Enhanced Ferroelectric and Piezoelectric Properties of (1−x)PMN-xPT Ceramics Based on a Partial Oxalate Process

Abstract

:1. Introduction

2. Materials and Methods

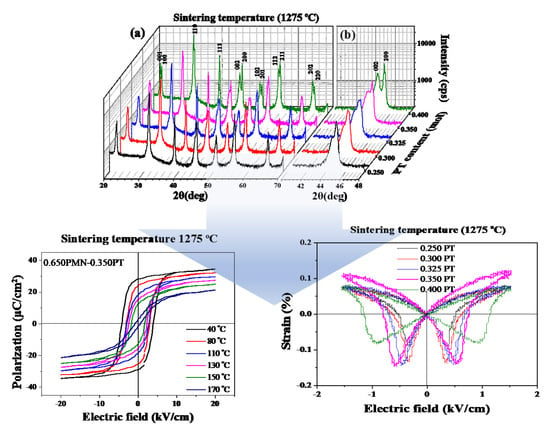

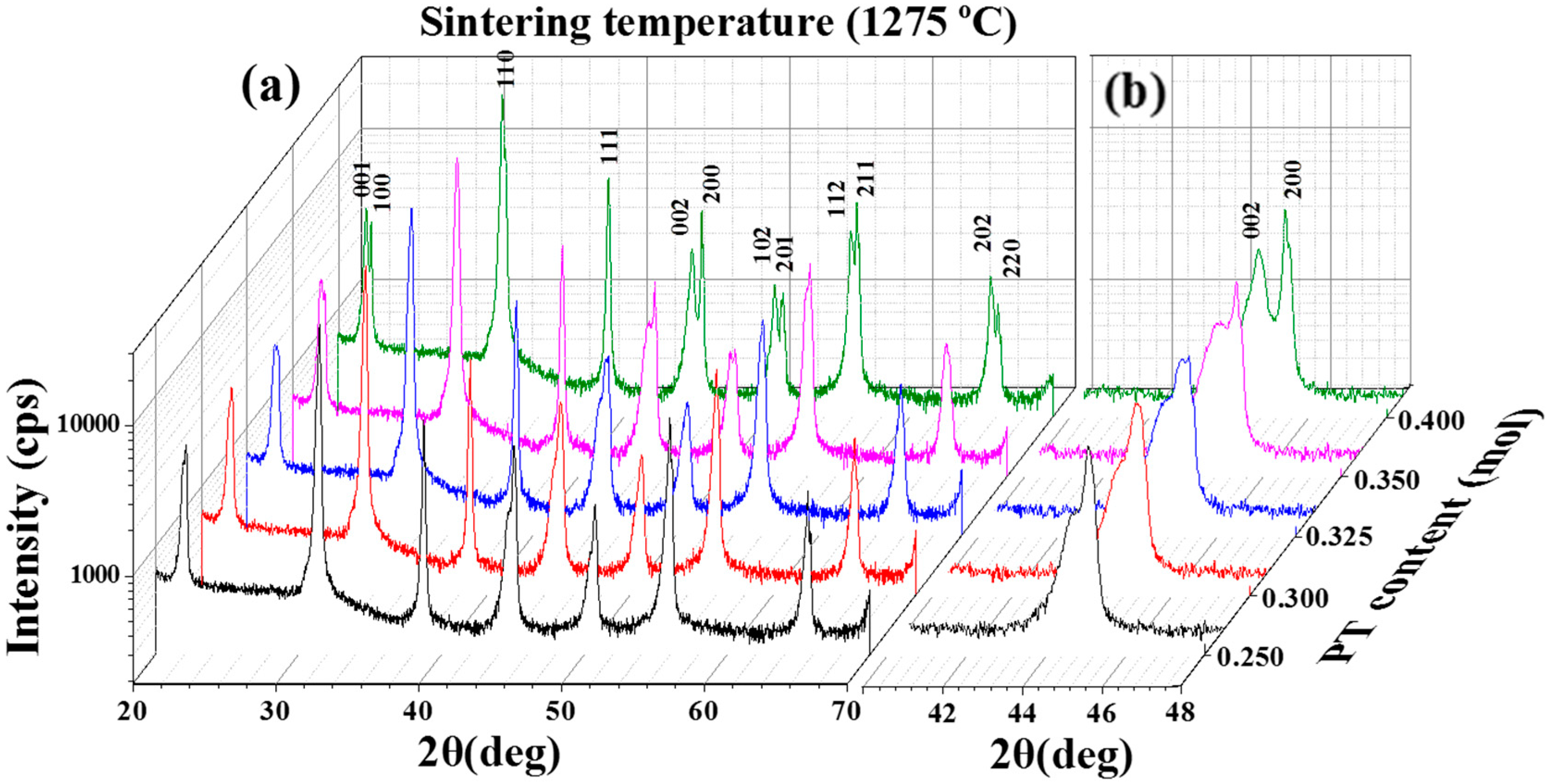

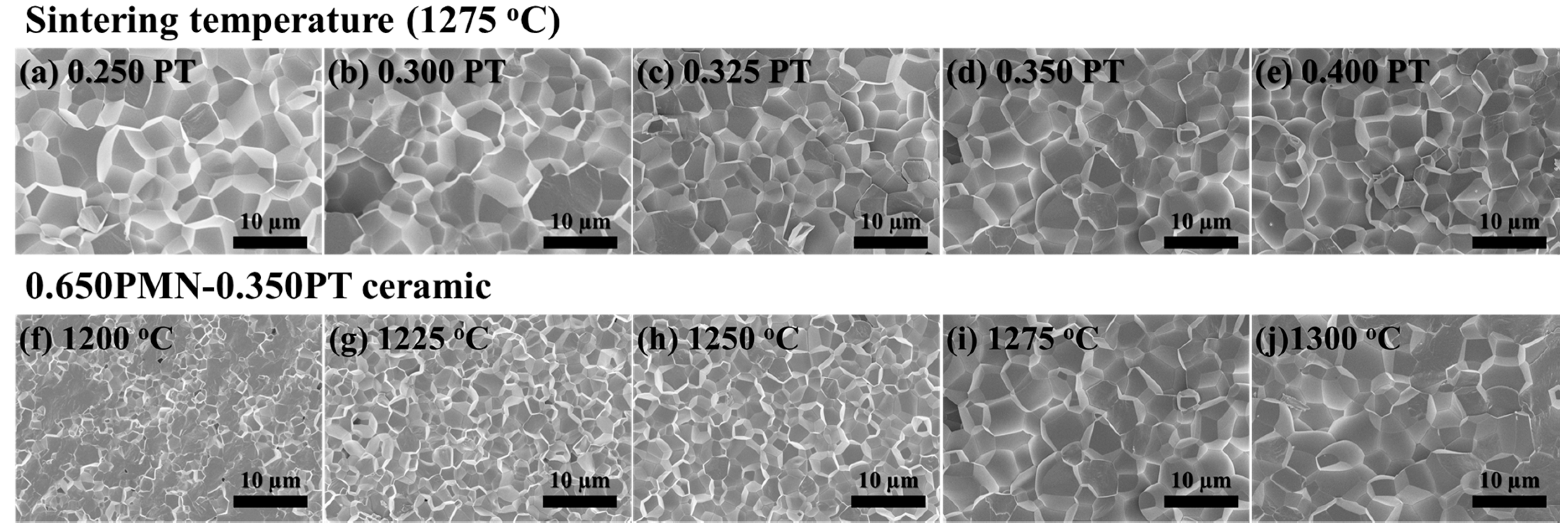

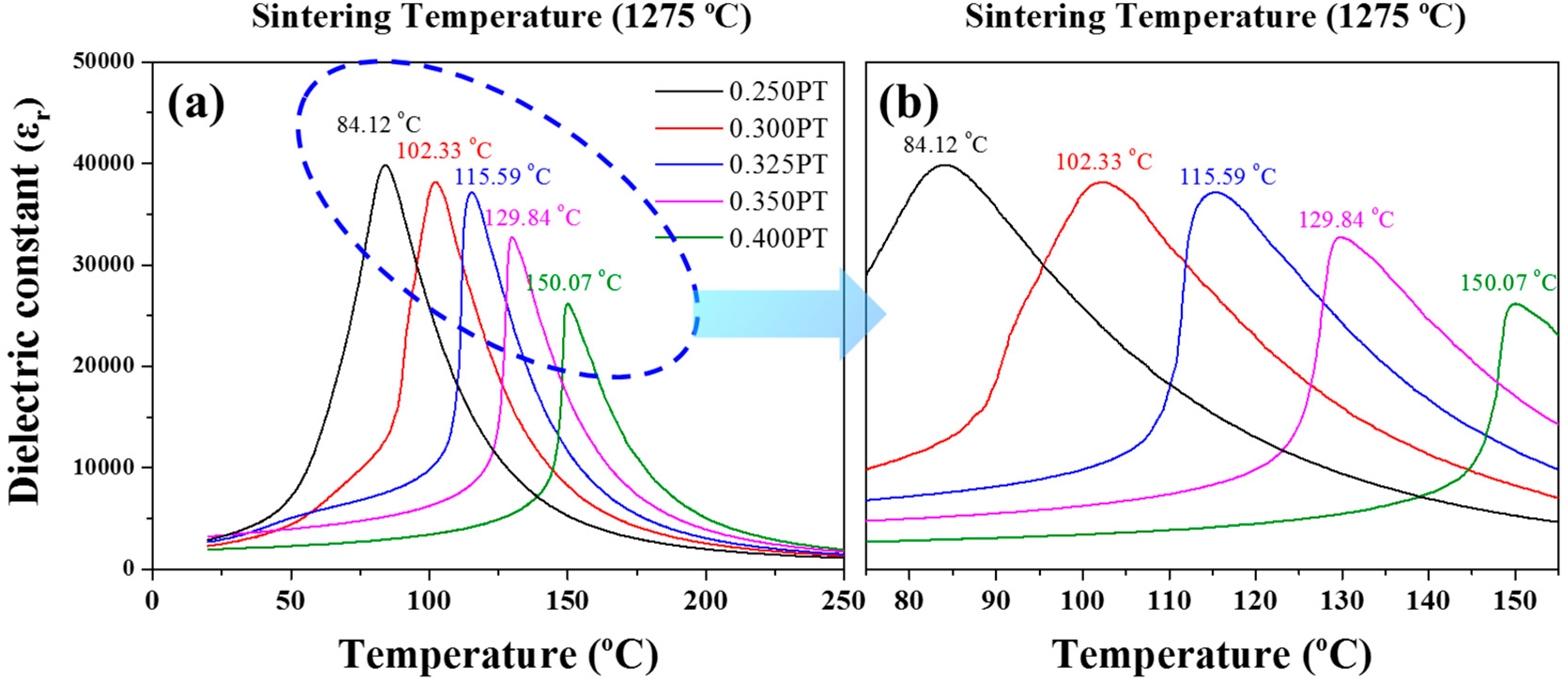

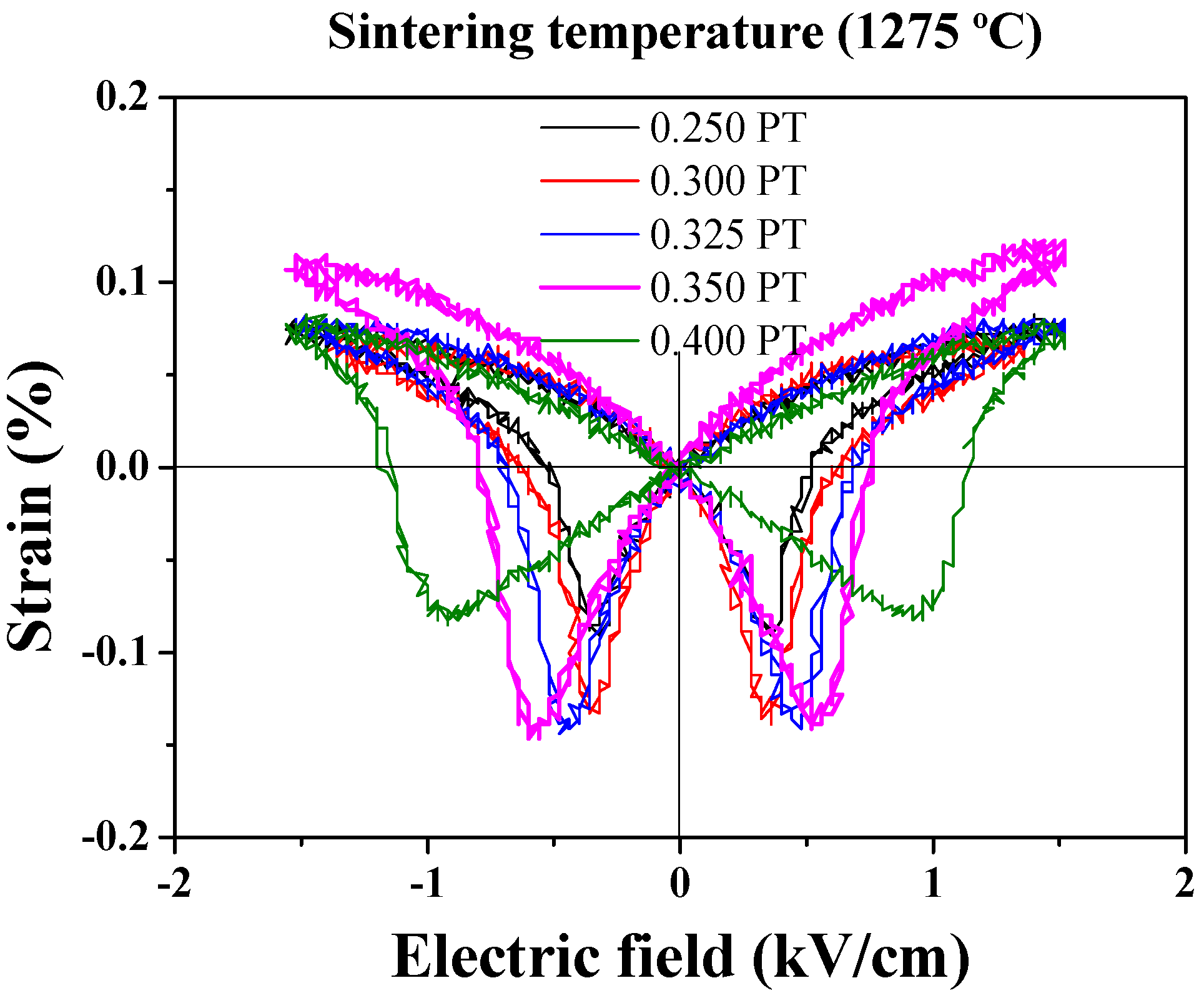

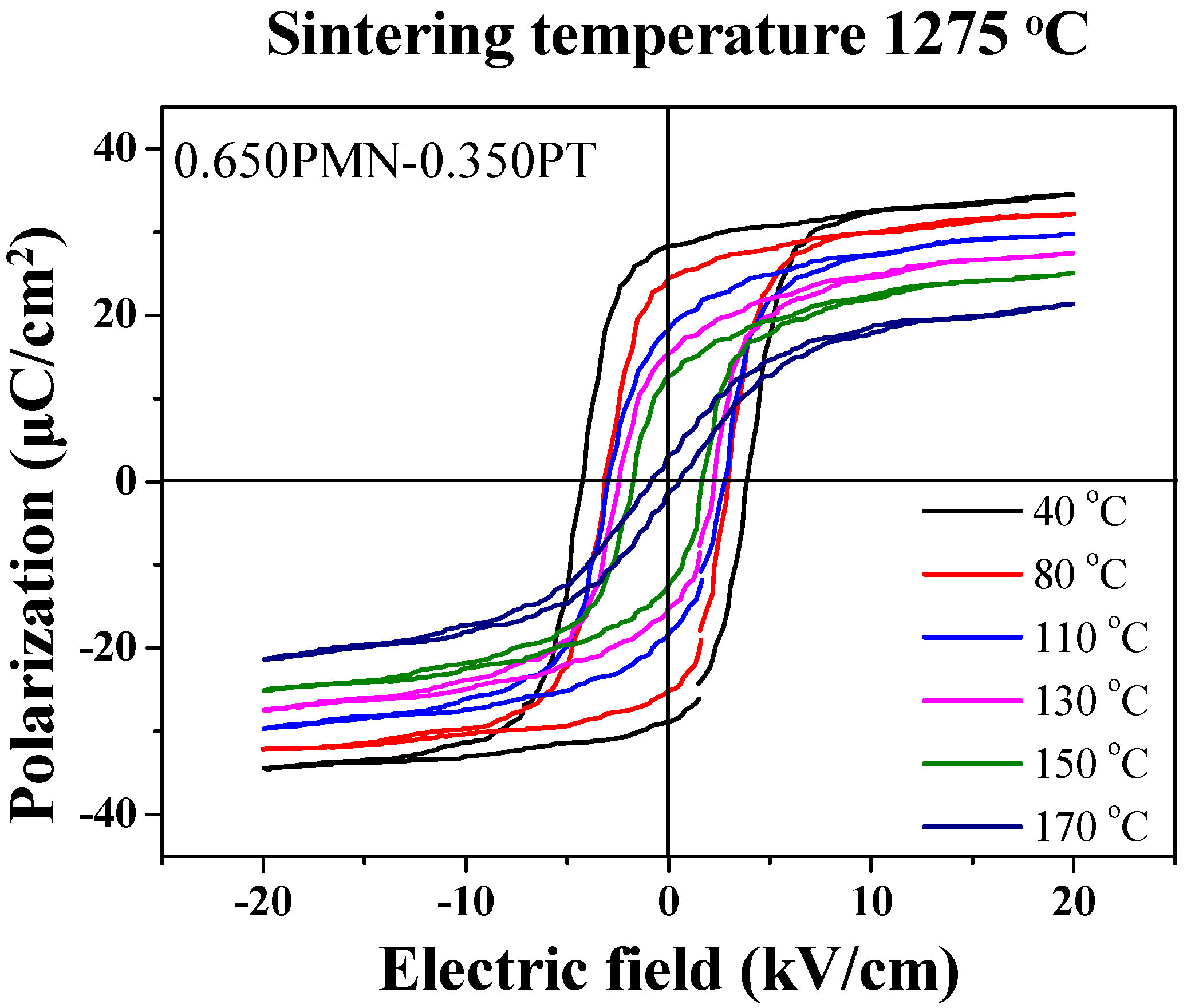

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Swartz, S.L.; Shrout, T.R.; Schulze, W.A.; Cross, L.E. Dielectric