Analysis of Favorable Process Conditions for the Manufacturing of Thin-Wall Pieces of Mild Steel Obtained by Wire and Arc Additive Manufacturing (WAAM)

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials for WAAM process

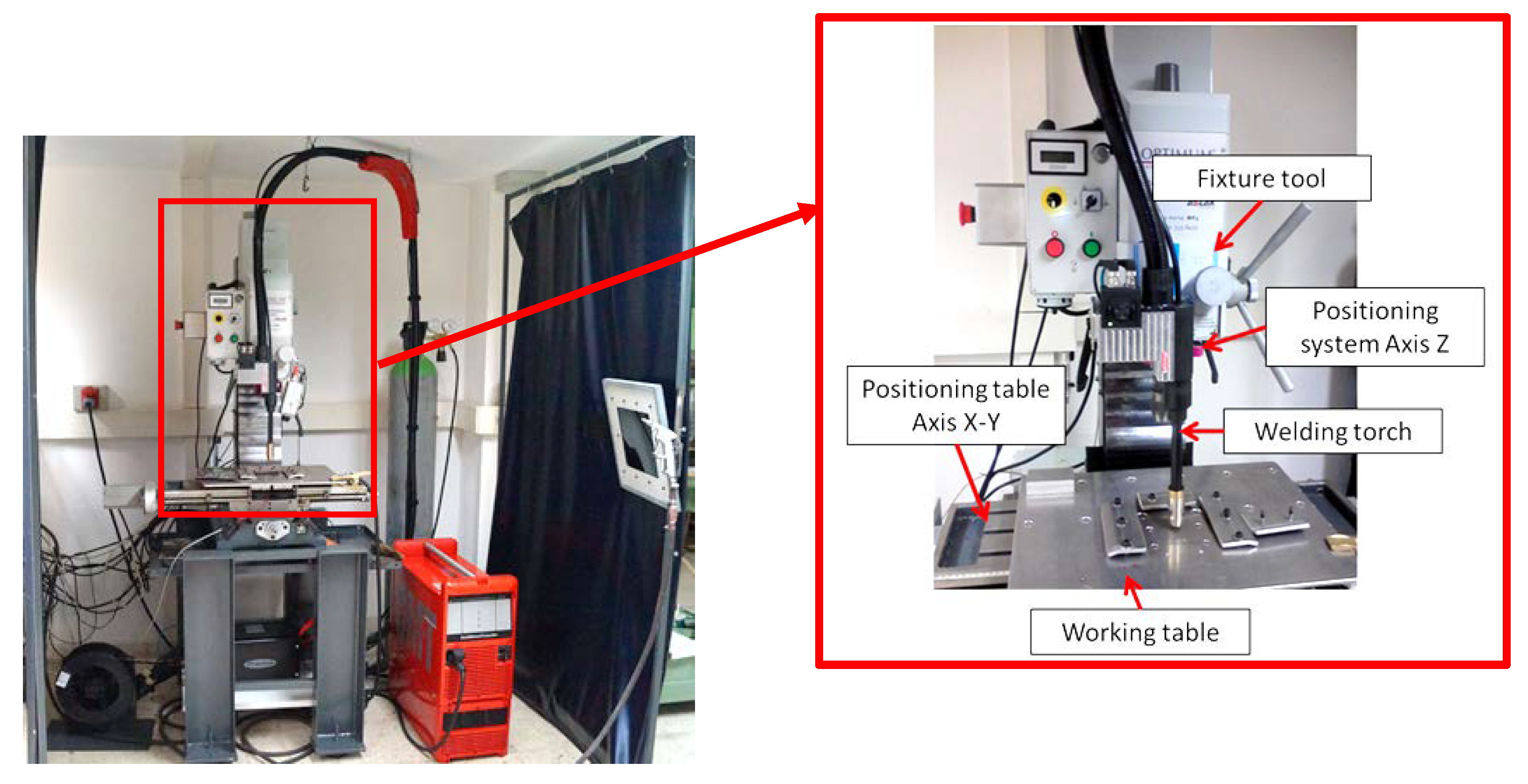

2.2. WAAM Equipment

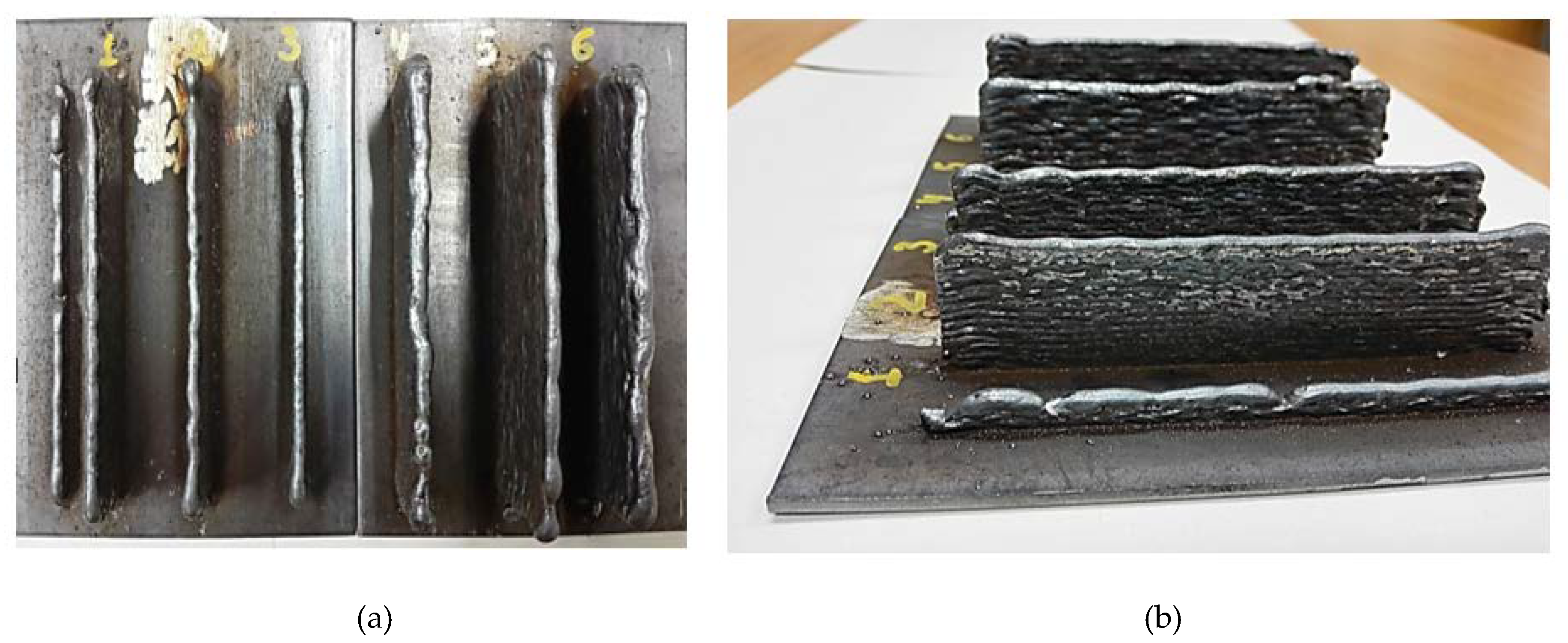

2.3. Fabrication of Samples by WAAM

- WAAM process:

- ◦

- Metal inert gas (MIG)

- ◦

- CMT

- ◦

- CMT Advanced polarity −5 (CMT Adv. pol. −5)

- ◦

- CMT Advanced polarity 0 (CMT Adv. pol. 0)

- ◦

- CMT Advanced polarity (CMT Adv. pol. +5)

- ◦

- CMT continuous trajectory (CMT Cont.)

- Welding speed (constant = 400 mm/min)

- Deposition speed (constant = 2.5 m/min)

- Arc voltage (constant = 9.2 V)

- Current intensity (50 A, 66 A, 70 A, 78 A)

- Layer step (1.0 mm, 1.5 mm)

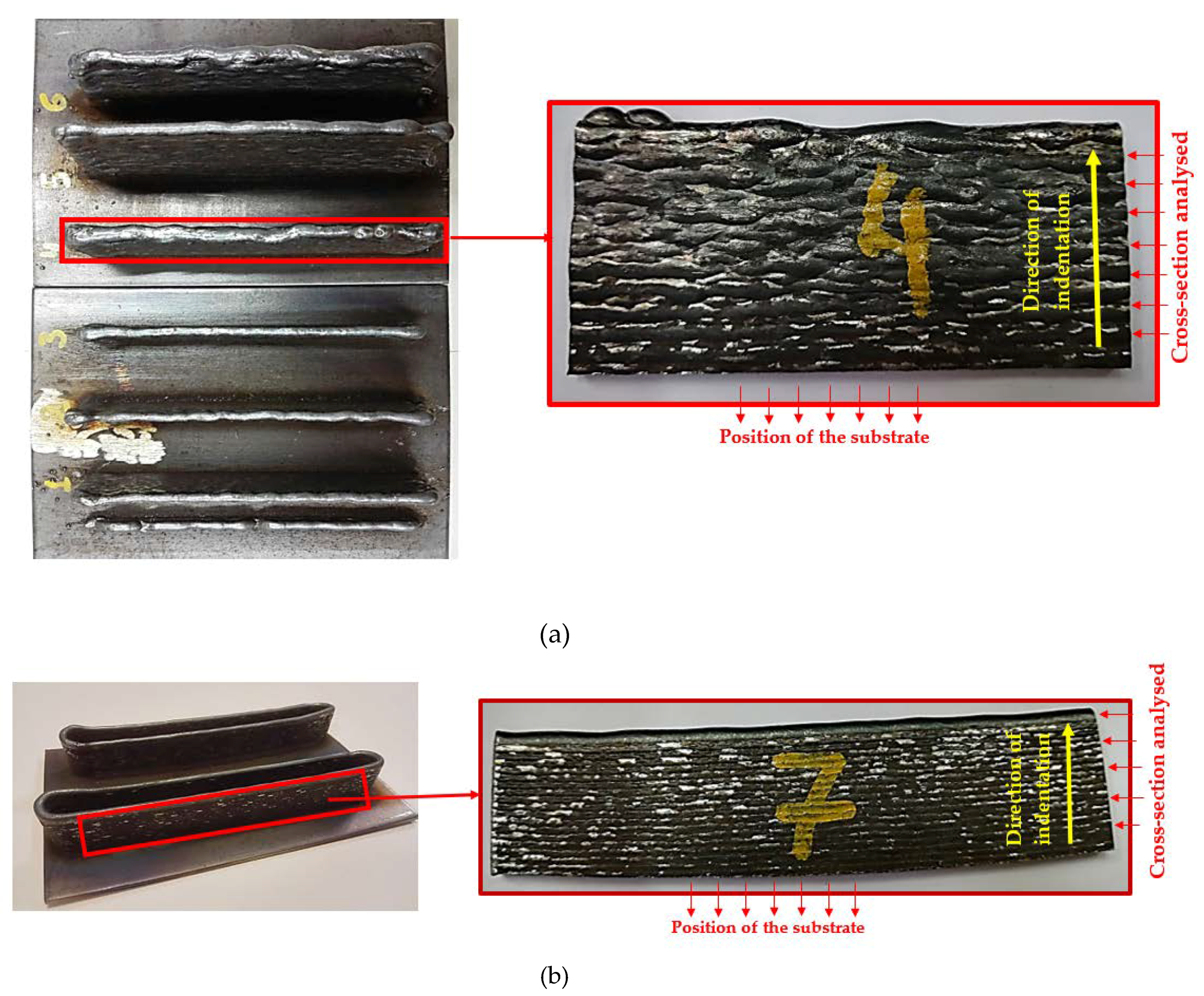

2.4. Brinell Hardness Tests

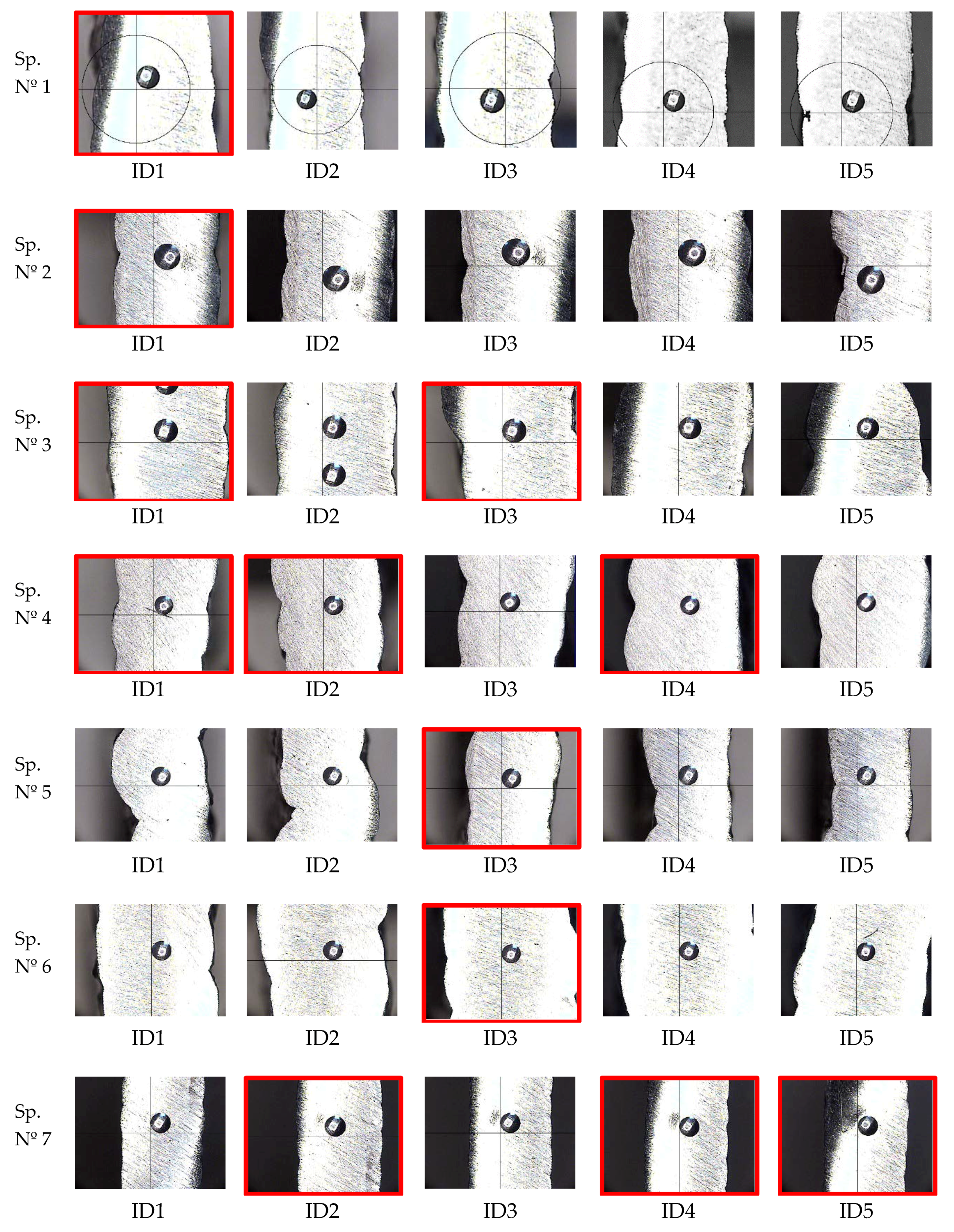

