Mechanical Properties of Hybrid Ultra-High Performance Engineered Cementitous Composites Incorporating Steel and Polyethylene Fibers

Abstract

1. Introduction

2. Experimental Program

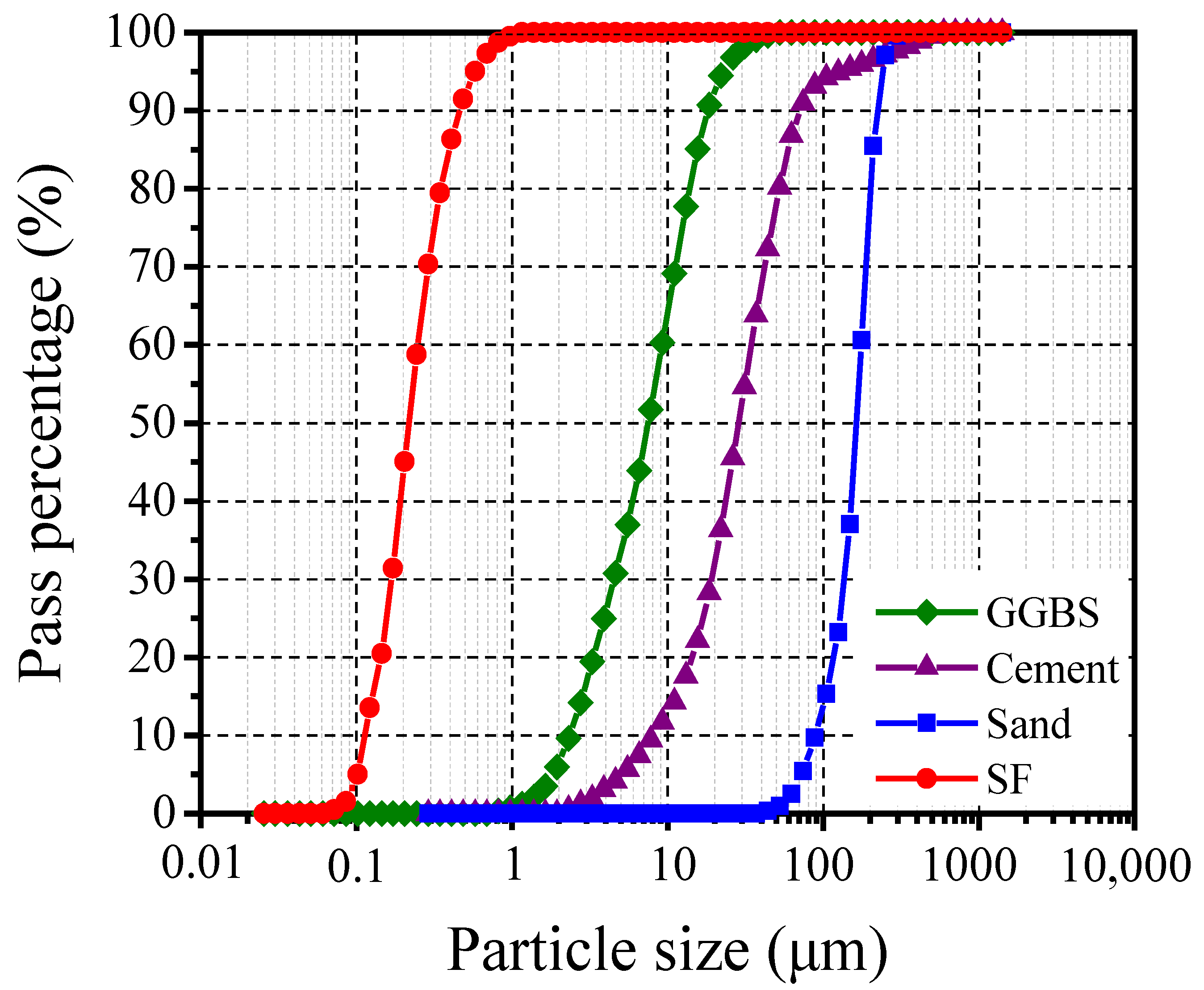

2.1. Materials and Mix Proportions

2.2. Mixing Procedure

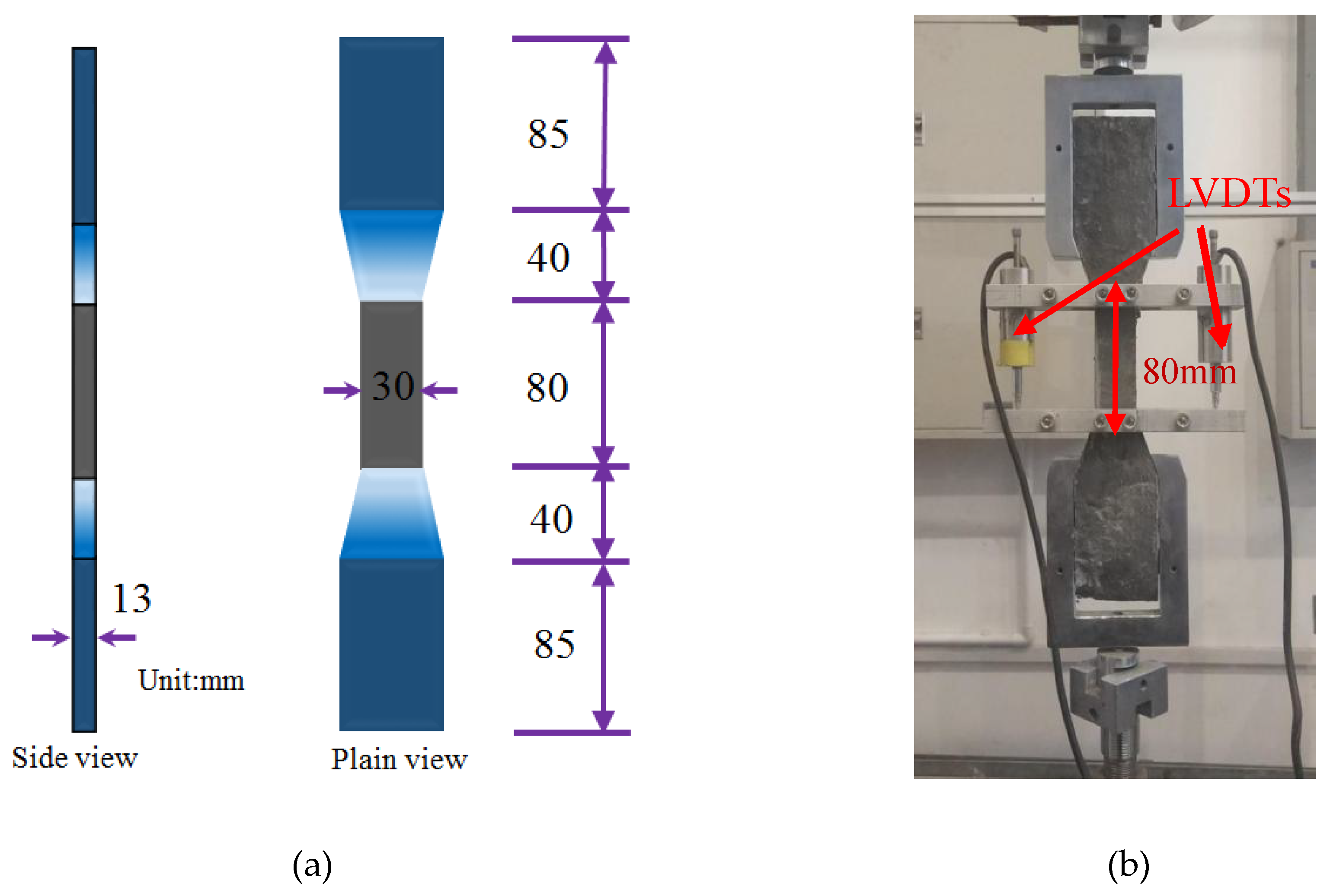

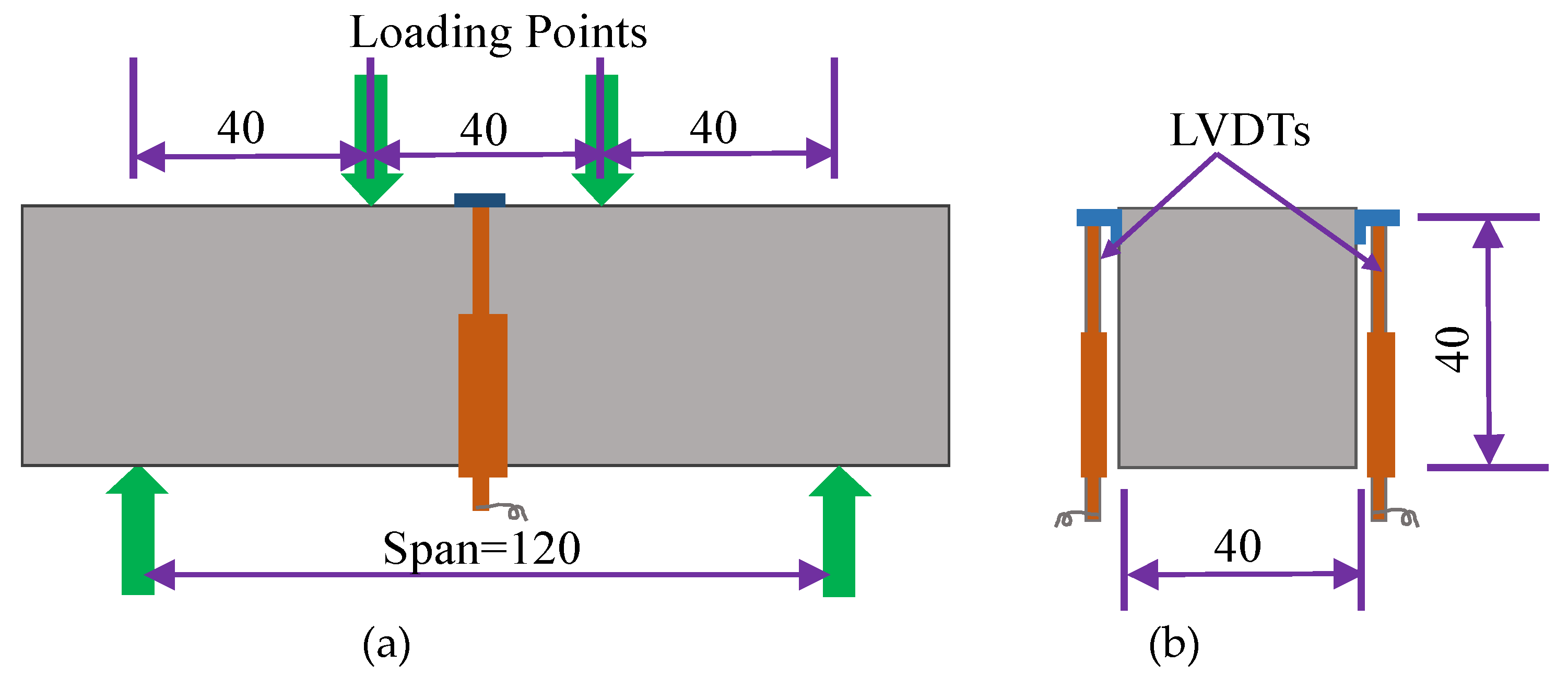

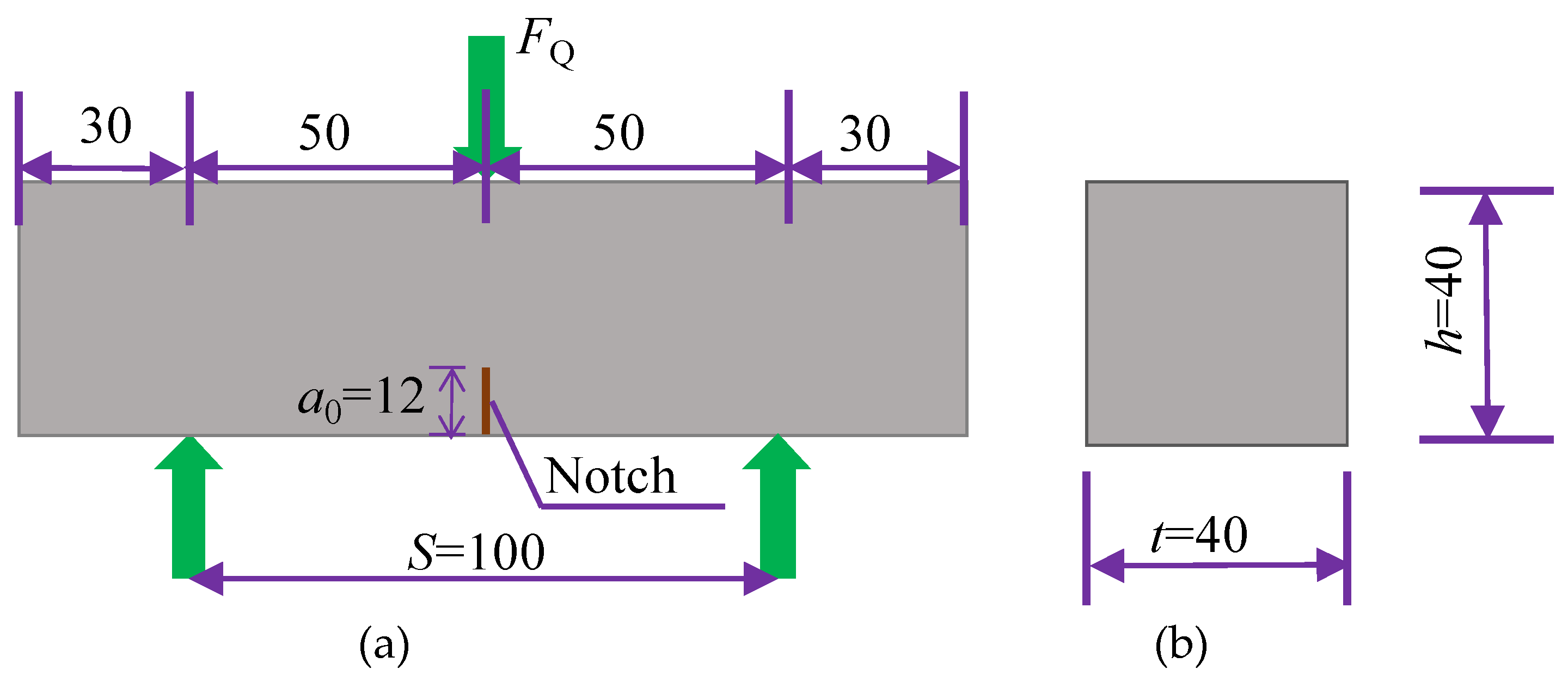

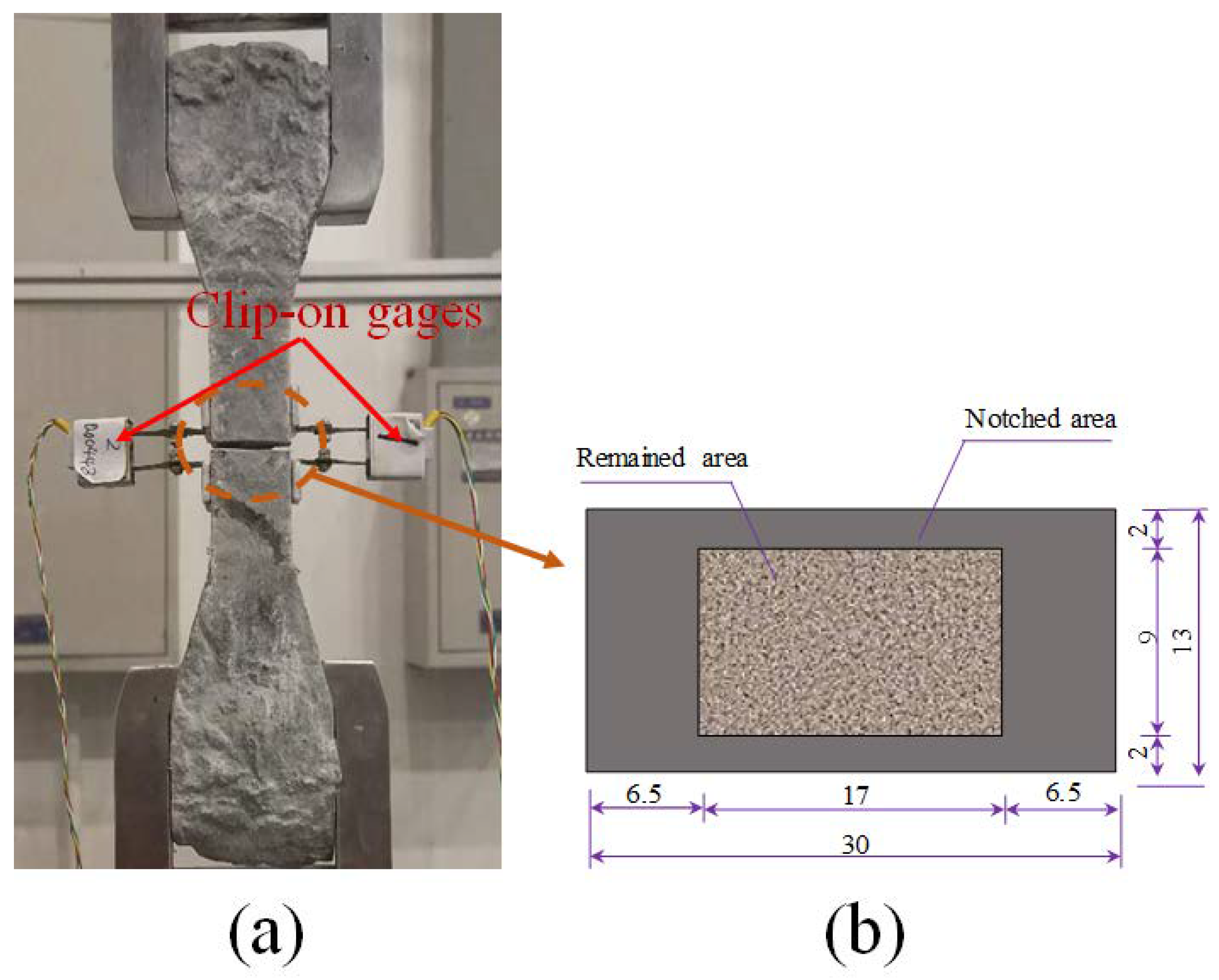

2.3. Test Specimens and Test Setups

3. Results and Discussion.

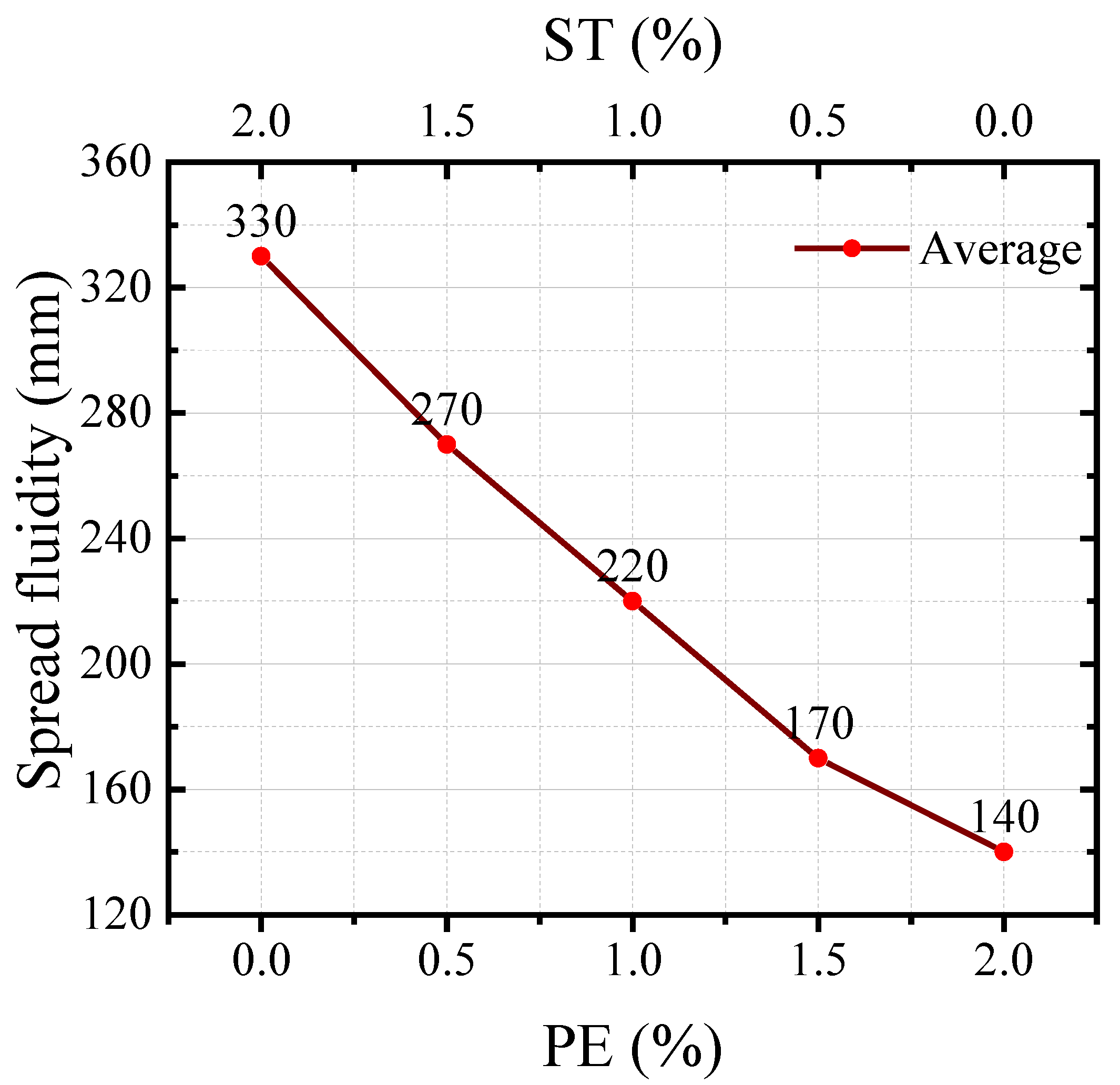

3.1. Tests of the Spread Fluidity

3.2. Tensile Properties

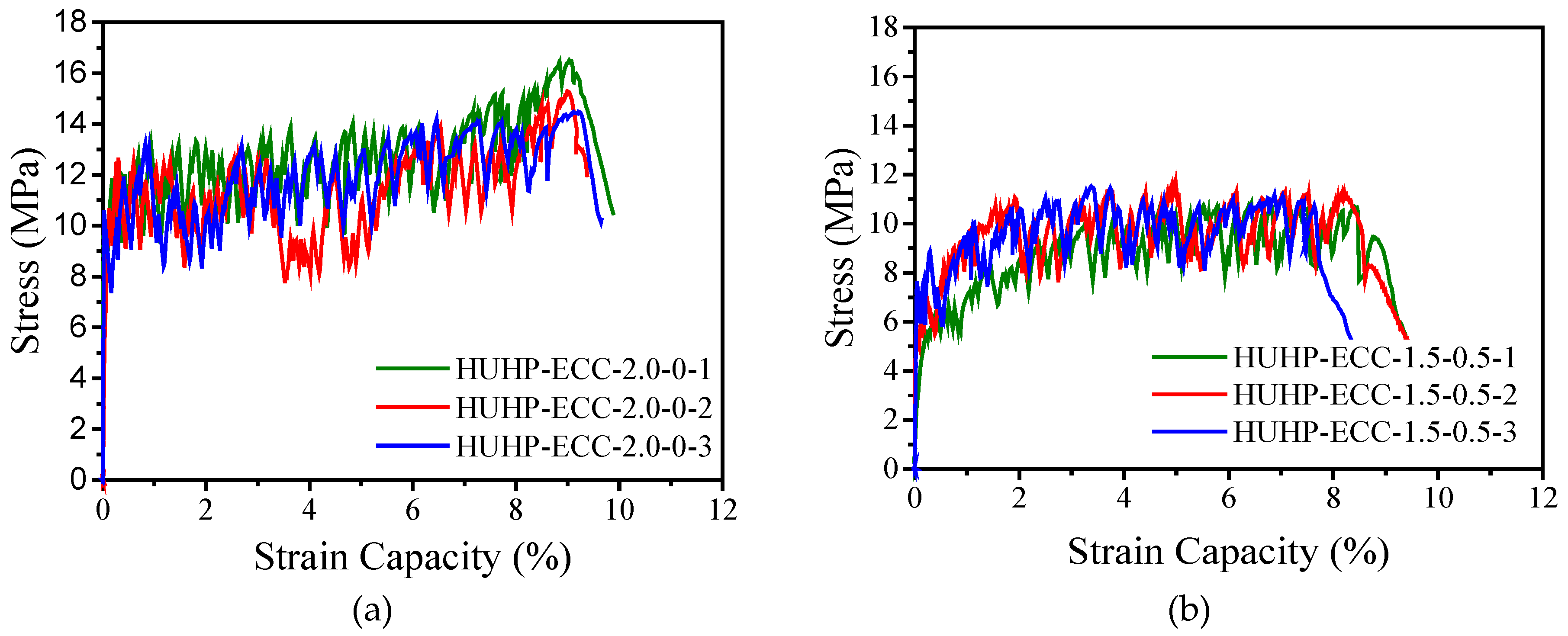

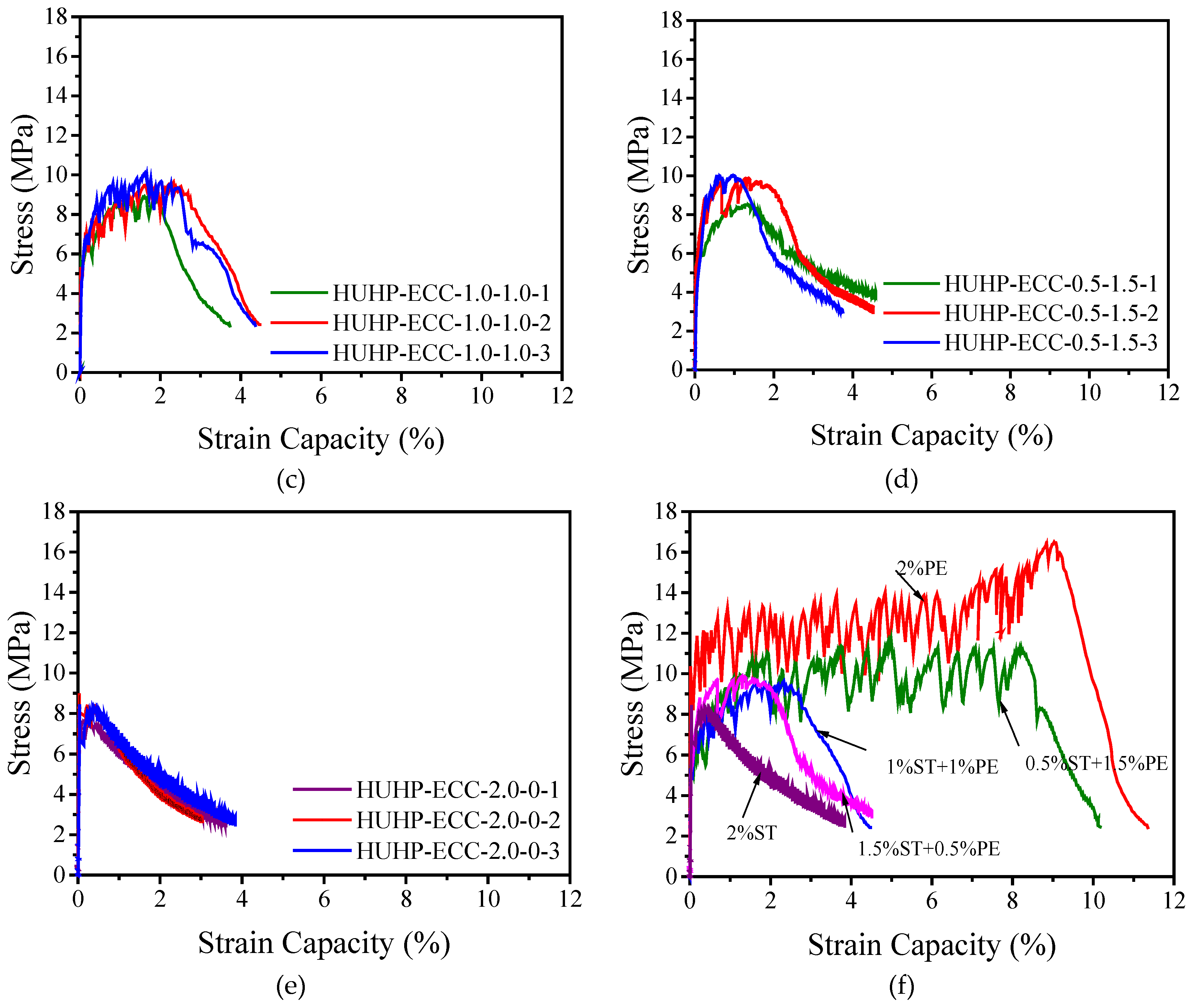

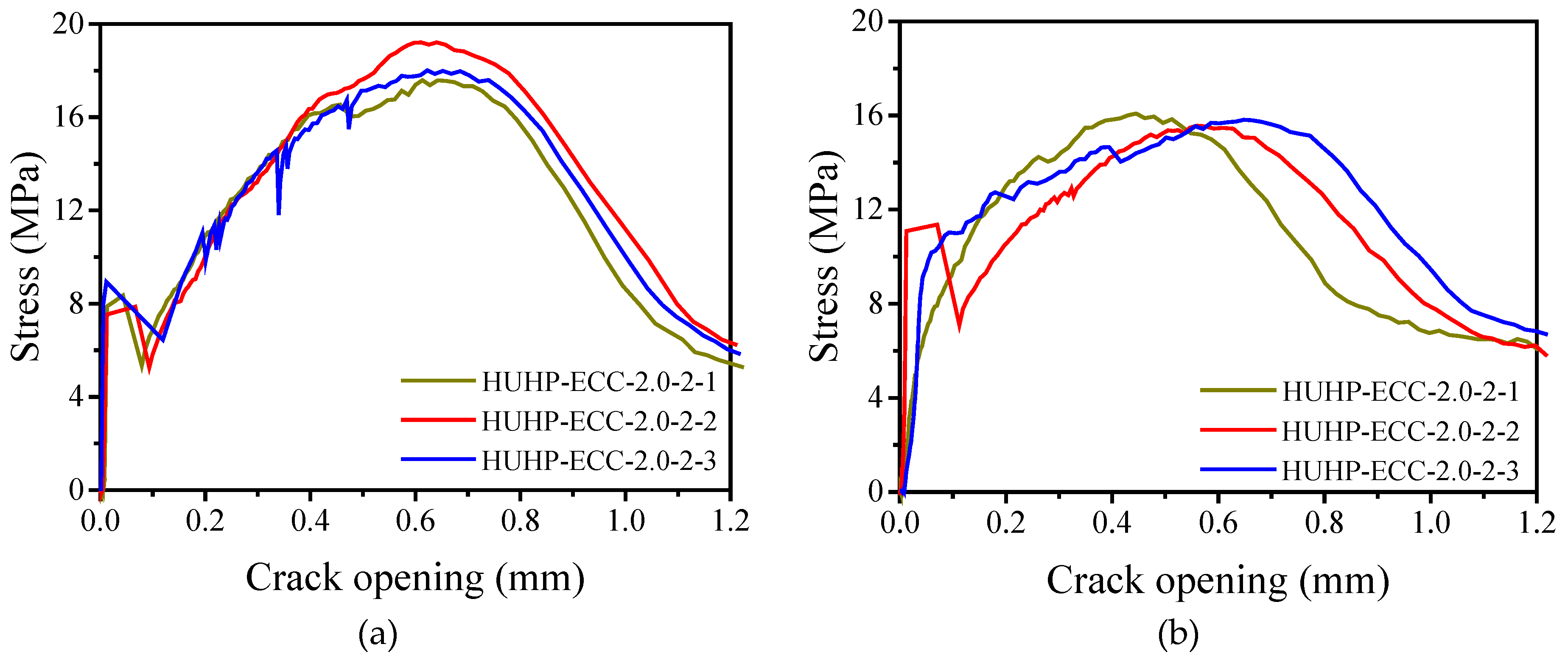

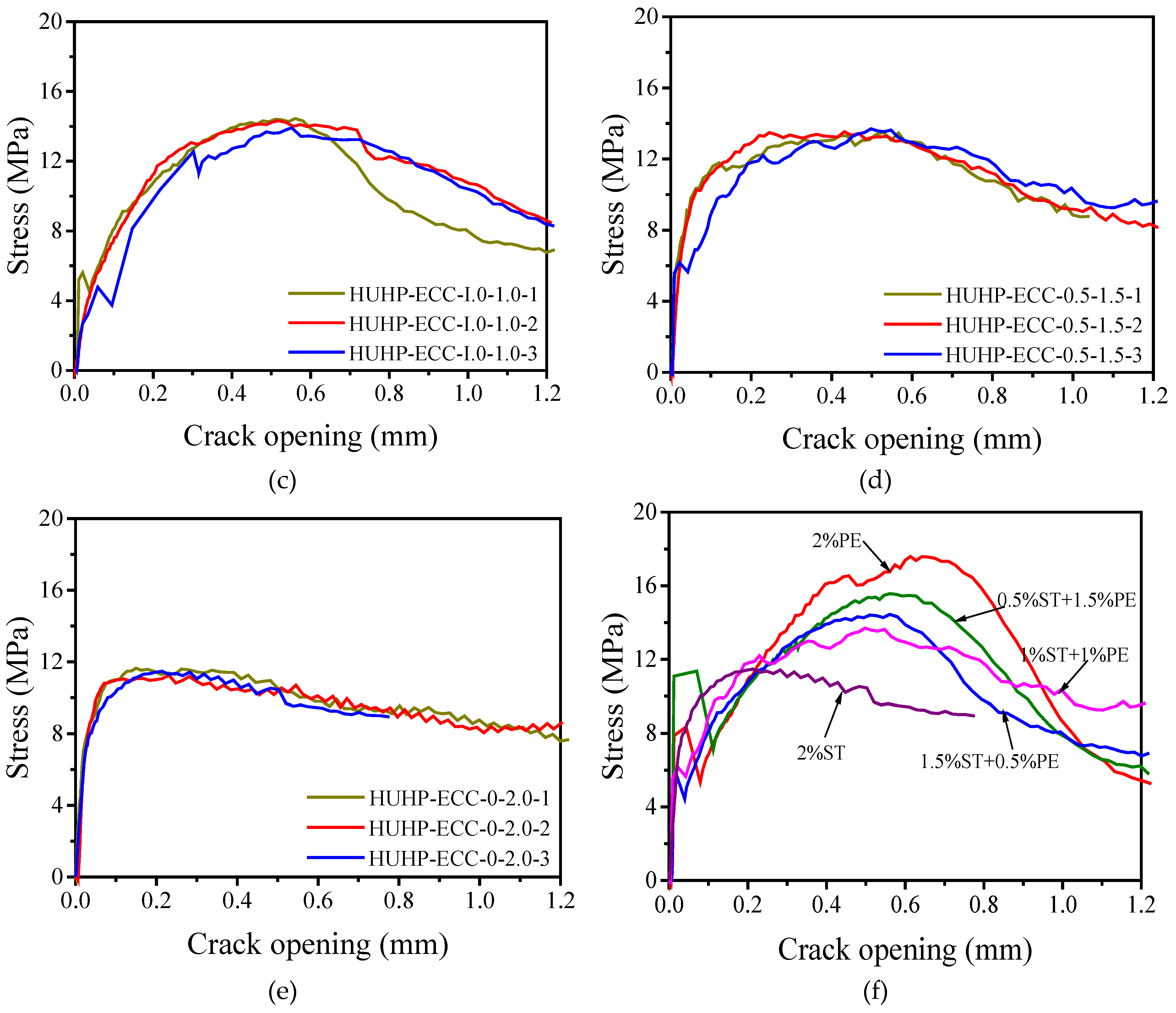

3.2.1. Tensile Stress-Strain of HUHP-ECCs

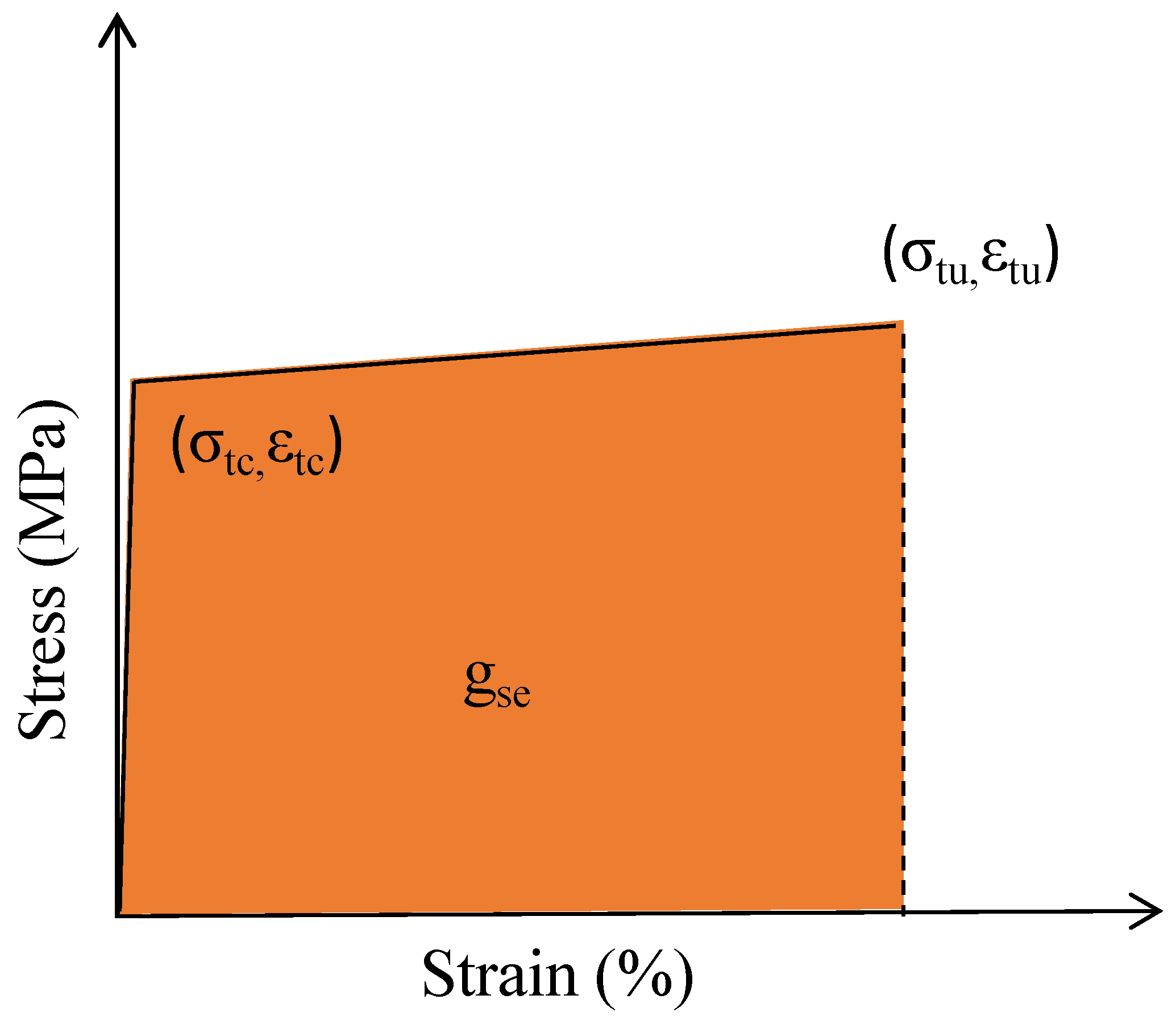

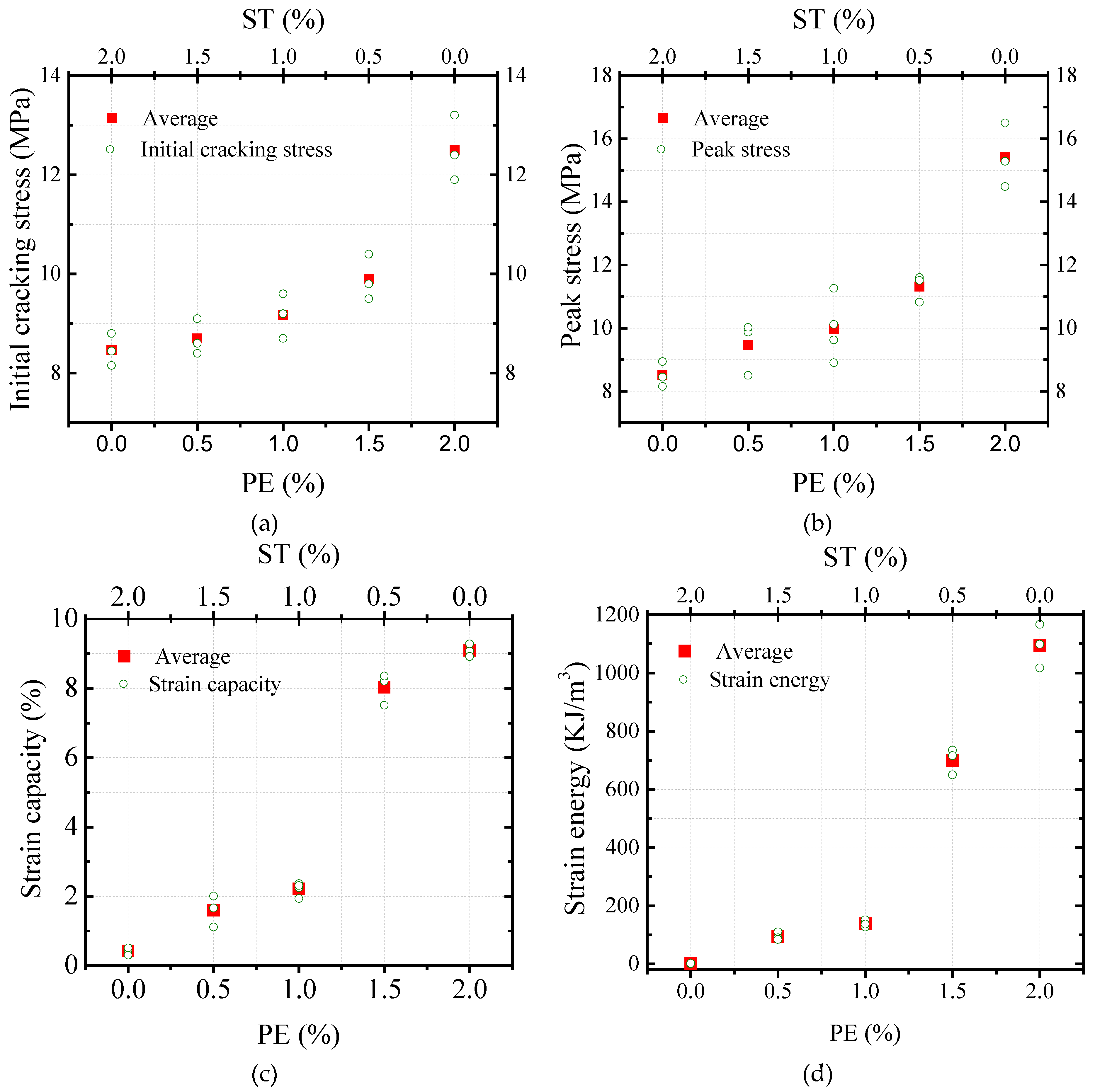

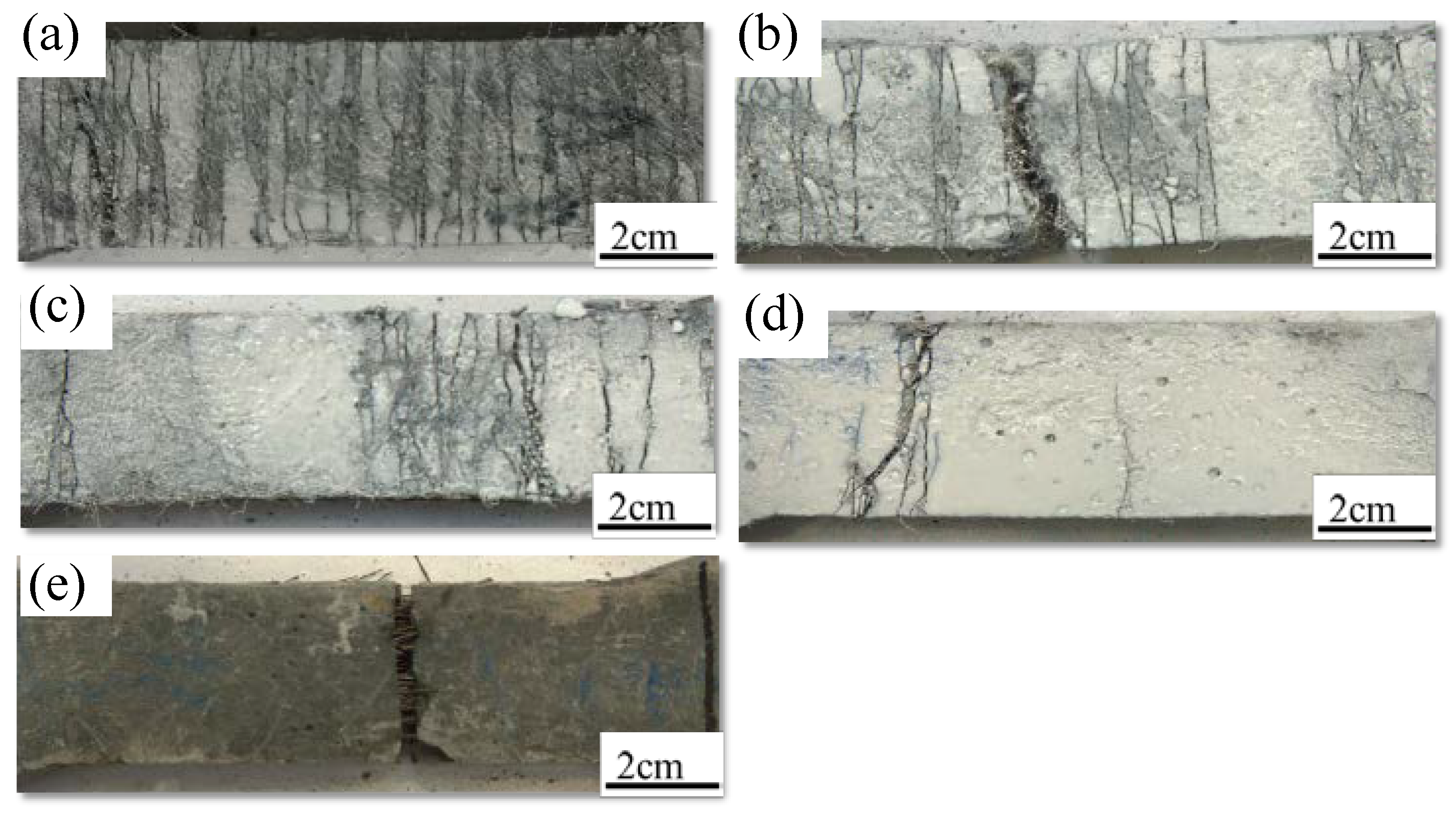

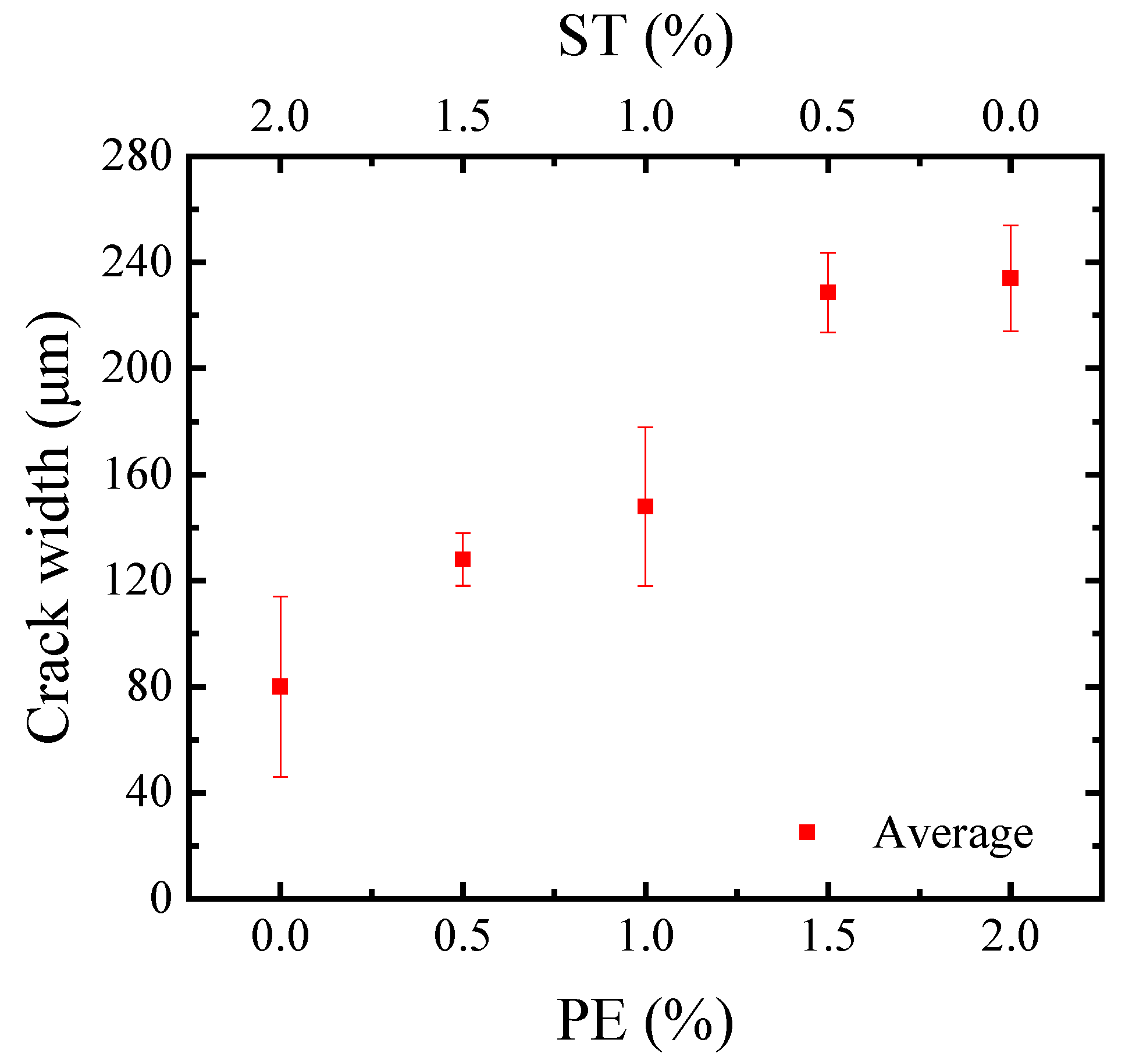

3.2.2. Tensile Parameters of HUHP-ECCs

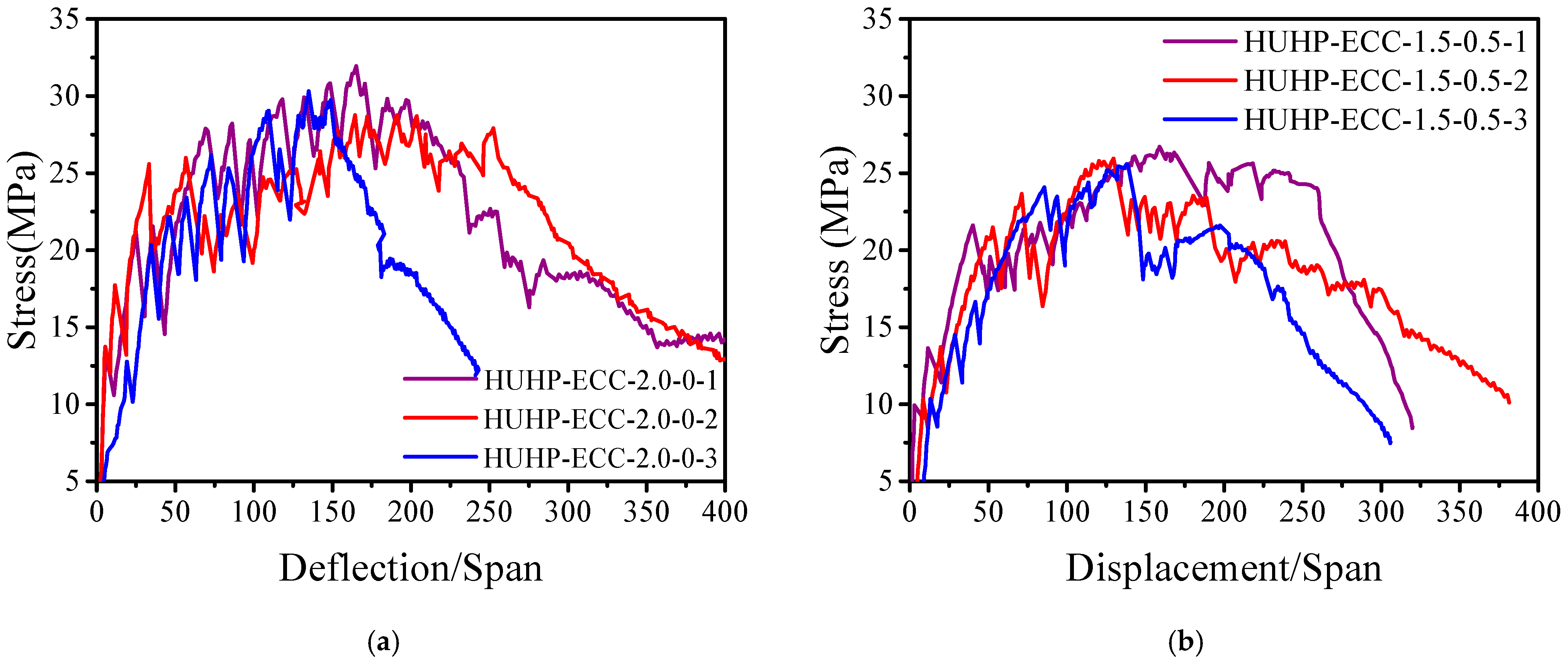

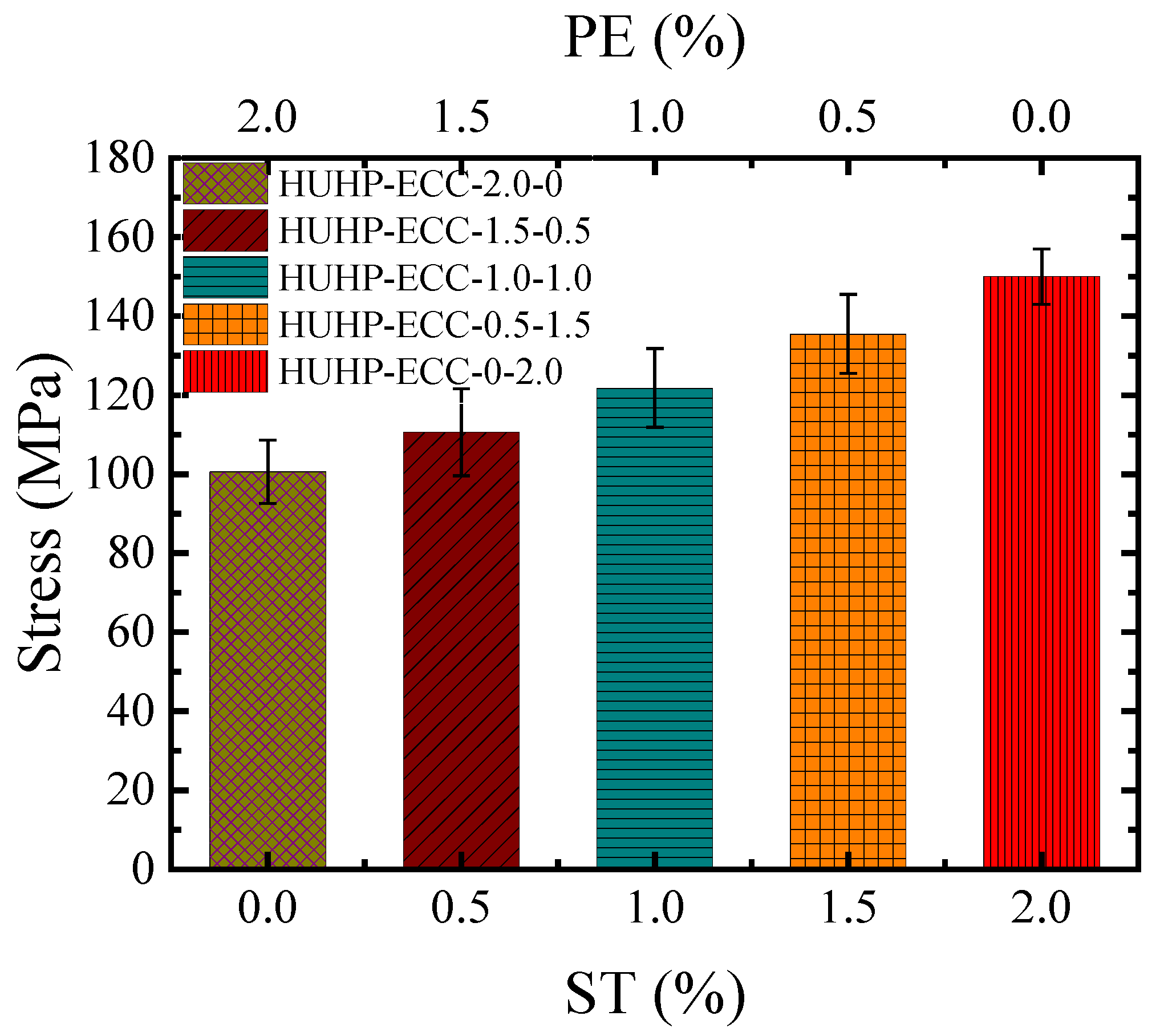

3.3. Flexural Properties

