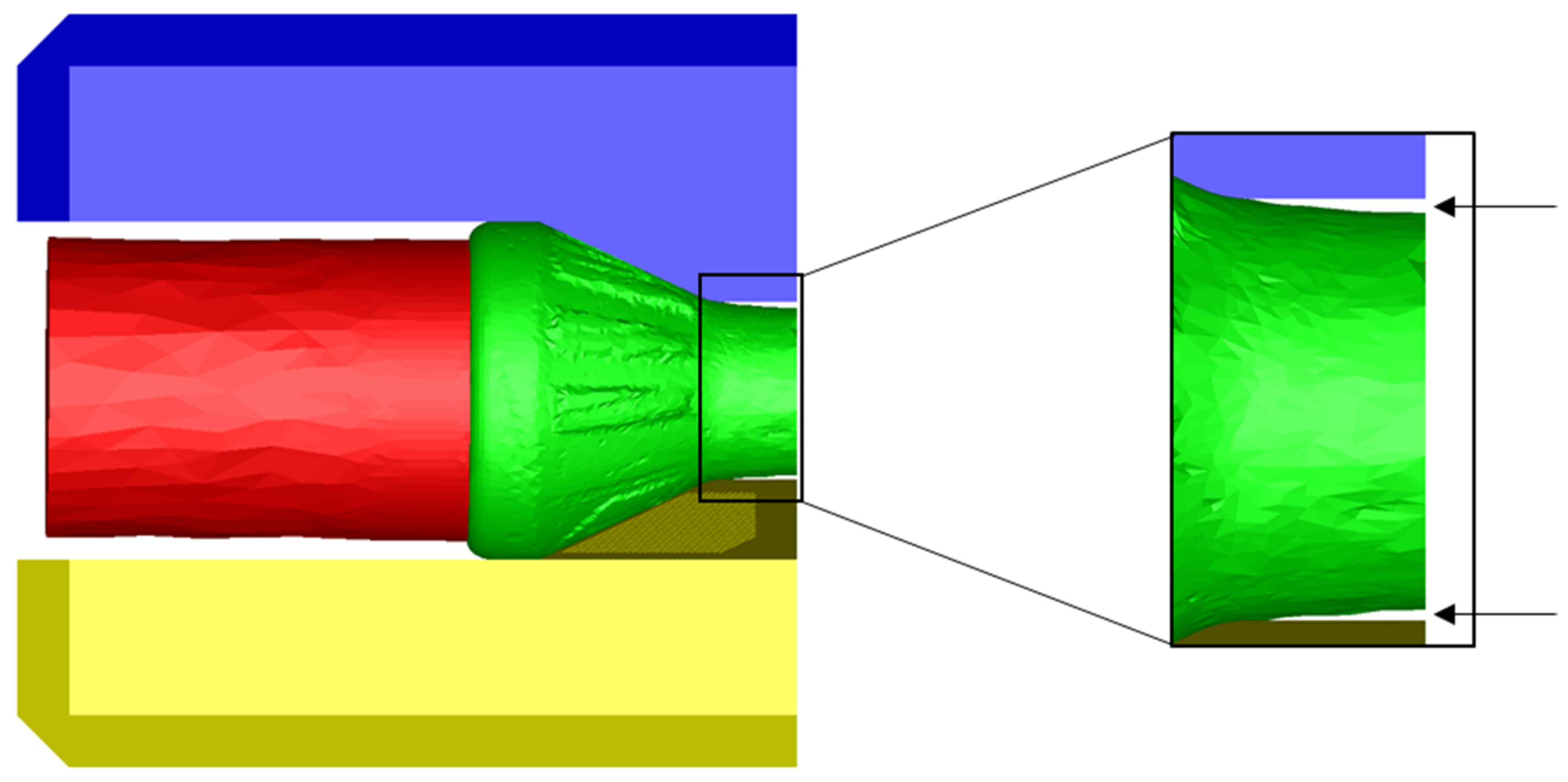

2.1. Setup of the Simulations

2.2. Setup of the Experimental Trials

3. Results and Comparison of Simulation and Trials

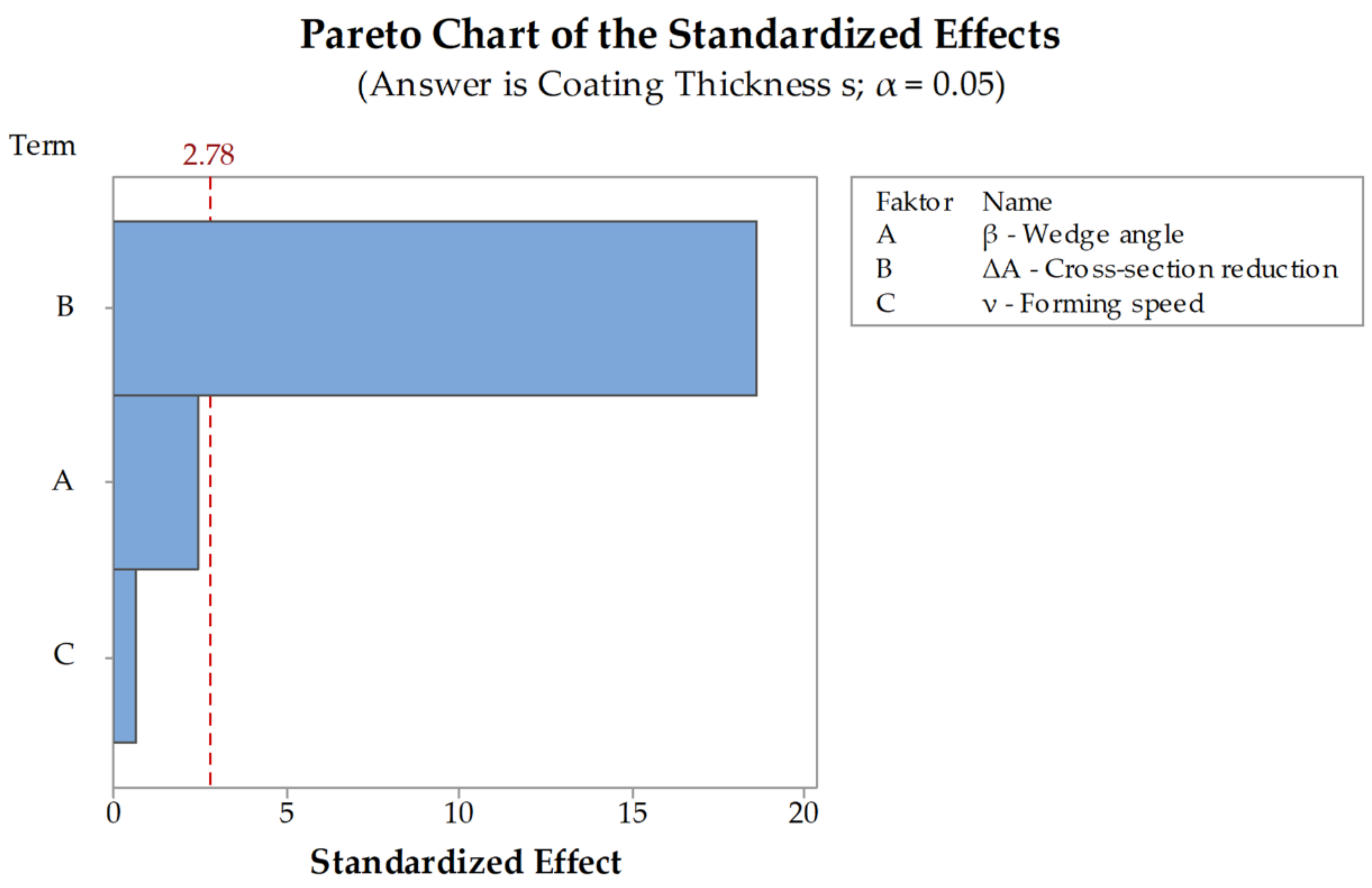

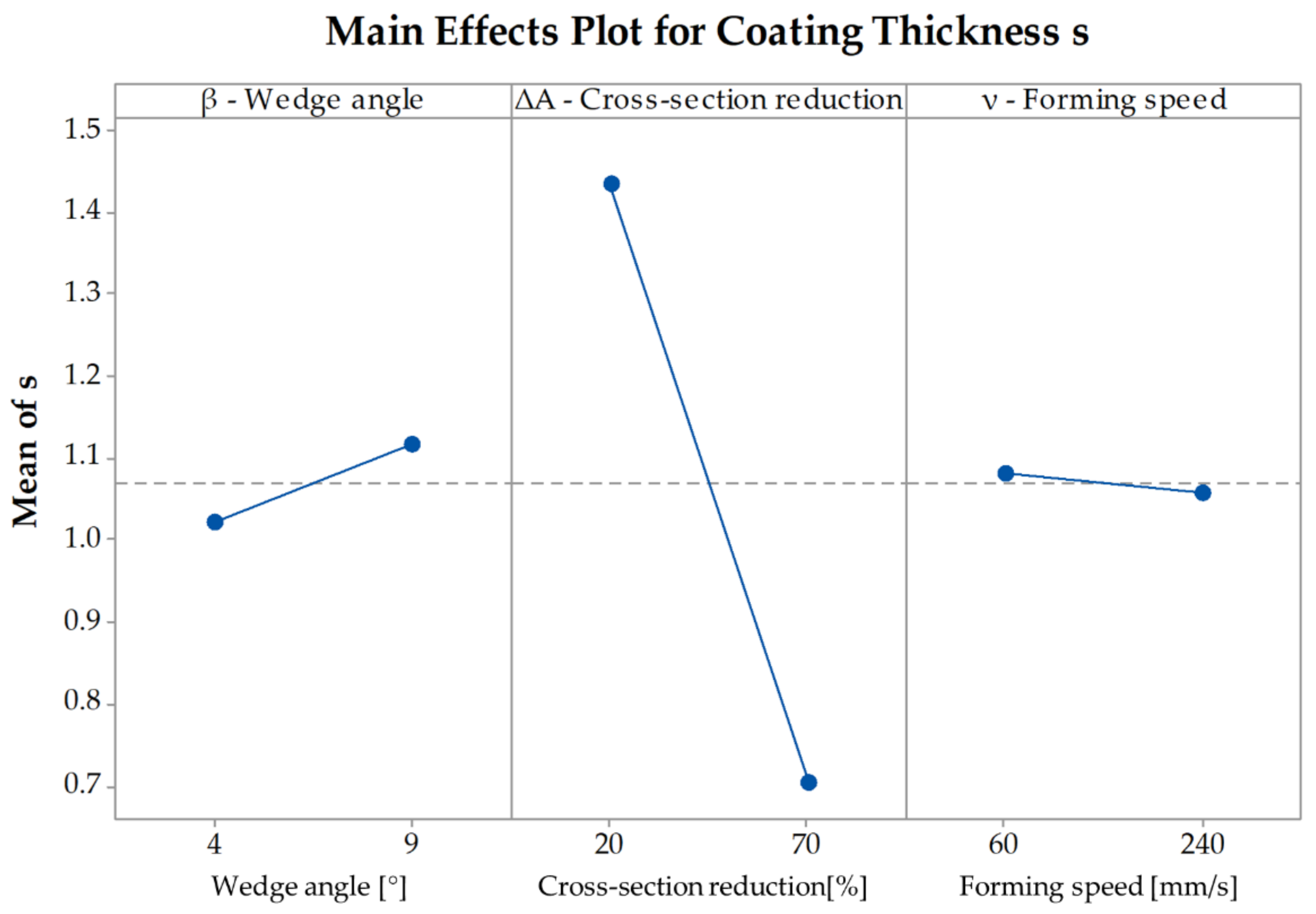

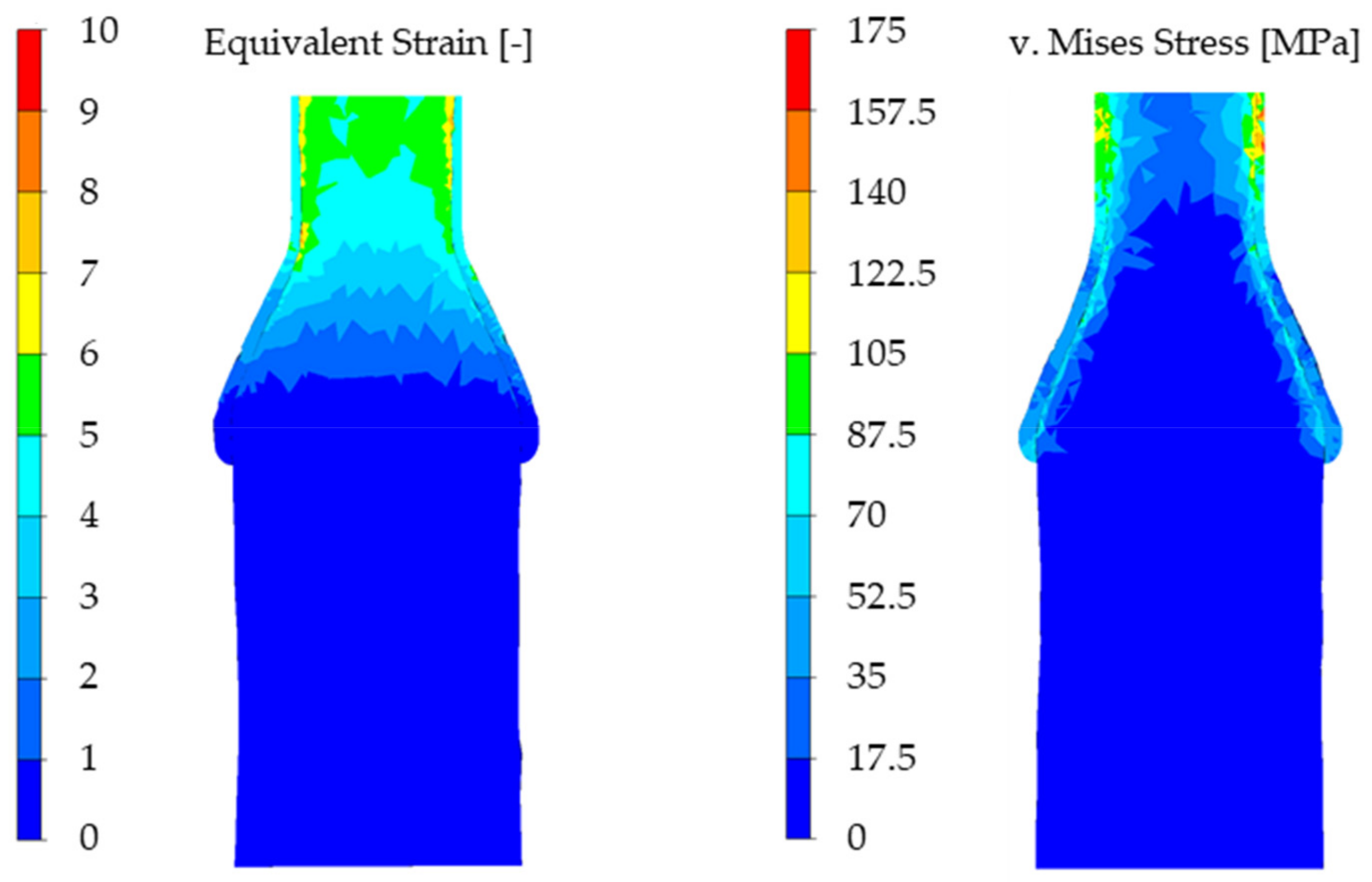

3.1. Results of the Simulations

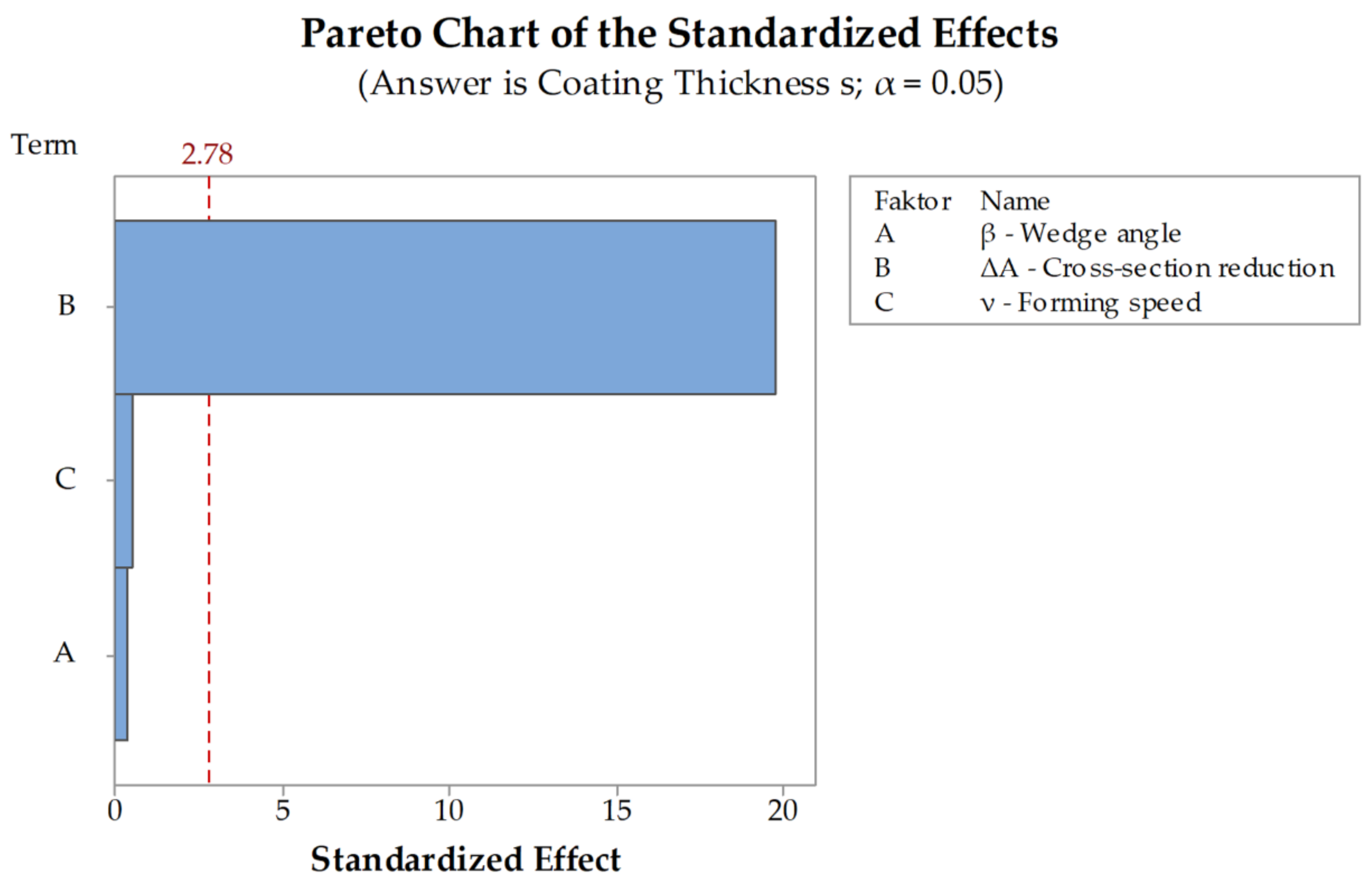

3.2. Results of the Experimental Trials

