Micro-Mechanical Response of an Al-Mg Hybrid System Synthesized by High-Pressure Torsion

Abstract

:1. Introduction

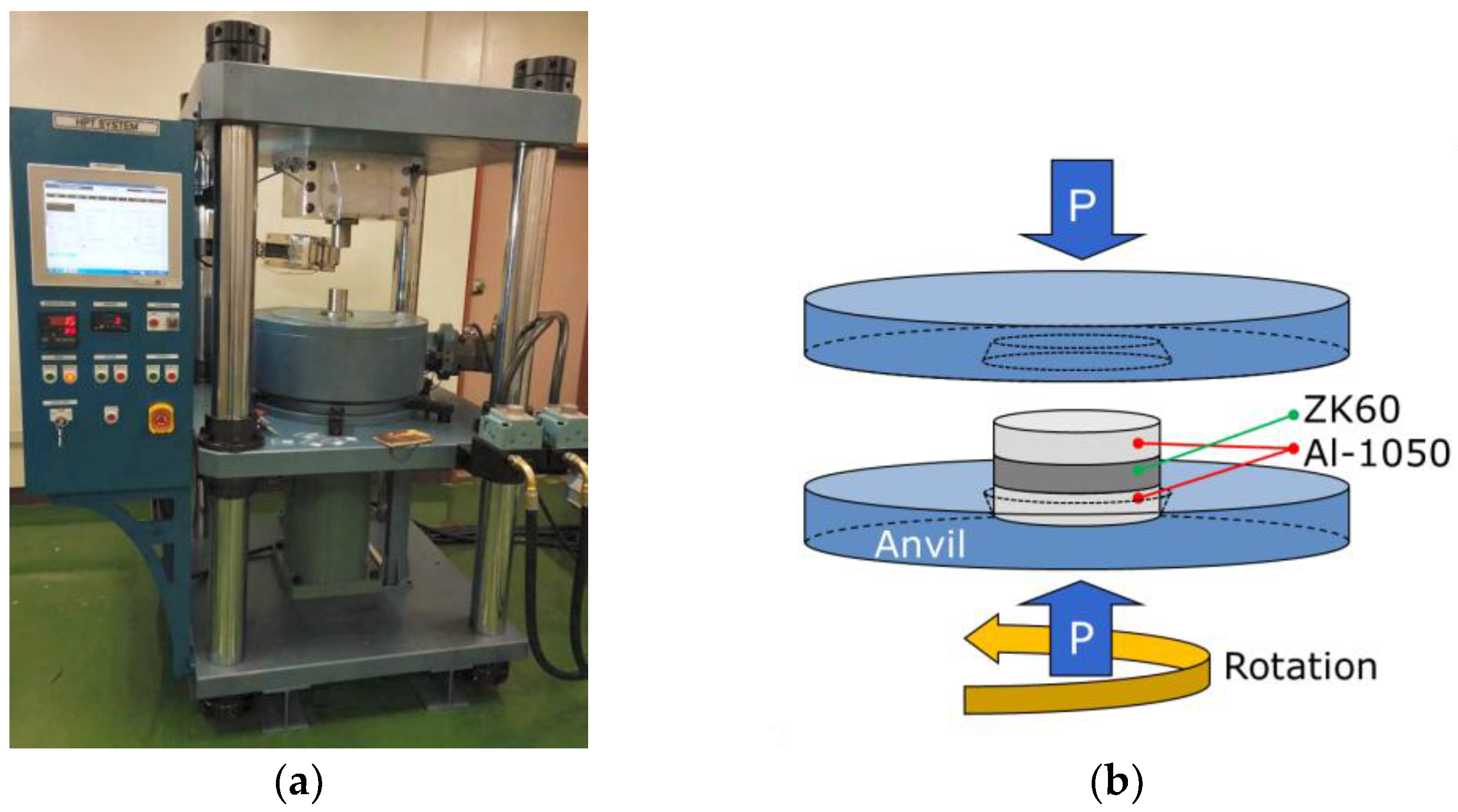

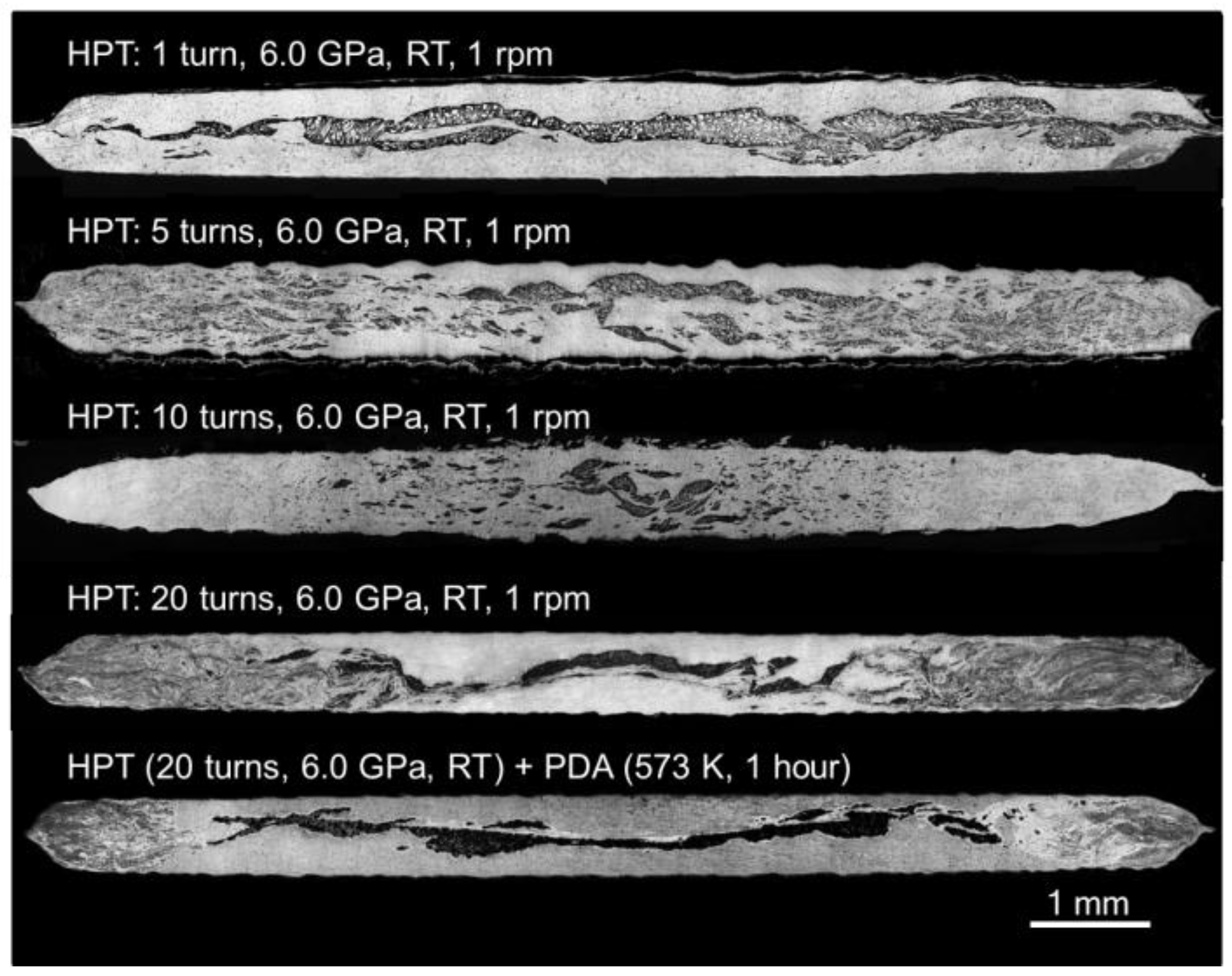

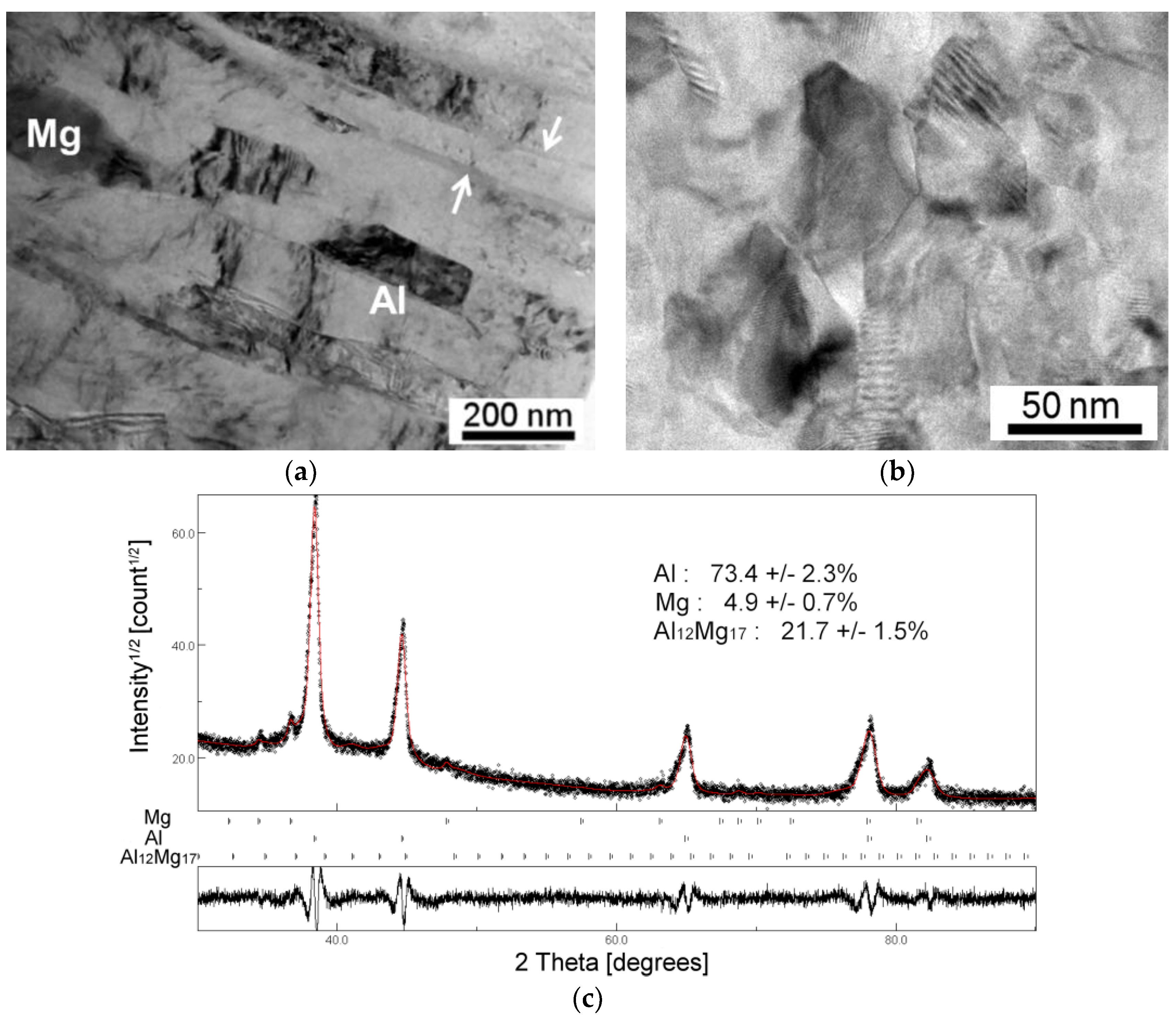

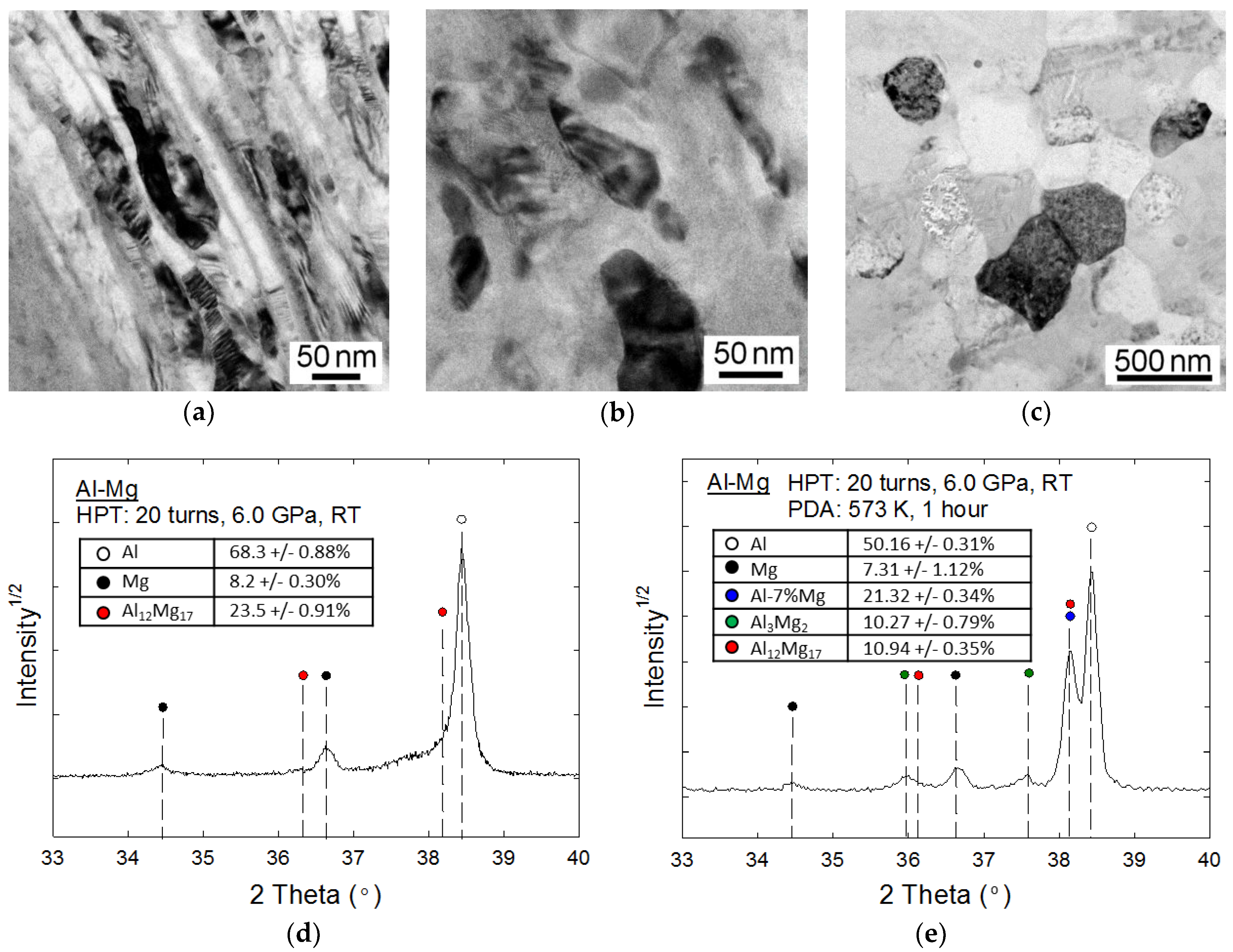

2. Synthesis of an Al-Mg Hybrid Metal System through Diffusion Bonding

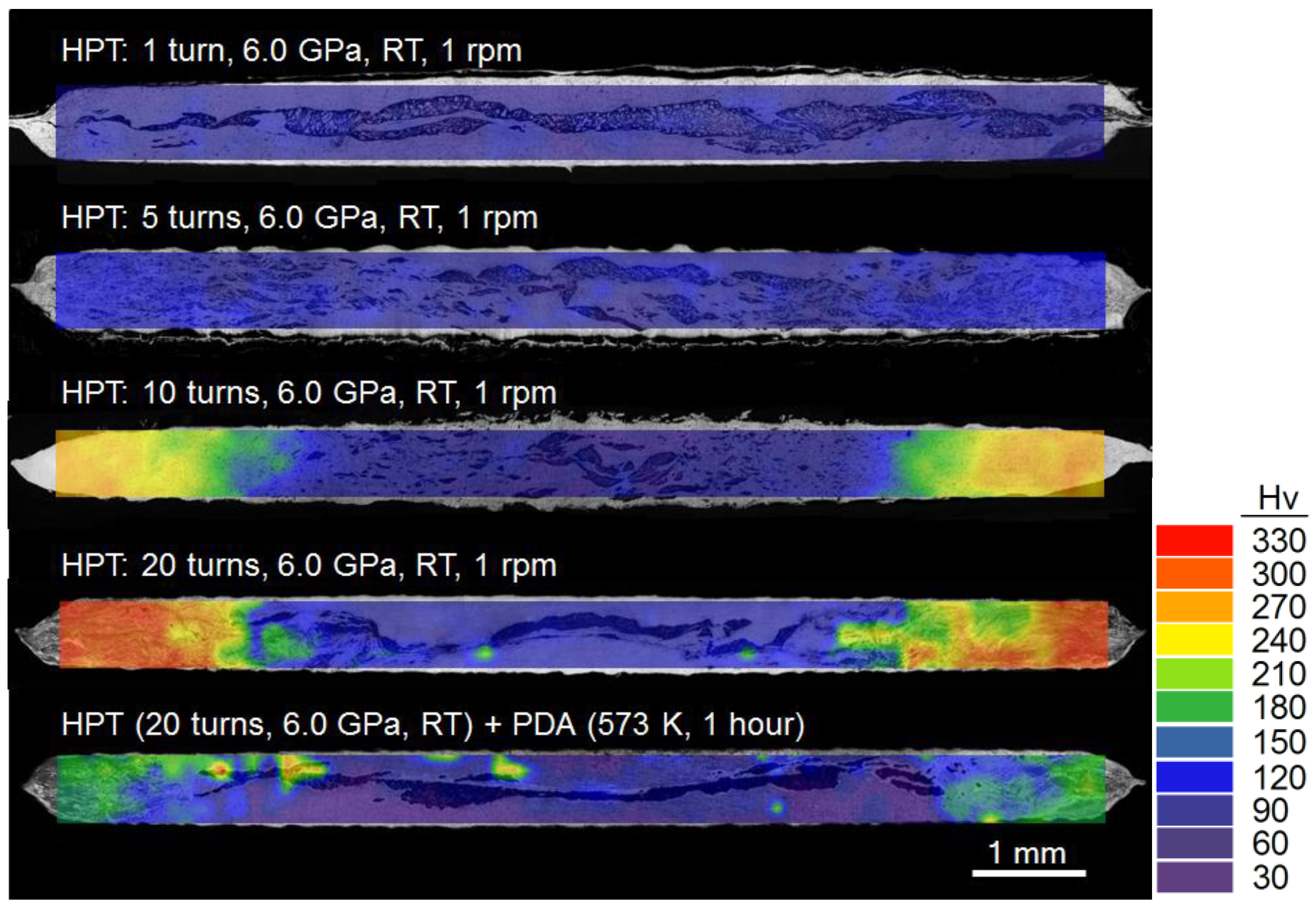

2.1. Microstructural Evolution and Hardness Development

2.2. Hardness Development in the Al-Mg Hybrid System

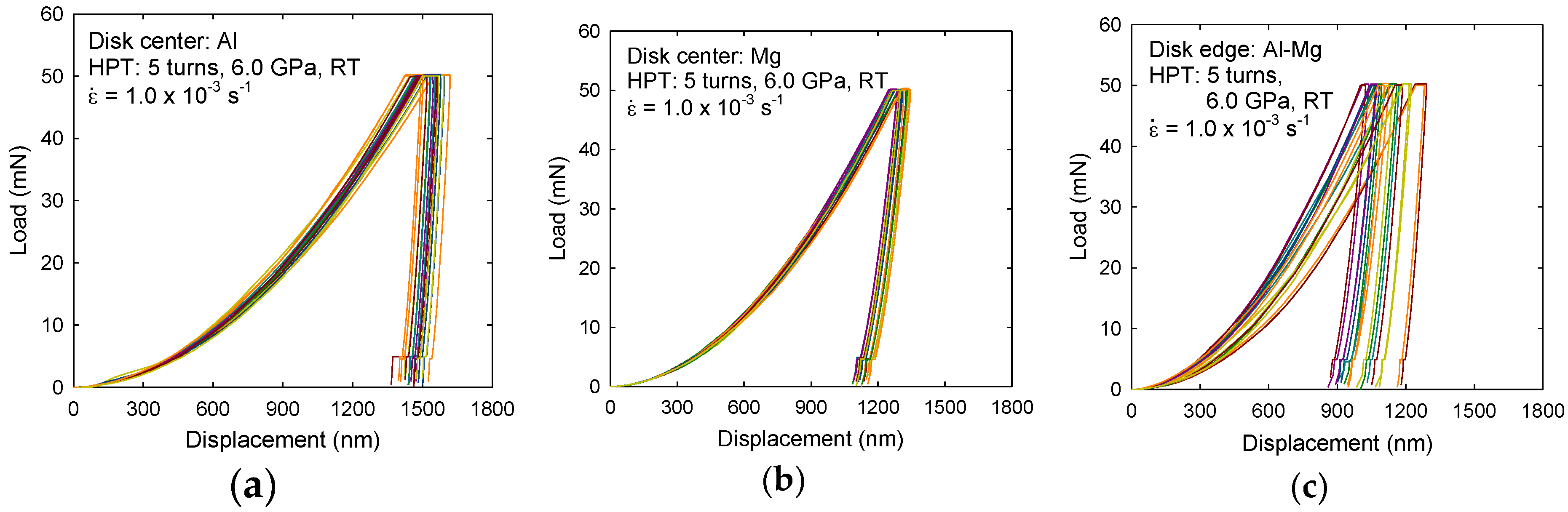

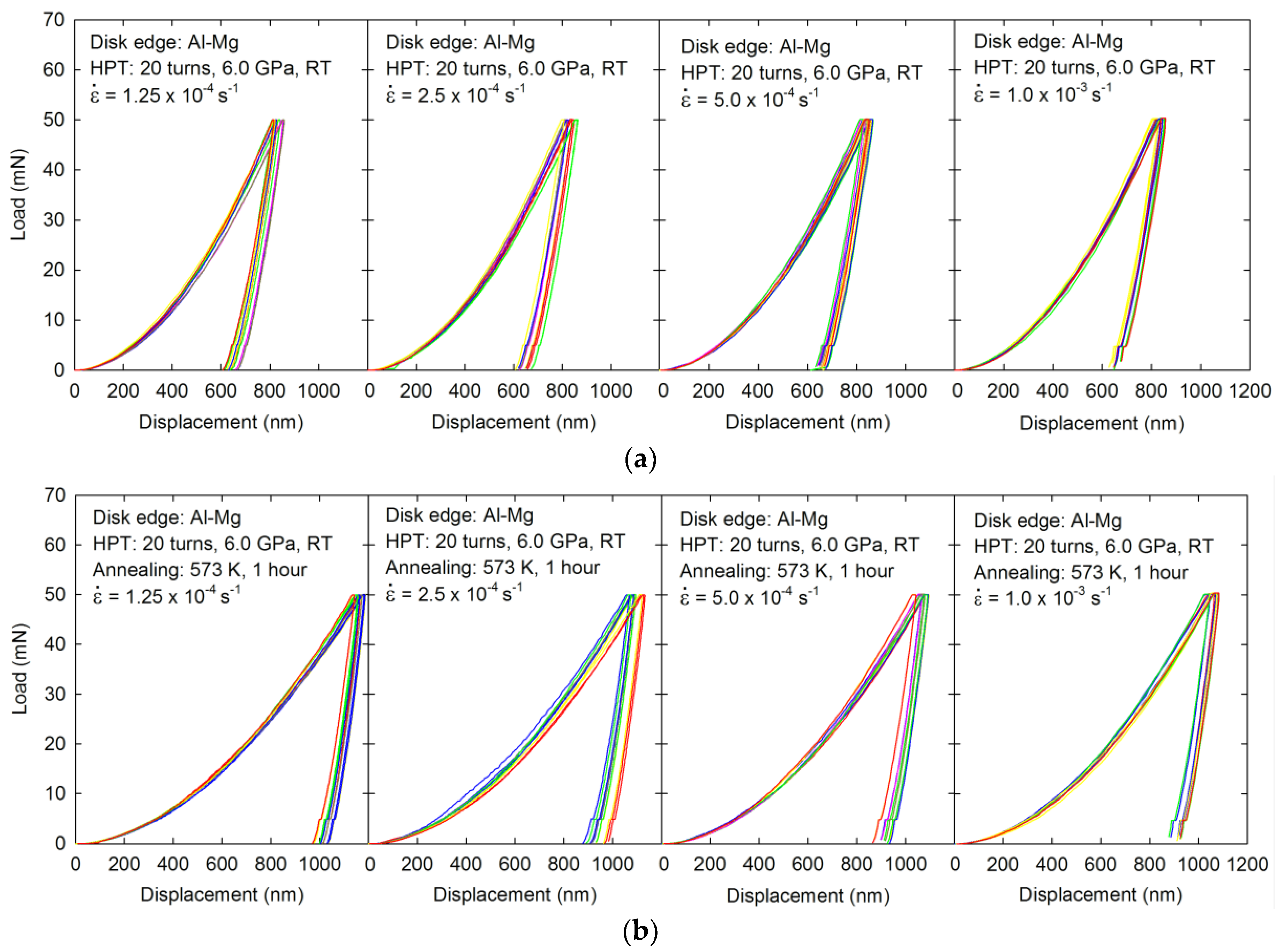

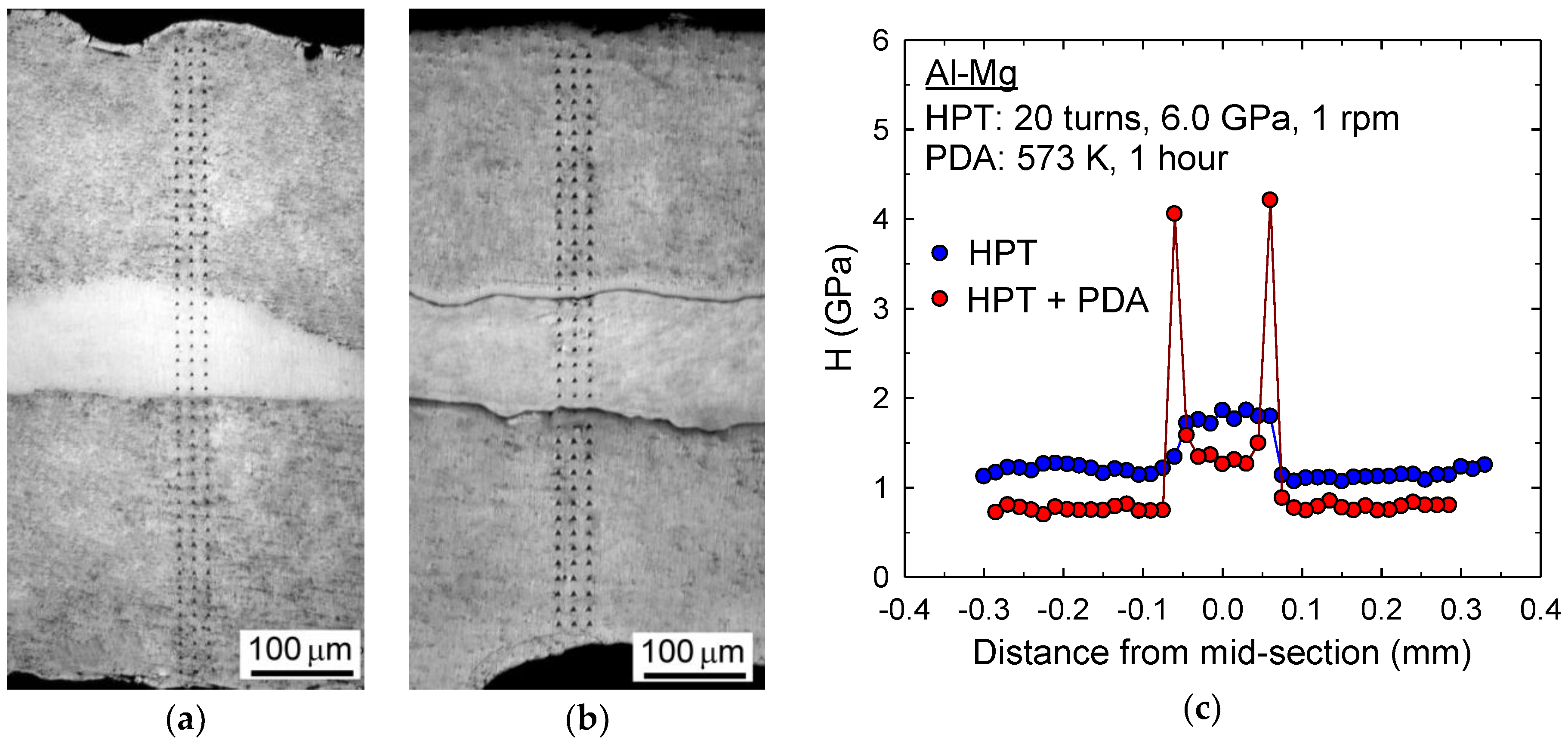

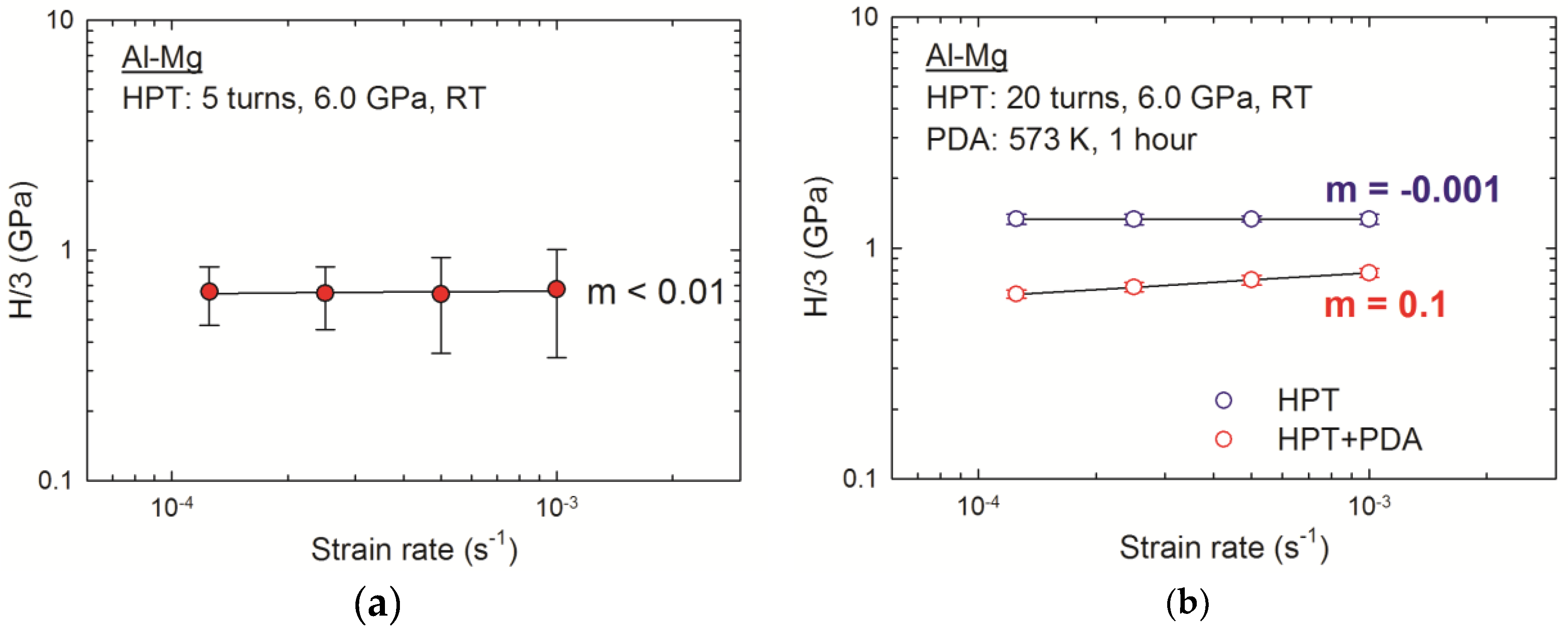

3. Micro-Mechanical Properties of the Al-Mg Hybrid System

4. Discussion

4.1. Improvement in Micro-Mechanical Response by PDA

