Abstract

This paper proposes a half-bridge parallel dual LLC resonant converter with wide output voltage range. The proposed converter uses a conventional parallel double half-bridge LLC resonant converter. On the primary side of the converter, only one of the two half bridges is used to control the two resonant loops. Due to the resonance of the converter, the active switches can achieve ZVS (zero-voltage switching), and the rectifier diode can also achieve ZCS (zero-current switching), and thus the switching loss is reduced. The current stress can be reduced and power can be distributed on both of the primary side and/or the secondary side. A voltage regulation circuit is designed on the secondary side to achieve the function of wide output voltage. The operation and analysis of the proposed converter are described in detail. The experiments were carried out on a circuit prototype, which is a converter with DC input voltage of 384 V and output voltage of 24–40 V and operating at a switching frequency of 107 kHz. The feasibility and performance of the proposed converter were verified by simulation and experimental results.

1. Introduction

DC–DC converters, such as the buck, boost, flyback, and forward converters, are widely used in low- to medium-power applications due to their simple topology and low cost [1,2]. However, the system power continues to rise, and even in high-power applications, voltage spikes may occur during switching due to the freewheeling problem caused by the inductors of the power converter. The higher the system power, the greater the voltage spike. Thus, a half-bridge isolated LLC converter appears to adapt to higher-output-power applications [3].

The traditional half-bridge LLC converter is operated by two power switches on the primary side, and a sinusoidal wave current is generated in the resonant circuit by complementary switching. The voltage gain is determined by the converter and the transformer. Thus, a stable output voltage is obtained by adjusting the switching frequency according to the input voltage.

The resonant current is a sinusoidal wave provided that the switches can be turned on at zero voltage. If the frequency is adjusted properly, the rectifier on the secondary side can be turned off at zero current. Therefore, the switching loss is significantly reduced and the efficiency is improved.

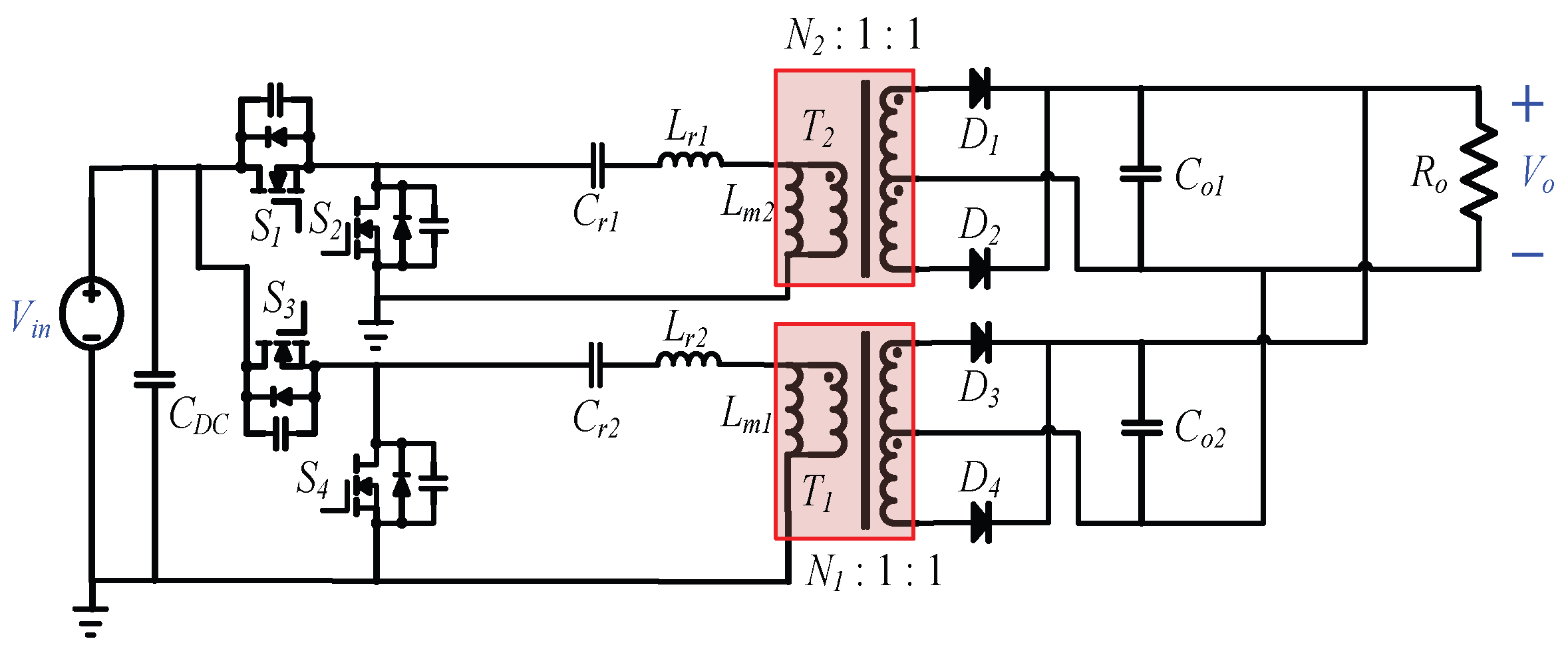

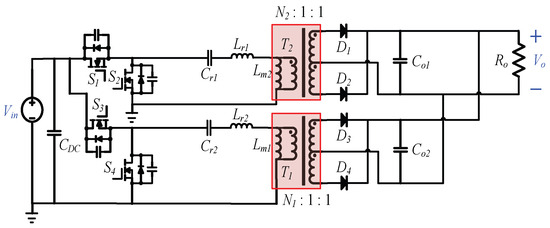

In [4], a converter with two parallel half-bridge resonant circuits was proposed, as shown in Figure 1. The proposed converter can improve the output power of the converter and reduce the power stress of the components. Several different parallel topologies have been reported. The use of fly capacitors to equalize the resonant current of a parallel two-phase circuit was proposed in [5]. However, the equalization performance was poor. In [6,7,8,9,10,11], two half bridges were connected in parallel on the primary side and the outputs in series on the secondary side. In [12], a TL DC–DC converter using phase-shift control was studied. Nevertheless, the circulating current problem cannot be ignored.

Figure 1.

Traditional parallel dual half-bridge LLC resonant converter.

In [13], a converter with a six-switch dual active bridge and a series transformer, which connected series on the primary side and the secondary side, was proposed. However, it can only reduce the voltage stress of upper and lower switches.

In the converters of [14,15], the magnetizing inductance of the transformer can be changed to reduce the conduction loss. In [16,17,18,19,20,21,22], the hybrid bridge structure of the primary side or topology morphing method was applied on an LLC converter. However, the current stress on the secondary side could not be effectively reduced.

In [23], the converter combined an interleaved boost circuit and a full-bridge resonant circuit on the primary side to narrow the voltage gain range and reduce the voltage stress of the switch. However, this made the circuit complicated, and the power stress on the secondary side could not be further reduced. In [24], a traditional half-bridge LLC converter was used and PFM and APWM methods were adopted for the switching operation. Although this was able to narrow the switching frequency range, the zero-voltage switching (ZVS) condition sometimes disappeared.

This paper proposes an LLC converter with parallel dual half-bridge resonant circuits. The dual circuits are used to distribute power to reduce the power stress of components and improve the power capacity of the proposed converter. The proposed converter is consisted of an LLC part and buck–boost part. The LLC part operates in a DCX state and the switching frequency is fixed at a resonant frequency. Moreover, the primary side switches and the secondary side diodes of the LLC part can satisfy the conditions of ZVS and zero-current switching (ZCS), respectively. The buck–boost part can achieve a wide output voltage range with pulse-width modulation (PWM).

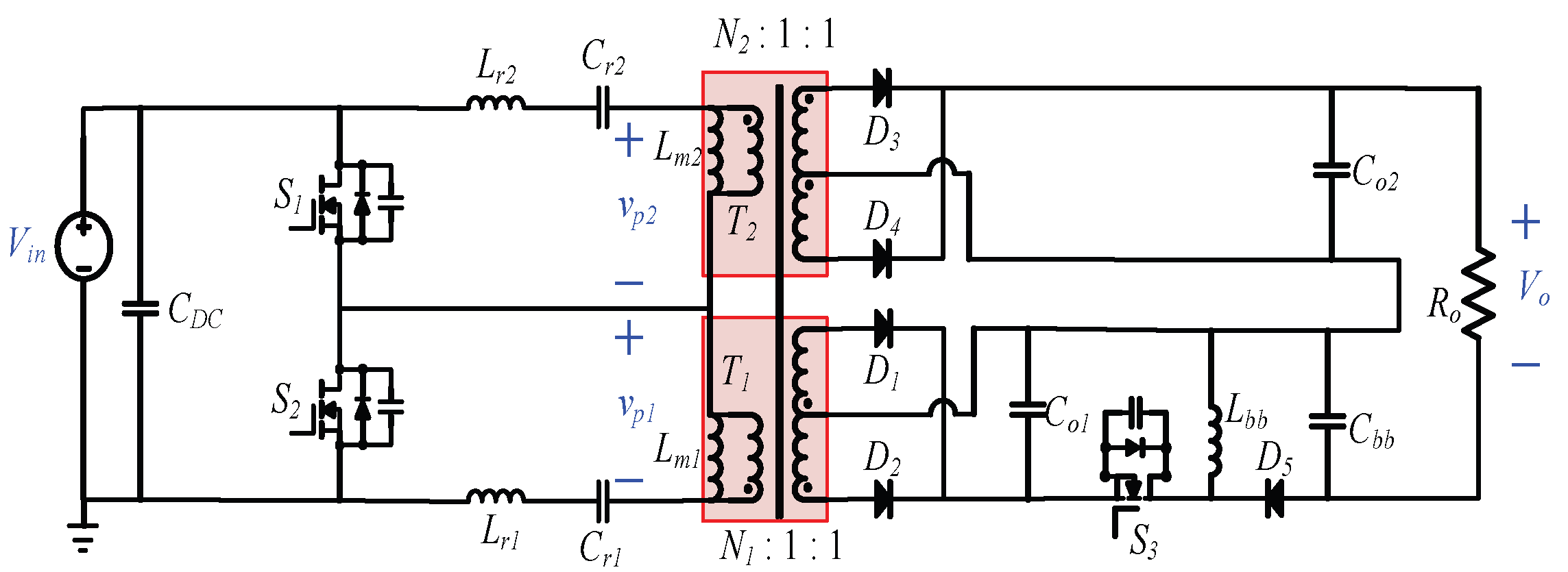

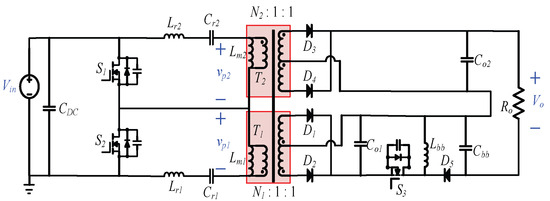

Compared with the traditional parallel dual half-bridge resonant converter, the proposed converter shown in Figure 2 saves two active switches. Thus, the additional conduction loss and switching loss caused by the two switches are reduced. The design of magnetic components becomes simple due to fixed-frequency operation. An experimental prototype with input voltage of 384 V, output voltage of 24–40 V, and power of 80 W was established and tested. The experimental results are provided to verify the system’s performance.

Figure 2.

The proposed dual LLC converter.

2. Principle of Operation

A parallel dual half-bridge resonant LLC converter with a wide range of output voltages, as shown in Figure 2, is proposed in this paper. The primary side of the proposed converter consists of two parallel half-bridge structures with shared switches S1 and S2. The LLC resonant tanks are constructed by the resonant elements Lr1, Lr2, Cr1, and Cr2 and the magnetizing inductances of transformers Lm1 and Lm2. Center-tapped transformers are used as T1 and T2. S3, Lbb, and D5 are combined to form the buck–boost part. The buck–boost part is operated in continuous conduction mode (CCM) and regulates the output voltage of the proposed converter with pulse-width modulation (PWM). The switching frequency of S3 is not equal to the switching frequencies of S1 and S2.

In order to simplify the analysis of the proposed converter, the following assumptions will be considered to describe the converter operation and steady-state analysis.

- The duty cycle of switches S1 and S2 in the primary side is fixed at 0.45.

- All switches have parasitic capacitances and bypass diodes, and transformers have certain magnetizing inductance, regardless of leakage inductance.

- The primary side switches S1 and S2 have a dead time.

- Each output capacitor in the secondary side is large enough to keep the output voltage constant.

- All capacitors, inductors, and diodes are ideal components.

