Industrial-Graded Epoxy Nanocomposites with Mechanically Dispersed Multi-Walled Carbon Nanotubes: Static and Damping Properties

Abstract

:1. Introduction

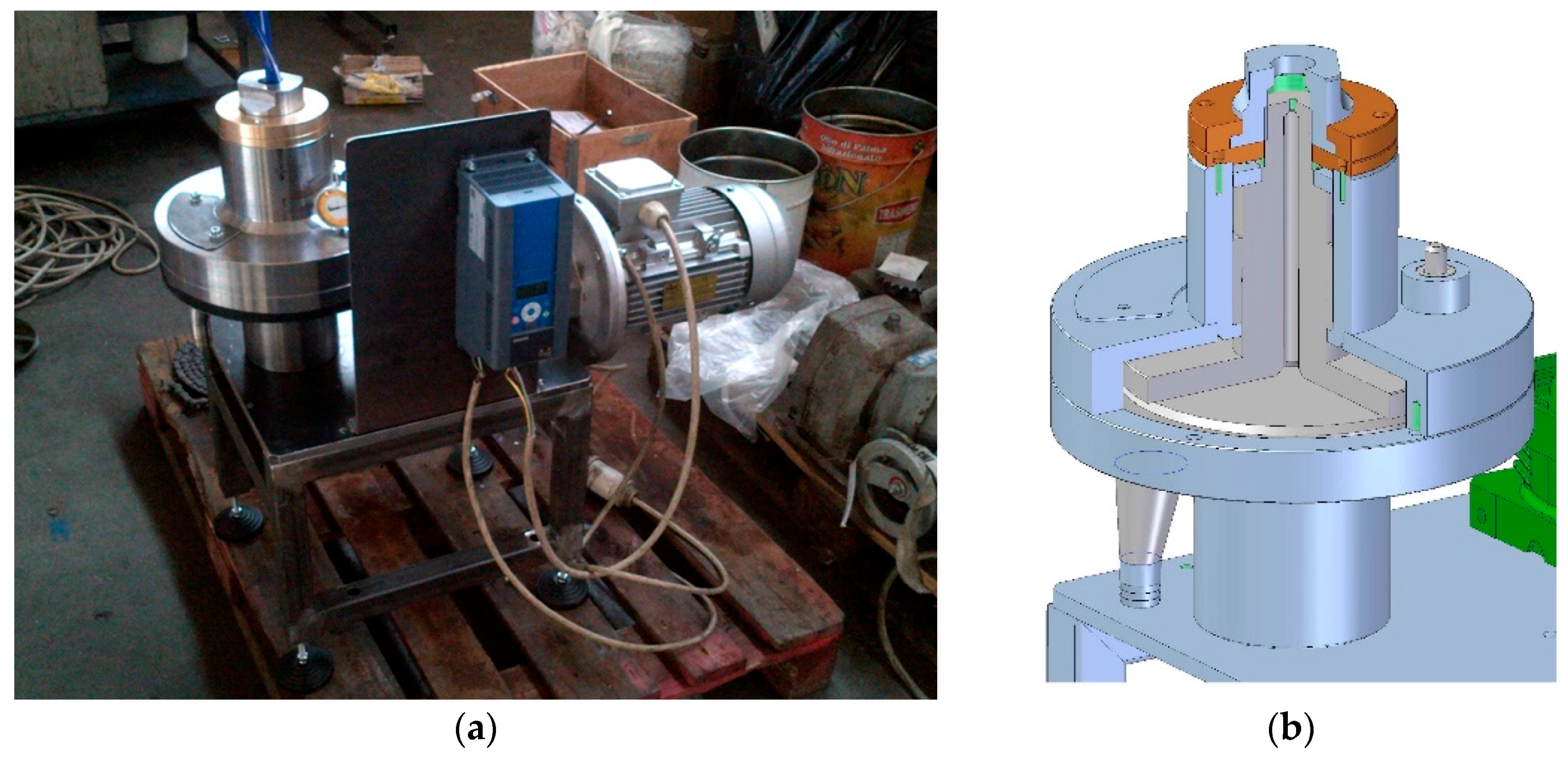

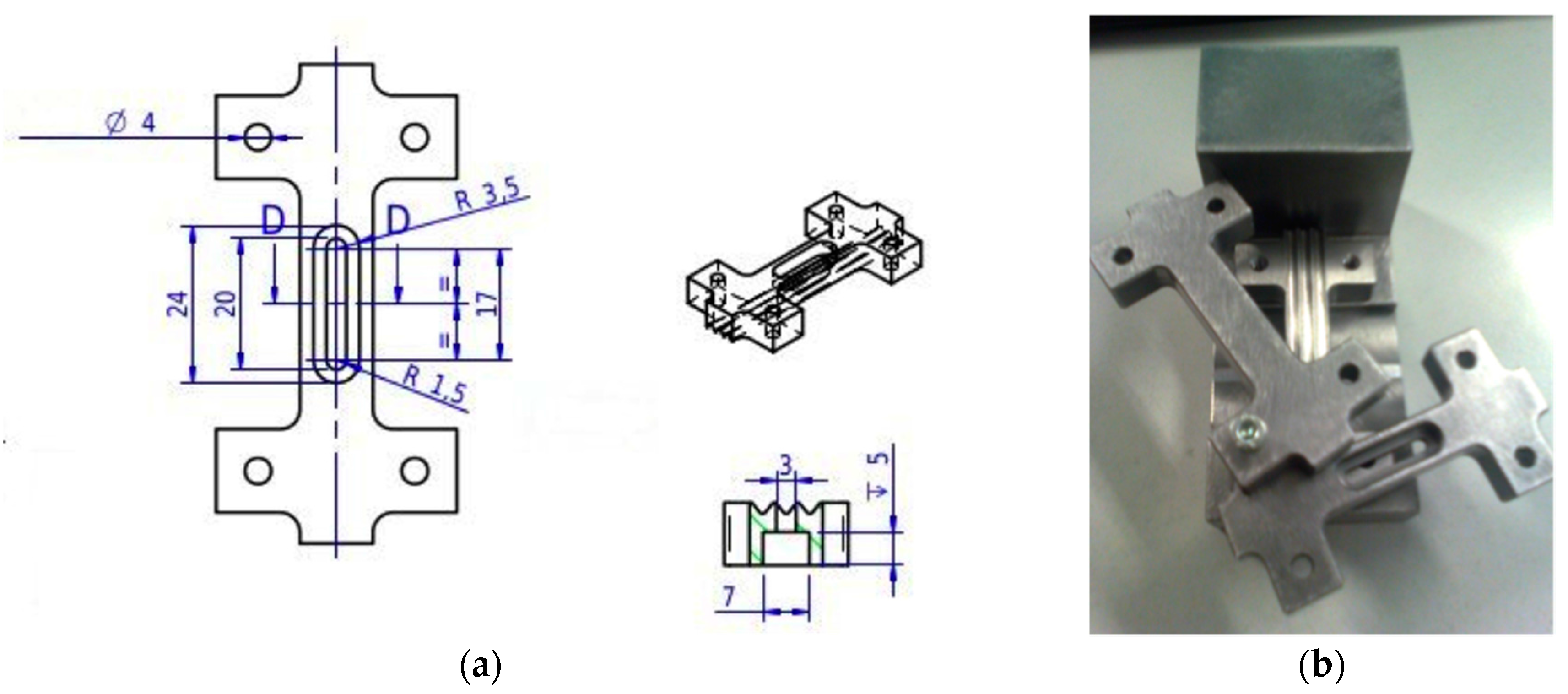

2. Materials, Manufacturing and Experimental Methods

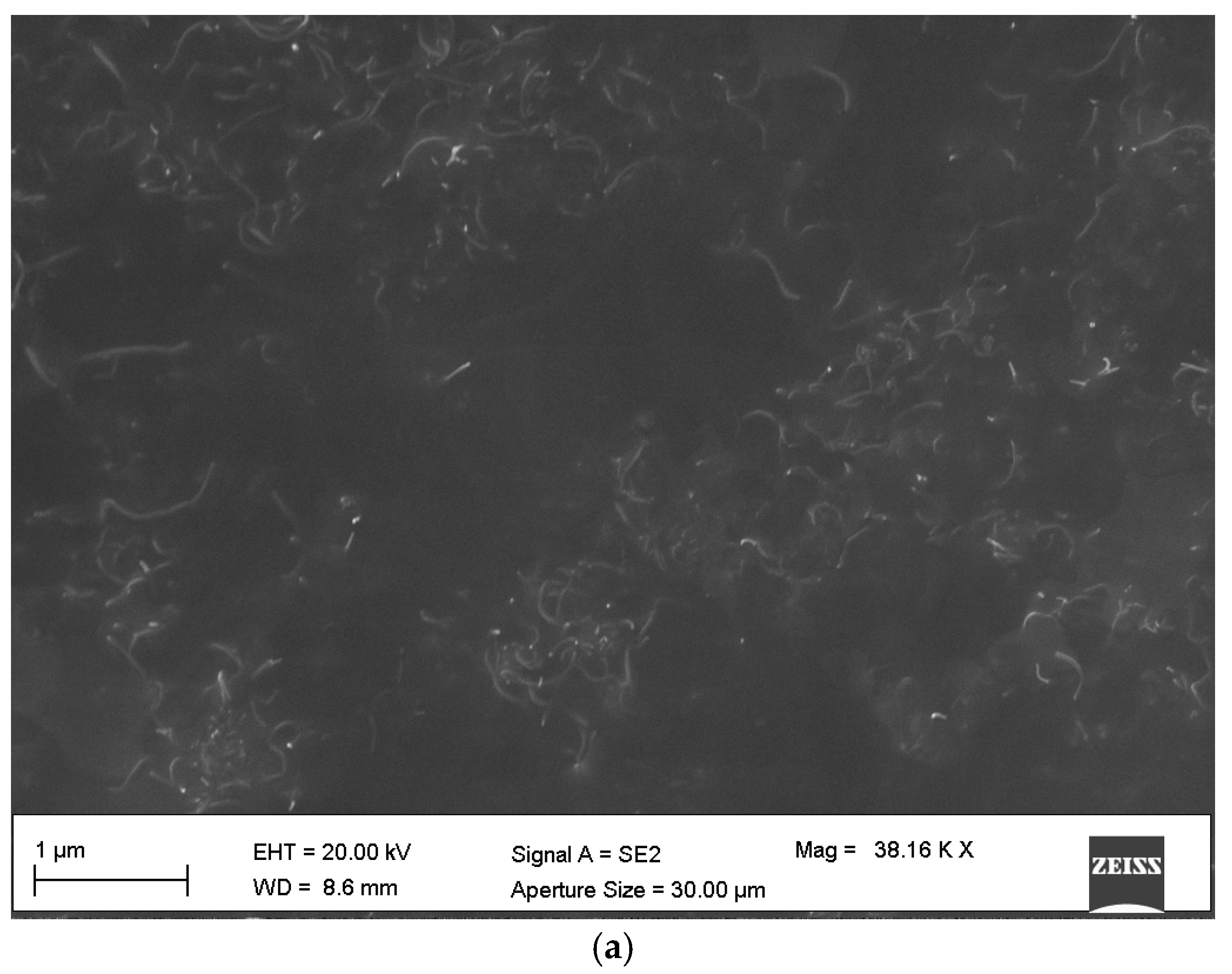

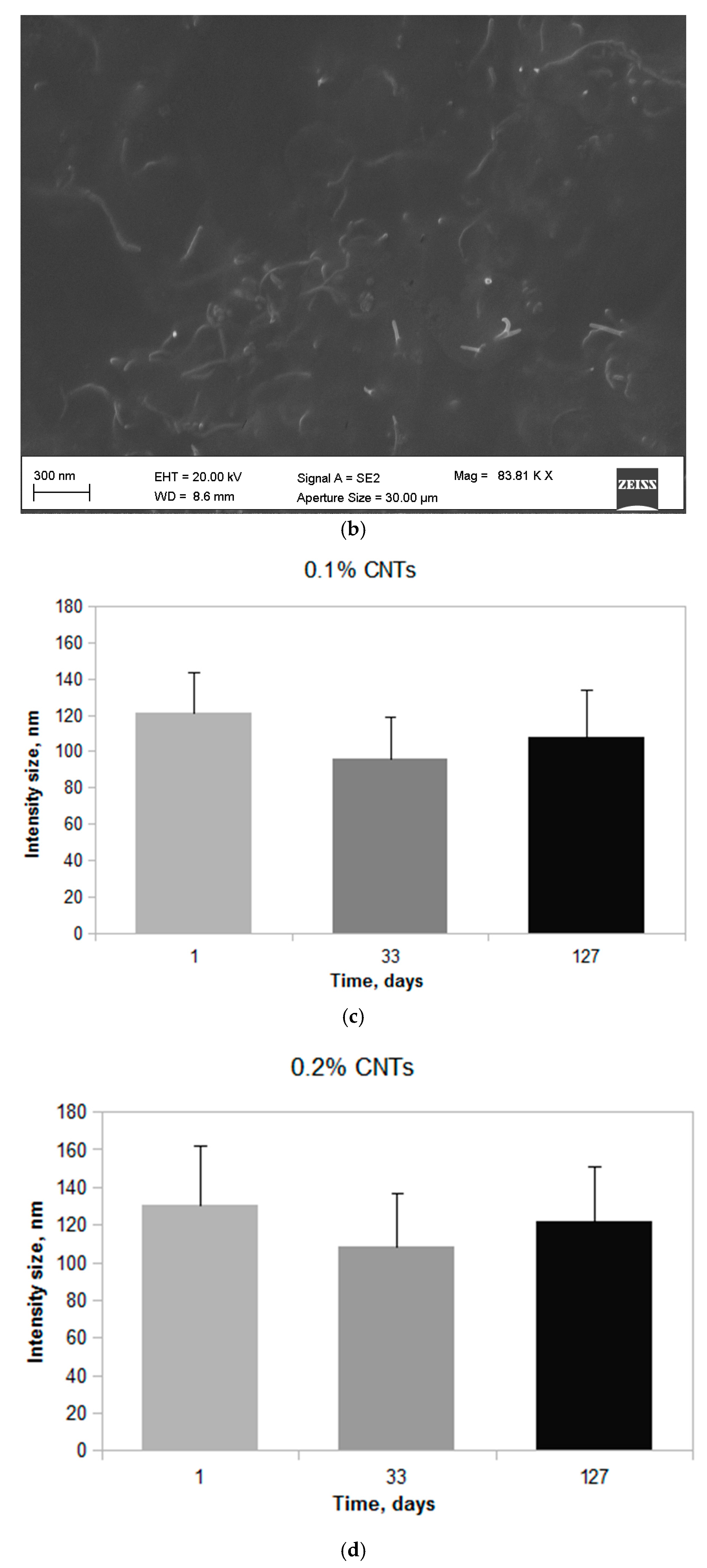

2.1. Epoxy and CNTs

2.2. CFRP Samples

2.3. Data Analysis

3. Results

