Fabrication of Polymer Microstructures of Various Angles via Synchrotron X-Ray Lithography Using Simple Dimensional Transformation

Abstract

:1. Introduction

2. Materials and Methods

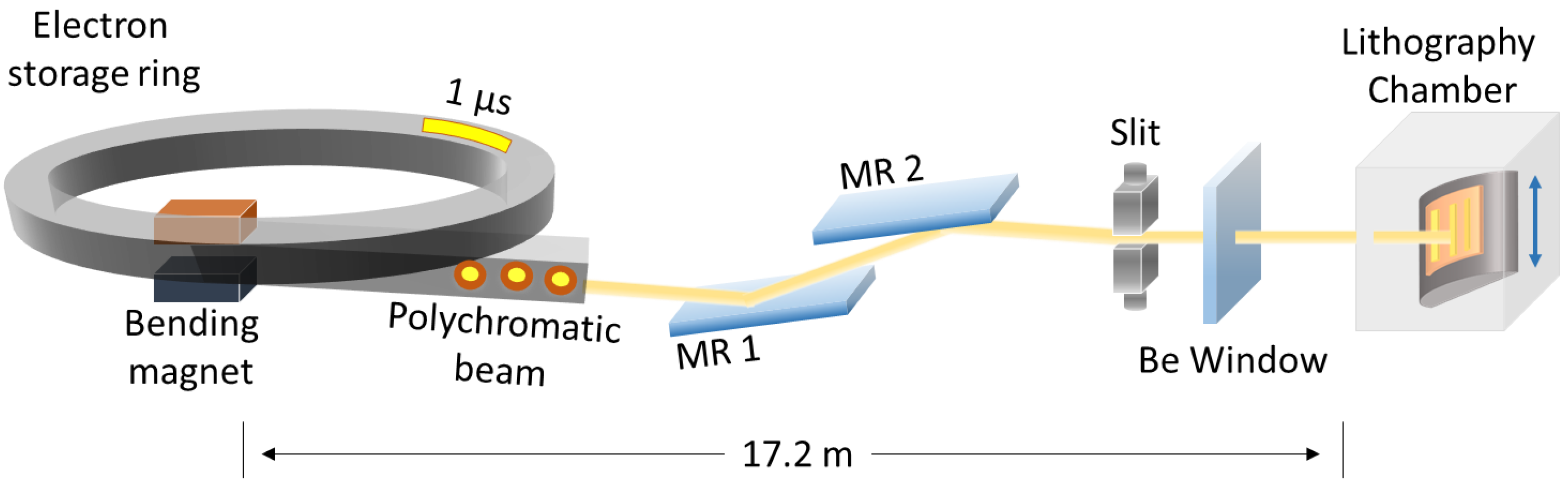

2.1. Experimental Setup

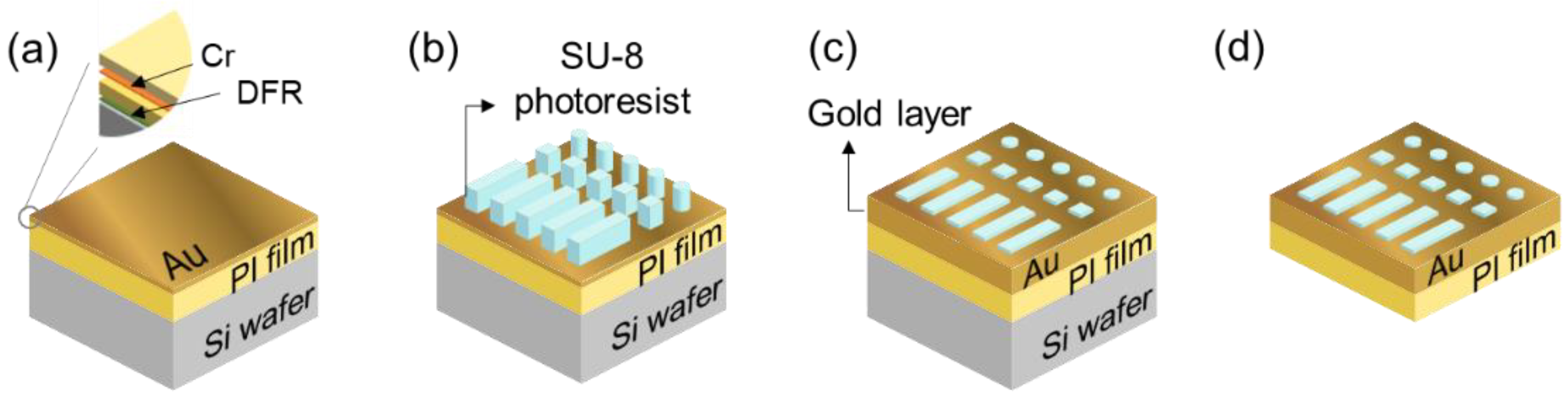

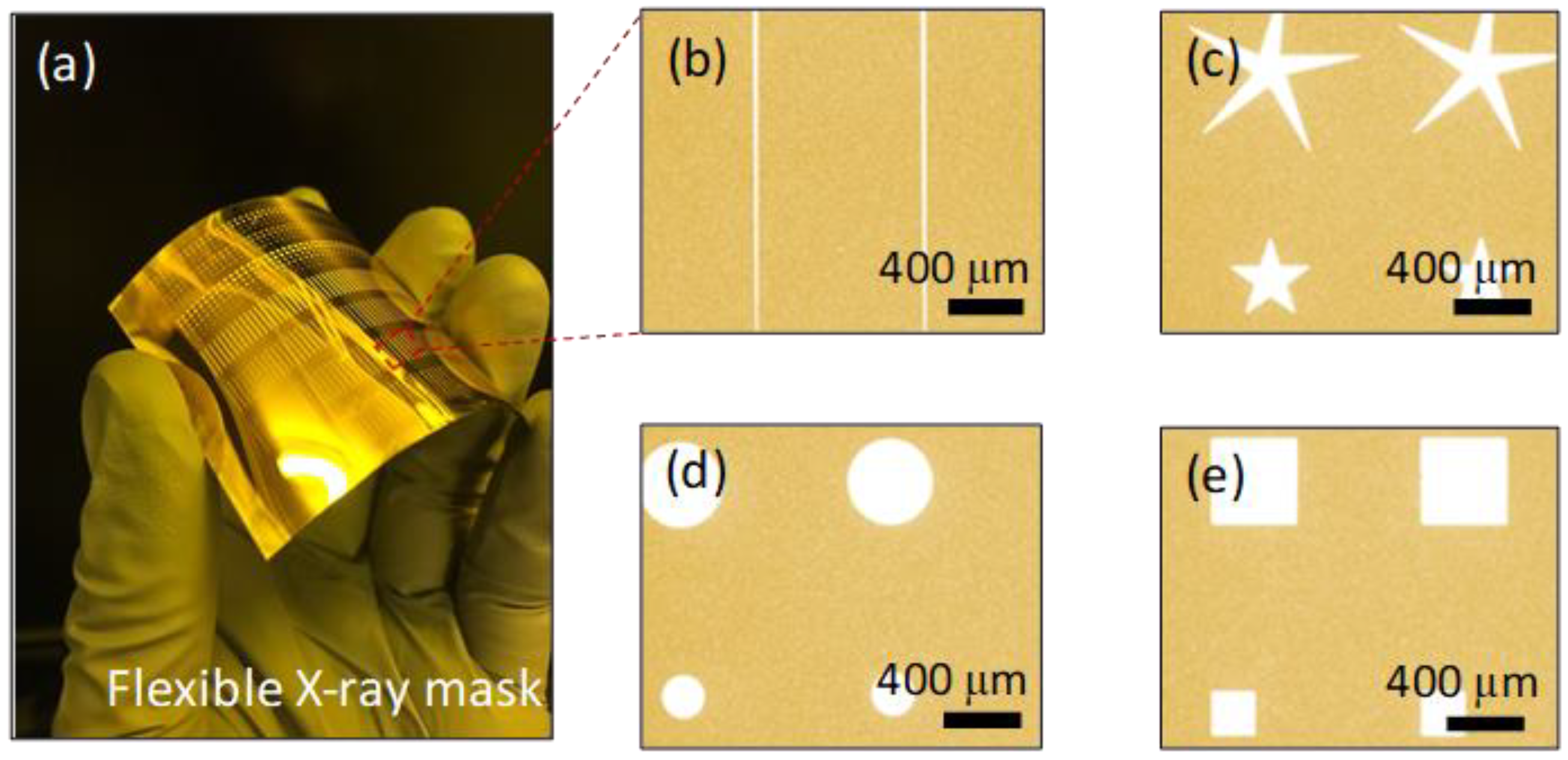

2.2. Fabrication of a Flexible X-Ray Mask

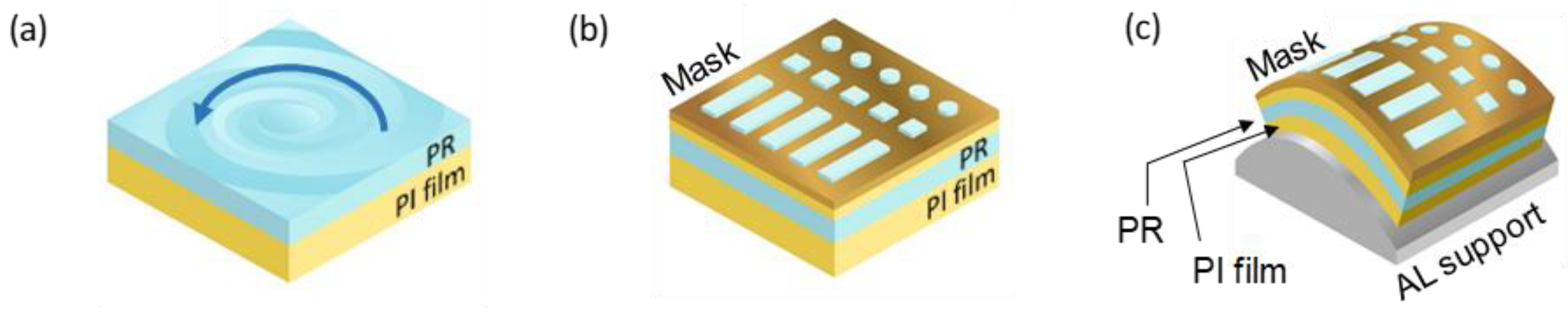

2.3. Fabrication of Microstructures of Various Angles

2.3.1. Spin-Coating