3.3. Comparison between the Simulations and the Experimental Trials

4. Discussion

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Behrens, B.-A.; Bouguecha, A.; Moritz, J.; Bonk, C.; Stonis, M.; Klose, C.; Blohm, T.; Chugreeva, A.; Duran, D.; Matthias, T.; et al. Aktuelle Forschungsschwerpunkte in der Massivumformung. In Innovationspotenziale in der Umformtechnik 22. Umformtechnisches Kolloquium Hannover (UKH 2017), Hanover, Germany, 15–26 March 2017; Behrens, B.-A., Ed.; TEWISS: Garbsen, Germany, 2017; pp. 15–32. [Google Scholar]

- Pater, Z.; Weronski, W.; Kazanecki, J.; Gontarz, A. Study of the process stability of cross wedge rolling. J. Mater. Process. Technol. 1999, 92–93, 458–462. [Google Scholar] [CrossRef]

- Li, Q.; Lovell, M. On the critical interfacial friction of a two-roll CWR process. J. Mater. Process. Technol. 2005, 160, 245–256. [Google Scholar] [CrossRef]

- Pater, Z. Tools optimization in cross wedge rolling. J. Mater. Process. Technol. 2003, 139, 153–159. [Google Scholar] [CrossRef]

- Li, Q.; Lovell, M.; Slaughter, W.; Tagavi, K. Investigation of the morphology of internal defects in cross wedge rolling. J. Mater. Process. Technol. 2002, 125–126, 248–257. [Google Scholar] [CrossRef]

- Çakırcalı, M.; Kılıçaslan, C.; Güden, M.; Kıranlı, E.; Shchukin, V.; Petronko, V. Cross wedge rolling of a Ti6Al4V (ELI) alloy: The experimental studies and the finite element simulation of the deformation and failure. Int. J. Adv. Manuf. Technol. 2013, 64, 1273–1287. [Google Scholar] [CrossRef]

