1. Introduction

Skin is the largest organ of the human body and acts as a protective barrier against pathogens and physical damage, and also has an important role in preventing excessive water loss from the body. Moreover, it is known that when the skin suffers physical trauma, a series of processes are initiated, involving the interactions between cells and matrix components, in order to restore its proper functioning. Damaged skin could be covered with a dressing that is designed to maintain a moist environment, helping the exchange process between the exterior and the wound, so that the oxygen reaches the affected skin, leading to a faster wound healing. Moreover, the properties of the materials used to obtain the dressing should promote the absorption of excess fluids [

1,

2]. Although the gaze wound dressing is still the most used in hospitals for minor injuries, the advancement of technology leads to a new approach to treat serious injuries, such as burns or infected wounds, using dressings in different forms depending on the properties they have to fulfill [

3,

4].

In recent years, organic-inorganic hybrid materials, particularly composite materials based on polymers and metal oxide nanoparticles, have attracted the attention of researchers [

5]. The dispersion of nanoparticles in a polymer matrix conducts special materials that could own new properties characteristic to both components (nanoparticles and polymer), such as flexibility, tensile strength and biodegradability [

6].

Some of the most used nano-composites used to treat wounds in the skin include zinc oxide, leading to a multifunctional material, due to its properties. Zinc oxide (ZnO) is non-toxic, has very good electrical and optical properties, is environmentally friendly, stable in reducing atmosphere, absorbs ultraviolet (UV) light, has antimicrobial properties, is a semiconductor and its price is very low [

7]. Although the antibacterial activity of ZnO is well known, the mechanism is not completely clear, and some questions in that regard still requiring detailed explanations. Researchers have studied the morphological changes induced by ZnO nanoparticles to the bacteria by scanning electron microscopy (SEM), field emission scanning electron microscopy (FESEM) and transmission electron microscopy (TEM), trying to identify the antimicrobial mechanisms. Therefore, various mechanisms of action for ZnO nanoparticles against bacteria have been published, such as direct contact between the ZnO nanoparticles and the bacterial cell wall, release of antimicrobial ions, mainly Zn

2+, and formation of reactive oxygen species (ROS) [

8,

9].

Antimicrobial dressings include those that incorporate an antiseptic agent, which is a biocide used to kill or inhibit the growth of microorganisms present in the wound or on intact skin. Recent advances in technology have led to the development of a large number of antiseptic products that are less harmful to healthy tissue while being extremely effective in pathogens colonization [

1]. These antiseptics include silver, zinc oxide, titanium oxide, iodine. Dressings that incorporate such antiseptics can be successfully used to avoid microbial contamination [

10,

11,

12].

The electrospinning technique was described by Rayleigh in 1897, and since then it was developed to obtain organized fibers [

13]. This method is used to obtain non-woven fabrics, with extremely small fiber diameter, in the range of nanometers. The fibers have a large surface area and are easy to be functionalized for various purposes. Over 200 types of synthetic, natural and mixt polymers can be electrospun to obtain various types of fibers [

14,

15,

16,

17].

Polyvinyl alcohol (PVA) is a linear synthetic polymer produced by partial or complete hydrolysis of polyvinyl acetate. The degree of hydrolysis determines its physical and chemical properties. The resulting polymer is adaptable for many applications. It is commonly used in textile industry, paper manufacturing, food packaging and the medical field. Polyvinyl alcohol is used as a biomaterial due to its biocompatibility, as well as non-toxic and non-carcinogen properties [

11,

18].

Sodium alginate is a biomaterial used in numerous applications in tissue engineering and regenerative medicine fields, because of its properties such as biocompatibility, and the ease of gelling and structural similarity of the obtained gels to the extracellular tissue matrix [

19].

In this paper, it was aimed to develop composite materials based on zinc oxide nanoparticles and polyvinyl alcohol and sodium alginate fibers, for the design of antimicrobial wound dressings. The nanoparticles were synthesized by the microwave assisted hydrothermal method or through the polyol method, which lead to various morphologies, depending on the synthesis parameters. The correlation between the synthesis parameters, antibacterial properties and in vitro testing results of the obtained composite materials were investigated.

2. Materials and Methods

2.1. Materials

Zinc chloride (ZnCl2, >98% purity, Mw = 136,30 g/mole), ammonium hydroxide solution (NH4OH, 25%), sodium hydroxide pellets (NaOH, >98% purity, Mw = 40 g/mole), sodium sulfate (Na2SO4, >98% purity, Mw = 142,04 g/mole), zinc sulphate (ZnSO4, >99% purity), zinc acetate dihydrate (Zn(CH3COO)2 · 2H2O, >98% purity, Mw = 219,51 g/mole), ethylene glycol (C2H6O2, >99.5% purity), ethanol (C2H5OH, >99.8% purity) and acetone (C3H6O, >99.9% purity) were used for preparing the zinc oxide (ZnO) powder.

For the synthesis of fibers, sodium alginate (C6H9NaO7), polyvinyl alcohol PVA (>98% purity), glutaraldehyde (25%), ammonium hydroxide solution (25%), methanol (>99.9% purity), calcium chloride (CaCl2, >97% purity) and ethanol (>99.8% purity) were used.

2.2. ZnO Nanostructures Synthesis

In order to determine which process would lead to a better antimicrobial activity of zinc oxide, two synthesis methods were used—the microwave-assisted hydrothermal and polyol methods.

