Influence of the Regime of Electropulsing-Assisted Machining on the Plastic Deformation of the Layer Being Cut

Abstract

1. Introduction

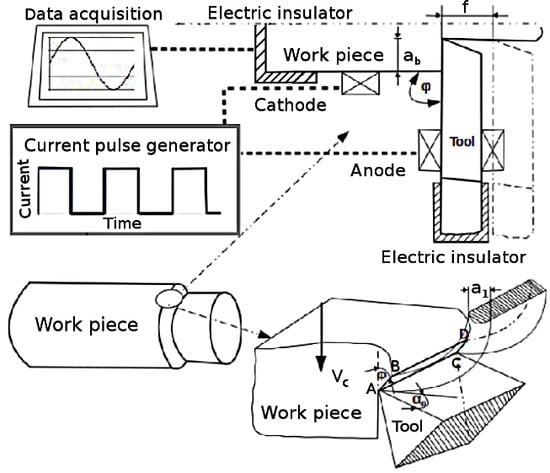

2. Experimental Setup

3. Results and Discussions

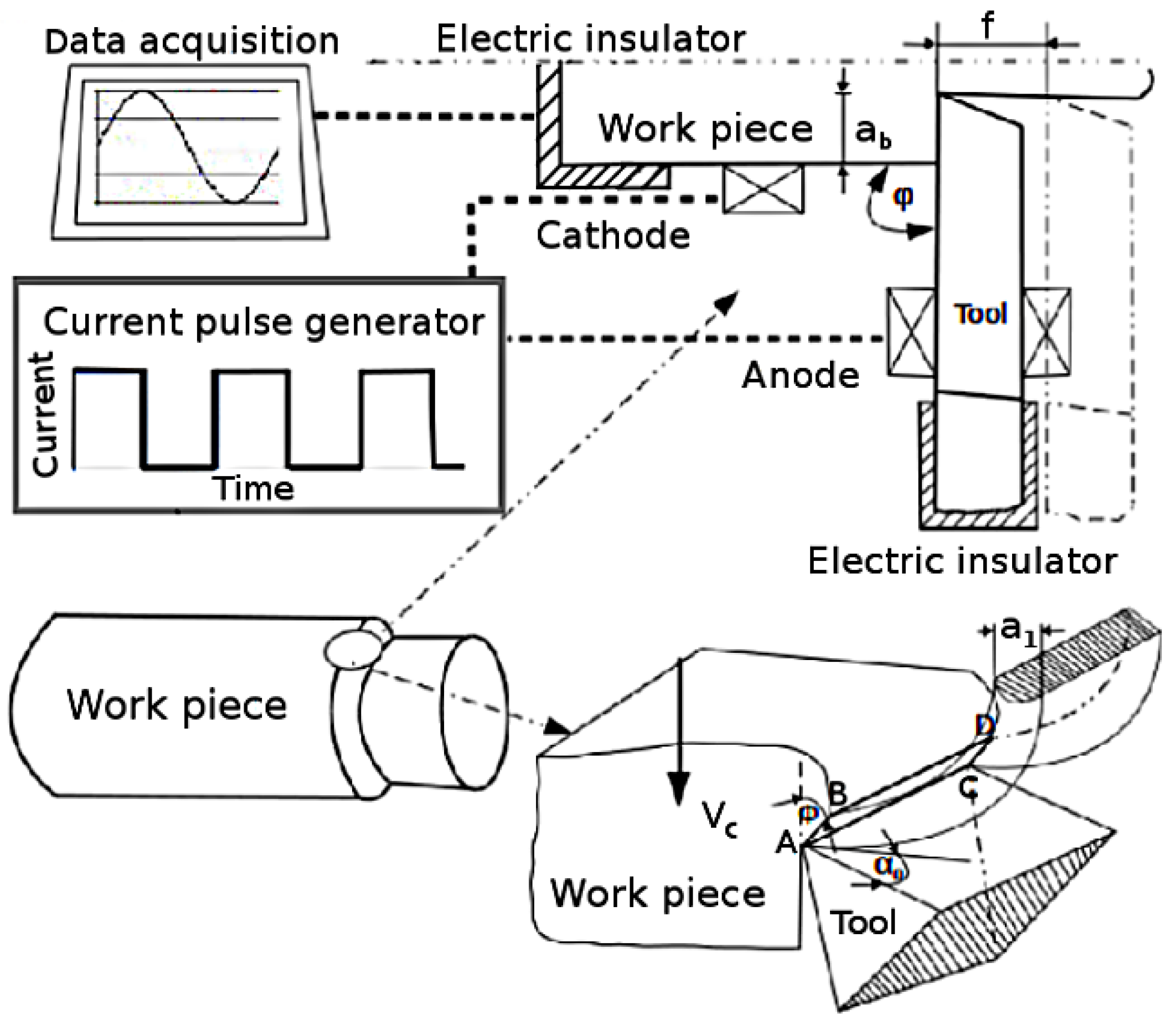

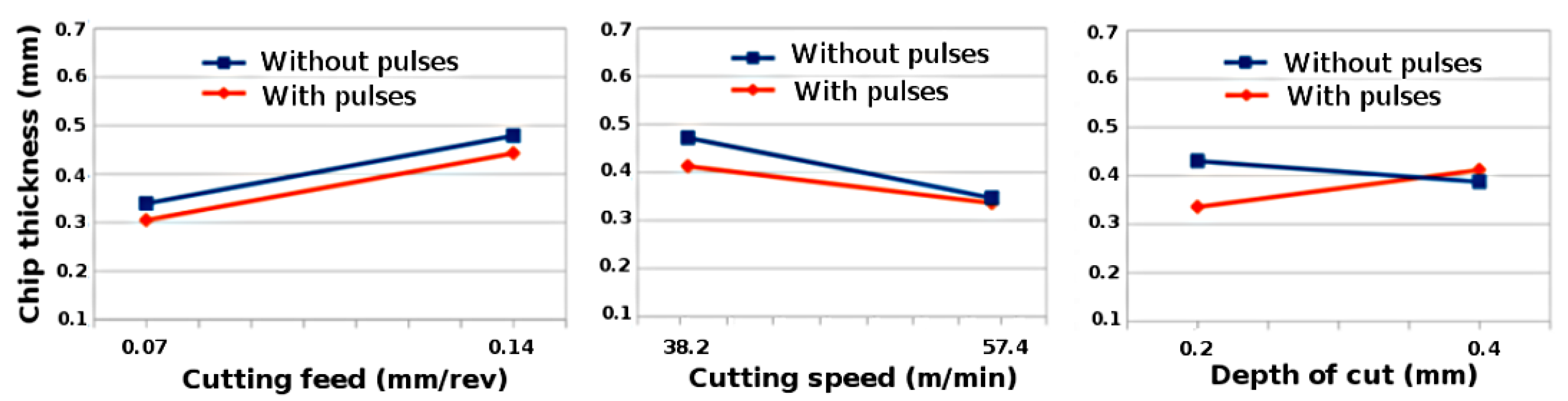

3.1. Current Density, Chip Thickness Ratio and Cutting Configurations

3.2. Specific Cutting Energy (SCE)

4. Conclusions

- By increasing the cutting speed, the chip compression ratio decreases and shear plane angle increases during conventional turning of steel S235. However, increase of cutting speed seems to have no effect on chip compression ratio and shear plane angle during electrically assisted turning of steel S235. In contrast, chip compression ratio increases and shear plane angle decreases with the increase in cutting speed while turning of aluminium 6060 during conventional and electrically assisted processes.

- The current density increases with the increase in cutting speed and decreases with the increase in cutting feed for steel S235. However, the current density has high values at higher feeds and decreases with the increase in cutting speed for aluminium 6060.