4.2. Future Potential of a Nanoindentation Technique for UFG Metals

5. Materials and Methods

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Valiev, R.Z.; Estrin, Y.; Horita, Z.; Langdon, T.G.; Zehetbauer, M.J.; Zhu, Y.T. Producing bulk ultrafine-grained materials by severe plastic deformation. JOM 2006, 58, 33–39. [Google Scholar] [CrossRef]

- Zhilyaev, A.P.; Langdon, T.G. Using high-pressure torsion for metal processing: Fundamentals and applications. Prog. Mater. Sci. 2008, 53, 893–979. [Google Scholar] [CrossRef]

- Langdon, T.G. Twenty-five years of ultrafine-grained materials: Achieving exceptional properties through grain refinement. Acta Mater. 2013, 61, 7035–7059. [Google Scholar] [CrossRef]

- Korznikov, A.V.; Safarov, I.M.; Laptionok, D.V.; Valiev, R.Z. Structure and properties of superfine-grained iron compacted out of ultradisperse powder. Acta Metall. Mater. 1991, 39, 3193–3197. [Google Scholar] [CrossRef]

- Stolyarov, V.V.; Zhu, Y.T.; Lowe, T.C.; Islamgaliev, R.K.; Valiev, R.Z. Processing nanocrystalline Ti and its nanocomposites from micrometer-sized Ti powder using high pressure torsion. Mater. Sci. Eng. A 2000, 282, 78–85. [Google Scholar] [CrossRef]

- Edalati, K.; Horita, Z.; Fujiwara, H.; Ameyama, K. Cold consolidation of ball-milled titanium powders using high-pressure torsion. Metall. Mater. Trans. A 2010, 41, 3308–3317. [Google Scholar] [CrossRef]

- Cubero-Sesin, J.M.; Horita, Z. Powder consolidation of Al–10 wt % Fe alloy by high-pressure torsion. Mater. Sci. Eng. A 2012, 558, 462–471. [Google Scholar] [CrossRef]

