Author Contributions

Conceptualization, J.M.-C. and J.R.G.A.; Methodology, J.M.-C., J.R.G.A. and S.M.P.; Software, S.M.P.; Validation, J.R.G.A. and M.A.d.l.S.L.; Formal Analysis, J.M.-C., S.M.P. and M.A.d.l.S.L.; Investigation, J.M.-C., S.M.P. and M.A.d.l.S.L.; Resources, S.M.P.; Data Curation, J.M.-C. and S.M.P.; Writing-Original Draft Preparation, J.M.-C., S.M.P. and M.A.d.l.S.L.; Writing-Review & Editing, J.M.-C.; Visualization, J.M.-C. and S.M.P.; Supervision, J.M.-C. and J.R.G.A.; Project Administration, J.M.-C. and S.M.P.; Funding Acquisition, J.M.-C. and M.A.d.l.S.L.

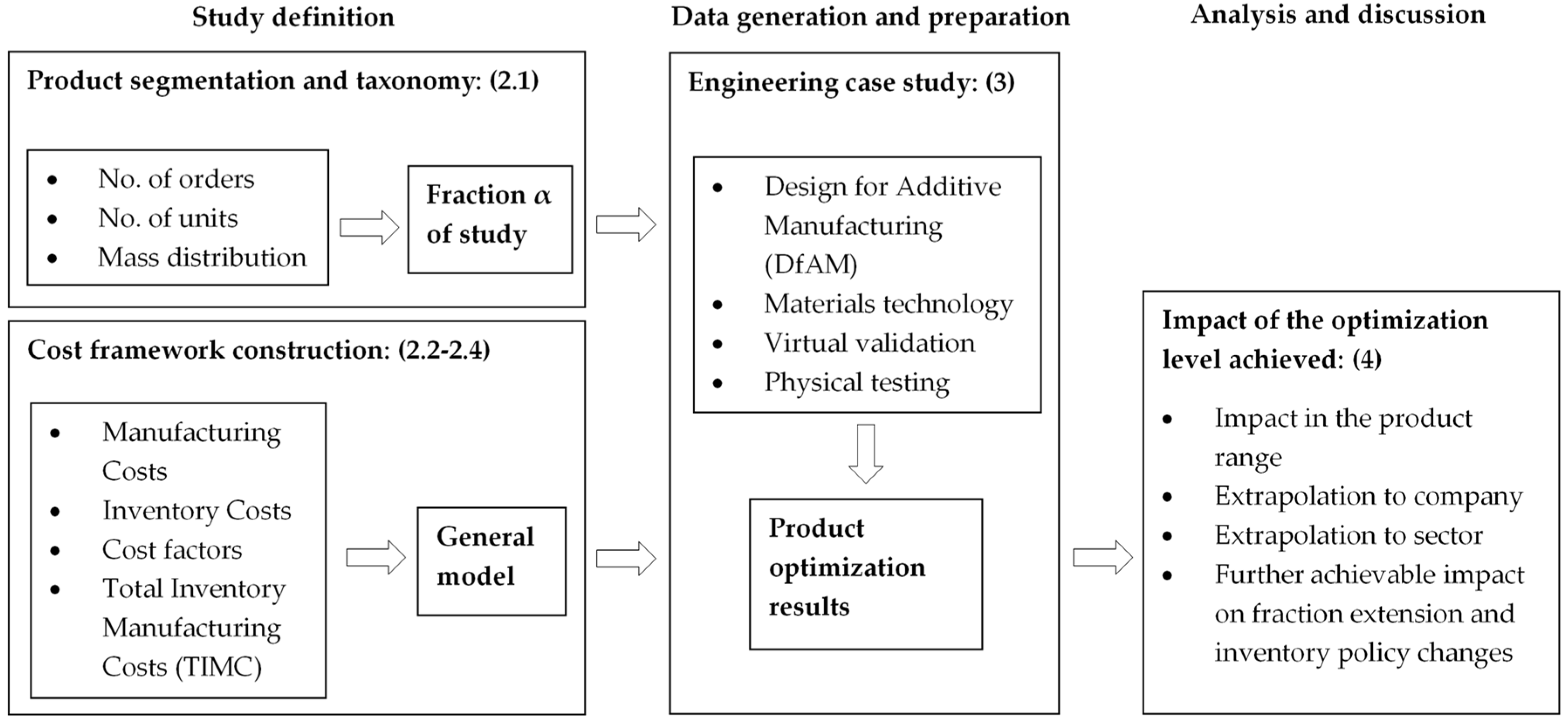

Figure 1.

Flow diagram of the present study methodology.

Figure 1.

Flow diagram of the present study methodology.