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Davis, D.C.; Wilkerson, J.W.; Zhu, J.; Hadjiev, V.G. A strategy for improving mechanical properties of a fiber reinforced epoxy composite using functionalized carbon nanotubes. Compos. Sci. Technol. 2011, 71, 1089–1097. [Google Scholar] [CrossRef]

- Rahman, M.M.; Zainuddin, S.; Hosur, M.V.; Malone, J.E.; Salam, M.B.A.; Kumar, A.; Jeelani, S. Improvements in mechanical and thermo-mechanical properties of e-glass/epoxy composites using amino functionalized MWCNTs. Compos. Struct. 2012, 94, 2397–2406. [Google Scholar] [CrossRef]

- Fiedler, B.; Gojny, F.H.; Wichmann, M.H.G.; Nolte, M.C.M.; Schulte, K. Fundamental aspects of nano-reinforced composites. Compos. Sci. Technol. 2006, 66, 3115–3125. [Google Scholar] [CrossRef]

- Xie, X.-L.; Mai, Y.-M.; Zhou, X.-P. Dispersion and alignment of carbon nanotubes in polymer matrix: A review. Mater. Sci. Eng. R Rep. 2005, 49, 89–112. [Google Scholar] [CrossRef]

- Gojny, F.H.; Wichmann, M.H.G. Influence of different carbon nanotubes on the mechanical properties of epoxy matrix composites—A comparative study. Compos. Sci. Technol. 2005, 65, 2300–2313. [Google Scholar] [CrossRef]

- Shaffer, M.S.P.; Sandler, J.K.W. Carbon Nanotube/Nanofiber Polymer Composites. In Processing and Properties of Nanocomposites; World Scientific: Singapore, 2006; pp. 1–59. Available online: http://www.worldscientific.com/doi/abs/10.1142/9789812772473_0001 (accessed on 11 October 2017).

