Industrial-Graded Epoxy Nanocomposites with Mechanically Dispersed Multi-Walled Carbon Nanotubes: Static and Damping Properties

Abstract

1. Introduction

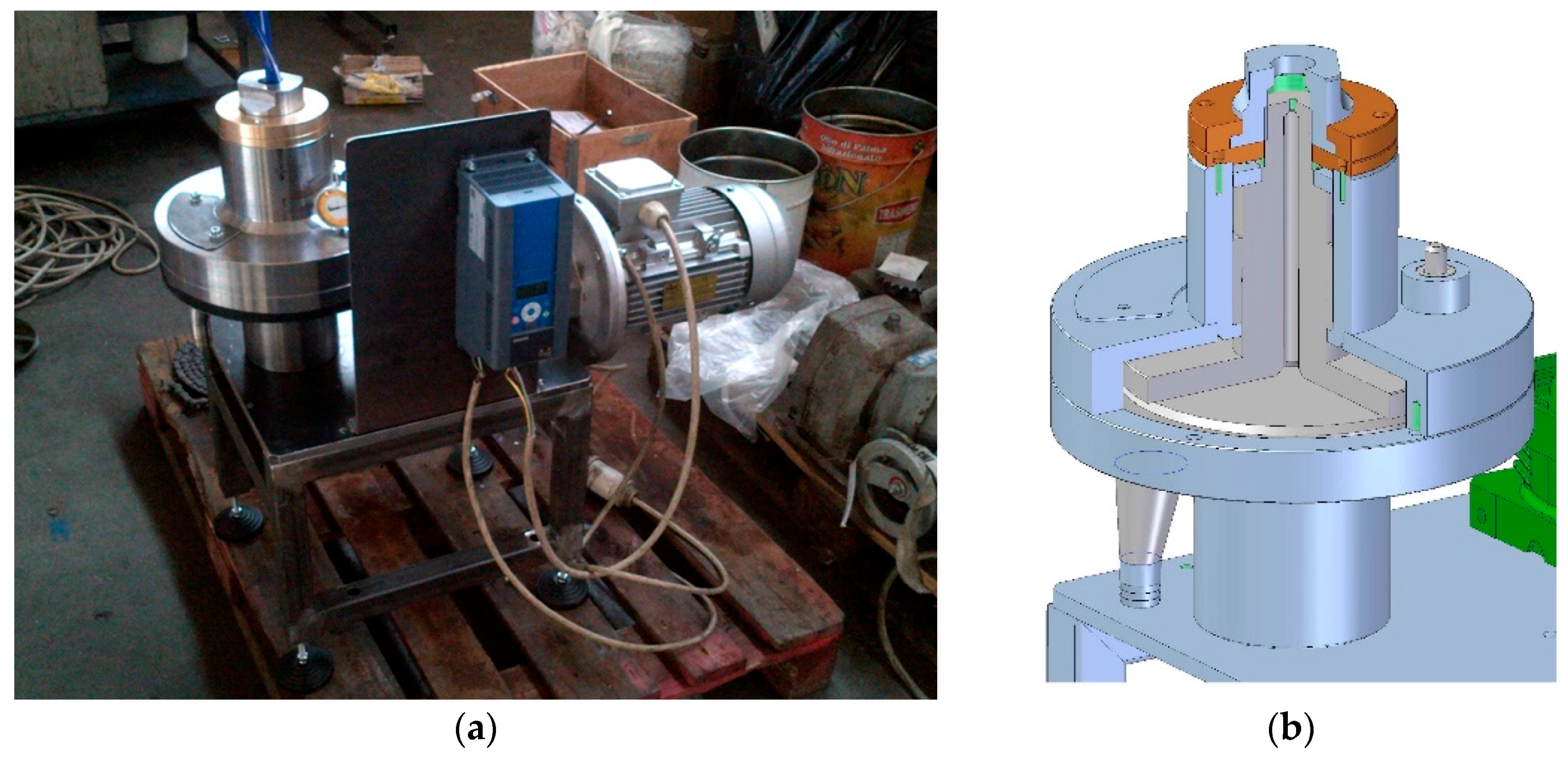

2. Materials, Manufacturing and Experimental Methods

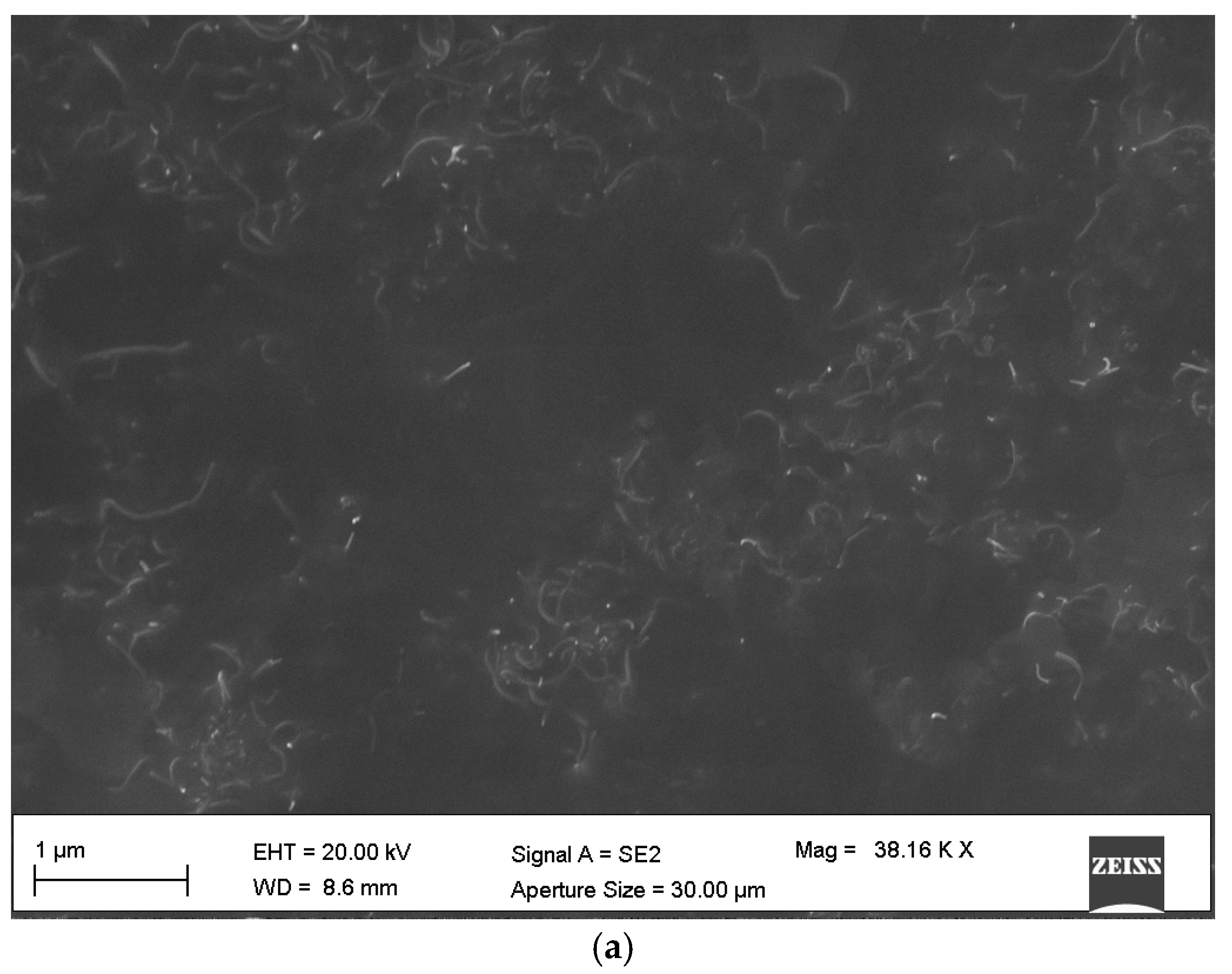

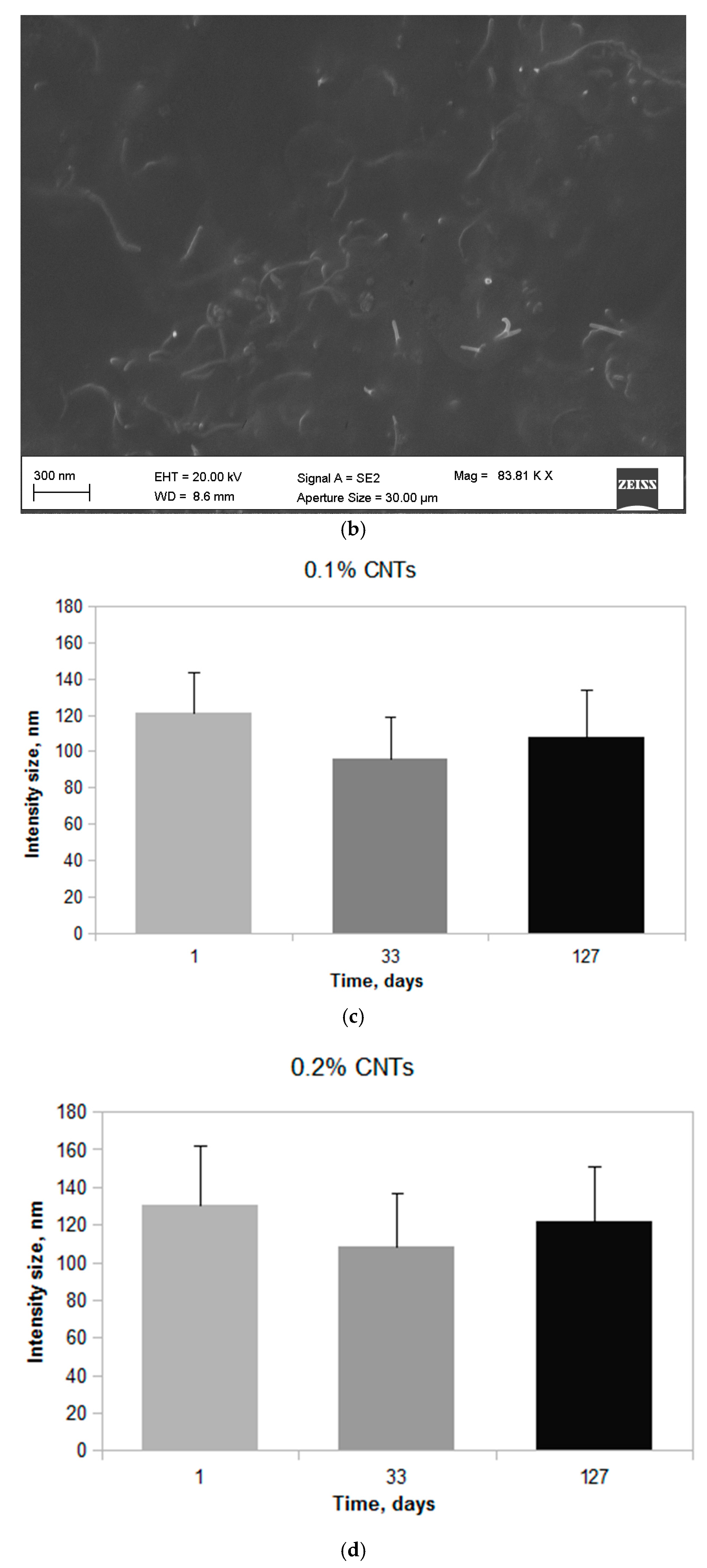

2.1. Epoxy and CNTs

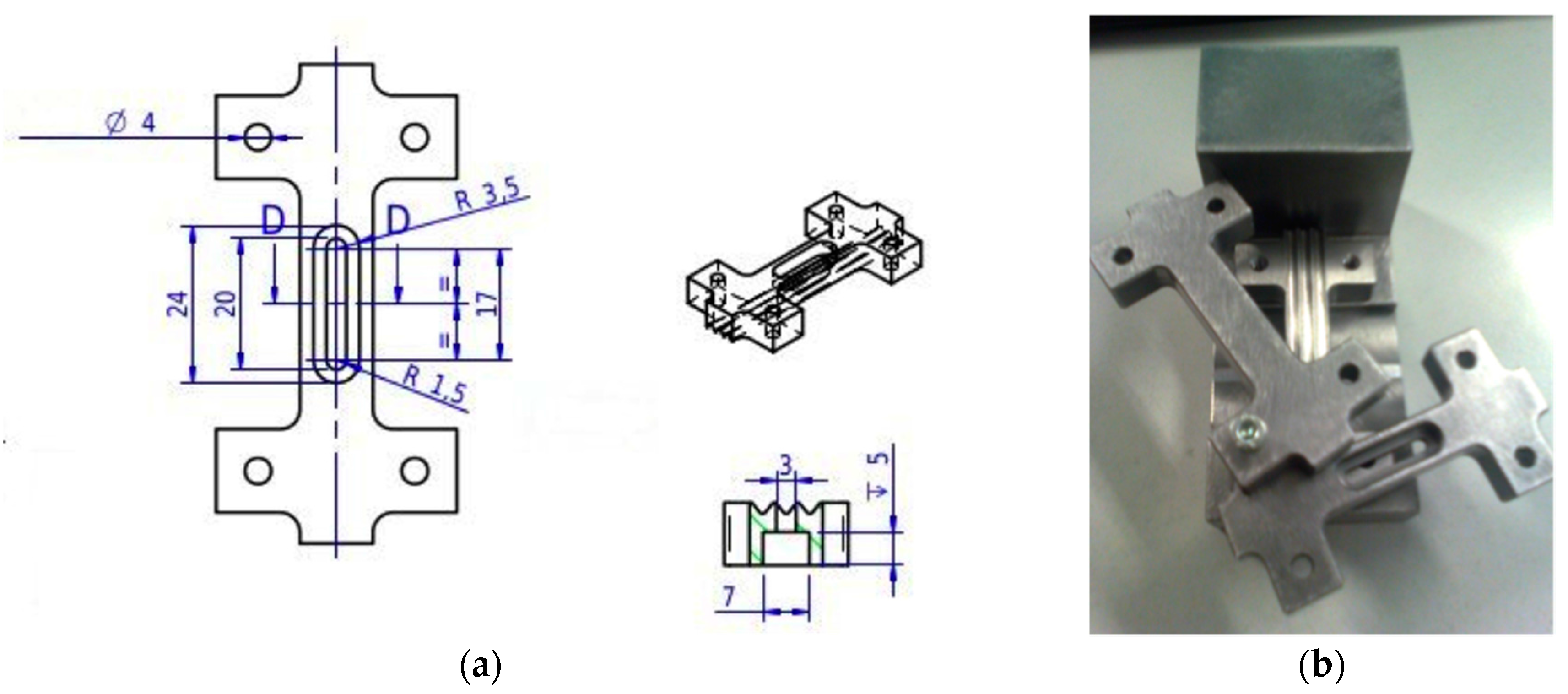

2.2. CFRP Samples

2.3. Data Analysis

3. Results

