Compatibility of a Silicone Impression/Adhesive System to FDM-Printed Tray Materials—A Laboratory Peel-off Study

Abstract

1. Introduction

2. Materials and Methods

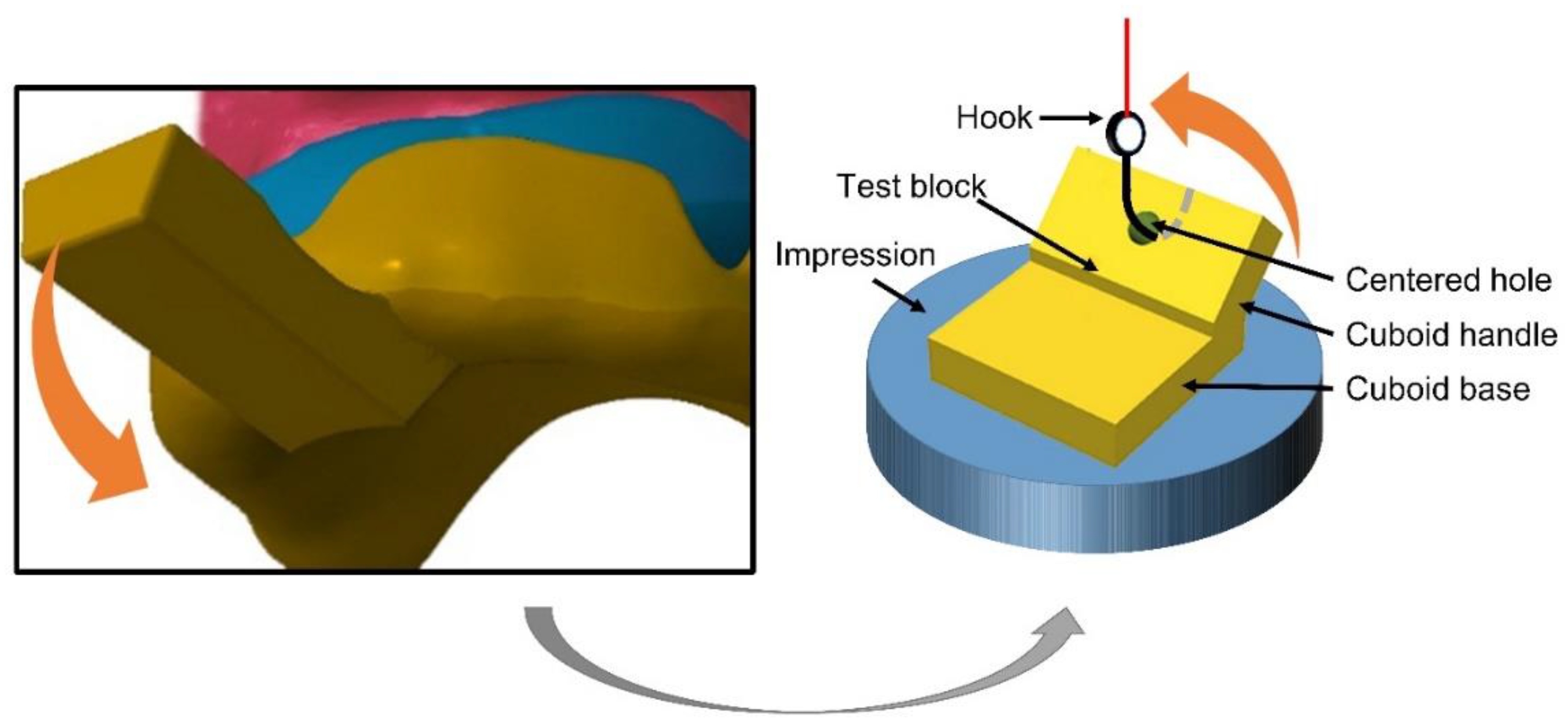

