Probing Slip Differential Heat of Magnetorheological Fluids Subjected to Shear Mode Operation and Its Effect on the Structure

Abstract

:1. Introduction

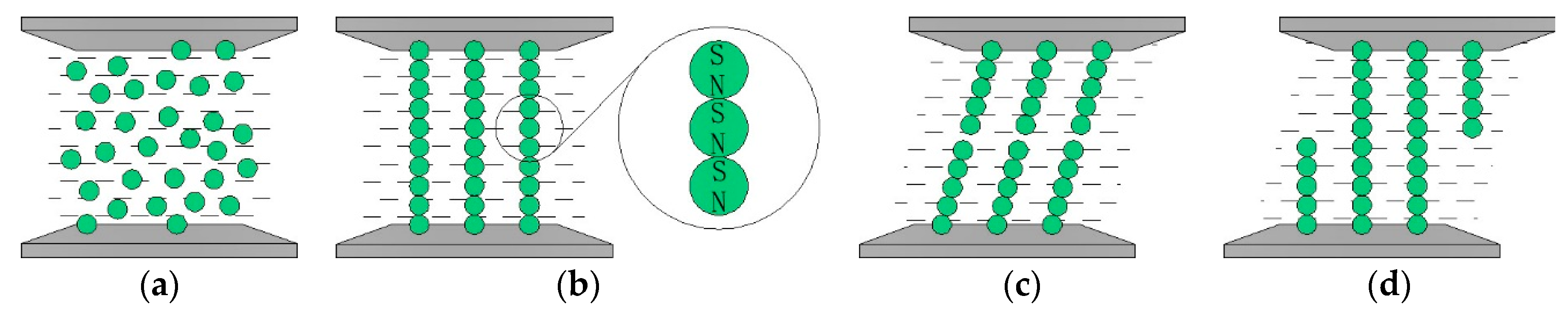

2. Micro-Macro Model of Slip Differential Heat of MRFs