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Davis, D.C.; Wilkerson, J.W.; Zhu, J.; Hadjiev, V.G. A strategy for improving mechanical properties of a fiber reinforced epoxy composite using functionalized carbon nanotubes. Compos. Sci. Technol. 2011, 71, 1089–1097. [Google Scholar] [CrossRef]

- Rahman, M.M.; Zainuddin, S.; Hosur, M.V.; Malone, J.E.; Salam, M.B.A.; Kumar, A.; Jeelani, S. Improvements in mechanical and thermo-mechanical properties of e-glass/epoxy composites using amino functionalized MWCNTs. Compos. Struct. 2012, 94, 2397–2406. [Google Scholar] [CrossRef]

- Fiedler, B.; Gojny, F.H.; Wichmann, M.H.G.; Nolte, M.C.M.; Schulte, K. Fundamental aspects of nano-reinforced composites. Compos. Sci. Technol. 2006, 66, 3115–3125. [Google Scholar] [CrossRef]

- Xie, X.-L.; Mai, Y.-M.; Zhou, X.-P. Dispersion and alignment of carbon nanotubes in polymer matrix: A review. Mater. Sci. Eng. R Rep. 2005, 49, 89–112. [Google Scholar] [CrossRef]

- Gojny, F.H.; Wichmann, M.H.G. Influence of different carbon nanotubes on the mechanical properties of epoxy matrix composites—A comparative study. Compos. Sci. Technol. 2005, 65, 2300–2313. [Google Scholar] [CrossRef]

- Shaffer, M.S.P.; Sandler, J.K.W. Carbon Nanotube/Nanofiber Polymer Composites. In Processing and Properties of Nanocomposites; World Scientific: Singapore, 2006; pp. 1–59. Available online: http://www.worldscientific.com/doi/abs/10.1142/9789812772473_0001 (accessed on 11 October 2017).