2.1. CAD of Test Blocks

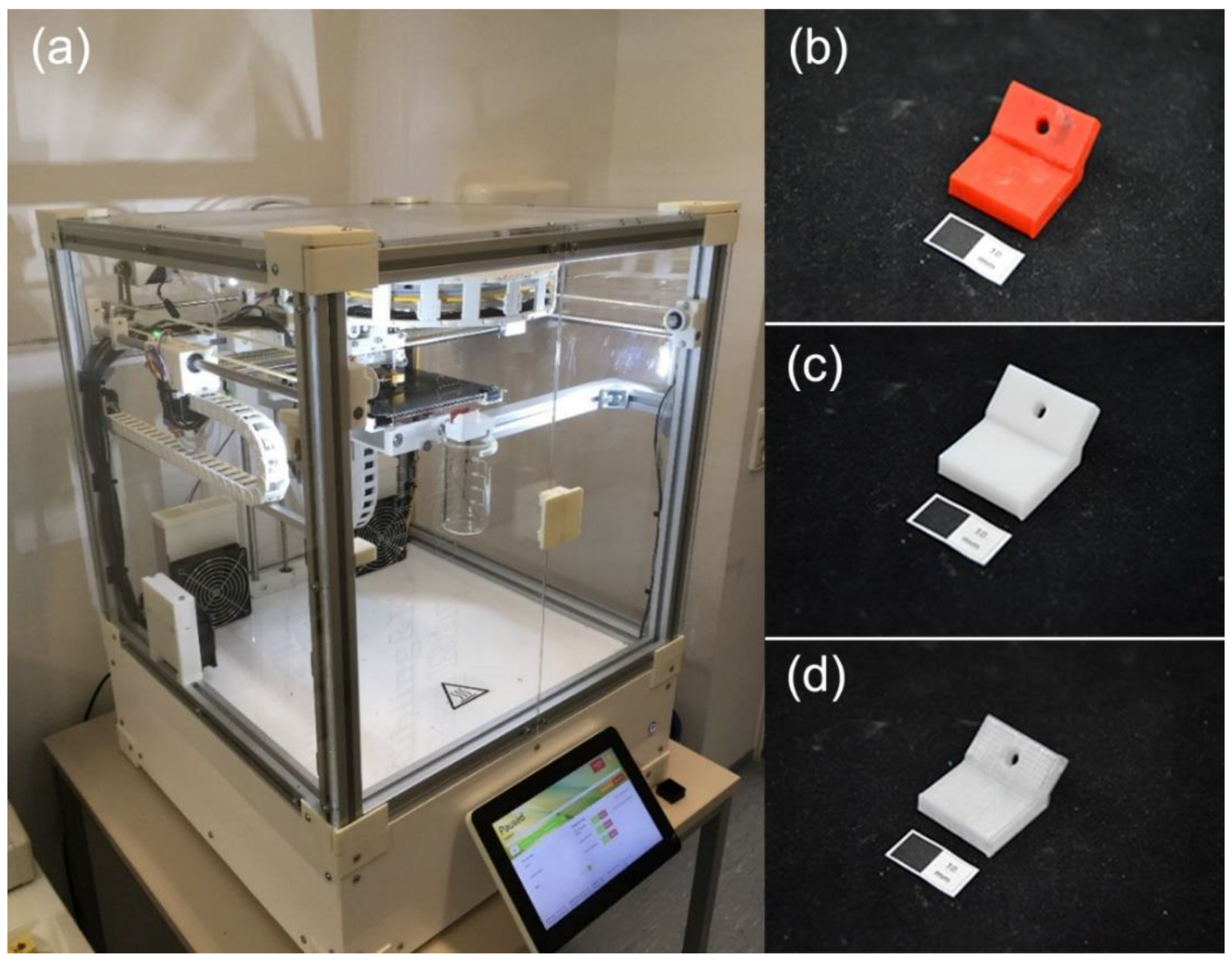

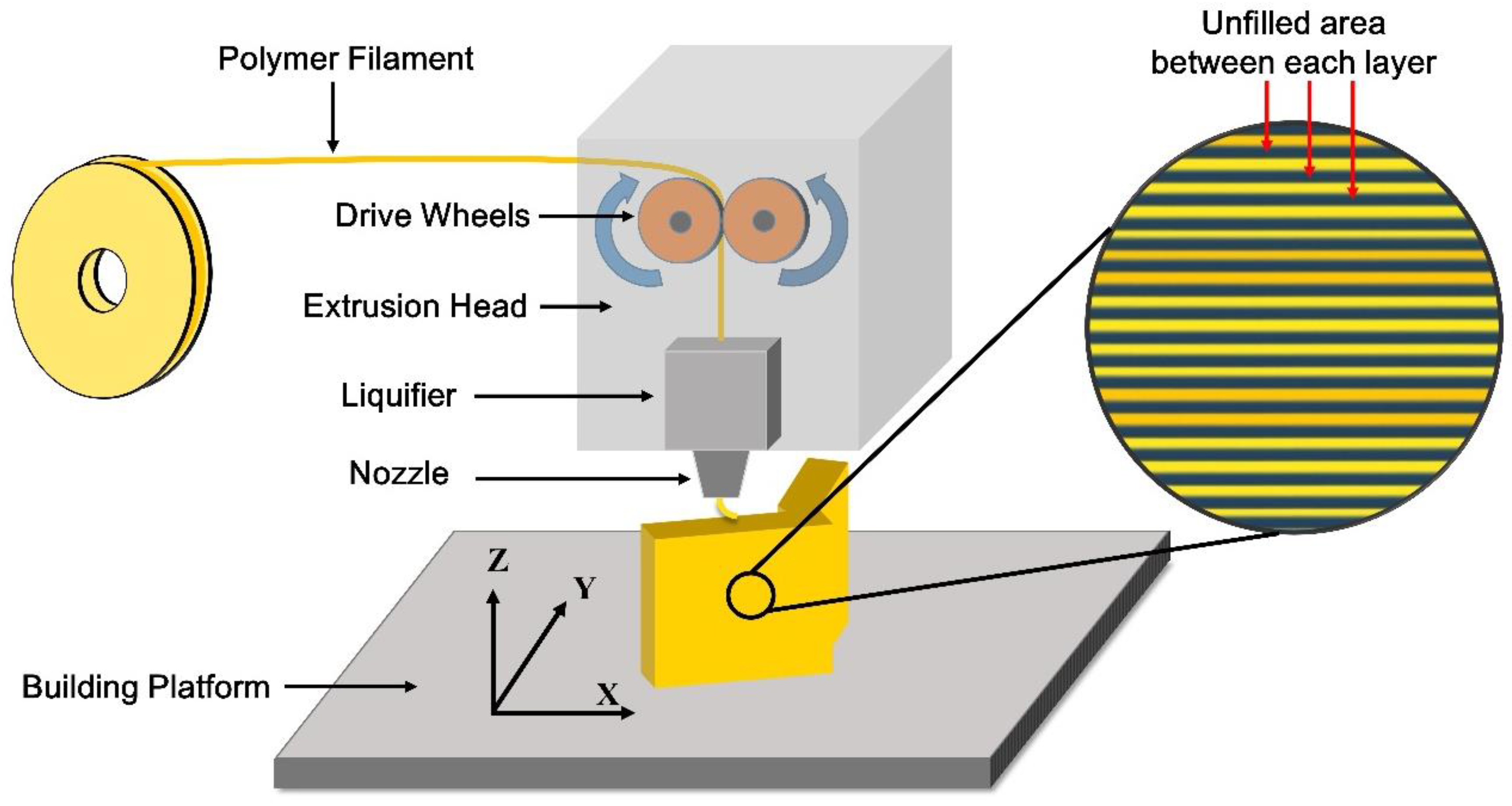

2.2. AM of Test Blocks

2.3. Fabrication of Reference Test Blocks

2.4. Roughness Measurement