In the microwave-assisted hydrothermal method, ZnCl2 and ZnSO4 were used as Zn2+ precursors. The general steps implied in this type of synthesis are as follows: Samples are weighed into vials, and suitable reagents are added. Vials are placed in a rack, which is automatically lowered into the reaction chamber. The chamber is sealed and pre-pressurized with inert gas, which physically acts as a cap for the vials, avoiding boiling of the solutions and preventing cross contamination. At the completion of the microwave run, a built-in cooling device rapidly lowers the temperature.

Firstly, if ZnSO4 is used as a precursor (synthesis H1), 6 mL of ammonia (25%) was mixed with distilled water to form 100 mL of solution. The mixture was added dropwise over 100 mL of 0.04 M Zn2+ precursor solution. The obtained mixture was placed in a Teflon vessel inside the autoclave, for a microwave-assisted hydrothermal treatment of 10 min at 120 °C and 7 bars pressure, then cooled to room temperature. Finally, the formed precipitate was collected by filtration, washed with distilled water twice and once with ethanol. The resulting powder was dried in a vacuum.

For the second synthesis of ZnO (H2), 60 mL of a 0.5 M aqueous solution of zinc chloride was added over 100 mL of 2 M NaOH solution. The obtained mixture was stirred for 15 min while maintaining pH to 12 (by adding NaOH solution, as needed). Following this, the solution was placed in an autoclave where it was maintained at a temperature of 90 °C and a pressure of 7 bars for 10 min. After the hydrothermal treatment, the obtained precipitate was collected by filtration, washed with distilled water twice and once with ethanol, then dried in the oven at 90 °C for 5 h [

20].

The third synthesis (H3) was performed starting from 0.60 g of Zn(OH)

2 previously prepared according to [

21], and 50 mL of 2 M solution of Na

2SO

4 that were mixed with 50 mL of 4 M solution of NaOH. After stirring for one hour, the solution was transferred to a vial and introduced into the microwave-assisted hydrothermal reaction chamber for 10 min, at a temperature of 140 °C and a pressure of 7 bar. The obtained precipitate was filtered, washed with distilled water twice and once with ethanol and oven dried at 80 °C for 6 h.

In regards to the polyol synthesis, two different routes were used, as described below. Firstly (P1), zinc acetate was dissolved in ethylene glycol by refluxing at 160 °C to form a 1 M solution. After the precursor has been completely dissolved, the mixture was refluxed for further 12 h at the same temperature. The formed suspension was centrifuged at 32,000 rpm for 15 min using an ultracentrifuge in order to separate the nanoparticles of the supernatant. Subsequently, ZnO was washed twice with ethanol, followed by a new forced separation by centrifugation. The obtained powder was dried in the oven at 80 °C for 6 h [

22].

The second polyol synthesis of ZnO nanoparticles (P2) started also from Zn(CH

3COO)

2 2H

2O as Zn

2+ precursor. It was dissolved in 1,3-propanediol, then heated to 160 °C and maintained at this temperature for 1 h. At the end of the reaction, the precipitate was centrifuged, washed several times with acetone and ethanol and then dried in a vacuum oven at 50 °C for 12 h in order to obtain the ZnO nanopowder [

23].

2.3. Composite Material Synthesis

A 2% Sodium alginate (SA) and polyvinyl alcohol (PVA) (16%) solutions were prepared, by dissolving 2 g of alginate, respectively 16 g of polyvinyl alcohol in deionized water. The SA/PVA solution was obtained by mixing both solutions in different (3:1, 1:1, 1:3) mass ratios, for 10 min. The optimal SA/PVA ratio for electrospinning, by means of viscosity of spinning solution, was found to be 1:1. ZnO nanoparticles previously prepared were added to the polymer solution so that the content of ZnO in the composite fibers (after electrospinning) to be 5% (wt.), depending on the SA and PVA quantities. The obtained suspension was sonicated and subjected to a magnetic stirring for 1 h. The equipment used for the fibers synthesis was a Tong LiTech Nanofiber Electrospinning Unit equipped with a Tong LiTech-TL-FG injectomat system with DC source (0–50 kV) (Shenzhen, China), equipped with 2 syringes of 20 mL with metallic needles, having 0.6 mm internal diameter. The collector was wrapped in a special paper to facilitate the fibers removal. The solutions were loaded into syringes and the pumping was performed at a rate of 0.5 mL/h. The tension applied to the needle was of 20 kV, at a distance of 5 cm from the collector [

10,

11].

Both polyvinyl alcohol and sodium alginate are poorly soluble in water, so their stability in water needs to be improved. The classic method of improving the stability properties of polyvinyl alcohol is to treat it with vapors of glutaraldehyde (2%) as well as with NH3 vapors.

In our study, the combination of polyvinyl alcohol and sodium alginate requires a combination of cross-linking methods [

24].

The obtained fibers were placed in a desiccator where they were subjected to NH3 vapor treatment for 48 h to crosslink the polyvinyl alcohol, and then introduced into a vacuum oven to remove unreacted NH3. For the crosslinking of sodium alginate, the fibers were introduced into a solution of CaCl2 (1%) in ethanol. This is done by trituration with methanol and CaCl2 solution, in order to replace Na+ ions with Ca2+ ions.

2.4. Structural and Morphological Characterization

X-ray diffraction analysis (XRD) was performed in order to characterize the synthesized powders from the point of view of their crystallinity as well as of the component phases. XRD analysis was performed using a Empyrean equipment from Malvern PANalytical, Bruno, Nederland in Bragg-Brentano geometry equipped with a Cu-anode (λCuKα = 1.541874 Å) X-ray tube with in-line focusing, programmable divergent slit on the incident side and a programmable anti-scatter slit mounted on the PIXcel3D detector on the diffracted side. The analysis was acquired on the 15–80° angle range, with the acquisition step of 0.02° and 100 s acquisition time per step.