Brinell Hardness Tests and Measurement of the Ball Prints

2.5. Determination of Mechanical Strength

2.6. Equipment and Measurement of Microstructure

3. Results

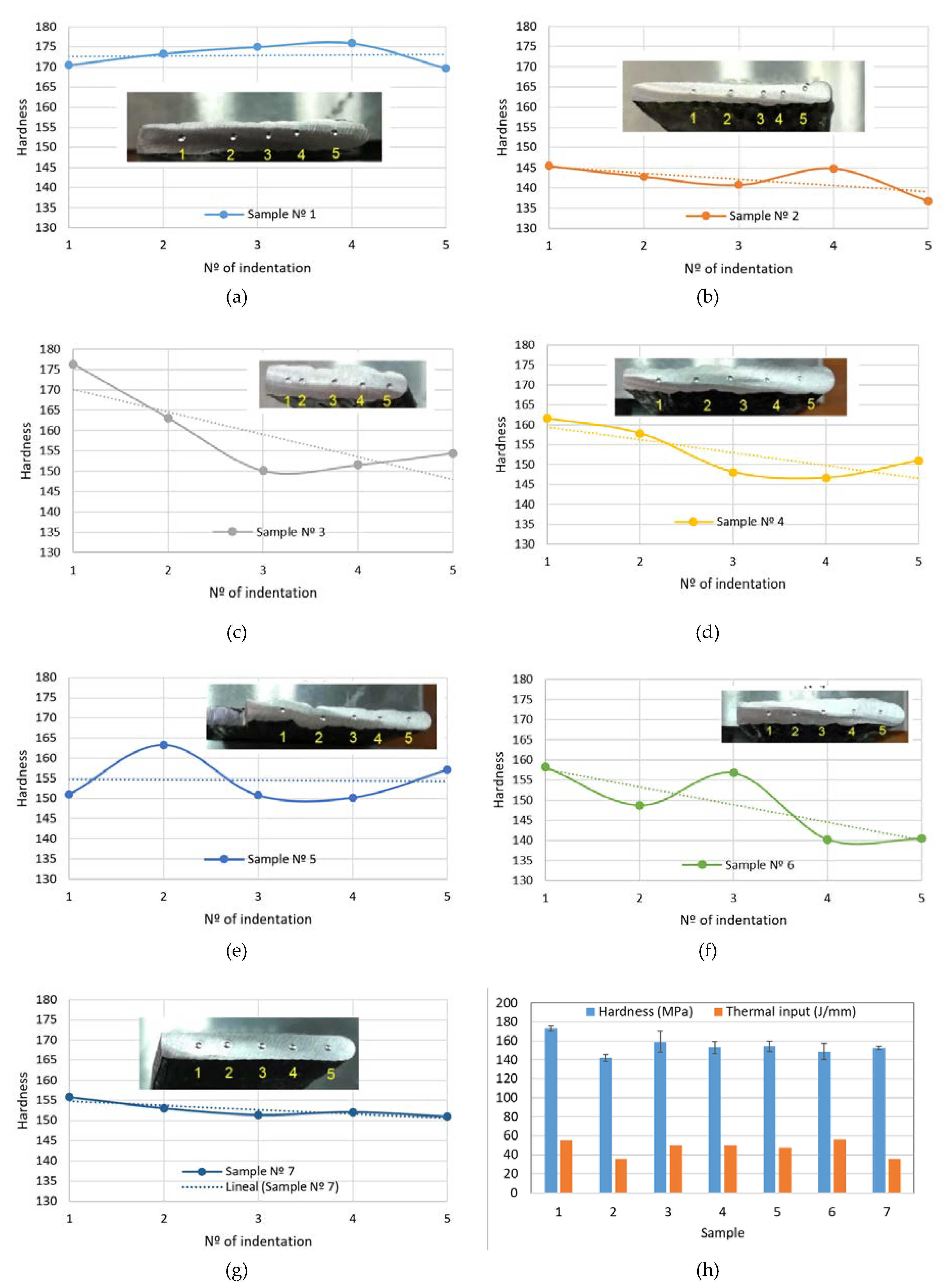

3.1. Evaluation of Hardness Profiles

3.2. Evaluation of Mechanical Strength

3.3. Microstructure Findings

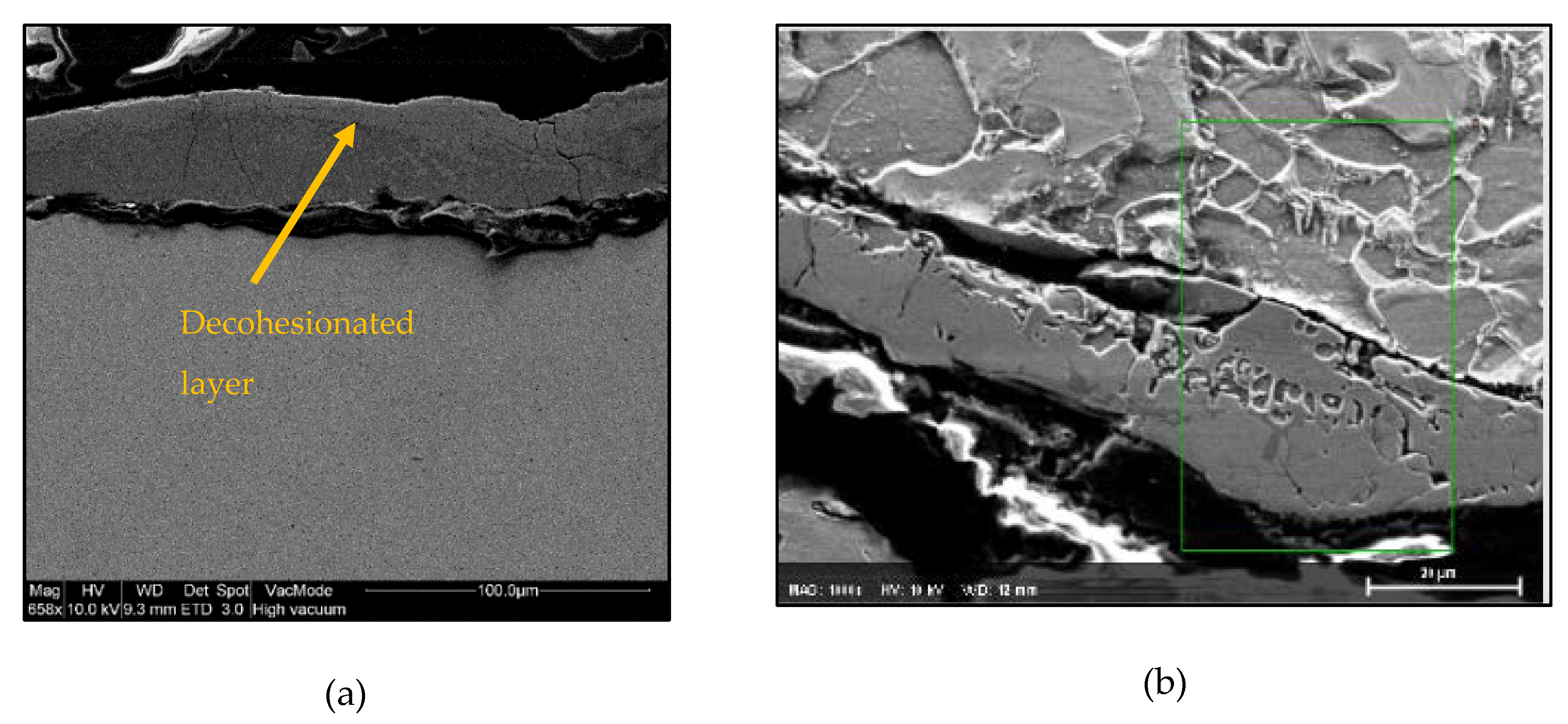

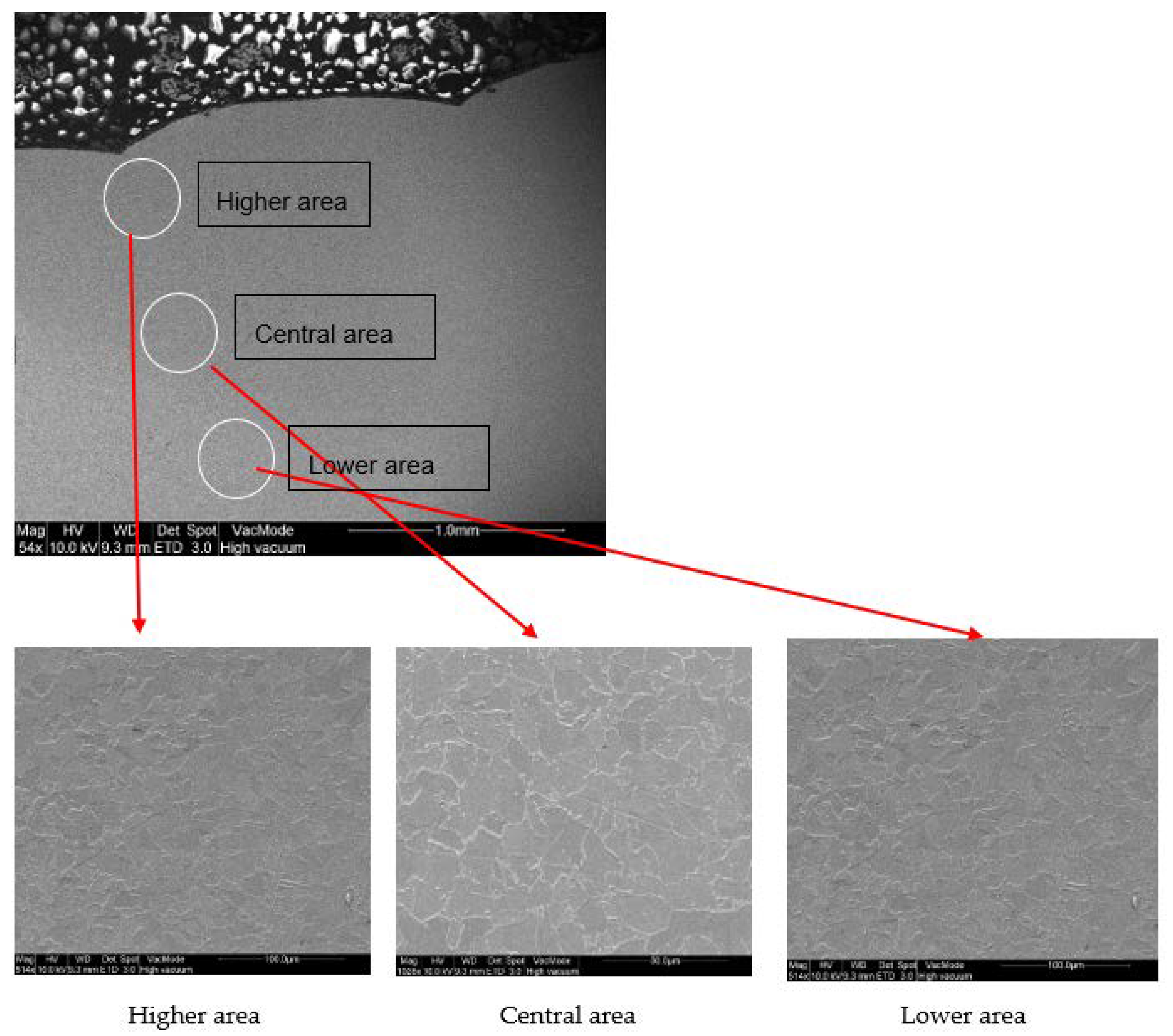

4. Discussion

5. Conclusions and Future Work

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

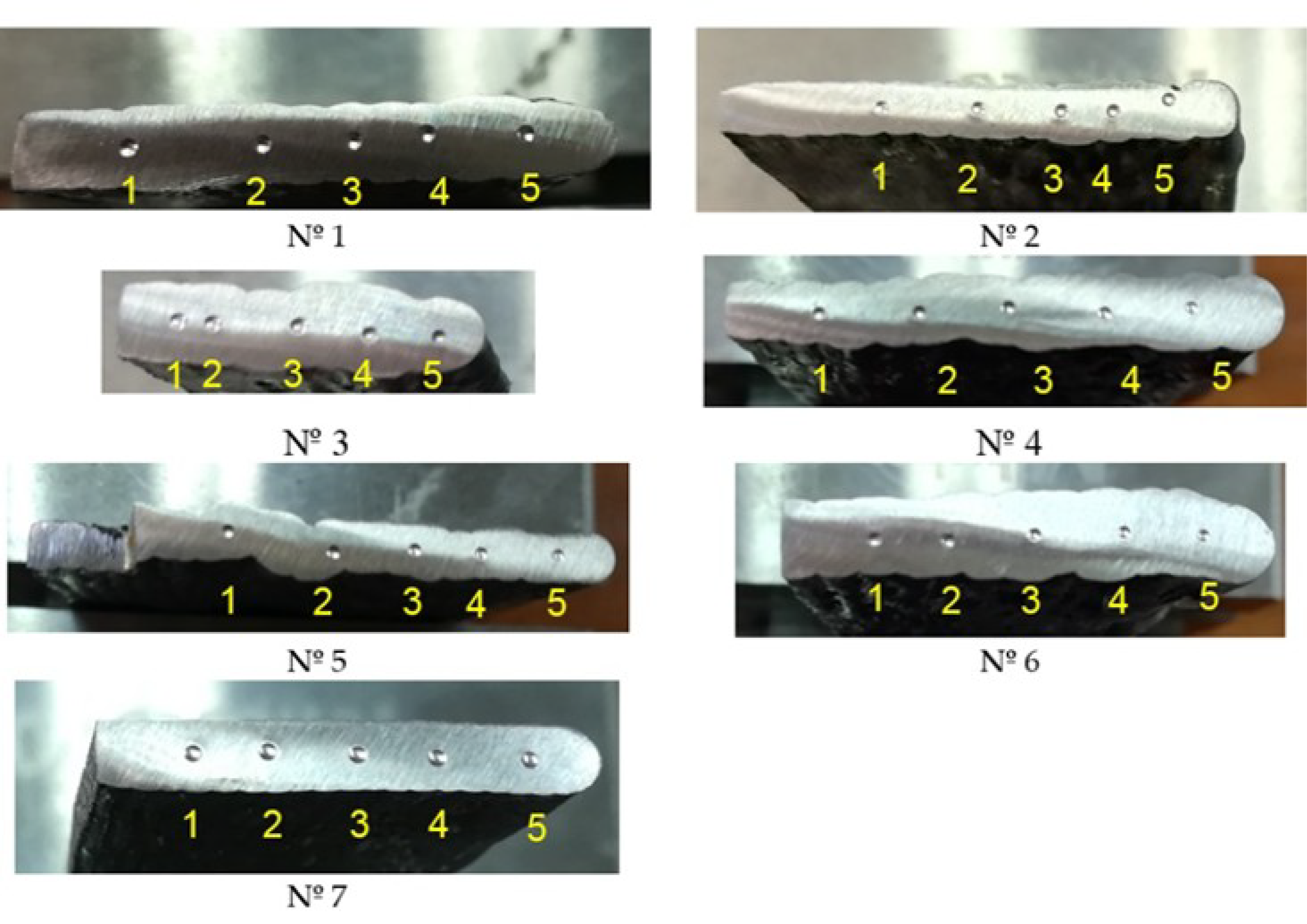

Appendix A. Position of the Indentations

Appendix B. Scanning Electronic Microscopy (SEM) to Detect Decohesionated Layer in the Upper Edge of the Surface

References

- Singh, S.; Ramakrishna, S.; Singh, R. Material issues in additive manufacturing: A review. J. Manuf. Process. 2017, 25, 185–200. [Google Scholar] [CrossRef]

- Bourell, D.; Kruth, J.P.; Leu, M.; Levy, G.; Rosen, D.; Beese, A.M.; Clare, A. Materials for additive manufacturing. CIRP Ann. 2017, 66, 659–681. [Google Scholar] [CrossRef]

- Frazier, W.E. Metal additive manufacturing: A review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Xu, X.F.; Ganguly, S.; Ding, J.L.; Guo, S.; Williams, S.; Martina, F. Microstructural evolution and mechanical properties of maraging steel produced by wire + arc additive manufacture process. Mater. Charact. 2017, in press. [Google Scholar]

- Ge, J.G.; Lin, J.; Lei, Y.P.; Fu, H.G. Location-related thermal history, microstructure, and mechanical properties of arc additively manufactured 2Cr13 steel using cold metal transfer welding. Mater. Sci. Eng. A 2018, 715, 144–153. [Google Scholar] [CrossRef]