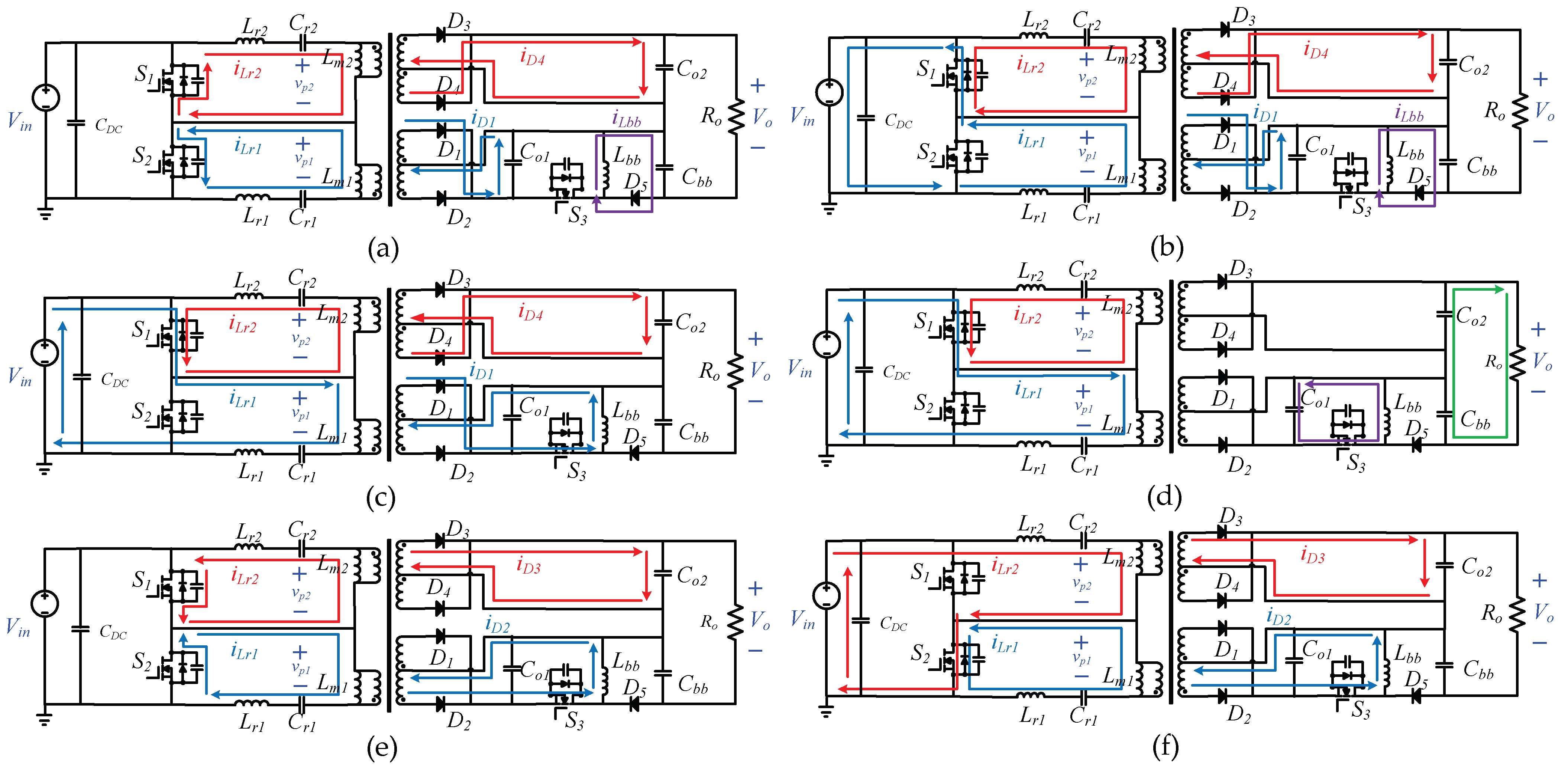

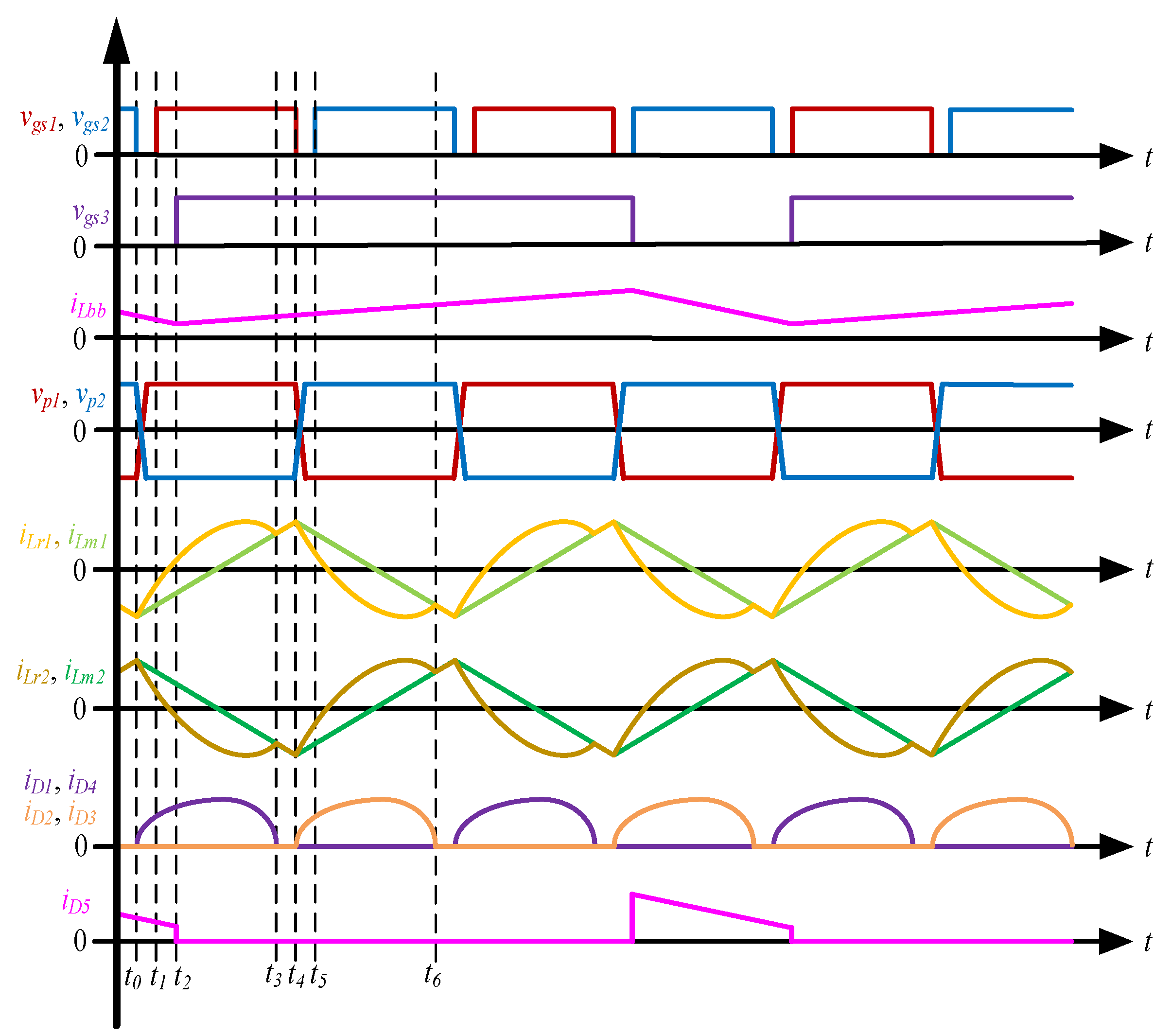

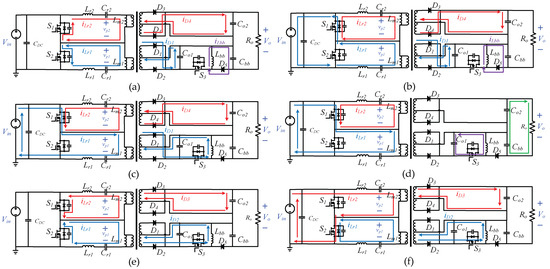

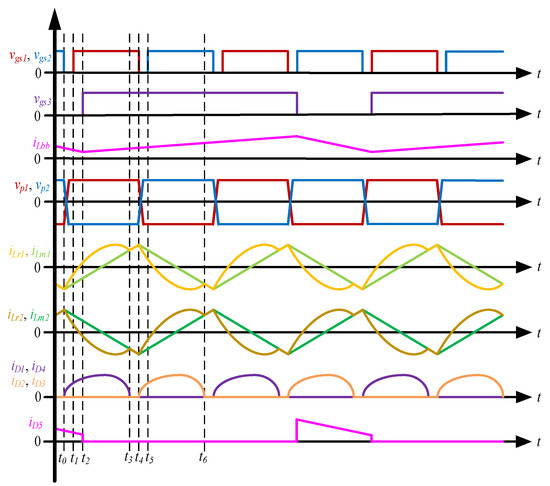

Based on the above assumptions, there are six modes during one period of the operation of the proposed converter. The operation modes and key waveforms of the converter are shown in Figure 3 and Figure 4, respectively.

Figure 3.

Operation of the proposed converter: (a) mode 1, (b) mode 2, (c) mode 3, (d) mode 4, (e) mode 5, and (f) mode 6.

Figure 4.

The key waveform of the proposed converter.

2.1. Operation Principle

There are six modes in one period of the converter operation.

Mode 1 [t0–t1]: As shown in Figure 3a, at t = t0, S2 is turned off, D1 and D4 turn into conduction mode, and the converter enters dead time. At this time, the resonant current iLr1 is negative and iLr2 is positive, and thus the parasitic capacitance of S2 (Coss2) begins to charge until it reaches Vin and then S2 turns off, and the parasitic capacitance of S1 (Coss1) begins to discharge. S3 remains turned off and Lbb continually releases energy to load through D5. Since the magnetizing inductance does not participate in the resonance, the magnetizing current of Lm1 and Lm2 rises and falls linearly, respectively. This mode ends when Vcoss2 is charged to Vin and Vcoss1 is discharged to 0 V.

Mode 2 [t1–t2]: As shown in Figure 3b, at t = t1, S1 is turned on with ZVS. iLm1 and iLm2 are increasing and decreasing, respectively, in this mode. S2 is completely turned off. At this time, due to the freewheeling of the resonant currents iLr1 and iLr2, they flow through S1. The resonant current iLr1 rises, and iLr2 falls as the sinusoidal waveform. The energy is delivered to the load through D1 and D5.

Mode 3 [t2–t3]: As shown in Figure 3c, at t = t2, S3 turns on, Lbb stores energy through D1, and the current of D5 is decreased to zero. At this time, the resonant current iLr1 begins to turn into a positive current, and iLr2 begins to turn into a negative current. This mode ends when iLr1 is equal to iLm1 and iLm2 is equal to iLr2.

Mode 4 [t3–t4]: As shown in Figure 3d, at t = t3, D1 and D4 are turned off with ZCS. Since the magnetizing inductances Lm1 and Lm2 represent part of the resonance with Lr1, Cr1, Lr2, and Cr2, iLr1 is the same as iLm1 and the difference between iLm2 and iLr2 is zero. Vin cannot deliver energy to load through D1 or D4 during this mode. iLbb increases continually due to Co1 supplying energy to Lbb, while Co2 and Cbb provide energy to the load. When S1 is turned off, this mode ends and enters the negative cycle of operation of the proposed converter.

Mode 5 [t4–t5]: As shown in Figure 3e, at t = t4, S1 is turned off, D2 and D3 are conducted, and the converter enters dead time. Vin is delivering energy to load and Lbb through D2 and D3. At this time, the resonant current iLr1 is positive and iLr2 is negative, and thus the parasitic capacitor of S1 starts to charge until it reaches Vin and the parasitic capacitor of S2 begins to discharge. This mode ends when Vcoss2 is discharged to 0 V and Vcoss1 is charged to Vin.

Mode 6 [t5–t6]: As shown in Figure 3f, at t = t5, S2 turns on with ZVS. At this time, the resonant current iLr1 begins to turn into a negative current and iLr2 begins to turn into a positive current. The input energy is sent to the load through D3. After the end of mode 6, iLr1 is equal to iLm1 and iLm2 is equal to iLr2.

2.2. Parameter Calculation

The input voltage of the proposed converter is 384 V, the output voltage is from 24 V to 40 V, the maximum output power is 80 W, and the switching frequency is 107 kHz. Since the output voltage is determined by the buck–boost circuit on the secondary side, the output of the LLC resonant tank is 12 V.