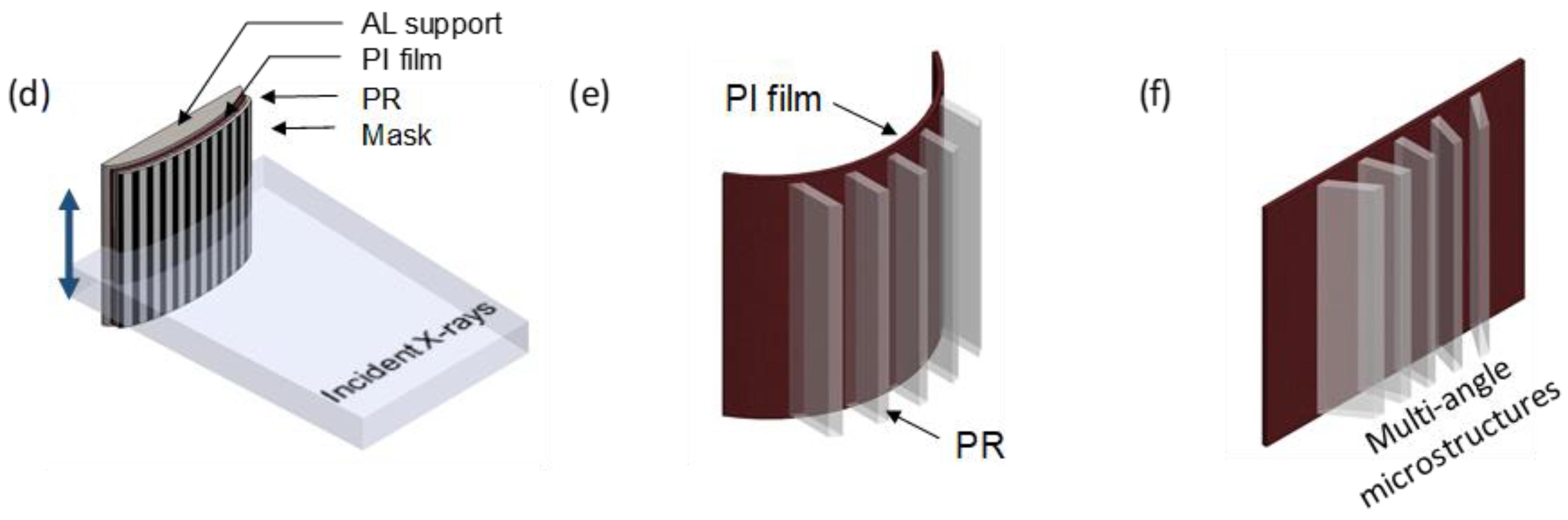

2.3.2. X-Ray Exposure

2.3.3. Development

3. Results

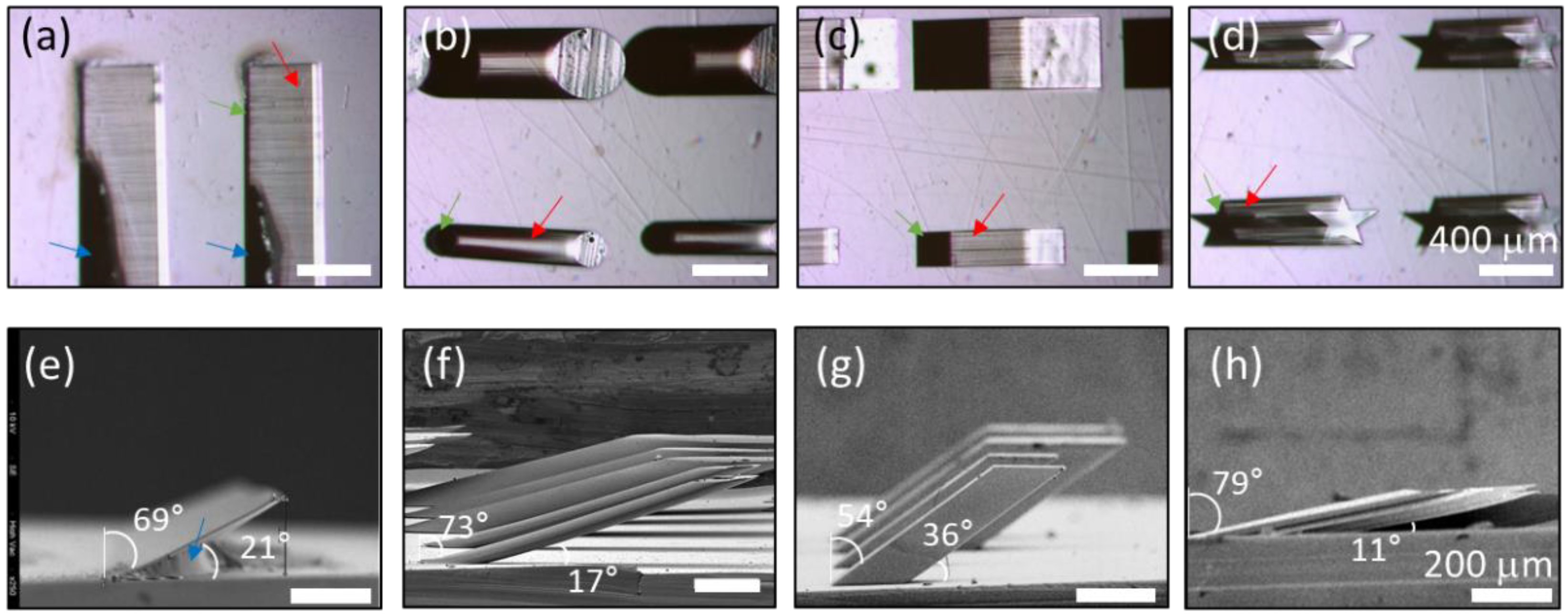

3.1. Fabricated Polymer Microstructures of Various Shapes on a Flexible Substrate.

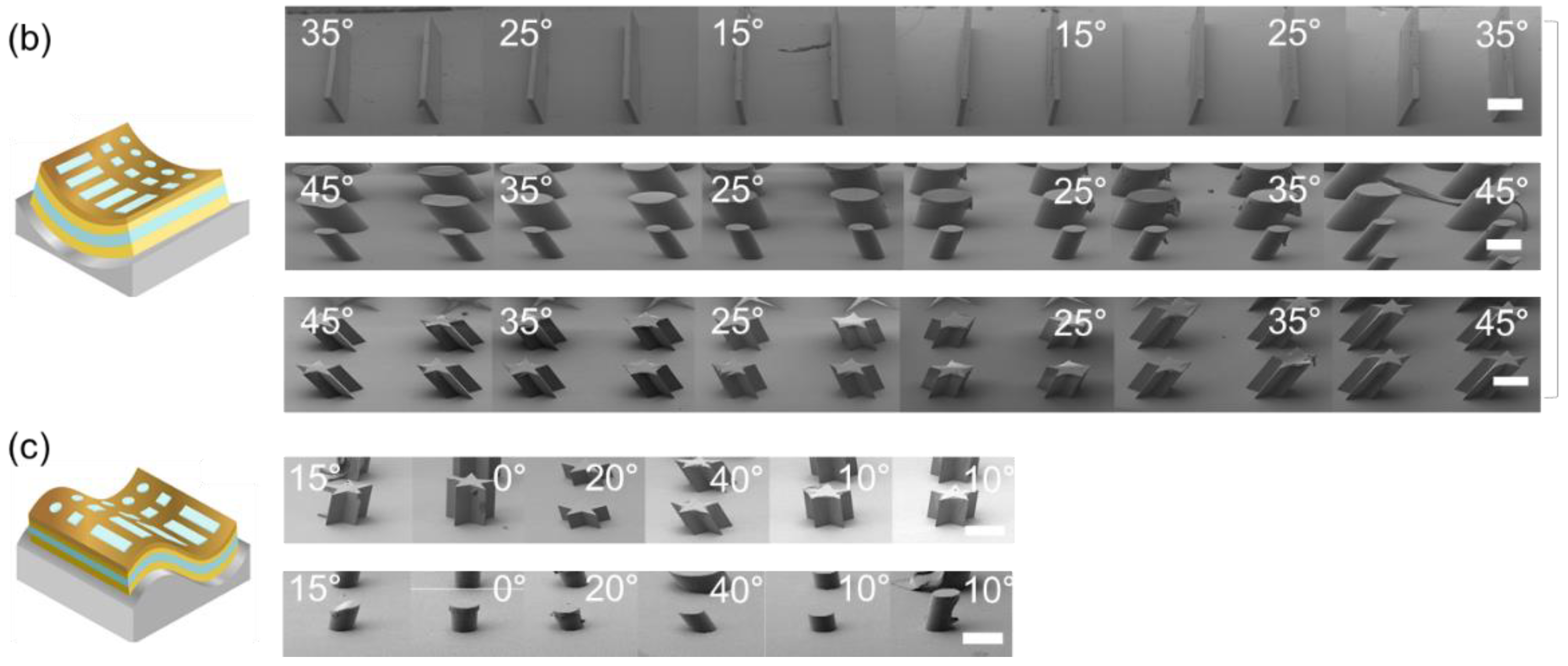

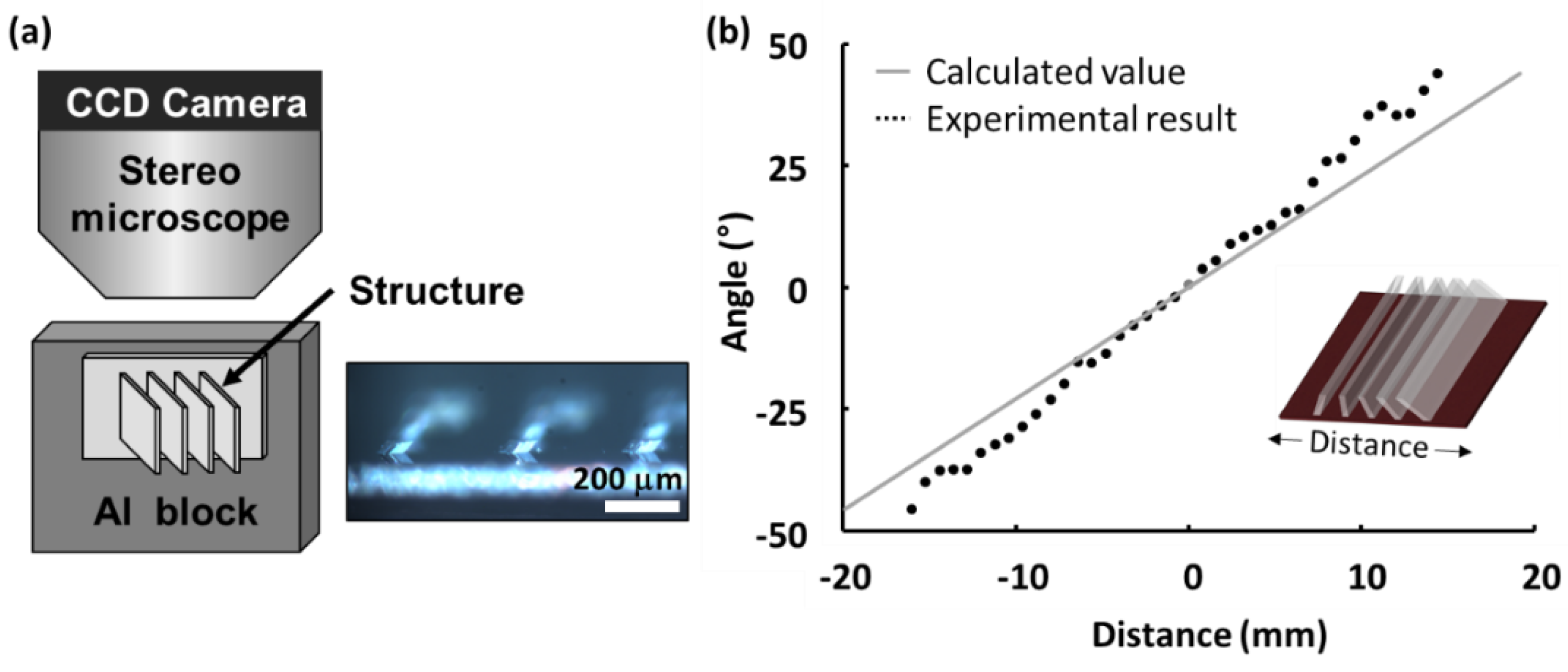

3.2. Fabricated Polymer Microstructures of Various Angles on a Flexible Substrate

4. Discussion

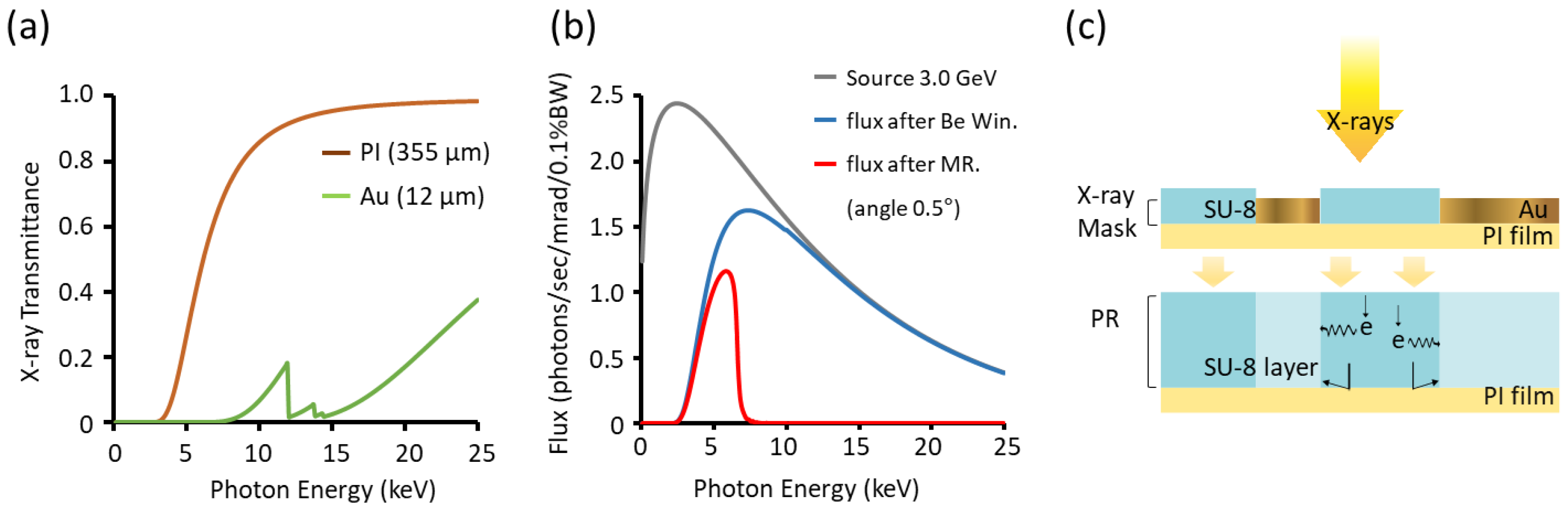

4.1. Interactions between the Beam Source and Materials