- Hu, Z.Q.; Qin, X.P.; Shao, T. Welding thermal simulation and metallurgical characteristics analysis in waam for 5crnimo hot forging die remanufacturing. Procedia Eng. 2017, 207, 2203–2208. [Google Scholar] [CrossRef]

- Artaza, T.; Alberdi, A.; Murua, M.; Gorrotxategi, J.; Frías, J.; Puertas, G.; Melchor, M.A.; Mugica, D.; Suárez, A. Design and integration of WAAM technology and in situ monitoring system in a gantry machine. Procedia Manuf. 2017, 13, 778–785. [Google Scholar] [CrossRef]

- Luo, Y.; Li, J.L.; Xu, J.; Zhu, L.; Han, J.T.; Zhang, C.Y. Influence of pulsed arc on the metal droplet deposited by projected transfer mode in wire-arc additive manufacturing. J. Mater. Process. Technol. 2018, 259, 353–360. [Google Scholar] [CrossRef]

- Wu, B.T.; Pan, Z.X.; Li, S.Y.; Cuiuri, D.; Ding, D.H.; Li, H.J. The anisotropic corrosion behaviour of wire arc additive manufactured Ti-6Al-4V alloy in 3.5% NaCl solution. Corros. Sci. 2018, 137, 176–183. [Google Scholar] [CrossRef]

- Shi, X.Z.; Ma, S.Y.; Liu, C.M.; Wu, Q.R.; Lu, J.P.; Liu, Y.D.; Shi, W.T. Selective laser melting-wire arc additive manufacturing hybrid fabrication of Ti-6Al-4V alloy: Microstructure and mechanical properties. Mater. Sci. Eng. A 2017, 684, 196–204. [Google Scholar] [CrossRef]

- Cunningham, C.R.; Wikshåland, S.; Xu, F.; Kemakolam, N.; Shokrani, A.; Dhokia, V.; Newman, S.T. Cost modelling and sensitivity analysis of wire and arc additive manufacturing. Procedia Manuf. 2017, 11, 650–657. [Google Scholar] [CrossRef]

- Venturini, G.; Montevecchi, F.; Bandini, F.; Scippa, A.; Campatelli, G. Feature based three axes computer aided manufacturing software for wire arc additive manufacturing dedicated to thin walled components. Addit. Manuf. 2018, 22, 643–657. [Google Scholar] [CrossRef]

- Williams, S.W.; Martina, F.; Addison, A.C.; Ding, J.; Pardal, G.; Colegrove, P. Wire + arc additive manufacturing. Mater. Sci. Technol. 2016, 32, 641–647. [Google Scholar] [CrossRef]

- MX3D A smarter bridge. Available online: http://mx3d.com/smart-bridge/ (accessed on 3 August 2018).

- Bekker, A.C.M.; Verlinden, J.C. Life cycle assessment of wire + arc additive manufacturing compared to green sand casting and CNC milling in stainless steel. J. Clean. Prod. 2018, 177, 438–447. [Google Scholar] [CrossRef]

- Ding, D.H.; Pan, Z.X.; Cuiuri, D.; Li, H.J. Wire-feed additive manufacturing of metal components: technologies, developments and future interests. Int. J. Adv. Manuf. Technol. 2015, 81, 465–481. [Google Scholar] [CrossRef]

- Geng, H.B.; Li, J.L.; Xiong, J.T.; Lin, X.; Zhang, F.S. Optimization of wire feed for GTAW based additive manufacturing. J. Mater. Process. Technol. 2017, 243, 40–47. [Google Scholar] [CrossRef]

- Venturini, G.; Montevecchi, F.; Scippa, A.; Campatelli, G. Optimization of WAAM Deposition Patterns for T-crossing Features. Procedia CIRP 2016, 55, 95–100. [Google Scholar] [CrossRef]

- Wang, T.T.; Zhang, Y.B.; Wu, Z.H.; Shi, C.W. Microstructure and properties of die steel fabricated by WAAM using H13 wire. Vacuum 2018, 149, 185–189. [Google Scholar] [CrossRef]

- Yan, F.Y.; Xiong, W.; Faierson, E.J. Grain structure control of additively manufactured metallic materials. Materials 2017, 10, 1260. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Kok, Y.; Tan, X.P.; Wang, P.; Nai, M.L.S.; Loh, N.H.; Liu, E.; Tor, S.B. Anisotropy and heterogeneity of microstructure and mechanical properties in metal additive manufacturing: A critical review. Mater. Des. 2018, 139, 565–586. [Google Scholar] [CrossRef]

- Wang, F.D.; Williams, S.; Colegrove, P.; Antonysamy, A.A. Microstructure and mechanical properties of wire and arc additive manufactured Ti-6Al-4V. Metall. Mater. Trans. A 2013, 44, 968–977. [Google Scholar] [CrossRef]

- Szost, B.A.; Terzi, S.; Martina, F.; Boisselier, D.; Prytuliak, A.; Pirling, T.; Hofmann, M.; Jarvis, D.J. A comparative study of additive manufacturing techniques: Residual stress and microstructural analysis of CLAD and WAAM printed Ti–6Al–4V components. Mater. Des. 2016, 89, 559–567. [Google Scholar] [CrossRef]

- Cong, B.Q.; Ding, J.L.; Williams, S. Effect of arc mode in cold metal transfer process on porosity of additively manufactured Al-6.3%Cu alloy. Int. J. Adv. Manuf. Technol. 2015, 76, 1593–1606. [Google Scholar] [CrossRef]

- Xu, X.F.; Ding, J.L.; Ganguly, S.; Diao, C.L.; Williams, S. Preliminary investigation of building strategies of maraging steel bulk material using wire + arc additive manufacture. J. Mater. Eng. Perform. 2018, 1–7. [Google Scholar] [CrossRef]

- Horgar, A.; Fostervoll, H.; Nyhus, B.; Ren, X.; Eriksson, M.; Akselsen, O.M. Additive manufacturing using WAAM with AA5183 wire. J. Mater. Process. Technol. 2018, 259, 68–74. [Google Scholar] [CrossRef]

- Wu, Q.R.; Lu, J.P.; Liu, C.M.; Fan, H.L.; Shi, X.Z.; Fu, J.; Ma, S.Y. Effect of molten pool size on microstructure and tensile properties of wire arc additive manufacturing of Ti-6Al-4V alloy. Materials 2017, 10, 749. [Google Scholar]

- Lewandowski, J.J.; Seifi, M. Metal additive manufacturing: a review of mechanical properties. Annu. Rev. Mater. Res. 2016, 46, 151–186. [Google Scholar] [CrossRef]