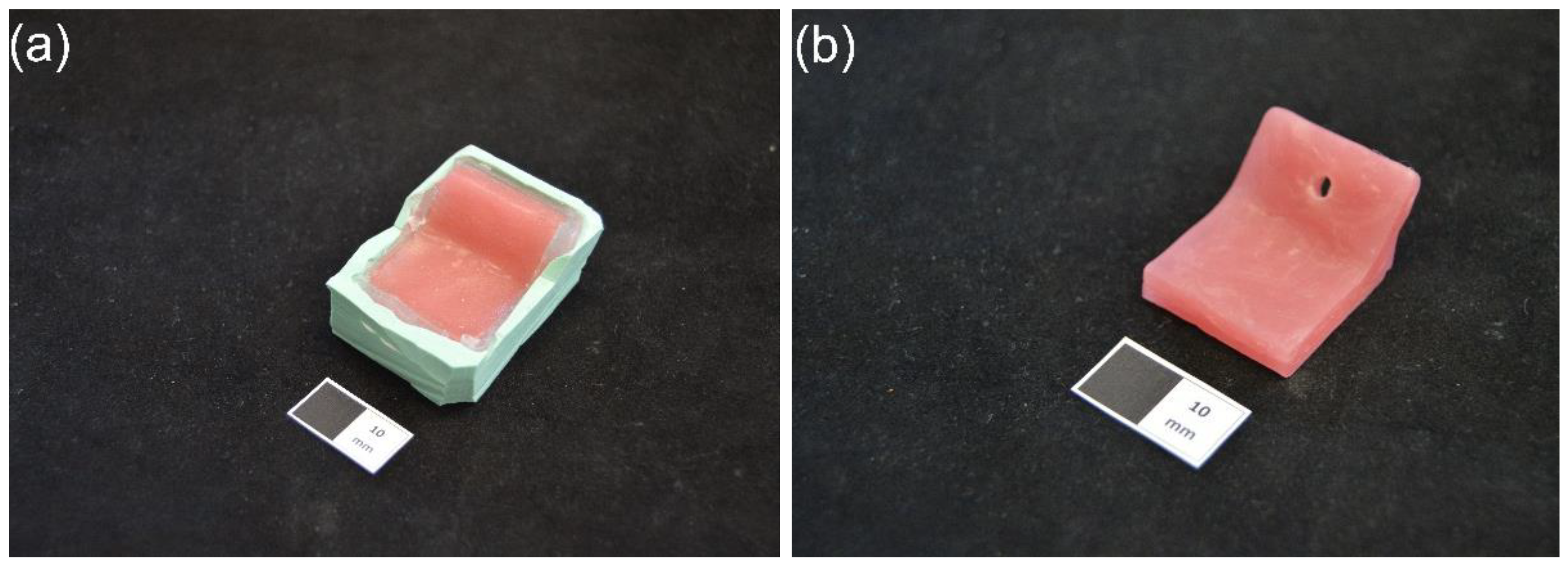

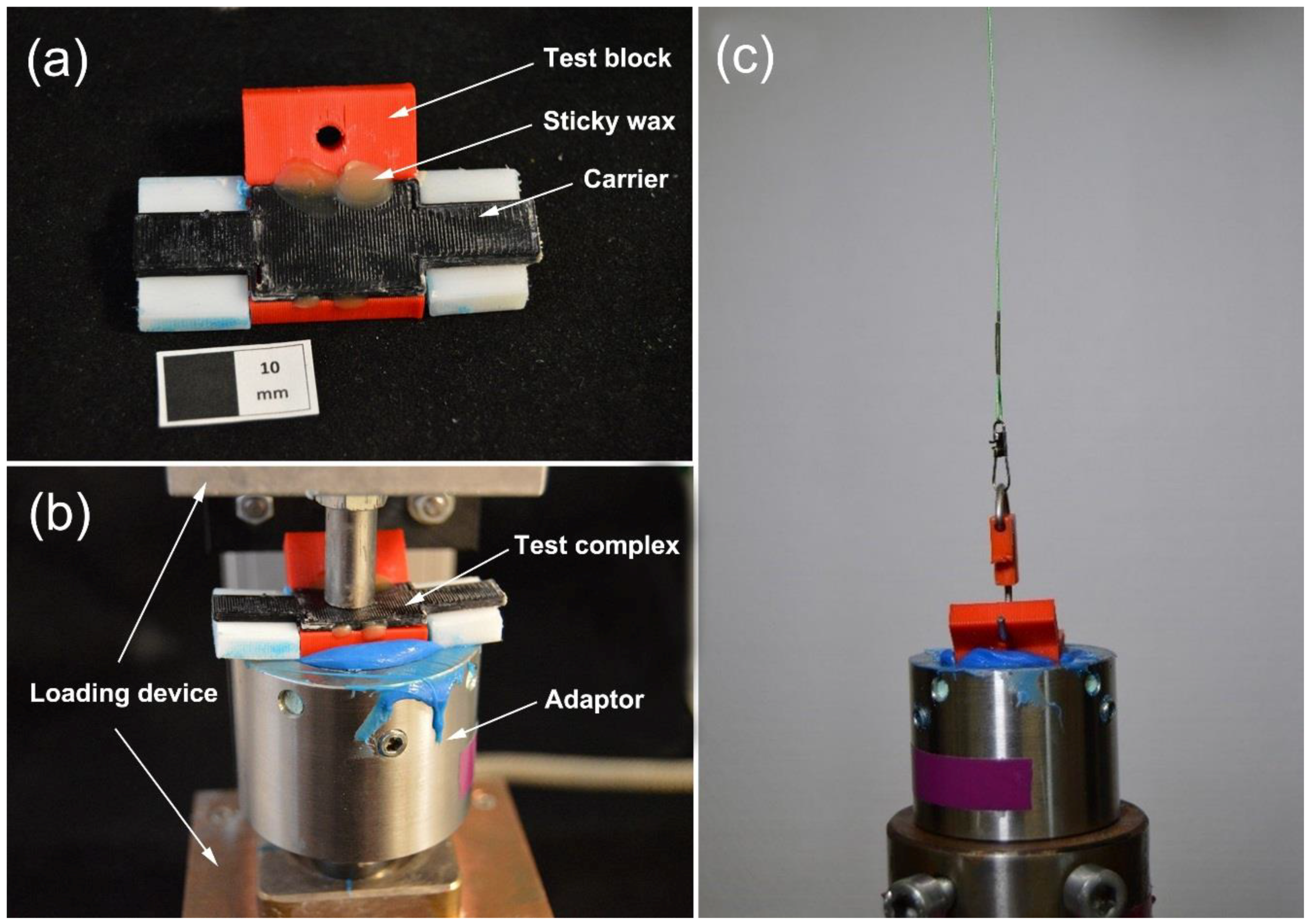

2.5. Peel-off Strength Test

2.6. GB

2.7. Scanning Electron Microscopy (SEM)

2.8. Statistical Analysis