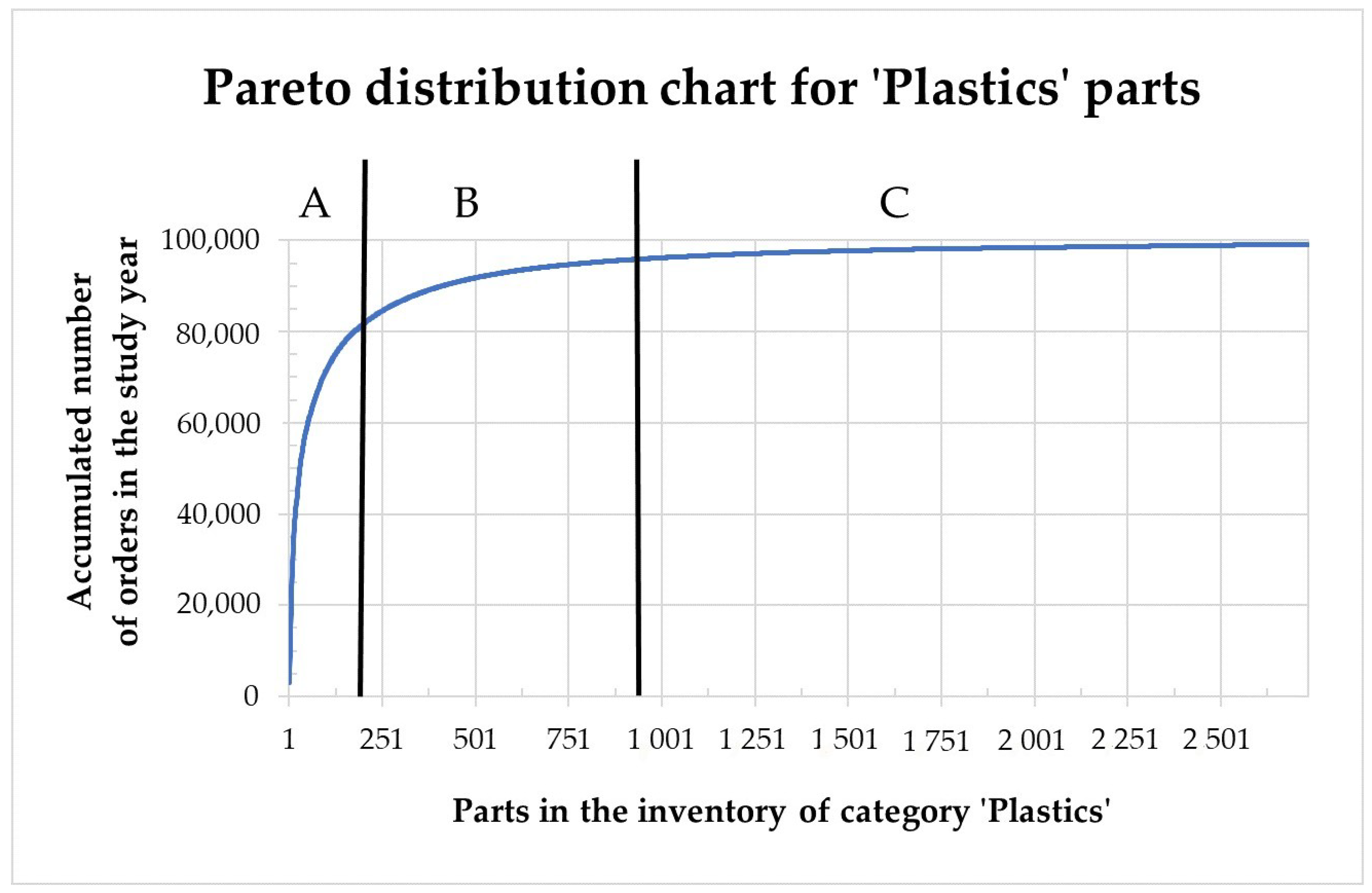

Figure 2.

Pareto distribution A-B-C of the orders received for all references within the category ‘Plastics’. Elaborated by the authors from Unistral Recambios data.

Figure 2.

Pareto distribution A-B-C of the orders received for all references within the category ‘Plastics’. Elaborated by the authors from Unistral Recambios data.

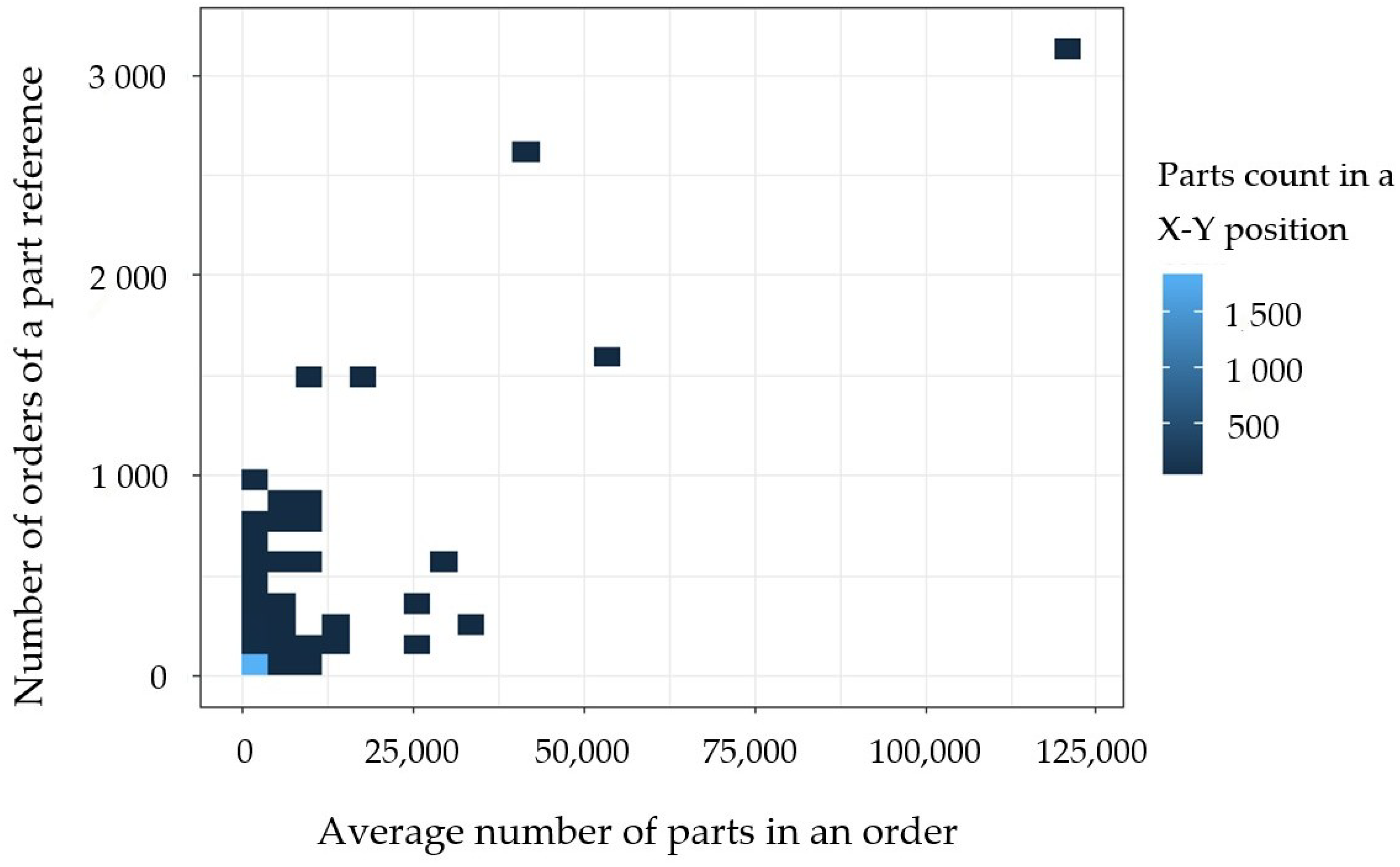

Figure 3.

3D quantification of the rotation of the products. For each part, a plot in X and Y is configured with the number of orders received and the average number of units sold in each order within the categories ‘Plastics’. Elaborated by the authors from Unistral Recambios data.

Figure 3.

3D quantification of the rotation of the products. For each part, a plot in X and Y is configured with the number of orders received and the average number of units sold in each order within the categories ‘Plastics’. Elaborated by the authors from Unistral Recambios data.