3. Model of Slip Differential Heat of Magnetorheological Clutches

3.1. Principle of Two Basic Disc-Type and Cylinder-Type Magnetorheological Clutches

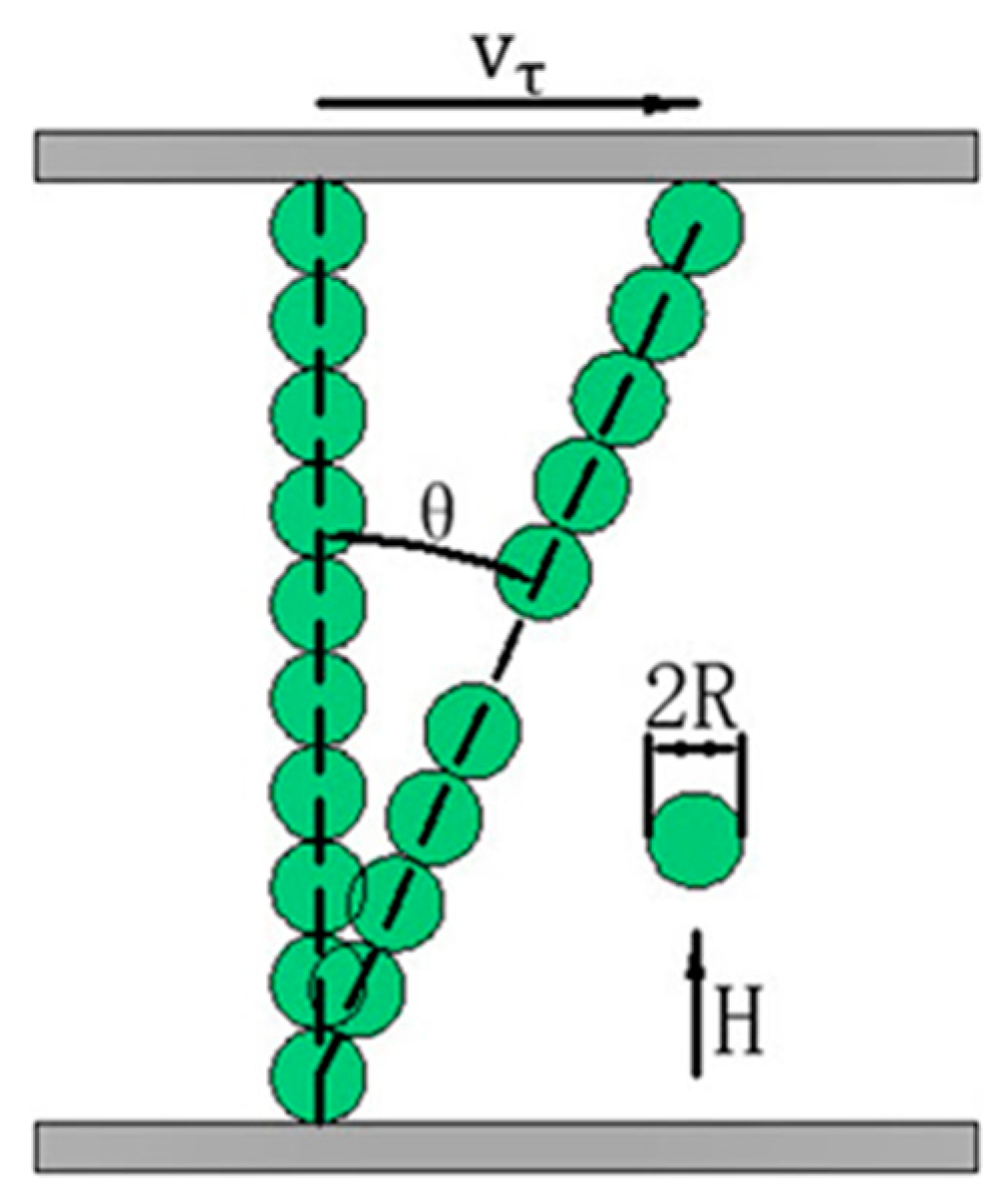

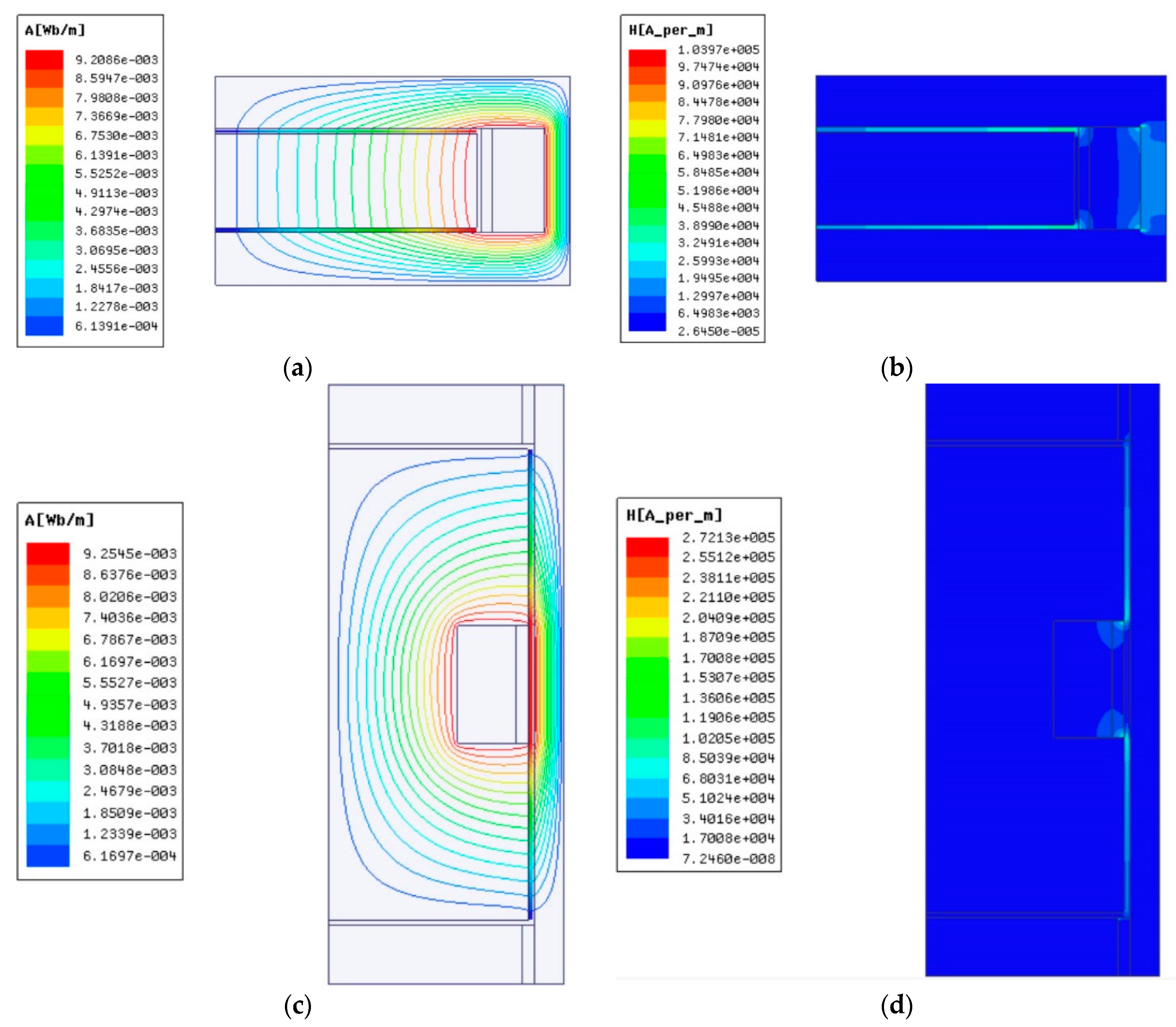

3.2. Electromagnetic Field Analysis

