Smart Hybrid Maintenance as a Pathway to Energy-Efficient Manufacturing

Abstract

1. Introduction

1.1. Energy Efficiency as a Driver of Predictive Maintenance Strategies

1.2. Predictive Maintenance as a Tool for Energy Optimization

- Identification of critical assets;

- Data acquisition;

- Development of a consistent data model;

- Data flow design and storage architecture;

- Data preprocessing;

- Implementation of predictive algorithms and model training;

- Evaluation of PdM process performance through KPI calculation;

- Visualization and interpretation of results;

- Decision-making and execution of maintenance actions;

- Continuous process improvement.

1.3. Reliability-Centered Maintenance (RCM)

1.3.1. Introduction to RCM

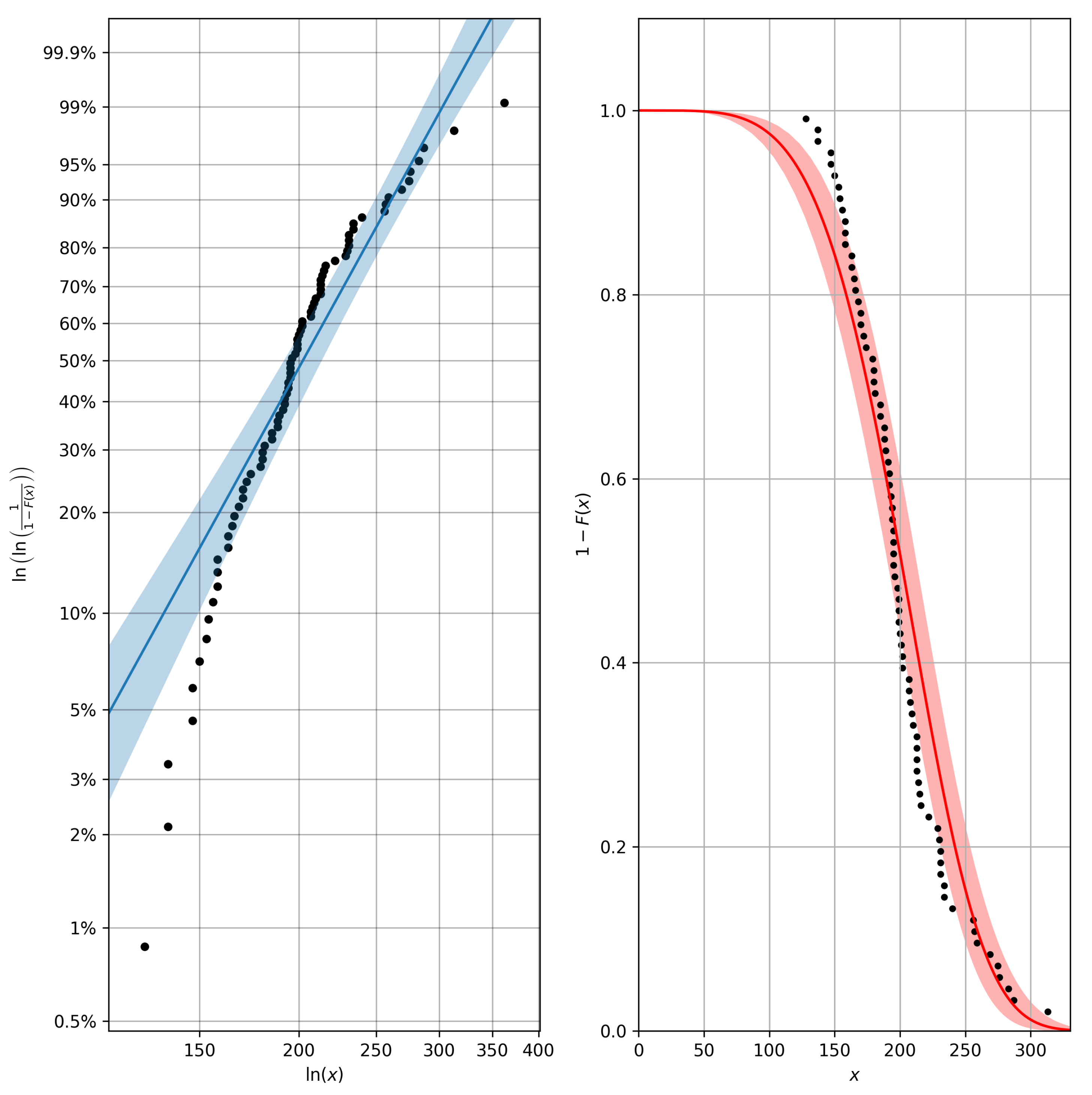

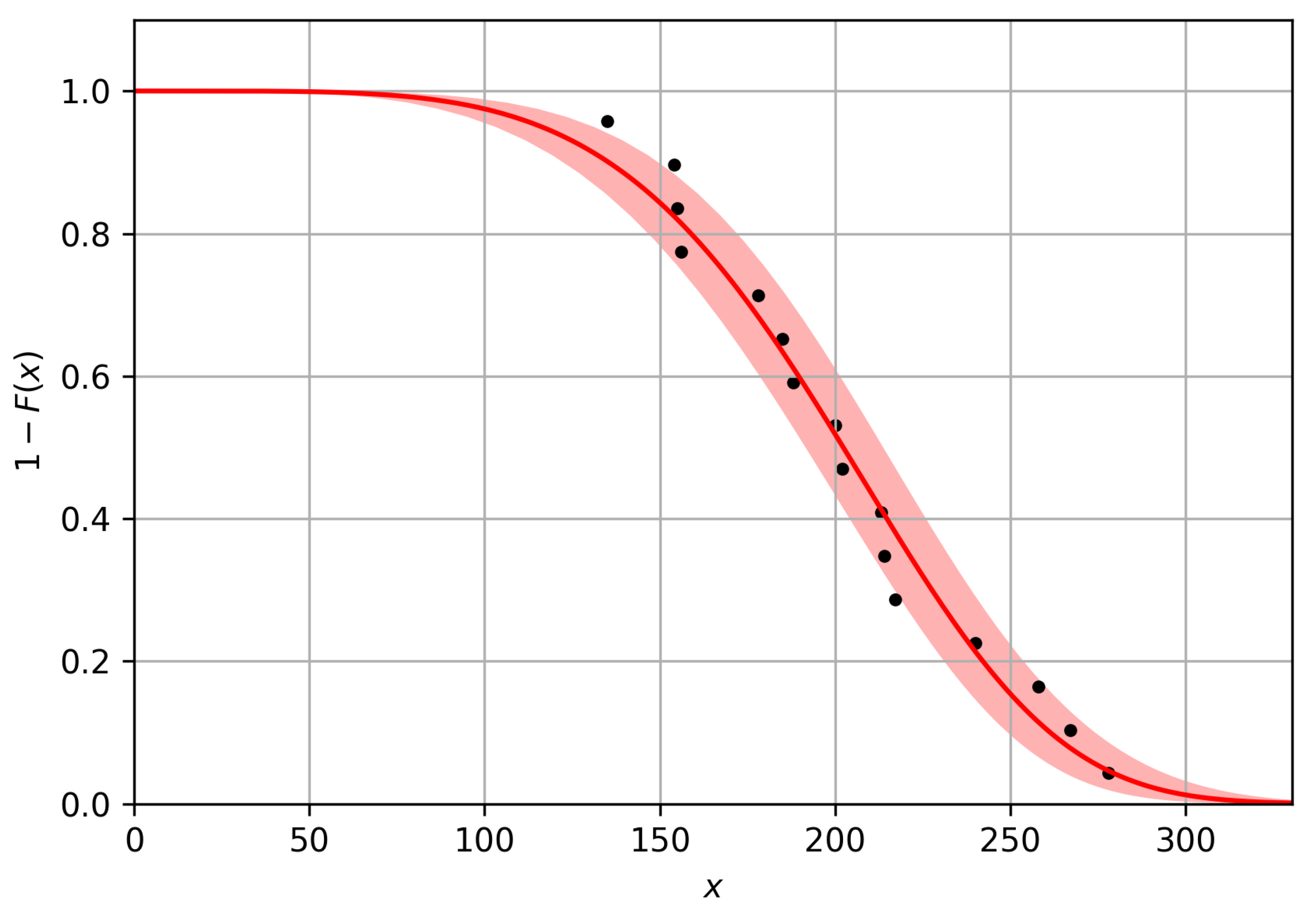

1.3.2. Application of the Weibull Distribution to Reliability Analysis

- Collect information on the number of operational cycles (e.g., hours) for individual machines and/or their components.

- Sort the operational cycle data in ascending order.

- Assign a probability value to each observation in the failure dataset.

- Determine the double-logarithmic probability measure and the logarithm of the number of cycles.

- Estimate the parameters of the Weibull distribution using linear regression.

1.4. Key Performance Indicators Used for PdM Process Scoring

1.5. Condition-Based Maintenance Framework

1.5.1. Application of Clustering Methods for Anomaly Detection and Failure Prediction

1.5.2. Machine Anomaly Detection Using Clustering Algorithms

- Initialization: Choose k initial cluster centroids (this can be done randomly).

- Point Assignment: Assign each data point to the nearest cluster centroid, typically using Euclidean distance as the measure of proximity.

- Centroid Update: Recalculate the centroids of the clusters as the mean of all points assigned to each cluster.

- Iteration: Repeat steps 2 and 3 until convergence, i.e., when cluster assignments no longer change significantly.

- Define the state space as the space encompassing all possible signal values. For instance, if data is collected from two sensors, the state space will be two-dimensional; if data is collected from five sensors, it will be five-dimensional.

- Define a subspace that contains only the combinations of signal values representing correct machine operating states. It is assumed that during proper operation, all signal value combinations belong to . This implies that the machine is functioning correctly if the current state lies within . Conversely, if the state does not belong to , it is classified as an anomaly (incorrect state). Additionally, the degree of anomaly is measured as the distance of the current state from the subspace . It is assumed that is a metric space with a specified metric (e.g., Euclidean distance).

- Define an analytical representation of as a collection of clusters. Multiple valid operating states may exist in the multidimensional feature space . Using a defined membership function, each data point/state in is assigned to a specific cluster. Model training primarily involves determining this membership function.