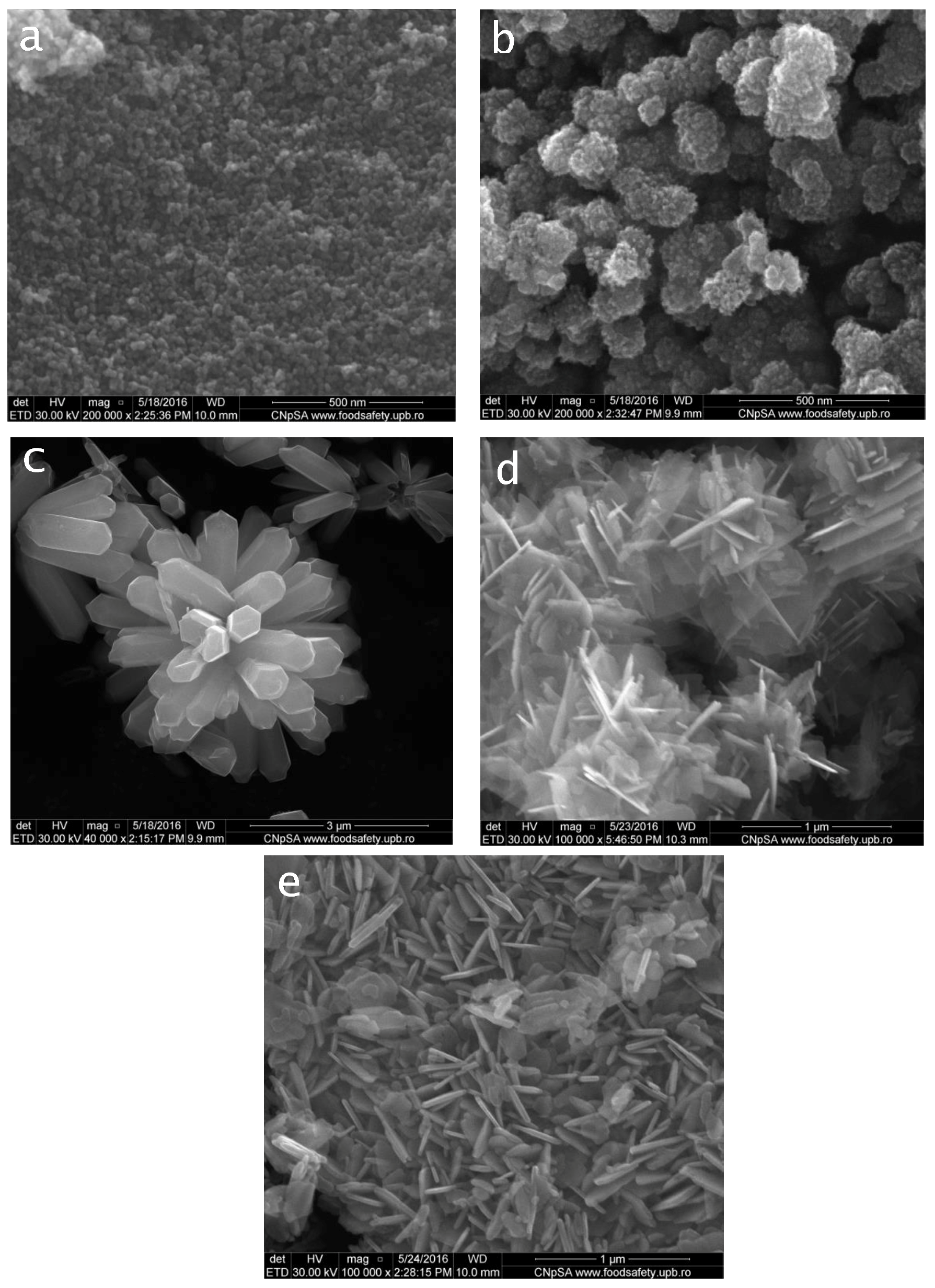

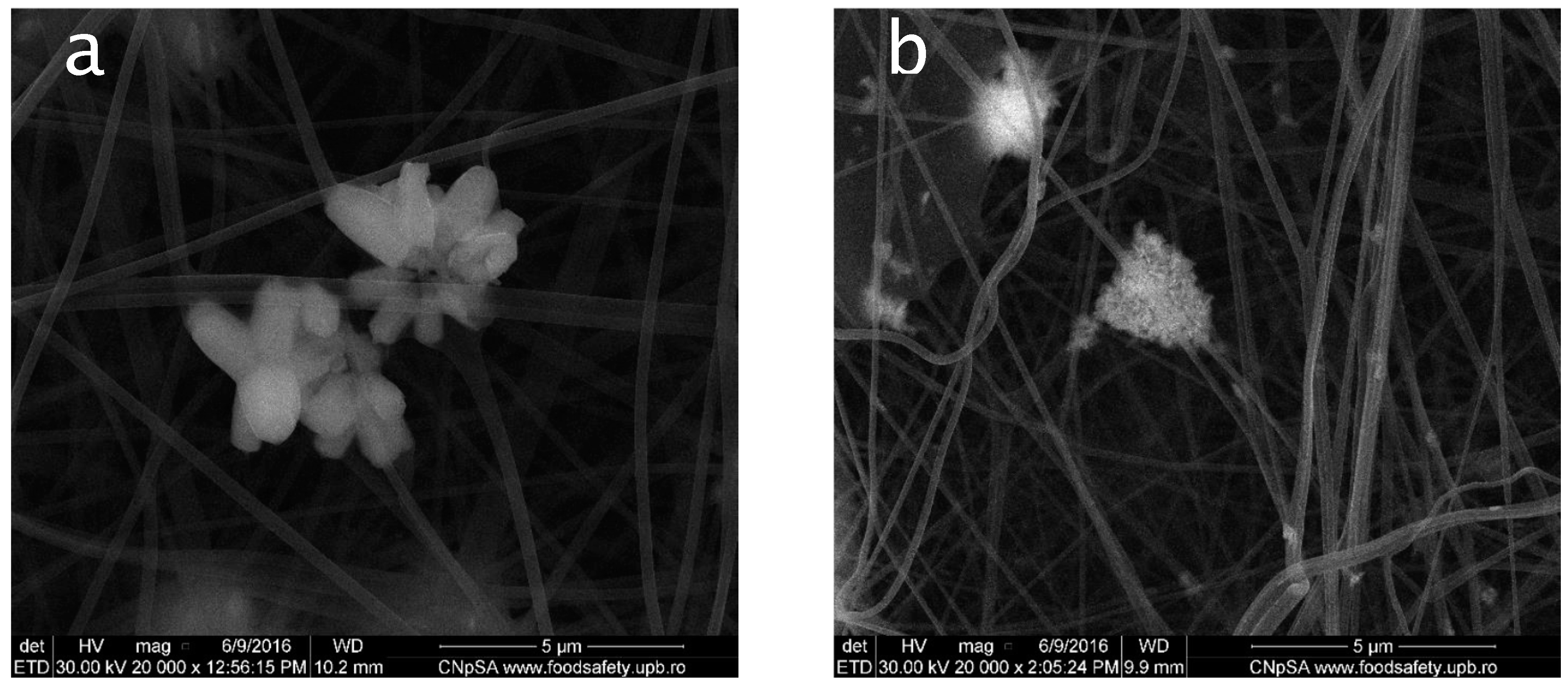

The morphology of the obtained powders and composite fibers was studied via scanning electron microscopy (SEM), with a Quanta Inspect F50 microscope coupled with an energy dispersive