- Ijima, S. Helical Microtubules of Graphitic Carbon. Nature 1991, 354, 56–58. [Google Scholar] [CrossRef]

- De Volder, M.F.L.; Tawfick, S.H.; Baughman, R.H.; Hart, A.J. Carbon Nanotubes: Present and Future Commercial Applications. Science 2013, 339, 535–539. [Google Scholar] [CrossRef] [PubMed]

- Hussain, F.; Hojjati, M.; Okamoto, M.; Gorga, R.E. Review Article: Polymer-Matrix nanocomposites, processing, manufacturing, and application: An overview. J. Compos. Mater. 2006, 40, 1511–1575. [Google Scholar] [CrossRef]

- Aitken, R.J.; Chaudhry, M.Q.; Boxall, A.B.A.; Hull, M. Manufacture and use of nanomaterials: Current status in the uk and global trends. Occup. Med. 2006, 56, 300–306. [Google Scholar] [CrossRef] [PubMed]

- Ma, P.-C.; Siddiqui, N.A.; Marom, G.; Kim, J.-K. Dispersion and functionalization of carbon nanotubes for polymer-based nanocomposites: A review. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1345–1367. [Google Scholar] [CrossRef]

- Song, Y.S.; Youn, J.R. Influence of dispersion states of carbon nanotubes on physical properties of epoxy nanocomposites. Carbon 2005, 43, 1378–1385. [Google Scholar] [CrossRef]

- Lachman, N.; Wagner, H.D. Correlation between interfacial molecular structure and mechanics in CNT/epoxy nano-composites. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1093–1098. [Google Scholar] [CrossRef]

- Huang, Y.Y.; Terentjev, E.M. Dispersion of carbon nanotubes: Mixing, sonication, stabilization, and composite properties. Polymers 2012, 4, 275–295. [Google Scholar] [CrossRef]

- Allaoui, A.; Bai, S.; Cheng, H.M.; Bai, J.B. Mechanical and electrical properties of a MWNT/epoxy composite. Compos. Sci. Technol. 2002, 62, 1993–1998. [Google Scholar] [CrossRef]

- Gojny, F.H.; Wichmann, M.H.G.; Köpke, U.; Fiedler, B.; Schulte, K. Carbon nanotube-reinforced epoxy-composites: Enhanced stiffness and fracture toughness at low nanotube content. Compos. Sci. Technol. 2004, 64, 2363–2371. [Google Scholar] [CrossRef]

- Mallick, P.K. Fiber-Reinforced Composites: Materials, Manufacturing, and Design, 2nd ed.; CRC Press: Boca Raton, FL, USA, 1993. [Google Scholar]

- Häberle, J.G.; Matthews, F.L. An improved technique for compression testing of unidirectional fiber-reinforced plastics; development and results. Composites 1994, 25, 358–371. [Google Scholar] [CrossRef]

- Dogra, J. The Development of a New Compression Test Specimen Design for Thick Laminate Composites. Ph.D. Thesis, Imperial College, London, UK, 2011. Available online: http://ethos.bl.uk/OrderDetails.do?uin=uk.bl.ethos.539268 (accessed on 11 October 2017).

- Anonym. ICATS Users’ Manual; Imperial College of Science, Technology and Medicine, ICON Suite: London, UK, 2013. [Google Scholar]

- Dobson, B.J. A straight-line technique for extracting modal properties from frequency response data. Mech. Syst. Signal Process. 1987, 1, 29–40. [Google Scholar] [CrossRef]

- Cesano, F. Relationship between morphology and electrical properties in PP/MWCNT composites: Processing-induced anisotropic percolation threshold. Mater. Chem. Phys. 2016, 180, 284–290. [Google Scholar] [CrossRef]

- Wong, K.-K.; Shi, S.-Q.; Lau, K.-T. Mechanical and thermal behavior of a polymer composite reinforced with functionalized carbon nanotubes. Key Eng. Mater. 2007, 334–335, 705–708. [Google Scholar] [CrossRef]