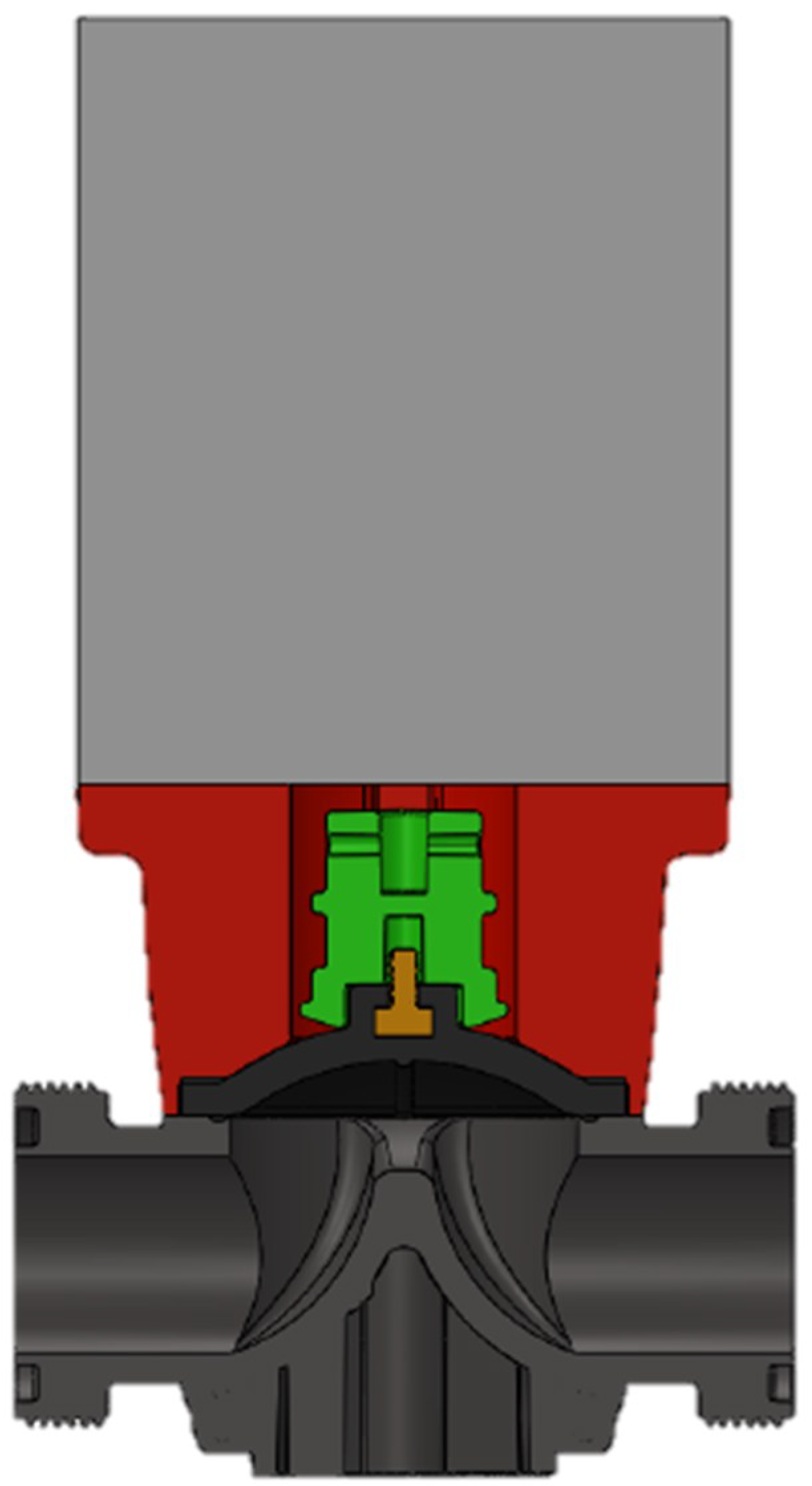

Figure 4.

Automatic valve section, in red the part to be redesigned and assessed (support).

Figure 4.

Automatic valve section, in red the part to be redesigned and assessed (support).

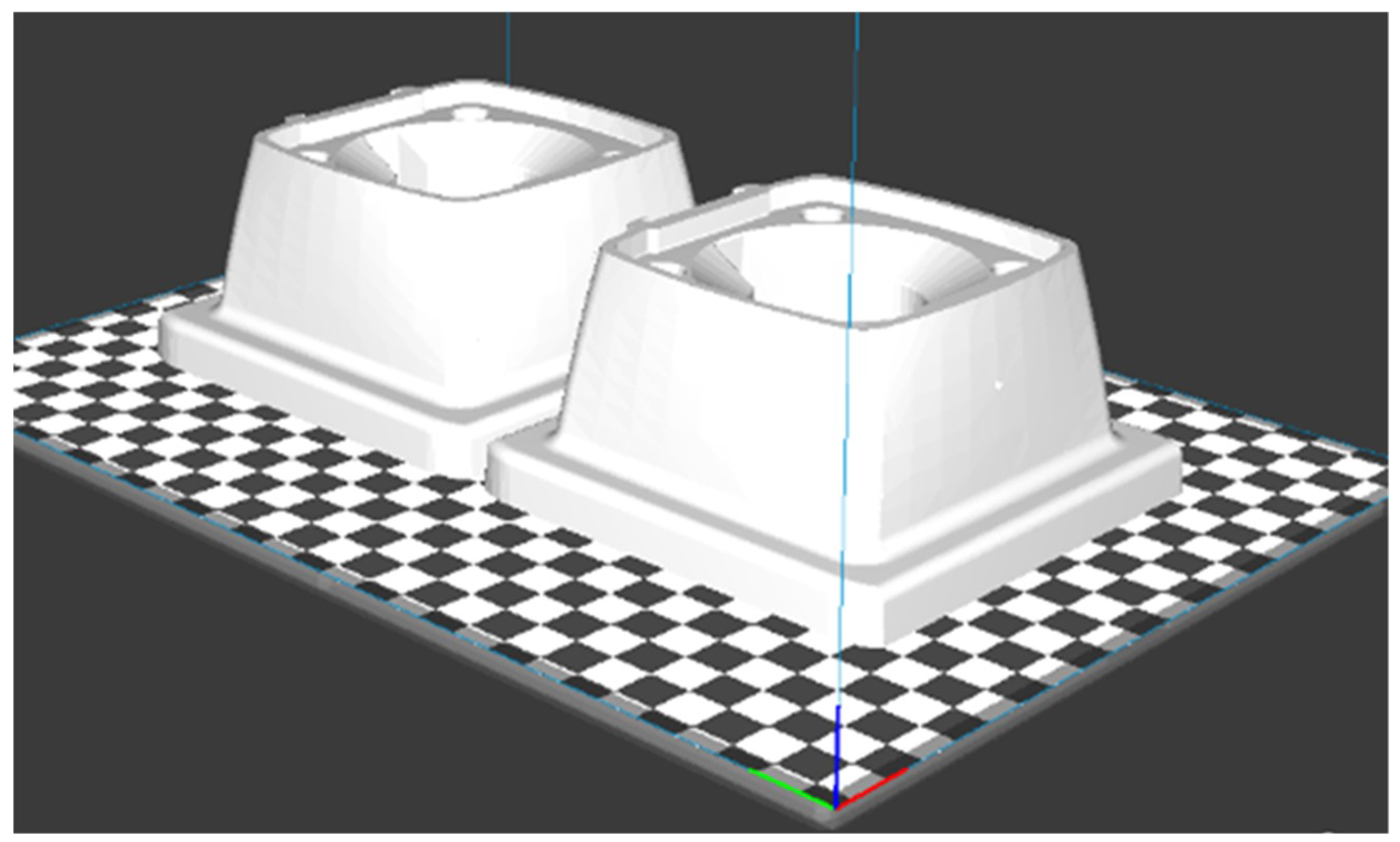

Figure 5.

BCN3D CURA software platform simulation the case study part (support) in the original design model.

Figure 5.

BCN3D CURA software platform simulation the case study part (support) in the original design model.

Figure 6.

Case study printed parts: (a) Support manufactured with an infill percentage of 25%; (b) support manufactured with an infill percentage of 75%.

Figure 6.

Case study printed parts: (a) Support manufactured with an infill percentage of 25%; (b) support manufactured with an infill percentage of 75%.

