Fused Filament Fabrication of Small Ceramic Components

Abstract

1. Introduction

- molten feedstock viscosity should be low for low-force nozzle extrusion,

- high strength of feedstock at room temperature for good filament and printed object stability,

- complete debinding and sintering of the parts without deformation,

- solid loads between 45 and 60 vol % for high densities and warpage-free shape after sintering,

- particle sizes of a maximum of 10% of the aspired structural details,

- complete binder wetting of the particles for best deagglomeration.

2. Materials and Sample Preparation

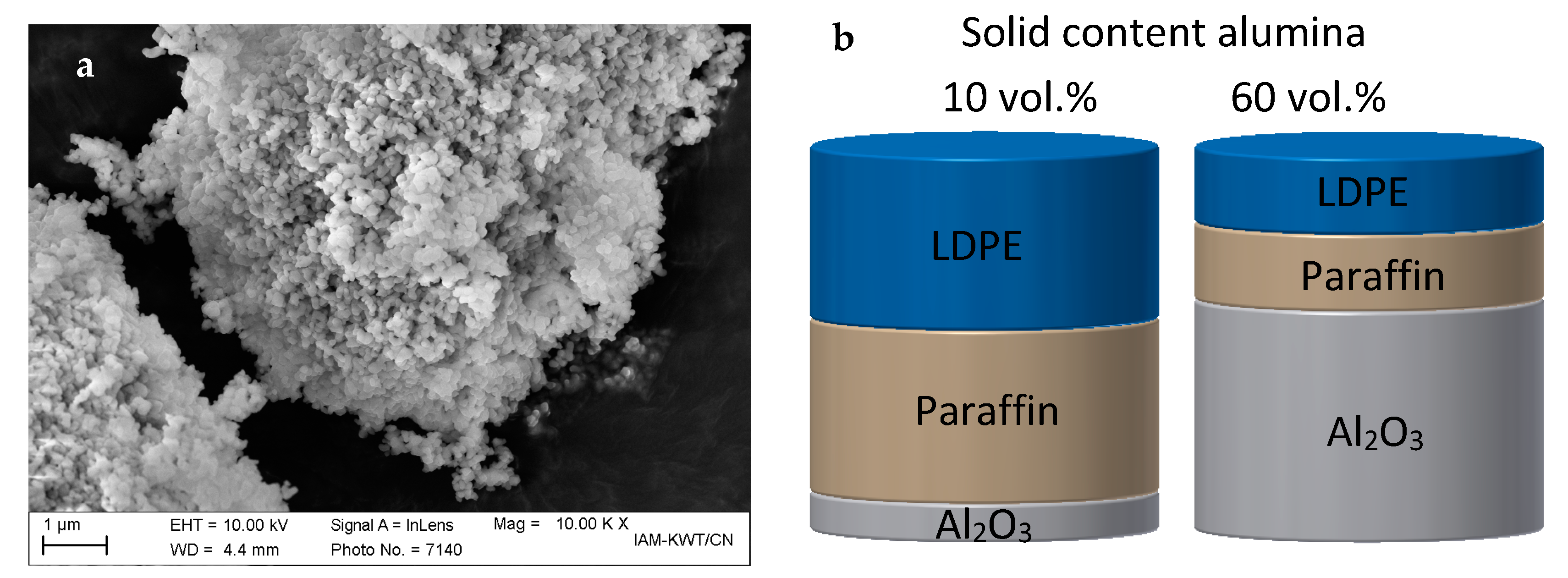

2.1. Materials

2.2. Compounding

2.3. Preparing Filaments