- Wei, C.; Cho, K.; Srivastava, D. Tensile strength of carbon nanotubes under realistic temperature and strain rate. Phys. Rev. B 2003, 67, 115407. [Google Scholar] [CrossRef]

- Yu, M.-F.; Lourie, O.; Dyer, M.J.; Moloni, K.; Kelly, T.F.; Ruoff, R.S. Strength and breaking mechanism of multiwalled carbon nanotubes under tensile load. Science 2000, 287, 637–640. [Google Scholar] [CrossRef] [PubMed]

- Ajayan, P.M.; Schadler, L.S.; Giannaris, C.; Rubio, A. Single-Walled carbon nanotube–polymer composites: Strength and weakness. Adv. Mater. 2000, 12, 750–753. [Google Scholar] [CrossRef]

- Lu, K.L.; Lago, R.M.; Chen, Y.K.; Green, M.L.H.; Harris, P.J.F.; Tsang, S.C. Mechanical damage of carbon nanotubes by ultrasound. Carbon 1996, 34, 814–816. [Google Scholar] [CrossRef]

- Shelimov, K.B.; Esenaliev, R.O.; Rinzler, A.G.; Huffman, C.B.; Smalley, R.E. Purification of single-wall carbon nanotubes by ultrasonically assisted filtration. Chem. Phys. Lett. 1998, 282, 429–434. [Google Scholar] [CrossRef]

- Zhang, M.; Yudasaka, M.; Koshio, A.; Iijima, S. Effect of polymer and solvent on purification and cutting of single-wall carbon nanotubes. Chem. Phys. Lett. 2001, 349, 25–30. [Google Scholar] [CrossRef]

- Laurent, C.; Flahaut, E.; Peigney, A. The Weight and density of carbon nanotubes versus the number of walls and diameter. Carbon 2010, 48, 2994–2996. [Google Scholar] [CrossRef]

- Ci, L.; Bai, J.-B. The reinforcement role of carbon nanotubes in epoxy composites with different matrix stiffness. Compos. Sci. Technol. 2006, 66, 599–603. [Google Scholar] [CrossRef]

- Arash, B.; Wang, Q. A review on the application of nonlocal elastic models in modeling of carbon nanotubes and graphenes. Comput. Mater. Sci. 2012, 51, 303–313. [Google Scholar] [CrossRef]

- Wichmann, H.G.; Schulte, K.; Wagner, H.D. On nanocomposite toughness. Compos. Sci. Technol. 2008, 68, 329–331. [Google Scholar] [CrossRef]

- Salvetat, J.-P.; Bonard, J.-M.; Thomson, N.H.; Kulik, A.J.; Forró, L.; Benoit, W.; Zuppiroli, L. Mechanical properties of carbon nanotubes. Appl. Phys. A 1999, 69, 255–260. [Google Scholar] [CrossRef]

- Cooper, C.A.; Cohen, S.R.; Barber, A.H.; Wagner, H.D. Detachment of nanotubes from a polymer matrix. Appl. Phys. Lett. 2002, 81, 3873–3875. [Google Scholar] [CrossRef]

- Barber, A.H.; Cohen, S.R.; Eitan, A.; Schadler, L.S.; Wagner, H.D. Fracture transitions at a carbon-nanotube/polymer interface. Adv. Mater. 2006, 18, 83–87. [Google Scholar] [CrossRef]

- Gou, J.; Minaie, B.; Wang, B.; Liang, Z.; Zhang, C. Computational and experimental study of interfacial bonding of single-walled nanotube reinforced composites. Comput. Mater. Sci. 2004, 31, 225–236. [Google Scholar] [CrossRef]

- Yogeeswaran, G.; Peng, C.; Lu, Y.; Loya, P.E.; Moloney, P.; Barrera, E.; Yakobson, B.I.; Tour, J.M.; Ballarini, R.; Lou, J. Interface toughness of carbon nanotube reinforced epoxy composites. ACS Appl. Mater. Interfaces 2011, 3, 129–134. [Google Scholar]

- Belytschko, T.; Xiao, S.P.; Schatz, G.C.; Ruoff, R.S. Atomistic simulations of nanotube fracture. Phys. Rev. B 2002, 65, 235430. [Google Scholar] [CrossRef]