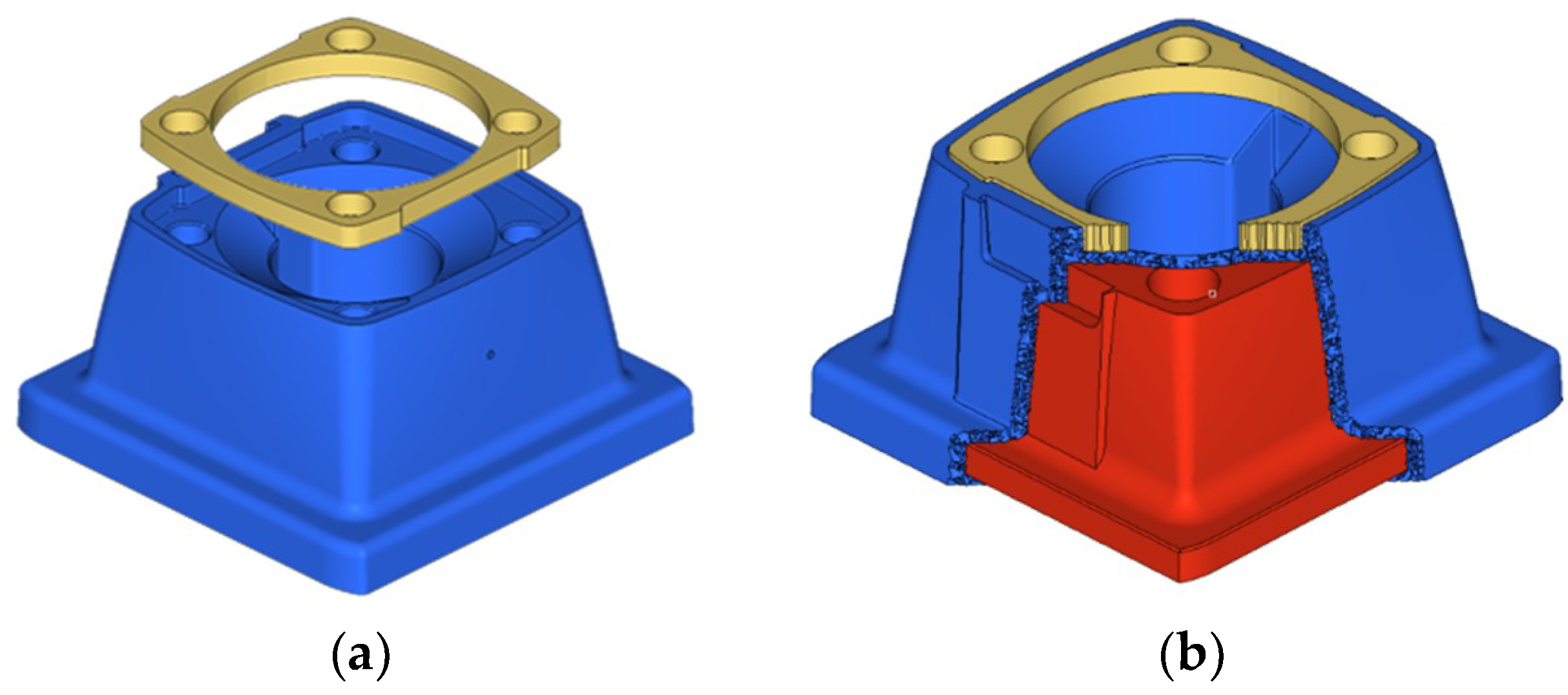

Figure 7.

Case study part: Support (in blue) and membrane (in gold). (a) Support and membrane; (b) design domain (red) and non-design domain (blue).

Figure 7.

Case study part: Support (in blue) and membrane (in gold). (a) Support and membrane; (b) design domain (red) and non-design domain (blue).

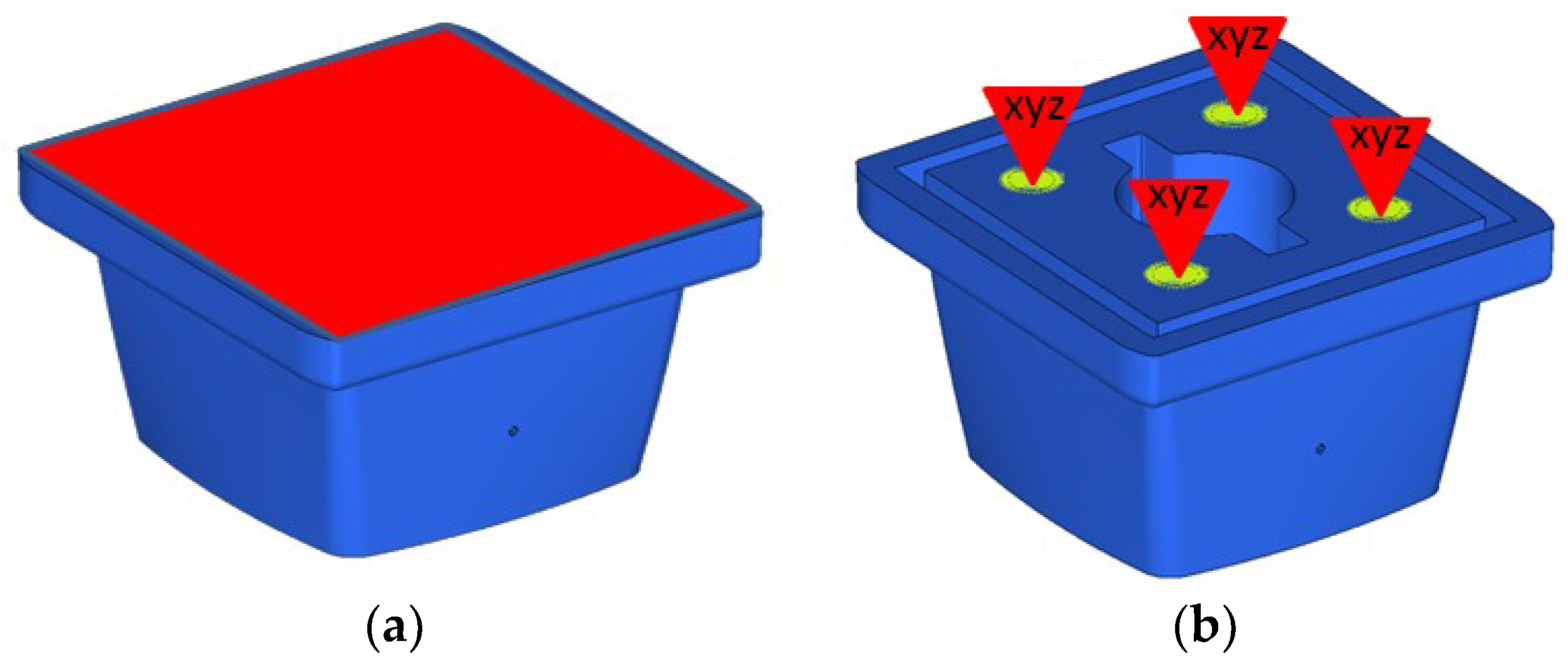

Figure 8.

Case study part (support, in blue) and membrane (in yellow): (a) Surface (red) including a restriction; and (b) four screw fasteners support (yellow), which are the points at where the model does not allow any physical displacement over any of the cartesian directions (X-Y-Z).

Figure 8.

Case study part (support, in blue) and membrane (in yellow): (a) Surface (red) including a restriction; and (b) four screw fasteners support (yellow), which are the points at where the model does not allow any physical displacement over any of the cartesian directions (X-Y-Z).