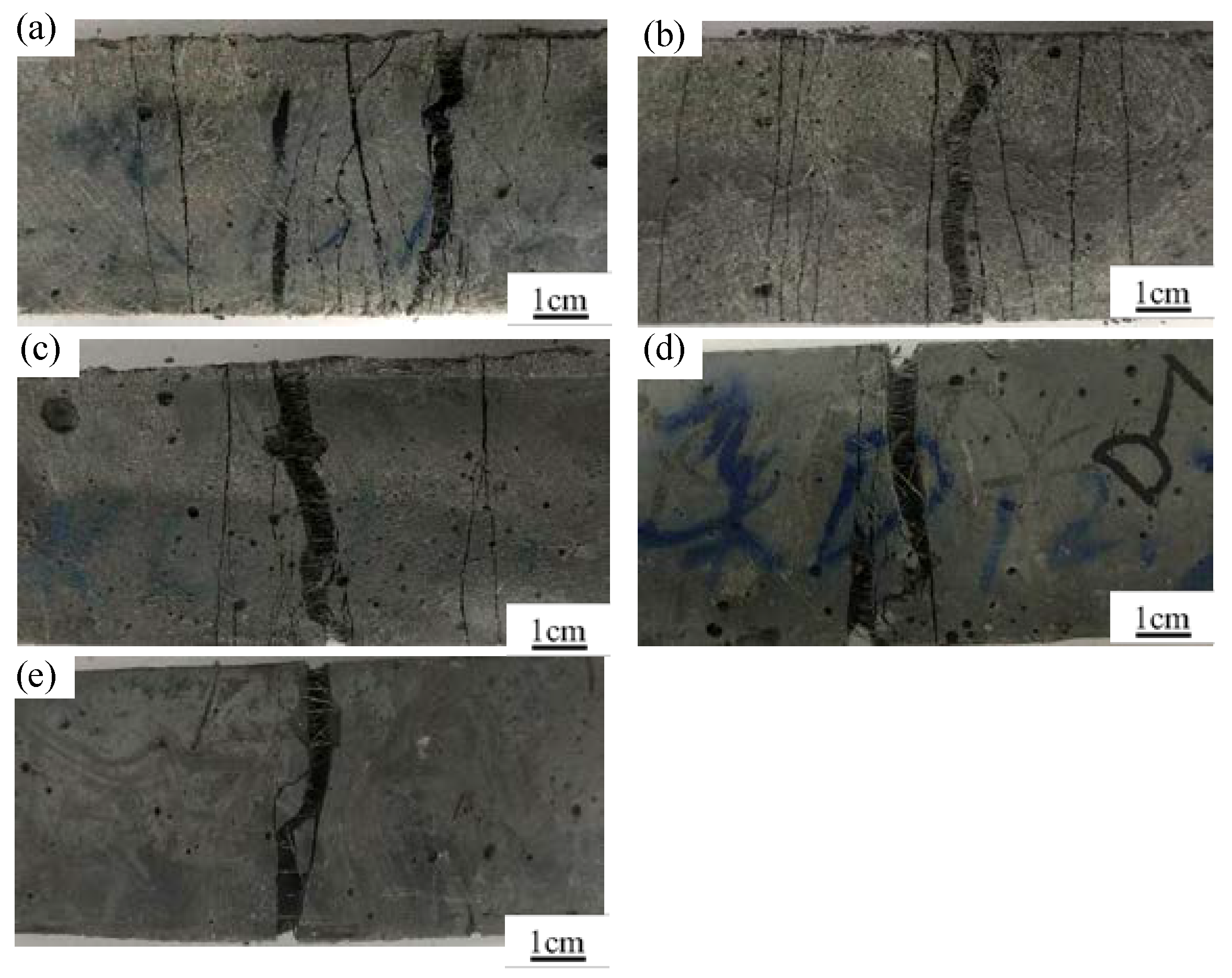

3.4. Compressive Properties

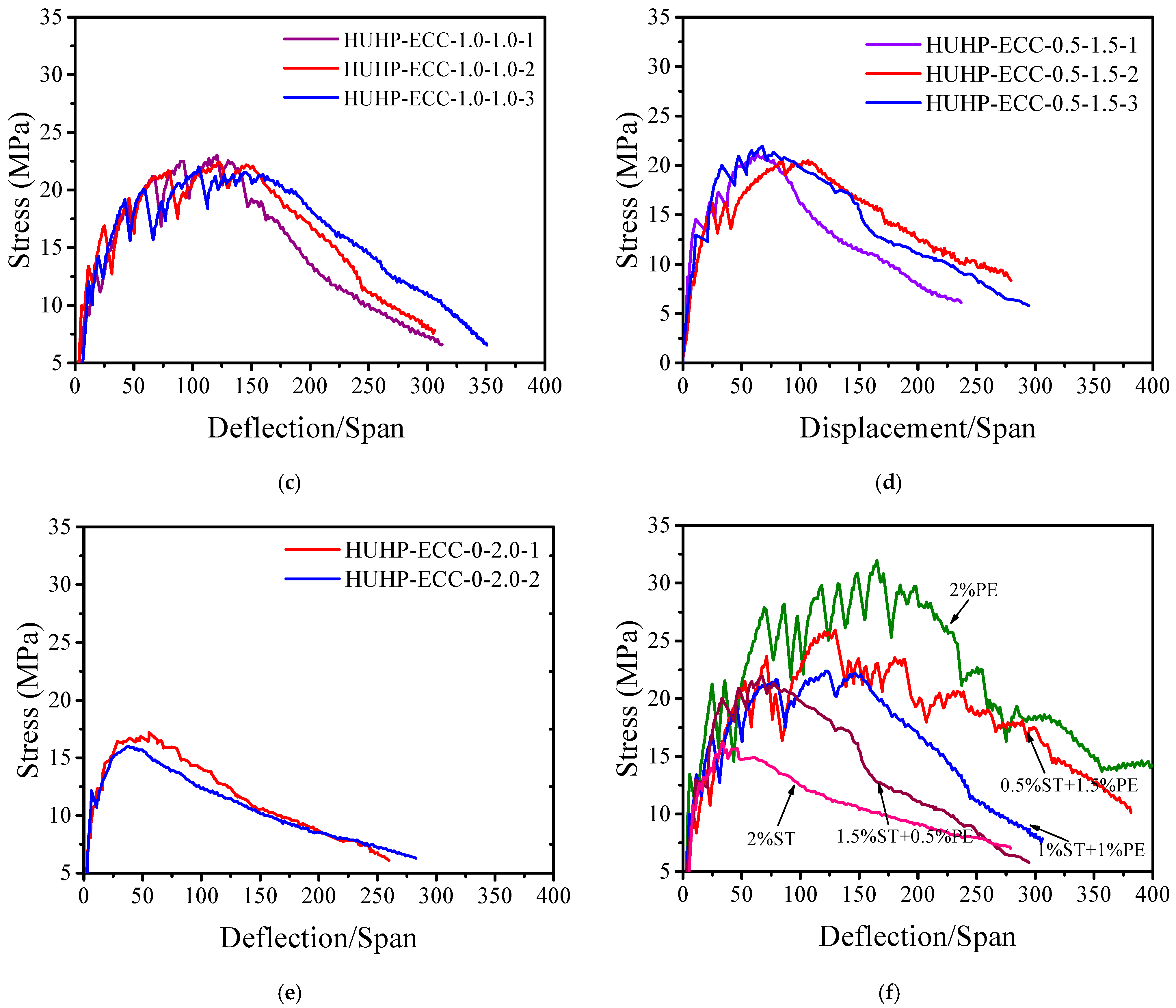

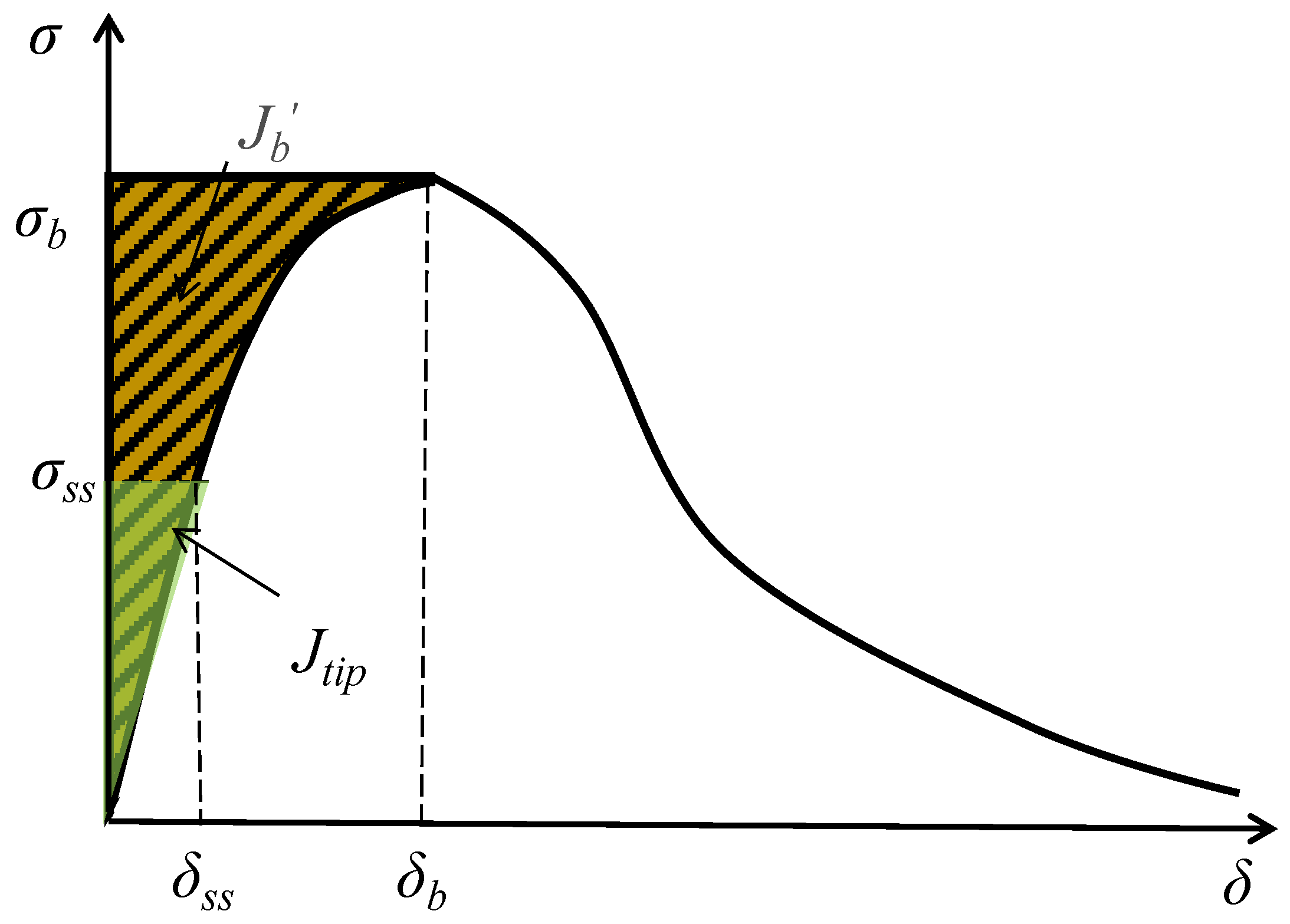

3.5. Interpretation of High Ductility in HUHP-ECC

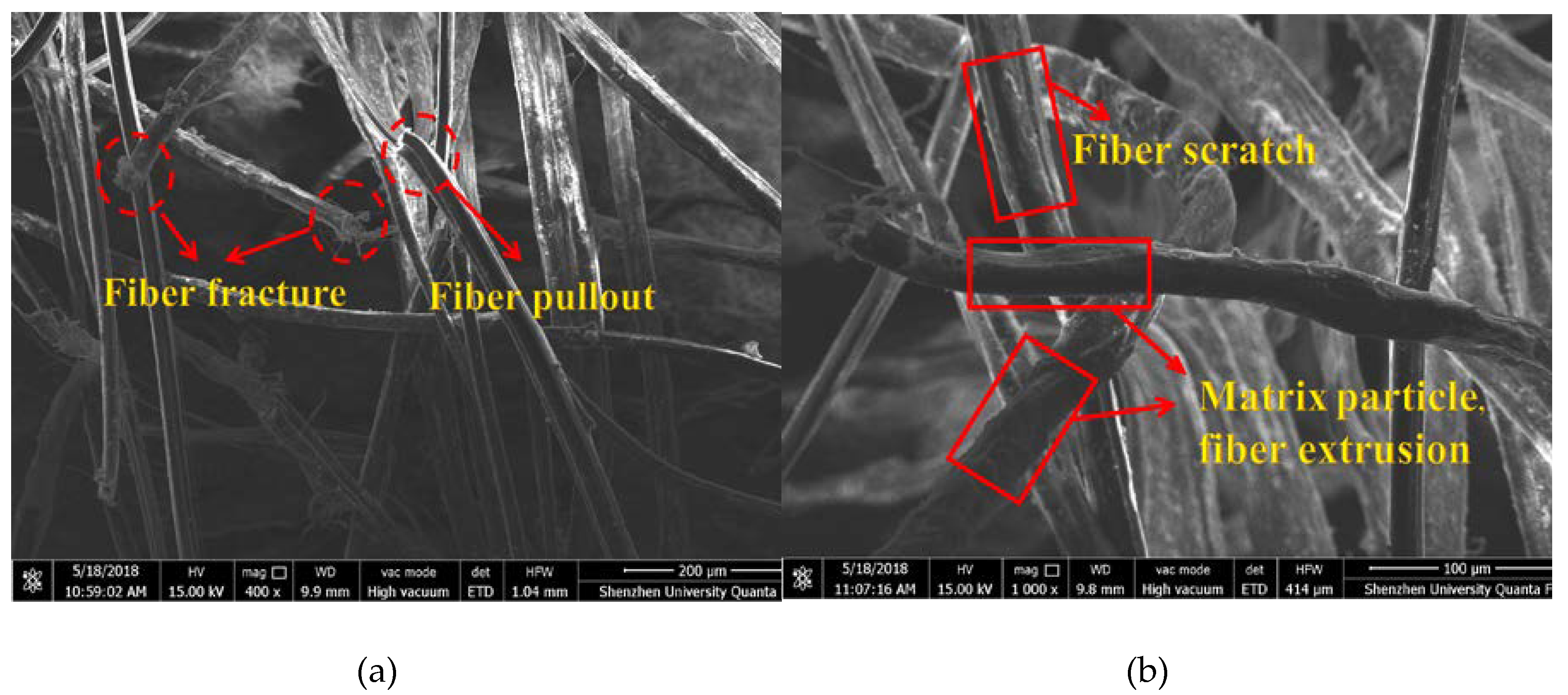

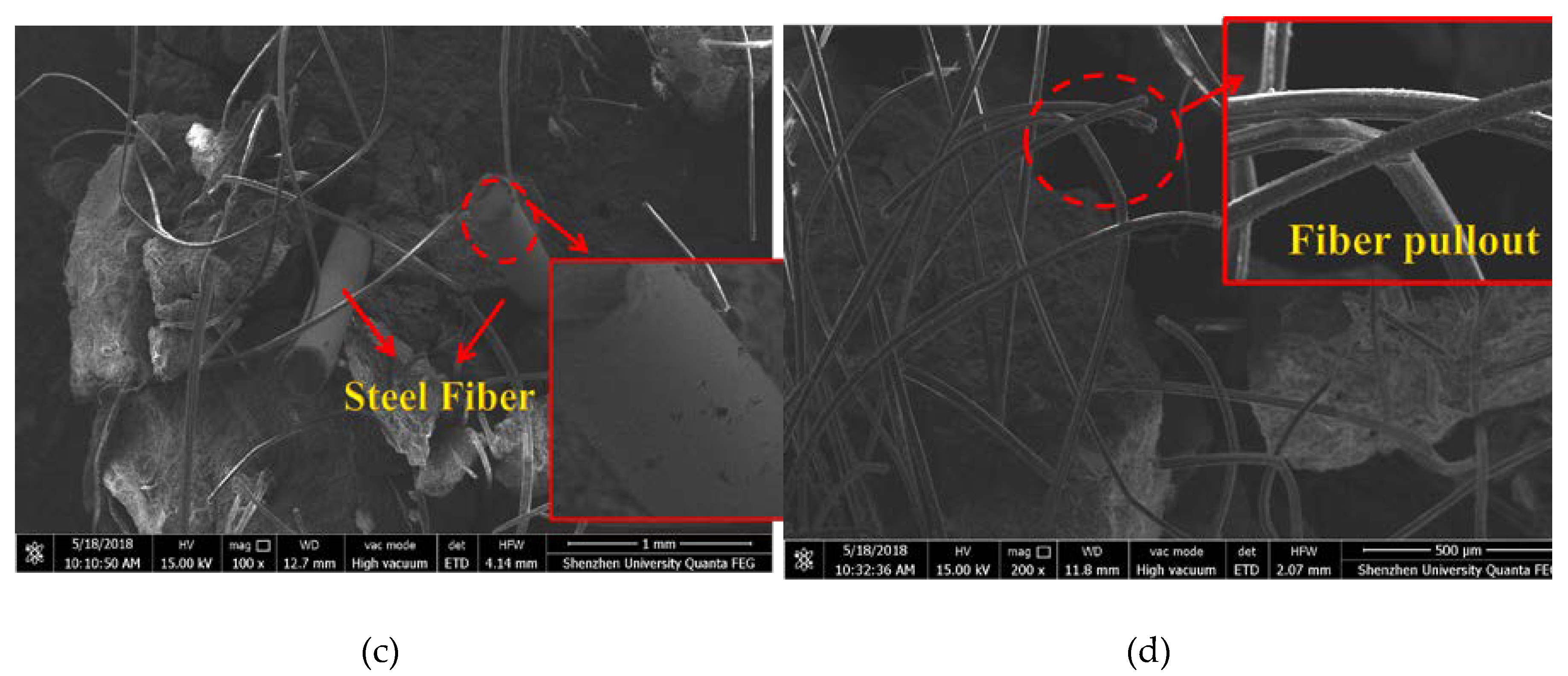

3.6. Microstructure of HUHP-ECC

4. Conclusions

- All the HUHP-ECCs demonstrated the strain-hardening phenomenon in tension except the HUHP-ECC-0-2.0 with mono ST fiber. The tensile properties, including both strength and ductility, increased with the amount of PE fiber. The tensile strain capacity of HUHP-ECC-0.5-1.5 with the 0.5% PE fiber reached 1.5%, which was much higher than the value of UHPC. The strain capacity reached 9.1% and 8.1% for HUHP-ECC-2.0-0 and HUHP-ECC-1.5-0.5, respectively. The tensile strength increased from 8.5 MPa to 15.5 MPa with an increase of 182%.

- All the HUHP-ECCs demonstrated the strain-hardening phenomenon in flexure and the flexural strength also increased with the amount of PE fiber. While the compressive strength had the opposite tendency with the increasing PE fiber volume fraction. The addition of PE