Properties of Lead-Magnesium Niobate Ceramics. J. Am. Ceram. Soc. 1984, 67, 311–315. [Google Scholar] [CrossRef]

- Papet, P.; Dougherty, J.P.; Shrout, T.R. Particle and grain size effects on the dielectric behavior of the relaxor ferroelectric Pb(Mg1/3Nb2/3)O3. J. Mater. Res. 1990, 5, 2902–2909. [Google Scholar] [CrossRef]

- Chaudhari, V.A.; Bichile, G.K. Systhesis, Structural, and Electrical Properties of Pure PbTiO3 Ferreelectric Ceramics. Smart Mater. Res. 2013, 132, 1031–1038. [Google Scholar] [CrossRef]

- Huang, H.; An, Z.; Huang, P.; Li, D.; Liao, Q. Phase transition and thermal depolarization of double perovskite modified low sintering temperature PbTiO3 piezoelectric ceramics. J. Eur. Ceram. Soc. 2016, 36, 925–929. [Google Scholar] [CrossRef]

- Slodczyk, A.; Colomban, P. Probing the Nanodomain Origin and Phase Transition Mechanisms in (Un)Poled PMN-PT Single Crystals and Textured Ceramics. Materials 2010, 3, 5007–5028. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pullano, S.A.; Mahbub, I.; Islam, S.K.; Fiorillo, A.S. PVDF Sensor Stimulated by Infrared