3. Results

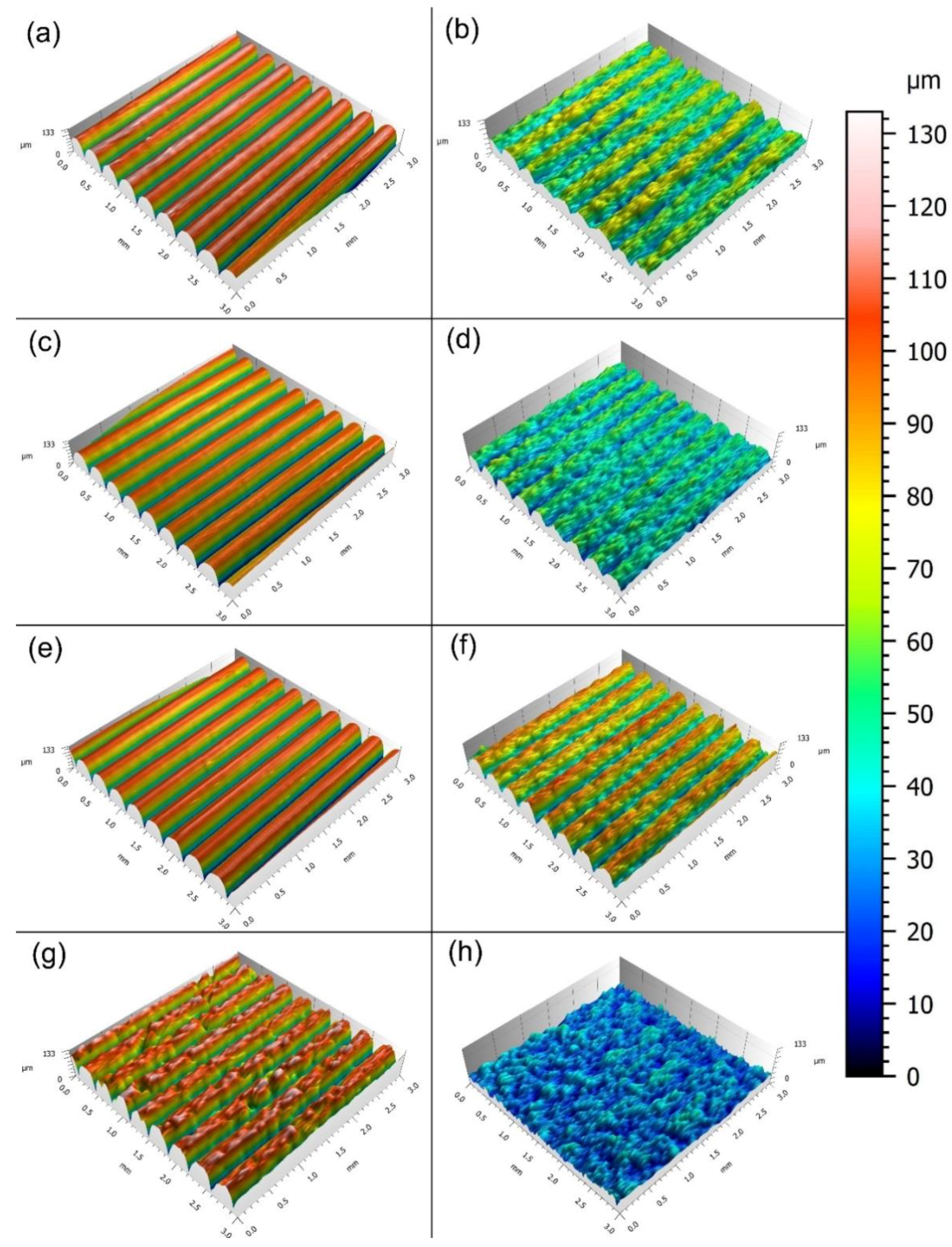

3.1. 3D Surface Reconstruction

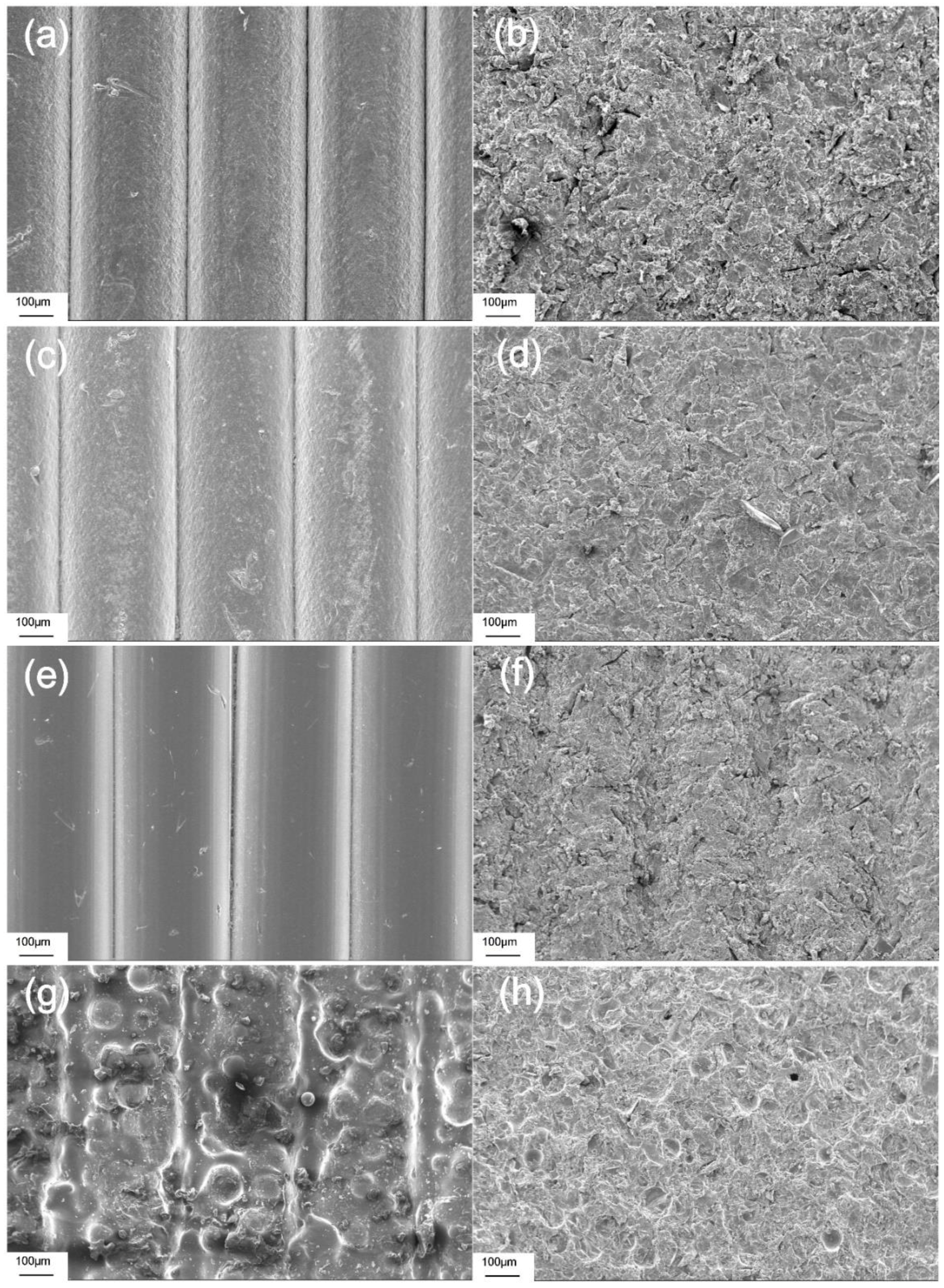

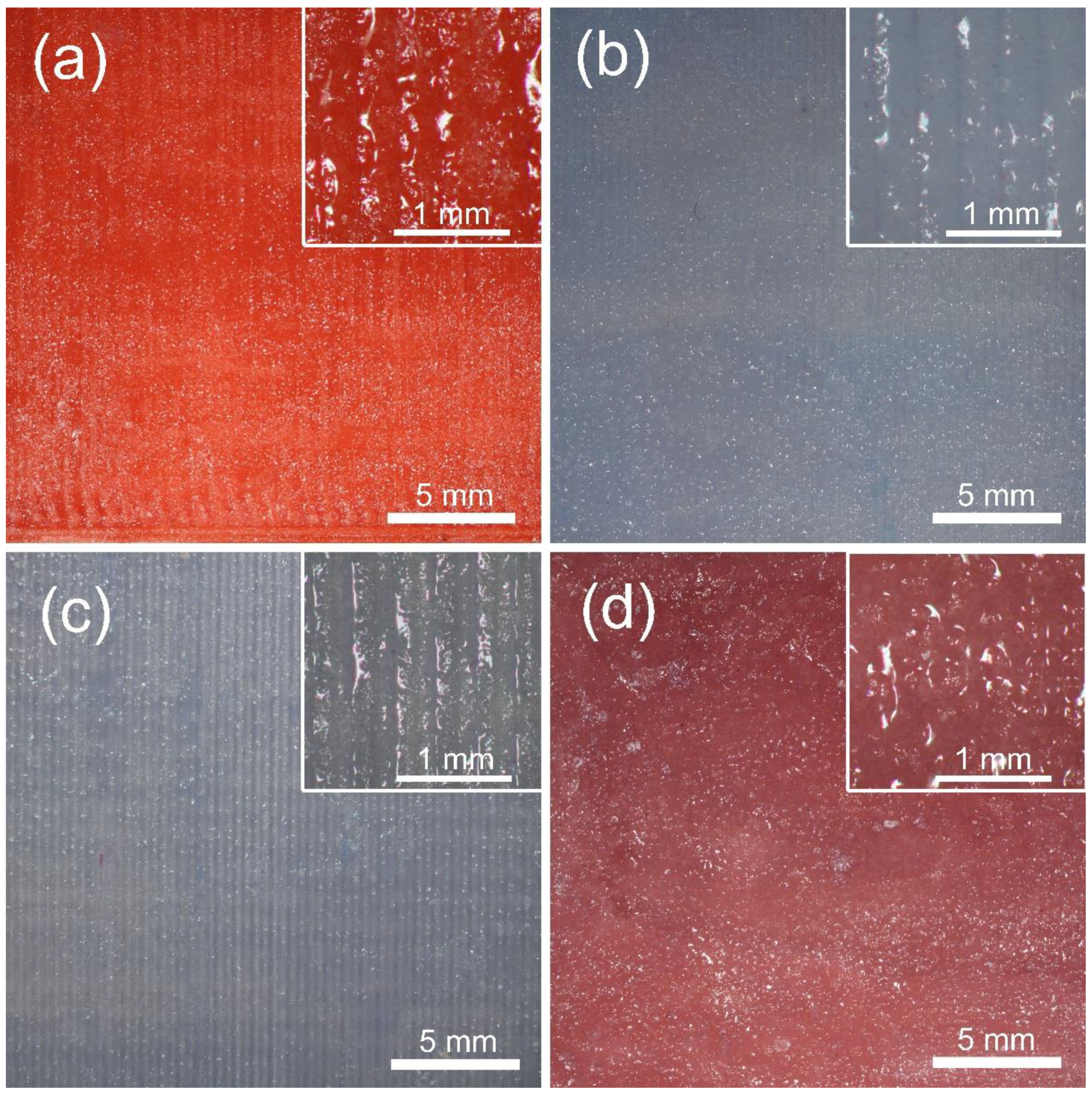

3.2. SEM

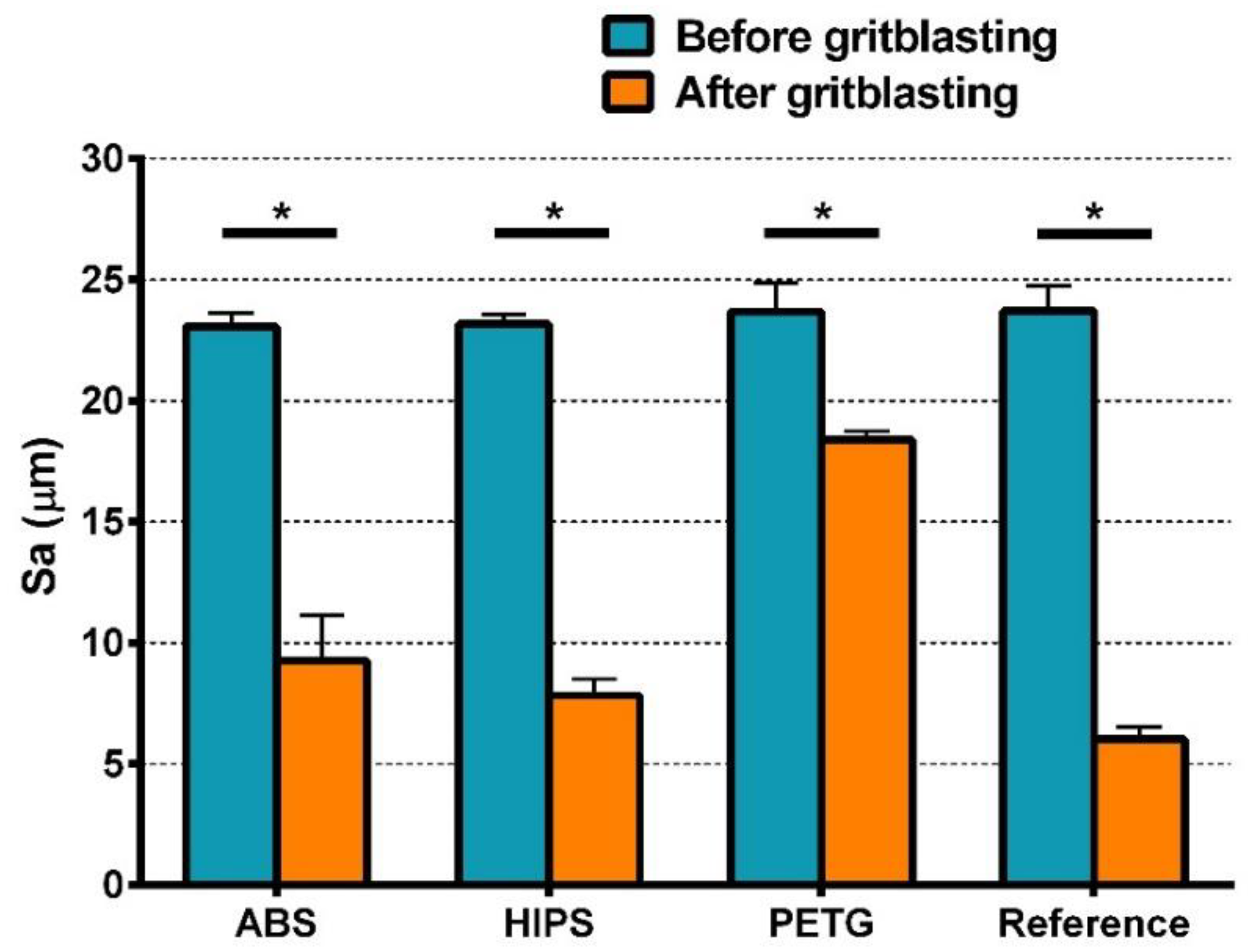