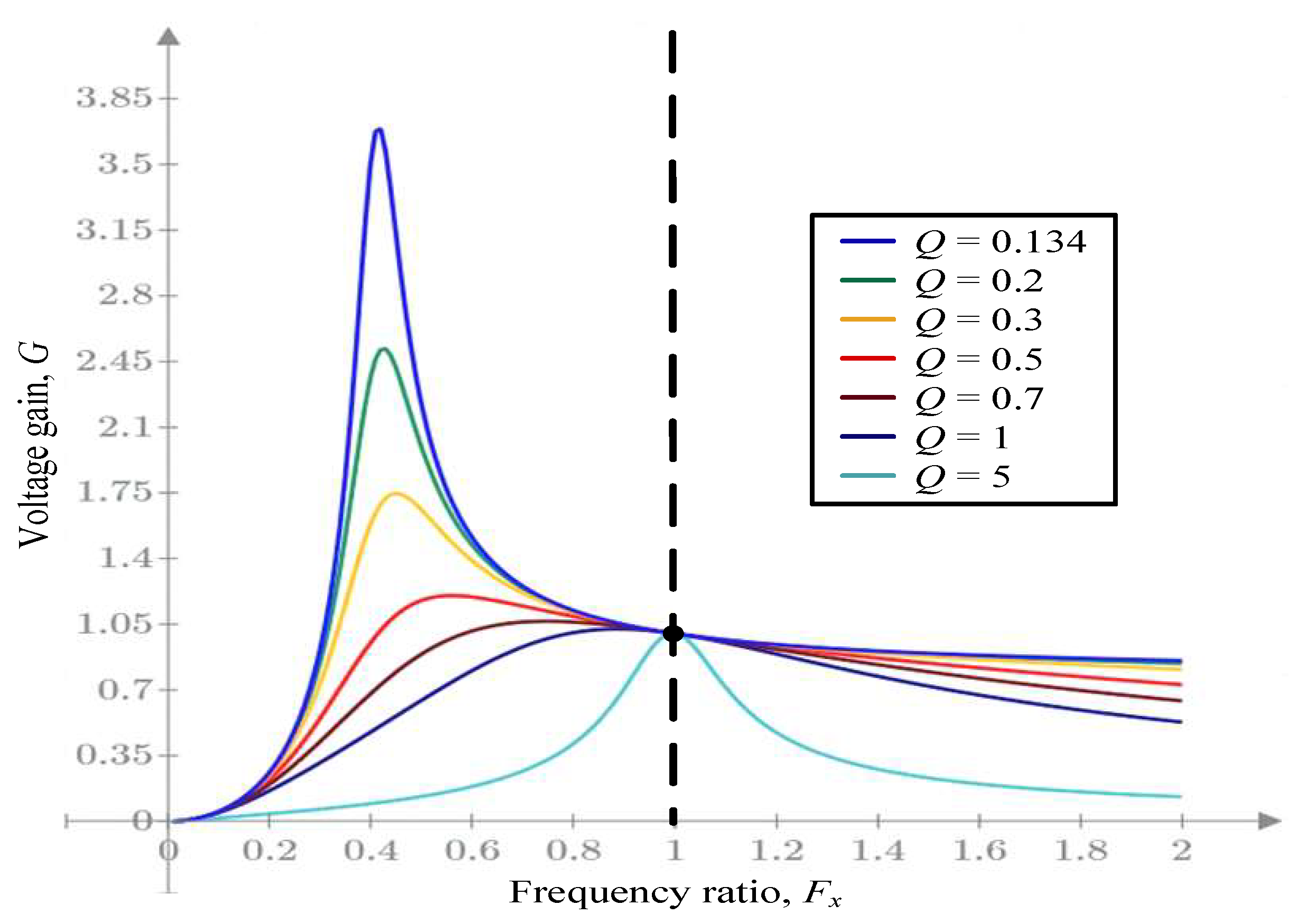

The voltage gain of the LLC resonant circuit is obtained from the equivalent impedance of the circuit, and the formula is expressed as follows.

If the gain G is 1, the turn ratio is 16 from (1), and Fx is the frequency ratio. In order to keep the gain G at 1, the resonance frequency selected is 107 kHz, which is the same as the switching frequency.

The resonant frequency can be obtained from Equation (3). Since 107 kHz is selected as the resonant frequency, the resonant inductor and resonant capacitor can be obtained. Thus, the resonant inductance is 81.04μH and the resonant capacitance is 27.3 nF.

In addition, m is the inductance ratio, which is designed to be 11 and makes the ratio of Lm/Lr = 10. The larger the inductance ratio, the smaller the resonant inductance value can be, thereby reducing the volume and loss of the resonant inductance.

The ratio cannot be too large: otherwise, the leakage inductance of the transformer may be greater than the resonant inductance, resulting in a different circuit from the original design.

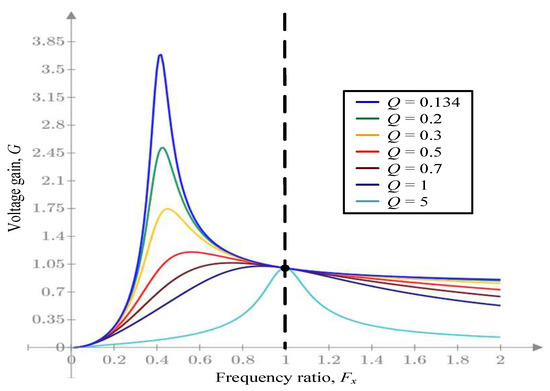

Q is the quality factor for the circuit. In order to keep a stable current gain on the secondary side, the quality factor selected is 0.134. This may make the voltage gain curve slightly steep and the range of variation wider than usual. Fortunately, the range of variation in input voltage is between −10 V and 10 V, which is acceptable.

The equivalent impedance Req in (5) is expressed as follows.

Figure 5 shows the gain curves of different quality factors (Q). It can be seen that the gain curve with Q = 0.134 is the steepest. This can be reserved for future adjustment if the voltage regulation circuit is removed, which would mean the range would be adjustable by frequency modulation only.

Figure 5.

The curve of voltage gain.

3. Simulation Results

To verify the performance of the proposed converter, simulations are carried out on a parallel dual half-bridge LLC resonant converter under different conditions. Table 1 lists the circuit specifications and component parameters for the converter.

Table 1.

The parameters of the proposed converter.

