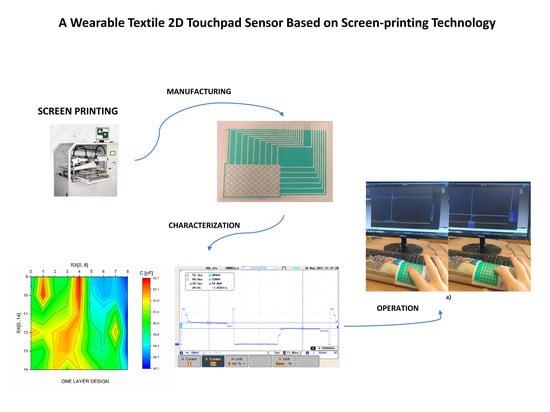

Sensor Development

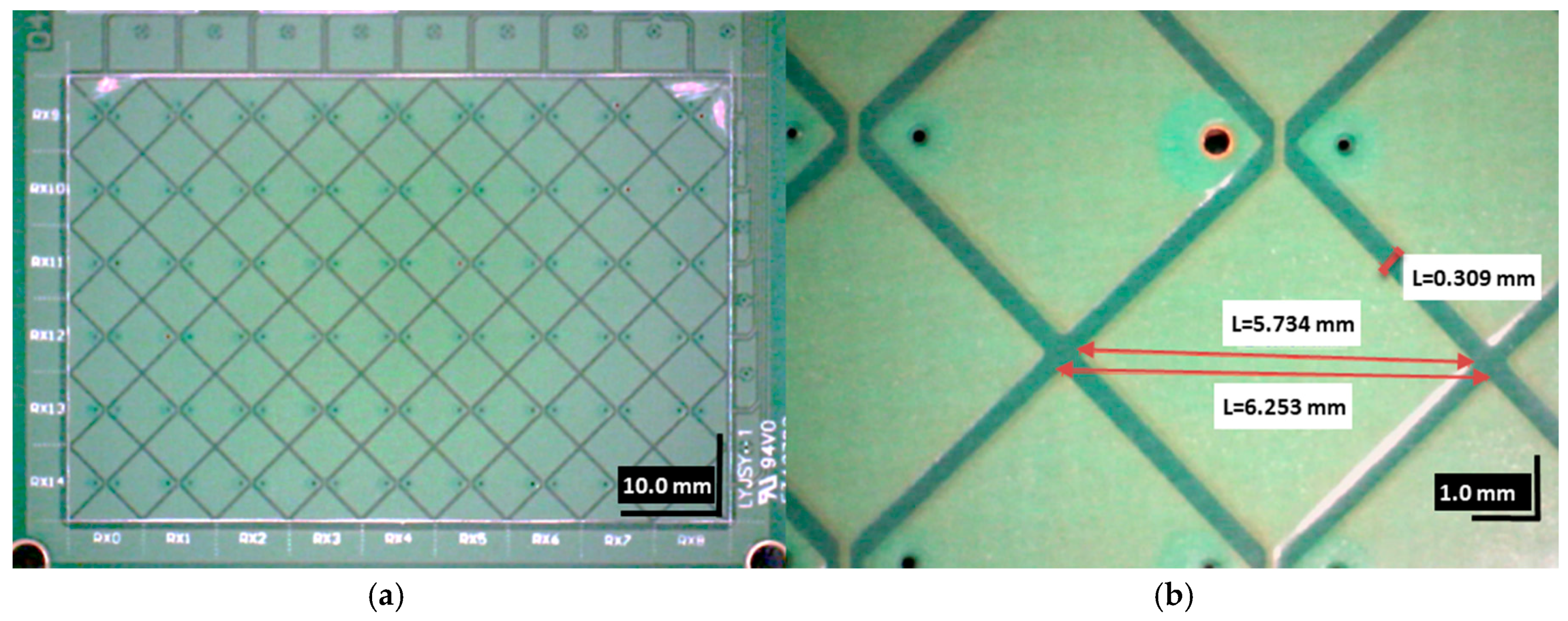

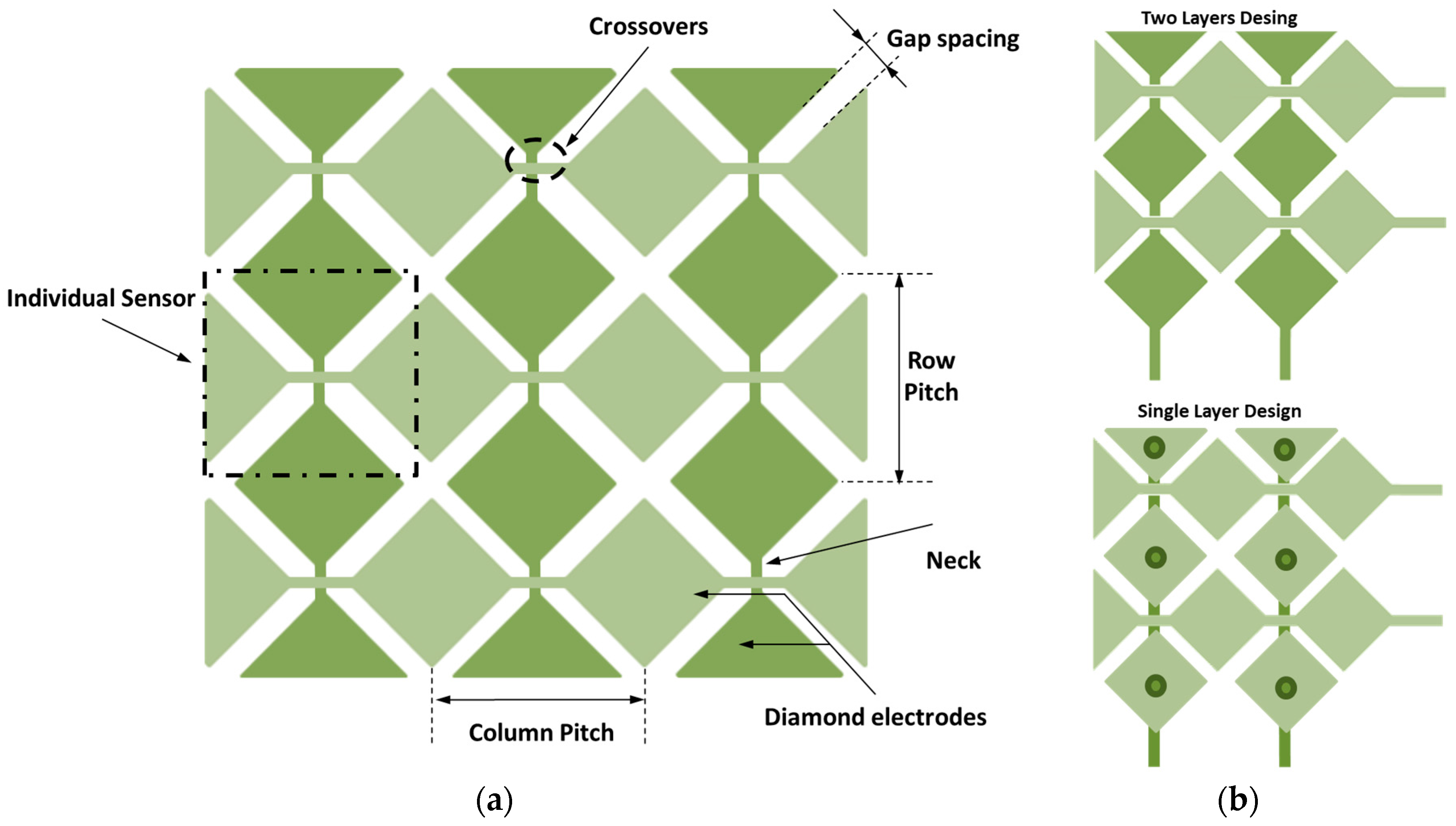

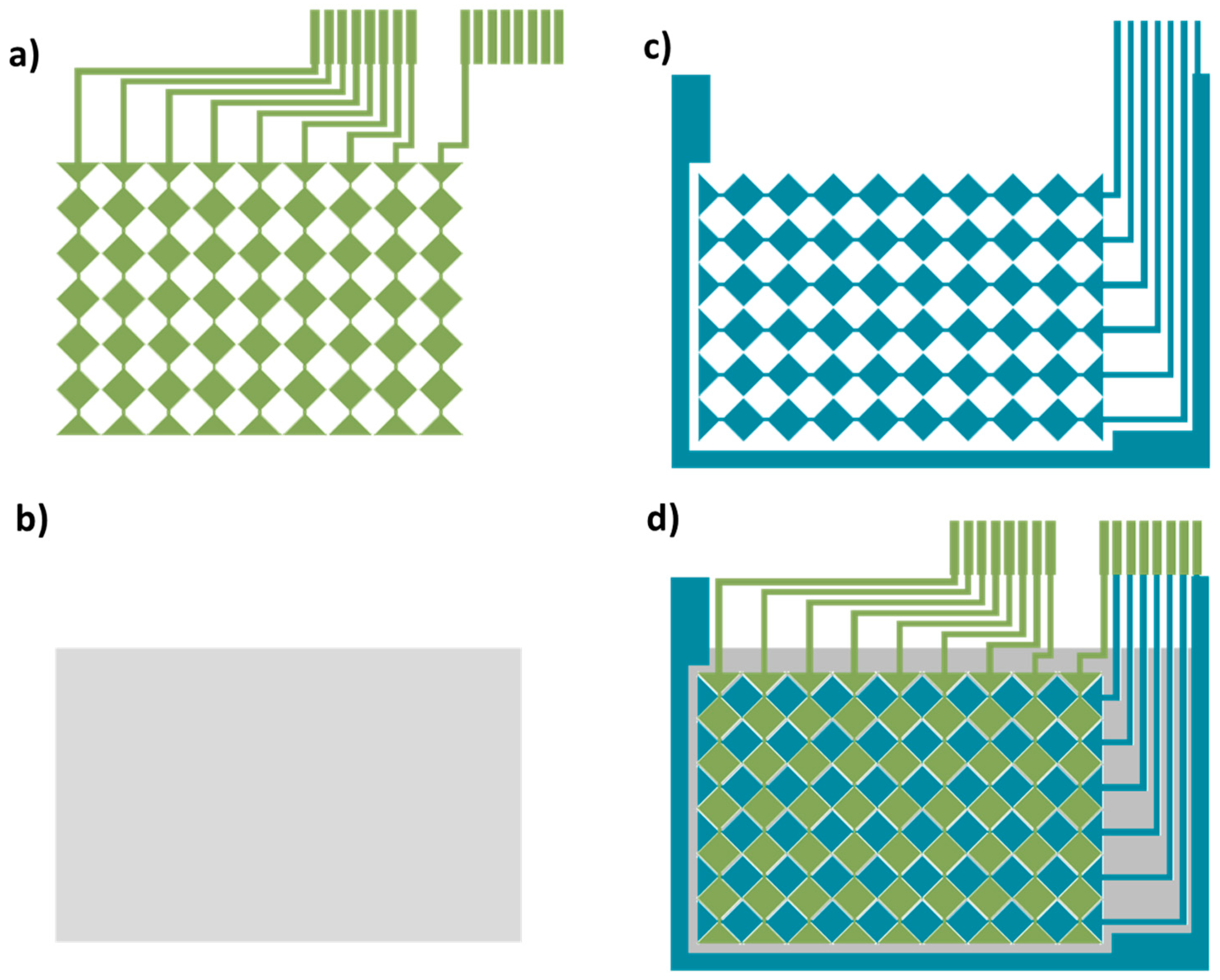

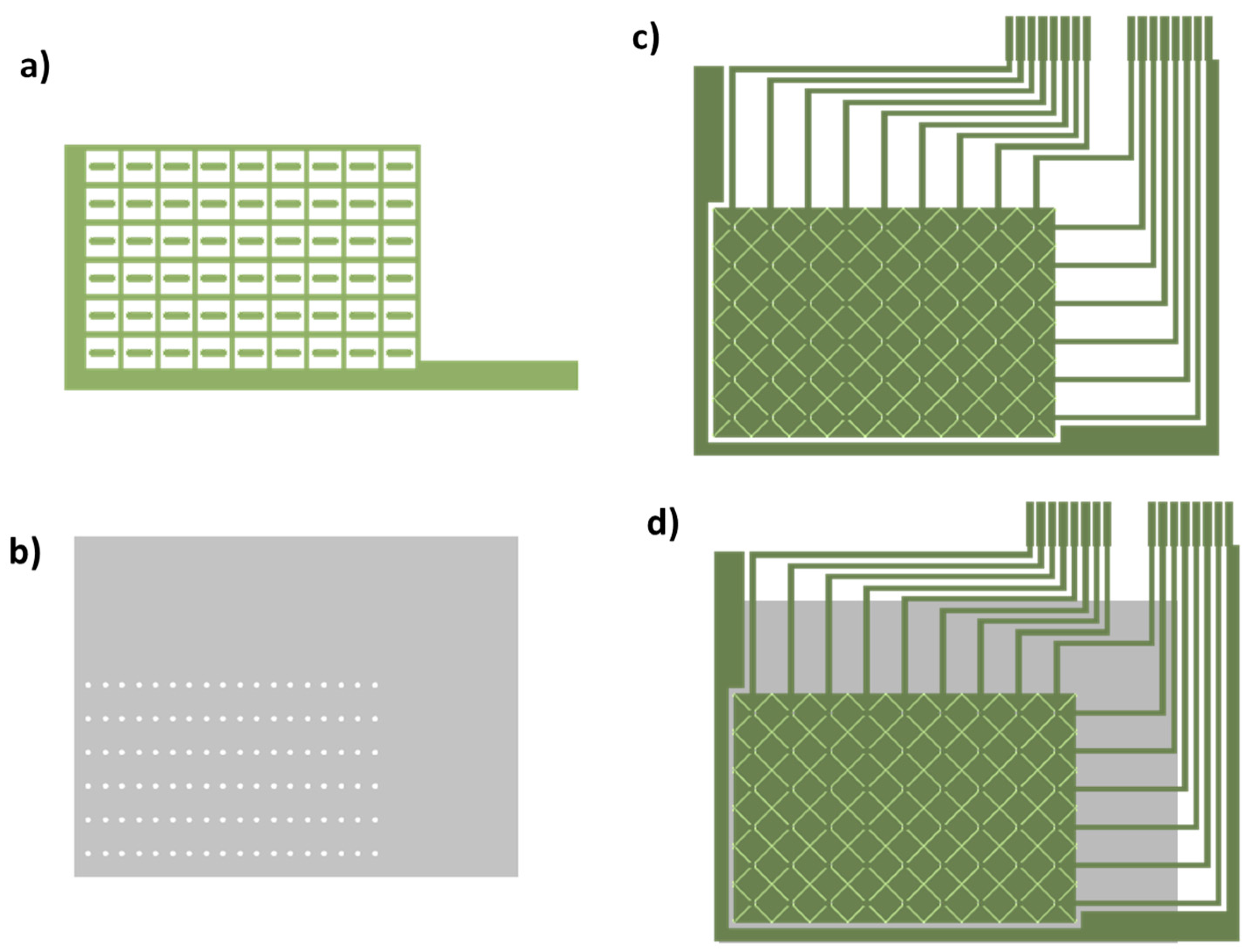

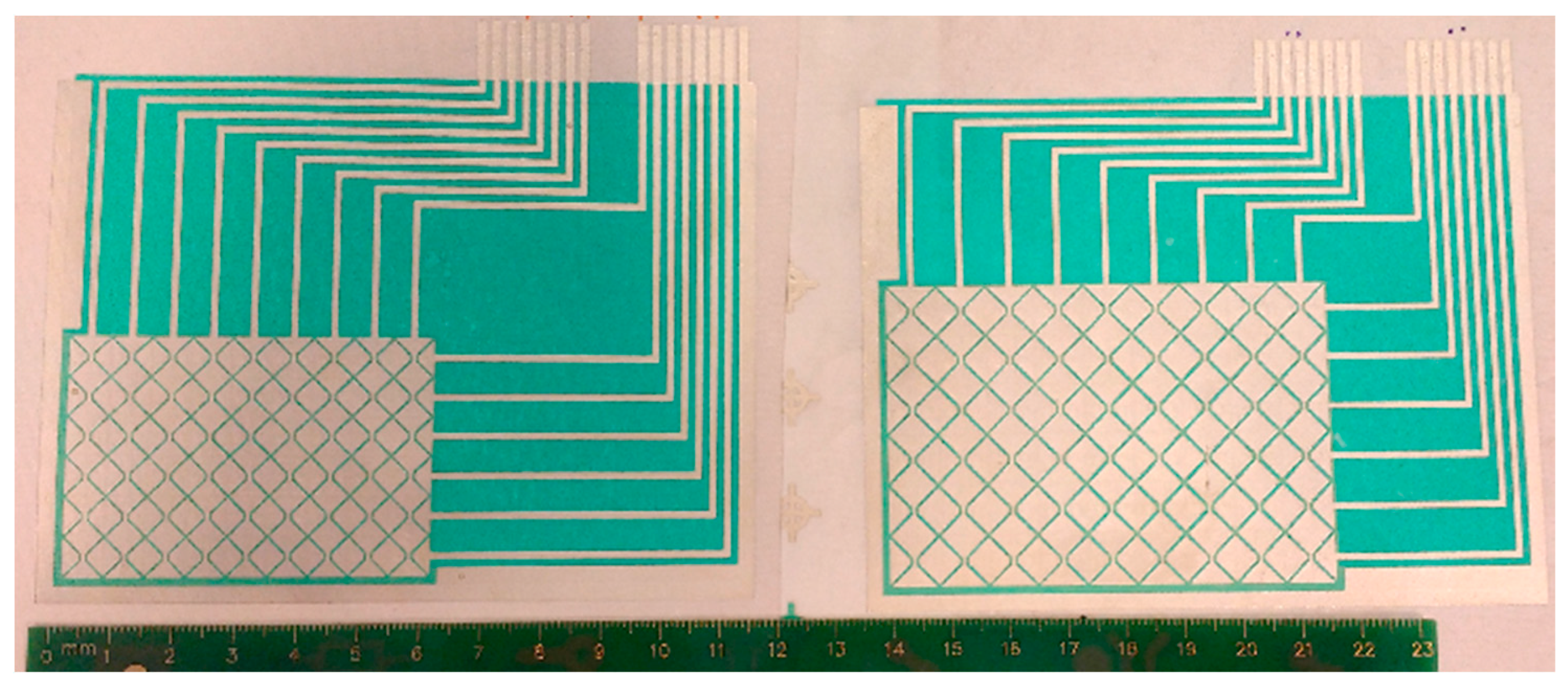

When screen-printing technology is used, it is necessary to manufacture frames with screen mesh for each layer of the design. Therefore, to build the sensor matrices, three screens were made in both designs.

The screen for the conductors was a 230 mesh polyester material (PET 1500 90/230-48 from Sefar, Hong Kong, China) and the screen for dielectric layer was a 175 mesh polyester material (PET 1500 68/175-64 PW from Sefar). Afterwards, to transfer the stencil to screen mesh, a UV film Dirasol 132 (Fujifilm, Tokyo, Japan) was used. The final screen thickness was 10 μm for the screen for conductors and 15 μm for the screen for the dielectric. The patterns were transferred to the screen by using a UV light source unit.

The materials used were, the textile Mediatex TT ACQ 120 μm (Technohard, São Paulo, Brazil) for the substrate, C2131014D3 Silver paste-58, 85% (Gwent Group, Pontypool, UK) as conductive paste and D2081009D6 Polymer dielectric (Gwent Group) as dielectric paste. Flexibility is one of the most important characteristic of these inks to use them with textiles.

Printing was carried out by using Ekra E2 XL screen- printer with a 75° shore squeegee hardness, 3.5 bar force, and 8 mm/s. After inks depositing, these were cured in an air oven at 130 °C for 10 min.