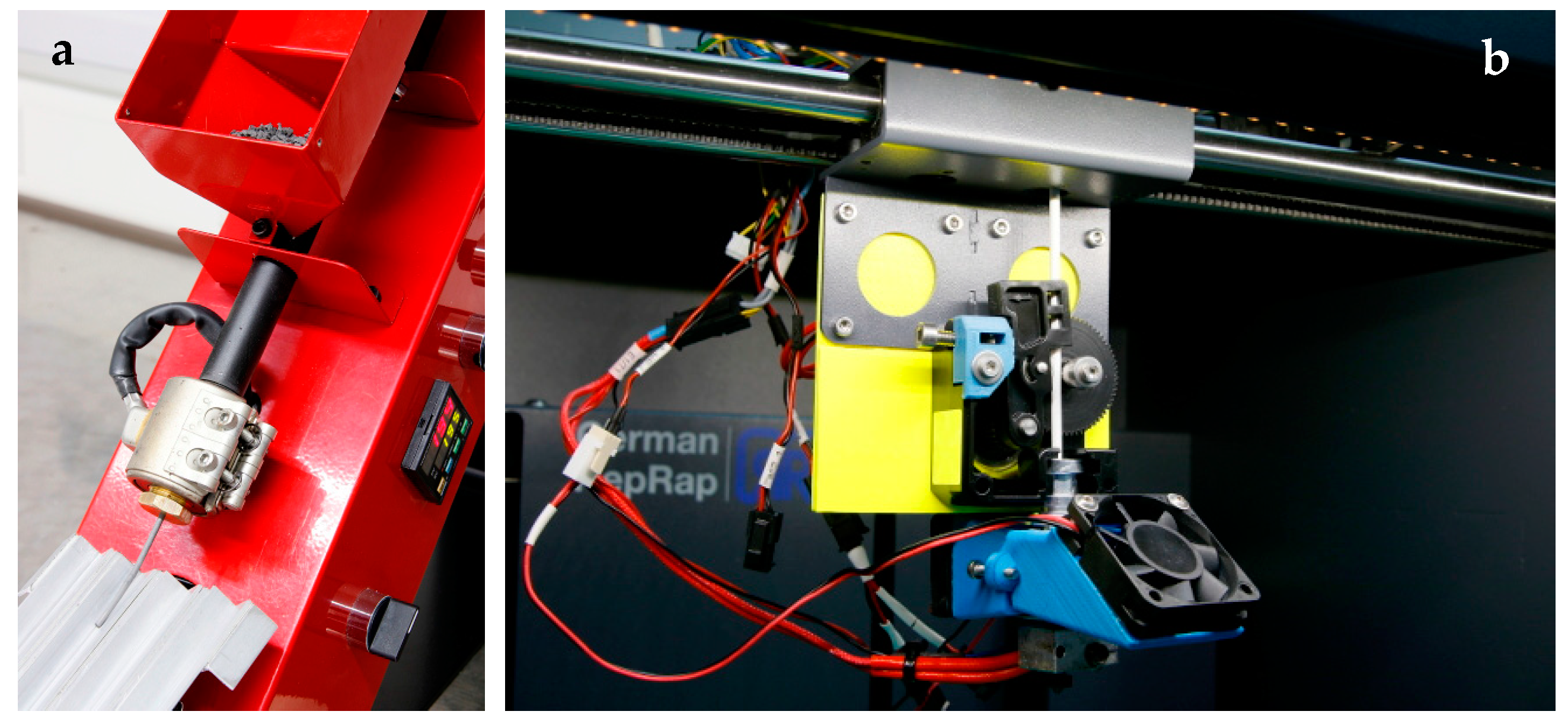

2.4. Printing via Fused Filament Fabrication

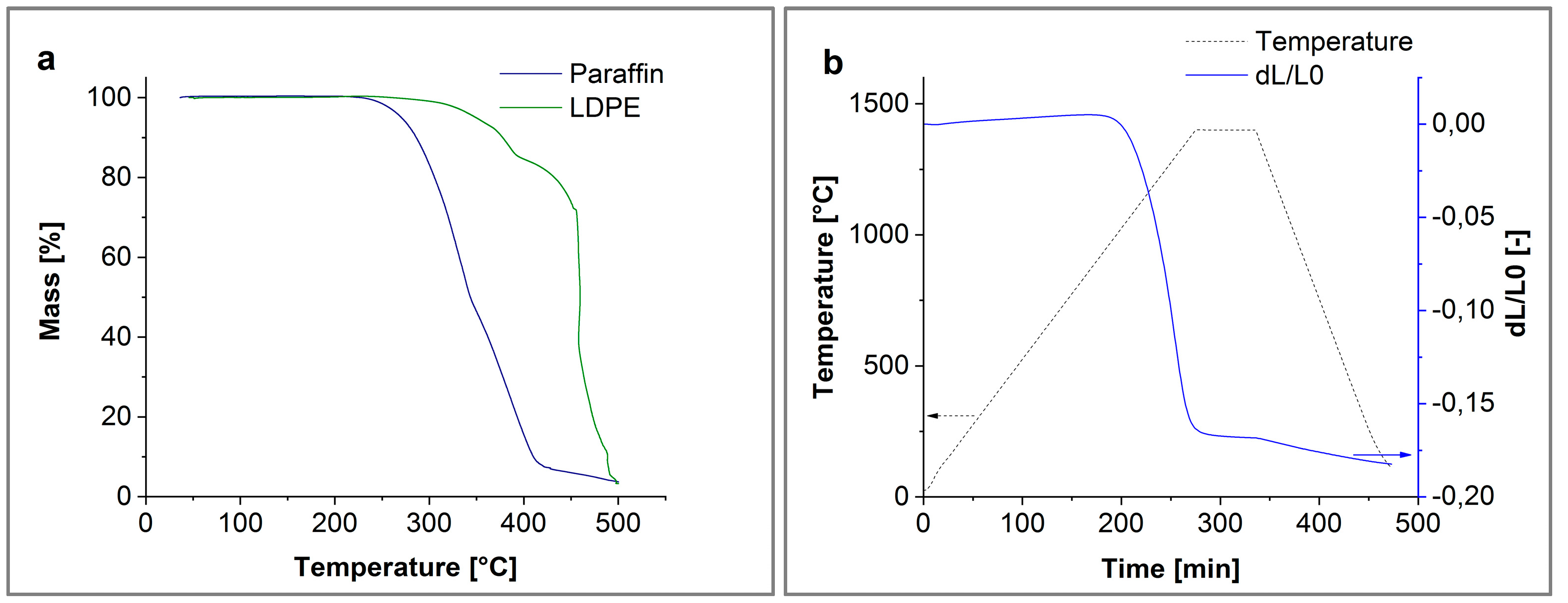

2.5. Post-Processing

3. Results and Discussion

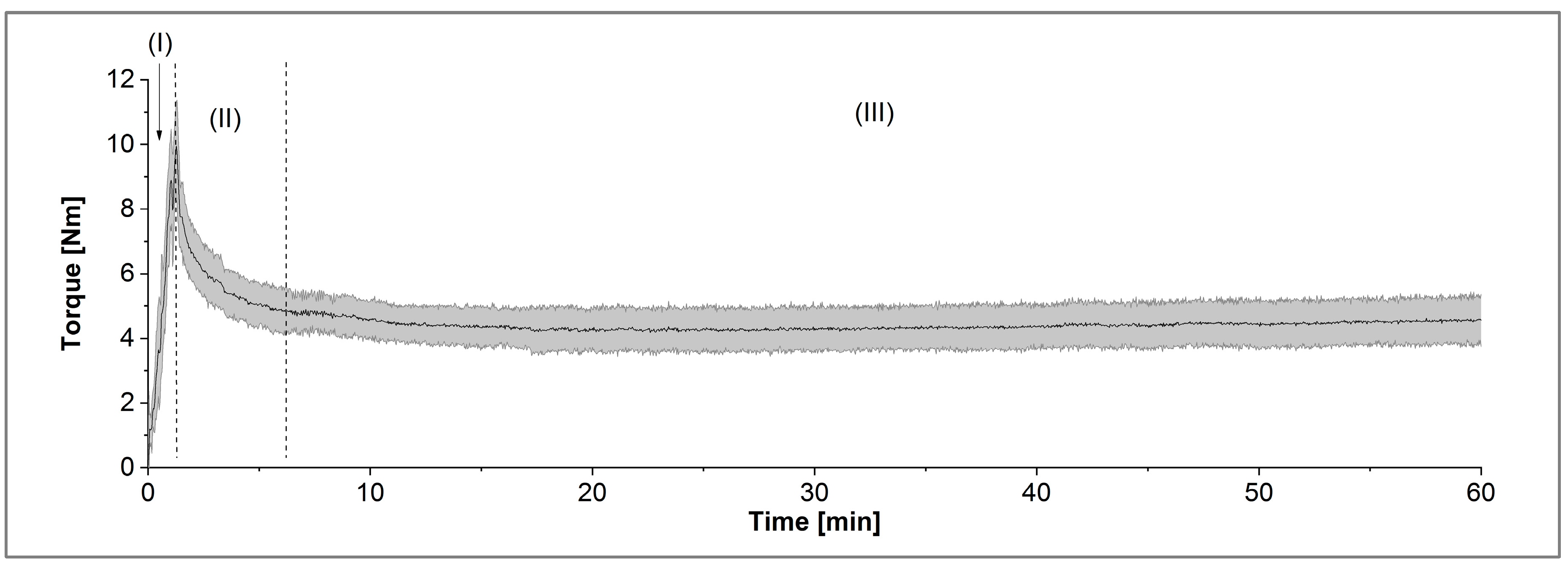

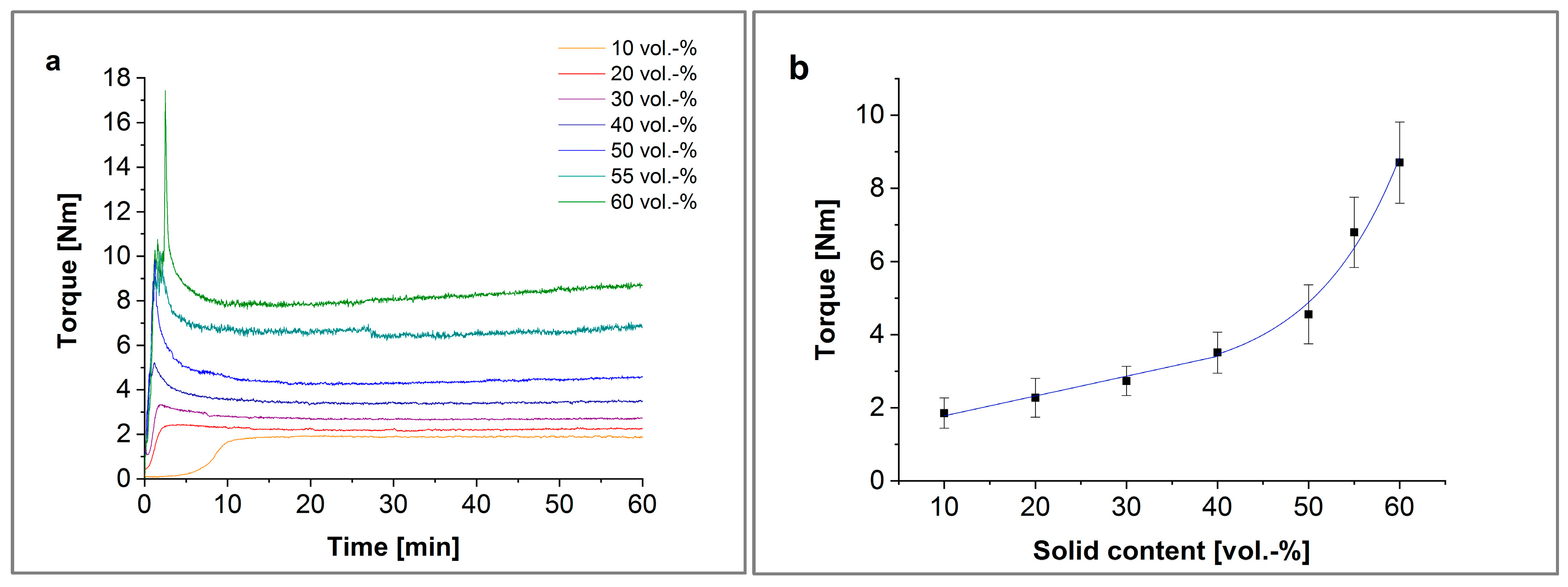

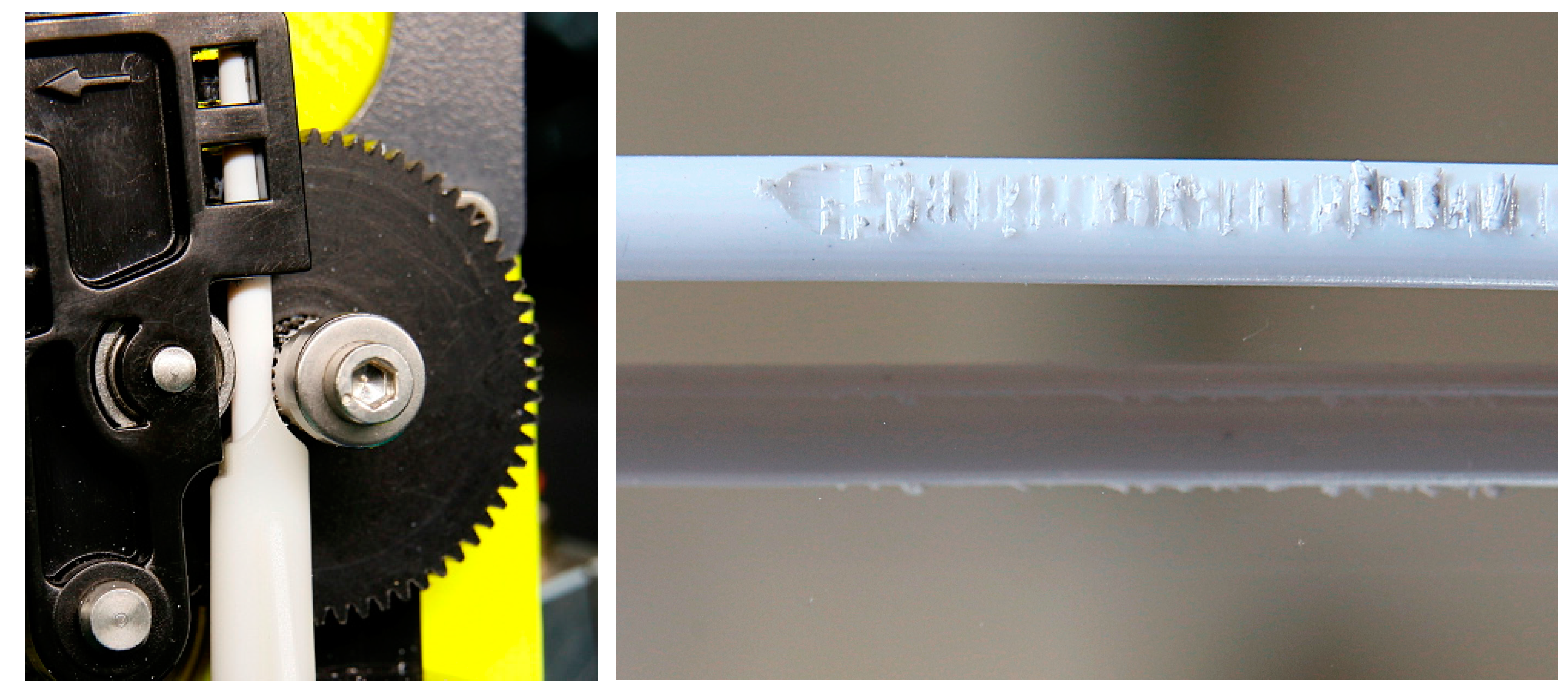

3.1. Compounding and Rheological Investigation

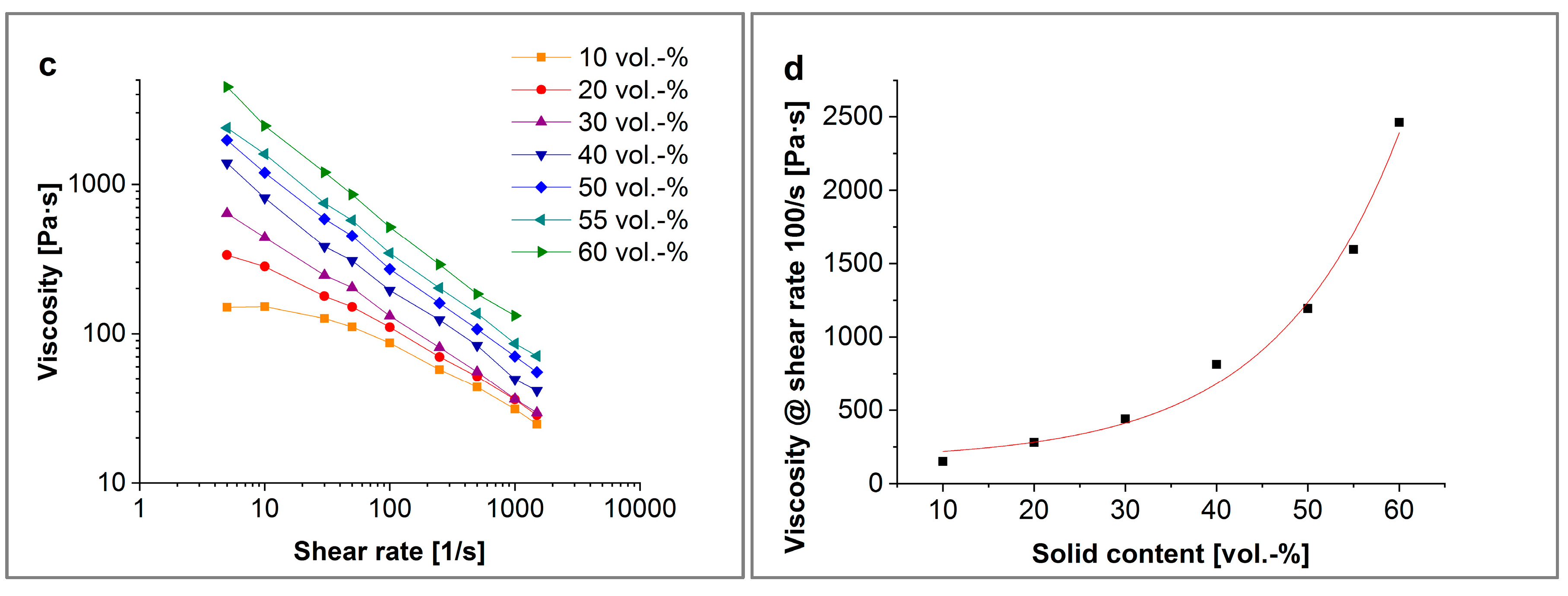

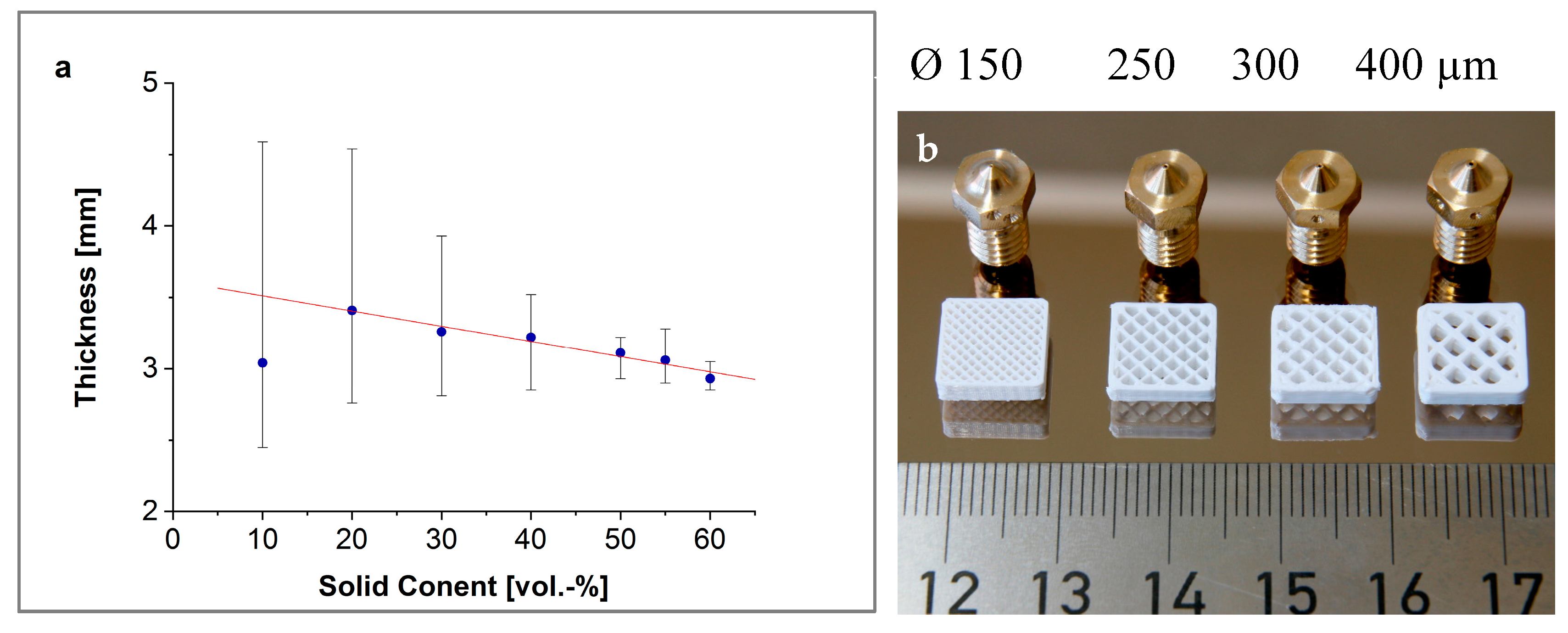

3.2. Filament Preparation

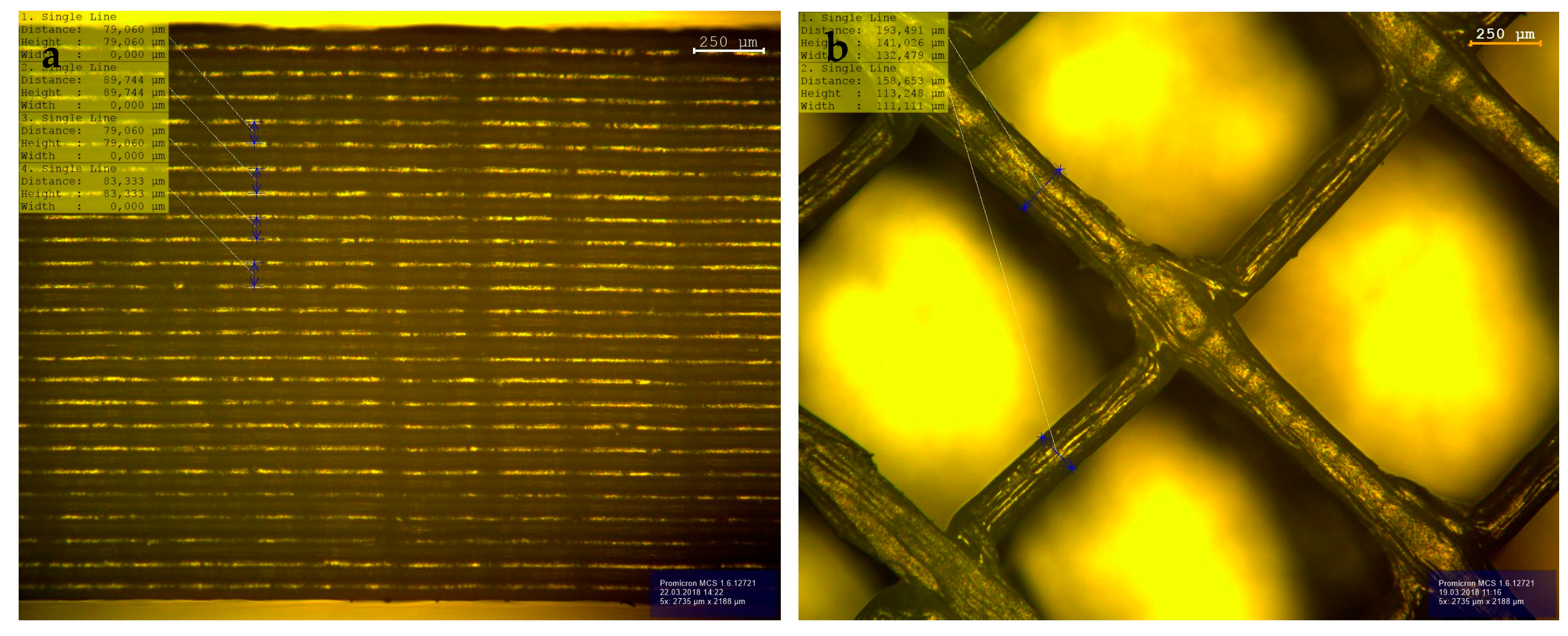

3.3. Printing

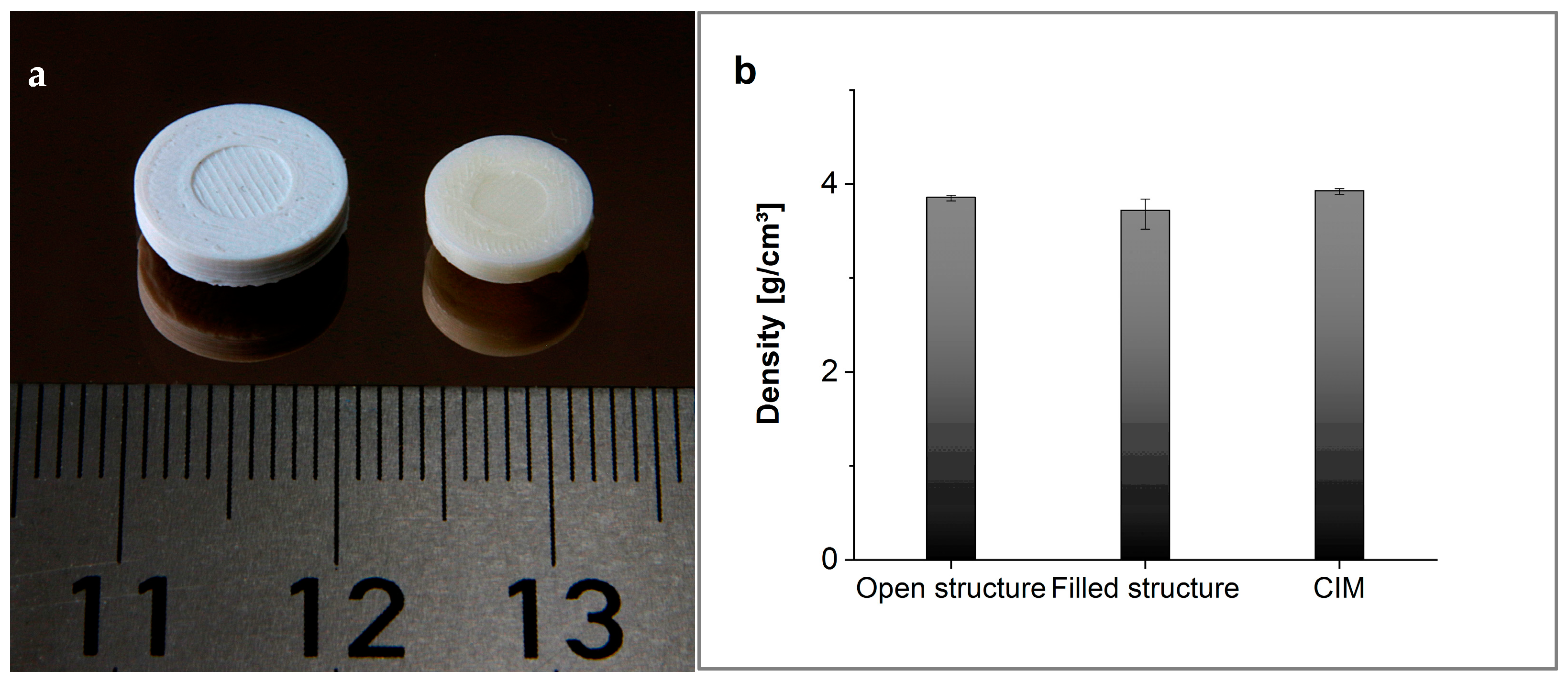

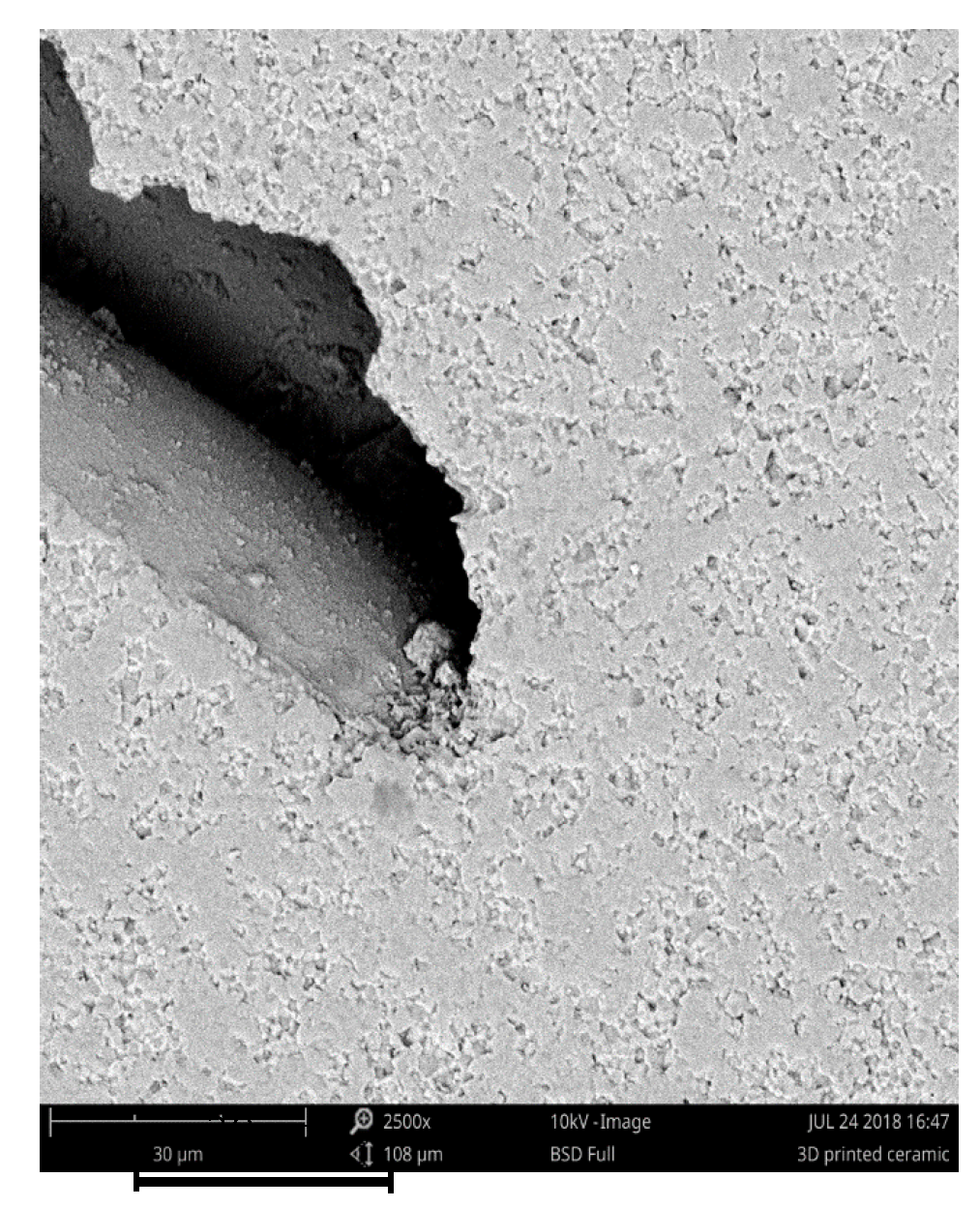

3.4. Post-Processed Samples