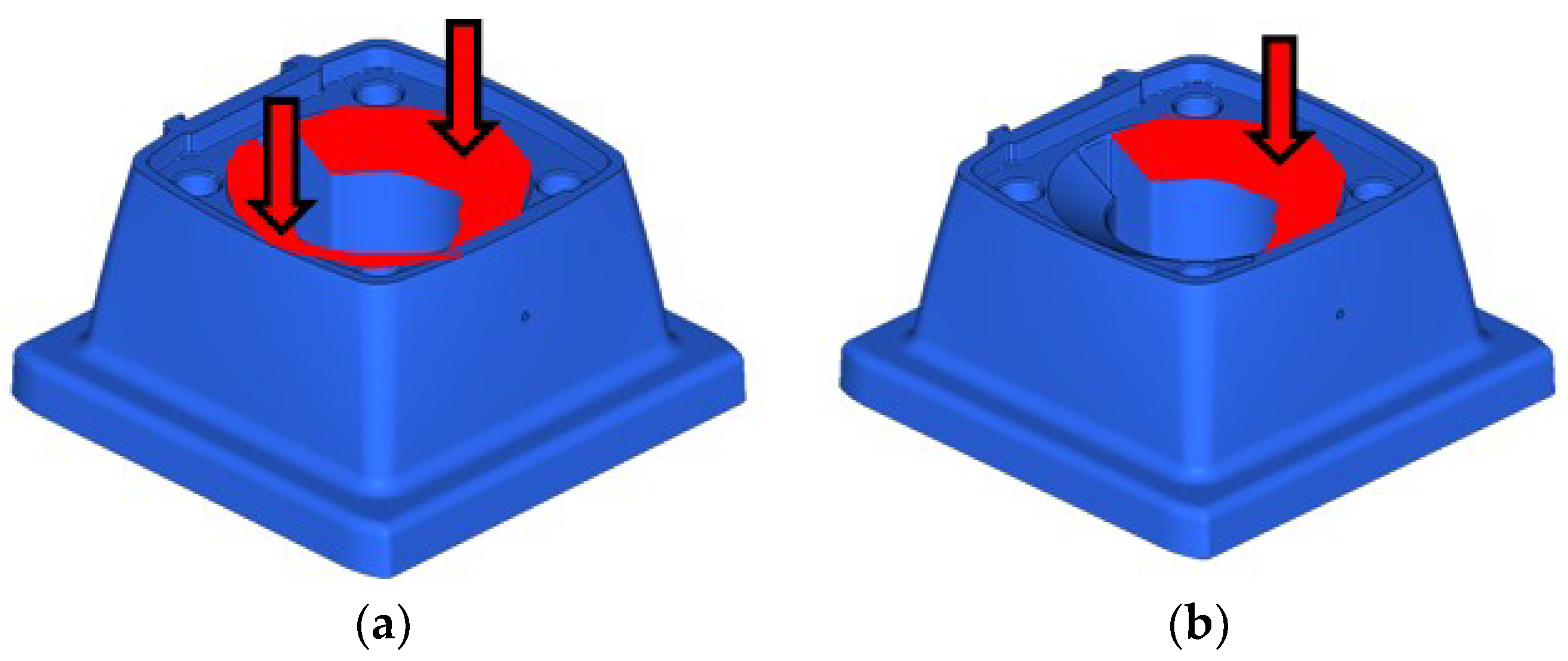

Figure 9.

Case study part (support, in blue) with load in the conditions of: (a) Valve totally open; and (b) valve totally closed.

Figure 9.

Case study part (support, in blue) with load in the conditions of: (a) Valve totally open; and (b) valve totally closed.

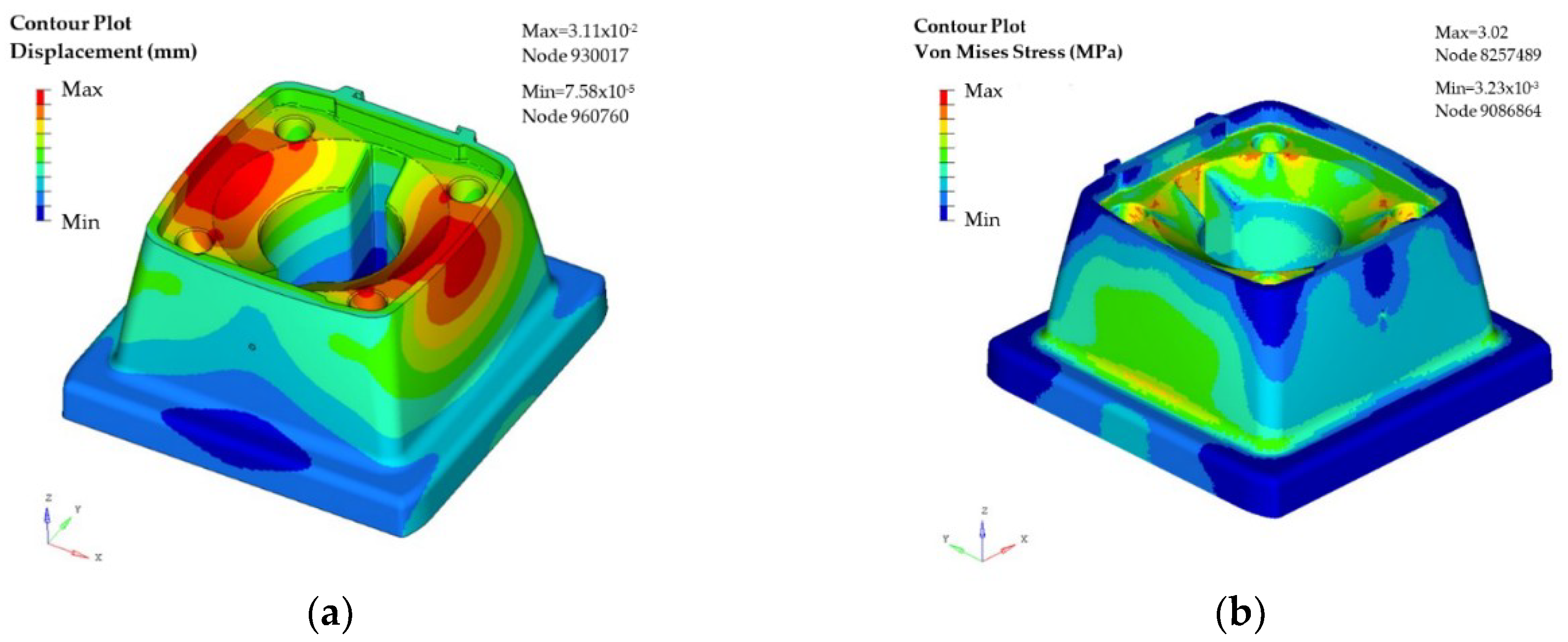

Figure 10.

Case study part (support): (a) Displacements of the material for the solid model; and (b) Von Mises stress for the solid model.

Figure 10.

Case study part (support): (a) Displacements of the material for the solid model; and (b) Von Mises stress for the solid model.