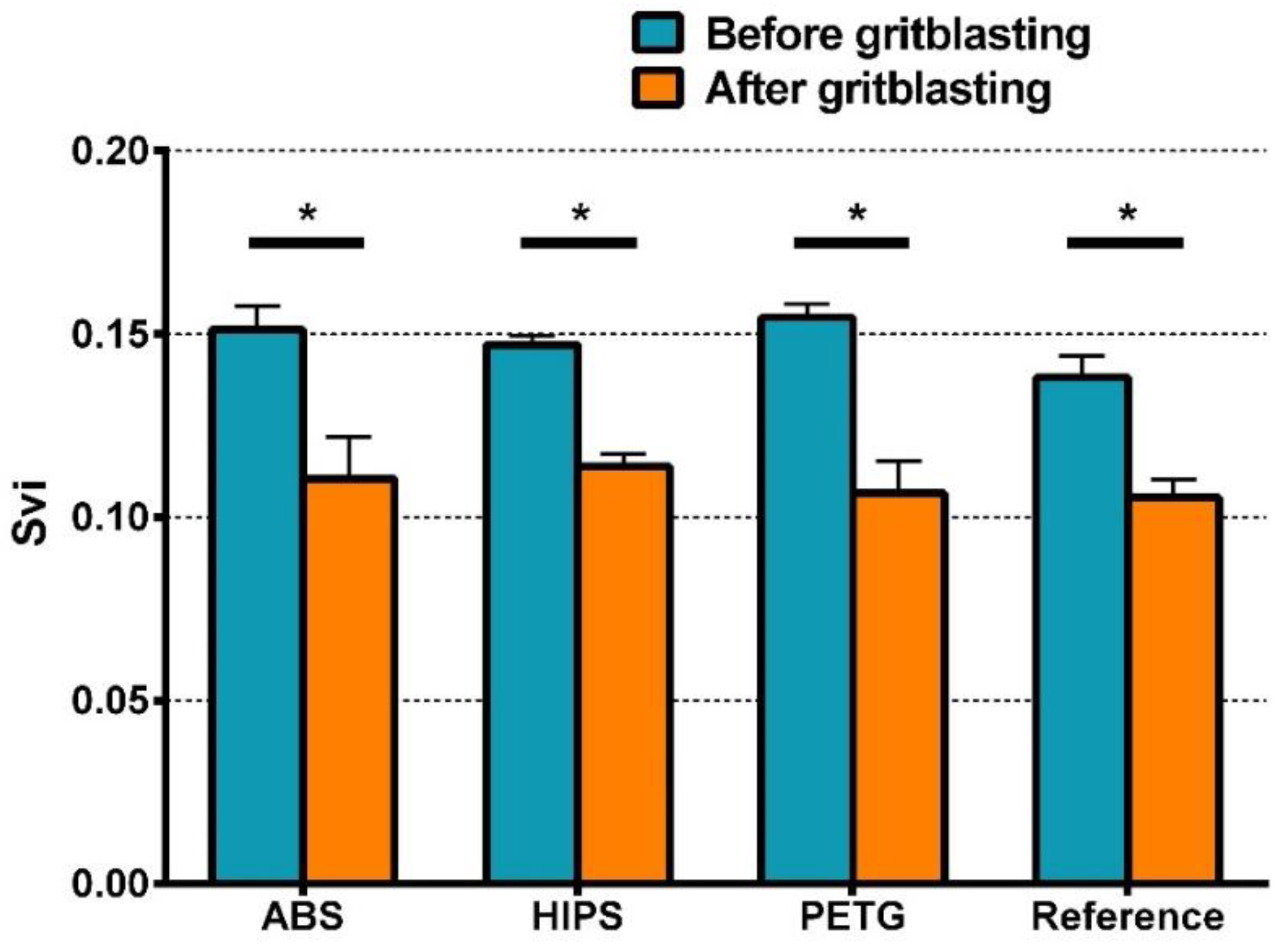

3.3. Roughness Measurements

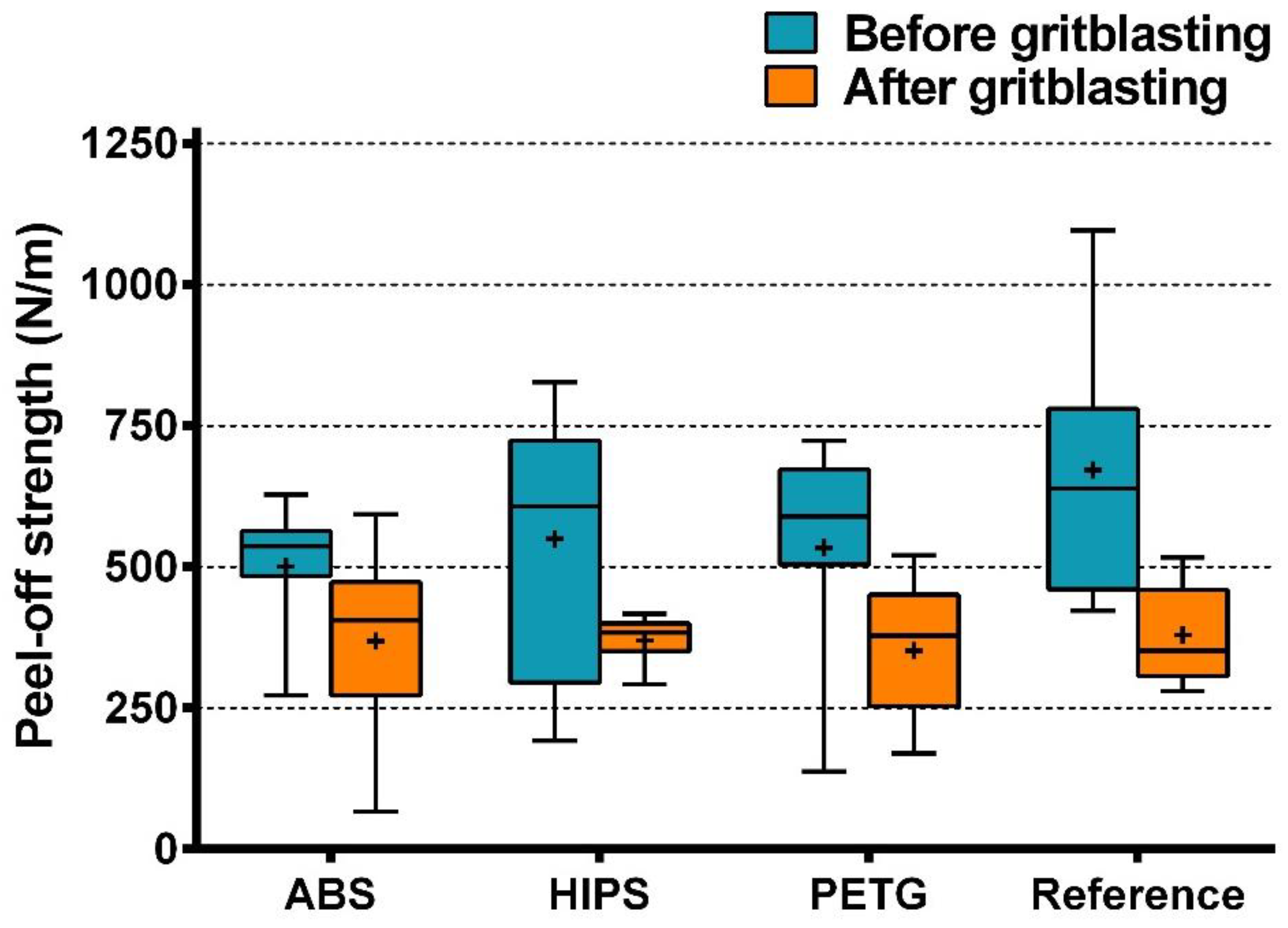

3.4. Peel-off Strength Test

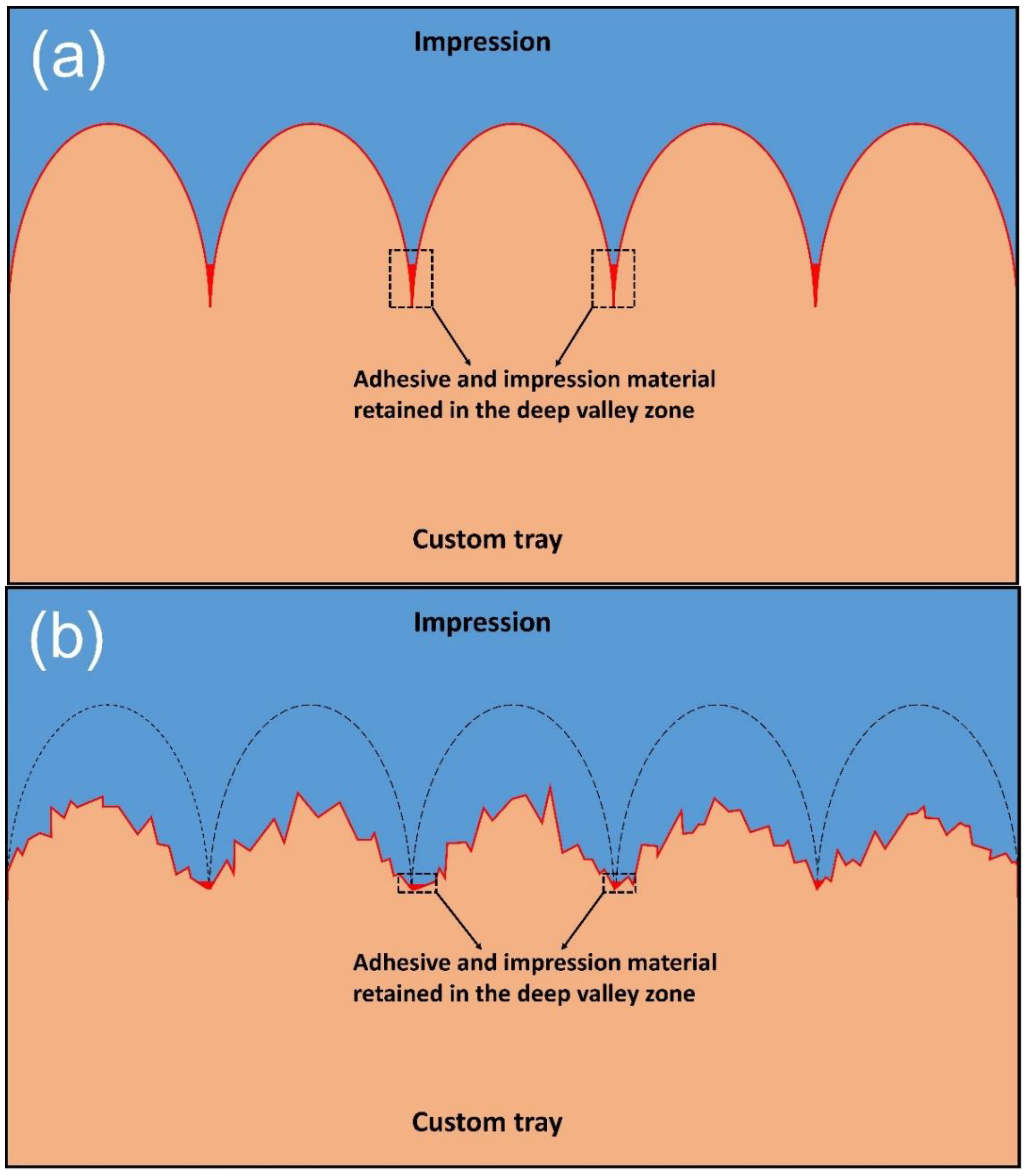

4. Discussion

5. Conclusions

- The three investigated FDM-printed tray materials (ABS, HIPS, and PETG) could provide sufficient adhesion to the adhesive compared to the conventional light-curing resin.