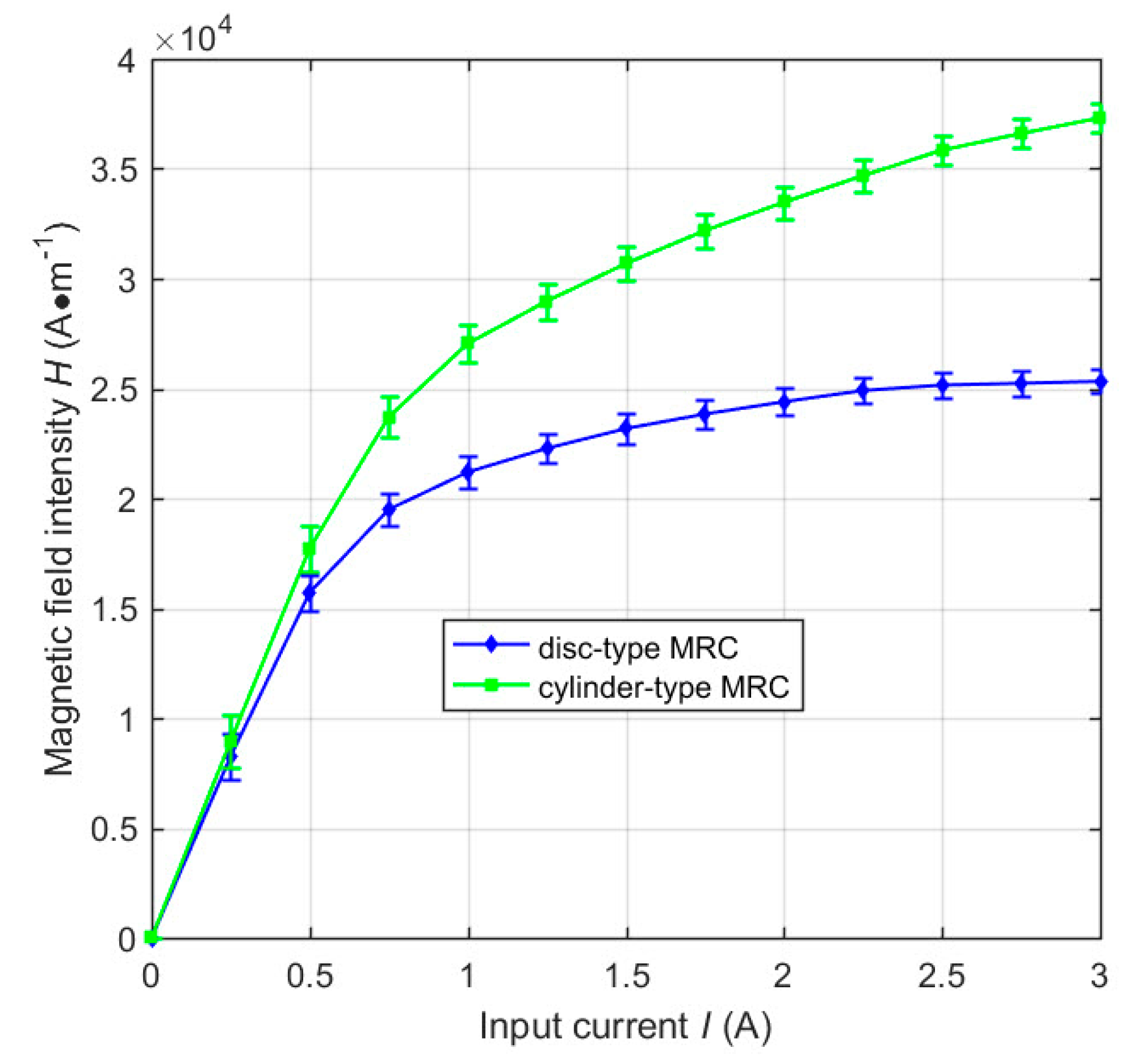

3.3. Thermal Field Analysis

4. Thermal Structure Field Analysis

5. Results and Discussion

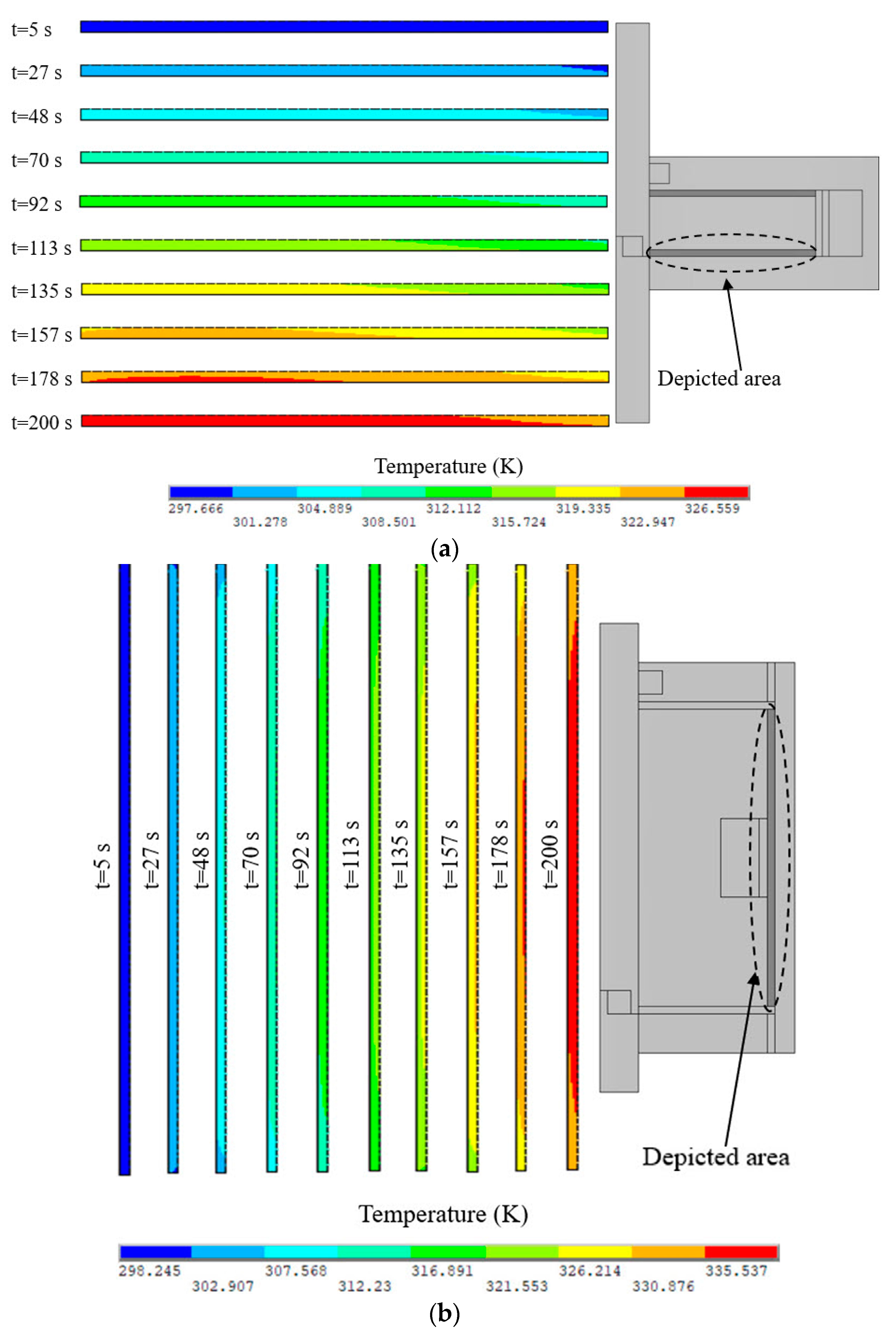

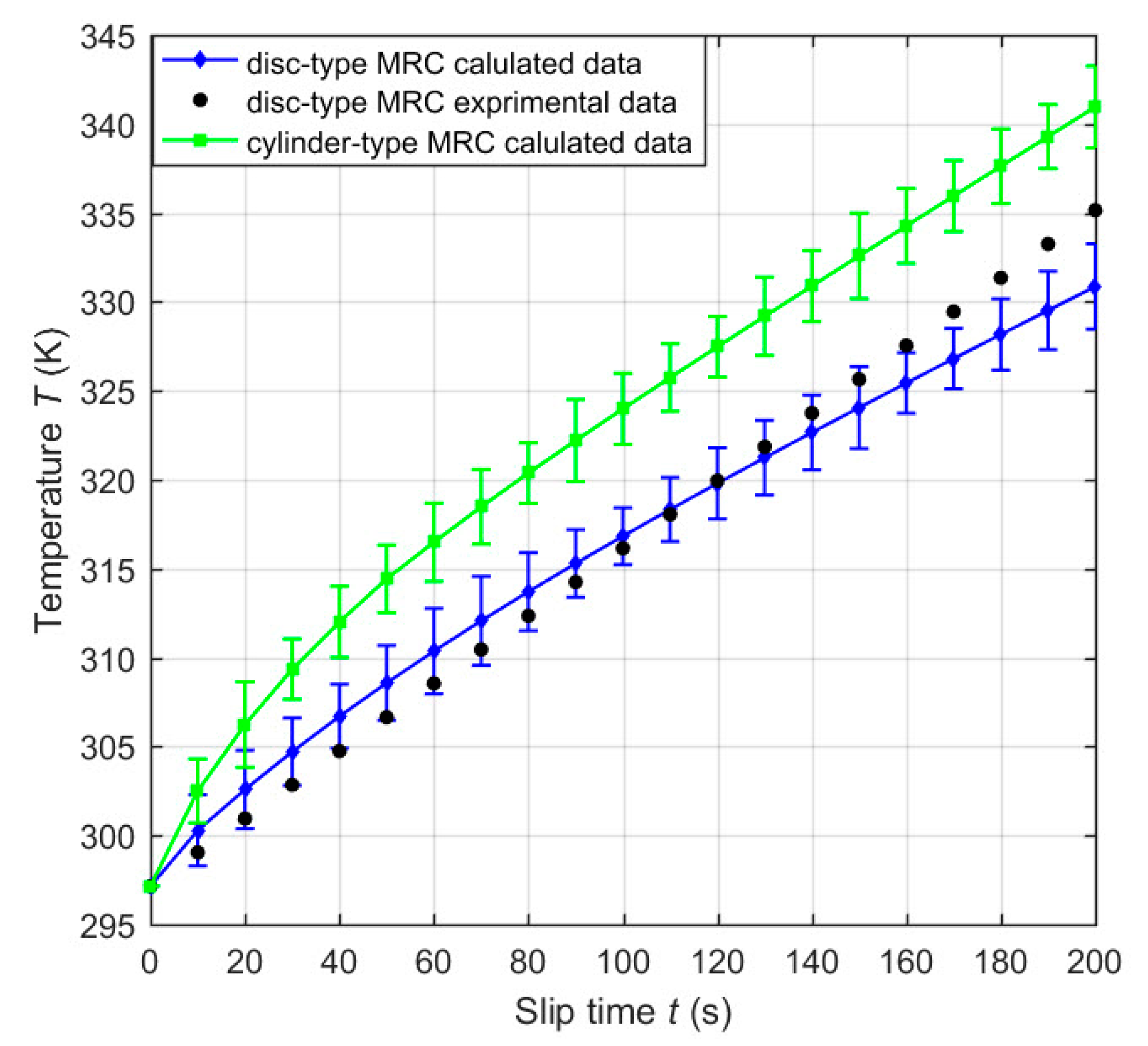

5.1. Temperature Variations of MRFs

5.2. Slip Power Variations of MRFs