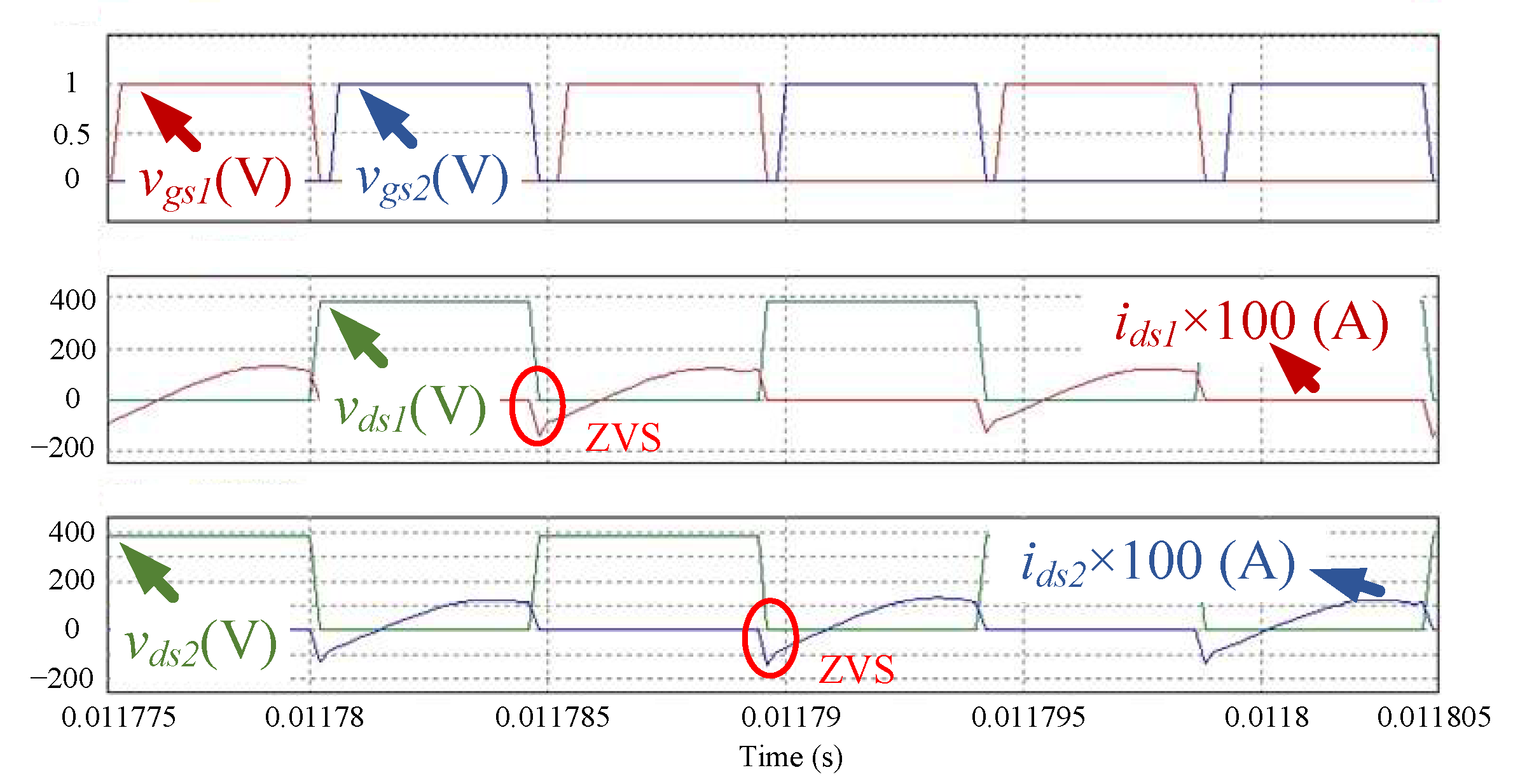

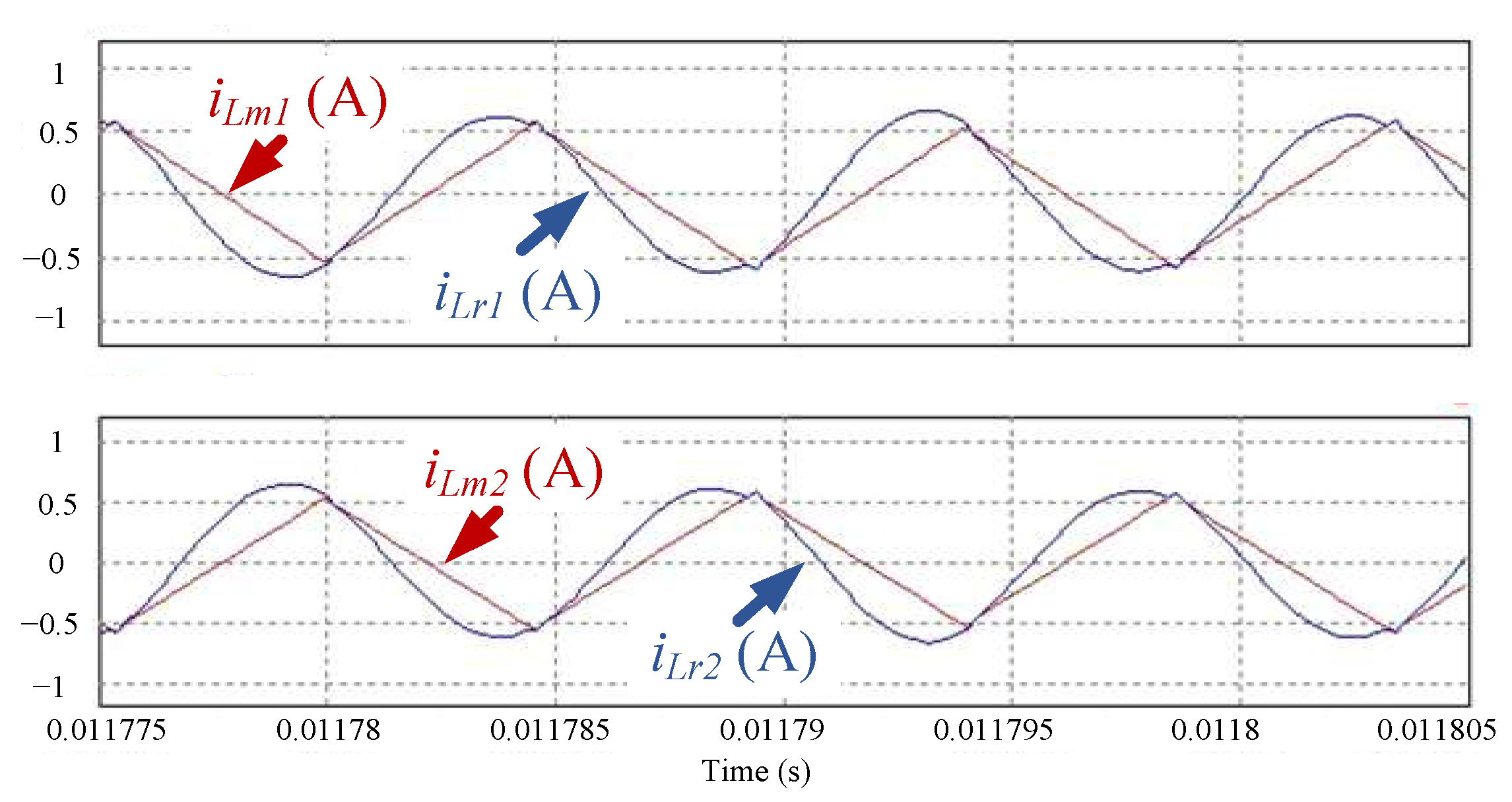

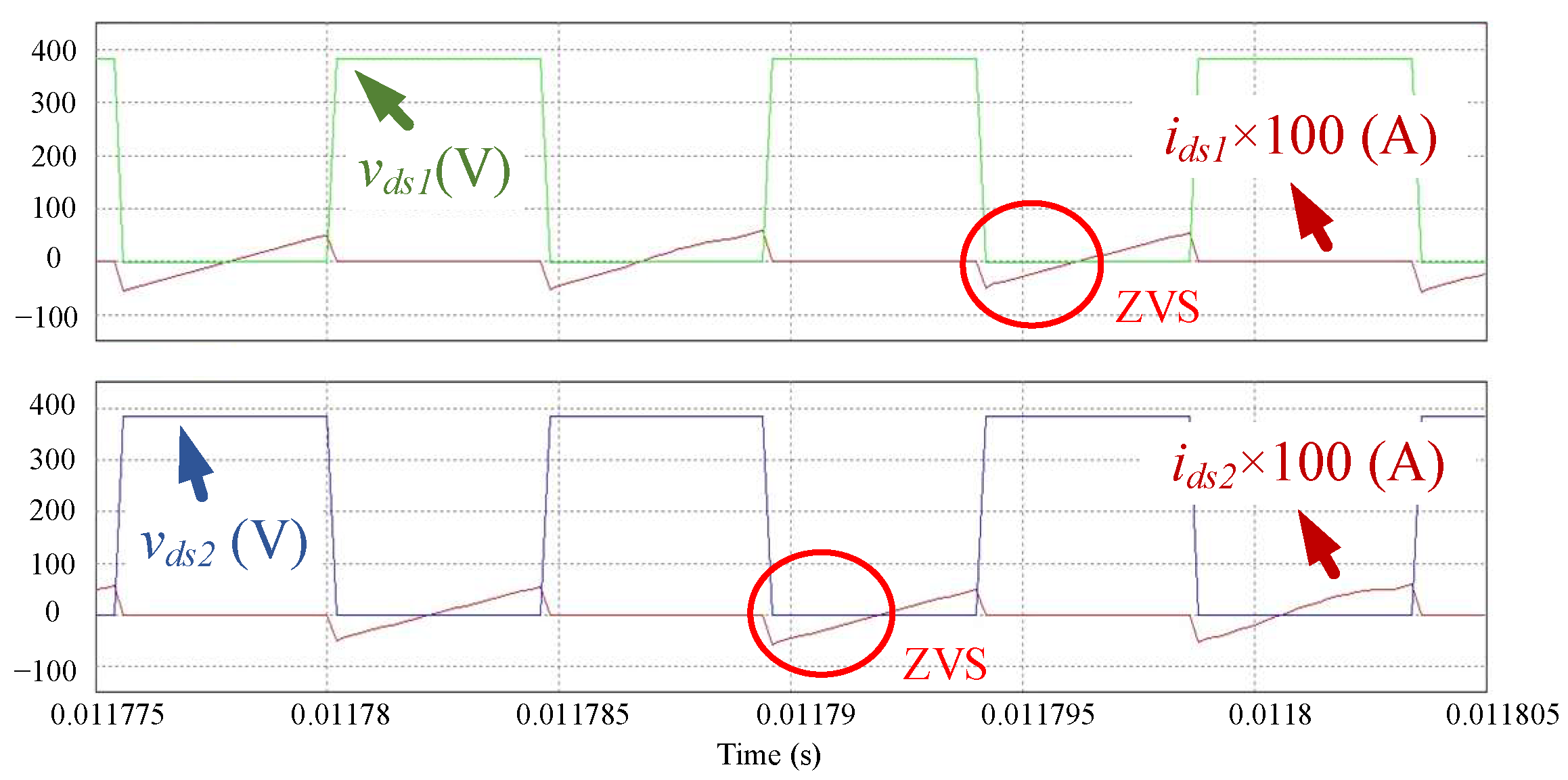

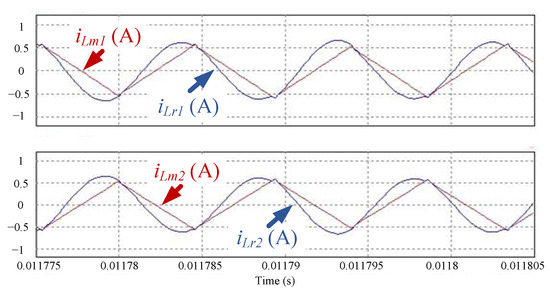

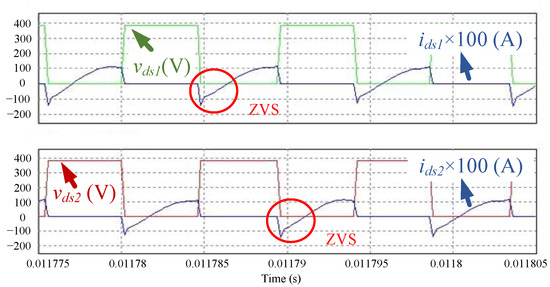

Figure 6 shows the driving signals, the waveforms of switches S1 and S2 on the primary side when the output voltage is fully loaded with 24 V. Figure 7 shows the waveforms of the resonant currents iLr1 and iLr2 of the resonant circuits and the magnetizing current iLm1 and iLm2 in the transformer when the output voltage is fully loaded at 24 V.

Figure 6.

Simulation waveforms of voltage and current of switches S1 and S2 (Vo = 24 V, full load).

Figure 7.

Simulation waveforms of resonant current and magnetizing current (Vo = 24 V, full load).