- Xiong, J.; Li, Y.J.; Li, R.; Yin, Z.Q. Influences of process parameters on surface roughness of multi-layer single-pass thin-walled parts in GMAW-based additive manufacturing. J. Mater. Process. Technol. 2018, 252, 128–136. [Google Scholar] [CrossRef]

- Li, F.; Chen, S.J.; Shi, J.B.; Tian, H.Y.; Zhao, Y. Evaluation and optimization of a hybrid manufacturing process combining wire arc additive manufacturing with milling for the fabrication of stiffened panels. Appl. Sci. 2017, 7, 1233. [Google Scholar] [CrossRef]

- Arrizubieta, J.I.; Cortina, M.; Ruiz, J.E.; Lamikiz, A. Combination of laser material deposition and laser surface processes for the holistic manufacture of inconel 718 components. Materials 2018, 11, 1247. [Google Scholar] [CrossRef] [PubMed]

- Ma, J.F.; Harstvedt, J.D.; Dunaway, D.; Bian, L.; Jaradat, R. An exploratory investigation of additively manufactured product life cycle sustainability assessment. J. Clean. Prod. 2018, 192, 55–70. [Google Scholar] [CrossRef]

- Rodríguez-Panes, A.; Claver, J.; Camacho, A.M. The influence of manufacturing parameters on the mechanical behaviour of pla and abs pieces manufactured by fdm: a comparative analysis. Materials 2018, 11, 1333. [Google Scholar] [CrossRef] [PubMed]

- Tabernero, I.; Paskual, A.; Álvarez, P.; Suárez, A. Study on arc welding processes for high deposition rate additive manufacturing. Procedia CIRP 2018, 68, 358–362. [Google Scholar]

- Selvi, S.; Vishvaksenan, A.; Rajasekar, E. Cold metal transfer (CMT) technology—An overview. Def. Technol. 2018, 14, 28–44. [Google Scholar] [CrossRef]

- Ding, J.; Colegrove, P.; Mehnen, J.; Ganguly, S.; Almeida, P.M.S.; Wang, F.; Williams, S. Thermo-mechanical analysis of wire and arc additive layer manufacturing process on large multi-layer parts. Comput. Mater. Sci. 2011, 50, 3315–3322. [Google Scholar] [CrossRef]

- Prado-Cerqueira, J.L.; Diéguez, J.L.; Camacho, A.M. Preliminary development of a wire and arc additive manufacturing system (WAAM). Procedia Manuf. 2017, 13, 895–902. [Google Scholar] [CrossRef]

- González, J.; Rodríguez, I.; Prado-Cerqueira, J.L.; Diéguez, J.L.; Pereira, A. Additive manufacturing with GMAW welding and CMT technology. Procedia Manuf. 2017, 13, 840–847. [Google Scholar] [CrossRef]

- Santos, E.C.; Shiomi, M.; Osakada, K.; Laoui, T. Rapid manufacturing of metal components by laser forming. Int. J. Mach. Tools Manuf. 2006, 46, 1459–1468. [Google Scholar] [CrossRef]

- Pickin, C.G.; Williams, S.W.; Lunt, M. Characterisation of the cold metal transfer (CMT) process and its application for low dilution cladding. J. Mater. Process. Technol. 2010, 211, 496–502. [Google Scholar] [CrossRef]

- Fronius CMT—Cold Metal Transfer: The Cold Welding Process for Premium Quality. Available online: http://www.fronius.com/en/welding-technology/our-expertise/welding-processes/cmt (accessed on 29 June 2018).

- Anwar, M.S.; Untawale, S.P. Measuring the process efficiency of controlled welding processes. Int. J. Instrum. Control Autom. 2012, 1, 33–39. [Google Scholar]

- Fronius CMT Advanced: A Higher Deposition Rate, Better Gap-Bridging Ability and Higher Stability. Available online: http://www.fronius.com/en/welding-technology/our-expertise/welding-processes/cmt-advanced (accessed on 29 June 2018).

- Metallic Materials—Brinell Hardness Test. Part 1—Test Method; ISO 6506-1:2014; International Standards Organisation: Geneva, Switzerland, 2014.

- Metallic Materials—Conversion of Hardness Values; ISO 18265:2013; International Standards Organisation: Geneva, Switzerland, 2013.

- Standard Test Methods and Definitions for Mechanical Testing of Steel Products; ASTM A370-17a; American Society for Testings and Materials International: West Conshohocken, PA, USA, 2017.

- Hardness Tests and Hardness Number Conversions; SAE J417:198312; SAE International: Troy, MI, USA, 1983.

- Guide to AWS Specification for Carbon Steel Electrodes and Rods for Gas Shielded Arc Welding; ASME SFA 5.18; American Society of Mechanical Engineers: New York, NY, USA, 2017.

- Specification for Carbon Structural Steel; ASME SA-36; American Society of Mechanical Engineers: New York, NY, USA, 2017.

- Specification for Pressure Vessels Plates, Carbon Steel, Low– and Intermediate- Tensile Strength; ASME SA-285; ASTM International: West Conshohocken, PA, 2017.

- Specification for Pressure Vessels Plates, Carbon Steel, Low– and Intermediate- and Higher Temperature Service; ASME SA-515; ASTM International: West Conshohocken, PA, USA, 2017.

- Specification for Pressure Vessels Plates, Carbon Steel, for Moderate– and Lower- Temperature Service; ASME SA-516; ASTM International: West Conshohocken, PA, USA, 2017.

- Liberini, M.; Astarita, A.; Campatelli, G.; Scippa, A.; Montevecchi, F.; Venturini, G.; Durante, M.; Boccarusso, L.; Minutolo, F.M.C.; Squillace, A. Selection of optimal process parameters for wire arc additive manufacturing. Procedia CIRP 2017, 62, 470–474. [Google Scholar] [CrossRef]

- Kobe Steel Welding Handbook; Kobe steel Ltd.: Hyōgo, Japan, 2014.