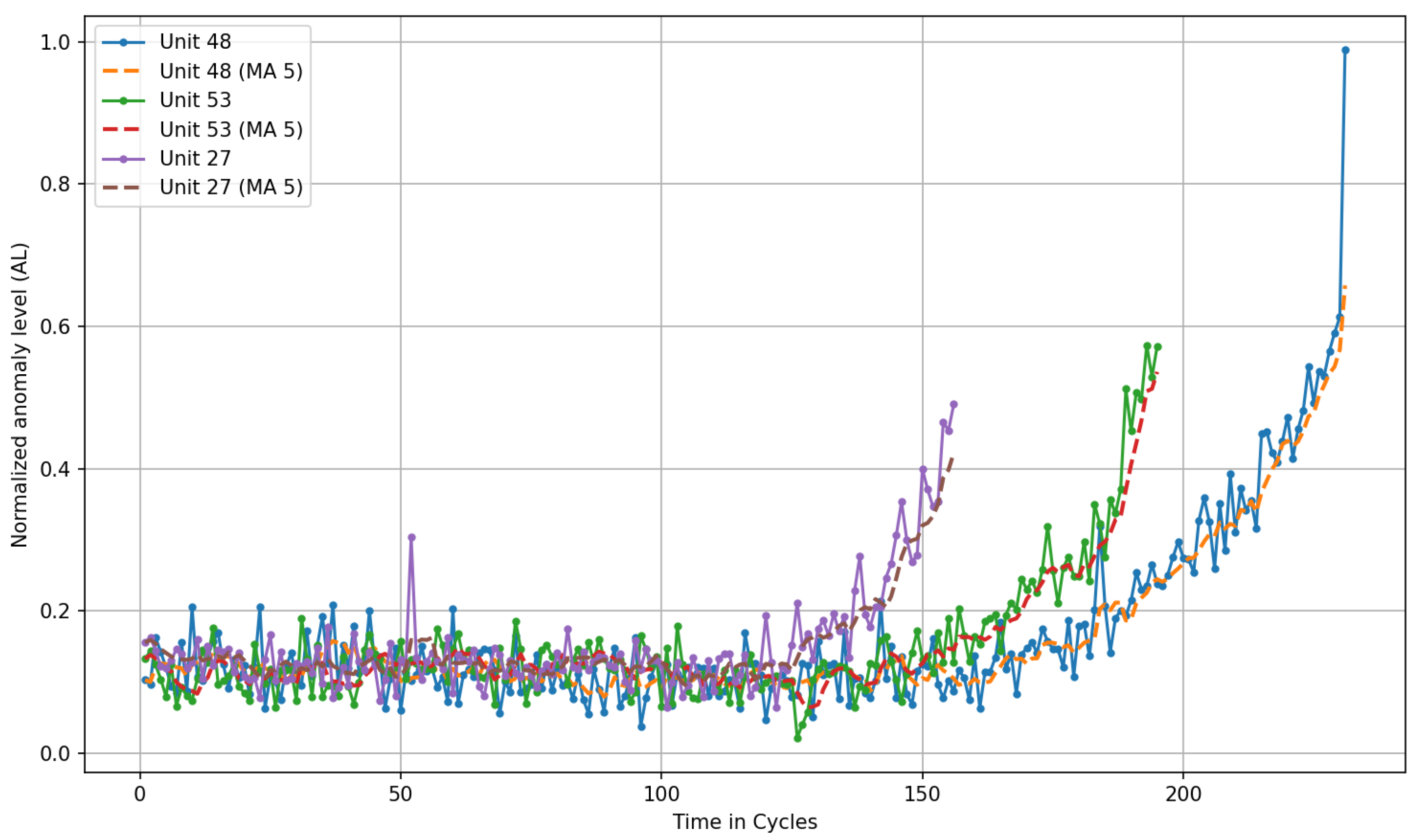

- Acquire new data/machine states and determine their position in the state space relative to clusters representing valid operating states. The distance between the current state and the nearest cluster is then calculated; this metric is referred to as Anomaly Level, . If the state lies within a cluster, the distance is zero; if it lies outside, the anomaly severity increases with the distance.

- Determine the extent to which the distance projected onto each individual feature contributes to the overall distance. This allows for the identification of the causes of the anomaly or the features with the most significant impact on the anomaly.

1.6. The Concept of a Hybrid Model

1.7. Plan of the Paper

2. Materials and Methods

2.1. Quantitative Relationships Between Maintenance Indicators and Energy Efficiency

2.2. Data Description

2.2.1. Modeling the Predictive Maintenance Process Using the NASA N-CMAPSS Dataset

2.2.2. Modeling the Predictive Maintenance Process in the Smart RDM Environment

- Analysis of the potential for reducing unplanned downtimes and increasing machine availability under production conditions;

- Evaluation of the cost-effectiveness of data-driven maintenance strategies compared to traditional preventive approaches;

- Verification of the impact of early fault detection and prognostic maintenance planning on production process continuity;

- Investigation of the potential for extending machine lifetime through continuous monitoring of critical components and timely interventions;

- Analysis of the influence of implemented solutions on improving workplace safety and reducing the likelihood of mechanical failures;

- Development of a methodology to support data-driven managerial decision-making based on diagnostics and KPI analysis;

- Evaluation of the integration capabilities of the developed system with ERP platforms to ensure enterprise-level informational consistency.

2.3. Research Methodology

- Preliminary data processing, including feature (signal) selection and data standardization.

- Modeling the predictive maintenance process according to the RCM methodology, i.e., estimating Weibull distribution parameters in accordance with Formula (9).

- Modeling the predictive maintenance process according to the CBM methodology, i.e., clustering the data and calculating Manhattan distances between clusters representing the normal operating state and the current state.

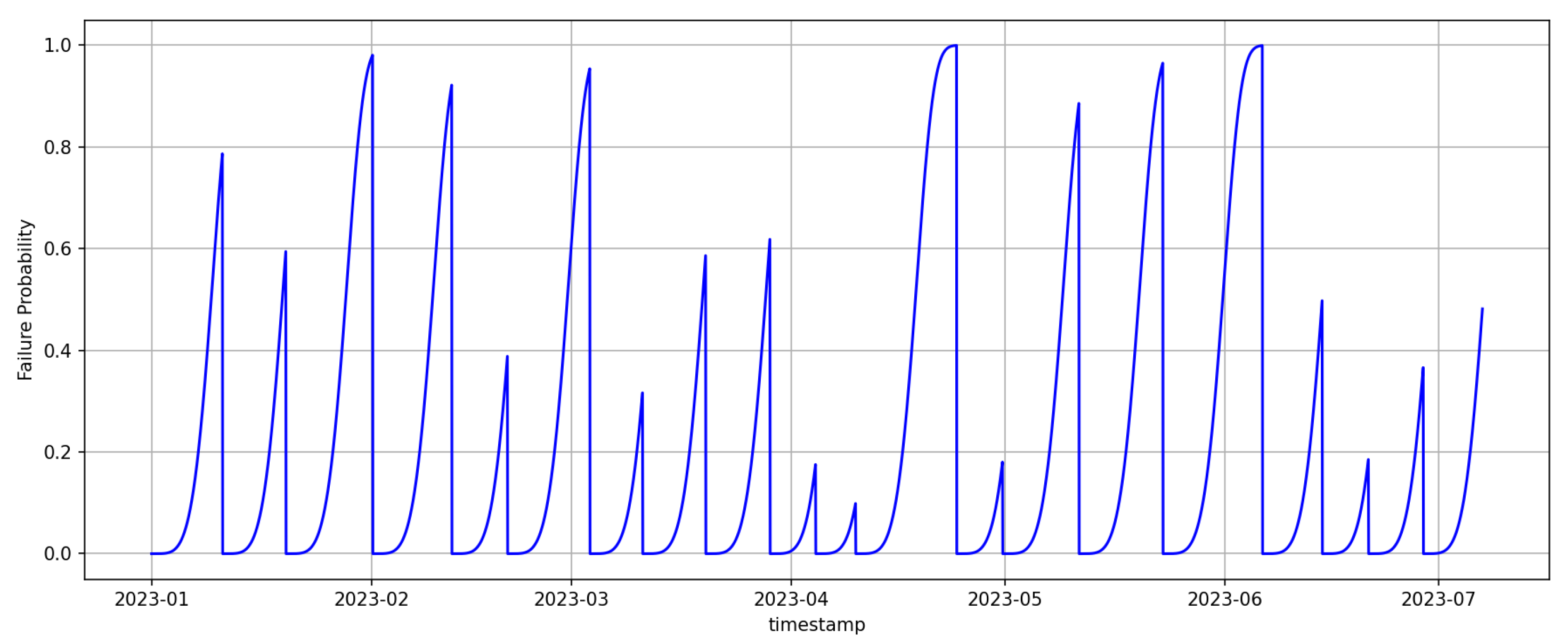

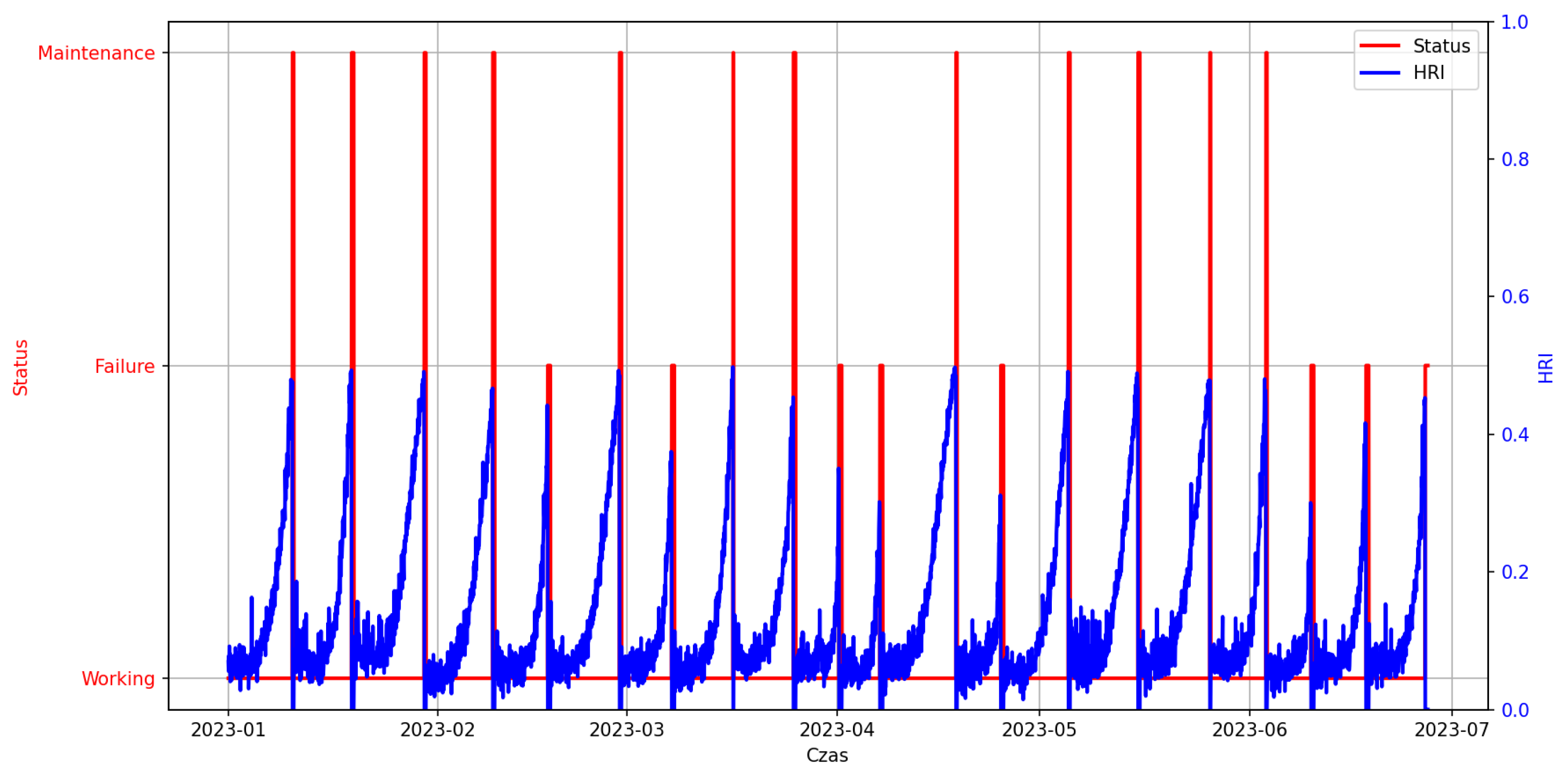

- Combining the RCM and CBM processes and determining the index with Formula (23).