fiber imposed a negative influence on the compressive strength due to the lower lateral elastic modulus of PE fiber. Additionally, the higher quantities of PE fiber disturbed the density of the matrix and induced more pores that would reduce the compressive strength. The compressive strength of HUHP-ECC-2.0-0 and HUHP-ECC-0-2.0 were 99.5 and 150.5 MPa.

- The fluidity of HUHP-ECC was adjustable by different combinations of ST and PE fibers. The fluidity of the HUHP-ECC increased from 140 mm with mono 2% PE fiber to 330 mm with mono 2% ST fiber. The hybrid fiber-reinforced UHP-ECCs had a spread fluidity, which ranged from 170 mm to 270 mm, with the combination of proper mechanical properties (tensile, flexural, and compressive properties) and fluidity, which may have a wider application in practical engineering.

- The fracture toughness of the matrix and the single-crack tension test of HUHP-ECCs were conducted to obtain the PSH values to explain the tensile strain-hardening phenomenon of HUHP-ECCs. Both the peak bridging stress and the corresponding crack opening displacement increased with the volume fraction of PE fiber, which led a higher value of Jb’ for PE fiber incorporated mixtures. The higher Lf/df of PE fiber helped to increase the bridging stress, while the lower bond strength between the PE fiber and matrix increased the crack opening displacement. The morphology of the samples was studied by ESEM analysis. Without ST fiber, most of the PE fibers ruptured along with the pull-out failure from the matrix; however, with the introduction of ST fiber, the failure mode of the PE fiber mainly changed to pull out failure. The lateral surface of PE fiber in HUHP-ECC-2.0-0 specimen was grooved severely on the surface. Conversely, the steel fiber surface was smooth and slightly stuck to matrix particles, making it obvious that the diameter of ST fiber was much larger than that of the PE fiber.

Author Contributions

Funding

Conflicts of Interest

References

- Li, V.C. On engineered cementitious composites (ECC): A review of the material and its applications. J. Adv. Concr. Technol. 2003, 1, 215–230. [Google Scholar] [CrossRef]

- Li, V.C.; Leung, C.K.Y. Steady-state and multiple cracking of short random fiber composites. J. Eng. Mech. 1992, 118, 2246–2264. [Google Scholar] [CrossRef]

