A (Permalloy + NiZn Ferrite) Moldable Magnetic Composite for Heterogeneous Integration of Power Electronics

Abstract

:1. Introduction

2. Experimental Procedure

2.1. Material Selection

2.2. Preparation of SM2C

2.3. Characterization

3. Results and Discussion

3.1. Relative Permeability versus Frequency

3.2. Core-Loss Density

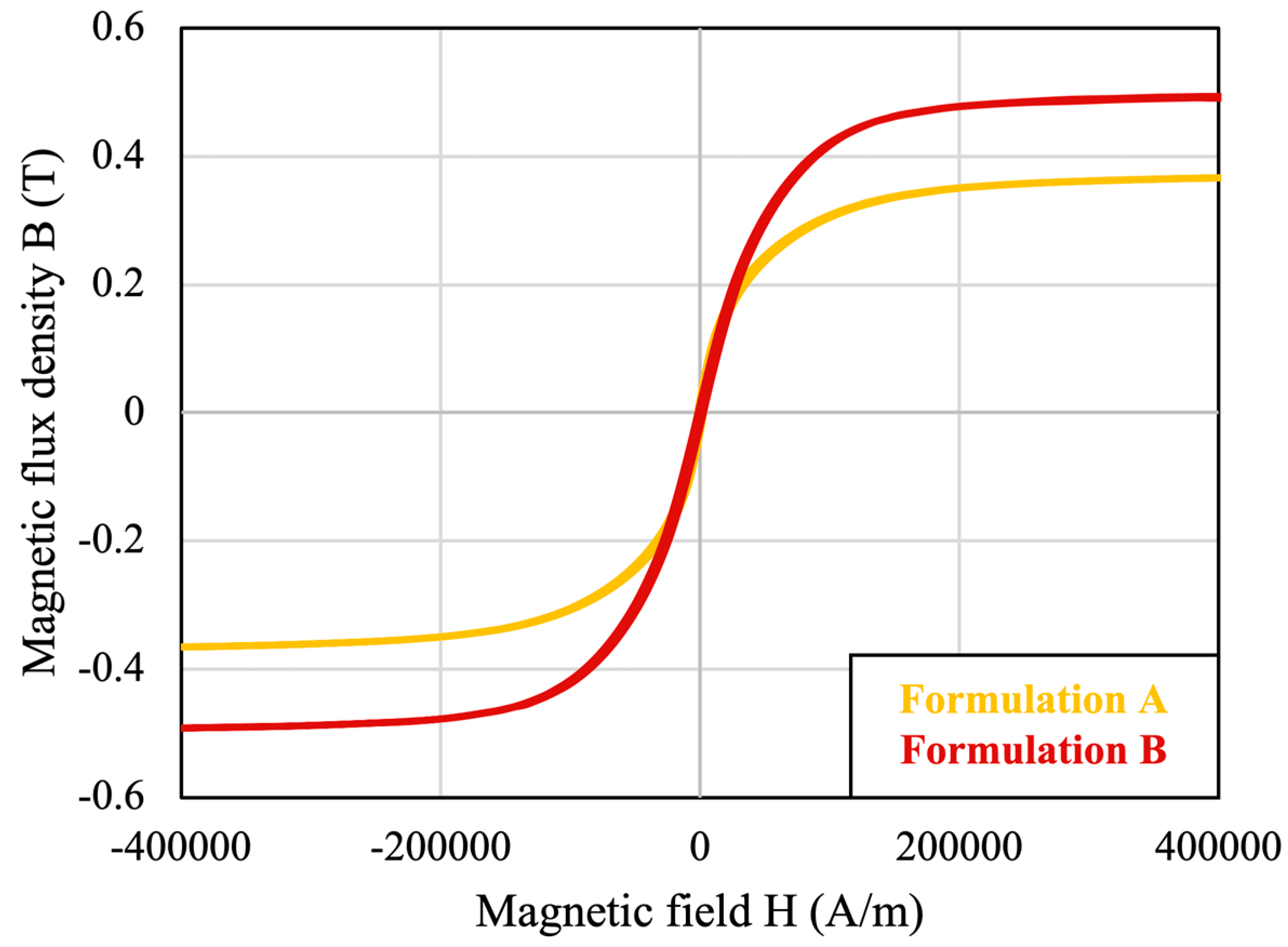

3.3. Magnetic Hysteresis Loop and Saturation Magnetic Flux Density

3.4. DC Bias Permeability

3.5. Microstructure

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Nour, Y.; Ouyang, Z.; Knott, A.; Jørgensen, I.H.H. Design and Implementation of High Frequency Buck Converter Using Multi-Layer PCB Inductor; IEEE: Piscataway, NJ, USA, 2016; pp. 1313–1317. [Google Scholar]

- Yang, Y.; Mu, M.; Lee, F.C.; Li, Q. Multiphase Coupled and Integrated Inductors with Printed Circuit Board (PCB) Windings for Power Factor Correction (PFC) Converters. U.S. Patent Application 15/484,641, 12 October 2017. [Google Scholar]

- Li, B.; Li, Q.; Lee, F. High frequency pcb winding transformer with integrated inductors for a bi-directional resonant converter. IEEE Trans. Power Electron. 2018, 99. [Google Scholar] [CrossRef]

- Schäfer, J.; Bortis, D.; Kolar, J.W. Optimal Design of Highly Efficient and Highly Compact PCB Winding Inductors; IEEE: Piscataway, NJ, USA, 2018; pp. 1–8. [Google Scholar]

- Hultman, L.O.; Jack, A.G. Soft magnetic composites-materials and applications. In Proceedings of the Electric Machines and Drives Conference (IEMDC’03), Chicago, IL, USA, 12–15 May 2003. [Google Scholar]