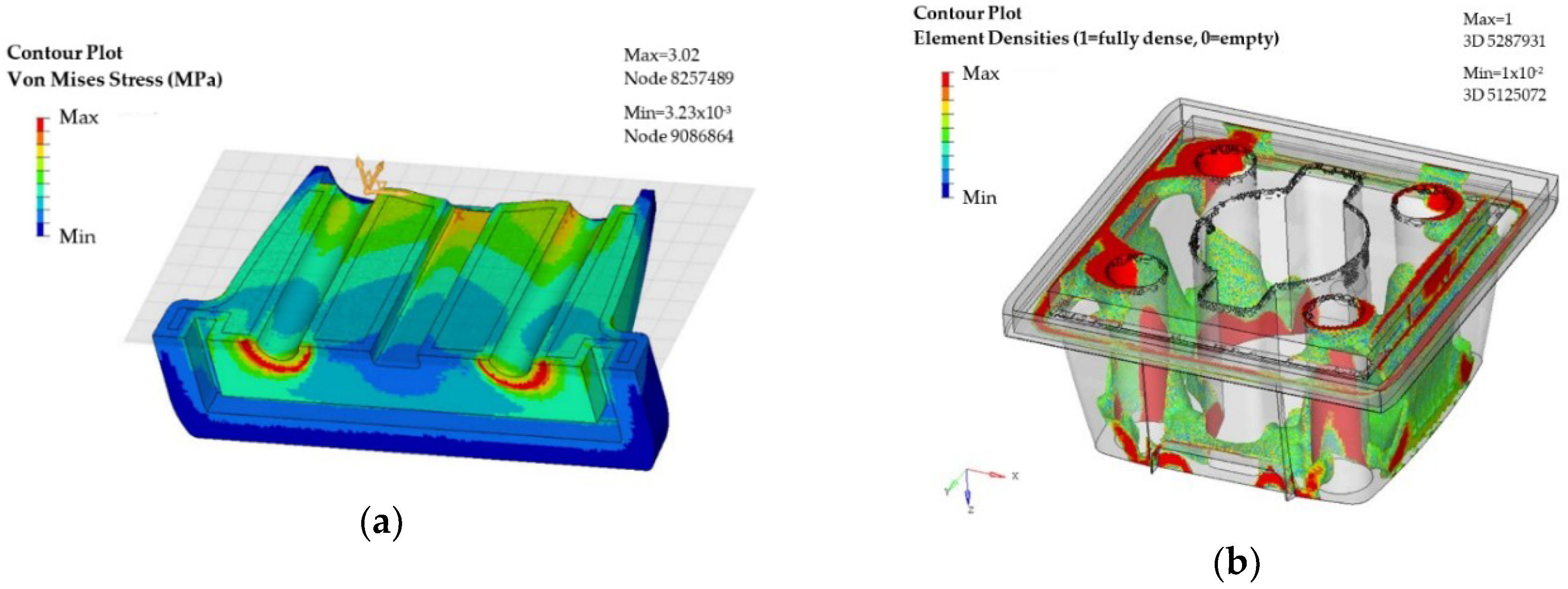

Figure 11.

Case study part (support): (a) Von Mises stress focused on fixations; and (b) results of topological optimization.

Figure 11.

Case study part (support): (a) Von Mises stress focused on fixations; and (b) results of topological optimization.

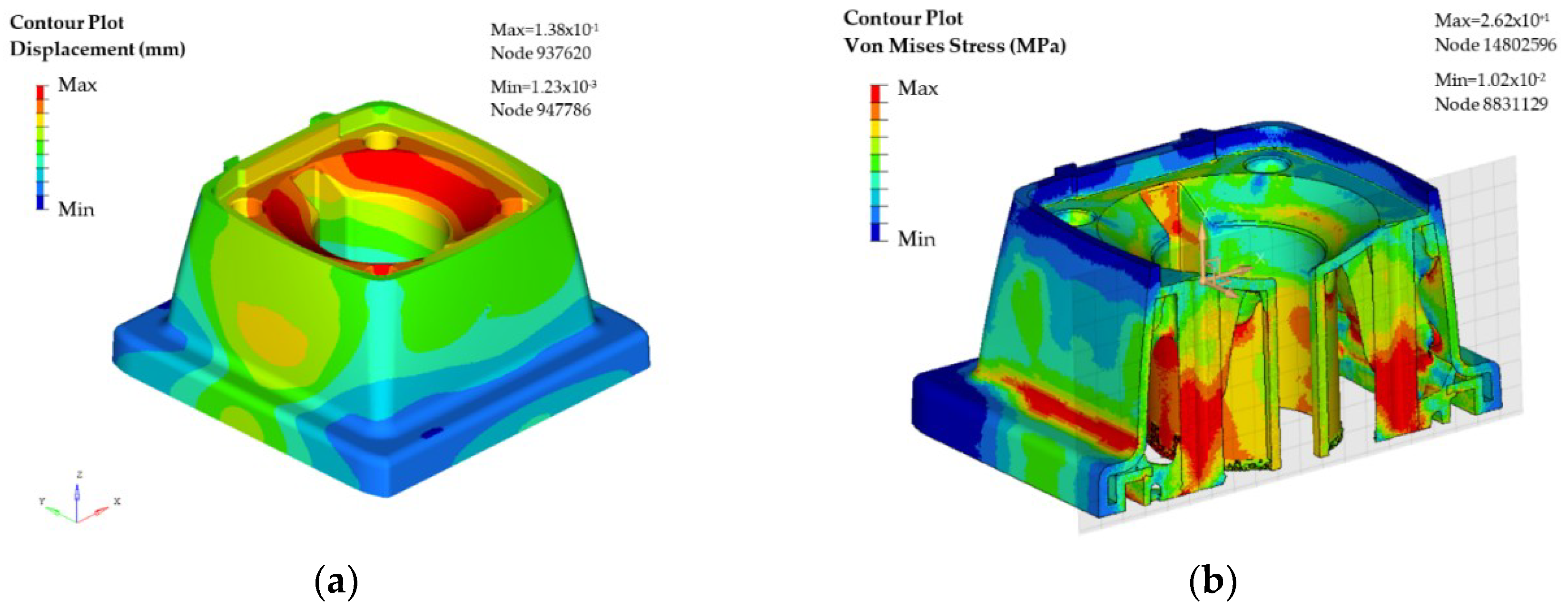

Figure 12.

CAE of the case study part (support): (a) Displacement results in the optimized design, and (b) Von Mises stress result in the optimized design.

Figure 12.

CAE of the case study part (support): (a) Displacement results in the optimized design, and (b) Von Mises stress result in the optimized design.