- Li, V.C.; Wang, S.; Wu, C. Tensile strain-hardening behavior of polyvinyl alcohol engineered cementitious composite (PVA-ECC). ACI. Mater. J. 2001, 98, 483–492. [Google Scholar]

- Herbert, E.N.; Li, V.C. Self-Healing of Microcracks in Engineered Cementitious Composites (ECC) Under a Natural Environment. Materials 2013, 6, 2831–2845. [Google Scholar] [CrossRef] [PubMed]

- Richard, P.; Cheyrezy, M. Composition of reactive powder concretes. Cem. Concr. Res. 1995, 25, 1501–1511. [Google Scholar] [CrossRef]

- Sui, L.; Luo, M.; Yu, K.; Xing, F.; Li, P.; Zhou, Y.; Chen, C. Effect of engineered cementitious composite on the bond behavior between fiber-reinforced polymer and concrete. Compos. Struct. 2018, 184, 775–788. [Google Scholar] [CrossRef]

- Li, V.C. Tailoring ECC for special attributes: A review. Int. J. Concr. Struct. Mater. 2012, 6, 135–144. [Google Scholar] [CrossRef]

- Yu, K.Q.; Dai, J.G.; Lu, Z.D.; Poon, C.S. Rate-dependent tensile properties of ultra-high performance engineered cementitious composites (UHP-ECC). Cem. Concr. Compos. 2018, 93, 218–234. [Google Scholar] [CrossRef]