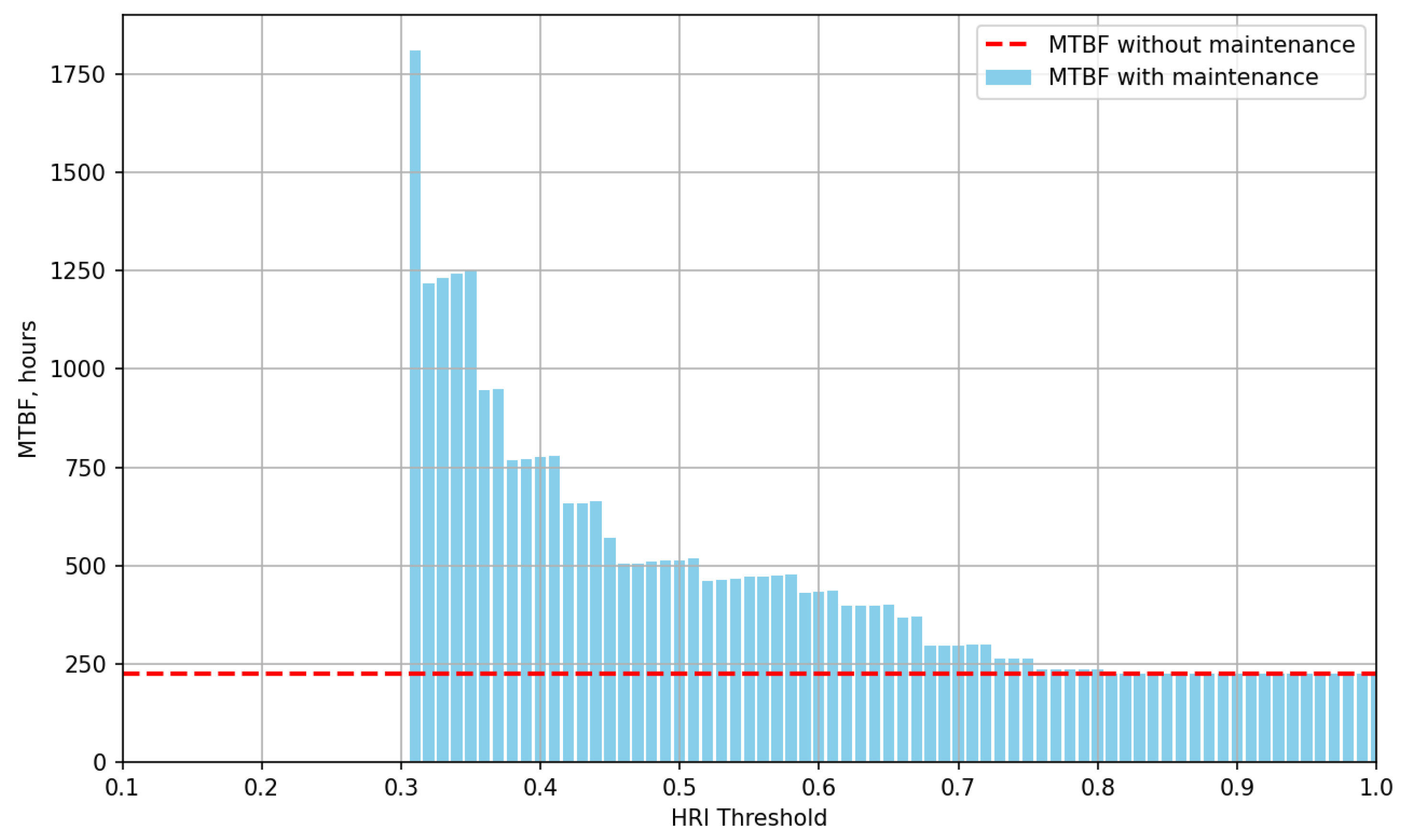

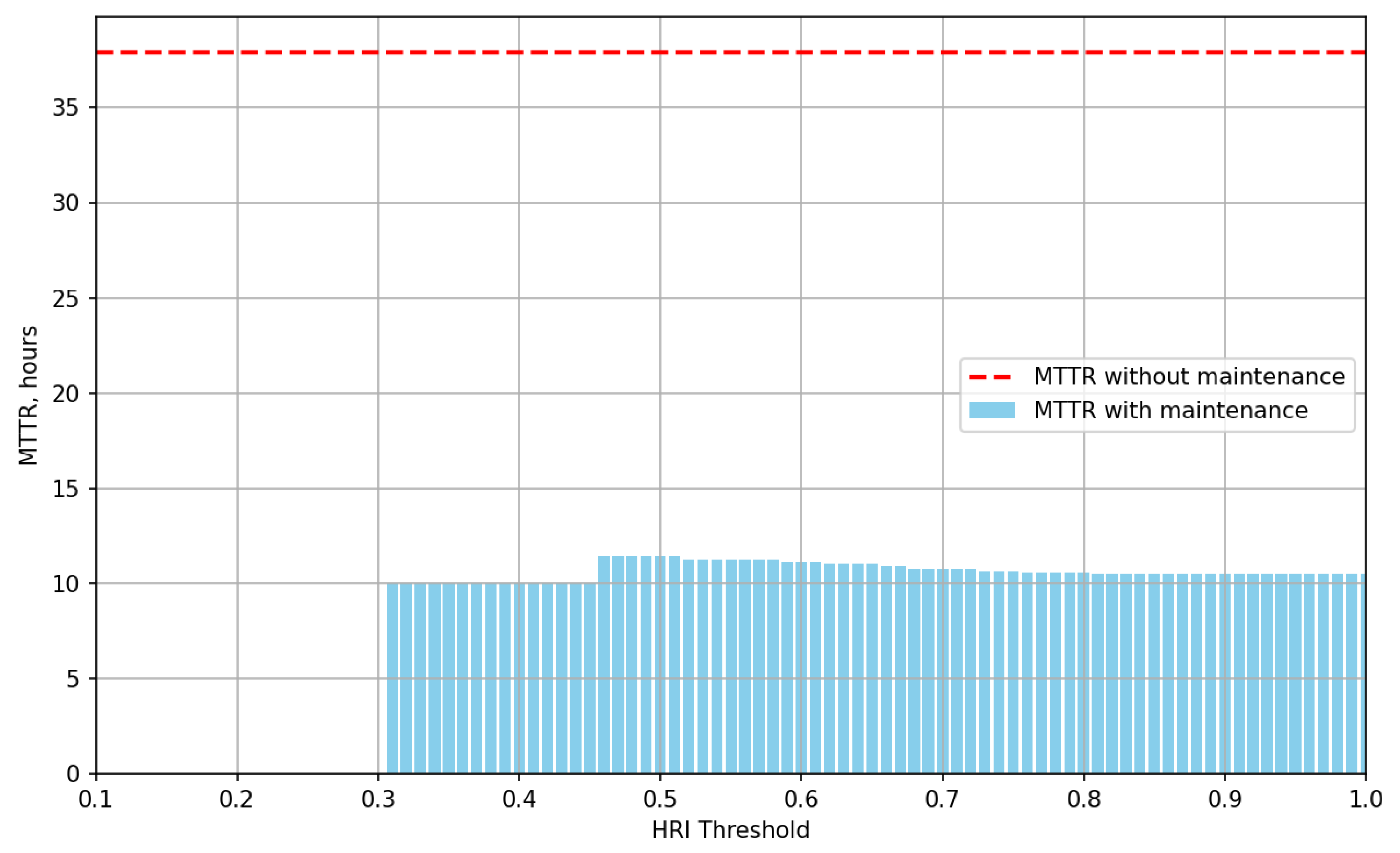

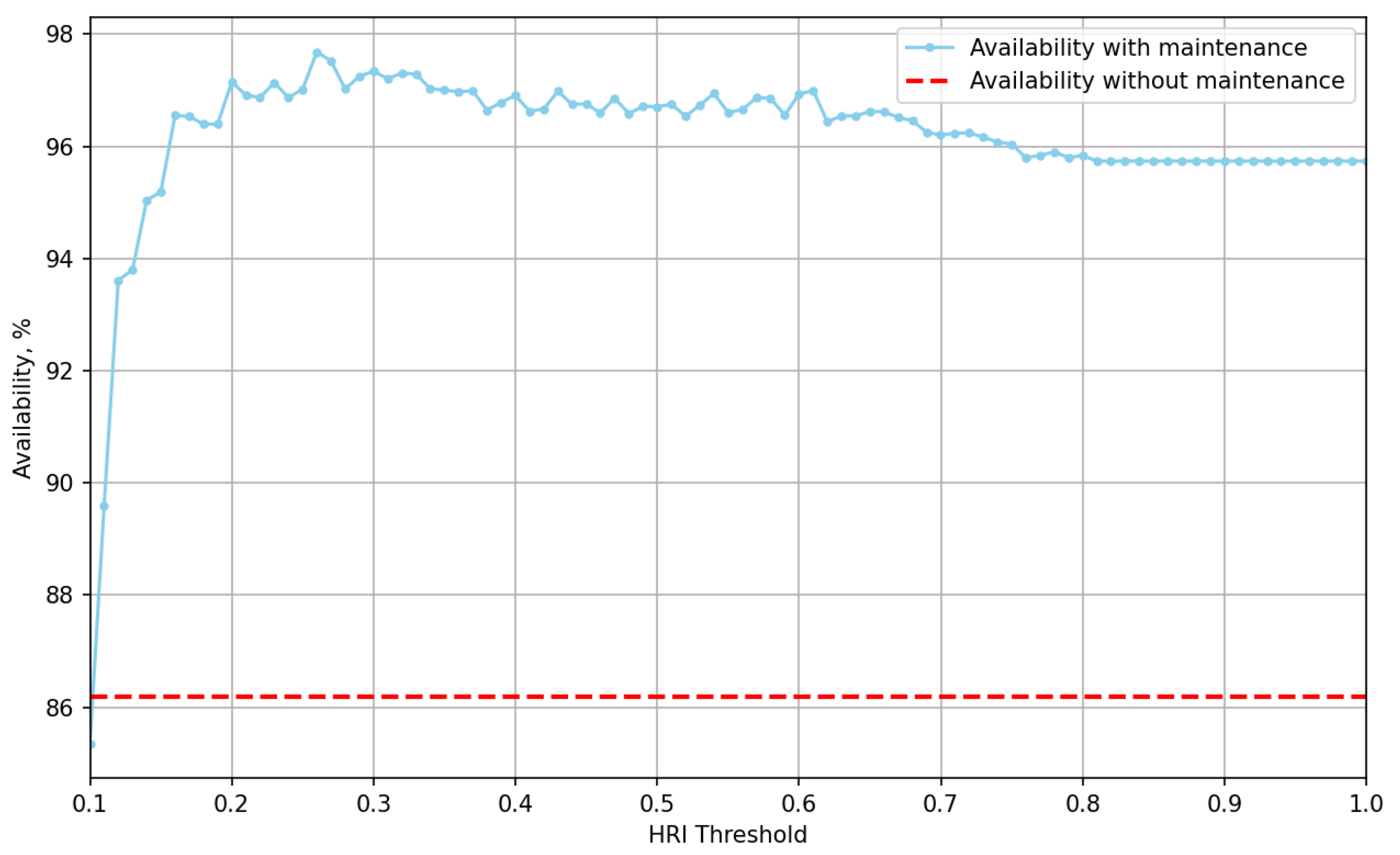

- Simulating the effects of maintenance actions taken based on and evaluating maintenance KPIs such as MTBF, MTTR, etc., compared to the process without predictive maintenance.

- Formulation of conclusions.