- Zhilyaev, A.P.; Ringot, G.; Huang, Y.; Cabrera, J.M.; Langdon, T.G. Mechanical behavior and microstructure properties of titanium powder consolidated by high-pressure torsion. Mater. Sci. Eng. A 2017, 688, 498–504. [Google Scholar] [CrossRef]

- Zhilyaev, A.P.; Gimazov, A.A.; Raab, G.I.; Langdon, T.G. Using high-pressure torsion for the cold-consolidation of copper chips produced by machining. Mater. Sci. Eng. A 2008, 486, 123–126. [Google Scholar] [CrossRef]

- Edalati, K.; Yokoyama, Y.; Horita, Z. High-pressure torsion of machining chips and bulk discs of amorphous Zr50Cu30Al10Ni10. Mater. Trans. 2010, 51, 23–26. [Google Scholar] [CrossRef]

- Beygelzimer, Y.; Estrin, Y.; Kulagin, R. Synthesis of hybrid materials by severe plastic deformation: A new paradigm of SPD processing. Adv. Eng. Mater. 2015, 17, 1853–1861. [Google Scholar] [CrossRef]

- Bachmaier, A.; Pippan, R. Generation of metallic nanocomposites by severe plastic deformation. Int. Mater. Rev. 2013, 58, 41–62. [Google Scholar] [CrossRef]