| Mechanical Properties | S235 JR | AWS ER70S-6 |

|---|---|---|

| Density (kg/m3) | 7800 | 7833 |

| Yield point (MPa) | 235 | 420 |

| UTS (MPa) | 370–510 | 500–640 |

| Element | C | Mn | S | Ni | V | Cr | Cu | Si | P | Mo |

|---|---|---|---|---|---|---|---|---|---|---|

| wt% | 0.06–0.15 | 1.40–1.85 | 0.035 max | 0.15 max | 0.03 max | 0.15 | 0.50 | 0.80–1.15 | 0.025 | 0.15 max |

| Nº | Process | Intensity (A) | Thermal Input * 1 (J/mm) | Welding Speed (mm/min) | Deposition Speed (m/min) | Wall Thickness (mm) | Layer Step (mm) | Total Height (mm) | Layer Height (mm) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | MIG | 50 | 55.19 | 400 | 2.5 | 3.8 | 1.0 | 27.0 | 0.90 |

| 2 | CMT | 50 | 35.87 | 400 | 2.5 | 3.7 | 1.0 | 30.7 | 1.02 |

| 3 | CMT Adv. pol. 0 | 70 | 50.22 | 400 | 2.5 | 4.2 | 1.0 | 20.2 | 1.44 |

| 4 | CMT Adv. pol. 0 | 70 | 50.22 | 400 | 2.5 | 5.5 | 1.5 | 35.5 | 0.92 |

| 5 | CMT Adv. pol. −5 | 66 | 47.36 | 400 | 2.5 | 4.5 | 1.5 | 41.2 | 1.07 |

| 6 | CMT Adv. pol. +5 | 78 | 55.97 | 400 | 2.5 | 6.6 | 1.5 | 33.4 | 0.80 |

| 7 | CMT Cont. | 50 | 35.87 | 400 | 2.5 | 3.1 | 1.0 | 30.5 | 1.02 |

| Sample nº | Process | Thermal Input (J/mm) | Brinell Hardness (Mean Value) | 〈d〉 | dmax | dmin | R |

|---|---|---|---|---|---|---|---|

| 1 | MIG | 55.19 | 172.89 | 0.729 | 0.731 | 0.7285 | 0.003 |

| 2 | CMT | 35.87 | 142.14 | 0.790 | 0.809 | 0.759 | 0.064 |

| 3 | CMT Adv. pol. 0 | 50.22 | 159.03 | 0.761 | 0.790 | 0.725 | 0.086 |

| 4 | CMT Adv. pol. 0 | 50.22 | 153.00 | 0.778 | 0.799 | 0.759 | 0.051 |

| 5 | CMT Adv. pol. −5 | 47.36 | 154.49 | 0.773 | 0.789 | 0.759 | 0.038 |

| 6 | CMT Adv. pol. +5 | 55.97 | 148.84 | 0.792 | 0.815 | 0.771 | 0.056 |

| 7 | CMT Cont. | 35.87 | 152.67 | 0.772 | 0.784 | 0.765 | 0.025 |

| UTS (MPa) Correlation per Indentation (ID) According to Figure 6. | |||||||

|---|---|---|---|---|---|---|---|

| Process | |||||||

| ID | MIG | CMT | CMT Adv. pol. 0 | CMT Adv. pol. 0 | CMT Adv. pol. −5 | CMT Adv. pol. +5 | CMT-Cont. |

| 1 | 573.33 | 479.99 | 516.38 | 498.34 | 498.39 | 467.42 | 528.44 |

| 2 | 583.30 | 473.06 | 499.98 | 483.64 | 562.20 | 465.82 | 505.24 |

| 3 | 587.47 | 468.90 | 495.17 | 488.64 | 497.70 | 534.68 | 499.66 |

| 4 | 589.84 | 477.92 | 561.66 | 541.73 | 495.74 | 490.68 | 501.99 |

| 5 | 572.46 | 454.32 | 590.94 | 558.59 | 537.12 | 544.38 | 498.00 |

| Mean | 581.28 | 470.84 | 532.82 | 514.19 | 518.23 | 500.59 | 506.67 |

| Base Material Specification | UTS (MPa) |

|---|---|

| SA-36 (equivalent to S235JR) | 400–550 |

| SA-285 | 310–515 |

| SA-515 | 415–485 |

| SA-516 | 380–485 |

| Element | Mn | C | O | Si | Cu | Fe |

|---|---|---|---|---|---|---|

| wt% | 1.58 | 7.59 | 1.79 | 0.83 | 0.44 | 87.77 |

| Sample nº | Process | Most Homogeneous Hardness Profiles (Figure 6a–g) | Highest Values of Mean Hardness (Figure 6h) | Best Estimated UTS [55] (Table 5) | Absence of Decohesionated Layer at the Surface (Figure A2) |

|---|---|---|---|---|---|

| 1 | MIG | X | X | ||

| 2 | CMT | X | X | X | |

| 3 | CMT Adv pol. 0 | X | |||

| 4 | CMT Adv pol. 0 | X | |||

| 5 | CMT Adv pol. −5 | X | |||

| 6 | CMT Adv pol. +5 | X | |||

| 7 | CMT Cont. | X | X | X |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Prado-Cerqueira, J.L.; Camacho, A.M.; Diéguez, J.L.; Rodríguez-Prieto, Á.; Aragón, A.M.; Lorenzo-Martín, C.; Yanguas-Gil, Á. Analysis of Favorable Process Conditions for the Manufacturing of Thin-Wall Pieces of Mild Steel Obtained by Wire and Arc Additive Manufacturing (WAAM). Materials 2018, 11, 1449. https://doi.org/10.3390/ma11081449

Prado-Cerqueira JL, Camacho AM, Diéguez JL, Rodríguez-Prieto Á, Aragón AM, Lorenzo-Martín C, Yanguas-Gil Á. Analysis of Favorable Process Conditions for the Manufacturing of Thin-Wall Pieces of Mild Steel Obtained by Wire and Arc Additive Manufacturing (WAAM). Materials. 2018; 11(8):1449. https://doi.org/10.3390/ma11081449

Chicago/Turabian StylePrado-Cerqueira, José Luis, Ana María Camacho, José Luis Diéguez, Álvaro Rodríguez-Prieto, Ana María Aragón, Cinta Lorenzo-Martín, and Ángel Yanguas-Gil. 2018. "Analysis of Favorable Process Conditions for the Manufacturing of Thin-Wall Pieces of Mild Steel Obtained by Wire and Arc Additive Manufacturing (WAAM)" Materials 11, no. 8: 1449. https://doi.org/10.3390/ma11081449

APA StylePrado-Cerqueira, J. L., Camacho, A. M., Diéguez, J. L., Rodríguez-Prieto, Á., Aragón, A. M., Lorenzo-Martín, C., & Yanguas-Gil, Á. (2018). Analysis of Favorable Process Conditions for the Manufacturing of Thin-Wall Pieces of Mild Steel Obtained by Wire and Arc Additive Manufacturing (WAAM). Materials, 11(8), 1449. https://doi.org/10.3390/ma11081449