- Ijima, S. Helical Microtubules of Graphitic Carbon. Nature 1991, 354, 56–58. [Google Scholar] [CrossRef]

- De Volder, M.F.L.; Tawfick, S.H.; Baughman, R.H.; Hart, A.J. Carbon Nanotubes: Present and Future Commercial Applications. Science 2013, 339, 535–539. [Google Scholar] [CrossRef] [PubMed]

- Hussain, F.; Hojjati, M.; Okamoto, M.; Gorga, R.E. Review Article: Polymer-Matrix nanocomposites, processing, manufacturing, and application: An overview. J. Compos. Mater. 2006, 40, 1511–1575. [Google Scholar] [CrossRef]

- Aitken, R.J.; Chaudhry, M.Q.; Boxall, A.B.A.; Hull, M. Manufacture and use of nanomaterials: Current status in the uk and global trends. Occup. Med. 2006, 56, 300–306. [Google Scholar] [CrossRef] [PubMed]

- Ma, P.-C.; Siddiqui, N.A.; Marom, G.; Kim, J.-K. Dispersion and functionalization of carbon nanotubes for polymer-based nanocomposites: A review. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1345–1367. [Google Scholar] [CrossRef]

- Song, Y.S.; Youn, J.R. Influence of dispersion states of carbon nanotubes on physical properties of epoxy nanocomposites. Carbon 2005, 43, 1378–1385. [Google Scholar] [CrossRef]

- Lachman, N.; Wagner, H.D. Correlation between interfacial molecular structure and mechanics in CNT/epoxy nano-composites. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1093–1098. [Google Scholar] [CrossRef]

- Huang, Y.Y.; Terentjev, E.M. Dispersion of carbon nanotubes: Mixing, sonication, stabilization, and composite properties. Polymers 2012, 4, 275–295. [Google Scholar] [CrossRef]

- Allaoui, A.; Bai, S.; Cheng, H.M.; Bai, J.B. Mechanical and electrical properties of a MWNT/epoxy composite. Compos. Sci. Technol. 2002, 62, 1993–1998. [Google Scholar] [CrossRef]

- Gojny, F.H.; Wichmann, M.H.G.; Köpke, U.; Fiedler, B.; Schulte, K. Carbon nanotube-reinforced epoxy-composites: Enhanced stiffness and fracture toughness at low nanotube content. Compos. Sci. Technol. 2004, 64, 2363–2371. [Google Scholar] [CrossRef]

- Mallick, P.K. Fiber-Reinforced Composites: Materials, Manufacturing, and Design, 2nd ed.; CRC Press: Boca Raton, FL, USA, 1993. [Google Scholar]

- Häberle, J.G.; Matthews, F.L. An improved technique for compression testing of unidirectional fiber-reinforced plastics; development and results. Composites 1994, 25, 358–371. [Google Scholar] [CrossRef]

- Dogra, J. The Development of a New Compression Test Specimen Design for Thick Laminate Composites. Ph.D. Thesis, Imperial College, London, UK, 2011. Available online: http://ethos.bl.uk/OrderDetails.do?uin=uk.bl.ethos.539268 (accessed on 11 October 2017).

- Anonym. ICATS Users’ Manual; Imperial College of Science, Technology and Medicine, ICON Suite: London, UK, 2013. [Google Scholar]

- Dobson, B.J. A straight-line technique for extracting modal properties from frequency response data. Mech. Syst. Signal Process. 1987, 1, 29–40. [Google Scholar] [CrossRef]

- Cesano, F. Relationship between morphology and electrical properties in PP/MWCNT composites: Processing-induced anisotropic percolation threshold. Mater. Chem. Phys. 2016, 180, 284–290. [Google Scholar] [CrossRef]

- Wong, K.-K.; Shi, S.-Q.; Lau, K.-T. Mechanical and thermal behavior of a polymer composite reinforced with functionalized carbon nanotubes. Key Eng. Mater. 2007, 334–335, 705–708. [Google Scholar] [CrossRef]