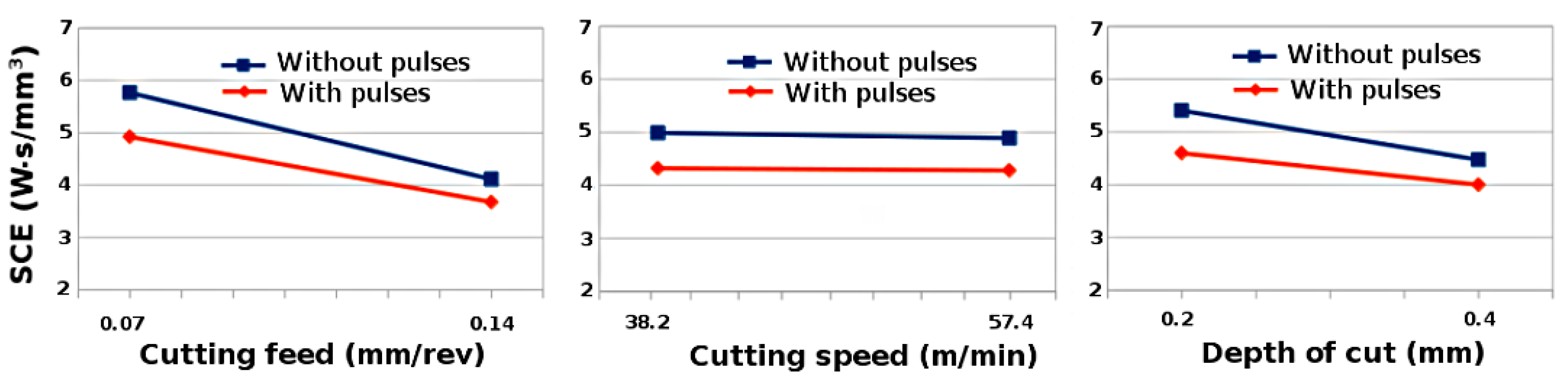

- The SCE decreases with the increase in cutting speed and depth of cut for both conventional and electrically assisted turning of steel S235. In addition, as compared to conventional process, the SCE values are lower during electrically assisted turning of steel S235. However, during conventional turning of aluminium 6060, the SCE decreases with the increase in cutting feed and depth of cut, while increases with the increase of cutting speed. In addition, the SCE values are higher during electrically assisted turning of aluminium 6060 as compared to conventional process.

- The electrically assisted turning processes tends to have influence in improving the machinability of steel S235 but for aluminium 6060, the machinability seems to be poor, which is probably due to its high ductility and higher degree of plastic deformation as compared to steel S235. Further investigations are required to further analyze the effect of EPs on machinability of materials by studying the cutting parameters and chip morphology.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Edward, M.T.; Paul, K.W. Metal Cutting, 4th ed.; Butterworth–Heinemann: Woburn, MA, USA, 2000; pp. 24–26. ISBN 0-7506-7069-X. [Google Scholar]

- Astakhov, V.P. Geometry of Single-Point Turning Tools and Drills: Fundamentals and Practical Applications; Springer: London, UK, 2010; pp. 6–9. ISBN 978-1-84996-052-6. [Google Scholar]

- Astakhov, V.P.; Shvets, S. The assessment of plastic deformation in metal cutting. J. Mater. Process. Technol. 2004, 146, 193–202. [Google Scholar] [CrossRef]

- Thamizhmanii, S.; Hasan, S. Machinability study using chip thickness ratio on difficult to cut metals by CBN cutting tool. Key Eng. Mater. 2012, 504–506, 1317–1322. [Google Scholar] [CrossRef]

- Astakhov, V.P. Tribology of Metal Cutting: Tribology and Interface Engineering Series; Briscoe, B.J., Ed.; Elsevier Ltd.: London, UK, 2006; Volume 52, pp. 83–87. ISBN 978-0-444-52881-0. [Google Scholar]

- Simoneau, A.; Meehan, J. The Impact of machining parameters on peak power and energy consumption in CNC endmilling. Energy Power 2013, 3, 85–90. [Google Scholar] [CrossRef]

- Ng, C.K.; Melkote, S.N.; Rahman, M.; Senthil, K.A. Experimental study of micro and nano-scale cutting of aluminum 7075-T6. Int. J. Mach. Tools Manuf. 2006, 46, 929–936. [Google Scholar] [CrossRef]

- Beranoagirre, A.; Olvera, D.; de Lacalle, L.N.L. Milling of gamma titanium—Aluminum alltoys. Int. J. Adv. Manuf. Technol. 2012, 62, 83–88. [Google Scholar] [CrossRef]

- Sourabh, P.; Bandyopadhyay, P.P.; Paul, S. Minimisation of specific cutting energy and back force in turning of AISI 1060 steel. Proc. Inst. Mach. Eng. Part B J. Eng. Manuf. 2017, 1–11. [Google Scholar] [CrossRef]