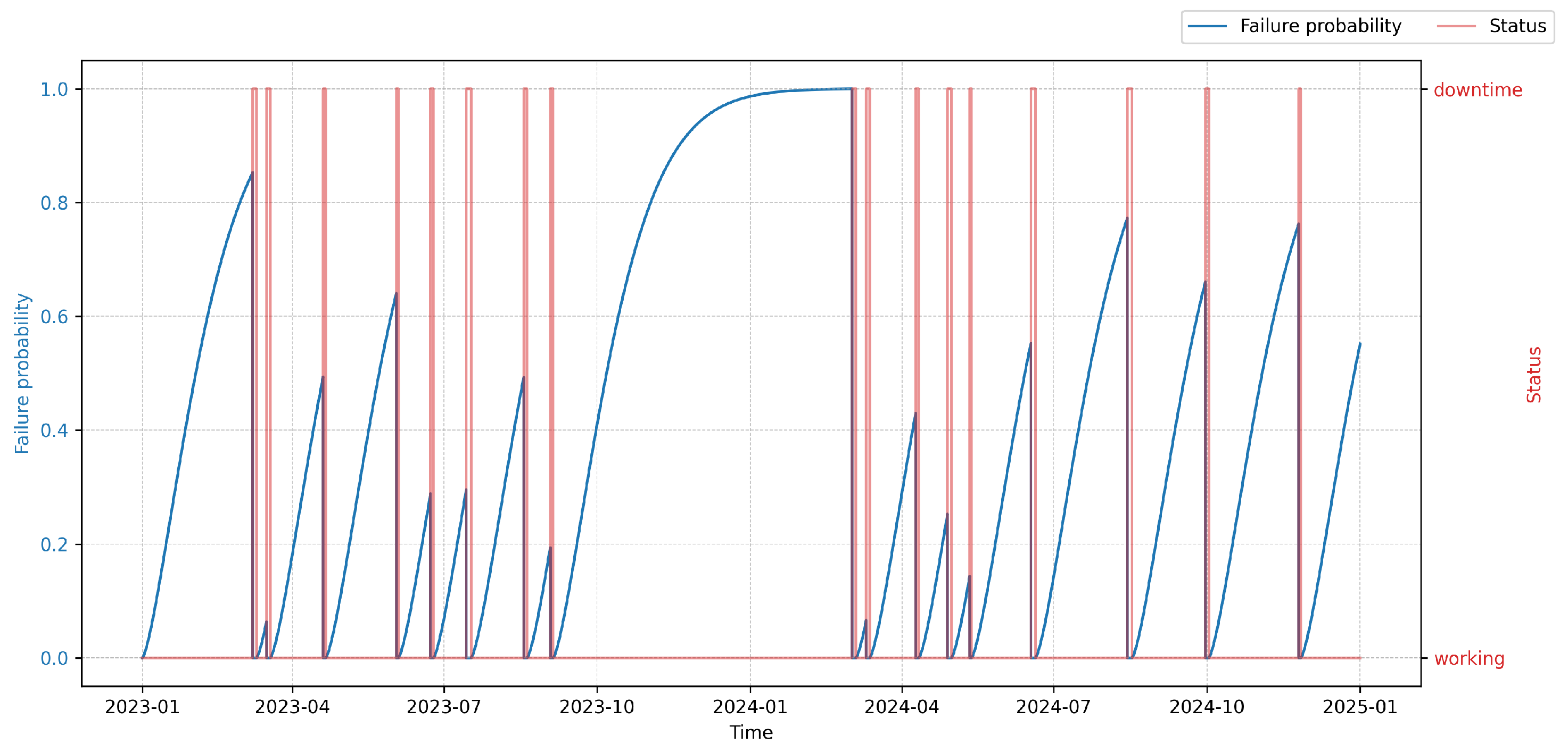

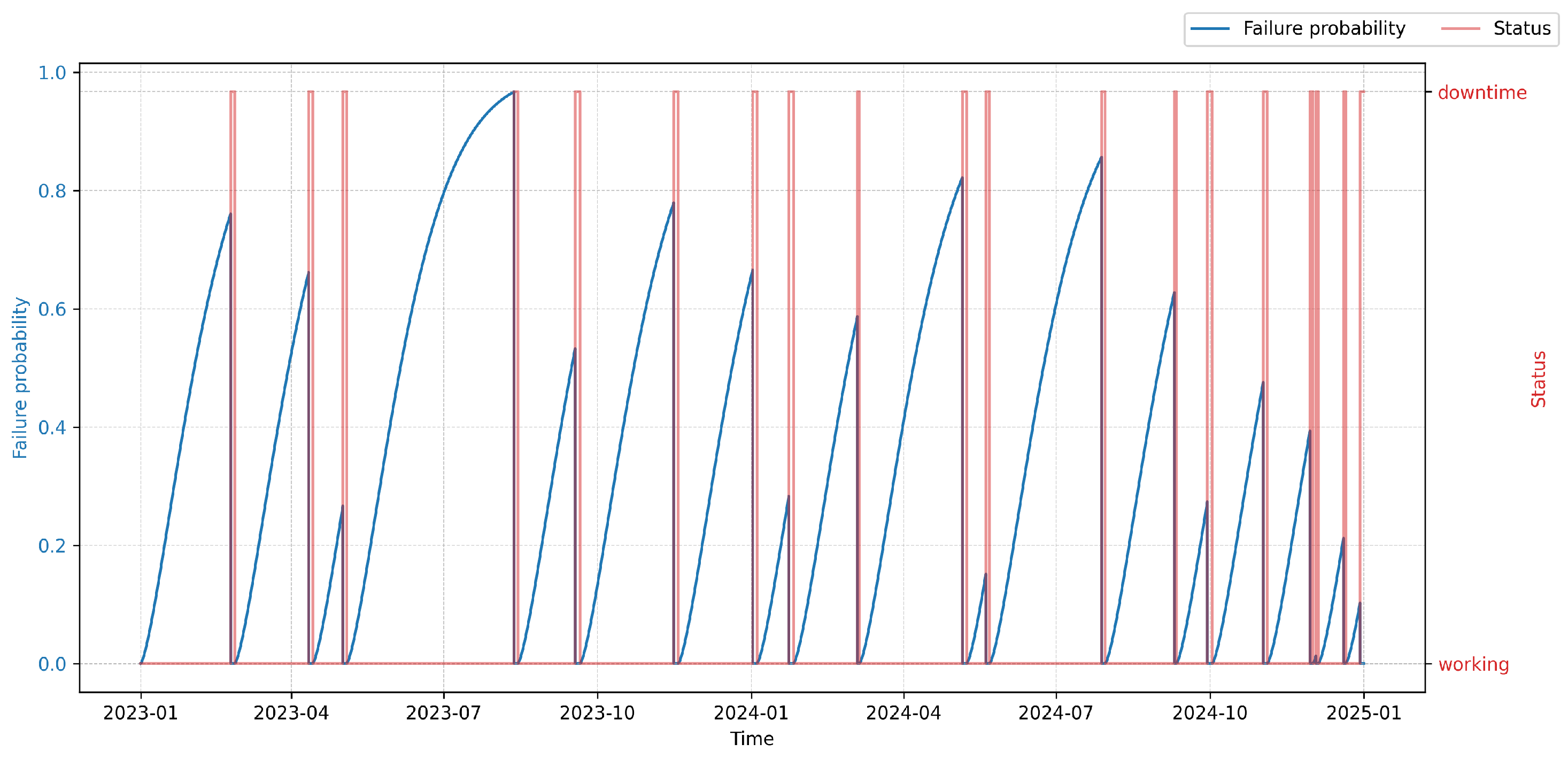

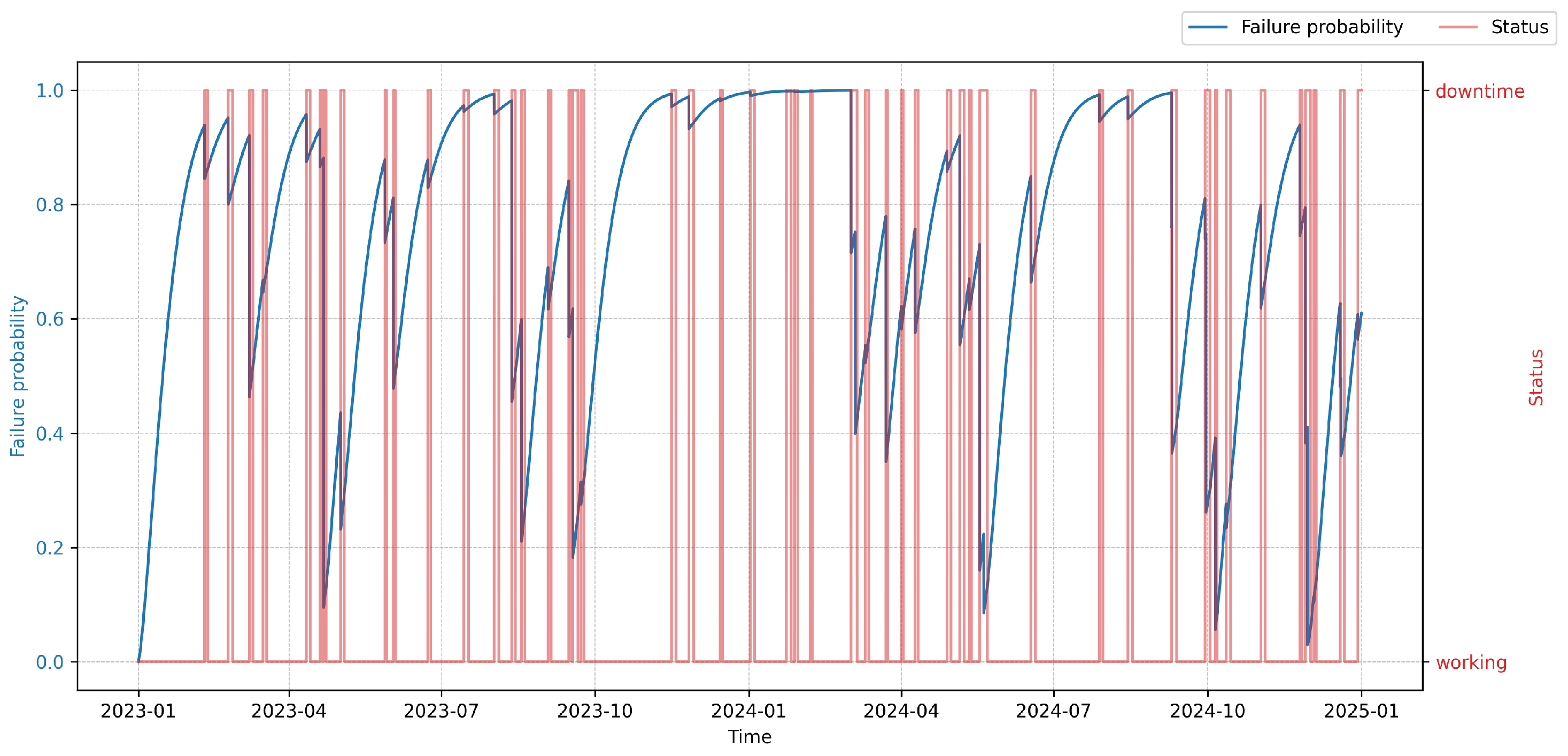

- Stage of RCM data generation without and with the implemented PdM process. In this stage, time series were generated based on the adopted assumptions (the total process duration was set to 5 years, and downtime caused by failures ranged from 24 to 72 h). The data were generated separately for the three press components, taking into account the FTA decomposition in accordance with Formula (24).

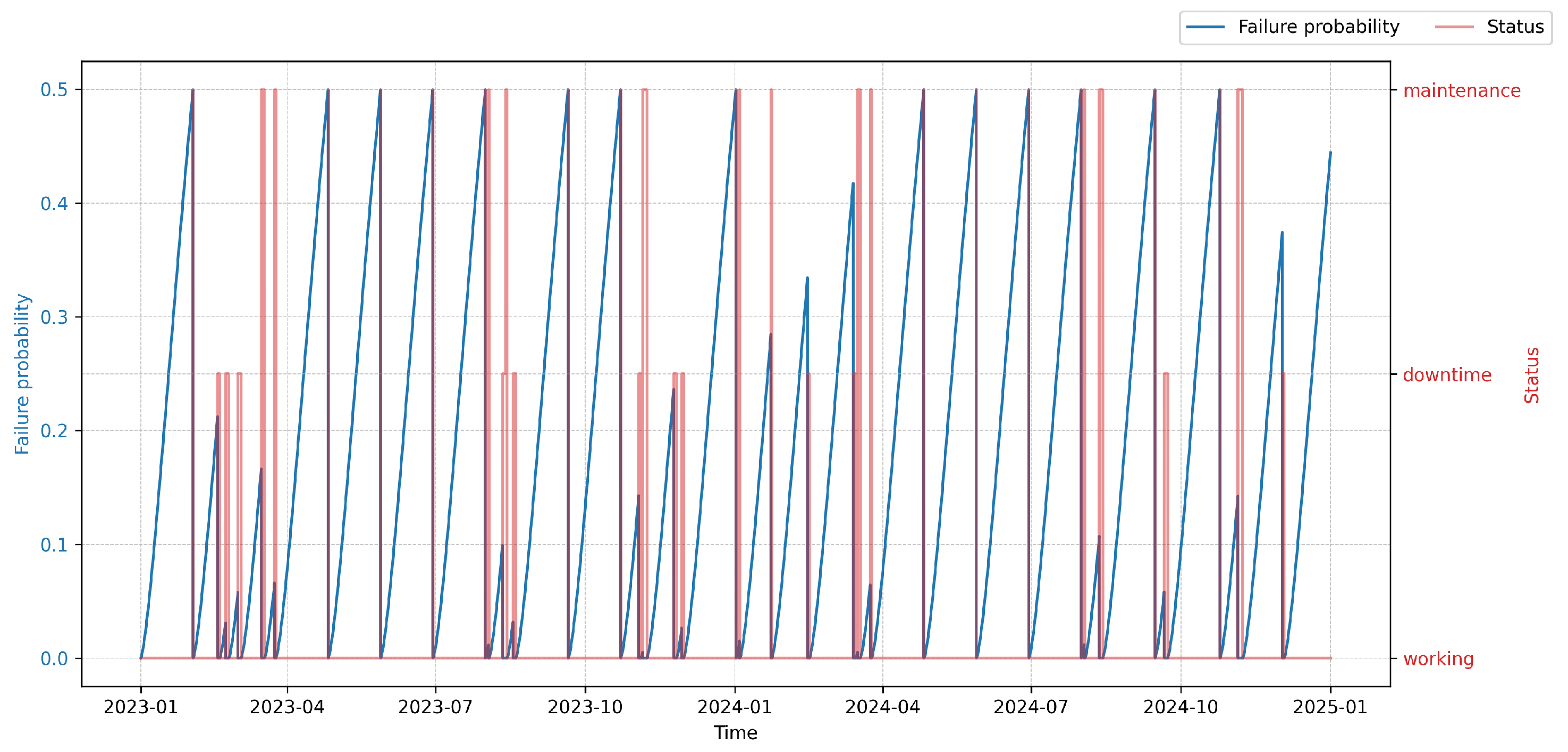

- Stage of CBM data generation without and with the implemented PdM process. In this stage, it was assumed that three process variables were monitored, namely: the press plate temperature, the pressing force, and the RMS value of the controller supply voltage. The variable ranges were adopted according to Table 1. Within the CBM methodology, the time series of the aforementioned variables was generated, taking into account both normal operating conditions and randomly generated anomalies. In the study, anomalies with different temporal characteristics were simulated, i.e., linear, exponential, and sinusoidal.

- Formulation of conclusions.