- Schuh, C.A. Nanoindentation studies of materials. Mater. Today 2006, 9, 32–40. [Google Scholar] [CrossRef]

- Mueller, J.; Durst, K.; Amberger, D.; Göken, M. Local Investigations of the Mechanical Properties of Ultrafine Grained Metals by Nanoindentations. Mater. Sci. Forum 2006, 503–504, 31–36. [Google Scholar] [CrossRef]

- Böhner, A.; Maier, V.; Durst, K.; Höppel, H.W.; Göken, M. Macro- and nanomechanical properties and strain rate sensitivity of accumulative roll bonded and equal channel angular pressed ultrafine-grained materials. Adv. Eng. Mater. 2011, 13, 251–255. [Google Scholar] [CrossRef]

- Maier, V.; Durst, K.; Mueller, J.; Backes, B.; Höppel, H.W.; Göken, M. Nanoindentation strain-rate jump tests for determining the local strain-rate sensitivity in nanocrystalline Ni and ultrafine-grained Al. J. Mater. Res. 2011, 26, 1421–1430. [Google Scholar] [CrossRef]

- Wheeler, J.M.; Maier, V.; Durst, K.; Göken, M.; Michler, J. Activation parameters for deformation of ultrafine-grained aluminium as determined by indentation strain rate jumps at elevated temperature. Mater. Sci. Eng. A 2013, 585, 108–113. [Google Scholar] [CrossRef]

- Maier, V.; Merle, B.; Göken, M.; Durst, K. An improved long-term nanoindentation creep testing approach for studying the local deformation processes in nanocrystalline metals at room and elevated temperatures. J. Mater. Res. 2013, 28, 1177–1188. [Google Scholar] [CrossRef]

- Chen, J.; Lu, L.; Lu, K. Hardness and strain rate sensitivity of nanocrystalline Cu. Scr. Mater. 2006, 54, 1913–1918. [Google Scholar] [CrossRef]