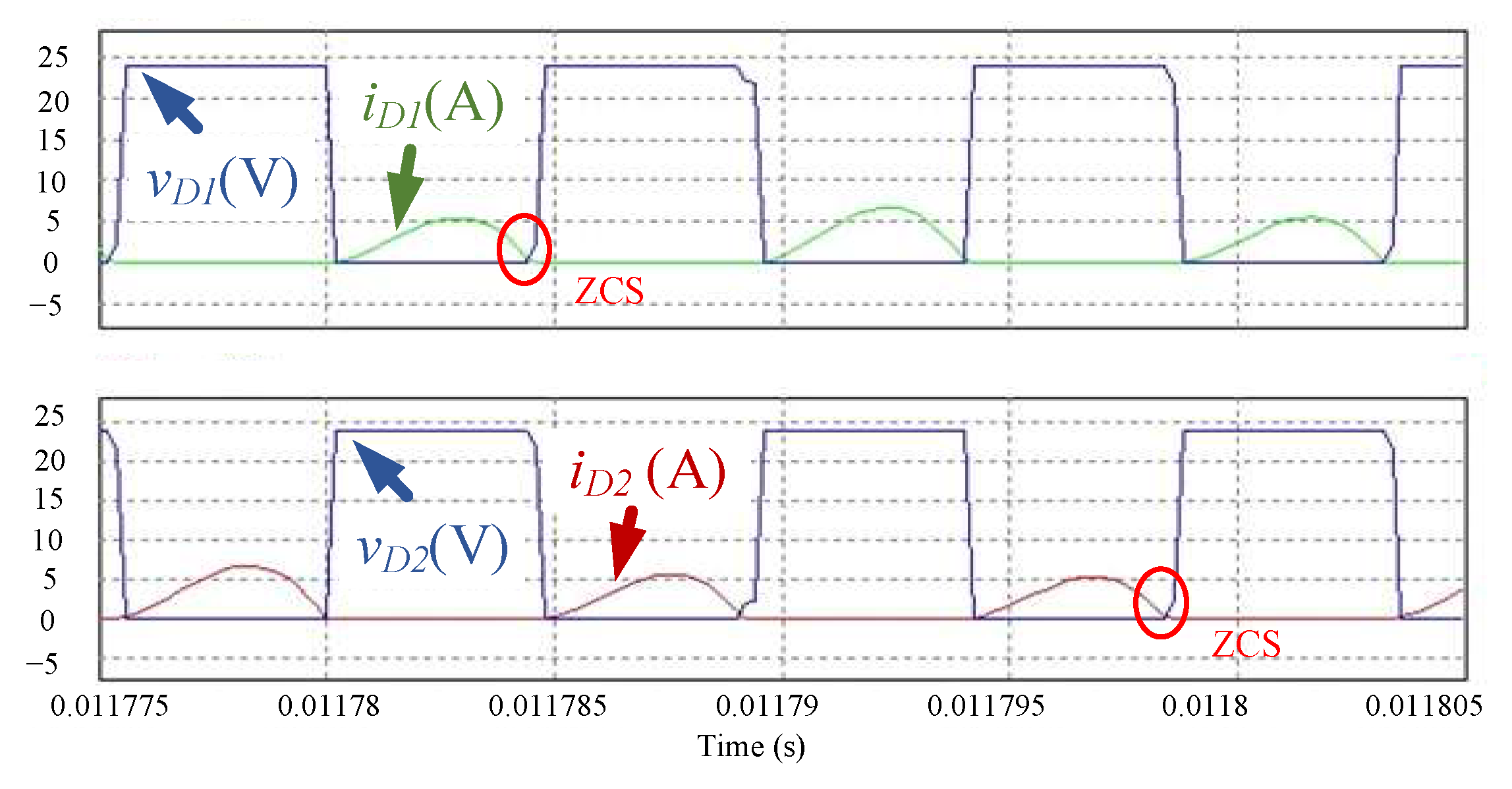

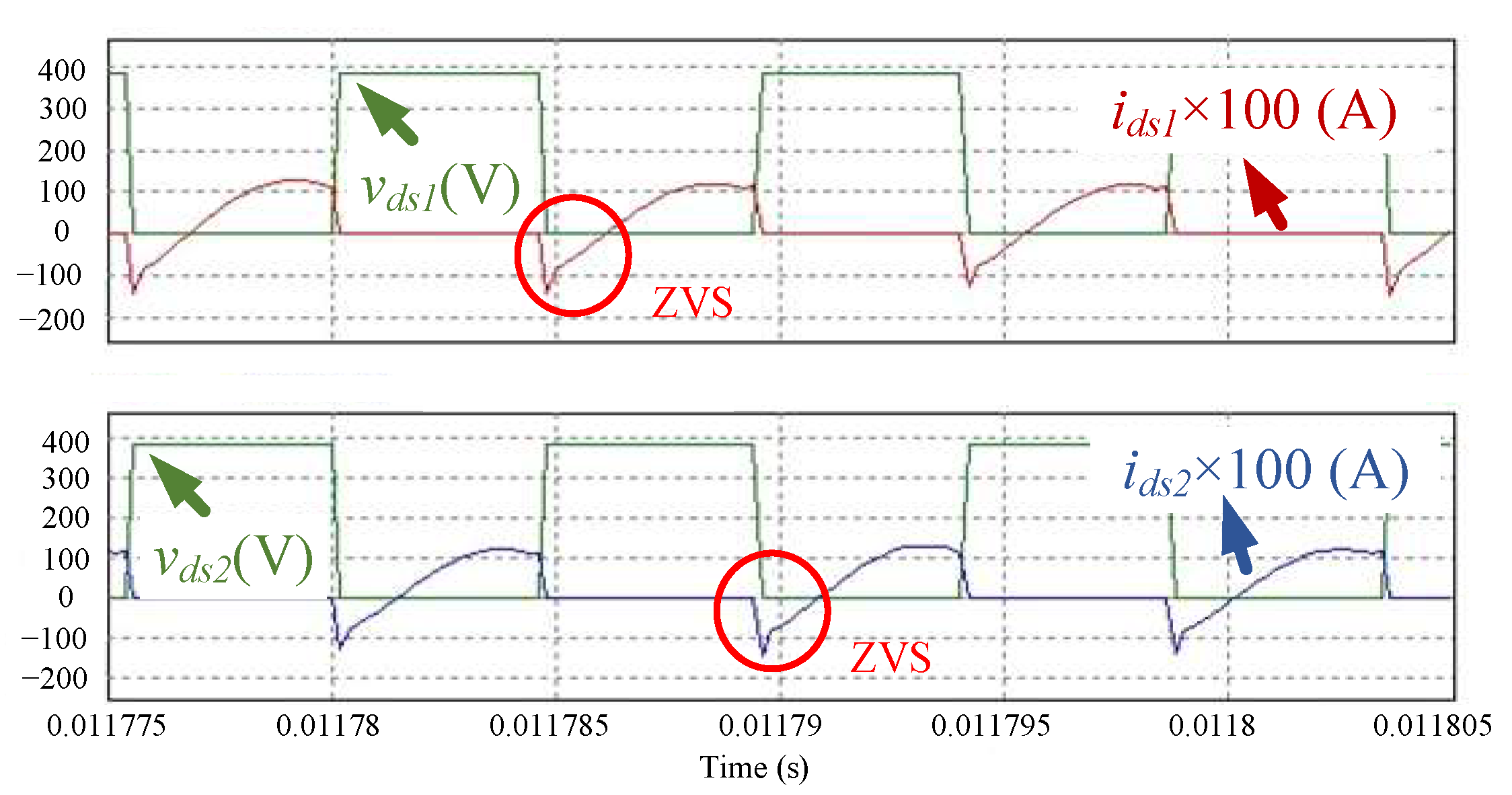

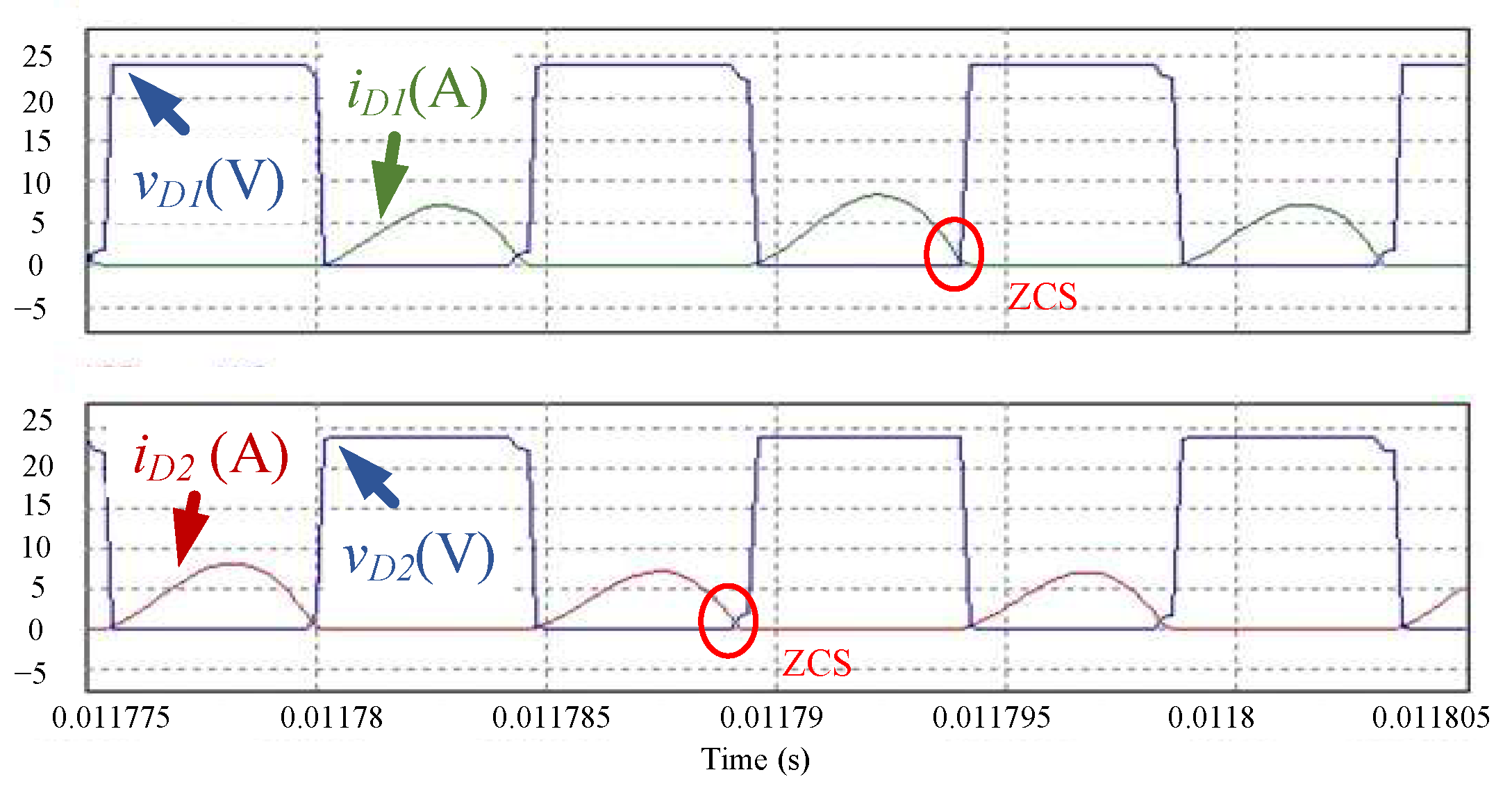

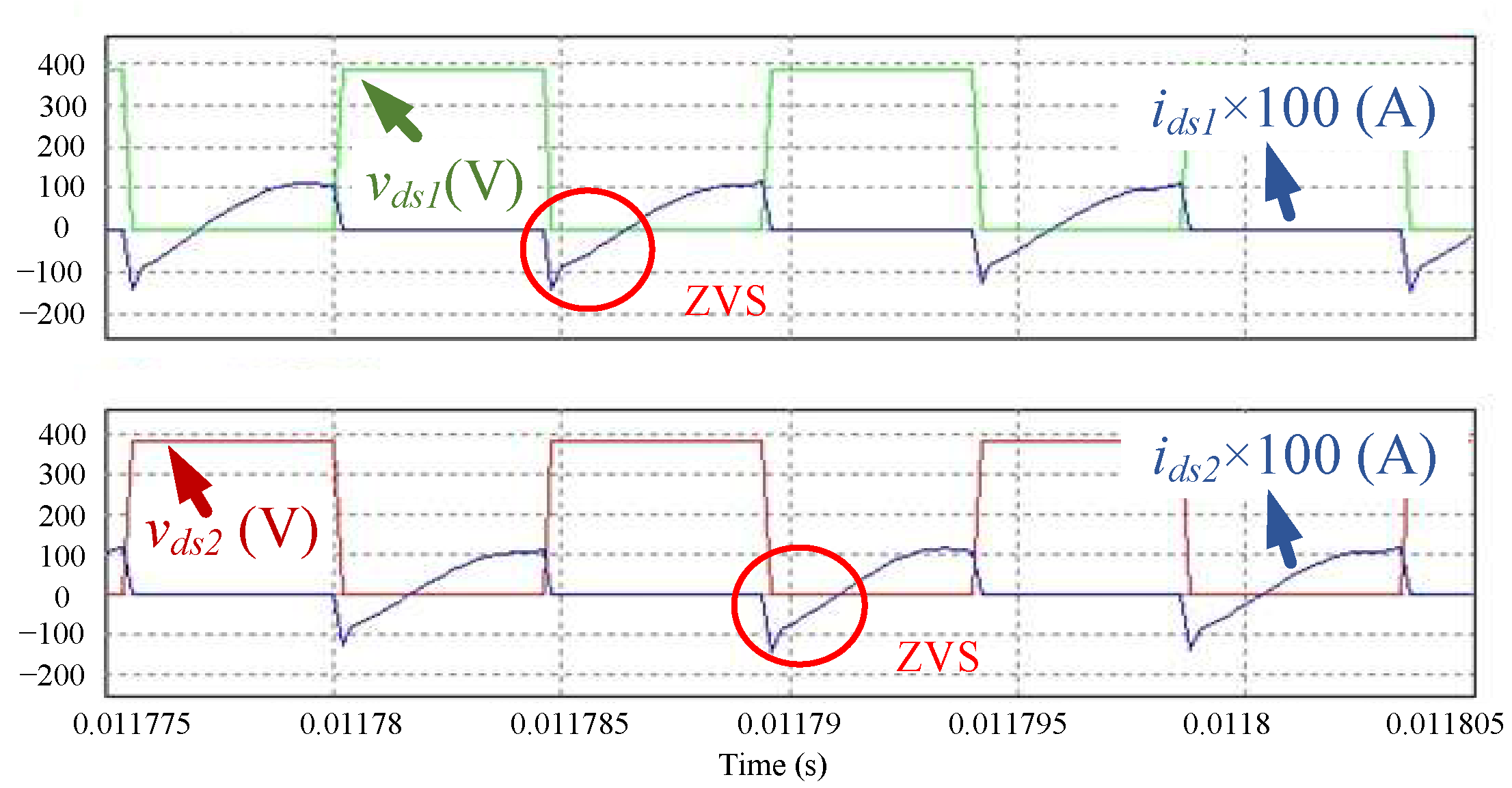

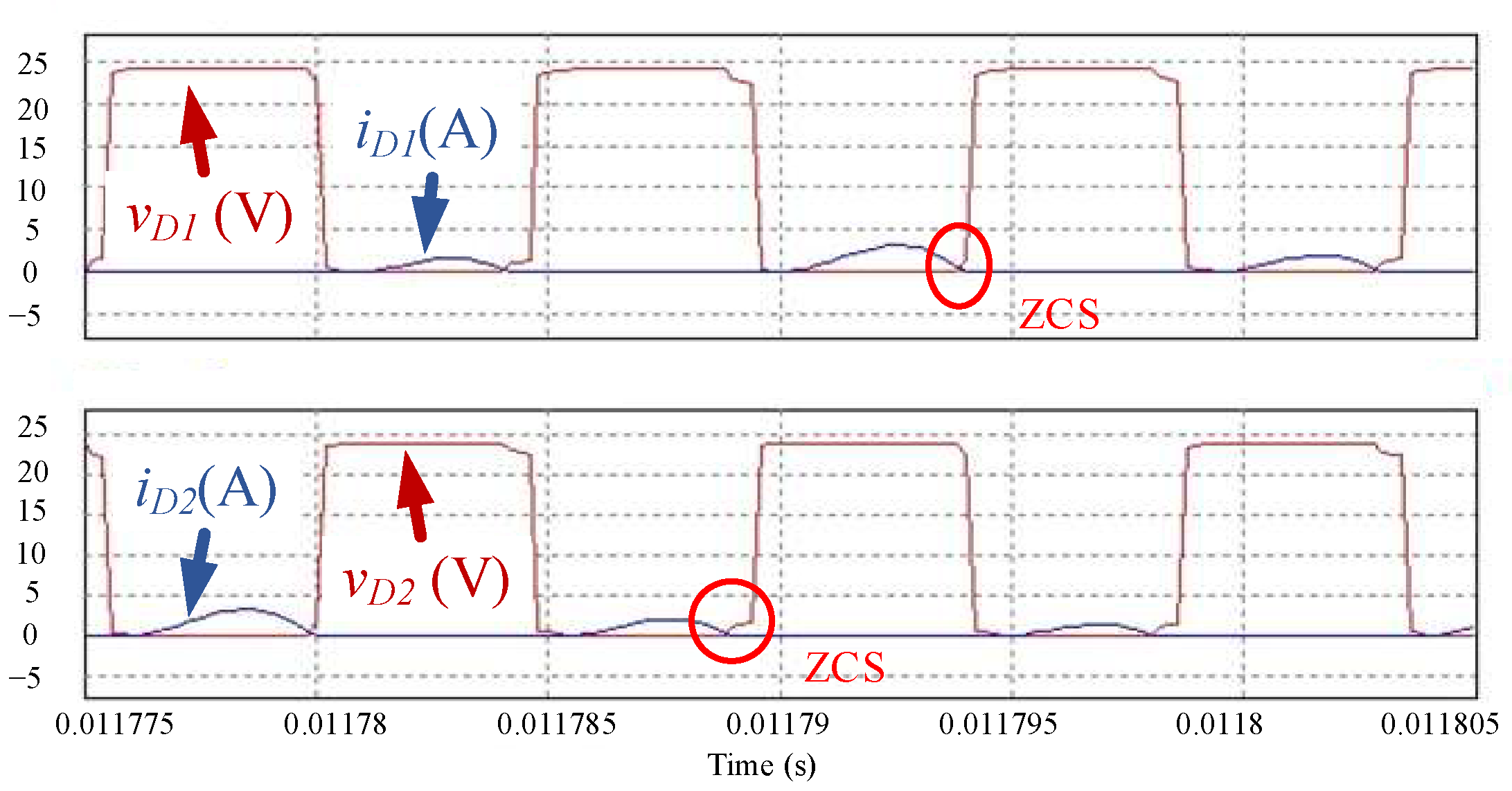

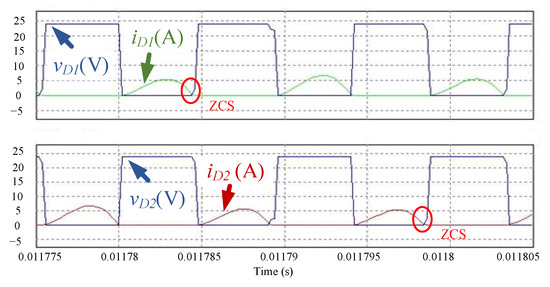

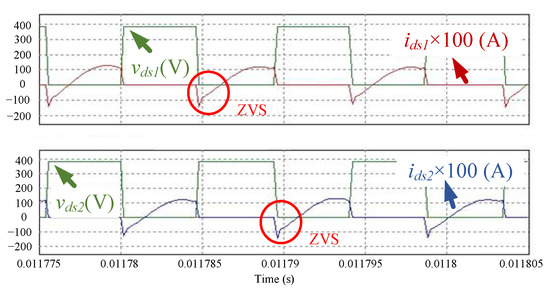

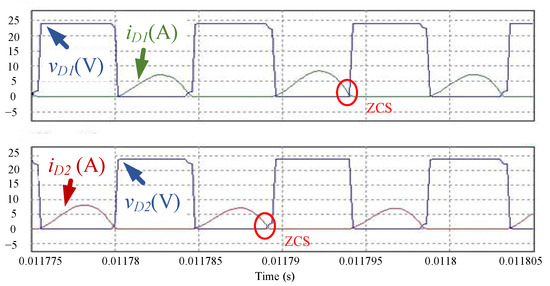

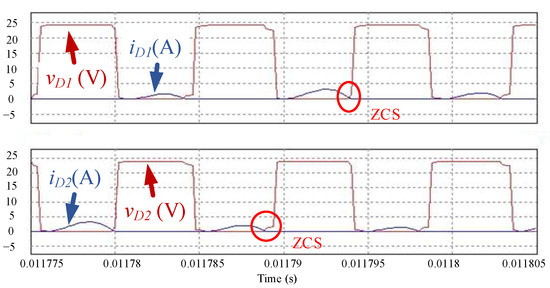

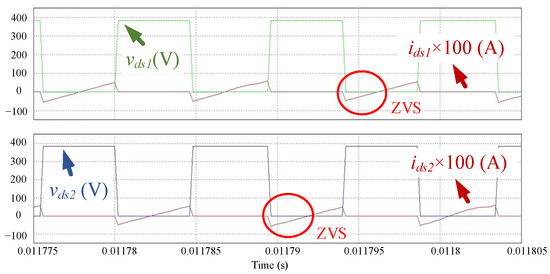

Figure 8 shows the waveforms for the voltages and currents of the secondary side rectifier diodes when the output voltage is 24 V at full load. Figure 9 shows the waveforms of the voltage and the current of the switches S1 and S2 on the primary side when the output voltage is fully loaded at 40 V. Figure 10 shows the waveforms of the voltages and the currents of the secondary side rectifier diode when the output voltage is fully loaded at 40 V. From these waveforms, regardless of whether the output voltage is 24 V or 40 V, the primary side switch can achieve ZVS and the secondary side rectifier diode can achieve ZCS. Soft switching is also achieved for the proposed converter under light-load and half-load conditions, as shown in Figure 11, Figure 12 and Figure 13.