Radiation for Temperature Monitoring in Microfluidic Devices. Sensors 2017, 17, 850. [Google Scholar] [CrossRef] [PubMed]

- Xia, Z.; Wang, L.; Yan, W.; Li, Q.; Zhang, Y. Comparative investigation of structure and dielectric properties of Pb(Mg1/3Nb2/3)O3-PbTiO3 (65/35) and 10% PbZrO3-doped Pb(Mg1/3Nb2/3)O3-PbTiO3 (65/35) ceramics prepared by a modified precursor method. Mater. Res. Bull. 2007, 42, 1715–1722. [Google Scholar] [CrossRef]

- Leite, E.R.; Scotch, A.M.; Khan, A.; Li, T.; Chan, H.M.; Harmer, M.P.; Liu, S.F.; Park, S.E. Chemical Heterogeneity in PMN-35PT Ceramics and Effects on Dielectric and Piezoelectric Properties. J. Am. Ceram. Soc. 2002, 85, 3018–3024. [Google Scholar] [CrossRef]

- Choi, S.W.; Shrout, T.R.; Jang, S.J.; Bhalla, A.S. Morphotropic Phase Boundary in Pb(Mg1/3Nb2/3)O3-PbTiO3 system. Mater. Lett. 1989, 8, 253–255. [Google Scholar] [CrossRef]

- Zhong, N.; Dong, X.L.; Sun, D.Z.; Xiang, P.H.; Du, H. Electrical properties of Pb(Mg1/3Nb2/3)O3-PbTiO3 ceramics modified with WO3. Mater. Res. Bull. 2004, 39, 175–184. [Google Scholar] [CrossRef]