- Wei, C.; Cho, K.; Srivastava, D. Tensile strength of carbon nanotubes under realistic temperature and strain rate. Phys. Rev. B 2003, 67, 115407. [Google Scholar] [CrossRef]

- Yu, M.-F.; Lourie, O.; Dyer, M.J.; Moloni, K.; Kelly, T.F.; Ruoff, R.S. Strength and breaking mechanism of multiwalled carbon nanotubes under tensile load. Science 2000, 287, 637–640. [Google Scholar] [CrossRef] [PubMed]

- Ajayan, P.M.; Schadler, L.S.; Giannaris, C.; Rubio, A. Single-Walled carbon nanotube–polymer composites: Strength and weakness. Adv. Mater. 2000, 12, 750–753. [Google Scholar] [CrossRef]

- Lu, K.L.; Lago, R.M.; Chen, Y.K.; Green, M.L.H.; Harris, P.J.F.; Tsang, S.C. Mechanical damage of carbon nanotubes by ultrasound. Carbon 1996, 34, 814–816. [Google Scholar] [CrossRef]

- Shelimov, K.B.; Esenaliev, R.O.; Rinzler, A.G.; Huffman, C.B.; Smalley, R.E. Purification of single-wall carbon nanotubes by ultrasonically assisted filtration. Chem. Phys. Lett. 1998, 282, 429–434. [Google Scholar] [CrossRef]

- Zhang, M.; Yudasaka, M.; Koshio, A.; Iijima, S. Effect of polymer and solvent on purification and cutting of single-wall carbon nanotubes. Chem. Phys. Lett. 2001, 349, 25–30. [Google Scholar] [CrossRef]

- Laurent, C.; Flahaut, E.; Peigney, A. The Weight and density of carbon nanotubes versus the number of walls and diameter. Carbon 2010, 48, 2994–2996. [Google Scholar] [CrossRef] [Green Version]

- Ci, L.; Bai, J.-B. The reinforcement role of carbon nanotubes in epoxy composites with different matrix stiffness. Compos. Sci. Technol. 2006, 66, 599–603. [Google Scholar] [CrossRef]

- Arash, B.; Wang, Q. A review on the application of nonlocal elastic models in modeling of carbon nanotubes and graphenes. Comput. Mater. Sci. 2012, 51, 303–313. [Google Scholar] [CrossRef]

- Wichmann, H.G.; Schulte, K.; Wagner, H.D. On nanocomposite toughness. Compos. Sci. Technol. 2008, 68, 329–331. [Google Scholar] [CrossRef]

- Salvetat, J.-P.; Bonard, J.-M.; Thomson, N.H.; Kulik, A.J.; Forró, L.; Benoit, W.; Zuppiroli, L. Mechanical properties of carbon nanotubes. Appl. Phys. A 1999, 69, 255–260. [Google Scholar] [CrossRef]

- Cooper, C.A.; Cohen, S.R.; Barber, A.H.; Wagner, H.D. Detachment of nanotubes from a polymer matrix. Appl. Phys. Lett. 2002, 81, 3873–3875. [Google Scholar] [CrossRef]

- Barber, A.H.; Cohen, S.R.; Eitan, A.; Schadler, L.S.; Wagner, H.D. Fracture transitions at a carbon-nanotube/polymer interface. Adv. Mater. 2006, 18, 83–87. [Google Scholar] [CrossRef]

- Gou, J.; Minaie, B.; Wang, B.; Liang, Z.; Zhang, C. Computational and experimental study of interfacial bonding of single-walled nanotube reinforced composites. Comput. Mater. Sci. 2004, 31, 225–236. [Google Scholar] [CrossRef]

- Yogeeswaran, G.; Peng, C.; Lu, Y.; Loya, P.E.; Moloney, P.; Barrera, E.; Yakobson, B.I.; Tour, J.M.; Ballarini, R.; Lou, J. Interface toughness of carbon nanotube reinforced epoxy composites. ACS Appl. Mater. Interfaces 2011, 3, 129–134. [Google Scholar]

- Belytschko, T.; Xiao, S.P.; Schatz, G.C.; Ruoff, R.S. Atomistic simulations of nanotube fracture. Phys. Rev. B 2002, 65, 235430. [Google Scholar] [CrossRef]