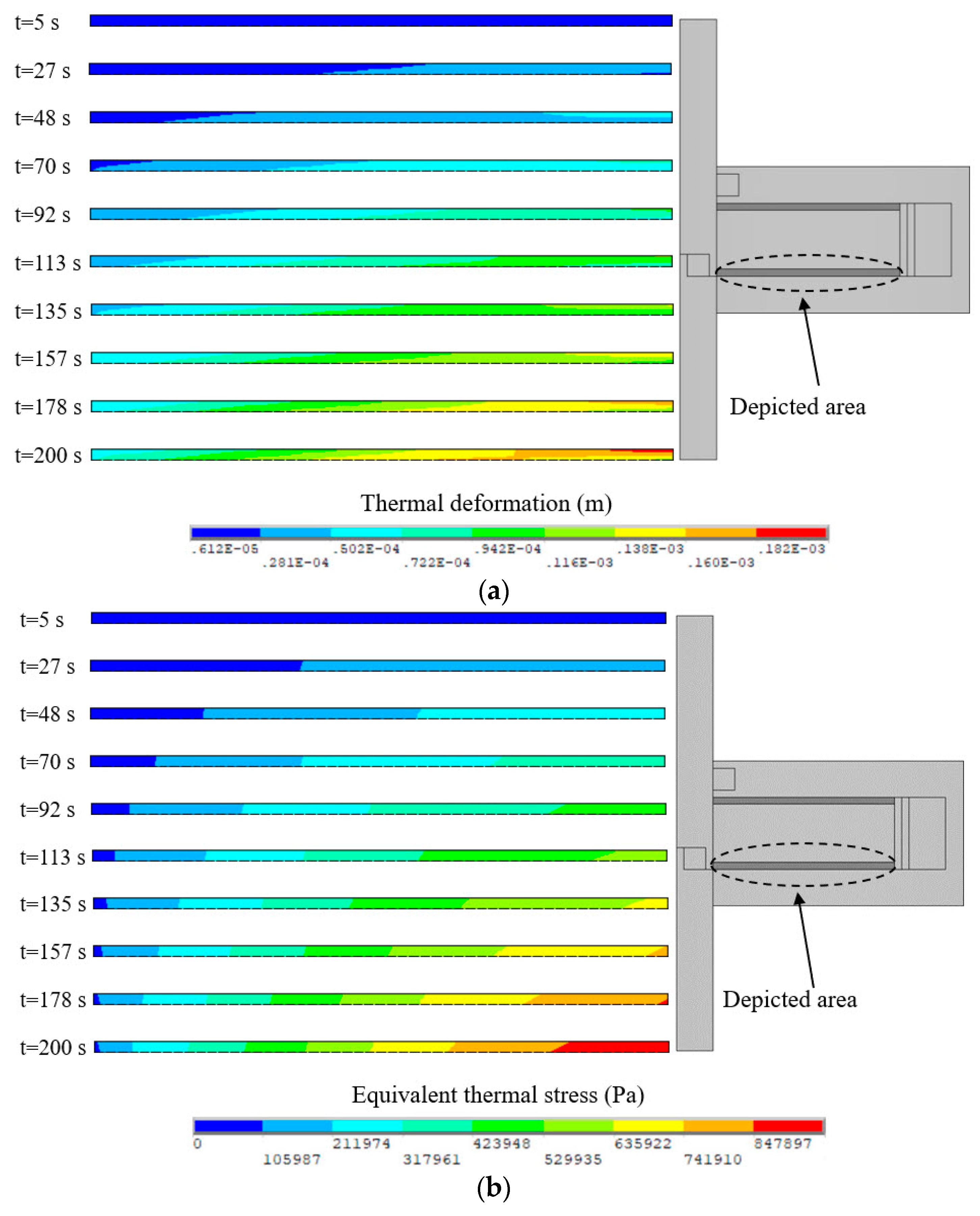

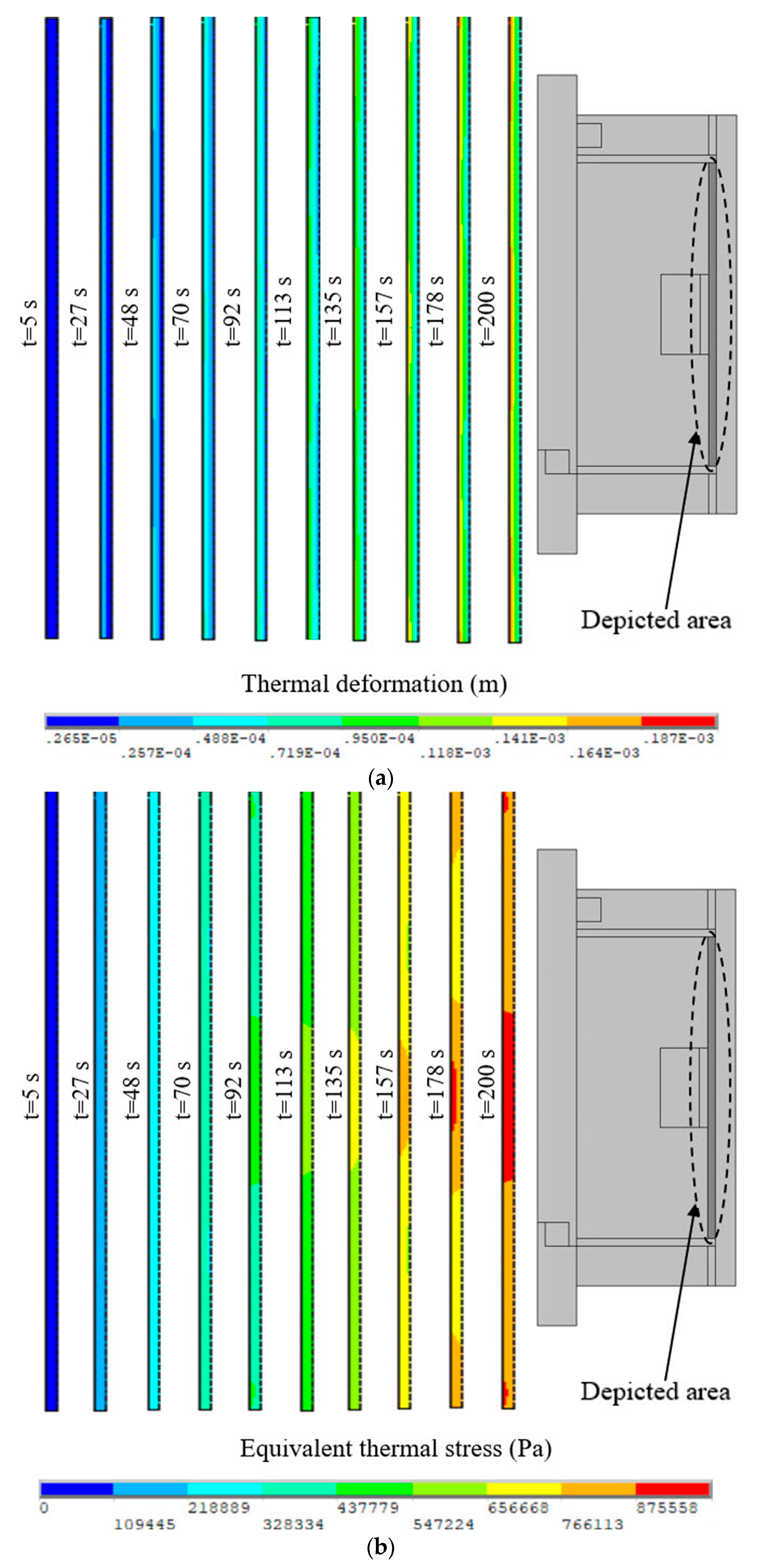

5.3. Effect of Slip Differential Heat on the Structure of MRFs

6. Conclusions

- The temperature of MRFs increases with the slip time due to the accumulation of slip differential heat.

- The slip power increases proportionally with the increase of the rotational speed difference of the clutches, but it first increases dramatically and then increases a little or even keeps constant at the input current I = 0.5 A with the increase of the input current.