- Liu, C.; Cheng, P.; Law, Y.; Chong, I.; Lam, D.C. Development of low temperature processable core material for embedded inductor. In Proceedings of the 2nd International IEEE Conference on Polymers and Adhesives in Microelectronics and Photonics, Zalaegerszeg, Hungary, 23–26 June 2002. [Google Scholar]

- Sunday, K.J.; Taheri, M.L. Soft magnetic composites: Recent advancements in the technology. Met. Powder Rep. 2017, 72, 425–429. [Google Scholar] [CrossRef]

- Svensson, L.; Frogner, K.; Jeppsson, P.; Cedell, T.; Andersson, M. Soft magnetic moldable composites: Properties and applications. J. Magn. Magn. Mater. 2012, 324, 2717–2722. [Google Scholar] [CrossRef]

- Yan, Y.; Liu, L.; Ding, C.; Nguyen, L.; Moss, J.; Mei, Y.; Lu, G.-Q. Additive manufacturing of magnetic components for heterogeneous integration. In Proceedings of the 2017 IEEE 67th Electronic Components and Technology Conference (ECTC), Orlando, FL, USA, 30 May–2 June 2017. [Google Scholar]

- Xu, Y.; Deng, C. An investigation on 3d printing technology for power electronic converters. In Proceedings of the 2017 IEEE 8th International Symposium on Power Electronics for Distributed Generation Systems (PEDG), Florianopolis, Brazil, 17–20 April 2017. [Google Scholar]

- Kowase, I.; Sato, T.; Yamasawa, K.; Miura, Y. A planar inductor using mn-zn ferrite/polyimide composite thick film for low-voltage and large-current dc-dc converter. IEEE Trans. Magn. 2005, 41, 3991–3993. [Google Scholar] [CrossRef]

- Xiao, T.; Ma, X.; Zhang, H.; Reisner, D.; Raj, P.; Wan, L.; Tummala, R. Magnetic nanocomposite paste: An ideal high-µ, k and q nanomaterial for embedded inductors in high frequency electronic applications. In Proceedings of the 9th World Multiconference Systemics, Cyberntics Informatics, Orlando, FL, USA, 10–13 July 2005. [Google Scholar]