spectrometer (EDAX) (Thermo Fisher (former FEI), Eindhoven, Nederland).

2.5. Antimicrobial Assay

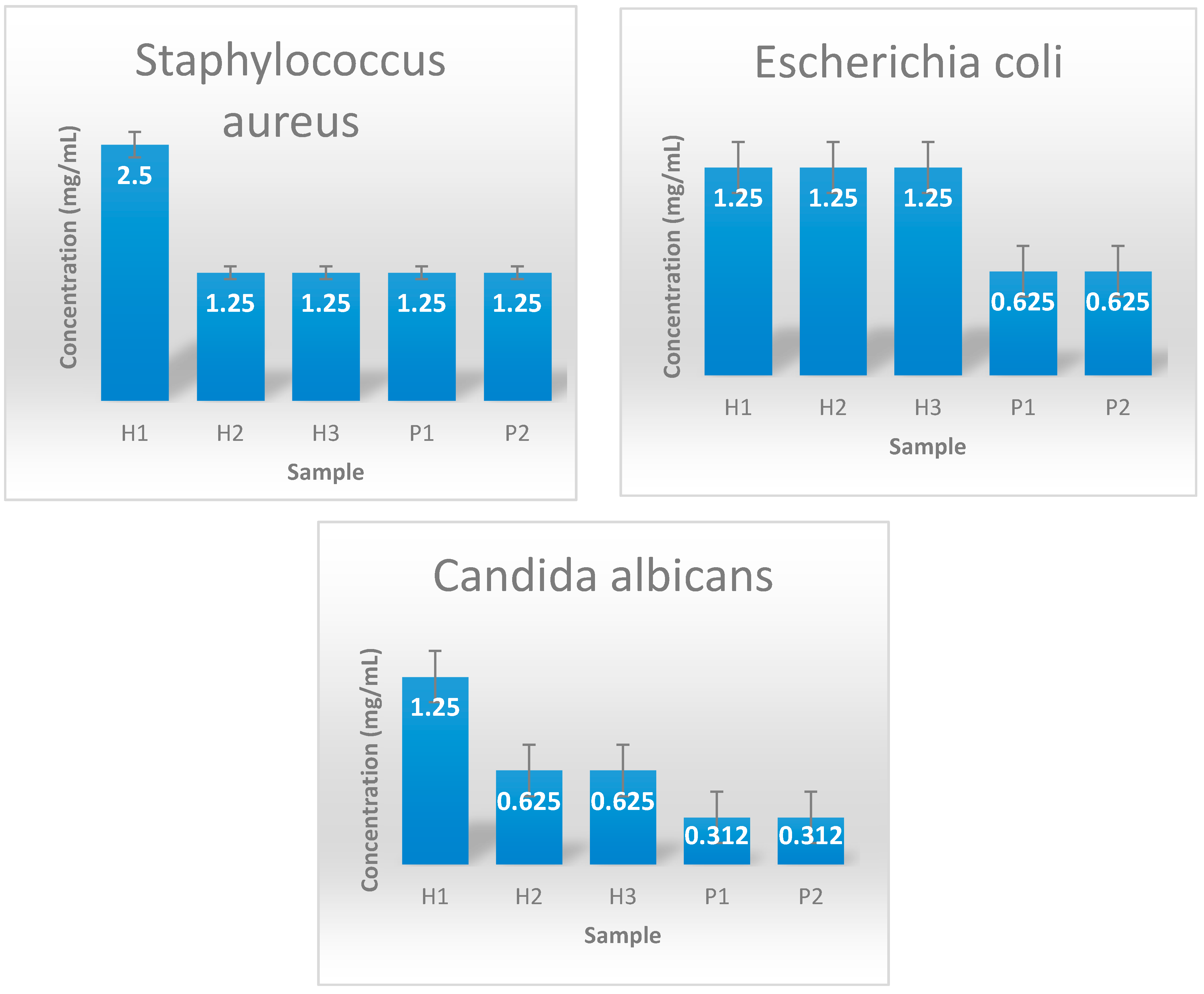

2.5.1. Minimal Inhibitory Concentration (MIC) of the ZnO Nanopowders

Strains of

Staphylococcus aureus ATCC 25923;