3. Results and Discussion

3.1. Results for NASA N-CMAPSS Dataset

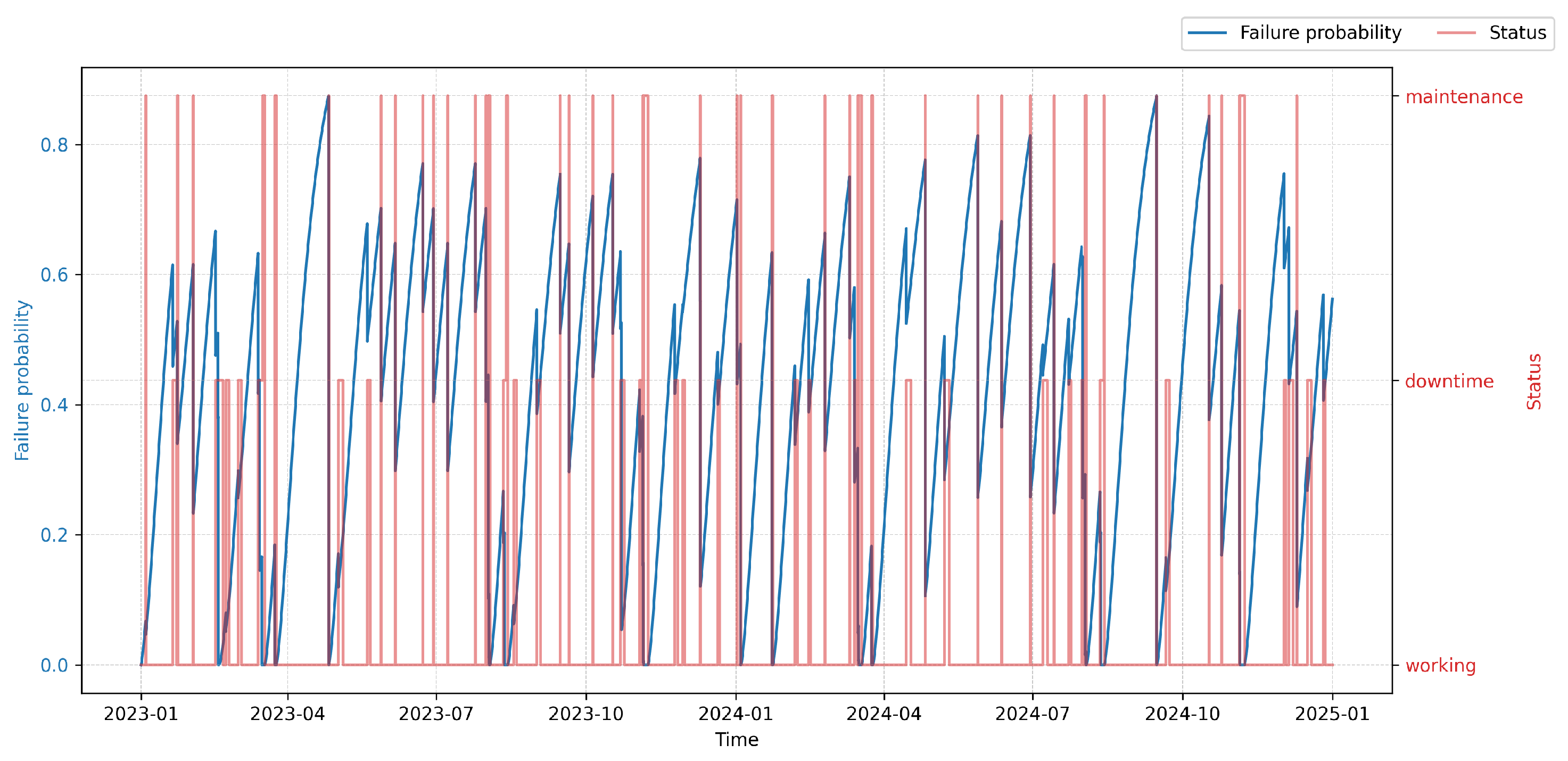

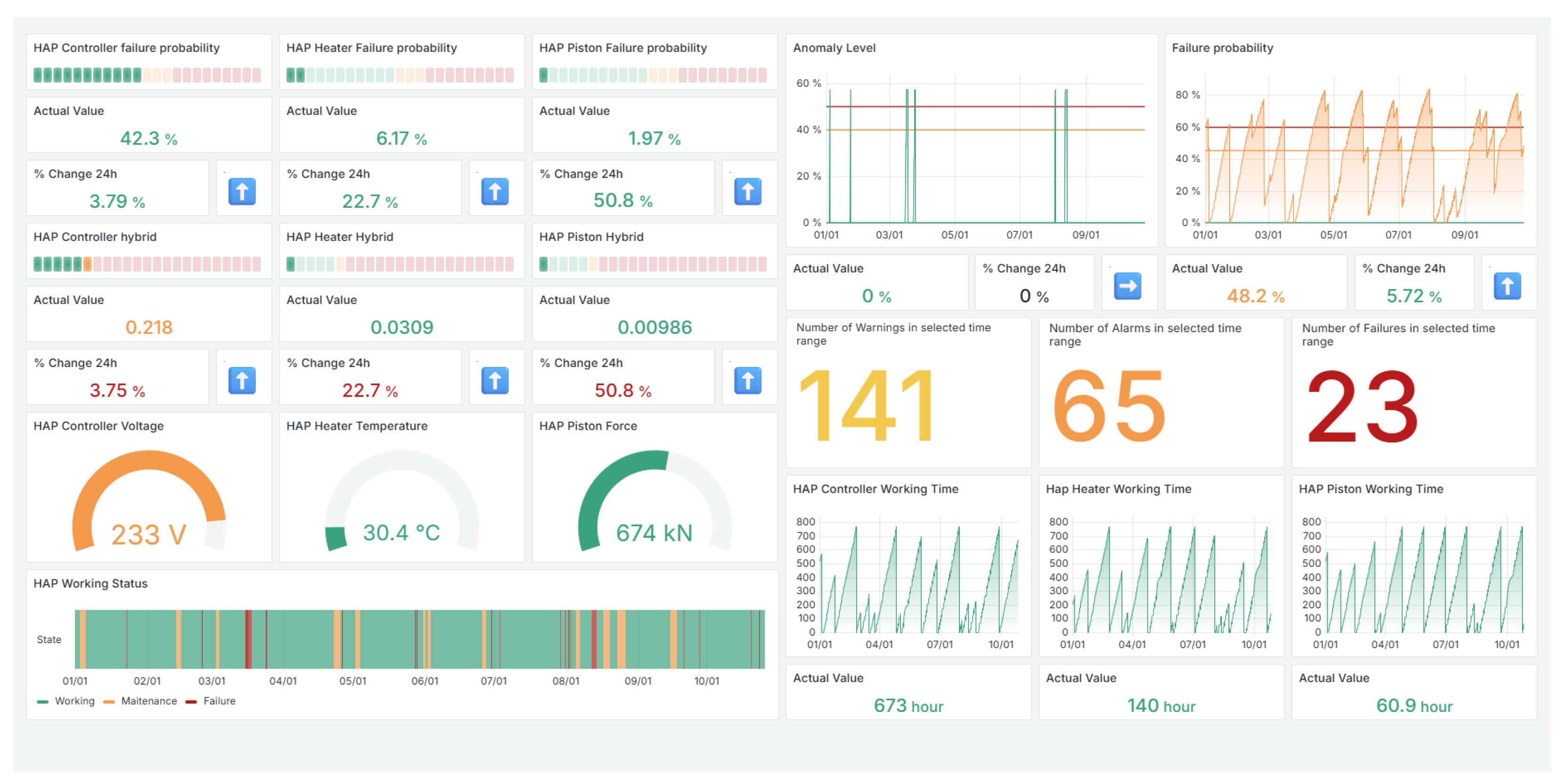

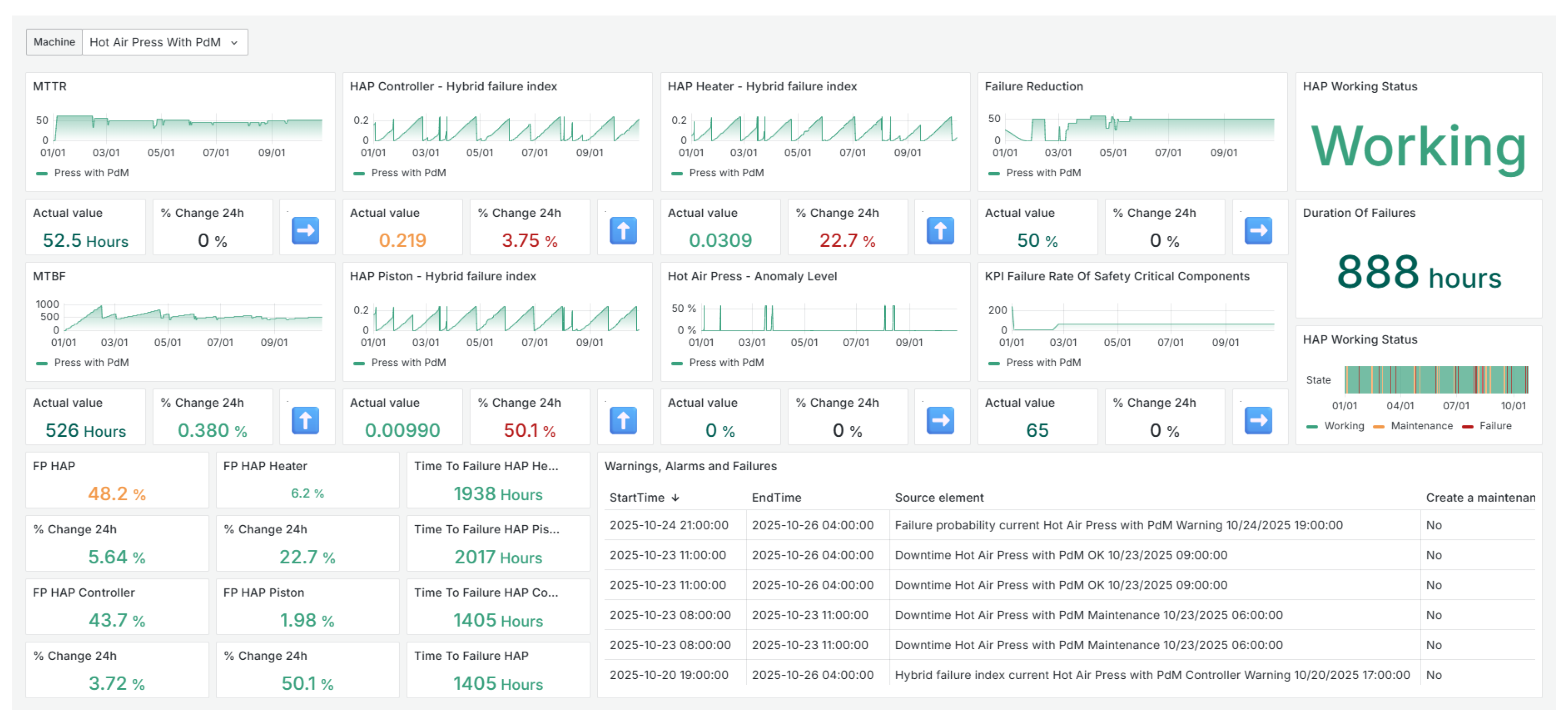

3.2. Results for Smart RDM Dataset

3.3. From Model to Operations: SHMS in the Smart RDM Platform

- (i)

- Data ingestion and harmonization: Time-stamped sensor signals, machine states, and event/maintenance logs are ingested from SCADA/OT and CMMS/ERP connectors into SRDM’s time series store. A harmonization layer aligns sampling rates, resolves missing data, and enforces the asset hierarchy and metadata schema.

- (ii)

- (iii)

- RCM estimation and update: Weibull parameters for each critical component are estimated from maintenance histories and downtime records and periodically re-estimated to incorporate new evidence (e.g., after interventions). The resulting reliability functions provide the probabilistic backbone for medium/long-term degradation.

- (iv)

- Hybrid risk computation and decision engine: At each evaluation tick, SHMS computes (23) using uncertainty-aware weights. The decision engine compares to the threshold and emits actions: advisory alerts for operators, planned-stop recommendations, or autonomous scheduling of maintenance tasks (virtual operator). All actions are versioned and auditable.

- (v)

- Human-in-the-loop visualization and supervision: SRDM dashboards present joint views of , , , estimated time-to-failure , and reliability KPIs (MTBF, MTTR, A, and ), together with 24-h deltas, event counters, and working-state timelines (see Figure 4 and the detailed snapshots in Figure 25, Figure 26 and Figure 27). This supports operator validation, root-cause triage (via feature contributions to distances), and post-event review.

- (vi)

- MLOps, governance, and drift monitoring: Model versions, thresholds, and policies are tracked with full provenance. Data- and concept-drift monitors flag calibration issues (e.g., shifts in or distributions) and trigger re-training or threshold recalibration. All alerts and interventions are logged back to CMMS for closed-loop learning.