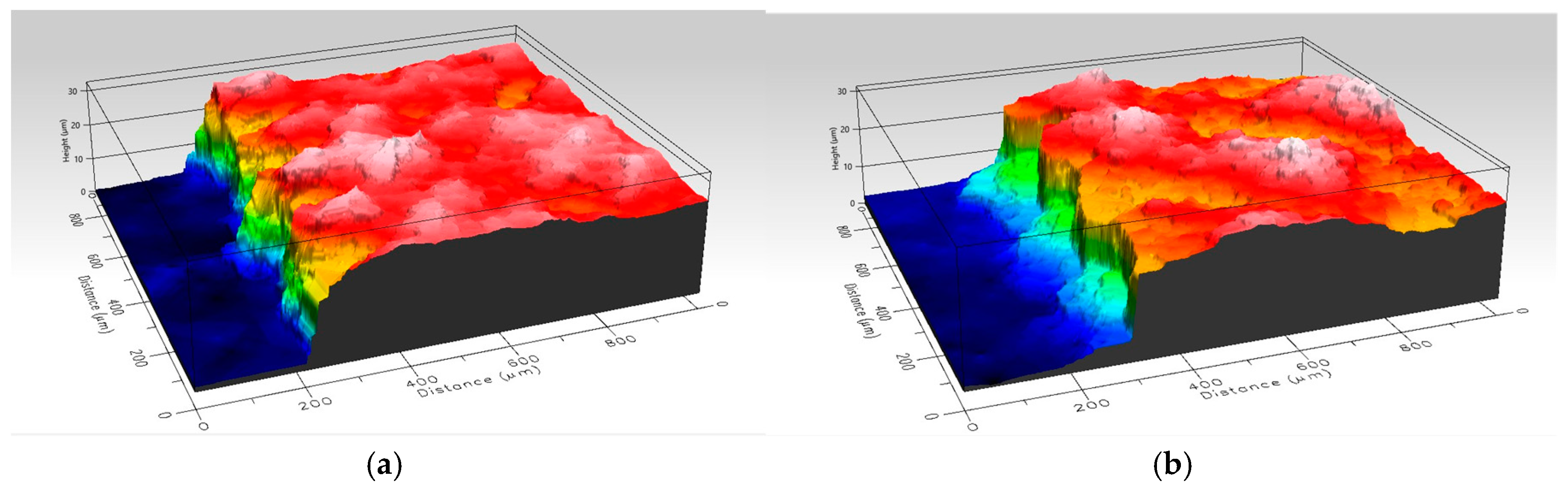

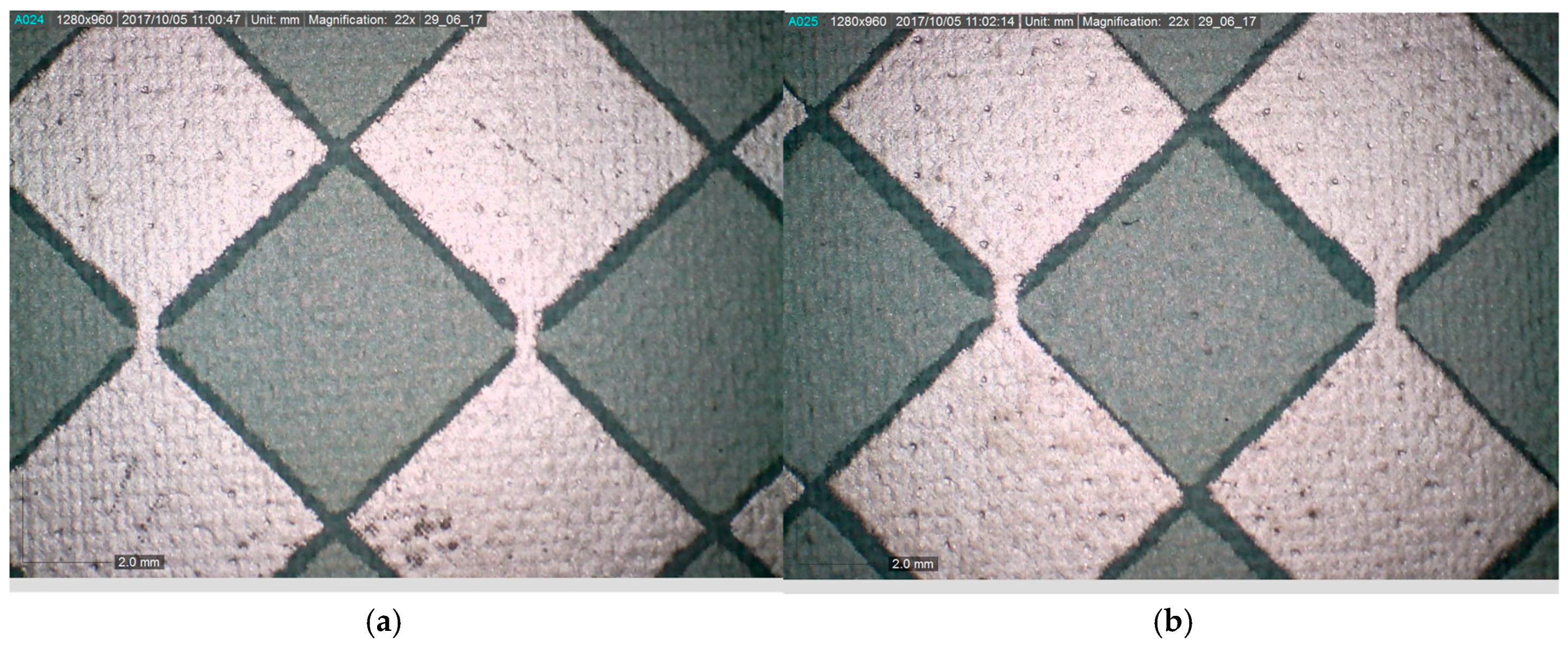

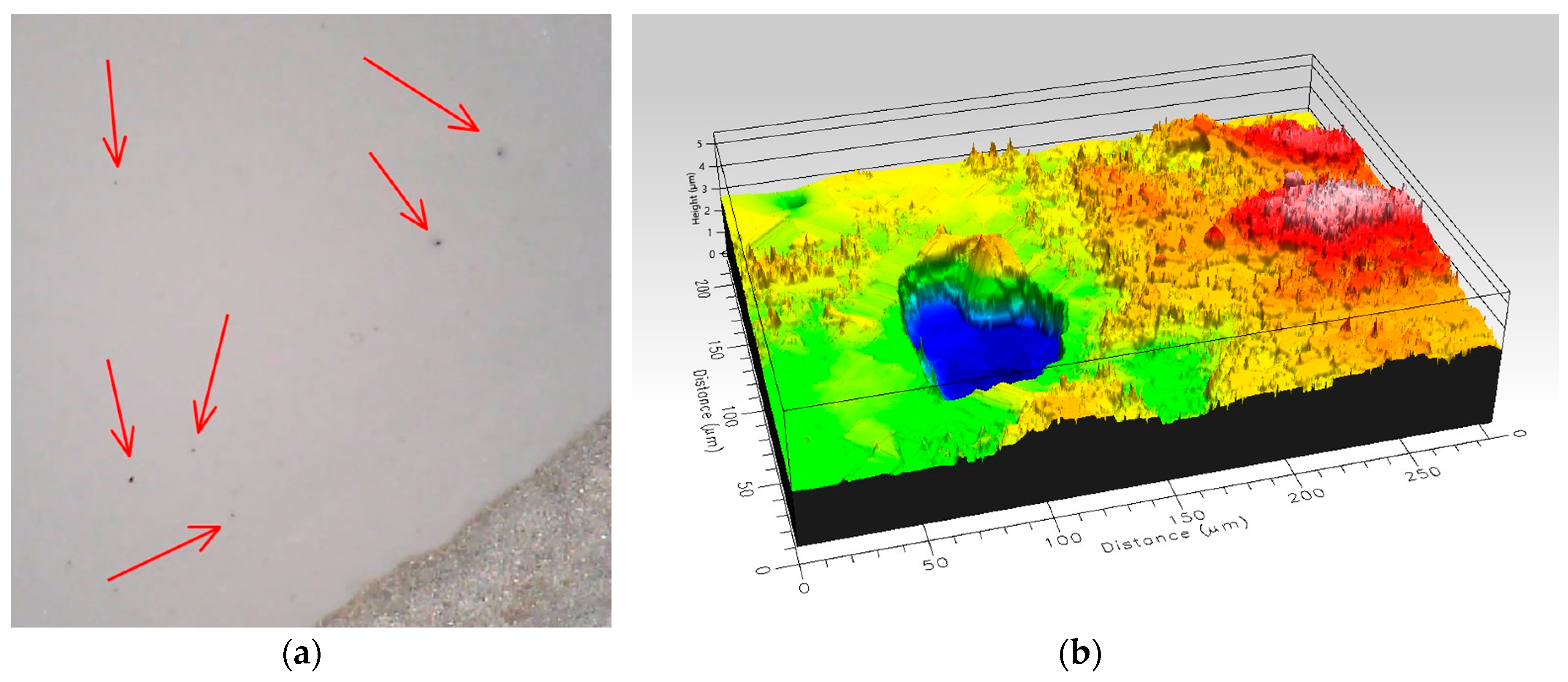

A high failure rate was found due to short-circuits between conductive layers. These short-circuits are due to pinholes in dielectric layer (

Figure 4), which occur during the curing process.

To avoid this trouble, two solutions were found. The first solution was to increase the number of dielectric layers; however, this solution implies an increase in cost and processing time. Therefore, the ideal solution would be minimize the number of dielectric layers by using a different mesh screen size. For this reason, a study about the influence of dielectric layer mesh screen size was made. The mesh screen sizes selected were 123 inches (PET 1500 48/123-70 PW from Sefar), 137 inches (PET 1500 54/137-70 PW from Sefar), 175 inches (PET 1500 68/175-64 PW from Sefar), 230 inches (PET 1500 90/230-48 PW from Sefar) and 330 inches (PET 1500 130/330-34 PW from Sefar).