- Bang, D.H.; Park, J.Y. Ni-zn ferrite screen printed power inductors for compact dc-dc power converter applications. IEEE Trans. Magn. 2009, 45, 2762–2765. [Google Scholar] [CrossRef]

- Chen, Y.-T.; Hung, C.-H.; Lee, Y.-C.; Liang, L.-C.; Yang, W.-T. Electrical and temperature characterization of flexible planar inductor. In Proceedings of the 2012 7th International Microsystems, Packaging, Assembly and Circuits Technology Conference (IMPACT), Taipei, Taiwan, 24–26 October 2012. [Google Scholar]

- Xiao, T.D.; Ma, X.; Zhang, H.; Zhou, J. Magnetic Composites and Methods of Making and Using. U.S. Patent 8,377,576, 19 February 2013. [Google Scholar]

- Fukuda, Y.; Inoue, T.; Mizoguchi, T.; Yatabe, S.; Tachi, Y. Planar inductor with ferrite layers for dc-dc converter. IEEE Trans. Magn. 2003, 39, 2057–2061. [Google Scholar] [CrossRef]

- Park, J.Y.; Allen, M.G. Low temperature fabrication and characterization of integrated packaging-compatible, ferrite-core magnetic devices. In Proceedings of the 1997 Applied Power Electronics Conference and Exposition (APEC’97 Conference), Atlanta, GA, USA, 23–27 February 1997. [Google Scholar]

- Kelly, A.; Symonds, F.P. Plastic-iron-powder distributed-air-gap magnetic material. In Proceedings of the 21st Annual IEEE, Power Electronics Specialists Conference, San Antonio, TX, USA, 11–14 June 1990. [Google Scholar]

- Sugimura, K.; Shibamoto, D.; Yabu, N.; Yamamoto, T.; Sonehara, M.; Sato, T.; Mizuno, T.; Mizusaki, H. Surface-oxidized amorphous alloy powder/epoxy-resin composite bulk magnetic core and its application to megahertz switching llc resonant converter. IEEE Trans. Magn. 2017, 53, 1–6. [Google Scholar] [CrossRef]

- Reinap, A.; Hagstedt, D.; Högmark, C.; Alaküla, M. Evaluation of a semi claw-pole machine with sm 2 c core. In Proceedings of the 2011 IEEE International Electric Machines & Drives Conference (IEMDC), Niagara Falls, ON, Canada, 15–18 May 2011. [Google Scholar]

- Yabu, N.; Sugimura, K.; Sonehara, M.; Sato, T. Fabrication and evaluation of composite magnetic core using iron-based amorphous alloy powder with different particle size distributions. IEEE Trans. Magn. 2018, 99, 1–5. [Google Scholar] [CrossRef]

- Yan, Y.; Sun, W.; Gao, S.; Ge, T.; Ngo, K.D.; Lu, G.-Q. Design, fabrication, and characterization of a low-temperature curable magnetic composite for power electronics integration. IEEE Trans. Magn. 2018, 54, 1–6. [Google Scholar] [CrossRef]

- Mu, M. High Frequency Magnetic Core Loss Study. Ph.D. Thesis, Virginia Polytechnic Institute and State University, Blacksburg, VA, USA, 2013. [Google Scholar]

- Mu, M.; Lee, F.C. A new high frequency inductor loss measurement method. In Proceedings of the Energy Conversion Congress and Exposition (ECCE), Phoenix, AZ, USA, 17–22 September 2011. [Google Scholar]

- Hou, D.; Mu, M.; Lee, F.C.; Li, Q. New high-frequency core loss measurement method with partial cancellation concept. IEEE Trans. Power Electron. 2017, 32, 2987–2994. [Google Scholar] [CrossRef]

- Snoek, J.L. Dispersion and absorption in magnetic ferrites at frequencies above one mc/s. Physica 1948, 14, 207–217. [Google Scholar] [CrossRef]

- Verma, A.; Goel, T.C.; Mendiratta, R.G. Frequency variation of initial permeability of nizn ferrites prepared by the citrate precursor method. J. Magn. Magn. Mater. 2000, 210, 274–278. [Google Scholar] [CrossRef]

- Contributors, W. Saturation (Magnetic). Available online: https://en.Wikipedia.Org/w/index.Php?Title=saturation_(magnetic)&oldid=844588732 (accessed on 22 June 2019).