Figure 8.

Simulation waveforms of voltage and current of diodes D1 and D2 (Vo = 24 V, full load).

Figure 9.

Simulation waveforms of voltage and current of switches S1 and S2 (Vo = 40 V, full load).

Figure 10.

Simulation waveforms of voltage and current of diodes D1 and D2 (Vo = 40 V, full load).

Figure 11.

Simulation waveforms of voltage and current of switches S1 and S2 (half load).

Figure 12.

Simulated waveform of voltage and current of diodes D1 and D2 (half load).

Figure 13.

Simulated waveform of voltage and current of switches S1 and S2 (light load).

4. Experimental Results

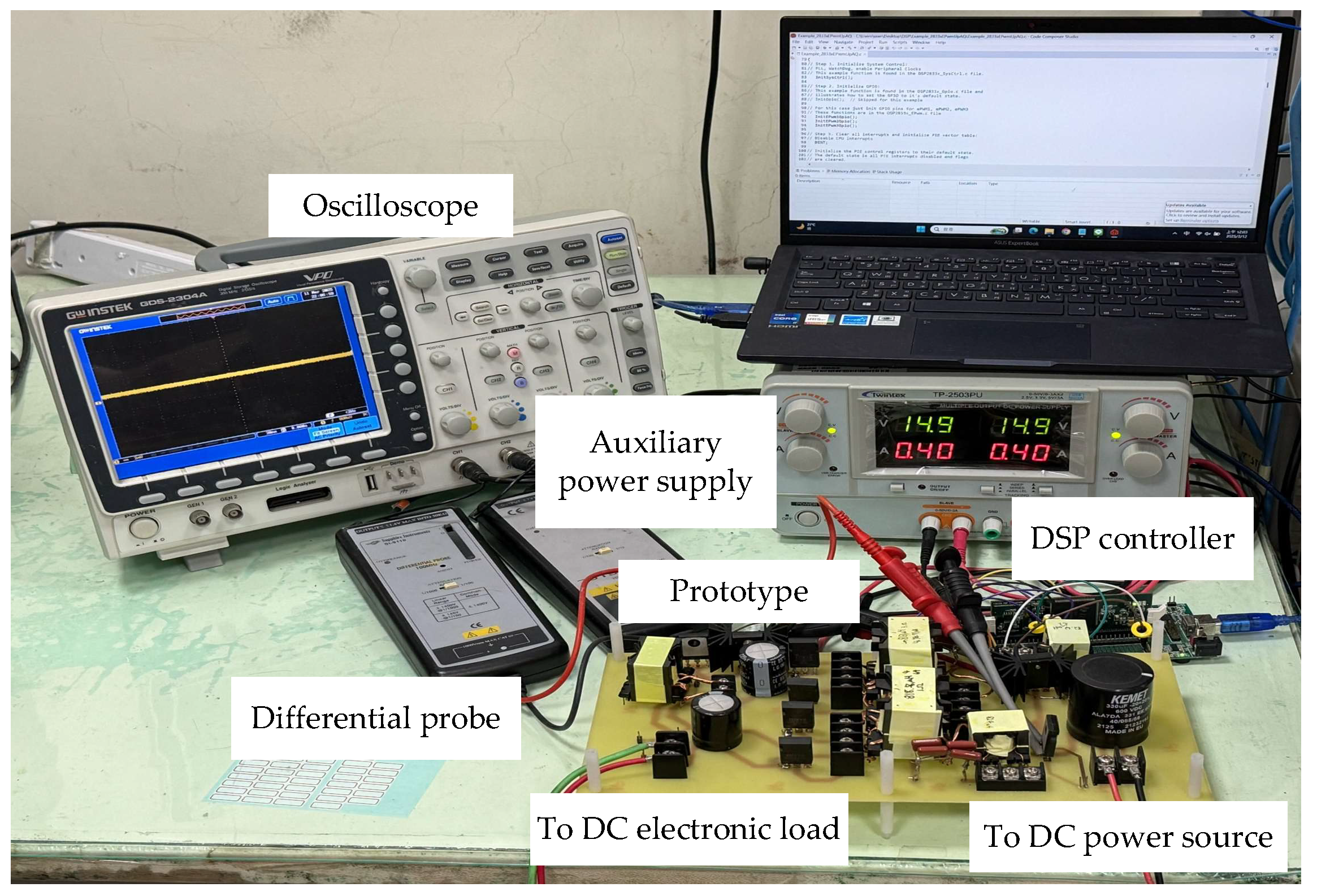

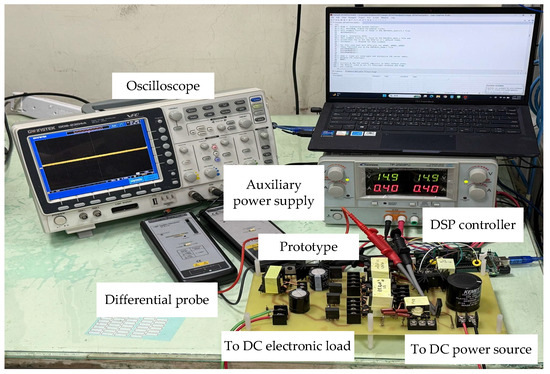

To verify the simulation results of the proposed converter, an experimental prototype of a dual half-bridge LLC resonant converter was constructed and tested with different output voltages, as shown in Figure 14. The circuit specifications are: Vin = 384 V, Vo = 24–40 V, and Po = 80 W. A TSM320F28335 DSP controller from Texas Instruments was used for the system control.

Figure 14.

Photograph of experimental setup.