- Sui, L.L.; Zhong, Q.L.; Yu, K.Q.; Xing, F.; Li, P.; Zhou, Y.W. Flexural Fatigue Properties of Ultra-High Performance Engineered Cementitious Composites (UHP-ECC) Reinforced by Polymer Fibers. Polymers 2018, 10, 892. [Google Scholar] [CrossRef]

- Yu, K.Q.; Wang, Y.C.; Yu, J.T.; Xu, S.L. A strain-hardening cementitious composites with the tensile capacity up to 8%. Constr. Build. Mater. 2017, 137, 410–419. [Google Scholar] [CrossRef]

- Yu, K.Q.; Yu, J.T.; Dai, J.G.; Lu, Z.D.; Shah, S.P. Development of ultra-high performance engineered cementitious composites using polyethylene (PE) fibers. Constr. Build. Mater. 2018, 158, 217–227. [Google Scholar] [CrossRef]

- Ding, Y.; Yu, J.T.; Yu, K.Q.; Xu, S.L. Basic mechanical properties of ultra-high ductility cementitious composites: From 40 MPa to 120 MPa. Compos. Struct. 2018, 185, 634–645. [Google Scholar] [CrossRef]

- Yu, K.Q.; Yu, J.T.; Dai, J.G.; Lu, Z.D.; Shah, S.P. Structural behaviors of ultra-high performance engineered cementitious composites (UHP-ECC) beams subjected to bending-experimental study. Constr. Build. Mater. 2018, 177, 102–115. [Google Scholar]