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Piotter, V.; Hanemann, T.; Heldele, R.; Mueller, M.; Mueller, T.; Plewa, K.; Ruh, A. Metal and ceramic parts fabricated by microminiature powder injection molding. Int. J. Powder Metall. 2010, 46, 21–28. [Google Scholar]

- Yunn, H.S.; Muhamad, N.; Sulong, A.B. Micro Powder Injection Molding (µPIM): Review. Appl. Mech. Mater. 2011, 52–54, 91–96. [Google Scholar] [CrossRef]

- Garino, T.J.; Morales, A.M.; Boyce, B.L. The mechanical properties, dimensional tolerance and microstructural characterization of micro-molded ceramic and metal components. Microsyst. Technol. 2004, 10, 506–509. [Google Scholar] [CrossRef]

- León-Cabezas, M.A.; Martínez-García, A.; Varela-Gandía, F.J. Innovative advances in additive manufactured moulds for short plastic injection series. Procedia Manuf. 2017, 13, 732–737. [Google Scholar] [CrossRef]

- Kovács, J.G.; Szabó, F.; Kovács, N.K.; Suplicz, A.; Zink, B.; Tábi, T.; Hargitai, H. Thermal simulations and measurements for rapid tool inserts in injection molding applications. Appl. Therm. Eng. 2015, 85, 44–51. [Google Scholar] [CrossRef]

- Kriesi, C.; Bjelland, Ø.; Steinert, M. Fast and iterative prototyping for injection molding—A case study of rapidly prototyping. Procedia Manuf. 2018, 21, 205–212. [Google Scholar] [CrossRef]

- Dizon, J.R.C.; Espera, A.H., Jr.; Chen, Q.; Advincula, R.C. Mechanical characterization of 3D-printed polymers. Addit. Manuf. 2018, 20, 44–67. [Google Scholar] [CrossRef]