3.4. Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AI | Artificial Intelligence |

| Anomaly Level | |

| AM | Autonomous Maintenance |

| CBM | Condition-Based Maintenance |

| CDF | Cumulative Distribution Function |

| EEI | Energy Efficiency Indicator |

| EENS | Expected Energy Not Supplied |

| Failure Probability | |

| FTA | Failure Tree Analysis |

| HAP | Hot Air Press |

| Hybrid Risk Index | |

| IIoT | Industrial IoT |

| IoT | Internet of Things |

| KPI | Key Performance Indicator |

| LSQ | Least Squares Method |

| LSTM | Long Short-Term Memory |

| ML | Machine Learning |

| MLE | Maximum Likelihood Estimation |

| MTBF | Mean Time Between Failures |

| MTTF | Mean Time to Failure |

| OEE | Overall Equipment Effectiveness |

| Optimal Maintenance Point | |

| PdM | Predictive Maintenance |

| PM | Preventive Maintenance |

| PFT | Predictive Failure Timeline |

| RCM | Reliability-Centered Maintenance |

| RUL | Remaining Useful Life |

| SCADA | Supervisory Control and Data Acquisition |

| SHMS | Smart Hybrid Maintenance System |

| SMOTE | Synthetic Minority Oversampling Technique |

| Time to Failure | |

| TPM | Total Productive Maintenance |

| Italicized abbreviations (e.g., AL, FP) denote the key indicators computed by the system presented in this work; this convention applies throughout the manuscript. | |

References

- Do, P.; Hoang, A.; Iung, B.; Vu, H.C. Energy efficiency for condition-based maintenance decision-making: Application to a manufacturing platform. Proc. Inst. Mech. Eng. Part O J. Risk Reliab. 2018, 232, 379–388. [Google Scholar] [CrossRef]

- Nazarychev, A.; Iliev, I.; Manukian, D.; Beloev, H.; Suslov, K.; Beloev, I. Review of Operating Conditions, Diagnostic Methods, and Technical Condition Assessment to Improve Reliability and Develop a Maintenance Strategy for Electrical Equipment. Energies 2025, 18, 5832. [Google Scholar] [CrossRef]

- Nacchia, M.; Fruggiero, F.; Lambiase, A.; Bruton, K. A Systematic Mapping of the Advancing Use of Machine Learning Techniques for Predictive Maintenance in the Manufacturing Sector. Appl. Sci. 2021, 11, 2546. [Google Scholar] [CrossRef]

- Jeon, S.H.; Yoo, S.; Yoo, Y.S.; Lee, I.W. ML- and LSTM-Based Radiator Predictive Maintenance for Energy Saving in Compressed Air Systems. Energies 2024, 17, 1428. [Google Scholar] [CrossRef]

- Yun, J.W.; Choi, S.W.; Lee, E.B. Study on Energy Efficiency and Maintenance Optimization of Run-Out Table in Hot Rolling Mills Using Long Short-Term Memory-Autoencoders. Energies 2025, 18, 2295. [Google Scholar] [CrossRef]

- Dao, C.D.; Kazemtabrizi, B.; Crabtree, C.J.; Tavner, P.J. Integrated condition-based maintenance modelling and optimisation for offshore wind turbines. Wind Energy 2021, 24, 1068–1088. [Google Scholar] [CrossRef]

- Patil, S.S.; Bewoor, A.K.; Kumar, R.; Ahmadi, M.H.; Sharifpur, M.; PraveenKumar, S. Development of Optimized Maintenance Program for a Steam Boiler System Using Reliability-Centered Maintenance Approach. Sustainability 2022, 14, 10073. [Google Scholar] [CrossRef]

- de Carvalho Chrysostomo, G.G.; de Aguiar Vallim, M.V.B.; da Silva, L.S.; Silva, L.A.; de Aguiar Vallim Filho, A.R. A Framework for Big Data Analytical Process and Mapping—BAProM: Description of an Application in an Industrial Environment. Energies 2020, 13, 6014. [Google Scholar] [CrossRef]

- Ayu, K.; Yunusa-Kaltungo, A. A Holistic Framework for Supporting Maintenance and Asset Management Life Cycle Decisions for Power Systems. Energies 2020, 13, 1937. [Google Scholar] [CrossRef]

- Bányai, Á. Energy Consumption-Based Maintenance Policy Optimization. Energies 2021, 14, 5674. [Google Scholar] [CrossRef]

- Ciobotaru, A.; Corches, C.; Gota, D.; Miclea, L. An Explainable Deep Learning-Based Predictive Maintenance Solution for Air Compressor Condition Monitoring. Sensors 2025, 25, 5797. [Google Scholar] [CrossRef]

- Gujrathi, S.M.; Bhosale, K.C. Energy-Efficient Condition-Based Maintenance: A Smart Framework for Predictive Decision-Making in Industry 4.0. J. Inf. Syst. Eng. Manag. 2024, 9. [Google Scholar] [CrossRef]

- Carvalho, T.P.; Soares, F.; Vita, R.; da Piedade Francisco, R.; Basto, J.P.T.V.; Soares, S.G. A systematic literature review of machine learning methods applied to predictive maintenance. Comput. Ind. Eng. 2019, 137, 106024. [Google Scholar] [CrossRef]

- Tsallis, C.; Papageorgas, P.; Piromalis, D.; Munteanu, R.A. Application-Wise Review of Machine Learning-Based Predictive Maintenance: Trends, Challenges, and Future Directions. Appl. Sci. 2025, 15, 4898. [Google Scholar] [CrossRef]

- Mobley, R.K. An Introduction to Predictive Maintenance, 2nd ed.; Butterworth-Heinemann: Boston, MA, USA, 2002. [Google Scholar] [CrossRef]

- Zhu, T.; Ran, Y.; Zhou, X.; Lin, P.; Wen, Y. A Survey of Predictive Maintenance: Systems, Purposes and Approaches. IEEE Commun. Surv. Tutor. 2019, 21, 1–36. [Google Scholar] [CrossRef]

- Achouch, M.; Dimitrova, M.; Ziane, K.; Sattarpanah Karganroudi, S.; Dhouib, R.; Ibrahim, H.; Adda, M. On Predictive Maintenance in Industry 4.0: Overview, Models, and Challenges. Appl. Sci. 2022, 12, 8081. [Google Scholar] [CrossRef]

- Chen, C.; Li, M.; Shi, J.; Yue, D.; Shi, G.; Bo, C. Constructing high-quality health indicators from multi-source sensor data for predictive maintenance applications. Expert Syst. Appl. 2025, 285, 127870. [Google Scholar] [CrossRef]

- Bublil, T.; Cohen, R.; Kenett, R.S.; Bortman, J. Machine Health Indicators and Digital Twins. Sensors 2025, 25, 2246. [Google Scholar] [CrossRef]

- Lee, J.; Bagheri, B.; Kao, H.A. A cyber-physical systems architecture for industry 4.0-based manufacturing systems. Manuf. Lett. 2015, 3, 18–23. [Google Scholar] [CrossRef]

- Xu, D.; Tian, Y. A Comprehensive Survey of Clustering Algorithms. Ann. Data Sci. 2015, 2, 165–193. [Google Scholar] [CrossRef]

- Dudzik, S.; Szeląg, P.; Gic-Grusza, G.; Pilc, D. Modeling of the Predictive Maintenance Process Using a Hybrid Risk Index. In Proceedings of the 16th Scientific Conference on Forecasting in Power Engineering: Forecasting, Optimization and Modeling in the Energy Sector, Złoty Potok near Częstochowa, Poland, 24–26 September 2025. (In Polish). [Google Scholar]

- Lei, Y.; Li, N.; Guo, L.; Li, N.; Yan, T.; Lin, J. Machinery health prognostics: A systematic review from data acquisition to RUL prediction. Mech. Syst. Signal Process. 2018, 104, 799–836. [Google Scholar] [CrossRef]

- Zonta, D.; Migliorino, P.; Selleri, A.; Valeri, E.; Marchiondelli, A.; Tonelli, D.; Bolognani, D.; Debiasi, E.; Bonelli, A.; Rossi, F. Structural Health Monitoring Based on Acoustic Emissions. Sensors 2020, 20, 7272. [Google Scholar] [CrossRef] [PubMed]

- Nakajima, S. Introduction to TPM; Productivity Press: Cambridge, MA, USA, 1988. [Google Scholar]

- Bamber, C.; Castka, P.; Sharp, J.; Motara, Y. Cross-functional team working for overall equipment effectiveness (OEE). J. Qual. Maint. Eng. 2003, 9, 223–238. [Google Scholar] [CrossRef]

- Almashaqbeh, S.; Munive Hernandez, J. Evaluation and Improvement of a Plastic Production System Using Integrated OEE Methodology: A Case Study. Manag. Syst. Prod. Eng. 2024, 32, 450–463. [Google Scholar] [CrossRef]

- Anvari, F.; Edwards, R.; Starr, A. Evaluation of overall equipment effectiveness based on market. J. Qual. Maint. Eng. 2010, 16, 256–270. [Google Scholar] [CrossRef]

- Mouhib, Z.; Gallab, M.; Merzouk, S.; Aziz, S.; Elbhiri, B. Towards a generic framework of OEE monitoring for driving effectiveness in digitalization era. Procedia Comput. Sci. 2024, 232, 2508–2520. [Google Scholar] [CrossRef]

- Prasetyawan, Y.; Rachmayanti, I. Proposing predictive maintenance strategy to increase OEE through system upgrade scenarios and AHP. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1072, 012031. [Google Scholar] [CrossRef]

- Brauer, D.; Brauer, G. Reliability-Centered Maintenance. Reliab. IEEE Trans. 1987, R-36, 17–24. [Google Scholar] [CrossRef]

- Geisbush, J.; Ariaratnam, S.T. Reliability centered maintenance (RCM): Literature review of current industry state of practice. J. Qual. Maint. Eng. 2022, 29, 313–337. [Google Scholar] [CrossRef]

- Wu, J. Cluster Analysis and K-means Clustering: An Introduction. In Advances in K-Means Clustering; Springer Theses; Springer: Berlin/Heidelberg, Germany, 2012. [Google Scholar] [CrossRef]

- Alshahrani, N. Machine Learning Approaches for Predictive Maintenance in Industrial Operations. In Proceedings of the 2024 IEEE 16th International Conference on Computational Intelligence and Communication Networks (CICN), Indore, India, 22–23 December 2024; pp. 365–372. [Google Scholar] [CrossRef]

- Ilawi, L.M.; Yafooz, W.M.S. Data Clustering Techniques and Methods: A Comprehensive Literature Review. Int. J. Contemp. Comput. Res. 2017, 1, 30–36. [Google Scholar]

- Kumar, K. A fast DBSCAN clustering algorithm by accelerating neighbor searching using Groups method. Pattern Recognit. 2016, 58, 39–48. [Google Scholar] [CrossRef]

- Chang, M.; Huang, X.; Coolen, F.P.; Coolen-Maturi, T. New reliability model for complex systems based on stochastic processes and survival signature. Eur. J. Oper. Res. 2023, 309, 1349–1364. [Google Scholar] [CrossRef]

- Alshenawy, R.; Feroze, N.; Tahir, U.; Al-alwan, A.; Ahmed, H.; Ali, R. On suitability of modified Weibull extension distribution in modeling product lifetimes and reliability. Adv. Mech. Eng. 2022, 14, 168781322211366. [Google Scholar] [CrossRef]