Escherichia coli ATCC 25922 and

Candida albicans ATCC 10231 were purchased from the American Type Culture Collection (Virginia, USA) and maintained in the Lab as Glycerol stocks. Fresh cultures obtained in nutritive broth from glycerol stocks were inoculated on LB agar (for bacteria) or Sabouraud agar (for

C. albicans) and incubated for 24 h at 37 °C to obtain cultures that were used for all subsequent studies. The antimicrobial activity of various zinc oxide nanoparticles has been studied by determining the minimum inhibitory concentration against

S. aureus,

E. coli and

C. albicans laboratory strains. Minimal inhibitory concentrations were established by an adapted microtiter method [

25]. Various concentrations (ranging 0.005—5 mg/mL) of the obtained nanoparticles were used to assess their effect against microbial growth, for 24h at 37 °C, in nutritive broth. MIC was considered as the lowest concentration to inhibit the microbial development. This was established by naked eye evaluation and spectroscopy measurement of microbial cultures at Abs = 600 nm.

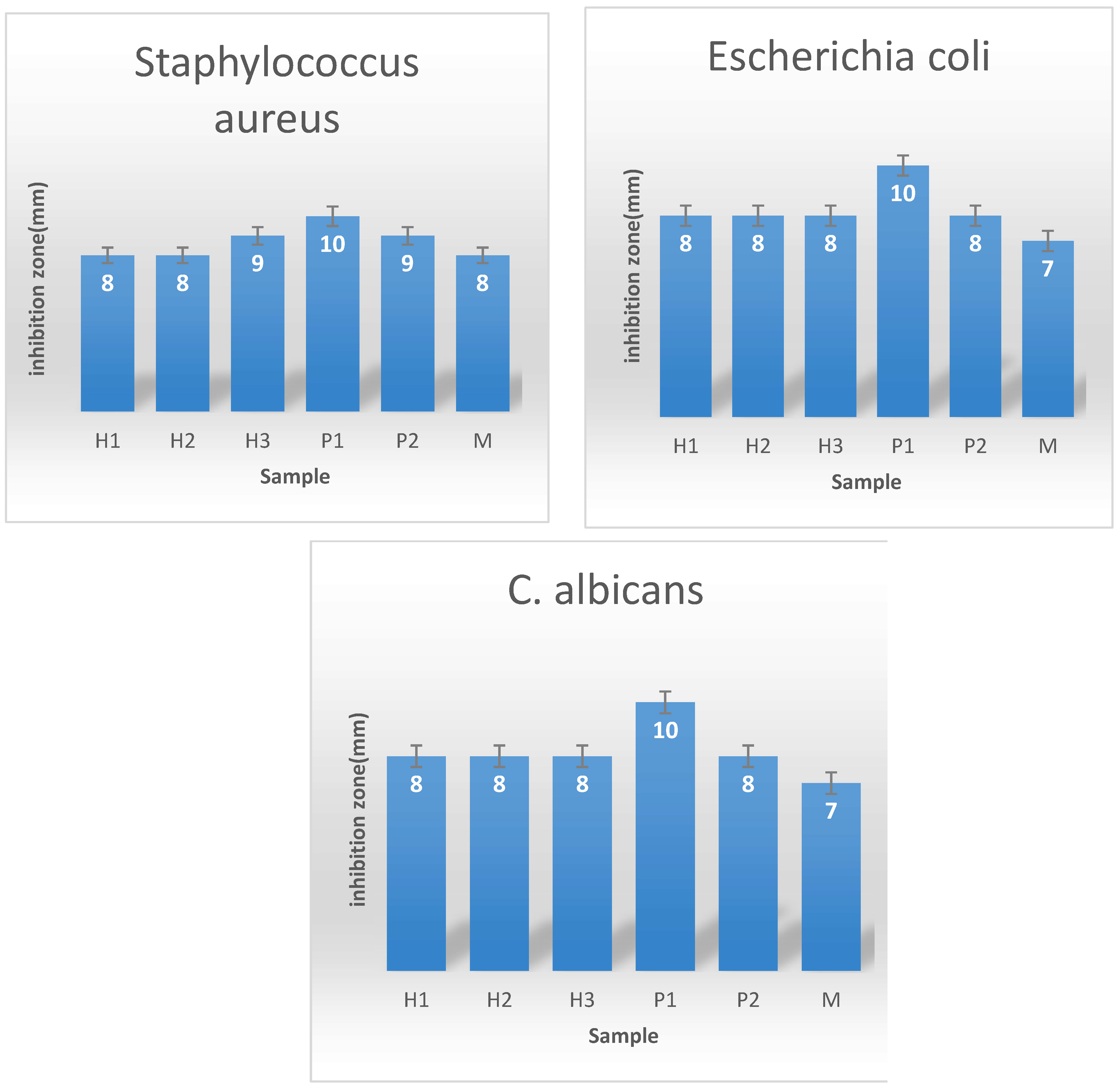

2.5.2. Growth Inhibition of the Obtained Dressings—Qualitative Assay

To evaluate the antimicrobial effect of the obtained dressings, an adapted version of the disc diffusion method was used. Microbial suspensions prepared in sterile saline buffer were obtained from each strain and adjusted to an optical density of 0.5 McFarland (1.5 × 108 CFU (colony forming units)/mL). These were used to inoculate the entire surface of the nutrient agar Petri dishes. After inoculation, 6 mm size samples of the sterile coatings were aseptically deposited on the inoculated agar surface. Petri dishes containing the samples were incubated for 24 h at 37 °C to allow the growth of bacteria. After incubation, the diameter of growth inhibition zone (mm) was measured. A wider inhibition zone suggests a higher antimicrobial effect of the fibrous dressing.