- Li, J.; Wang, B.; Ji, H.; Huang, X.; Tang, X.; Ma, W. Effects of the cross-wedge rolling parameters on the formability of Ti-6Al-4V alloy. Int. J. Adv. Manuf. Technol. 2017, 92, 2217–2229. [Google Scholar] [CrossRef]

- Blohm, T.; Stonis, M.; Behrens, B.-A. Investigation of Simulation Parameters for Cross Wedge Rolling Titanium and Bainitic Grade Steel. Appl. Mech. Mater. 2014, 736, 167–170. [Google Scholar] [CrossRef]

- Yuan, W.; Wang, L.; Yuan, T.X. Experimental study on cross wedge rolling processes of aluminum alloy material. In Proceedings of the 5th International Conference on Advanced Engineering Materials and Technology (AEMT 2015), Guangzhou, China, 22–23 August 2015; Kim, Y.H., Ed.; Atlantis Press: Paris, France, 2015; pp. 279–293. [Google Scholar] [CrossRef]

- Pater, Z.; Tomczak, J. Experimental tests for cross wedge rolling of forgings made from non-ferrous metal alloys. Arch. Metall. Mater. 2012, 57, 919–928. [Google Scholar] [CrossRef]

- Rasche, N.; Stonis, M.; Behrens, B.-A. Influence of the cross section area reduction in cross wedge rolling on the multi-directional forging of crankshafts. Adv. Mater. Process. Technol. 2017, 3, 286–299. [Google Scholar] [CrossRef]

- Assunção, E.; Quintino, L.; Miranda, R. Comparative study of laser welding in tailor blanks for the automotive industry. Int. J. Adv. Manuf. Technol. 2009, 49, 123–131. [Google Scholar] [CrossRef]

- Peng, W.F.; Zhang, J.H.; Huang, G.X.; Liu, W.P.; Shu, X.D.; Zhu, J. Stress distributions during the cross-wedge rolling of composite 42CrMo/Q235 laminated shafts. Int. J. Adv. Manuf. Technol. 2015, 83, 145–155. [Google Scholar] [CrossRef]

- Sun, B.; Xu, J.; Peng, W.; Shu, X.; Yin, A.; Huang, G. Experimental investigation on cross wedge rolling of composite 42CrMo/Q235 laminated shaft. Int. J. Adv. Manuf. Technol. 2018, 96, 895–903. [Google Scholar] [CrossRef]

- Behrens, B.-A.; Overmeyer, L.; Barroi, A.; Frischkorn, C.; Hermsdorf, J.; Kaierle, S.; Stonis, M.; Huskic, A. Basic study on the process combination of deposition welding and subsequent hot bulk forming. Prod. Eng. Res. Dev. 2013, 6, 585–591. [Google Scholar] [CrossRef]

- Blohm, T.; Mildebrath, M.; Stonis, M.; Langner, J.; Hassel, T.; Behrens, B.-A. Investigation of the coating thickness of plasma-transferred arc deposition welded and cross wedge rolled hybrid parts. Prod. Eng. Res. Dev. 2017, 11, 255–263. [Google Scholar] [CrossRef]

- Blohm, T.; Langner, J.; Stonis, M.; Behrens, B.-A. Basic study of incremental forming of serially arranged hybrid parts using cross-wedge rolling. In Proceedings of the 12th International Conference on the Technology of Plasticity (ICTP 2017), Cambridge, UK, 17–22 September 2017; Allwood, J., Ed.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 1677–1683. [Google Scholar] [CrossRef]

- Barroi, A.; Gonçalves, D.A.; Hermsdorf, J.; Kaierle, S.; Overmeyer, L. Influence of laser power on the shape of single tracks in scanner based laser wire cladding. Phys. Procedia 2016, 83, 667–673. [Google Scholar] [CrossRef]

- Barroi, A.; Hermsdorf, J.; Kaierle, S.; Overmeyer, L. Influence of scan width and wire feed speed on seam geometry and the substrate surface in laser wire cladding. In Proceedings of the 35th International Congress on Applications of Lasers & Electro-Optics (ICALEO 2016), San Diego, CA, USA, 16–20 October 2016; Pflueger, S., Ed.; Laser Institute of America: Orlando, FL, USA, 2016. [Google Scholar]