- Bhat, P.S.; Chang, V.; Li, M. Effect of elevated temperature on strain-hardening engineered cementitious composites. Constr. Build. Mater. 2014, 69, 370–380. [Google Scholar] [CrossRef]

- Liu, J.C.; Tan, K.H.; Zhang, D. Multi-response optimization of post-fire performance of strain hardening cementitious composite. Cem. Concr. Compos. 2017, 80, 80–90. [Google Scholar] [CrossRef]

- Yu, K.Q.; Dai, J.G.; Lu, Z.D.; Leung, C.K.Y. Mechanical properties of engineered cementitious composites subjected to elevated temperatures. J. Mater. Civ. Eng. 2015, 27, 04014268. [Google Scholar] [CrossRef]

- Li, X.; Bao, Y.; Xue, N.; Chen, G. Bond strength of steel bars embedded in high-performance fiber-reinforced cementitious composite before and after exposure to elevated temperature. Fire. Safety. J. 2017, 92, 98–106. [Google Scholar] [CrossRef]

- Cheyrezy, M.; Maret, V.; Frouin, L. Microstructural analysis of RPC (reactive powder concrete). Cem. Concr. Res. 1995, 25, 1491–1500. [Google Scholar] [CrossRef]

- Reda, M.M.; Shrive, N.G.; Gillott, J.E. Microstructural investigation of innovative UHPC. Cem. Concr. Res. 1999, 29, 323–329. [Google Scholar] [CrossRef]