2.6. Biocompatibility In Vitro

2.6.1. MTT Assay

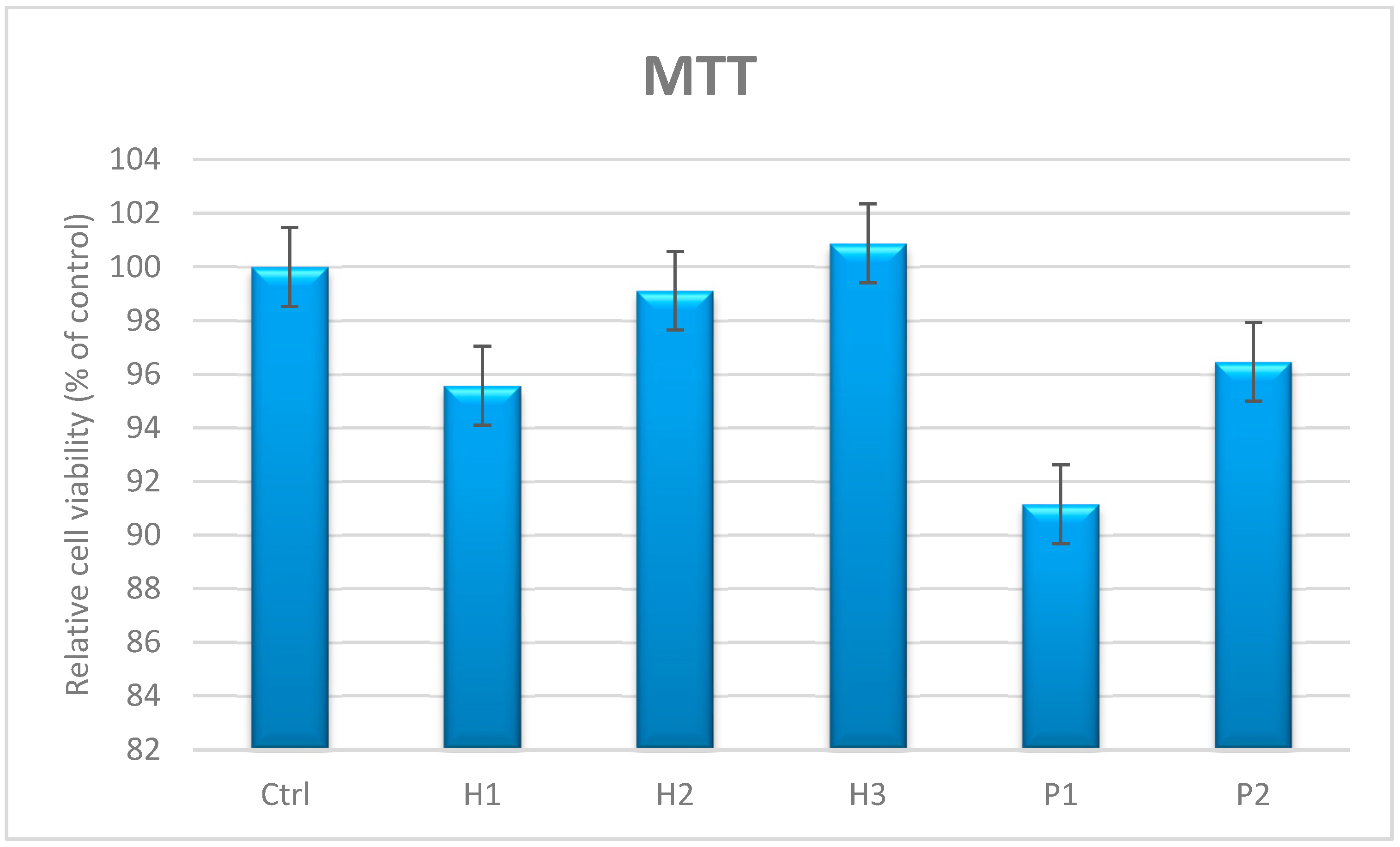

The human mesenchymal amniotic fluid stem cells (AFSC) were used to evaluate the biocompatibility of ZnO nanoparticles. The cells were cultured in DMEM medium (Sigma–Aldrich, Missouri, MO, USA) supplemented with 10% fetal bovine serum, 1% penicillin and 1% streptomycin antibiotics (Sigma–Aldrich, Missouri, MO, USA). To maintain optimal culture conditions, the medium was changed twice a week. The biocompatibility was assessed using MTT assay (Vybrant® MTT Cell Proliferation Assay Kit, Thermo Fischer Scientific, Massachusetts, MA, USA). The assay is a colorimetric method that allows quantitative assessment of proliferation, cell viability and cytotoxicity. The viable cells reduce yellow tetrazolium salt MTT (3- (4,5dimetiltiazoliu) -2,5-diphenyltetrazolium bromide) to a dark blue formazan via mitochondrial enzymes. Briefly, the AFSC were grown in 96-well plates, with a seeding density of 3000 cells / well in the presence of the analyzed samples (5 mg/mL concentration of each ZnO nanopowder) for 72 h. Then, 15 mL of Solution I was added and incubated at 37 °C for 4 h. Solution II was added and pipettes vigorously to solubilize formazan crystals. After 1 h, the absorbance was read using a spectrophotometer at 570 nm (TECAN Infinite M200, Männedorf, Switzerland).