4.2. The Utility of the Fabricated Structures in Real Applications

4.3. Limitations of the Fabrication Process

5. Conclusion

Supplementary Materials

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Becker, E.W. Fabrication of microstructures with high aspect ratios and great structural heights by synchrotron radiation lithography, galvanoforming, and plastic moulding (LIGA process). Microelectron. Eng. 1986, 4, 35–56. [Google Scholar] [CrossRef]

- Backer, E.W. Production of separation-nozzle systems for uranium enrichment by a combination of X-ray lithography and galvanoplastics. Naturwissenschaften 1982, 69, 520–523. [Google Scholar] [CrossRef]

- Rousseaux, F. Study of large area high density magnetic dot arrays fabricated using synchrotron radiation based x-ray lithography. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. Process. Meas. Phenom. 1995, 13, 2787–2791. [Google Scholar] [CrossRef]

- Ishihara, S. A vertical stepper for synchrotron x-ray lithography. J. Vac. Sci. Technol. B Microelectron. Process. Phenom. 1989, 7, 1652–1656. [Google Scholar] [CrossRef]

- Guckel, K. Fabrication of assembled micromechanical components via deep X-ray lithography. In Proceedings of the IEEE Micro Electro Mechanical Systems, Nara, Japan, 30 December 1990–2 January 1991. [Google Scholar]

- Zhang, X.; Jiang, X.; Sun, C. Micro-stereolithography of polymeric and ceramic microstructures. Sens. Actuators A Phys. 1999, 77, 149–156. [Google Scholar] [CrossRef]

- Cima, M. Three-dimensional printing techniques. US5387380A, 7 February 1995. [Google Scholar]

- Jian, L.; Desta, Y.M.; Goettert, J. Multilevel microstructures and mold inserts fabricated with planar and oblique x-ray lithography of SU-8 negative photoresist. In Proceedings of the Micromachining and Microfabrication Process Technology VII, San Francisco, CA, USA, 28 September 2001. [Google Scholar]

- O’Neill, F.T.; Sheridan, J.T. Photoresist reflow method of microlens production Part I: Background and experiments. Optik Int. J. Light Electron Optics 2002, 113, 391–404. [Google Scholar] [CrossRef]

- Kim, K. A tapered hollow metallic microneedle array using backside exposure of SU-8. J. Micromech. Microeng. 2004, 14, 597. [Google Scholar] [CrossRef]

- Rammohan, A. One-step maskless grayscale lithography for the fabrication of 3-dimensional structures in SU-8. Sens. Actuators B Chem. 2011, 153, 125–134. [Google Scholar] [CrossRef]

- Chou, S.Y.; Krauss, P.R.; Renstrom, P.J. Nanoimprint lithography. J. Vac. Sci. Technol. B 1996, 14, 4129–4133. [Google Scholar] [CrossRef]