- Alguero, M.; Alemany, C.; Jimenez, B.; Holc, J.; Kosec, M.; Pardo, L. Piezoelectric PMN-PT ceramics from mechanochemically activated precursors. J. Eur. Ceram. Soc. 2004, 247, 937–940. [Google Scholar] [CrossRef]

- Koo, T.Y.; Cheong, S.W. Dielectric and piezoelectric enhancement due to 90° domain rotation in the tetragonal phase of Pb(Mg1/3Nb2/3)O3-PbTiO3. Appl. Phys. Lett. 2002, 80, 4205–4207. [Google Scholar] [CrossRef]

- Pham-Thi, M.; Augier, C.; Dammak, H.; Gaucher, P. Fine grains ceramics of PIN-PT, PIN-PMN-PT and PMN-PT systems: Drift of the dielectric constant under high electric field. Ultrasonics 2006, 44, e627–e631. [Google Scholar] [CrossRef] [PubMed]

- Kumar, P.; Singh, S.; Thakur, O.P.; Prakash, C.; Goel, T.C. Study of lead Magnesium Niobate-Lead Titanate Ceramics for Piezo-Actuator Applications. Jpn. J. Appl. Phys. 2004, 43, 1501–1506. [Google Scholar] [CrossRef]

- Zuo, R.; Granzow, T.; Lupascu, D.C.; Rodel, J. PMN-PT Ceramics Prepared By Spark Plasma Sintering. J. Am. Ceram. Soc. 2007, 90, 1101–1106. [Google Scholar] [CrossRef]

- Park, J.K.; Chung, U.J.; Hwang, N.M.; Kim, D.Y. Preparation of Dense Lead Magnesium Niobate-Lead Titanate (Pb(Mg1/3Nb2/3)O3-PbTiO3) Ceramics by Spark Plasma Sintering. J. Am. Ceram. Soc. 2001, 84, 3057–3059. [Google Scholar] [CrossRef]

- Zhao, S.; Li, Q.; Feng, Y.; Nan, C. Microstructure and dielectric properties of PMN-PT ceramics prepared by the molten salts method. J. Phys. Chem. Solids 2009, 70, 639–644. [Google Scholar] [CrossRef]

- Xia, F.; Wang, X.; Zhang, L.; Yao, X. Dielectric and piezoelectric properties of PMN-PT ceramics prepared by molten salt synthesis. Ferroelectrics 1998, 215, 181–186. [Google Scholar] [CrossRef]

- Fang, B.; Qian, K.; Chen, Z.; Yuan, N.; Ding, J.; Zhao, X.; Xu, H.; Luo, H. Large strain and pyroelectric properties of Pb(Mg1/3Nb2/3)O3-PbTiO3 ceramics prepared by partial oxalate route. Funct. Mater. Lett. 2014, 7, 1450059. [Google Scholar] [CrossRef]

- Qian, K.; Fang, B.; Du, Q.; Ding, J.; Zhao, X.; Luo, H. Phase development and electrical properties of Pb(Mg1/3Nb2/3)O3-PbTiO3 ceramics prepared by partial oxalate route. Phys. Status Solidi A 2013, 210, 1149–1156. [Google Scholar] [CrossRef]

- Kelly, J.; Leonard, M.; Tantigate, C.; Safari, A. Effect of Composition on the Electromechanical Properties of (1−x)Pb(Mg1/3Nb2/3)O3-xPbTiO3 Ceramics. J. Am. Ceram. Soc. 1997, 80, 957–964. [Google Scholar] [CrossRef]

- Ravindranathan, P.; Komarneni, S.; Bhalla, A.S.; Roy, R. Systhesis and Dielectric Properties of Solution Sol-Gel-Derived 0.9Pb(Mg1/3Nb2/3)O3-0.1PbTiO3 Ceramics. J. Am. Ceram. Soc. 1991, 74, 2996–2999. [Google Scholar] [CrossRef]

- Katayama, K.; Abe, M.; Akiba, T. Sintering and Dielectric Properties of Single-Phase Pb(Mg1/3Nb2/3)O3-PbTiO3. J. Eur. Ceram. Soc. 1989, 5, 183–191. [Google Scholar] [CrossRef]