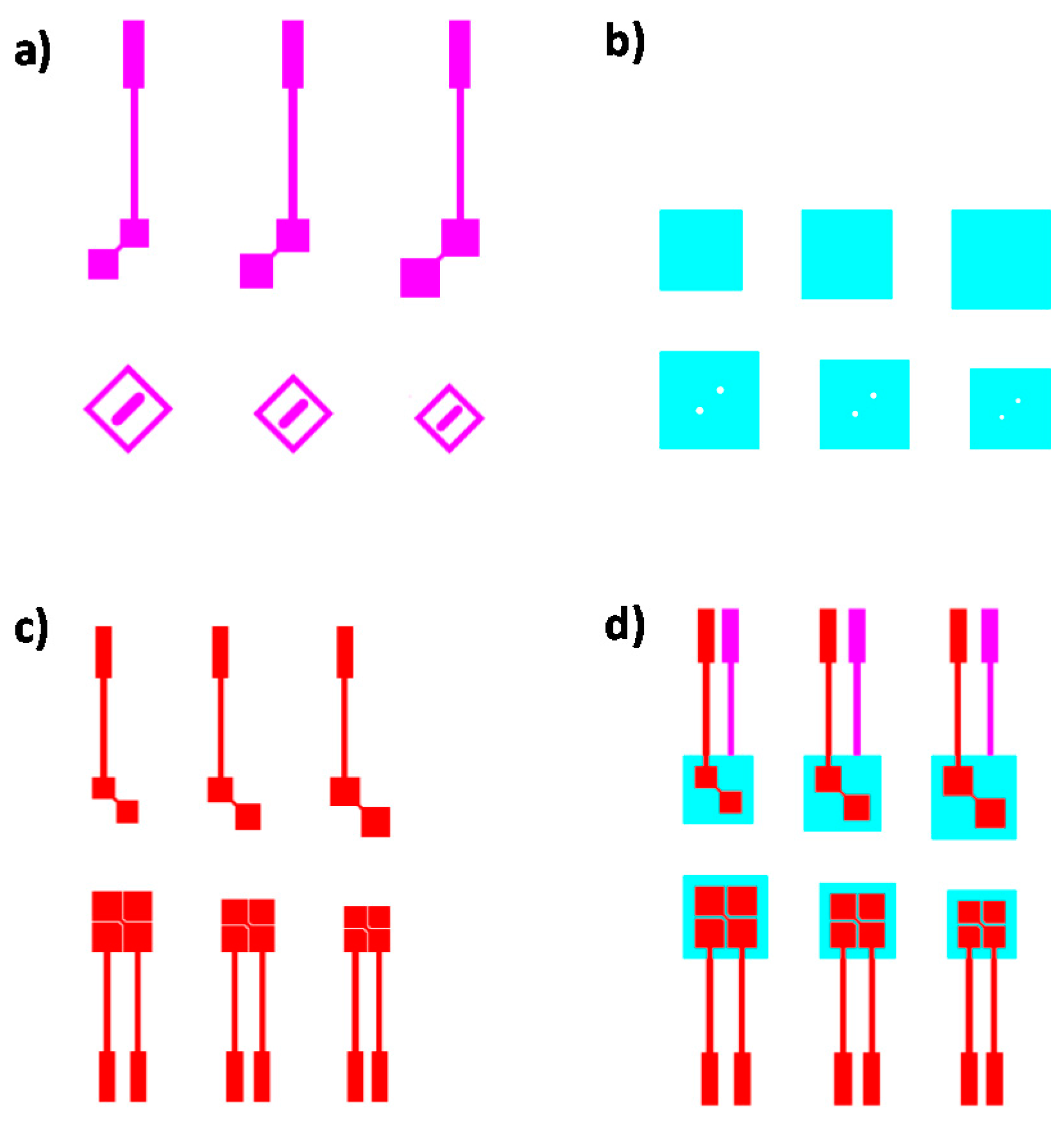

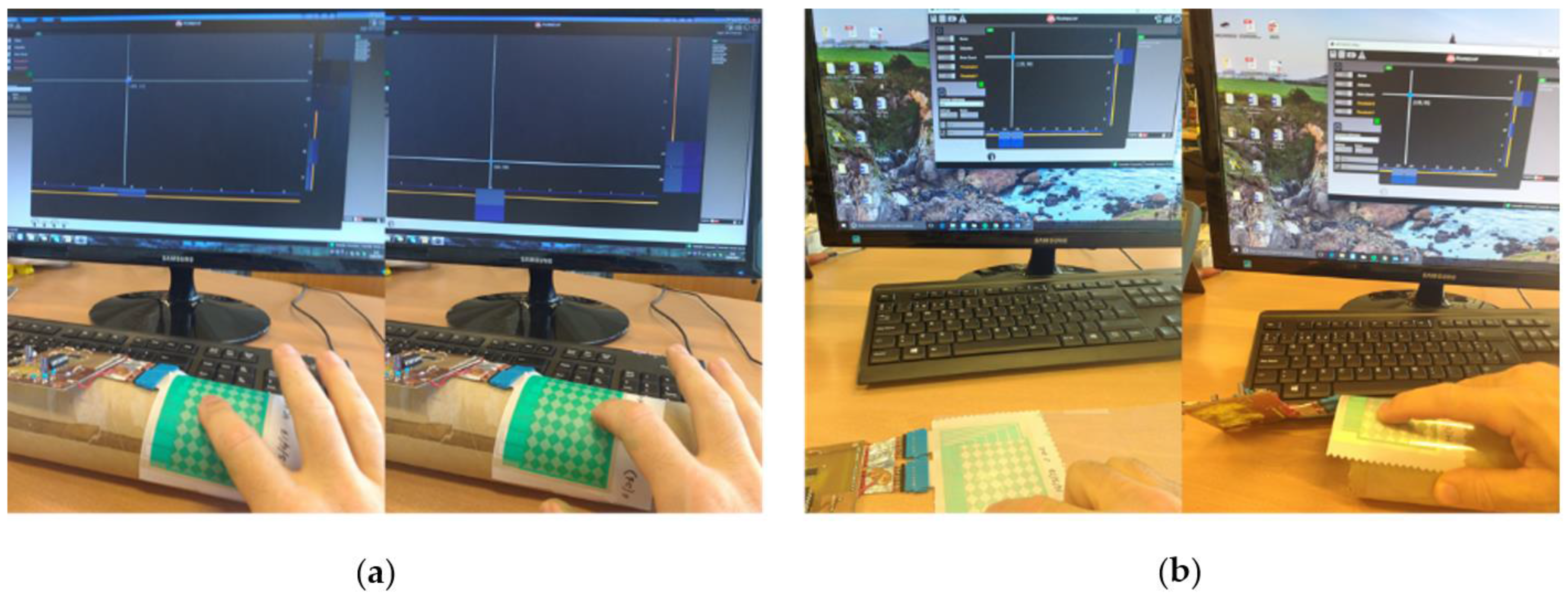

A single design pattern was designed (

Figure 5) to study the influence of the mesh screen size for both cases, TLD and OLD. In both cases, three different single electrode sizes, which are designed called A, B and C; the conductive plates are square and their areas are 18, 24.5 and 32 mm

2, respectively. Type C corresponds to the size of the electrodes used in the general design. The number of dielectric layers varied between one and three layers; to obtain the different layers, first one layer was printed and it was cured thermally; then the second one was printed and thermally cured; and, finally, the third one with the same process.

Table 1 and

Table 2 show the percentage of failures found.

Table 3 shows the dielectric layer total thickness obtained for each mesh value and number of layers. For total layer thicknesses less than 10 μm, insulation faults are detected, as shown in

Table 1 and

Table 2. As a result, with a minimum of two layers, and using a mesh between 123 and 230, no errors are obtained in the manufacture of the devices. It is important to note that, as can be seen in

Table 3, a similar layer thickness with two or three layers of dielectric can be obtained. For example, the thickness obtained with two layers and mesh 137 (

Figure A6b) is similar to the thickness obtained with three layers and 175 mesh (

Figure A6a). However, in the case of three layers, the surface obtained is more uniform than in the case of two layers, so a design with three layers would be more reliable than one with two layers. This may be because the ink is distributed through the different hollows left in the lower layers.

To look for dielectrics with different viscosities, a second solution was used. However, this change of viscosity adds a problem: the dielectric constant of the ink can change the value of the capacitance; therefore, it was necessary to study the influence of the dielectric on the value of the electrode capacitance. The ink D2081009D6 (Gwent) has a viscosity of 13.0–17.0 Pas (Haake VT550, PK1.1° at 230 s−1 at 25 °C) so a new dielectric ink was used, D2070209P6 (Gwent), which has a viscosity of 1.4–2.3 Pas (Haake VT550, PK1.1° at 230 s−1 at 25 °C).

The capacitances of the sensors were measured by using an inductance-capacitance-resistence (LCR) meter at 1 kHz (Agilent U1731A).