2.6.2. Evaluation of Cell Morphology and Viability by Fluorescence Microscopy

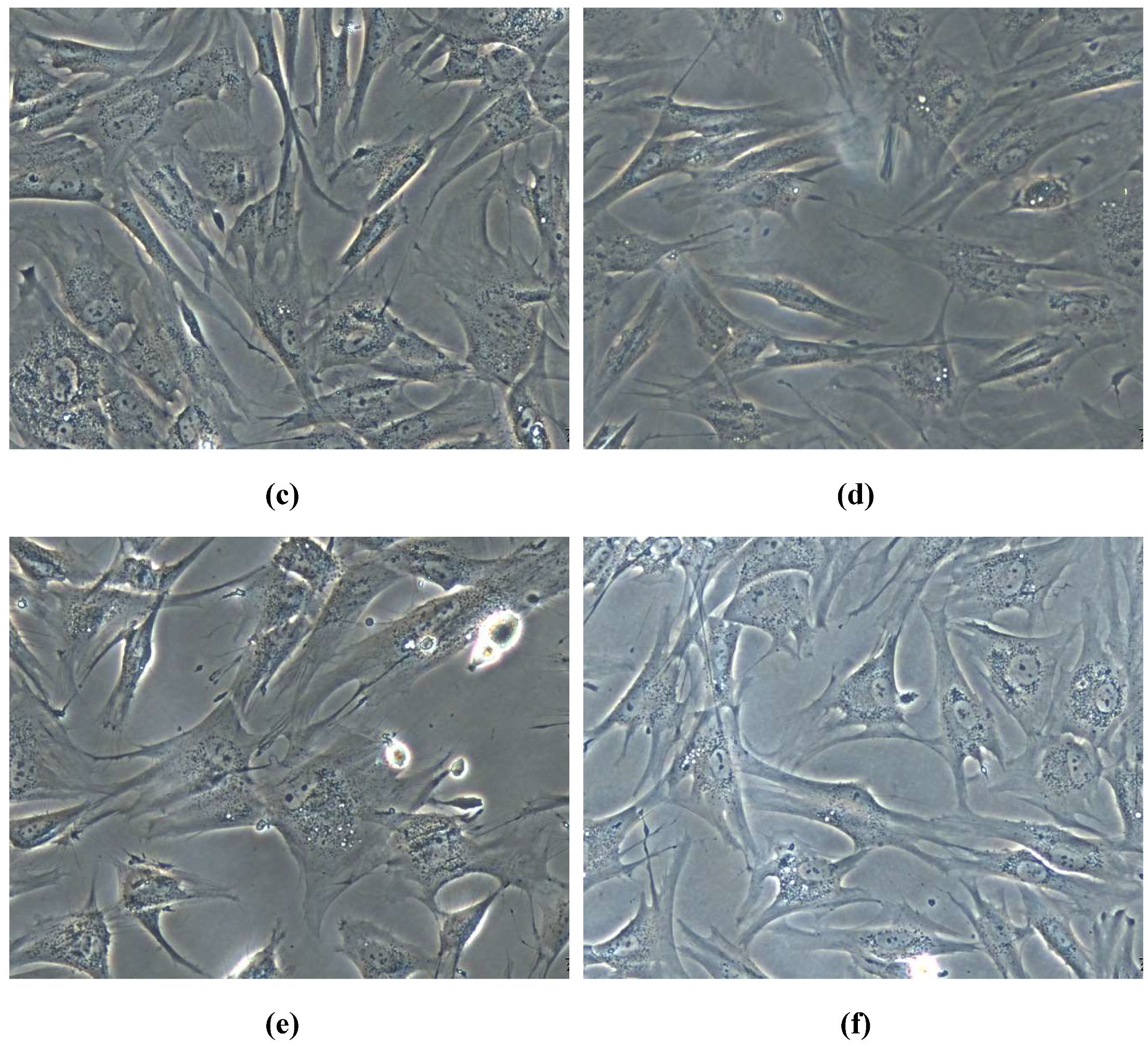

The biocompatibility of the obtained powder materials with AFSC was also evaluated based on fluorescence microscopy using RED CMTPX fluorophore (Thermo Fischer Scientific, Massachusetts, MA, USA), which is a cell tracker for long-term tracing of living cells. The CMTPX tracker was added in cell culture treated with ZnO nanoparticles and the viability and morphology of the AFSC was evaluated after 5 days. The CMTPX fluorophore was added in the culture medium at a final concentration of 5 μM, incubated for 30 min in order to allow the dye penetration into the cells. Next, the AFSC were washed with PBS and visualized by fluorescent microscopy. The photomicrographs were taken with Olympus CKX 41 digital camera driven by CellSense Entry software (Olympus, Tokyo, Japan).

4. Discussion

The degree of crystallinity and the size of the crystals can be estimated from the width of the diffraction peaks, which in this case varies depending on the synthesis method and the conditions used. Thus, the highest degree of crystallinity was obtained by the hydrothermal method starting from Zn(SO4), and the lowest by the polyol method using 1,3-propanediol as the solvent.