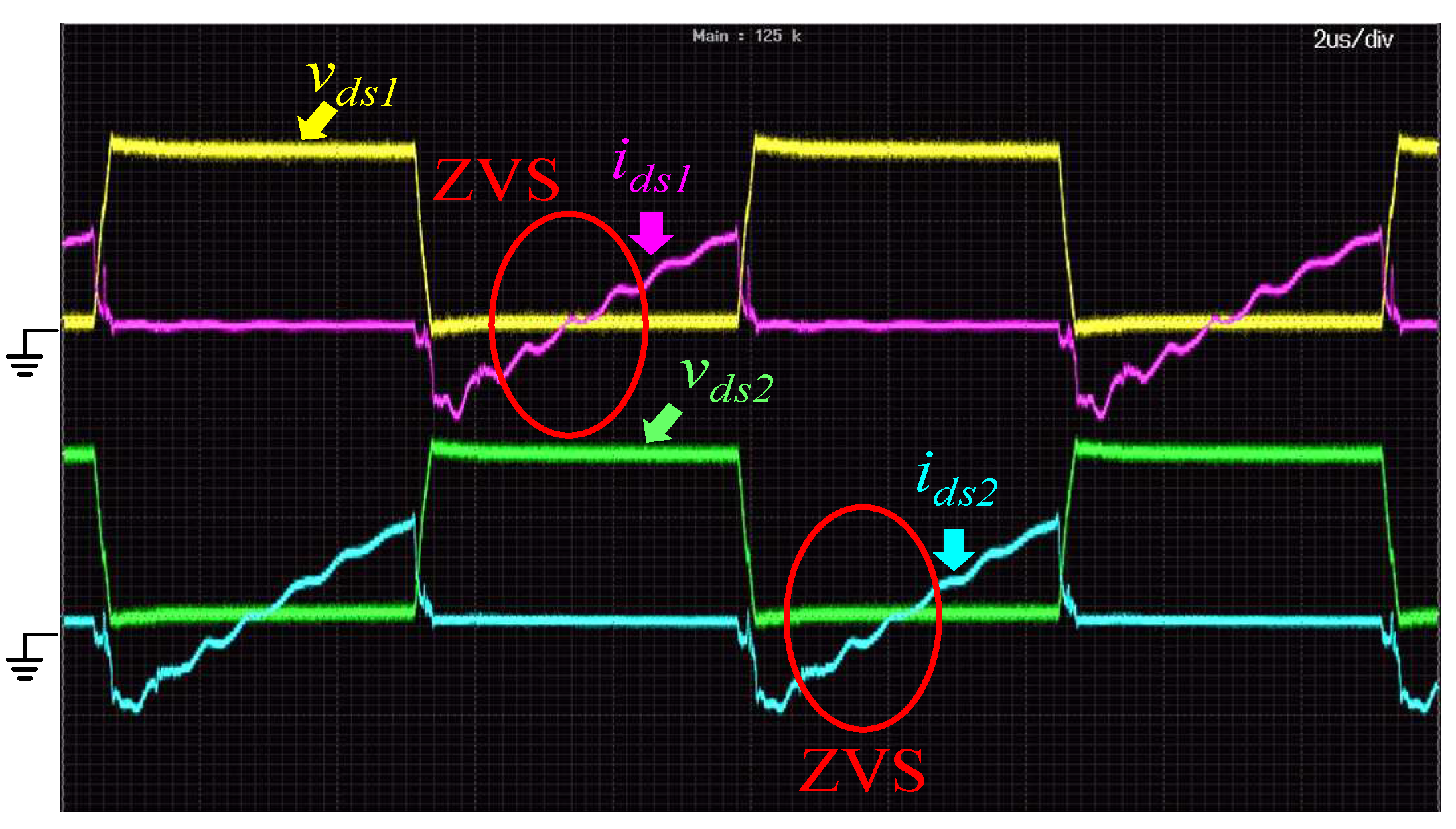

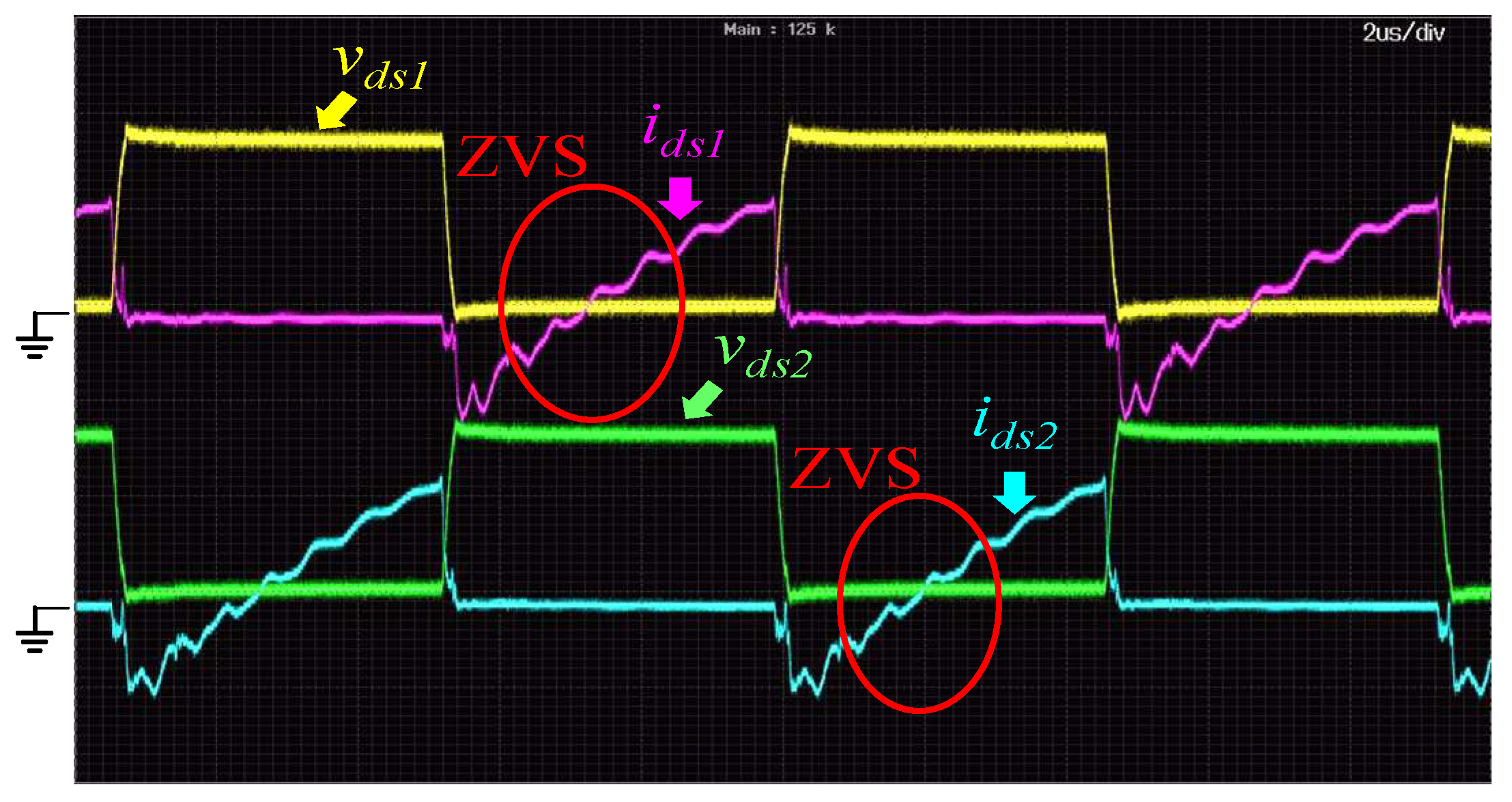

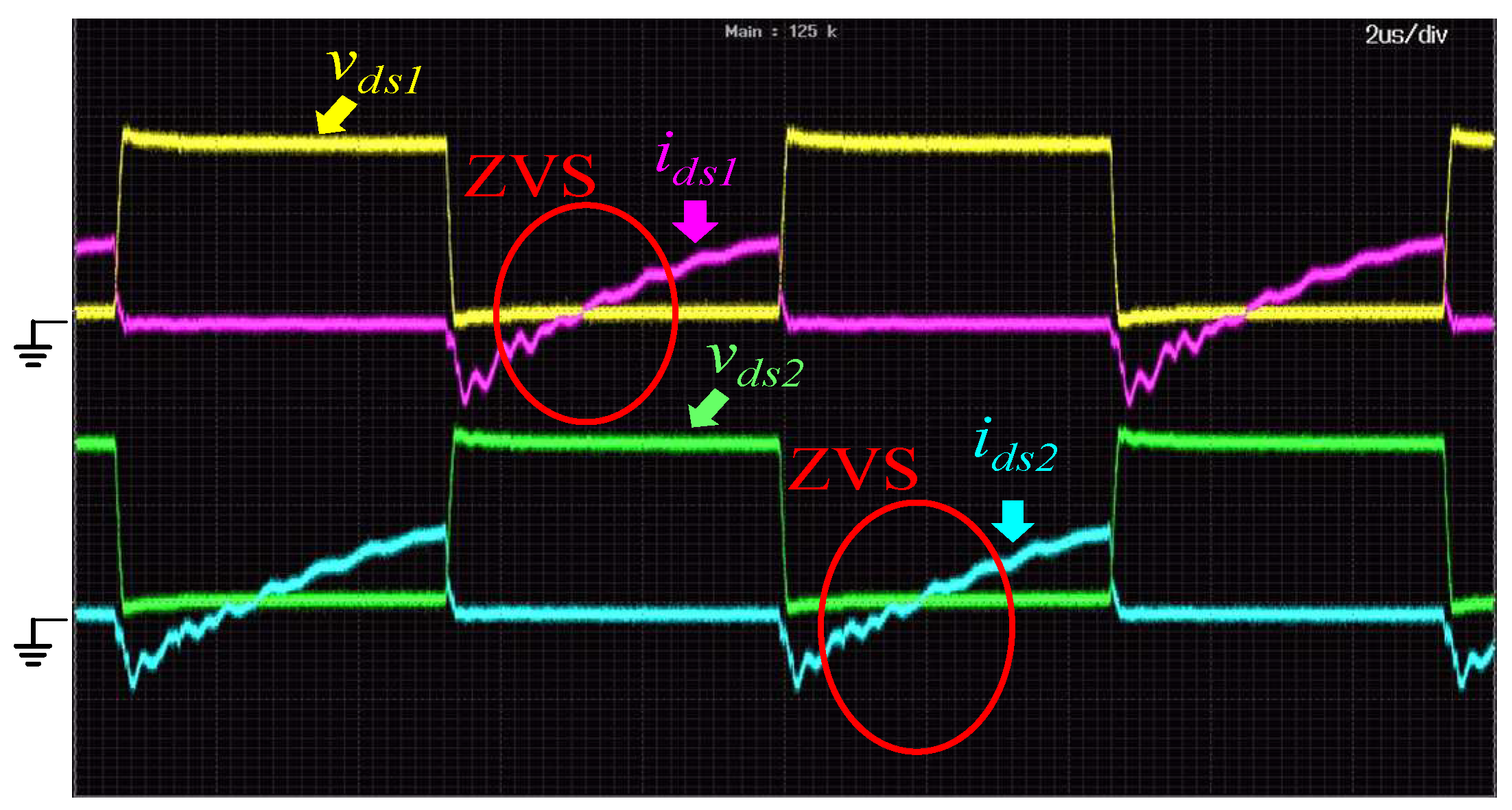

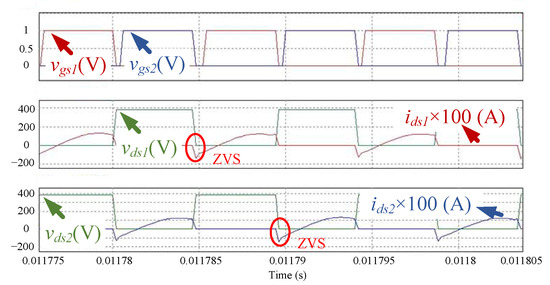

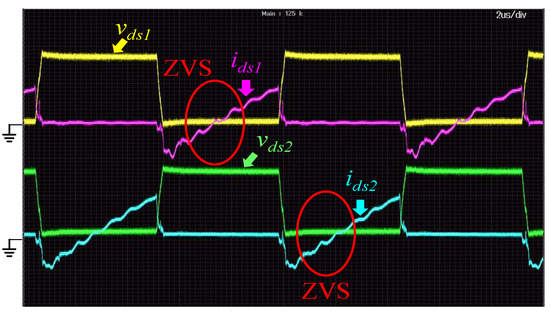

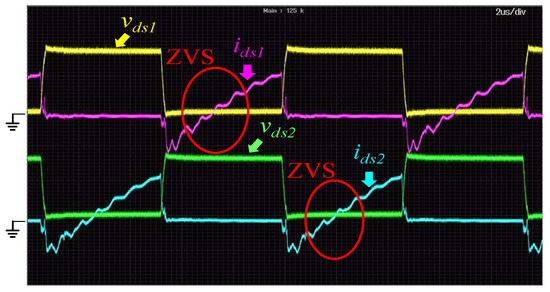

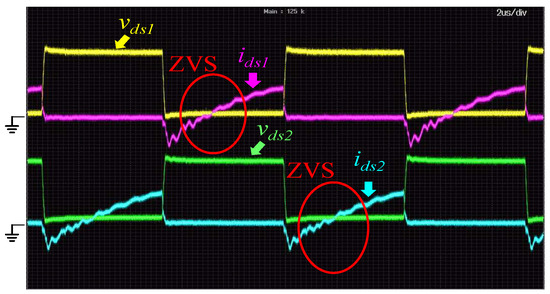

Figure 15 shows the measured waveforms of the primary side switches S1 and S2 when the input voltage is 384 V and the output is 10% of rated load. Figure 16 shows the measured waveforms of the primary side switches S1 and S2 when the input voltage is 384 V and the output is 50% rated load. Figure 17 shows the measured waveforms of the primary side switches S1 and S2 when the input voltage is 384 V and the output is 100% rated load. It can be found from the measured waveforms that ZVS turn-on of the proposed converter is achieved for the light-load, half-load, and full-load conditions.

Figure 15.

The current and voltage waveforms of switches S1 and S2 (light load) (vds1: 100 V/div, vds2: 100 V/div, ids1: 2 A/div, ids2: 2 A/div, time: 2 μs/div).

Figure 16.

The current and voltage waveforms of switches S1 and S2 (half load) (vds1: 100 V/div, vds2: 100 V/div, ids1: 2 A/div, ids2: 2 A/div, time: 2 μs/div).

Figure 17.

The current and voltage waveforms of switches S1 and S2 (full load) (vds1: 100 V/div, vds2: 100 V/div, ids1: 5 A/div, ids2: 5 A/div, time: 2 μs/div).