- Custom trays made by FDM seems to possess intrinsic surface roughness that might improve bonding.

- GB could reduce the surface roughness of FDM-printed custom tray materials and thus weaken the bonding between the adhesive and the impression.

- The Svi index of the tray materials’ topography may have a certain correlation with the peel-off strength between the adhesive and the impression.

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Petrie, C.S.; Walker, M.P.; Williams, K. A survey of US prosthodontists and dental schools on the current materials and methods for final impressions for complete denture prosthodontics. J. Prosthodont. 2005, 14, 253–262. [Google Scholar] [CrossRef] [PubMed]

- Schmitt, S.; Schmitt, R. Going Digital: Unlimited Potential for Dentures. Available online: http://schmittdds.com/PDF/GoingDigital_Unlimited_potential_for_dentures.pdf (accessed on 28 September 2018).

- Gebhardt, A. 3D-Drucken: Grundlagen und Anwendungen des Additive Manufacturing (AM); Carl Hanser Verlag GmbH Co KG: Munich, Germany, 2016; ISBN 3446448454. [Google Scholar]

- Zanetti, E.M.; Aldieri, A.; Terzini, M.; Calì, M.; Franceschini, G.; Bignardi, C. Additively manufactured custom load-bearing implantable devices: Grounds for caution. Australas. Med. J. 2017, 10, 694. [Google Scholar] [CrossRef]

- Stansbury, J.W.; Idacavage, M.J. 3D printing with polymers: Challenges among expanding options and opportunities. Dent. Mater. 2016, 32, 54–64. [Google Scholar] [CrossRef] [PubMed]

- Huang, S.H.; Liu, P.; Mokasdar, A.; Hou, L. Additive manufacturing and its societal impact: A literature review. Int. J. Adv. Manuf. Technol. 2013, 67, 1191–1203. [Google Scholar] [CrossRef]

- Maschio, F.; Pandya, M.; Olszewski, R. Experimental Validation of Plastic Mandible Models Produced by a “Low-Cost” 3-Dimensional Fused Deposition Modeling Printer. Med. Sci. Monit. 2016, 22, 943–957. [Google Scholar] [CrossRef] [PubMed]

- Unkovskiy, A.; Spintzyk, S.; Axmann, D.; Engel, E.-M.; Weber, H.; Huettig, F. Additive manufacturing: A comparative analysis of dimensional accuracy and skin texture reproduction of auricular prostheses replicas. J. Prosthodont. 2017. [Google Scholar] [CrossRef] [PubMed]

- Marro, A.; Bandukwala, T.; Mak, W. Three-Dimensional Printing and Medical Imaging: A Review of the Methods and Applications. Curr. Probl. Diagn. Radiol. 2016, 45, 2–9. [Google Scholar] [CrossRef] [PubMed]

- Saunders, W.P.; Sharkey, S.W.; Smith, G.M.; Taylor, W.G. Effect of impression tray design and impression technique upon the accuracy of stone casts produced from a putty-wash polyvinyl siloxane impression material. J. Dent. 1991, 19, 283–289. [Google Scholar] [CrossRef]

- Terry, D.A.; Tric, O.; Blatz, M.; Burgess, J.O. The custom impression tray: Fabrication and utilization. Dent. Today 2010, 29, 132–134. [Google Scholar] [PubMed]

- Dixon, D.L.; Breeding, L.C.; Bosser, M.J.; Nafso, A.J. The effect of custom tray material type and surface treatment on the tensile bond strength of an impression material/adhesive system. Int. J. Prosthodont. 1993, 6, 303–306. [Google Scholar] [PubMed]

- Chai, J.Y.; Jameson, L.M.; Moser, J.B.; Hesby, R.A. Adhesive properties of several impression material systems: Part I. J. Prosthet. Dent. 1991, 66, 201–209. [Google Scholar] [CrossRef]

- Kumar, S.; Gandhi, U.V.; Banerjee, S. An In Vitro Study of the Bond Strength of Five Adhesives Used for Vinyl Polysiloxane Impression Materials and Tray Materials. J. Indian Prosthodont. Soc. 2014, 14, 61–66. [Google Scholar] [CrossRef] [PubMed]

- Maruo, Y.; Nishigawa, G.; Oka, M.; Minagi, S.; Irie, M.; Suzuki, K. Tensile bond strength between custom tray and elastomeric impression material. Dent. Mater. J. 2007, 26, 323–328. [Google Scholar] [CrossRef] [PubMed]

- Dixon, D.L.; Breeding, L.C.; Brown, J.S. The effect of custom tray material type and adhesive drying time on the tensile bond strength of an impression material/adhesive system. Int. J. Prosthodont. 1994, 7, 129–133. [Google Scholar] [PubMed]

- Ashwini, B.L.; Manjunath, S.; Mathew, K.X. The Bond Strength of Different Tray Adhesives on Vinyl Polysiloxane to Two Tray Materials: An In Vitro Study. J. Indian Prosthodont. Soc. 2014, 14, 29–37. [Google Scholar] [CrossRef] [PubMed]

- Payne, J.A.; Pereira, B.P. Bond strength of two nonaqueous elastomeric impression materials bonded to two thermoplastic resin tray materials. J. Prosthet. Dent. 1995, 74, 563–568. [Google Scholar] [CrossRef]

- Thongthammachat, S.; Moore, B.K.; Barco, M.T.; Hovijitra, S.; Brown, D.T.; Andres, C.J. Dimensional accuracy of dental casts: Influence of tray material, impression material, and time. J. Prosthodont. 2002, 11, 98–108. [Google Scholar] [CrossRef] [PubMed]

- Byeon, M.S.; Lee, H.M.; Bae, S.T. Shear Bond Strength of Al2O3 Sandblasted Y-TZP Ceramic to the Orthodontic Metal Bracket. Materials 2017, 10, 148. [Google Scholar] [CrossRef] [PubMed]

- Peregrina, A.; Land, M.F.; Wandling, C.; Johnston, W.M. The effect of different adhesives on vinyl polysiloxane bond strength to two tray materials. J. Prosthet. Dent. 2005, 94, 209–213. [Google Scholar] [CrossRef] [PubMed]

- Yi, M.-H.; Shim, J.-S.; Lee, K.-W.; Chung, M.-K. Drying time of tray adhesive for adequate tensile bond strength between polyvinylsiloxane impression and tray resin material. J. Adv. Prosthodont. 2009, 1, 63–67. [Google Scholar] [CrossRef] [PubMed]