- Graybeal, B.; Davis, M. Cylinder or cube: strength testing of 80 to 200 MPa (11.6 to 29 ksi) ultra-high-performance fiber-reinforced concrete. Mater. J. 2008, 105, 603–609. [Google Scholar]

- Hrynyk, T.D.; Vecchio, F.J. Behavior of steel fiber-reinforced concrete slabs under impact load. ACI. Struct. J. 2014, 111, 1213. [Google Scholar] [CrossRef]

- Zheng, W.; Luo, B.; Wang, Y. Compressive and tensile properties of reactive powder concrete with steel fibers at elevated temperatures. Constr. Build. Mater. 2013, 41, 844–851. [Google Scholar] [CrossRef]

- Lau, A.; Anson, M. Effect of high temperatures on high performance steel fiber reinforced concrete. Cem. Concr. Res. 2006, 36, 1698–1707. [Google Scholar] [CrossRef]

- Wang, R.; Gao, X. Relationship between flowability, entrapped air content and strength of UHPC mixtures containing different dosage of steel fiber. Appl. Sci. 2016, 6, 216. [Google Scholar] [CrossRef]

- Lee, M.G.; Huang, Y.S. Fire-damage or freeze-thaw of strengthening concrete using ultra high performance concrete. Adv. Mater. Res. 2009, 79, 2047–2050. [Google Scholar] [CrossRef]

- Kang, S.H.; Lee, J.H.; Hong, S.G.; Moon, J. Microstructural investigation of heat-treated ultra-high performance concrete for optimum production. Materials 2017, 10, 1106. [Google Scholar] [CrossRef] [PubMed]

- Wille, K.; Kim, D.J.; Naaman, A.E. Strain-hardening UHP-FRC with low fiber contents. Mater. Struct. 2011, 44, 583–598. [Google Scholar] [CrossRef]

- Naaman, A.E.; Reinhardt, H.W. Proposed classification of HPFRC composites based on their tensile response. Mater. Struct. 2006, 39, 547–555. [Google Scholar] [CrossRef]

- Park, J.-J.; Yoo, D.-Y.; Park, G.-J.; Kim, S.-W. Feasibility of Reducing the Fiber Content in Ultra-High-Performance Fiber-Reinforced Concrete under Flexure. Materials 2017, 10, 118. [Google Scholar] [CrossRef] [PubMed]

- Rossi, P.; Acker, P.; Malier, Y. Effect of steel fibers at two different stages, the material and the structure. Mater. Struct. 1987, 20, 436–439. [Google Scholar] [CrossRef]

- Wuest, J.; Denarie, E.; Bruehwiler, E. Model for predicting the UHP-FRC tensile hardening response. In Proceedings of the second international symposium on ultra high performance concrete, Kassel, Germany, 5–7 March 2008; Fehling, E., Schmidt, M., Stűrwald, S., Eds.; Kassel University Publications: Kassel, Germany, 2008; pp. 153–160. [Google Scholar]

- Park, S.H.; Kim, D.J.; Ryu, G.S.; Koh, K.T. Tensile behavior of ultra high performance hybrid fiber reinforced concrete. Cem. Concr. Compos. 2012, 34, 172–184. [Google Scholar] [CrossRef]

- Qian, C.X.; Stroeven, P. Development of hybrid polypropylene-steel fibre-reinforced concrete. Cem. Concr. Res. 2000, 30, 63–69. [Google Scholar] [CrossRef]

- Ahmed, S.F.U.; Maalej, M.; Paramasivam, P. Flexural responses of hybrid steel–polyethylene fiber reinforced cement composites containing high volume fly ash. Constr. Build. Mater. 2007, 21, 1088–1097. [Google Scholar] [CrossRef]

- Zhang, W.; Yin, C.; Ma, F.; Huang, Z. Mechanical Properties and Carbonation Durability of Engineered Cementitious Composites Reinforced by Polypropylene and Hydrophilic Polyvinyl Alcohol Fibers. Materials 2018, 11, 1147. [Google Scholar] [CrossRef] [PubMed]

- Chen, B.; Liu, J. Residual strength of hybrid-fiber-reinforced high-strength concrete after exposure to high temperatures. Cem. Concr. Res. 2004, 34, 1065–1069. [Google Scholar] [CrossRef]

- Ahmed, S.F.U.; Maalej, M. Tensile strain hardening behaviour of hybrid steel-polyethylene fibre reinforced cementitious composites. Constr. Build. Mater. 2009, 23, 96–106. [Google Scholar] [CrossRef]

- Li, V.C. Engineered cementitious composites—a tailored composite through micromechanical modeling. In Fiber Reinforced Concrete: Present and the Future; Banthia, N., Bentur, A., Mufti, A., Eds.; Canadian Society of Civil Engineer s: Montreal, Canada, 1998; pp. 64–97. [Google Scholar]

- Wang, S.; Wu, C.; Li, V.C. Interface Tailoring for Strain-Hardening Polyvinyl Alcohol-Engineered Cementitious Composite (PVA-ECC). Mater. J. 2002, 99, 463–472. [Google Scholar]

- GB/T2419-2005. Cement Mortar Fluidity Analyzer, the NLD,-3 Cement Mortar Fluidity Tester; Standardization Administration of China: Beijing, China, 2005.

- JSCE 1-16. Recommendations for Design and Construction of High Performance Fiber Reinforced Cement Composites with Multiple Fine Cracks; Japan Society of Civil Engineers Press: Tokyo, Japan, 2008.

- CECS 44-8. Standard Test Methods for Fiber Reinforced Concrete; China Engineering and Construction Society Press: Beijing, China, 2009.

- Rilem, T.C. Determination of the fracture energy of mortar and concrete by means of three-point bend tests on notched beams. Mater. Struct. 1985, 18, 285–290. [Google Scholar]

- Graybeal, B.A. Compressive behavior of ultra-high-performance fiber-reinforced concrete. ACI. Mater. J. 2007, 104, 146. [Google Scholar]

- Kanda, T.; Li, V.C. New micromechanics design theory for pseudostrain hardening cementitious composite. J. Eng. Mech. 1999, 125, 373–381. [Google Scholar] [CrossRef]

- Marshall, D.B.; Cox, B.N. A J-integral method for calculating steady-state matrix cracking stresses in composites. Mech. Mater. 1988, 7, 127–133. [Google Scholar] [CrossRef]

- Xu, S.; Reinhardt, H.W. Determination of double-K criterion for crack propagation in quasi-brittle fracture, Part II, Analytical evaluating and practical measuring methods for three-point bending notched beams. Int. J. Fract. 1999, 98, 151–177. [Google Scholar] [CrossRef]

- Kanda, T.; Li, V.C. Multiple cracking sequence and saturation in fiber reinforced cementitious composites. Conc. Res. Technol. JCI 1998, 9, 19–33. [Google Scholar] [CrossRef]

| Chemical Composition (%) | Ingredients | OPC | GGBFS | SF |

| Na2O | 0.08 | 0.20 | 0.42 | |

| MgO | 0.66 | 6.94 | 0.96 | |

| Al2O3 | 4.42 | 12.94 | 0.89 | |

| SiO2 | 19.9 | 39.66 | 92.26 | |

| P2O5 | 0.10 | / | / | |

| SO3 | 2.67 | 0.72 | 0.33 | |

| K2O | 0.79 | 1.44 | 1.31 | |

| CaO | 64.9 | 34.20 | 0.49 | |

| TiO2 | 0.21 | / | / | |

| MnO | 0.10 | / | / | |

| Fe2O3 | 3.00 | 1.58 | 1.97 |

| Fiber Types | Length (mm) | Diameter (μm) | Fiber Aspect Ratio Lf/df | Modulus of Elasticity (GPa) | Fiber Strength (MPa) | Fiber Density (gm/cm3) |

|---|---|---|---|---|---|---|

| Straight Steel | 13 | 200 | 65 | 200 | 2750 | 7.85 |

| PE | 18 | 25 | 750 | 116 | 2900 | 0.97 |

| Mixture ID | Cement | SF | GGBFS | Sand | Water | Fiber volume fraction (%) | HRWRA | |

|---|---|---|---|---|---|---|---|---|

| PE | ST | |||||||

| HUHP-ECC-2.0-0 | 700 | 230 | 750 | 500 | 230 | 2.0 | 0 | 45 |

| HUHP-ECC-1.5-0.5 | 700 | 230 | 750 | 500 | 230 | 1.5 | 0.5 | 45 |

| HUHP-ECC-1.0-1.0 | 700 | 230 | 750 | 500 | 230 | 1.0 | 1.0 | 45 |

| HUHP-ECC-0.5-1.5 | 700 | 230 | 750 | 500 | 230 | 0.5 | 1.5 | 45 |

| HUHP-ECC-0-2.0 | 700 | 230 | 750 | 500 | 230 | 0 | 2.0 | 45 |

| Mixture ID | HUHP-ECC-2.0-0 | HUHP-ECC-1.5-0.5 | HUHP-ECC-1.0-1.0 | HUHP-ECC-0.5-1.5 | HUHP-ECC-0-2.0 |

| Uniaxial Tension Test | 8 | 8 | 8 | 8 | 8 |

| Uniaxial Compression Test (cube) | 6 | 6 | 6 | 6 | 6 |

| Four-Point Flexural Test | 6 | 6 | 6 | 6 | 6 |

| Single Crack Tension Test | 8 | 8 | 8 | 8 | 8 |

| Specimen | Em (GPa) | m (kg) | FQ (kN) | Km (MPa m1/2) | Jtip(J/m2) |

|---|---|---|---|---|---|

| Matrix of HUHP-ECC | 35.9 | 0.586 | 1.6 | 0.973 | 26.6 |

| S.D. | 0.12 | 0.21 | 0.08 | 0.15 | 0.26 |

| Specimen | HUHP-ECC -2.0-0 | HUHP-ECC -1.5-0.5 | HUHP-ECC -1.0-1.0 | HUHP-ECC -0.5-1.5 | HUHP-ECC -0-2.0 | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| σb (MPa) | δb (mm) | σb (MPa) | δb (mm) | σb (MPa) | δb (mm) | σb (MPa) | δb (mm) | σb (MPa) | δb (mm) | |

| Average | 17.33 | 0.642 | 14.81 | 0.551 | 14.44 | 0.492 | 12.53 | 0.452 | 12.43 | 0.224 |

| S.D. | 0.22 | 0.36 | 0.04 | 0.75 | 1.47 | 2.46 | 0.76 | 1.34 | 2.34 | 0.67 |

| Specimens | HUHP-ECC-2.0-0 | HUHP-ECC-1.5-0.5 | HUHP-ECC-1.0-1.0 | HUHP-ECC-0.5-1.5 | HUHP-ECC-0-2.0 |

|---|---|---|---|---|---|

| Jb′(J/m2) | 3000 | 1938 | 1520 | 500 | 47 |

| PSH | 112.6 | 72.7 | 57.1 | 18.8 | 1.8 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Y.; Xi, B.; Yu, K.; Sui, L.; Xing, F. Mechanical Properties of Hybrid Ultra-High Performance Engineered Cementitous Composites Incorporating Steel and Polyethylene Fibers. Materials 2018, 11, 1448. https://doi.org/10.3390/ma11081448

Zhou Y, Xi B, Yu K, Sui L, Xing F. Mechanical Properties of Hybrid Ultra-High Performance Engineered Cementitous Composites Incorporating Steel and Polyethylene Fibers. Materials. 2018; 11(8):1448. https://doi.org/10.3390/ma11081448

Chicago/Turabian StyleZhou, Yingwu, Bin Xi, Kequan Yu, Lili Sui, and Feng Xing. 2018. "Mechanical Properties of Hybrid Ultra-High Performance Engineered Cementitous Composites Incorporating Steel and Polyethylene Fibers" Materials 11, no. 8: 1448. https://doi.org/10.3390/ma11081448

APA StyleZhou, Y., Xi, B., Yu, K., Sui, L., & Xing, F. (2018). Mechanical Properties of Hybrid Ultra-High Performance Engineered Cementitous Composites Incorporating Steel and Polyethylene Fibers. Materials, 11(8), 1448. https://doi.org/10.3390/ma11081448