- Fernàndez-Abia, A.I.; Barreiro, J.; de Lacalle, L.N.L.; Martìnez, S. Effect of Very High Cutting Speeds on Shearing, Cutting Forces and Roughness in Dry Turning of Austenitic Stainless Steels. Int. J. Adv. Manuf. Technol. 2011, 57, 61–71. [Google Scholar] [CrossRef]

- Astakhov, V.P.; xinran, x. A methodology for practical cutting force evaluation based on the energy spent in the cutting system. Mach. Sci. Technol. 2008, 12, 325–347. [Google Scholar] [CrossRef]

- Yousefi, R.; Ichida, Y. A study on ultra–high-speed cutting of aluminium alloy: Formation of welded metal on the secondary cutting edge of the tool and its effects on the quality of finished surface. Precis. Eng. 2000, 24, 371–376. [Google Scholar] [CrossRef]

- Becze, C.E.; Worswick, M.J.; Elbestawi, M.A. High strain rate shear evaluation and characterization of AISI D2 tool steel in its hardened state. Mach. Sci. Technol. 2001, 5, 131–149. [Google Scholar] [CrossRef]

- Boothroyd, G.; Bailey, J.A. Effects of strain rate and temperature in orthogonal metal cutting. J. Mech. Eng. Sci. 1966, 8, 264–275. [Google Scholar] [CrossRef]

- Lee, S.; Hwang, J.R.S.M.; Chandrasekar, S.; Compton, W.D. Large strain deformation field in machining. Metall. Mater. Trans. 2006, 37, 1633–1643. [Google Scholar] [CrossRef]

- Wang, X.; Xu, J.; Shan, D.; Guo, B.; Cao, J. Effects of specimen and grain size on electrically-induced softening behavior in uniaxial micro-tension of AZ31 magnesium alloy: Experiment and modeling. Mater. Des. 2017, 127, 134–143. [Google Scholar] [CrossRef]

- Wang, X.; Xu, J.; Shan, D.; Guo, B.; Cao, J. Modeling of thermal and mechanical behavior of amagnesium alloy AZ31 during electrically-assistedmicro-tension. Int. J. Plast. 2016, 85, 230–257. [Google Scholar] [CrossRef]

- Sànchez, E.A.J.; González, R.H.A.; Celentano, D.J.; Jorba, P.J.; Cao, J. Thermomechanical analisys of an electrically-assisted wire drawing process. J. Manuf. Sci. Eng. 2017, 139, 111017. [Google Scholar] [CrossRef]

- Astakhov, V.P.; Shvets, S.V. A novel approach to operating force evolution in high strain rate metal-deforming technological processes. J. Mater. Process. Technol. 2001, 117, 226–237. [Google Scholar] [CrossRef]

- Gui, G.Y.; Shi, F.X.; Xing, H.T.; Lan, H.D. Influence of cutting conditions on the cutting performance of TiAl6V4. Adv. Mater. Res. 2011, 337, 387–391. [Google Scholar] [CrossRef]

- Bakkal, M.; Shih, A.J.; Scattergood, R.O. Chip formation, cutting forces and tool wear in turning of Zr-based bulk metallic glass. Int. J. Mach. Tools Manuf. 2004, 44, 915–925. [Google Scholar] [CrossRef]

- Baranov, S.A.; Staschenko, V.I.; Sukhov, A.V.; Troitskiy, O.A.; Tyapkin, A.V. Electroplastic Metal Cutting. Russ. Electr. Eng. 2011, 82, 477–479. [Google Scholar] [CrossRef]

- Brandt, J.R.; Elizabeth, G.; Farbod, A.N.; Laine, M. Electroplastic Drilling of Low and High Strength Steels. J. Manuf. Sci. Eng. 2018, 140, 061017. [Google Scholar] [CrossRef]

- Sànchez, E.A.J.; Gonzàlez, R.H.A.; Montilla, C.A.; Echeverri, V.K. Effect of electroplastic cutting on the manufacturing process and surface properties. J. Mater. Process. Technol. 2015, 222, 327–334. [Google Scholar] [CrossRef]

- Hameed, S.; Gonzàlez, R.H.A.; Sànchez, E.A.J.; Alberro, A.N. Electroplastic cutting influence on power consumption during drilling process. Int. J. Adv. Manuf. Technol. 2016, 87, 1835–1841. [Google Scholar] [CrossRef]