- Grant, B.E.; Tjan, A.H.L. Tensile and peel bond strengths of tray adhesives. J. Prosthet. Dent. 1988, 59, 165–168. [Google Scholar] [CrossRef]

- Stout, K.J.; Blunt, L. Three Dimensional Surface Topograpgy; Penton Press: London, UK, 2000; ISBN 1857180267. [Google Scholar]

- Sawada, T.; Spintzyk, S.; Schille, C.; Schweizer, E.; Scheideler, L.; Geis-Gerstorfer, J. Influence of Different Framework Designs on the Fracture Properties of Ceria-Stabilized Tetragonal Zirconia/Alumina-Based All-Ceramic Crowns. Materials 2016, 9, 339. [Google Scholar] [CrossRef] [PubMed]

- Abdullah, M.A.; Talic, Y.F. The effect of custom tray material type and fabrication technique on tensile bond strength of impression material adhesive systems. J. Oral Rehabil. 2003, 30, 312–317. [Google Scholar] [CrossRef] [PubMed]

- Huang, Z.; Wang, X.; Hou, Y. Novel Method of Fabricating Individual Trays for Maxillectomy Patients by Computer-Aided Design and Rapid Prototyping. J. Prosthodont. 2015, 24, 115–120. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Yang, X.; Chen, L.; Wang, Y.; Sun, Y. Application of FDM three-dimensional printing technology in the digital manufacture of custom edentulous mandible trays. Sci. Rep. 2016, 6, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Wei, L.; Chen, H.; Zhou, Y.S.; Sun, Y.C.; Pan, S.X. Evaluation of production and clinical working time of computer-aided design/computer-aided manufacturing (CAD/CAM) custom trays for complete denture. J. Peking Univ. Heal. Sci. 2017, 49, 86–91. [Google Scholar]

- Grewal Bach, G.K.; Torrealba, Y.; Lagravère, M.O. Orthodontic bonding to porcelain: A systematic review. Angle Orthod. 2013, 84, 555–560. [Google Scholar] [CrossRef] [PubMed]

- Mair, L.; Padipatvuthikul, P. Variables related to materials and preparing for bond strength testing irrespective of the test protocol. Dent. Mater. 2010, 26, 17–23. [Google Scholar] [CrossRef] [PubMed]

- Gajdoš, I.; Slota, J. Influence of printing conditions on structure in FDM prototypes. Teh. Vjesn. 2013, 20, 231–236. [Google Scholar]

- Alsoufi, M.S.; Elsayed, A.E. How Surface Roughness Performance of Printed Parts Manufactured by Desktop FDM 3D Printer with PLA+ is Influenced by Measuring Direction. Am. J. Mech. Eng. 2017, 5, 211–222. [Google Scholar]

- Ituarte, I.F.; Chekurov, S.; Salmi, M.; Tuomi, J.; Partanen, J. Post-processing opportunities of professional and consumer grade 3D printing equipment: A comparative study. Int. J. Rapid Manuf. 2015, 5, 58–75. [Google Scholar] [CrossRef]

- Kournetas, N.; Spintzyk, S.; Schweizer, E.; Sawada, T.; Said, F.; Schmid, P.; Geis-Gerstorfer, J.; Eliades, G.; Rupp, F. Comparative evaluation of topographical data of dental implant surfaces applying optical interferometry and scanning electron microscopy. Dent. Mater. 2017, 8, e317–e327. [Google Scholar] [CrossRef] [PubMed]

- Shipway, P.H.; Ngao, N.K. Microscale abrasive wear of polymeric materials. Wear 2003, 255, 742–750. [Google Scholar] [CrossRef]

- Jarnstrom, J.; Sinervo, L.; Toivakka, M.; Peltonen, J. Topography and gloss of precipitated calcium carbonate coating layers on a model substrate. Tappi. J. 2007, 6, 23. [Google Scholar]

- Davis, G.B.; Moser, J.B.; Brinsden, G.I. The bonding properties of elastomer tray adhesives. J. Prosthet. Dent. 1976, 36, 278–285. [Google Scholar] [CrossRef]

- Bindra, B. Adhesion of elastomeric impression materials to trays. J. Oral Rehabil. 1997, 24, 63–69. [Google Scholar] [CrossRef] [PubMed]

- Ona, M.; Takahashi, H.; Sato, M.; Igarashi, Y.; Wakabayashi, N. Effect of reactive adhesives on the tensile bond strength of polyvinyl siloxane impression materials to methyl methacrylate tray material. Dent. Mater. J. 2010, 29, 336–340. [Google Scholar] [CrossRef] [PubMed]

- Lakshmi, C.B.S.; Umamaheswari, B.; Devarhubli, A.R.; Pai, S.; Wadambe, T.N. An evaluation of compatibility of three different impression materials to three different tray acrylic materials using tray adhesives: An In vitro Study. Indian J. Dent. Sci. 2018, 10, 37. [Google Scholar]

- MacSween, R.; Price, R.B. Peel bond strengths of five impression material tray adhesives. J. Can. Dent. Assoc. 1991, 57, 654–657. [Google Scholar] [PubMed]

| Settings | ABS | HIPS | PETG |

|---|---|---|---|

| Printing bed temperature | 105 °C | 110 °C | 60 °C |

| Printing chamber temperature | 70 °C | 70 °C | 0–35 °C |

| Printing nozzle temperature | 275 °C | 235 °C | 275–285 °C |

| Printing speed | 28 mm/s | 28 mm/s | 28 mm/s |

| Layer thickness | 0.35 mm | 0.35 mm | 0.35 mm |

| Infill | 100% | 100% | 100% |

| Group after GB | Sa (μm) |

|---|---|

| ABS | 9.26 (1.86) A |

| HIPS | 7.82 (0.68) AC |

| PETG | 18.40 (0.35) B |

| Reference | 6.03 (0.50) C |

| Group before GB | Svi |

|---|---|

| ABS | 0.151 (0.007) AB |

| HIPS | 0.147 (0.003) AB |

| PETG | 0.155 (0.004) A |

| Reference | 0.138 (0.006) B |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, Y.; Unkovskiy, A.; Klaue, F.; Rupp, F.; Geis-Gerstorfer, J.; Spintzyk, S. Compatibility of a Silicone Impression/Adhesive System to FDM-Printed Tray Materials—A Laboratory Peel-off Study. Materials 2018, 11, 1905. https://doi.org/10.3390/ma11101905

Xu Y, Unkovskiy A, Klaue F, Rupp F, Geis-Gerstorfer J, Spintzyk S. Compatibility of a Silicone Impression/Adhesive System to FDM-Printed Tray Materials—A Laboratory Peel-off Study. Materials. 2018; 11(10):1905. https://doi.org/10.3390/ma11101905

Chicago/Turabian StyleXu, Yichen, Alexey Unkovskiy, Felix Klaue, Frank Rupp, Juergen Geis-Gerstorfer, and Sebastian Spintzyk. 2018. "Compatibility of a Silicone Impression/Adhesive System to FDM-Printed Tray Materials—A Laboratory Peel-off Study" Materials 11, no. 10: 1905. https://doi.org/10.3390/ma11101905

APA StyleXu, Y., Unkovskiy, A., Klaue, F., Rupp, F., Geis-Gerstorfer, J., & Spintzyk, S. (2018). Compatibility of a Silicone Impression/Adhesive System to FDM-Printed Tray Materials—A Laboratory Peel-off Study. Materials, 11(10), 1905. https://doi.org/10.3390/ma11101905