- Gupta, S.M.; Kulkarmi, A.R. Synthesis of perovskite lead magnesium niobate using partial oxalate method. Mater. Res. Bull. 1993, 28, 1295–1301. [Google Scholar] [CrossRef]

- Mergen, A.; Lee, W.E. Fabrication, Characterisation and Formation Mechanim of Ph1.83Mg0.29Nb1.17O6.39 Phrochlore. J. Eur. Ceram. Soc. 1997, 17, 1033–1047. [Google Scholar] [CrossRef]

- Jayasingh, E.M.; Prabhakaran, K.; Sooraj, R.; Durgaprasad, C.; Sharma, S.C. Syntheis of pyrochlore free PMN-PT powder by partial oxalate process route. Ceram. Int. 2009, 35, 591–596. [Google Scholar] [CrossRef]

- Chang, L.M.; Hou, Y.D.; Zhu, M.K.; Yan, H. Effect of sintering temperature on the phase transition and dielectrical response in the relaxor-ferroelectric-system 0.5PZN-0.5PZT. J. Appl. Phys. 2007, 101, 034101. [Google Scholar] [CrossRef]

- Chen, T.Y.; Chu, S.Y.; Juang, Y.D. Effects of sintering temperature on the dielectric and piezoelectric properties of Sr additive Sm-modified PbTiO3 ceramics. Sens. Actuators A 2002, 102, 6–10. [Google Scholar] [CrossRef]

- Kwon, Y.H.; Shin, D.J.; Lee, G.H.; Koh, J.H. Sintering temperature dependent piezoelectric properties of (Bi,Na)TiO3-(Ba,Sr)TiO3 ceramics. Ceram. Int. 2016, 42, 10422–10427. [Google Scholar] [CrossRef]

- Park, H.H.; Yoon, S.; Park, H.H.; Hill, R.H. Electrical properties of PZT thin films by photochemical deposition. Thin Solid Films 2004, 447–448, 669–673. [Google Scholar] [CrossRef]

- Singh, R.; Chandra, S.; Sharma, S.; Tripathi, A.K.; Goel, T.C. Sol-Gel Derived La Modified PZT Thin Films: Structure and Properties. IEEE Trans. Dielect. Electr. Insul. 2004, 11, 264–270. [Google Scholar] [CrossRef]