- Suhas, M.; Abisset-Chavanne, E.; Rey, P.A. Cooperative Hybrid Modelling and Dimensionality Reduction for a Failure Monitoring Application in Industrial Systems. Sensors 2025, 25, 1952. [Google Scholar] [CrossRef] [PubMed]

- Fan, L.; Hu, Z.; Ling, Q.; Li, H.; Qi, H.; Chen, H. Reliability analysis of computed tomography equipment using the q-Weibull distribution. Eng. Rep. 2023, 5, e12613. [Google Scholar] [CrossRef]

- Lu, M.W.; Wang, C.J. Weibull Data Analysis with Few or No Failures. In Recent Advances in Reliability and Quality in Design; Pham, H., Ed.; Springer: London, UK, 2008; pp. 201–210. [Google Scholar] [CrossRef]

- Lai, C.D.; Murthy, D.; Xie, M. Weibull Distributions and Their Applications. In Springer Handbook of Engineering Statistics; Springer: Berlin/Heidelberg, Germany, 2006; Chapter 3; pp. 63–78. [Google Scholar] [CrossRef]

- Basheer, A. Alpha power inverse Weibull distribution with reliability application. J. Taibah Univ. Sci. 2019, 13, 423–432. [Google Scholar] [CrossRef]

- Roohanizadeh, Z.; Baloui Jamkhaneh, E.; Deiri, E. Parameters and reliability estimation for the weibull distribution based on intuitionistic fuzzy lifetime data. Complex Intell. Syst. 2022, 8, 4881–4896. [Google Scholar] [CrossRef]

- Nelson, W. Applied Life Data Analysis; John Wiley & Sons: New York, NY, USA, 1982. [Google Scholar]

- Weibull, W. A Statistical Distribution Function of Wide Applicability. J. Appl. Mech. 1951, 18, 293–297. [Google Scholar] [CrossRef]

- Modarres, M.; Kaminskiy, M.; Krivtsov, V. Reliability Engineering and Risk Analysis: A Practical Guide, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Meeker, W.Q.; Escobar, L.A. Statistical Methods for Reliability Data; John Wiley & Sons: New York, NY, USA, 1998. [Google Scholar]

- Lawless, J.F. Statistical Models and Methods for Lifetime Data, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2003. [Google Scholar]

- Jokiel-Rokita, A.; Piątek, S. Estimation of parameters and quantiles of the Weibull distribution. Stat. Pap. 2024, 65, 1–18. [Google Scholar] [CrossRef]

- D’Ambrosio, A.; Iorio, C.; Staiano, M.; Siciliano, R. Median constrained bucket order rank aggregation. Comput. Stat. 2019, 34, 787–802. [Google Scholar] [CrossRef]

- Kececioglu, D. Reliability & Life Testing Handbook; Prentice Hall: Englewood Cliffs, NJ, USA, 1993; Volume 2. [Google Scholar]

- ISO 22400-2:2014; Automation Systems and Integration—Key Performance Indicators (KPIs) for Manufacturing Operations Management—Part 2: Definitions and Descriptions. International Organization for Standardization: Geneva, Switzerland, 2014.

- ISO 14224:2016; Petroleum, Petrochemical and Natural Gas Industries—Collection and Exchange of Reliability and Maintenance Data for Equipment. International Organization for Standardization: Geneva, Switzerland, 2016.

- Brink, H.; Krych, A.; Cardenas, O.R.; Tiwari, S. Establishing the Right Analytics-Based Maintenance Strategy. 2021. Available online: https://www.mckinsey.com/capabilities/operations/our-insights/establishing-the-right-analytics-based-maintenance-strategy (accessed on 12 August 2025).

- Molęda, M.; Małysiak-Mrozek, B.; Ding, W.; Sunderam, V.; Mrozek, D. From Corrective to Predictive Maintenance—A Review of Maintenance Approaches for the Industrial Internet of Things. Sensors 2023, 23, 5970. [Google Scholar] [CrossRef] [PubMed]

- Ahuja, A.; Gupta, M. Optimizing Predictive Maintenance with Machine Learning And IoT: A Business Strategy For Reducing Downtime And Operational Costs. J. Emerg. Technol. Innov. Res. 2024, 11, 286–292. [Google Scholar] [CrossRef]

- Sisode, M.; Devare, M. A Review on Machine Learning Techniques for Predictive Maintenance in Industry 4.0. In Proceedings of the International Conference on Applications of Machine Intelligence and Data Analytics (ICAMIDA 2022); Atlantis Press: Dordrecht, The Netherlands, 2023; pp. 774–783. [Google Scholar] [CrossRef]

- Oyewole, G.; Thopil, G. Data clustering: Application and trends. Artif. Intell. Rev. 2022, 56, 6439–6475. [Google Scholar] [CrossRef] [PubMed]

- Suyal, M.; Sharma, S. A Review on Analysis of K-Means Clustering Machine Learning Algorithm based on Unsupervised Learning. J. Artif. Intell. Syst. 2024, 6, 85–95. [Google Scholar] [CrossRef]

- Sinaga, K.; Yang, M.S. Unsupervised K-Means Clustering Algorithm. IEEE Access 2020, 8, 80716–80727. [Google Scholar] [CrossRef]

- Nielsen, F. Hierarchical Clustering. In Introduction to HPC with MPI for Data Science; Springer International Publishing: Cham, Switzerland, 2016; pp. 195–211. [Google Scholar] [CrossRef]

- Ran, X.; Xi, Y.; Lu, Y.; Wang, X.; Lu, Z. Comprehensive survey on hierarchical clustering algorithms and the recent developments. Artif. Intell. Rev. 2022, 56, 8219–8264. [Google Scholar] [CrossRef]

- Schubert, E.; Sander, J.; Ester, M.; Kriegel, H.; Xu, X. DBSCAN revisited, revisited: Why and how you should (still) use DBSCAN. ACM Trans. Database Syst. 2017, 42, 19. [Google Scholar] [CrossRef]

- Chen, Y.; Ruys, W.; Biros, G. KNN-DBSCAN: A DBSCAN in high dimensions. ACM Trans. Parallel Comput. 2024, 12, 3. [Google Scholar] [CrossRef]

- Wang, X.; Qian, B.; Davidson, I. On Constrained Spectral Clustering and Its Applications. Data Min. Knowl. Discov. 2012, 28, 1–30. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, H.; Yang, C.; Li, B.; Zhao, X.; Long, Y. Spectral clustering with scale fairness constraints. In Knowledge and Information Systems; Springer Nature: New York, NY, USA, 2024; pp. 1–28. [Google Scholar] [CrossRef]

- Legendre, P.; Legendre, L. Numerical Ecology, 3rd english ed.; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Garcia, J.; Rios-Colque, L.; Peña, A.; Rojas, L. Condition Monitoring and Predictive Maintenance in Industrial Equipment: An NLP-Assisted Review of Signal Processing, Hybrid Models, and Implementation Challenges. Appl. Sci. 2025, 15, 5465. [Google Scholar] [CrossRef]

- Eti, M.C.; Ogaji, S.O.T.; Probert, S.D. Development and Implementation of Preventive-Maintenance Practices in Nigerian Industries. Appl. Energy 2006, 83, 1163–1179. [Google Scholar] [CrossRef]

- Kasprowicz, R.; Schulz, C. Availability-based Payback Method for Energy Efficiency Measures. Procedia CIRP 2015, 29, 710–715. [Google Scholar] [CrossRef]

- Caballé, N.C.; Castro, I.T. Assessment of the Maintenance Cost and Analysis of Availability Measures in a Finite Life Cycle for a System Subject to Competing Failures. OR Spectr. 2019, 41, 255–290. [Google Scholar] [CrossRef]

- Arias Chao, M.; Kulkarni, C.; Goebel, K.; Fink, O. Aircraft Engine Run-to-Failure Dataset under Real Flight Conditions for Prognostics and Diagnostics. Data 2021, 6, 5. [Google Scholar] [CrossRef]

- Arias Chao, M.; Kulkarni, C.; Goebel, K.; Fink, O. Fusing physics-based and deep learning models for prognostics. Reliab. Eng. Syst. Saf. 2022, 217, 107961. [Google Scholar] [CrossRef]

- Chawla, N.V.; Bowyer, K.W.; Hall, L.O.; Kegelmeyer, W.P. SMOTE: Synthetic minority over-sampling technique. J. Artif. Intell. Res. 2002, 16, 321–357. [Google Scholar] [CrossRef]

- Frederick, D.; DeCastro, J.; Litt, J. User’s Guide for the Commercial Modular Aero-Propulsion System Simulation (C-MAPSS); Technical Report 2007–215026, NASA Technical Manuscript; NASA: Washington, DC, USA, 2007. [Google Scholar]

- Mo, H.; Iacca, G. Multi-Objective Optimization of Extreme Learning Machine for Remaining Useful Life Prediction. In Proceedings of the EvoApplications, Part of EvoStar 2022, Madrid, Spain, 20–22 April 2022. [Google Scholar]

| Variable | Normal Range | Warning Range | Critical Range |

|---|---|---|---|

| Press plate temperature | 10–225 °C | 225–250 °C | >250 °C |

| Pressing force | 40–850 kN | 850–1000 kN | >1000 kN |

| RMS supply voltage | 220–240 V | 180–200 V | <200 V |

| MTBF [h] | MTTR [h] | A [%] | N | ||

|---|---|---|---|---|---|

| Without maintenance | 224.65 | 37.89 | 86.2 | 20 | − |

| With maintenance | 513.88 | 11.33 | 96.6 | 8 | 60 |

| MTBF [h] | MTTR [h] | A [%] | N | ||

|---|---|---|---|---|---|

| Without maintenance | 216.6 | 69.2 | 63.0 | 92 | − |

| With maintenance | 475.5 | 51.7 | 90.0 | 49 | 46.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Dudzik, S.; Gic-Grusza, G.; Pilc, D.; Szeląg, P. Smart Hybrid Maintenance as a Pathway to Energy-Efficient Manufacturing. Energies 2026, 19, 132. https://doi.org/10.3390/en19010132

Dudzik S, Gic-Grusza G, Pilc D, Szeląg P. Smart Hybrid Maintenance as a Pathway to Energy-Efficient Manufacturing. Energies. 2026; 19(1):132. https://doi.org/10.3390/en19010132

Chicago/Turabian StyleDudzik, Sebastian, Gabriela Gic-Grusza, Dawid Pilc, and Piotr Szeląg. 2026. "Smart Hybrid Maintenance as a Pathway to Energy-Efficient Manufacturing" Energies 19, no. 1: 132. https://doi.org/10.3390/en19010132

APA StyleDudzik, S., Gic-Grusza, G., Pilc, D., & Szeląg, P. (2026). Smart Hybrid Maintenance as a Pathway to Energy-Efficient Manufacturing. Energies, 19(1), 132. https://doi.org/10.3390/en19010132