- Sung, H.W.F.; Rudowicz, C. Physics behind the magnetic hysteresis loop—A survey of misconceptions in magnetism literature. J. Magn. Magn. Mater. 2003, 260, 250–260. [Google Scholar] [CrossRef]

- Zhan, Y.D.; Wang, S.H.; Xiao, D.T.; Budnick, J.I.; Hines, W.A. Nanocomposite co/sio/sub 2/soft magnetic materials. IEEE Trans. Magn. 2001, 37, 2275–2277. [Google Scholar] [CrossRef]

- Fiske, T.; Gokturk, H.S.; Yazici, R.; Kalyon, D.M. Effects of flow induced orientation of ferromagnetic particles on relative magnetic permeability of injection molded composites. Polym. Eng. Sci. 1997, 37, 826–837. [Google Scholar] [CrossRef]

- Zheng, Y.; Wang, Y.; Xia, G. Amorphous soft magnetic composite-cores with various orientations of the powder-flakes. J. Magn. Magn. Mater. 2015, 396, 97–101. [Google Scholar] [CrossRef]

| Formula | Formulation A | Formulation B | ||||

|---|---|---|---|---|---|---|

| Ingredients | NiZn Ferrite Flakes from Powdertech | Permalloy | Binder | NiZn Ferrite Flakes from 3M | Permalloy | Binder |

| Weight fraction | 47.5% | 47.5% | 5.0% | 28.5% | 66.5% | 5.0% |

| Mass density (g/cm3) | 5.20 | 8.72 | 1.20 | 5.20 | 8.72 | 1.20 |

| Volume fraction | 49% | 29% | 22% | 32% | 44% | 24% |

| Formula | Formulation A | Formulation B | Formulation in [22] | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Ingredients | NiZn Ferrite Flakes From Powdertech | Permalloy | Binder | NiZn Ferrite Flakes From 3M | Permalloy | Binder | Metglas Flakes | Permalloy | Binder |

| Volume fraction | 49% | 29% | 22% | 32% | 44% | 24% | 10% | 63% | 27% |

| Bsat of raw materials (T) | 0.30 | 0.75 | 0 | 0.30 | 0.75 | 0 | 0.77 | 0.75 | 0 |

| Calculated Bsat of composite (T) | 0.360 | 0.494 | 0.570 | ||||||

| Measured Bsat of composite (T) | 0.364 | 0.484 | 0.547 | ||||||

| Error | 4.3% | −1.1% | 2.0% | ||||||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, C.; Mei, Y.; Ngo, K.D.T.; Lu, G. A (Permalloy + NiZn Ferrite) Moldable Magnetic Composite for Heterogeneous Integration of Power Electronics. Materials 2019, 12, 1999. https://doi.org/10.3390/ma12121999

Ding C, Mei Y, Ngo KDT, Lu G. A (Permalloy + NiZn Ferrite) Moldable Magnetic Composite for Heterogeneous Integration of Power Electronics. Materials. 2019; 12(12):1999. https://doi.org/10.3390/ma12121999

Chicago/Turabian StyleDing, Chao, Yunhui Mei, Khai D. T. Ngo, and Guoquan Lu. 2019. "A (Permalloy + NiZn Ferrite) Moldable Magnetic Composite for Heterogeneous Integration of Power Electronics" Materials 12, no. 12: 1999. https://doi.org/10.3390/ma12121999

APA StyleDing, C., Mei, Y., Ngo, K. D. T., & Lu, G. (2019). A (Permalloy + NiZn Ferrite) Moldable Magnetic Composite for Heterogeneous Integration of Power Electronics. Materials, 12(12), 1999. https://doi.org/10.3390/ma12121999