- Maier, V.; Hohenwarter, A.; Pippan, R.; Kiener, D. Thermally activated deformation processes in body-centered cubic Cr–How microstructure influences strain-rate sensitivity. Scr. Mater. 2015, 106, 42–45. [Google Scholar] [CrossRef]

- Choi, I.-C.; Lee, D.-H.; Ahn, B.; Durst, K.; Kawasaki, M.; Langdon, T.G.; Jang, J.-I. Enhancement of strain-rate sensitivity and shear yield strength of a magnesium alloy processed by high-pressure torsion. Scr. Mater. 2015, 94, 44–47. [Google Scholar] [CrossRef]

- Alkorta, J.; Martínez-Esnaola, J.M.; Sevillano, J.G. Critical examination of strain-rate sensitivity measurement by nanoindentation methods: Application to severely deformed niobium. Acta Mater. 2008, 56, 884–893. [Google Scholar] [CrossRef]

- Zhang, N.X.; Chinh, N.Q.; Kawasaki, M.; Huang, Y.; Langdon, T.G. Self-annealing in a two-phase Pb-Sn alloy after processing by high-pressure torsion. Mater. Sci. Eng. A 2016, 666, 350–359. [Google Scholar] [CrossRef]

- Choi, I.-C.; Kim, Y.-J.; Ahn, B.; Kawasaki, M.; Langdon, T.G.; Jang, J.-I. Evolution of plasticity, strain-rate sensitivity and the underlying deformation mechanism in Zn–22% Al during high-pressure torsion. Scr. Mater. 2014, 75, 102–105. [Google Scholar] [CrossRef]

- Lee, D.-H.; Choi, I.-C.; Seok, M.-Y.; He, J.; Lu, Z.; Suh, J.-Y; Kawasaki, M.; Langdon, T.G.; Jang, J.-I. Nanomechanical behavior and structural stability of a nanocrystalline CoCrFeNiMn high-entropy alloy processed by high-pressure torsion. J. Mater. Res. 2015, 30, 2804–2815. [Google Scholar] [CrossRef]

- Lee, D.-H.; Seok, M.-Y.; Zhao, Y.; Choi, I.-C.; He, J.; Lu, Z.; Suh, J.-Y.; Ramamurty, U.; Kawasaki, M.; Langdon, T.G.; et al. Spherical nanoindentation creep behavior of nanocrystalline and coarse-grained CoCrFeMnNi high-entropy alloys. Acta Mater. 2016, 109, 314–322. [Google Scholar] [CrossRef]

- Maier-Kiener, V.; Schuh, B.; Clemens, H.; Hohenwarter, A. Nanoindentation testing as a powerful screening tool for assessing phase stability of nanocrystalline high-entropy alloys. Mater. Des. 2017, 115, 479–485. [Google Scholar] [CrossRef]

- Kawasaki, M.; Ahn, B.; Kumar, P.; Jang, J.-I.; Langdon, T.G. Nano- and Micro- mechanical properties of ultrafine-grained materials processed by severe plastic deformation techniques. Adv. Eng. Mater. 2017, 19, 1600578. [Google Scholar] [CrossRef]

- Figueiredo, R.B.; Cetlin, P.R.; Langdon, T.G. Using finite element modeling to examine the flow processes in quasi-constrained high-pressure torsion. Mater. Sci. Eng. A 2011, 528, 8198–8204. [Google Scholar] [CrossRef]

- Figueiredo, R.B.; Pereira, P.H.R.; Aguilar, M.T.P.; Cetlin, P.R.; Langdon, T.G. Using finite element modeling to examine the temperature distribution in quasi-constrained high-pressure torsion. Acta Mater. 2012, 60, 3190–3198. [Google Scholar] [CrossRef]

- Oh-ishi, K.; Edalati, K.; Kim, H.S.; Hono, K.; Horita, Z. Diffusion and promoting solid-state reactions in aluminum-copper system. Acta Mater. 2013, 61, 3482–3489. [Google Scholar] [CrossRef]

- Edalati, K.; Toh, S.; Iwaoka, H.; Watanabe, M.; Horita, Z.; Kashioka, D.; Kishida, K.; Inui, H.

- Alfreider, M.; Jeong, J.; Esterl, R.; Oh, S.H.; Kiener, D. Synthesis and Mechanical characterisation of an ultra-fine grained Ti-Mg composite. Materials 2016, 9, 688. [Google Scholar] [CrossRef]

- Ahn, B.; Zhilyaev, A.P.; Lee, H.-J.; Kawasaki, M.; Langdon, T.G. Rapid synthesis of an extra hard metal matrix nanocomposite at ambient temperature. Mater. Sci. Eng. A 2015, 635, 109–117. [Google Scholar] [CrossRef]

- Kawasaki, M.; Ahn, B.; Lee, H.-J.; Zhilyaev, A.P.; Langdon, T.G. Using high-pressure torsion to process an aluminum-magnesium nanocomposite through diffusion bonding. J. Mater. Res. 2016, 31, 88–99. [Google Scholar] [CrossRef]

- Lutterotti, L. Total pattern fitting for the combined size-strain-stress-texture determination in thin film diffraction. Nucl. Instrum. Methods Phys. Res. Sect. B 2010, 268, 334–340. [Google Scholar] [CrossRef]

- Han, J.-K.; Lee, H.-J.; Jang, J.-I.; Kawasaki, M.; Langdon, T.G. Micro-mechanical and tribological properties of aluminum-magnesium nanocomposites processed by high-pressure torsion. Mater. Sci. Eng. A 2017, 684, 318–327. [Google Scholar] [CrossRef]

- Kawasaki, M.; Alhajeri, S.N.; Xu, C.; Langdon, T.G. The development of hardness homogeneity in pure aluminum and aluminum alloy disks processed by high-pressure torsion. Mater. Sci. Eng. A 2011, 529, 345–351. [Google Scholar] [CrossRef]

- Lee, H.-J.; Lee, S.K.; Jung, K.H.; Lee, G.A.; Ahn, B.; Kawasaki, M.; Langdon, T.G. Evolution in hardness and texture of a ZK60A magnesium alloy processed by high-pressure torsion. Mater. Sci. Eng. A 2015, 630, 90–98. [Google Scholar] [CrossRef]

- Divinski, S.V.; Reglitz, G.; Rösner, H.; Estrin, Y.; Wilde, G. Ultra-fast diffusion channels in pure Ni severely deformed by equal-channel angular pressing. Acta Mater. 2011, 59, 1974–1985. [Google Scholar] [CrossRef]