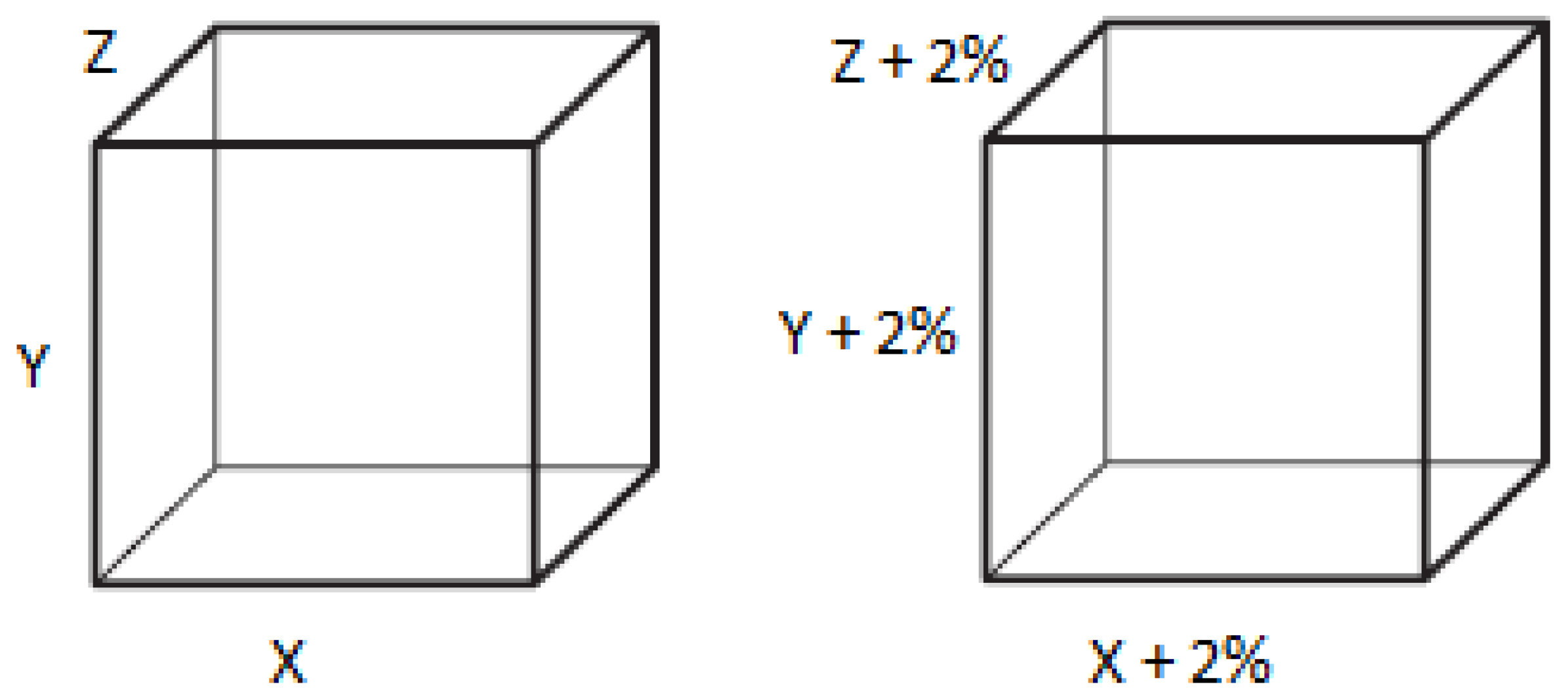

Figure 13.

Original model (left). Corrected model (right).

Figure 13.

Original model (left). Corrected model (right).

Figure 14.

Schematics of the testing set for the pneumatic valve according to the protocol at the Fluidra group. Contains the solenoid valve, the piston and the compressor.

Figure 14.

Schematics of the testing set for the pneumatic valve according to the protocol at the Fluidra group. Contains the solenoid valve, the piston and the compressor.

Figure 15.

Physical testing of the printed part. It can be seen how the command circuit is mounted on a main fluid circuit. (a) Detailed view of the support mounted under the pneumatic piston. On top, the solenoid valve. (b) General overview of the fluid testing set, containing the compressor, valves, piston and the case study support.

Figure 15.

Physical testing of the printed part. It can be seen how the command circuit is mounted on a main fluid circuit. (a) Detailed view of the support mounted under the pneumatic piston. On top, the solenoid valve. (b) General overview of the fluid testing set, containing the compressor, valves, piston and the case study support.

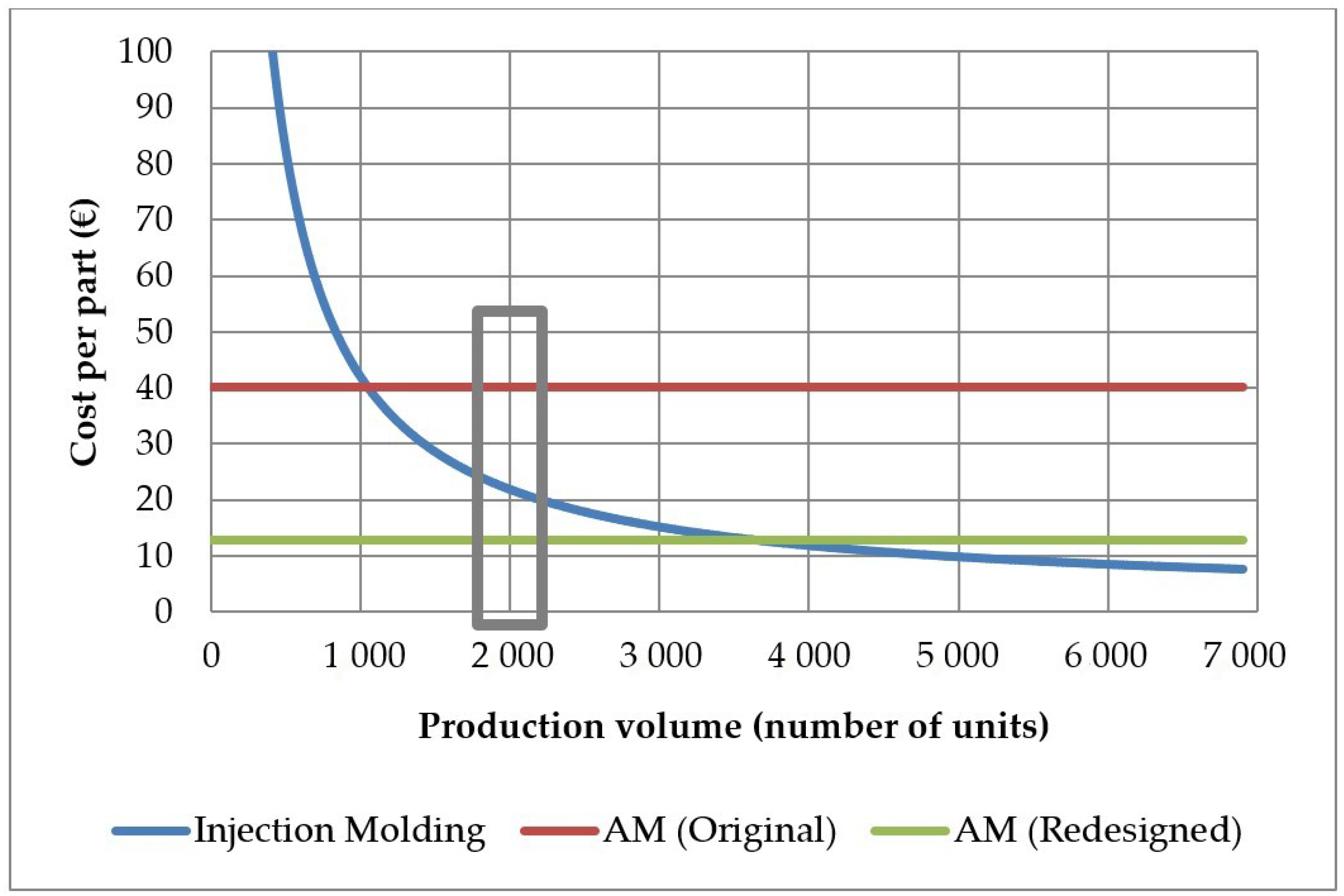

Figure 16.