- Deng, W.J.; Lin, P.; Xie, Z.C.; Li, Q. Analysis of large-strain extrusion machining with different chip compression ratios. J. Nanomater. 2012, 2012, 1–12. [Google Scholar] [CrossRef]

- Feng, K.; Jun, N.; Stephenson, D.A. Chip thickening in deep-hole drilling. Int. J. Mach. Tools Manuf. 2006, 46, 1500–1507. [Google Scholar] [CrossRef]

- Silva, L.R.; Abrão, A.M.; Faria, P.; Davim, J.P. Machinability study of steels in precision orthogonal cutting. Mater. Res. 2012, 15, 589–595. [Google Scholar] [CrossRef]

- Adam, U.A.; Noordin, M.Y.; Mohamed, H.S.E.; Hasan, F. Influence of cutting conditions on chip formation when turning ASSAB DF-3 Hardened tool steel. Int. J. Mater. Mech. Manuf. 2013, 1, 76–79. [Google Scholar] [CrossRef]

- Natasha, A.R.; Othman, H.; Ghani, J.A.; Haron, C.H.C.; Syarif, J. Chip formation and coefficient of friction in turning S45C medium carbon steel. Int. J. Mech. Mechatron. Eng. 2014, 14, 89–92. [Google Scholar]

- Magargee, J.; Morestin, F.; Cao, J. Characterization of flow stress for commercially pure titanium subjected to electrically assisted deformation. J. Eng. Mater. Technol. 2013, 135, 041003. [Google Scholar] [CrossRef]

- Thakur, D.G.; Ramamoorthy, B.; Vijayaraghavan, L. A study on the parameters in high-speed turning of superalloy Inconel 718. J. Mater. Manuf. Process. 2009, 24, 497–503. [Google Scholar] [CrossRef]

- Conrad, H.; Sprecher, A.F.; Cao, W.D.; Lu, X.P. Electroplasticity—The effect of electricity on the mechanical properties of metals. JOM 1990, 42, 28–33. [Google Scholar] [CrossRef]

| Aluminium 6060 | % Al | % Zn | % Mg | % Cu | % Fe | % Si | % Mn | % Cr |

| balance | 0.15 | 0.35 | 0.1 | 0.1 | 0.3 | 0.1 | 0.05 | |

| Steel S235 | % C | % P | % Cu | % Fe | % Si | % Mn | % S | |

| 0.24 | 0.04 | 0.20 | balance | 0.04 | 0.9 | 0.05 |

| Materials | E | D | Hardness | |||

|---|---|---|---|---|---|---|

| (m) | (J/Kg C) | (GPa) | (C) | (Kg/m3) | (95% Data Interval) | |

| Aluminium 6060 | 900 | 70 | 2700 | (HB) | ||

| Steel S235 | 470 | 190 | 7800 | (HRB) |

| Material | Spindle | Cutting | Depth of | Current | Pulse | Frequency |

|---|---|---|---|---|---|---|

| Speed | Feed | Cut | Intensity | Duration | ||

| (rpm) | (mm/rev) | (mm) | (A) | (s) | (Hz) | |

| Aluminium 6060 | 600/900 | 0.07/0.14 | 0.2/0.4 | 140 | 250 | 300 |

| Steel S235 |

| Material | Workpiece | Cutting | Cutting | Depth | Compression | Shear Plane | Current |