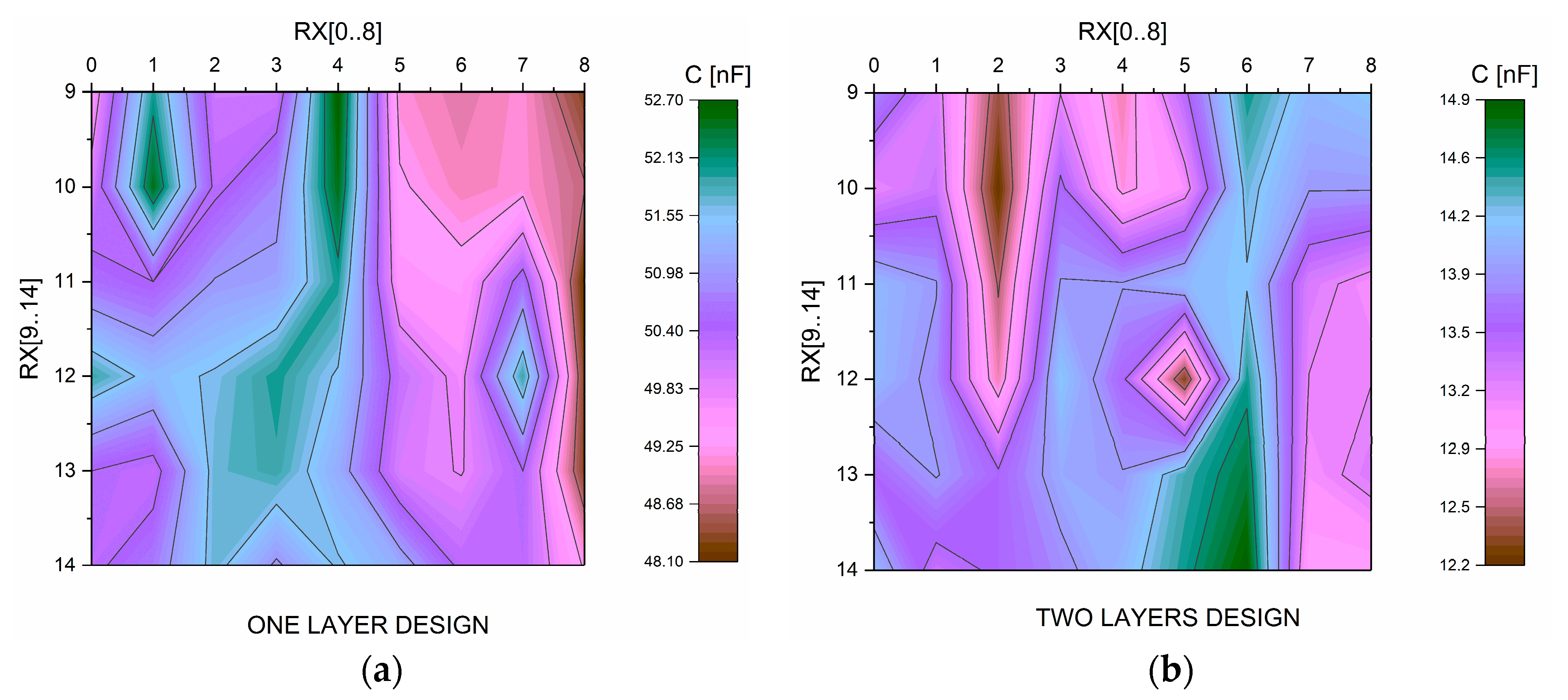

Table 4 and

Table 5 show capacitances for the dielectric D2081009D6. It is observed that there is very little variation (between 9 and 13) in capacitance in the case of the TLD design. However, in the OLD design, there is greater variation (between 13 and 60 pF) because, in this design, the influence of the variation of the surface of the electrodes and of their layer thickness is more noticeable. At higher mesh value, the layer thickness decreases; therefore, the capacitance increases, and the greater the surface of the electrode, the greater the capacitance.

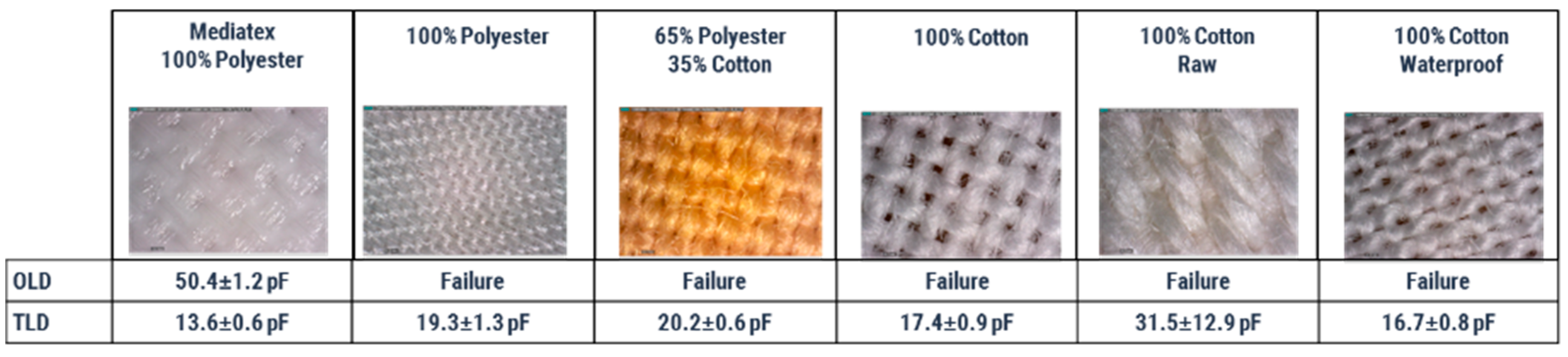

The measurements for dielectric D2070209P6 show an increase in the capacitance of the electrodes (

Table 6; to simplify, in this case, only the results are shown for a mesh of 175). The resulting capacitances are higher than those obtained with dielectric D2081009D6. Dielectric D2081009D6 was chosen for the final development of the touchpad since an increase of the capacitance supposes an incorrect operation of the controller.

The dielectric layer for the final designs was made with a screen of 175 mesh, using ink D2081009D6 and with two layers of dielectric in each prototype.