- Schadler, L.S.; Giannaris, S.C.; Ajayan, P.M. Load transfer in carbon nanotube epoxy composites. Appl. Phys. Lett. 1998, 73, 3842–3844. [Google Scholar] [CrossRef]

- Zhou, X.; Shin, E.; Wang, K.W.; Bakis, C.E. Interfacial damping characteristics of carbon nanotube-based composites. Compos. Sci. Technol. 2004, 64, 2425–2437. [Google Scholar] [CrossRef]

- Himanshu, R.; Jalili, N. Passive vibration damping enhancement using carbon nanotube-epoxy reinforced composites. Compos. Sci. Technol. 2005, 65, 2079–2093. [Google Scholar]

- Jones, D.I.G. Handbook of Viscoelastic Vibration Damping; John Wiley & Sons: New York, NY, USA, 2001. [Google Scholar]

| Name | CNT | Method | wt % | AR (×103) | Young’s Modulus [GPa] | Strength [MPa] | Reference | Note | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Mean | Std | Mean | Std | |||||||

| DEGBA Epoxy | 0.1 | |||||||||

| EP-502, Polymer Gvulot | MW | S | 0.34 | 0.4 | 1.6 | 0.34 | 5.7 | 12.6 | [13] | |

| EP-502, Polymer Gvulot | MW | S | 0.34 | 0.3 | 1.8 | 0.64 | 54 | 14.9 | [13] | Well dispersed |

| L135i, MGS Kunstharzprodukte | MW | M | 0.1 | 3.3 | 2.8 | 0.08 | 63 | 0.5 | [5] | |

| L135i, MGS Kunstharzprodukte | MW | M | 0.3 | 3.3 | 2.8 | 0.11 | 63 | 0.26 | [5] | |

| L135i, MGS Kunstharzprodukte | MW | M | 0.5 | 3.3 | 2.6 | 0.03 | 61 | 0.38 | [5] | Voids detected |

| DGEBA Epoxy | DW-H2 | M | 0.1 | 3.6 | 3.5 | 0.22 | 64 | 1.6 | [16] | |

| Bisphenol A-epichlorhydrine | MW | methanol | 1 | 0.2 | 3 | [15] | ||||

| Bisphenol A-epichlorhydrine | MW | methanol | 4 | 0.5 | 6 | [15] | ||||

| Araldite GY 251 | SW | S | 1 | 2.3 | 40 | [18] | ||||

| Araldite GY 252 | F-SW | S | 1 | 2.8 | 51 | [18] | ||||

| SX 10 EVO | 2.9 | 65 | ||||||||

| Araldite LY 1564 | 2.5 | 80 | ||||||||

| Super Sap 100 | 2.5 | 62 | ||||||||

| C System 10 10 CFS | 53 | |||||||||

| Epon 828 + Epicure 3223 | 2.8 | 75 | High viscosity | |||||||

| phr | σ | εyp | ε | Young’s Modulus | |||||

|---|---|---|---|---|---|---|---|---|---|

| MPa | p * | % | p | % | p | GPa | p | ||

| 0.00% | Average | 73.96 | 4.14 | 4.76 | 3.3 | ||||

| std | 1.32 | 0.13 | 0.19 | 0.37 | |||||

| C.V. | 1.78 | 3.24 | 4.01 | 11.32 | |||||

| 0.10% | Average | 73.93 | 0.9820 ns | 4.07 | 0.8419 ns | 4.69 | 0.9373 ns | 3.64 | 0.24 ns |

| std | 1.72 | 0.64 | 1.34 | 0.39 | |||||

| C.V. | 2.33 | 15.76 | 28.43 | 10.65 | |||||

| 0.20% | Average | 72.09 | 0.3255 ns | 3.19 | 0.0013 *** | 3.27 | 0.0002 *** | 3.89 | 0.03 * |

| std | 2.28 | 0.25 | 0.27 | 0.2 | |||||

| C.V. | 3.16 | 7.73 | 8.3 | 5.11 | |||||

| phr | σ | εyp | Young’s Modulus | Young’s Modulus | |||||

|---|---|---|---|---|---|---|---|---|---|

| MPa | p * | % | p | GPa (0.5–0.7%) | p | GPa (0.5–2%) | p | ||

| 0.00% | Average | 94.86 | 4.9 | 2.84 | 2.897 | ||||

| std | 4.65 | 0.36 | 0.15 | 0.31 | |||||

| C.V. | 4.9 | 7.39 | 5.25 | 10.78 | |||||

| 0.10% | Average | 96.62 | 0.5781 ns | 3.91 | 0.0524 | 2.9 | 0.6707 ns | 3.135 | 0.33 ns |