- Schadler, L.S.; Giannaris, S.C.; Ajayan, P.M. Load transfer in carbon nanotube epoxy composites. Appl. Phys. Lett. 1998, 73, 3842–3844. [Google Scholar] [CrossRef]

- Zhou, X.; Shin, E.; Wang, K.W.; Bakis, C.E. Interfacial damping characteristics of carbon nanotube-based composites. Compos. Sci. Technol. 2004, 64, 2425–2437. [Google Scholar] [CrossRef]

- Himanshu, R.; Jalili, N. Passive vibration damping enhancement using carbon nanotube-epoxy reinforced composites. Compos. Sci. Technol. 2005, 65, 2079–2093. [Google Scholar]

- Jones, D.I.G. Handbook of Viscoelastic Vibration Damping; John Wiley & Sons: New York, NY, USA, 2001. [Google Scholar]

| Name | CNT | Method | wt % | AR (×103) | Young’s Modulus [GPa] | Strength [MPa] | Reference | Note | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Mean | Std | Mean | Std | |||||||

| DEGBA Epoxy | 0.1 | |||||||||

| EP-502, Polymer Gvulot | MW | S | 0.34 | 0.4 | 1.6 | 0.34 | 5.7 | 12.6 | [13] | |

| EP-502, Polymer Gvulot | MW | S | 0.34 | 0.3 | 1.8 | 0.64 | 54 | 14.9 | [13] | Well dispersed |

| L135i, MGS Kunstharzprodukte | MW | M | 0.1 | 3.3 | 2.8 | 0.08 | 63 | 0.5 | [5] | |

| L135i, MGS Kunstharzprodukte | MW | M | 0.3 | 3.3 | 2.8 | 0.11 | 63 | 0.26 | [5] | |

| L135i, MGS Kunstharzprodukte | MW | M | 0.5 | 3.3 | 2.6 | 0.03 | 61 | 0.38 | [5] | Voids detected |

| DGEBA Epoxy | DW-H2 | M | 0.1 | 3.6 | 3.5 | 0.22 | 64 | 1.6 | [16] | |

| Bisphenol A-epichlorhydrine | MW | methanol | 1 | 0.2 | 3 | [15] | ||||

| Bisphenol A-epichlorhydrine | MW | methanol | 4 | 0.5 | 6 | [15] | ||||

| Araldite GY 251 | SW | S | 1 | 2.3 | 40 | [18] | ||||

| Araldite GY 252 | F-SW | S | 1 | 2.8 | 51 | [18] | ||||

| SX 10 EVO | 2.9 | 65 | ||||||||

| Araldite LY 1564 | 2.5 | 80 | ||||||||

| Super Sap 100 | 2.5 | 62 | ||||||||

| C System 10 10 CFS | 53 | |||||||||

| Epon 828 + Epicure 3223 | 2.8 | 75 | High viscosity | |||||||

| phr | σ | εyp | ε | Young’s Modulus | |||||

|---|---|---|---|---|---|---|---|---|---|

| MPa | p * | % | p | % | p | GPa | p | ||

| 0.00% | Average | 73.96 | 4.14 | 4.76 | 3.3 | ||||

| std | 1.32 | 0.13 | 0.19 | 0.37 | |||||

| C.V. | 1.78 | 3.24 | 4.01 | 11.32 | |||||

| 0.10% | Average | 73.93 | 0.9820 ns | 4.07 | 0.8419 ns | 4.69 | 0.9373 ns | 3.64 | 0.24 ns |

| std | 1.72 | 0.64 | 1.34 | 0.39 | |||||

| C.V. | 2.33 | 15.76 | 28.43 | 10.65 | |||||

| 0.20% | Average | 72.09 | 0.3255 ns | 3.19 | 0.0013 *** | 3.27 | 0.0002 *** | 3.89 | 0.03 * |

| std | 2.28 | 0.25 | 0.27 | 0.2 | |||||

| C.V. | 3.16 | 7.73 | 8.3 | 5.11 | |||||

| phr | σ | εyp | Young’s Modulus | Young’s Modulus | |||||

|---|---|---|---|---|---|---|---|---|---|

| MPa | p * | % | p | GPa (0.5–0.7%) | p | GPa (0.5–2%) | p | ||

| 0.00% | Average | 94.86 | 4.9 | 2.84 | 2.897 | ||||

| std | 4.65 | 0.36 | 0.15 | 0.31 | |||||

| C.V. | 4.9 | 7.39 | 5.25 | 10.78 | |||||

| 0.10% | Average | 96.62 | 0.5781 ns | 3.91 | 0.0524 | 2.9 | 0.6707 ns | 3.135 | 0.33 ns |