The spherical morphology observed through SEM analysis for ZnO samples obtained by using the polyol method may be possible due to the coordination between ethylene glycol / 1,3-propanediol and Zn2+ molecules or to selective anchoring of solvent molecules on ZnO crystals, both favoring the production of spherical morphology. Both ethylene glycol and 1,3-propanediol contain two hydroxyl groups in the molecule, which could inhibit preferential growth in the, c, direction, leading to spherical morphology. The low particle size can be attributed to the spontaneous formation of Zn(OH)2 monomers resulting from the reaction between zinc acetate and solvent, which results in a higher nucleation rate. Therefore, more particles are formed, which means smaller sizes of the particles, in correlation with higher concentration of the initial nuclei.

For ZnO samples obtained via microwave-assisted hydrothermal method, the possible mechanism of formation of flower-type morphologies can be explained by the decomposition of zinc chloride and ammonia at the reaction temperature. The concentration of Zn2+ and OH ions gradually increases and ZnO nuclei begin to form when the degree of over-saturation exceeds the critical value. The concentration of NH4OH plays a vital role in the formation of the flower structures. High values mean that the supplied OH− ions are enough for the zinc oxide nucleation, while for too low concentrations irregular or rod type morphologies would have been obtained.

By correlating X-ray diffraction with scanning electron microscopy results, it can be stated that in the samples obtained via microwave-assisted hydrothermal method, a preferential increase is observed in the direction of the, c, axis. This increase can be attributed to the high temperature at which the reaction takes place (140 °C).

For the polymer/ZnO fibers, the SEM analysis revealed a porous structure and a random orientation of fibers. Due to the formation of aggregates and agglomerates which sometimes are larger than the diameter of the fibers, zinc oxide nanoparticles are not fully incorporated into the structure, resulting in less uniform deposition of nanoparticles on fibers. A homogeneous dispersion of oxide nanoparticles in the fiber structure could be obtained only for those prepared through the polyol method, starting from zinc acetate and ethylene glycol.

In vitro experiments revealed that all nanostructured fibrous coatings have a significant antimicrobial activity, their effect being influenced by the ZnO nanoparticle concentration and the synthesis method. Both qualitative (diameter of growth inhibition zone) and quantitative (MIC assay) tests proved that samples containing ZnO nanoparticles have the greatest antimicrobial effects, although sodium alginate may potentate the antimicrobial activity of the coating, since it seems to have an intrinsic antibacterial activity [

27]. Their high antimicrobial effect was correlated with a very good in vitro biocompatibility, as revealed by the microscopy evaluation and MTT assay.

It seems that the use of ZnO nanoparticles improves acute and chronic wounds healing due to antibacterial, anti-inflammatory and increased re-epithelialization properties [

28]. The mechanisms of action of ZnO nanoparticles involves its participation as a cofactor in the enzymatic complexes that promote migration of keratinocytes and the implication in the formation of reactive oxygen species which penetrate the bacterial cell membrane [

29]. One of the main conditions of drug therapy is to be non-toxic to the host cells. The viability of cells in the presence of ZnO nanoparticles is influenced by particle sizes and concentration. ZnO nanoparticles with a smaller size (higher specific surface areas) showed highest cellular viability in vitro [

30]. Also, low concentrations of ZnO nanoparticles are nontoxic to eukaryotic cells, according to recent results [

31]. Pati et al. (2015) showed that ZnO nanoparticles at the bactericidal dose have no detrimental effects on monocytes cell lines. Our results showed that ZnO nanoparticles synthetized by hydrothermal and polyol methods present no cytotoxicity on human amniotic fluid derived stem cells (AFSC) [

32].

The obtained results correlate with recent literature demonstrating the antimicrobial effect of ZnO nanoparticles and their utility for biomedical applications [

33], and highlights that electrospinning may be an efficient technique to obtain coatings and fibrous materials with multiple applications. The discussed properties recommend the designed nanostructured fibrous coatings for biomedical applications, suggesting they could be efficiently used for wound healing, being able to avoid microbial colonization and multiplication of the wound, which is one of the main causes of complication and delayed healing in chronic wounds [

34].

5. Conclusions

This study reports on the design and characterization of a new type of antimicrobial dressings based on polyvinyl alcohol, sodium alginate and zinc oxide nanoparticles. ZnO nanoparticles were synthesized by the microwave assisted hydrothermal and polyol methods, using different synthesis parameters and Zn2+ precursors. It was observed that the synthesis approach impacts on the subsequent biological effects of ZnO nanoparticles, due to different morphology and size of powders.

The resulting powders were characterized by X-ray diffraction that demonstrated the production of zinc oxide in hexagonal form. The sample morphology was analyzed by scanning electron microscopy that showed different microstructure of particles, for different processing parameters. Thus, flower-like shaped agglomerates, plates, rods and cvasi-spherical nanoparticles were obtained. Polymeric fibers were obtained by electrospinning and Zinc oxide powders were used to enhance their antimicrobial properties.

The nanopowders and fibers have shown significant antimicrobial activity, being efficient against Gram positive (S. aureus), Gram negative (E. coli) and opportunistic yeast (C. albicans) models. By correlating the dimensions and morphologies of the obtained particles with their antimicrobial action, it can be concluded that zinc oxide with the smallest particle size exhibited the best activity, as expected. As for the composite materials, the high degree of dispersion of ZnO-P1 in the structure has led to remarkable improvement in their antimicrobial properties. Cellular viability tests confirm that the addition of 5% (wt.) ZnO nanopowder to the obtained fibers does not induce any cytotoxic effects in vitro, with the tested diploid cells presenting a normal morphology and development in the presence of the designed coatings.