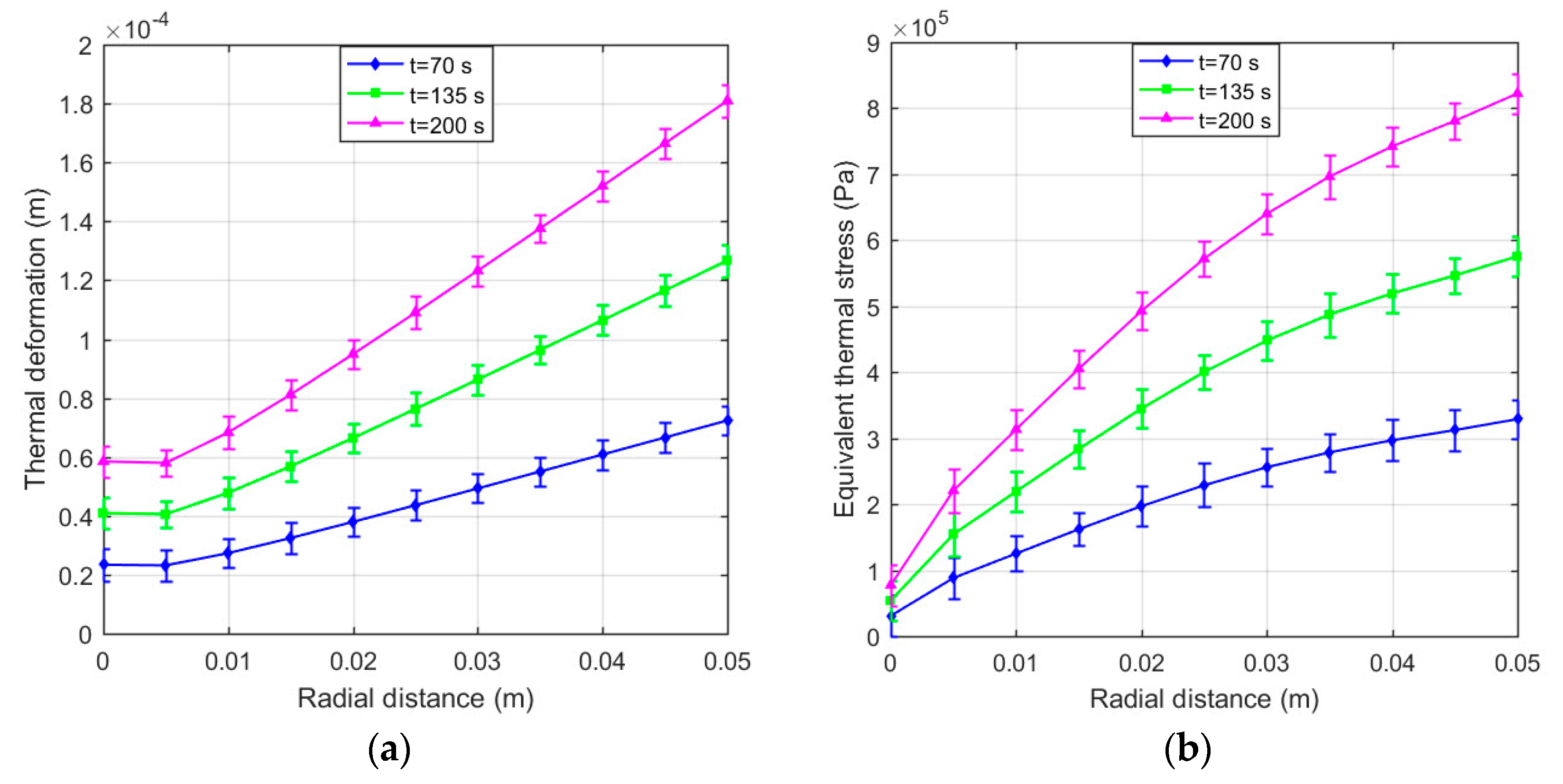

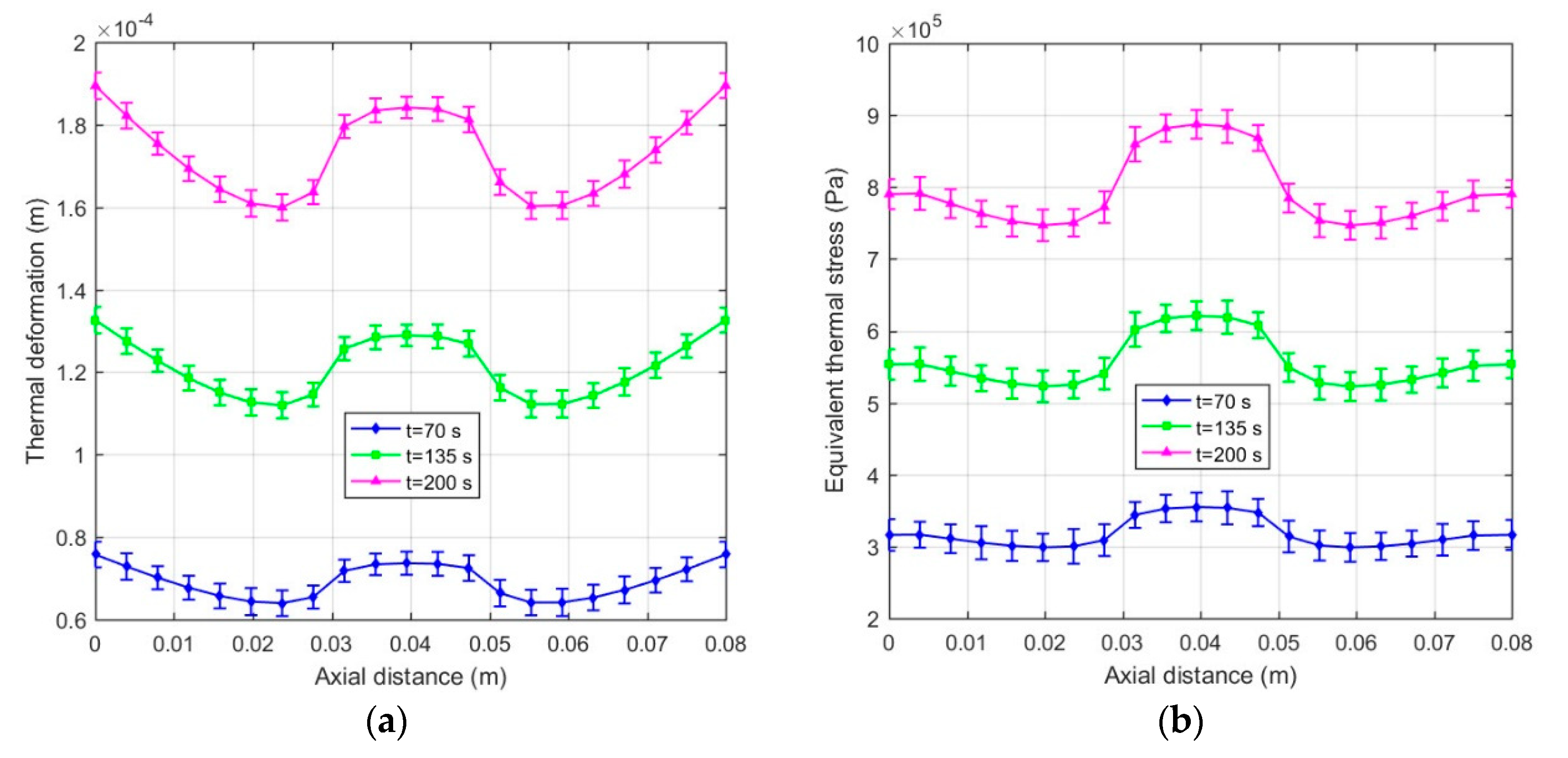

- The thermal deformation and equivalent thermal stress of MRFs are uneven along the working gaps, and their values that respectively reach 10−4 m and 105 Pa are all within the scope of the license under the conditions of the study. However, this undoubtedly has a certain influence on the micro-structure of MRFs. An increase in micro-structure detail can indicate the effect of the thermal deformation and equivalent thermal stress of MRFs on the worn surfaces of the friction disc and cylinder, if desired [16].

- All the above results of the disc-type MRC are slightly smaller than that of the cylinder-type MRC under the same conditions including the same input current of the excitation coil, the same rotational speed difference of the clutches, and the same volume of MRFs.

Author Contributions

Funding

Conflicts of Interest

References

- Ashour, O.; Rogers, C.A.; Kordonsky, W. Magnetorheological Fluids: Materials, Characterization, and Devices. J. Intell. Mater. Syst. Struct. 1996, 7, 123–130. [Google Scholar] [CrossRef]

- Huang, J.; Fu, L.J.; Zhong, L.R. Analysis of a Magnetorheological Transmission for Fan Clutch. Adv. Mater. Res. 2011, 287, 173–177. [Google Scholar] [CrossRef]

- Yao, G.Z.; Yeo, S.H.; Yap, F.F.; Li, W.H.; Chen, G. Testing and steady state modeling of a linear MR damper under sinusoidal loading. Smart Mater. Struct. 2000, 9, 95–102. [Google Scholar]

- Facey, W.B.; Rosenfeld, N.C.; Choi, Y.-T.; Wereley, N.M.; Choi, S.B.; Chen, P. DESIGN AND TESTING OF A COMPACT MAGNETORHEOLOGICAL DAMPER FOR HIGH IMPULSIVE LOADS. Int. J. Mod. Phys. B 2005, 19, 1549–1555. [Google Scholar] [CrossRef]

- Utami, D.; Sabino, U.; Mazlan, S.A.; Imaduddin, F.; Nordin, N.A.; Bahiuddin, I.; Aziz, S.A.; Mohamad, N.; Choi, S.-B. Material Characterization of a Magnetorheological Fluid Subjected to Long-Term Operation in Damper. Materials 2018, 11, 2195. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.; Zi, B.; Zeng, Y.; Hou, Y.; Meng, Q. Temperature-dependent material properties of the components of magnetorheological fluids. J. Mater. Sci. 2014, 49, 8459–8470. [Google Scholar] [CrossRef]