| std | 3.91 | 0.71 | 0.18 | 0.34 | |||||

| C.V. | 4.05 | 18.19 | 6.09 | 10.75 | |||||

| 0.20% | Average | 106.27 | 0.0050 *** | 3.8 | 0.0623 | 2.96 | 0.601 ns | 3.028 | 0.66 ns |

| std | 3.5 | 0.69 | 0.4 | 0.48 | |||||

| C.V. | 3.3 | 18.03 | 13.66 | 15.94 | |||||

| 0.50% | Average | 113.74 | 0.0004 *** | 6.48 | 0.206 | 3.22 | 0.0311 * | 3.156 | 0.24 ns |

| std | 3.38 | 2.08 | 0.18 | 0.26 | |||||

| C.V. | 2.97 | 32.16 | 5.44 | 8.32 | |||||

| CNT | Mode I | Mode II | Mode III | Fiber vol. Fraction | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| phr | f [Hz] | η | p * | f [Hz] | η | p | f [Hz] | η | p | ||

| 0.00% | Mean | 40.51 | 0.063 | 107.36 | 0.009 | 271.39 | 0.021 | 49.31% | |||

| std | 0.45 | 0 | 1.38 | 0 | 0.7 | 0.01 | 0.004 | ||||

| C.V. | 1.12 | 4.83 | 1.28 | 26.83 | 0.26 | 36.48 | 0.9 | ||||

| 0.10% | Mean | 0.067 | 0.235 ns | 120.06 | 0.007 | 0.263 ns | 298.53 | 0.043 | 0.006 ** | 43.44% | |

| std | 40.74 | 0.01 | 1.92 | 0 | 4.5 | 0 | 0.01 | ||||

| C.V. | 0.32 | 7.52 | 1.6 | 17.22 | 1.51 | 8.9 | 2.17 | ||||

| 0.20% | Mean | 0.78 | 0.063 | 0.945 ns | 108.76 | 0.01 | 0.816ns | 277.79 | 0.032 | 0.064 ns | 49.03% |

| std | 0.01 | 3.95 | 0 | 6.65 | 0 | 0.03 | |||||

| C.V. | 40.43 | 18.85 | 3.63 | 39.38 | 2.4 | 15.05 | 5.22 | ||||

| 0.50% | Mean | 0.93 | 0.081 | 0.611 ns | 107.29 | 0.053 | 0.0003 *** | 253.78 | 0.044 | 0.0053 ** | 52.97% |

| std | 2.3 | 0.09 | 3.5 | 0.02 | 3.43 | 0.01 | 0 | ||||

| C.V. | 106.74 | 3.27 | 30.98 | 1.35 | 29.06 | 0 | |||||

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Giovannelli, A.; Di Maio, D.; Scarpa, F. Industrial-Graded Epoxy Nanocomposites with Mechanically Dispersed Multi-Walled Carbon Nanotubes: Static and Damping Properties. Materials 2017, 10, 1222. https://doi.org/10.3390/ma10101222

Giovannelli A, Di Maio D, Scarpa F. Industrial-Graded Epoxy Nanocomposites with Mechanically Dispersed Multi-Walled Carbon Nanotubes: Static and Damping Properties. Materials. 2017; 10(10):1222. https://doi.org/10.3390/ma10101222

Chicago/Turabian StyleGiovannelli, Andrea, Dario Di Maio, and Fabrizio Scarpa. 2017. "Industrial-Graded Epoxy Nanocomposites with Mechanically Dispersed Multi-Walled Carbon Nanotubes: Static and Damping Properties" Materials 10, no. 10: 1222. https://doi.org/10.3390/ma10101222

APA StyleGiovannelli, A., Di Maio, D., & Scarpa, F. (2017). Industrial-Graded Epoxy Nanocomposites with Mechanically Dispersed Multi-Walled Carbon Nanotubes: Static and Damping Properties. Materials, 10(10), 1222. https://doi.org/10.3390/ma10101222