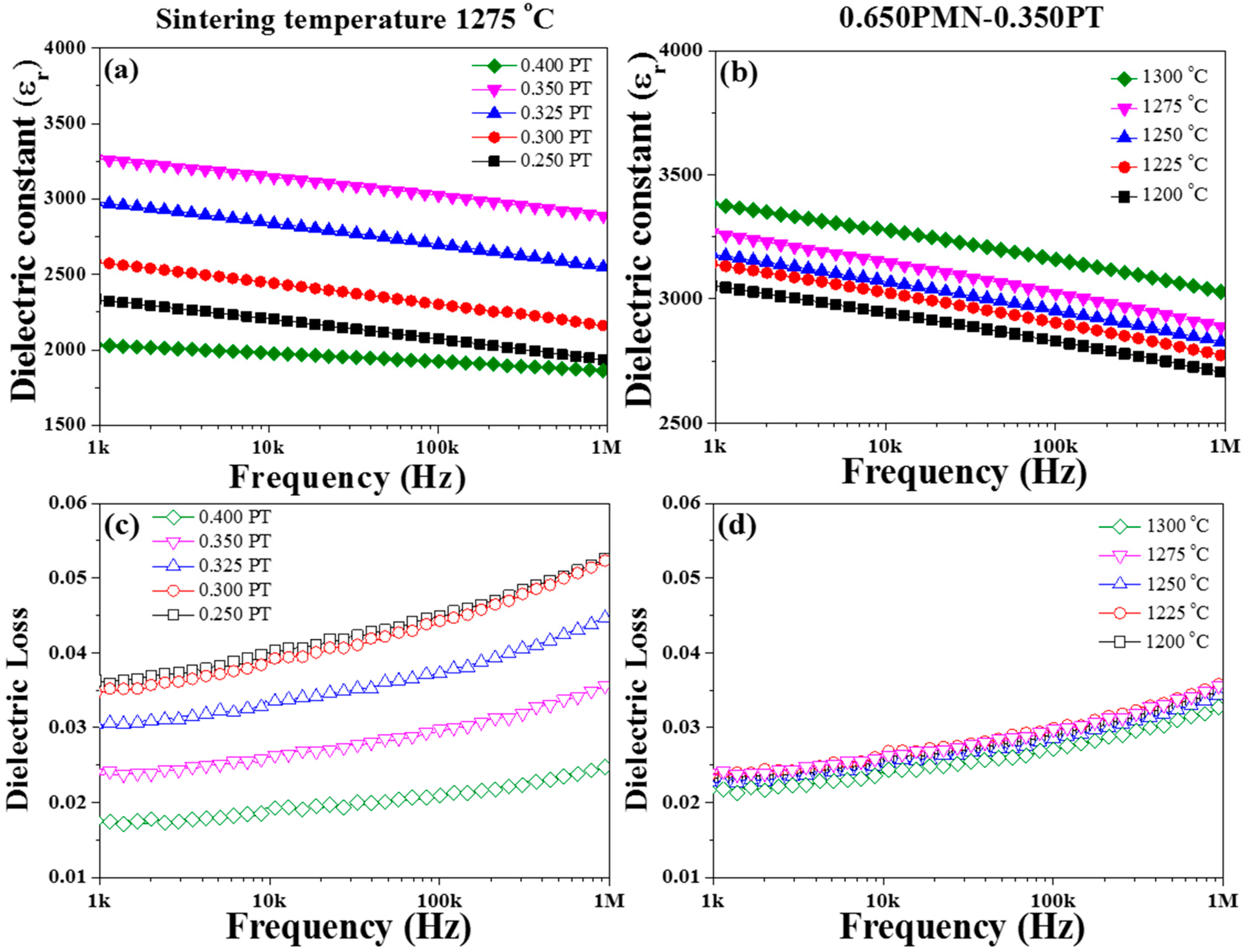

| Method | d33 (pC/N) | kp (%) | ρ (g/cm3) | εr (1 kHz) | Tc (°C) | Ref. |

|---|---|---|---|---|---|---|

| Mixed oxide | 430 | 56.4 | 7.85 | 2547 | 162 | [10] |

| Mechanochemical | 570 | - | - | - | 171 | [11] |

| Columbite | 610 | - | - | 6350 | - | [12] |

| Columbite | 499 | 52 | - | 4830 | 180 | [13] |

| Columbite | 530 | - | 7.8 | - | 153 | [14] |

| Spark plasma sintering | 350 | 57 | - | - | - | [15] |

| Spark plasma sintering | 590 | 63.4 | - | - | 160 | [16] |

| Molten salts | 660 | - | - | - | 165 | [17] |

| Molten salts | 540 | 66 | 7.73 | - | 144.5 | [18] |

| Partial oxalate | 590 | 57 | 7.828 | 2617.9 (100 Hz) | [19] | |

| Partial oxalate | 581 | 56.5 | 7.97 | - | 151 | [20] |

| Partial oxalate | 665 | 77.8 | 8.23 | 3230 | 129.84 | Our sample |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.; Yoon, S.; Ji, J.-H.; Ko, Y.-H.; Cho, K.-H.; Lee, S.-K.; Koh, J.-H. Enhanced Ferroelectric and Piezoelectric Properties of (1−x)PMN-xPT Ceramics Based on a Partial Oxalate Process. Materials 2018, 11, 2247. https://doi.org/10.3390/ma11112247

Kim J, Yoon S, Ji J-H, Ko Y-H, Cho K-H, Lee S-K, Koh J-H. Enhanced Ferroelectric and Piezoelectric Properties of (1−x)PMN-xPT Ceramics Based on a Partial Oxalate Process. Materials. 2018; 11(11):2247. https://doi.org/10.3390/ma11112247

Chicago/Turabian StyleKim, Jinhwan, Sanghyun Yoon, Jae-Hoon Ji, Young-Ho Ko, Kyung-Ho Cho, Sang-Kwon Lee, and Jung-Hyuk Koh. 2018. "Enhanced Ferroelectric and Piezoelectric Properties of (1−x)PMN-xPT Ceramics Based on a Partial Oxalate Process" Materials 11, no. 11: 2247. https://doi.org/10.3390/ma11112247

APA StyleKim, J., Yoon, S., Ji, J.-H., Ko, Y.-H., Cho, K.-H., Lee, S.-K., & Koh, J.-H. (2018). Enhanced Ferroelectric and Piezoelectric Properties of (1−x)PMN-xPT Ceramics Based on a Partial Oxalate Process. Materials, 11(11), 2247. https://doi.org/10.3390/ma11112247