- Weiss, K.D.; Duclos, T.G. CONTROLLABLE FLUIDS: THE TEMPERATURE DEPENDENCE OF POST-YIELD PROPERTIES. Int. J. Mod. Phys. B 1994, 8, 3015–3032. [Google Scholar] [CrossRef]

- Kavlicoglu, B.M.; Gordaninejad, F.; Evrensel, C.A.; Fuchs, A.; Korol, G. A multiplate magnetorheological fluid limited slip differential clutch. Proc. SPIE-Int. Soc. Opt. Eng. 2003, 5054, 341–349. [Google Scholar]

- Kavlicoglu, B.M.; Gordaninejad, F.; Evrensel, C.A.; Liu, Y.M.; Kavlicoglu, N.; Fuchs, A. Heating of a high-torque magnetorheological fluid limited slip differential clutch. J. Intell. Mater. Syst. Struct. 2008, 19, 235–241. [Google Scholar] [CrossRef]

- Park, E.J.; Stoikov, D.; Da Luz, L.F.; Suleman, A. A performance evaluation of an automotive magnetorheological brake design with a sliding mode controller. Mechatronics 2006, 16, 405–416. [Google Scholar] [CrossRef]

- Karakoc, K.; Park, E.J.; Suleman, A. Design considerations for an automotive magnetorheological brake. Mechatronics 2008, 18, 434–447. [Google Scholar] [CrossRef]

- Wang, D.; Hou, Y. Design and experimental evaluation of a multidisk magnetorheological fluid actuator. J. Intell. Mater. Syst. Struct. 2013, 24, 640–650. [Google Scholar] [CrossRef]

- Wang, D.M.; Hou, Y.F.; Tian, Z.Z. A novel high-torque magnetorheological brake with a water cooling method for heat dissipation. Smart Mater. Struct. 2013, 22, 25019. [Google Scholar] [CrossRef]

- Wang, D.; Zi, B.; Zeng, Y.; Xie, F.; Hou, Y. An investigation of thermal characteristics of a liquid-cooled magnetorheological fluid-based clutch. Smart Mater. Struct. 2015, 24, 55020. [Google Scholar] [CrossRef]

- Wang, D.; Zeng, Y.; Zi, B.; Qian, S. Simulation and experiment on transient temperature field of a magnetorheological clutch for vehicle application. Smart Mater. Struct. 2017, 26, 095020. [Google Scholar] [CrossRef]