- Sauvage, X.; Wilde, G.; Divinski, S.V.; Horita, Z.; Valiev, R.Z. Review: Grain boundaries in ultrafine grained materials processed by severe plastic deformation and related phenomena. Mater. Sci. Eng. A 2012, 540, 1–12. [Google Scholar] [CrossRef]

- Ahn, B.; Lee, H.-L.; Choi, I.-C.; Kawasaki, M.; Jang, J.-I.; Langdon, T.G. Micro-mechanical behavior of an exceptionally strong metal matrix nanocomposite processed by high-pressure torsion. Adv. Eng. Mater. 2016, 18, 1001–1008. [Google Scholar] [CrossRef]

- Shim, S.; Jang, J.-I.; Pharr, G.M. Extraction of flow properties of single-crystal silicon carbide by nanoindentation and finite-element simulation. Acta Mater. 2008, 56, 3824–3832. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Zhang, H.; Ramesh, K.T.; Chin, E.S.C. High strain rate response of aluminum 6092/B4C composites. Mater. Sci. Eng. A 2004, 384, 26–34. [Google Scholar] [CrossRef]

- Kumar, P.; Kawasaki, M.; Langdon, T.G. Review: Overcoming the paradox of strength and ductility in ultrafine-grained materials at low temperatures. J. Mater. Sci. 2016, 51, 7–18. [Google Scholar] [CrossRef]

- Andreau, O.; Gubicza, J.; Zhang, N.X.; Huang, Y.; Jenei, P.; Langdon, T.G. Effect of short-term annealing on the microstructures and flow properties of an Al–1% Mg alloy processed by high-pressure torsion. Mater. Sci. Eng. A 2014, 615, 231–239. [Google Scholar] [CrossRef]

- Maury, N.; Zhang, N.X.; Huang, Y.; Zhilyaev, A.P.; Langdon, T.G. A critical examination of pure tantalum processed by high-pressure torsion. Mater. Sci. Eng. A 2015, 638, 174–182. [Google Scholar] [CrossRef]

- Huang, Y.; Lemang, M.; Zhang, N.X.; Pereira, P.H.R.; Langdon, T.G. Achieving superior grain refinement and mechanical properties in vanadium through high-pressure torsion and subsequent short-term annealing. Mater. Sci. Eng. A 2016, 655, 60–69. [Google Scholar] [CrossRef]

- Shahmir, H.; He, J.; Lu, Z.; Kawasaki, M.; Langdon, T.G. Effect of annealing on mechanical properties of a nanocrystalline CoCrFeNiMn high-entropy alloy processed by high-pressure torsion. Mater. Sci. Eng. A 2016, 676, 294–303. [Google Scholar] [CrossRef]

- ASTM. Available online: http://www.astm.org (accessed on 29 May 2017).

- Kang, J.Y.; Kim, J.G.; Park, H.W.; Kim, H.S. Multiscale architectured materials with composition and grain size gradients manufactured using high-pressure torsion. Sci. Rep. 2016, 6, 26590. [Google Scholar] [CrossRef] [PubMed]

- Bouaziz, O.; Bréchet, Y.; Embury, J.D. Heterogeneous and architectured materials: A possible strategy for design of structural materials. Adv. Eng. Mater. 2008, 10, 24–36. [Google Scholar] [CrossRef]

- Fang, T.H.; Li, W.L.; Tao, N.R.; Lu, K. Revealing extraordinary intrinsic tensile plasticity in gradient nano-grained copper. Science 2011, 331, 1587–1590. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.L.; Jiang, P.; Chen, L.; Yuan, F.P.; Zhu, Y.T. Extraordinary strain hardening by gradient structure. Proc. Natl. Acad. Sci. USA 2011, 111, 7197–7201. [Google Scholar] [CrossRef] [PubMed]

- Lu, K. Making strong nanomaterials ductile with gradients. Science 2014, 345, 1455–1456. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.L.; Jiang, P.; Chen, L.; Zhang, J.F.; Yuan, F.P.; Zhu, Y.T. Synergetic strengthening by gradient structure. Mater. Res. Lett. 2015, 2, 185–191. [Google Scholar] [CrossRef]

- Durst, K.; Maier, V. Dynamic nanoindentation testing for studying thermally activated processes from single to nanocrystalline metals. Curr. Opin. Solid State Mater. Sci. 2015, 19, 340–353. [Google Scholar] [CrossRef]

- Wheeler, J.M.; Armstrong, D.E.J.; Heinz, W.; Schwaiger, R. High temperature nanoindentation: The state of the art and future challenges. Curr. Opin. Solid State Mater. Sci. 2015, 19, 354–366. [Google Scholar] [CrossRef]

- Kawasaki, M.; Langdon, T.G. The significance of strain reversals during processing by high-pressure torsion. Mater. Sci. Eng. A 2008, 498, 341–348. [Google Scholar] [CrossRef]

- Wang, C.L.; Lai, Y.H.; Huang, J.C.; Nieh, T.G. Creep of nanocrystalline nickel: A direct comparison between uniaxial and nanoindentation creep. Scr. Mater. 2010, 62, 175–178. [Google Scholar] [CrossRef]

- Choi, I.-C.; Yoo, B.-G.; Kim, Y.-J.; Seok, M.-Y.; Wang, Y.M.; Jang, J.-I. Estimating the stress exponent of nanocrystalline nickel: Sharp vs. spherical indentation. Scr. Mater. 2011, 65, 300–303. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kawasaki, M.; Jang, J.-i. Micro-Mechanical Response of an Al-Mg Hybrid System Synthesized by High-Pressure Torsion. Materials 2017, 10, 596. https://doi.org/10.3390/ma10060596

Kawasaki M, Jang J-i. Micro-Mechanical Response of an Al-Mg Hybrid System Synthesized by High-Pressure Torsion. Materials. 2017; 10(6):596. https://doi.org/10.3390/ma10060596

Chicago/Turabian StyleKawasaki, Megumi, and Jae-il Jang. 2017. "Micro-Mechanical Response of an Al-Mg Hybrid System Synthesized by High-Pressure Torsion" Materials 10, no. 6: 596. https://doi.org/10.3390/ma10060596

APA StyleKawasaki, M., & Jang, J.-i. (2017). Micro-Mechanical Response of an Al-Mg Hybrid System Synthesized by High-Pressure Torsion. Materials, 10(6), 596. https://doi.org/10.3390/ma10060596