- Balletti, C.; Ballarin, M.; Guerra, F. 3D printing: State of the art and future perspectives. J. Cult. Herit. 2017, 26, 172–182. [Google Scholar] [CrossRef]

- Kim, S.Y.; Shin, Y.S.; Jung, H.D.; Hwang, C.J.; Baik, H.S.; Cha, J.Y. Precision and trueness of dental models manufactured with different 3-dimensional printing techniques. Am. J. Orthod. Dentofac. Orthop. 2018, 153, 144–153. [Google Scholar] [CrossRef] [PubMed]

- Travitzky, N.; Bonet, A.; Dermeik, B.; Fey, T.; Filbert-Demut, I.; Schlier, L.; Schlordt, T.; Greil, P. Additive Manufacturing of Ceramic-Based Materials. Adv. Eng. Mater. 2014, 16, 729–754. [Google Scholar] [CrossRef]

- Tay, B.Y.; Evans, J.R.G.; Edirsinghe, M.J. Solid freeform fabrication of ceramics. Int. Mater. Rev. 2003, 48, 341–370. [Google Scholar] [CrossRef]

- Gonzalez-Gutierrez, J.; Cano, S.; Schuschnigg, S.; Kukla, C.; Sapkota, J.; Holzer, C. Additive Manufacturing of Metallic and Ceramic Components by the Material Extrusion of Highly-Filled Polymers: A Review and Future Perspectives. Materials 2018, 11, 840. [Google Scholar] [CrossRef] [PubMed]

- Masood, S.H.; Song, W.Q. Development of new metal/polymer materials for rapid tooling using Fused deposition modelling. Mater. Des. 2004, 25, 587–594. [Google Scholar] [CrossRef]

- Khatri, B.; Lappe, K.; Noetzel, D.; Pursche, K.; Hanemann, T. A 3D-Printable Polymer-Metal Soft-Magnetic Functional Composite—Development and Characterization. Materials 2018, 11, 189. [Google Scholar] [CrossRef] [PubMed]

- Hwang, S.; Reyes, E.I.; Moon, K.S.; Rumpf, R.C.; Kim, N.S. Thermo-mechanical Characterization of Metal/Polymer Composite Filaments and Printing Parameter Study for Fused Deposition Modeling in the 3D Printing Process. J. Electron. Mater. 2015, 44, 771–777. [Google Scholar] [CrossRef]

- Gnanasekaran, K.; Heijmans, T.; van Bennekom, S.; Woldhuis, H.; Wijnia, S.; de With, G.; Friedrich, H. 3D printing of CNT- and graphene-based conductive polymer nanocomposites by fused deposition modeling. Appl. Mater. Today 2017, 9, 21–28. [Google Scholar] [CrossRef]