- Song, W.; Wang, S.; Choi, S.-B.; Wang, N.; Xiu, S. Thermal and tribological characteristics of a disc-type magnetorheological brake operated by the shear mode. J. Intell. Mater. Syst. Struct. 2018, 30, 722–733. [Google Scholar] [CrossRef]

- Wang, N.; Liu, X.; Królczyk, G.; Li, Z.; Li, W. Effect of temperature on the transmission characteristics of high-torque magnetorheological brakes. Smart Mater. Struct. 2019, 28, 057002. [Google Scholar] [CrossRef]

- Yang, J.; Chen, S.; Huang, J.; Zhang, B. Micro-analysis of slip differential heat of magnetorheological fluids based on micromechanics and microstructures. Mater. Res. Express 2019, 6, 065708. [Google Scholar] [CrossRef]

- Hossain, M.; Steinmann, P. Modelling electro-active polymers with a dispersion-type anisotropy. Smart Mater. Struct. 2018, 27, 025010. [Google Scholar] [CrossRef]

- Peng, X.; Li, H. Analysis of the magnetomechanical behavior of MRFs based on micromechanics incorporating a statistical approach. Smart Mater. Struct. 2007, 16, 2477–2485. [Google Scholar] [CrossRef]

- Fang, S.; Zhang, P. Simulation of the structure and the dynamics of the particles of MRFs in rotating magnetic fields. Chin. J. Chem. Phys. 2001, 14, 562–566. [Google Scholar]

- Li, H.; Peng, X. Dynamic analysis on ferromagnetic particles of magnetorheological fluids. J. Chongqing Univ. 2010, 33, 100–104. [Google Scholar]

- Wu, W. Fluid mechanics (Part 2), 13th ed.; Peking University Press: Beijing, China, 2004; pp. 265–266. [Google Scholar]

- Melle, S.; Calderon, O.G.; Fuller, G.G.; Rubio, M.A. Polarizable Particle Aggregation Under Rotating Magnetic Fields Using Scattering Dichroism. J. Colloid Interface Sci. 2002, 247, 200–209. [Google Scholar] [CrossRef]

- Ginder, J.M.; Davis, L.C. Shear stresses in magnetorheological fluids: Role of magnetic saturation. Appl. Phys. Lett. 1994, 65, 3410–3412. [Google Scholar] [CrossRef]

- Furst, E.M.; Gast, A.P. Micromenchanics of magnetor-heological suspensions. Phys. Rev. E. 2000, 61, 6732–6739. [Google Scholar] [CrossRef]

- Zhao, C.; Peng, X.; Huang, J.; Hu, N. An enhanced dipole model based micro-macro description for constitutive behavior of MRFs. Comput. Mater. Con. 2012, 30, 219–236. [Google Scholar]

- Choi, Y.T.; Cho, J.U.; Choi, S.B.; Wereley, N.M. Constitutive models of electrorheological and magnetorheological fluids using viscometers. Smart Mater. Struct. 2005, 14, 1025–1036. [Google Scholar] [CrossRef]

- 2D Magnetostatic Analysis ANSYS-Maxwell 16.0; ANSYS®, Inc.: Houston, TX, USA, 2015.

- Park, E.J.; Da Luz, L.F.; Suleman, A. Multidisciplinary design optimization of an automotive magnetorheological brake design. Comput. Struct. 2008, 86, 207–216. [Google Scholar] [CrossRef]

- Thermal Analysis Guide and Coupled-Field Analysis Guide ANSYS 16.0; ANSYS®, Inc.: Houston, TX, USA, 2015.

- Sun, Q.; Zhou, J.-X.; Zhang, L. An adaptive beam model and dynamic characteristics of magnetorheological materials. J. Sound Vib. 2003, 261, 465–481. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Shaft radius | 0.01 m |

| Drive rotor radius (disc-type MRC) | 0.06 m |

| Drive rotor radius (cylinder-type MRC) | 0.044 m |

| Drive rotor length (disc-type MRC) | 0.02 m |

| Drive rotor length (cylinder-type MRC) | 0.08 m |

| MRF gap thickness | 0.001 m |

| Number of coil turns | 200 |

| Component | Material |

|---|---|

| Drive shaft | Stainless steel (AISI 304) |

| Driven shaft | Stainless steel (AISI 304) |

| Drive rotor | Fine carbon steel (AISI 1020) |

| Driven rotor | Fine carbon steel (AISI 1020) |

| Working gap | MRFs (SG-MRF2035) |

| Isolation ring | Brass (UNS C27400) |

| Excitation coil | Copper |

| Parameter | Value |

|---|---|

| Permeability in free space μ0 | 4π × 10−7 A·m−1 |

| Friction coefficient μk | 0.15 |

| Initial susceptibility χ0 | 1000 |

| Saturation intensity of magnetization MS | 1.671 × 106 A·m−1 |

| Volume fraction of particles ψ | 20% |

| Maximum tilt angle θ0 | π/4 rad |

| Particle radius R | 5 × 10−6 m |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, S.; Yang, J. Probing Slip Differential Heat of Magnetorheological Fluids Subjected to Shear Mode Operation and Its Effect on the Structure. Materials 2019, 12, 1860. https://doi.org/10.3390/ma12111860

Chen S, Yang J. Probing Slip Differential Heat of Magnetorheological Fluids Subjected to Shear Mode Operation and Its Effect on the Structure. Materials. 2019; 12(11):1860. https://doi.org/10.3390/ma12111860

Chicago/Turabian StyleChen, Song, and Jing Yang. 2019. "Probing Slip Differential Heat of Magnetorheological Fluids Subjected to Shear Mode Operation and Its Effect on the Structure" Materials 12, no. 11: 1860. https://doi.org/10.3390/ma12111860

APA StyleChen, S., & Yang, J. (2019). Probing Slip Differential Heat of Magnetorheological Fluids Subjected to Shear Mode Operation and Its Effect on the Structure. Materials, 12(11), 1860. https://doi.org/10.3390/ma12111860