- Guo, L.J. Nanoimprint lithography: Methods and material requirements. Adv. Mater. 2007, 19, 495–513. [Google Scholar] [CrossRef]

- Hamdana, G. Towards fabrication of 3D isotopically modulated vertical silicon nanowires in selective areas by nanosphere lithography. Microelectron. Eng. 2017, 179, 74–82. [Google Scholar] [CrossRef]

- Yang, S.M. Nanomachining by colloidal lithography. Small 2006, 2, 458–475. [Google Scholar] [CrossRef] [PubMed]

- Gu, X.D. High Aspect Ratio Sub-15 nm Silicon Trenches From Block Copolymer Templates. Adv. Mater. 2012, 24, 5688–5694. [Google Scholar] [CrossRef] [PubMed]

- Manfrinato, V.R. Resolution Limits of Electron-Beam Lithography toward the Atomic Scale. Nano Lett. 2013, 13, 1555–1558. [Google Scholar] [CrossRef] [PubMed]

- Park, J.; Fujita, H.; Kim, B. Fabrication of metallic microstructure on curved substrate by optical soft lithography and copper electroplating. Sens. Actuators Phys. 2011, 168, 105–111. [Google Scholar] [CrossRef]

- Park, J.; Kim, B. 3D micro patterning on a concave substrate for creating the replica of a cylindrical PDMS stamp. Microelectron. Eng. 2012, 98, 540–543. [Google Scholar] [CrossRef]

- Jeong, K.H.; Kim, J.; Lee, L.P. Biologically inspired artificial compound eyes. Science 2006, 312, 557–561. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.H.; Chang, S.S.; Lim, G. Fabrication of multi-scale structures with multiple X-ray masks and synchrotron hard X-ray irradiations. Curr. Appl. Phys. 2014, 14, 833–837. [Google Scholar] [CrossRef]

- Pantenburg, F.J.; Mohr, J. Influence of Secondary Effects on the Structure Quality in Deep X-Ray-Lithography. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 1995, 97, 551–556. [Google Scholar] [CrossRef]

- Becnel, C.; Desta, Y.; Kelly, K. Ultra-deep x-ray lithography of densely packed SU-8 features: II. Process performance as a function of dose, feature height and post exposure bake temperature. J. Micromechan. Microeng. 2005, 15, 1249–1259. [Google Scholar] [CrossRef]

- Sugiyama, S.; Khumpuang, S.; Kawaguchi, G. Plain-pattern to cross-section transfer (PCT) technique for deep x-ray lithography and applications. J. Micromechan. Microeng. 2004, 14, 1399–1404. [Google Scholar] [CrossRef]

| Specification | 9D Beamline |

|---|---|

| Electron energy | 3 GeV 1 |

| Beam current | 400 mA |

| Horizontal beam span | 8 mrad |

| Vertical beam span | 0.34 mrad |

| Beam size at sample | 100 mm (H) × 10 mm (V) |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, K.; Kim, K.; Lee, S.C.; Lim, G.; Kim, J.H. Fabrication of Polymer Microstructures of Various Angles via Synchrotron X-Ray Lithography Using Simple Dimensional Transformation. Materials 2018, 11, 1460. https://doi.org/10.3390/ma11081460

Park K, Kim K, Lee SC, Lim G, Kim JH. Fabrication of Polymer Microstructures of Various Angles via Synchrotron X-Ray Lithography Using Simple Dimensional Transformation. Materials. 2018; 11(8):1460. https://doi.org/10.3390/ma11081460

Chicago/Turabian StylePark, Kyungjin, Kanghyun Kim, Seung Chul Lee, Geunbae Lim, and Jong Hyun Kim. 2018. "Fabrication of Polymer Microstructures of Various Angles via Synchrotron X-Ray Lithography Using Simple Dimensional Transformation" Materials 11, no. 8: 1460. https://doi.org/10.3390/ma11081460

APA StylePark, K., Kim, K., Lee, S. C., Lim, G., & Kim, J. H. (2018). Fabrication of Polymer Microstructures of Various Angles via Synchrotron X-Ray Lithography Using Simple Dimensional Transformation. Materials, 11(8), 1460. https://doi.org/10.3390/ma11081460