- Kariz, M.; Sernek, M.; Obućina, M.; Kuzman, M.K. Effect of wood content in FDM filament on properties of 3D printed parts. Mater. Today Commun. 2018, 14, 135–140. [Google Scholar] [CrossRef]

- Brenken, B.; Barocio, E.; Favaloro, A.; Kunc, V.; Pipes, R.B. Fused filament fabrication of fiber-reinforced polymers: A review. Addit. Manuf. 2018, 21, 1–16. [Google Scholar] [CrossRef]

- Weng, Z.; Wang, J.; Senthil, T.; Wu, L. Mechanical and thermal properties of ABS/montmorillonite nanocomposites for fused deposition modeling 3D printing. Mater. Des. 2016, 102, 276–283. [Google Scholar] [CrossRef]

- Singh, R.; Bedi, P.; Fraternali, F.; Ahuja, I.P.S. Effect of single particle size, double particle size and triple particle size Al2O3 in Nylon-6 matrix on mechanical properties of feed stock filament for FDM. Compos. Part B Eng. 2016, 106, 20–27. [Google Scholar] [CrossRef]

- Kalita, S.J.; Bose, S.; Hosick, H.L.; Bandyopadhyay, A. Development of controlled porosity polymer-ceramic composite scaffolds via fused deposition modeling. Mater. Sci. Eng. C 2003, 26, 611–620. [Google Scholar] [CrossRef]

- Vaidyanathan, R.; Walish, J.; Lombardi, J.L.; Kasichainula, S.; Calvert, P.; Cooper, K.C. The Extrusion Freeforming of Functional Ceramic Prototypes. JOM 2000, 52, 34–37. [Google Scholar] [CrossRef]

- Agarwala, M.K.; Bandyopadhyay, A.; van Weeren, R.; Langrana, N.A.; Safari, A.; Danforth, S.C. Fused deposition of Ceramics (FDC) for Structural Silicon Nitride Components. In Proceedings of the Solid Freeform Fabrication Symposium; Marcus, H.L., Beaman, J.J., Barlow, J.W., Bourell, D.L., Crawford, R.H., Eds.; The University of Texas at Austin: Austin, TX, USA, 1990–1996; pp. 335–344.

- Iyer, S.; McIntosh, J.; Bandyopadhyay, A.; Langrana, N.; Safari, A.; Danforth, S.C.; Clancy, R.B.; Gasdaska, C.; Whalen, P.J. Microstructural Characterization and Mechanical Properties of Si3N4 Formed by Fused Deposition of Ceramics. Int. J. Appl. Ceram. Technol. 2008, 5, 127–137. [Google Scholar] [CrossRef]

- Abel, J.; Scheithauer, U.; Klemm, H.; Moritz, T.; Mechaelis, A.; Schmidt, T. Fused Filament Fabrication (FFF) of Technical Ceramics. Ceram. App. 2018, 6, 36–38. [Google Scholar]

- Liu, Z.Y.; Loh, N.H.; Tor, S.B.; Khor, K.A.; Murakoshi, Y.; Maeda, R. Binder system for micropowder injection molding. Mater. Lett. 2001, 48, 31–38. [Google Scholar] [CrossRef]

- Salea, A.; Prathumwan, R.; Junpha, J.; Subannajui, K. Metal oxide semiconductor 3D printing: Preparation of Copper(II) oxide by fused deposition modelling for multi-functional semiconducting applications. J. Mater. Chem. C 2017, 5, 4614–4620. [Google Scholar] [CrossRef]

- Hajek, K. Ceramic Injection Moulding: Binder innovations an Additive Manufacturing open up new opportunities. PIM Int. 2018, 12, 67–71. [Google Scholar]

- Hanemann, T.; Heldele, R.; Mueller, T.; Hausselt, J. Influence of Stearic Acid Concentration on the Processing of ZrO2-Containing Feedstocks Suitable for Micropowder Injection Molding. Int. J. Appl. Ceram. Technol. 2011, 8, 865–872. [Google Scholar] [CrossRef]

- Hanemann, T.; Heldele, R.; Honnef, K.; Rath, S.; Schumacher, B.; Haußelt, J. Properties and Application of Polymer-Nanoparticle-Composites. cfi/Ber. DKG 2007, 84, 49–54. [Google Scholar]

- Qiu, D.; Langrana, N.A. Void eliminating toolpath for extrusion-based multi-material layered manufacturing. Rapid Prototyp. J. 2002, 8, 38–45. [Google Scholar] [CrossRef]

| Solid Content [vol %] | Average Diameter [mm] | Standard Deviation [mm] |

|---|---|---|

| 10 | 3.04 | 0.57 |

| 20 | 3.41 | 0.42 |

| 30 | 3.26 | 0.26 |

| 40 | 3.22 | 0.13 |

| 50 | 3.11 | 0.07 |

| 55 | 3.06 | 0.07 |

| 60 | 2.93 | 0.03 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nötzel, D.; Eickhoff, R.; Hanemann, T. Fused Filament Fabrication of Small Ceramic Components. Materials 2018, 11, 1463. https://doi.org/10.3390/ma11081463

Nötzel D, Eickhoff R, Hanemann T. Fused Filament Fabrication of Small Ceramic Components. Materials. 2018; 11(8):1463. https://doi.org/10.3390/ma11081463

Chicago/Turabian StyleNötzel, Dorit, Ralf Eickhoff, and Thomas Hanemann. 2018. "Fused Filament Fabrication of Small Ceramic Components" Materials 11, no. 8: 1463. https://doi.org/10.3390/ma11081463

APA StyleNötzel, D., Eickhoff, R., & Hanemann, T. (2018). Fused Filament Fabrication of Small Ceramic Components. Materials, 11(8), 1463. https://doi.org/10.3390/ma11081463