|---|---|---|---|---|---|---|---|

| Diameter | Feed | Speed | of Cut | Ratio | Angle Density | ||

| Steel | (f) | () | () | () | () | () | |

| S235 | (mm) | (mm/rev) | (m/min) | (mm) | () | (A/mm2) | |

| Without pulses | 0.07 | 38.213 | 0.2 | 6.357 | 9.049 | - | |

| 0.14 | 38.213 | 0.2 | 4.321 | 13.356 | - | ||

| 0.07 | 57.461 | 0.2 | 3.685 | 15.663 | - | ||

| 20 | 0.14 | 57.461 | 0.2 | 2.957 | 19.484 | - | |

| 0.07 | 38.213 | 0.4 | 5.257 | 10.964 | - | ||

| 0.14 | 38.213 | 0.4 | 3.343 | 17.262 | - | ||

| 0.07 | 57.461 | 0.4 | 4.085 | 14.123 | - | ||

| 0.14 | 57.461 | 0.4 | 3.057 | 18.856 | - | ||

| With pulses | 0.07 | 38.213 | 0.2 | 3.100 | 18.599 | 3190 | |

| 0.14 | 38.213 | 0.2 | 2.492 | 23.007 | 1954 | ||

| 0.07 | 57.461 | 0.2 | 3.171 | 18.186 | 3121 | ||

| 20 | 0.14 | 57.461 | 0.2 | 2.557 | 22.449 | 1909 | |

| 0.07 | 38.213 | 0.4 | 4.214 | 13.697 | 1184 | ||

| 0.14 | 38.213 | 0.4 | 4.228 | 13.651 | 590 | ||

| 0.07 | 57.461 | 0.4 | 4.128 | 13.982 | 1208 | ||

| 0.14 | 57.461 | 0.4 | 3.378 | 17.081 | 734 |

| Material | Workpiece | Cutting | Cutting | Depth | Compression | Shear plane | Current |

|---|---|---|---|---|---|---|---|

| Diameter | Feed | Speed | of Cut | Ratio | Angle | Density | |

| Aluminium | (f) | () | () | () | () | () | |

| 6060 | (mm) | (mm/rev) | (m/min) | (mm) | () | (A/mm) | |

| Without pulses | 0.07 | 38.213 | 0.2 | 2.371 | 24.571 | - | |

| 0.14 | 38.213 | 0.2 | 1.214 | 45.312 | - | ||

| 0.07 | 57.461 | 0.2 | 3.771 | 15.375 | - | ||

| 20 | 0.14 | 57.461 | 0.2 | 2.214 | 26.287 | - | |

| 0.07 | 38.213 | 0.4 | 4.028 | 14.372 | - | ||

| 0.14 | 38.213 | 0.4 | 2.085 | 27.866 | - | ||

| 0.07 | 57.461 | 0.4 | 5.285 | 10.877 | - | ||

| 0.14 | 57.461 | 0.4 | 2.971 | 19.600 | - | ||

| With pulses | 0.07 | 38.213 | 0.2 | 3.514 | 16.526 | 2844 | |

| 0.14 | 38.213 | 0.2 | 1.114 | 48.470 | 3743 | ||

| 0.07 | 57.461 | 0.2 | 5.001 | 11.515 | 1996 | ||

| 20 | 0.14 | 57.461 | 0.2 | 2.914 | 19.999 | 1709 | |

| 0.07 | 38.213 | 0.4 | 3.971 | 14.583 | 1259 | ||

| 0.14 | 38.213 | 0.4 | 2.085 | 27.321 | 1147 | ||

| 0.07 | 57.461 | 0.4 | 8.628 | 6.583 | 573 | ||

| 0.14 | 57.461 | 0.4 | 2.914 | 19.999 | 854 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hameed, S.; González Rojas, H.A.; Perat Benavides, J.I.; Nápoles Alberro, A.; Sánchez Egea, A.J. Influence of the Regime of Electropulsing-Assisted Machining on the Plastic Deformation of the Layer Being Cut. Materials 2018, 11, 886. https://doi.org/10.3390/ma11060886

Hameed S, González Rojas HA, Perat Benavides JI, Nápoles Alberro A, Sánchez Egea AJ. Influence of the Regime of Electropulsing-Assisted Machining on the Plastic Deformation of the Layer Being Cut. Materials. 2018; 11(6):886. https://doi.org/10.3390/ma11060886

Chicago/Turabian StyleHameed, Saqib, Hernán A. González Rojas, José I. Perat Benavides, Amelia Nápoles Alberro, and Antonio J. Sánchez Egea. 2018. "Influence of the Regime of Electropulsing-Assisted Machining on the Plastic Deformation of the Layer Being Cut" Materials 11, no. 6: 886. https://doi.org/10.3390/ma11060886

APA StyleHameed, S., González Rojas, H. A., Perat Benavides, J. I., Nápoles Alberro, A., & Sánchez Egea, A. J. (2018). Influence of the Regime of Electropulsing-Assisted Machining on the Plastic Deformation of the Layer Being Cut. Materials, 11(6), 886. https://doi.org/10.3390/ma11060886