- Behrens, B.-A.; Bouguecha, A.; Bonk, C.; Matthias, T. Importance of Material and Friction Characterisation for FE-aided Process Design of Hybrid Bevel Gears. In Proceedings of the 20th International ESAFORM Conference of Material Forming (ESAFORM 2017), Dublin, Ireland, 26–28 April 2017; Brabazon, D., Naher, S., Ul Ahad, I., Eds.; AIP Publishing: Melville, NY, USA, 2017. [Google Scholar] [CrossRef]

| Billet Material | Billet Dimension | Tool Geometry | Cross-Section Reduction | Forming Speed | Workpiece Temperature |

|---|---|---|---|---|---|

| 1.0460 + 1.4718 | Ø 29/32.6 mm length 120 mm | 25° 4°–9° | 20–70% | 60–240 mm/s | 1250 °C |

| 552.26996 | −0.00153 | 0.00339 | −0.14771 | −0.00131 |

| 1.44 mm | 1.46 mm | 1.41 mm | 1.41 mm | 1.46 mm |

| 0.70 mm | 0.70 mm | 0.71 mm | 0.63 mm | 0.78 mm |

| 1.34 mm | 1.32 mm | 1.36 mm | 1.34 mm | 1.33 mm |

| 0.84 mm | 0.84 mm | 0.83 mm | 0.84 mm | 0.83 mm |

| β | ΔA | ν | s | Deviation | ||

|---|---|---|---|---|---|---|

| Simulation | Experiment | Absolute | Relative | |||

| 4 | 20 | 60 | 1.467 mm | 1.313 mm | 0.154 mm | 10.52% |

| 4 | 20 | 240 | 1.361 mm | 1.373 mm | 0.011 mm | 0.83% |

| 4 | 70 | 60 | 0.603 mm | 0.818 mm | 0.215 mm | 26.24% |

| 4 | 70 | 240 | 0.657 mm | 0.863 mm | 0.206 mm | 23.85% |

| 9 | 20 | 60 | 1.459 mm | 1.325 mm | 0.134 mm | 9.19% |

| 9 | 20 | 240 | 1.454 mm | 1.341 mm | 0.113 mm | 7.74% |

| 9 | 70 | 60 | 0.8 mm | 0.868 mm | 0.068 mm | 7.88% |

| 9 | 70 | 240 | 0.757 mm | 0.797 mm | 0.041 mm | 5.11% |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jagodzinski, A.; Kruse, J.; Barroi, A.; Mildebrath, M.; Langner, J.; Stonis, M.; Lammers, M.; Hermsdorf, J.; Hassel, T.; Behrens, B.-A.; et al. Investigation of the Prediction Accuracy of a Finite Element Analysis Model for the Coating Thickness in Cross-Wedge Rolled Coaxial Hybrid Parts. Materials 2019, 12, 2969. https://doi.org/10.3390/ma12182969

Jagodzinski A, Kruse J, Barroi A, Mildebrath M, Langner J, Stonis M, Lammers M, Hermsdorf J, Hassel T, Behrens B-A, et al. Investigation of the Prediction Accuracy of a Finite Element Analysis Model for the Coating Thickness in Cross-Wedge Rolled Coaxial Hybrid Parts. Materials. 2019; 12(18):2969. https://doi.org/10.3390/ma12182969

Chicago/Turabian StyleJagodzinski, Arne, Jens Kruse, Alexander Barroi, Maximilian Mildebrath, Jan Langner, Malte Stonis, Marius Lammers, Jörg Hermsdorf, Thomas Hassel, Bernd-Arno Behrens, and et al. 2019. "Investigation of the Prediction Accuracy of a Finite Element Analysis Model for the Coating Thickness in Cross-Wedge Rolled Coaxial Hybrid Parts" Materials 12, no. 18: 2969. https://doi.org/10.3390/ma12182969

APA StyleJagodzinski, A., Kruse, J., Barroi, A., Mildebrath, M., Langner, J., Stonis, M., Lammers, M., Hermsdorf, J., Hassel, T., Behrens, B.-A., & Overmeyer, L. (2019). Investigation of the Prediction Accuracy of a Finite Element Analysis Model for the Coating Thickness in Cross-Wedge Rolled Coaxial Hybrid Parts. Materials, 12(18), 2969. https://doi.org/10.3390/ma12182969