Graphical comparison of the levels of manufacturing costs of the injection molding and AM strategies.

Figure 16.

Graphical comparison of the levels of manufacturing costs of the injection molding and AM strategies.

Table 1.

Pareto distribution A-B-C of all references. Elaborated by the authors from thanks to the data facilitated by Unistral Recambios data.

Table 1.

Pareto distribution A-B-C of all references. Elaborated by the authors from thanks to the data facilitated by Unistral Recambios data.

| References and Orders in eEach Pareto Sector | Sector A | Sector B | Sector C |

|---|

| Total number of references in the sector | 166 | 513 | 2056 |

| Maximum number of orders for a part in the sector | 3078 | 80 | 9 |

| Average number of orders for a part in the sector | 477.5 | 29.9 | 2.4 |

| Minimum number of orders for a part in the sector | 80 | 10 | 0 |

Table 2.

Distribution of the number of units demanded in each independent order.

Table 2.

Distribution of the number of units demanded in each independent order.

| Total Number of Orders | Max. no. of Units in an Order | Average no. of Units in an Order | Min. no. of Units in an Order | Max. no. of Units in an Order on Percentile 25 | Max. no. of Units in an Order on Percentile 50 | Max. no. of Units in an Order on Percentile 75 |

|---|

| 99,009 | 118,893 | 78.9 | 1 | 1 | 4 | 15 |

Table 3.

Distribution of the mass in the product references.

Table 3.

Distribution of the mass in the product references.

| Total Number of References | Max. Part Weight (kg) | Av. Part weight (kg) | Min. Part Weight (kg) | Part Weight on Percentile 25 | Part Weight on Percentile 50 | Part Weight on Percentile 75 |

|---|

| 2735 | 25 | 2.179 | 1.0 × 10−12 | 0.252 | 0.655 | 1.005 |

Table 4.

Injection molding costs assessment for the original product at a maximum production rates and at an order level of 2000 units.

Table 4.

Injection molding costs assessment for the original product at a maximum production rates and at an order level of 2000 units.

| Injection Molding Manufacturing Cost Per Part |

|---|

| Operation data | | |

| Production rate per hour (h−1) | 35 | 35 |

| Hours per year in operation (h) | 7884 | 7884 |

| Production volume total (per year) | 275,940 | 2000 |

| Cost of Equipment | | |

| Machine and ancillary equipment (€) | 400,000 | 400,000 |

| Equipment depreciation cost per year (€) | 40,000 | 40,000 |

| Machine maintenance cost per year (€) | 8000 | 8000 |

| Total machine cost per year (€) | 48,000 | 48,000 |

| Total machine cost during the time of operation (€) | 48,000 | 347.9 |

| (CE) Machine cost per part (€) | 0.17 | 0.17 |

| Cost of Tooling | | |

| Mold cost (€) | 40,000 | 40,000 |

| (CT) Mold cost per part (€) | 0.14 | 20 |

| Cost of Labor | | |

| Machine operator cost per hour (€) | 17 | 17 |

| Post-processing time per part (min) | 0.5 | 0.5 |

| (CL) Labor cost per part (€) | 0.14 | 0.14 |

| Cost of Material | | |

| Material per part (kg) | 0.862 | 0.862 |

| Build material cost per kg (€) | 1.5 | 1.5 |

| (CMAT) Material cost per part (€) | 1.293 | 1.293 |

| (CIM) Total cost per part (€) | 1.75 | 21.61 |

Table 5.

Additive manufacturing (AM) costs assessment for the original product.

Table 5.

Additive manufacturing (AM) costs assessment for the original product.

| Additive Manufacturing Cost Per Part (Original Design) |

|---|

| Operation data | |

| Number of parts manufactured per platform | 2 |

| Platform build time (h) | 143 |

| Hours per year in operation (h) | 7884 |

| Production volume total (per year) | 110 |

| Cost of Equipment | |

| Machine and ancillary equipment (€) | 2100 |

| Equipment depreciation cost per year (€) | 262.5 |

| Machine maintenance cost per year (€) | 100 |

| Total machine cost per year (€) | 362.5 |

| (CE) Machine cost per part (€) | 3.29 |

| Cost of Labor | |

| Machine operator cost per hour (€) | 17 |

| Set-up time to control machine (min) | 5 |

| Post-processing time per part (min) | 3 |

| (CL) Labor cost per part (€) | 1.13 |

| Cost of Material | |

| Material per part (kg) | 0.862 |

| Build material cost per kg (€) | 41.35 |

| (CMAT) Material cost per part (€) | 35.64 |

| (CAM) Total cost per part (€) | 40.06 |

Table 6.

Mechanical properties of Novamid® ID1070.

Table 6.

Mechanical properties of Novamid® ID1070.

| Parameters | E [MPa] | ε [%] | σ [MPa] |

|---|

| 0-90 | X-Y | 1,714 ± 103.83 | 7.21 ± 2.97 | 44.85 ± 2.62 |

| 45-45 | X-Y | 2,124 ± 80.05 | 14.89 ± 6.97 | 50.14 ± 1.86 |

Table 7.

Mechanical properties imposed in the virtual testing conditions.

Table 7.

Mechanical properties imposed in the virtual testing conditions.

| Parameters | E (MPa) | σ (MPa) |

|---|

| 0–90 | X–Y | 1600 | 42 |

Table 8.

AM costs assessment for the redesigned product.

Table 8.

AM costs assessment for the redesigned product.

| Additive Manufacturing Cost Per Part (Original and Redesigned Parts) |

|---|

| Operation data | | |

| Number of parts manufactured per platform | 2 | 2 |

| Platform build time (h) | 143 | 84 |

| Hours per year in operation (h) | 7884 | 7884 |

| Production volume total (per year) | 110 | 188 |

| Cost of Equipment | | |

| Machine and ancillary equipment (€) | 2100 | 2100 |

| Equipment depreciation cost per year (€) | 262.5 | 262.5 |

| Machine maintenance cost per year (€) | 100 | 100 |

| Total machine cost per year (€) | 362.5 | 362.5 |

| (CE) Machine cost per part (€) | 3.29 | 1.93 |

| Cost of Labor | | |

| Machine operator cost per hour (€) | 17 | 17 |

| Set-up time to control machine (min) | 5 | 5 |

| Post-processing time per part (min) | 3 | 3 |

| (CL) Labor cost per part (€) | 1.13 | 1.13 |

| Cost of Material | | |

| Material per part (kg) | 0.862 | 0.237 |

| Build material cost per kg (€) | 41.35 | 41.35 |

| (CMAT) Material cost per part (€) | 35.64 | 9.8 |

| (CAM) Total cost per part (€) | 40.06 | 12.86 |

Table 9.

(Ki) constants associated to the different cost factors, calculated for the 2017 inventory figures at Unistral Recambios.

Table 9.

(Ki) constants associated to the different cost factors, calculated for the 2017 inventory figures at Unistral Recambios.

| (Ki) Constants | Values | Units |

|---|

| 0.4504 | €/h |

| 1 | €/kg |

| 0.0333 | €/kg |

| 0.0556 | €/kg |

| 0.0222 | €/kg |