| std | 3.91 | 0.71 | 0.18 | 0.34 | |||||

| C.V. | 4.05 | 18.19 | 6.09 | 10.75 | |||||

| 0.20% | Average | 106.27 | 0.0050 *** | 3.8 | 0.0623 | 2.96 | 0.601 ns | 3.028 | 0.66 ns |

| std | 3.5 | 0.69 | 0.4 | 0.48 | |||||

| C.V. | 3.3 | 18.03 | 13.66 | 15.94 | |||||

| 0.50% | Average | 113.74 | 0.0004 *** | 6.48 | 0.206 | 3.22 | 0.0311 * | 3.156 | 0.24 ns |

| std | 3.38 | 2.08 | 0.18 | 0.26 | |||||

| C.V. | 2.97 | 32.16 | 5.44 | 8.32 | |||||

| CNT | Mode I | Mode II | Mode III | Fiber vol. Fraction | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| phr | f [Hz] | η | p * | f [Hz] | η | p | f [Hz] | η | p | ||

| 0.00% | Mean | 40.51 | 0.063 | 107.36 | 0.009 | 271.39 | 0.021 | 49.31% | |||

| std | 0.45 | 0 | 1.38 | 0 | 0.7 | 0.01 | 0.004 | ||||

| C.V. | 1.12 | 4.83 | 1.28 | 26.83 | 0.26 | 36.48 | 0.9 | ||||

| 0.10% | Mean | 0.067 | 0.235 ns | 120.06 | 0.007 | 0.263 ns | 298.53 | 0.043 | 0.006 ** | 43.44% | |

| std | 40.74 | 0.01 | 1.92 | 0 | 4.5 | 0 | 0.01 | ||||

| C.V. | 0.32 | 7.52 | 1.6 | 17.22 | 1.51 | 8.9 | 2.17 | ||||

| 0.20% | Mean | 0.78 | 0.063 | 0.945 ns | 108.76 | 0.01 | 0.816ns | 277.79 | 0.032 | 0.064 ns | 49.03% |

| std | 0.01 | 3.95 | 0 | 6.65 | 0 | 0.03 | |||||

| C.V. | 40.43 | 18.85 | 3.63 | 39.38 | 2.4 | 15.05 | 5.22 | ||||

| 0.50% | Mean | 0.93 | 0.081 | 0.611 ns | 107.29 | 0.053 | 0.0003 *** | 253.78 | 0.044 | 0.0053 ** | 52.97% |

| std | 2.3 | 0.09 | 3.5 | 0.02 | 3.43 | 0.01 | 0 | ||||

| C.V. | 106.74 | 3.27 | 30.98 | 1.35 | 29.06 | 0 | |||||

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Giovannelli, A.; Di Maio, D.; Scarpa, F. Industrial-Graded Epoxy Nanocomposites with Mechanically Dispersed Multi-Walled Carbon Nanotubes: Static and Damping Properties. Materials 2017, 10, 1222. https://doi.org/10.3390/ma10101222

Giovannelli A, Di Maio D, Scarpa F. Industrial-Graded Epoxy Nanocomposites with Mechanically Dispersed Multi-Walled Carbon Nanotubes: Static and Damping Properties. Materials. 2017; 10(10):1222. https://doi.org/10.3390/ma10101222

Chicago/Turabian StyleGiovannelli, Andrea, Dario Di Maio, and Fabrizio Scarpa. 2017. "Industrial-Graded Epoxy Nanocomposites with Mechanically Dispersed Multi-Walled Carbon Nanotubes: Static and Damping Properties" Materials 10, no. 10: 1222. https://doi.org/10.3390/ma10101222

APA StyleGiovannelli, A., Di Maio, D., & Scarpa, F. (2017). Industrial-Graded Epoxy Nanocomposites with Mechanically Dispersed Multi-Walled Carbon Nanotubes: Static and Damping Properties. Materials, 10(10), 1222. https://doi.org/10.3390/ma10101222