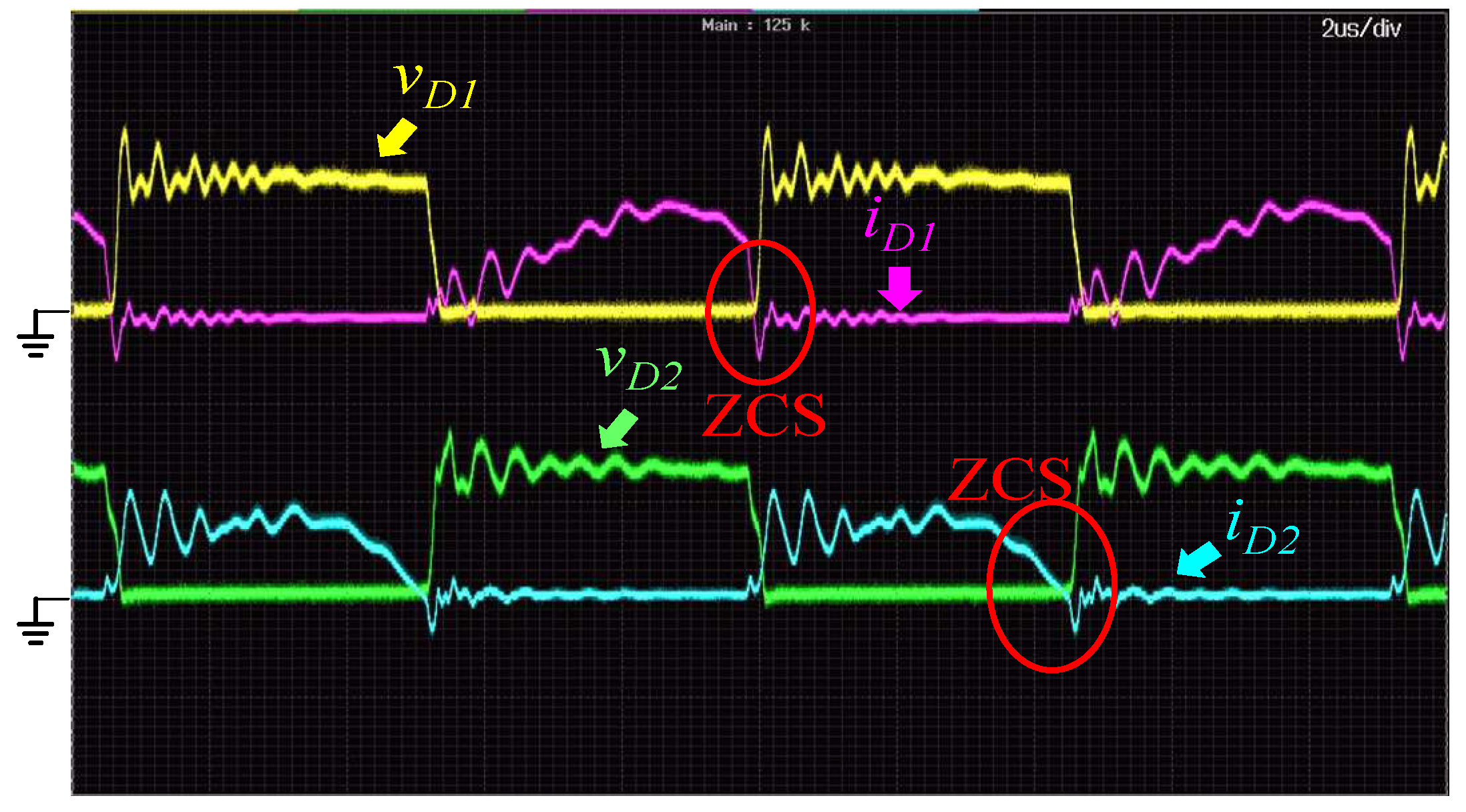

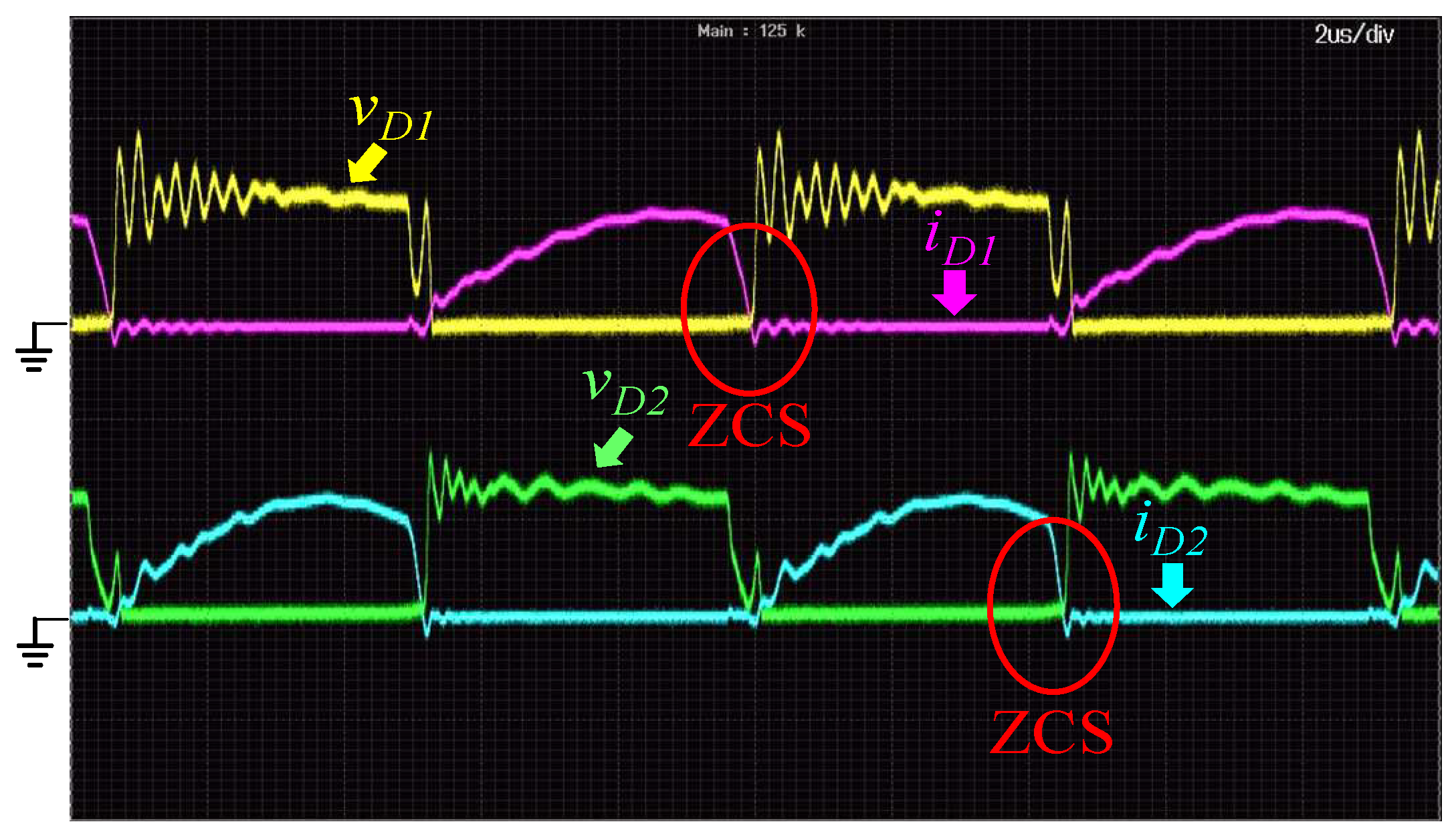

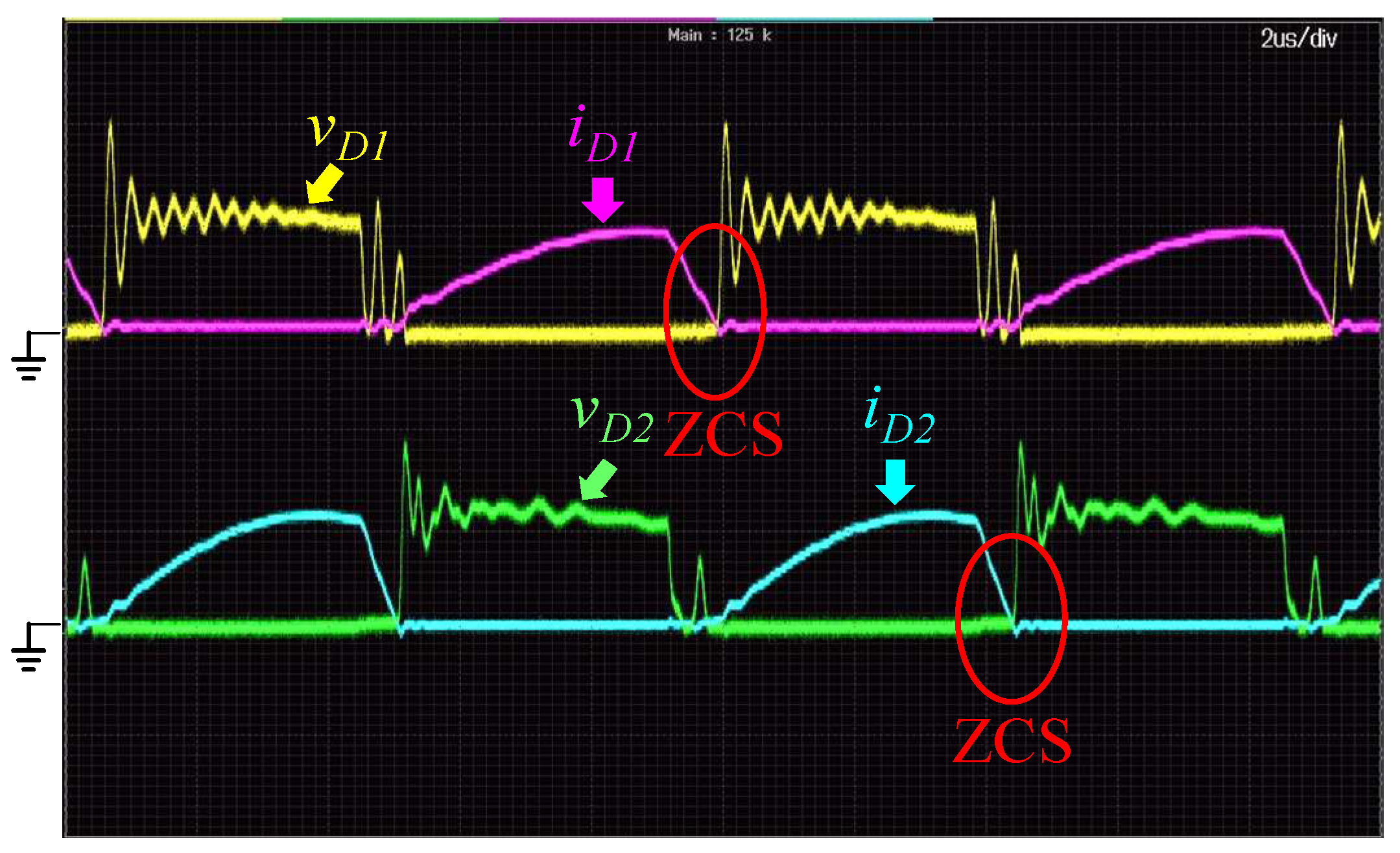

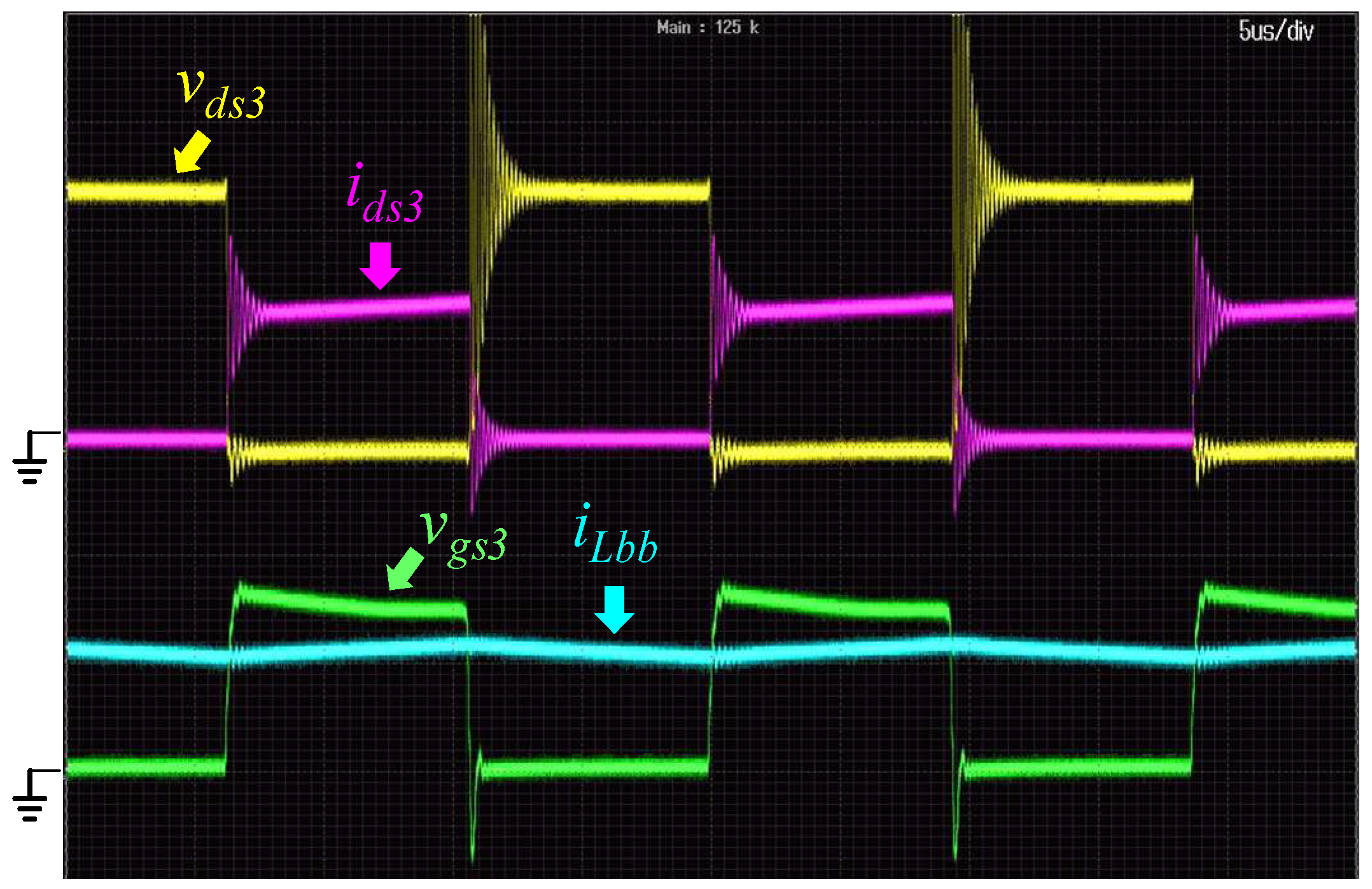

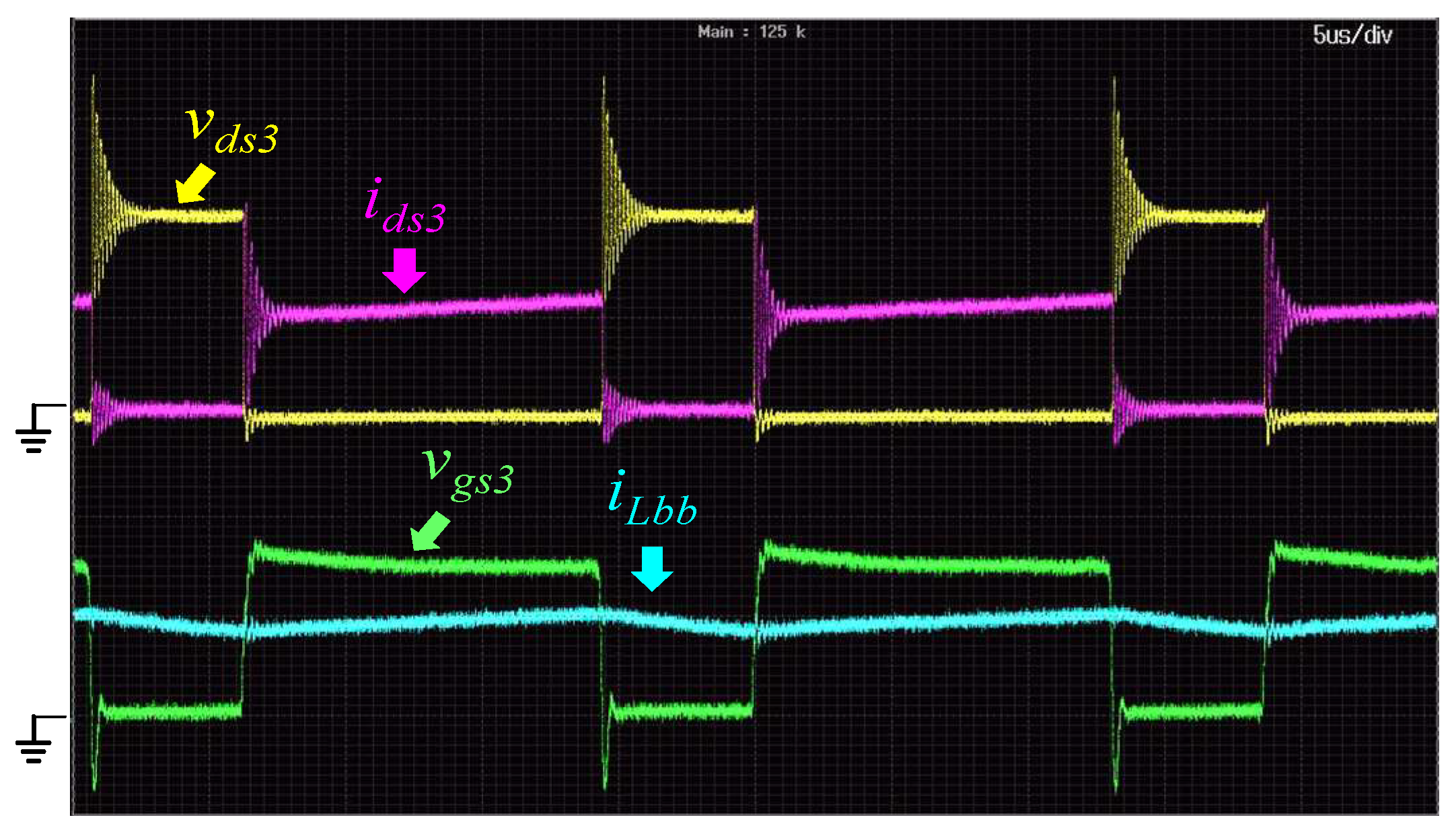

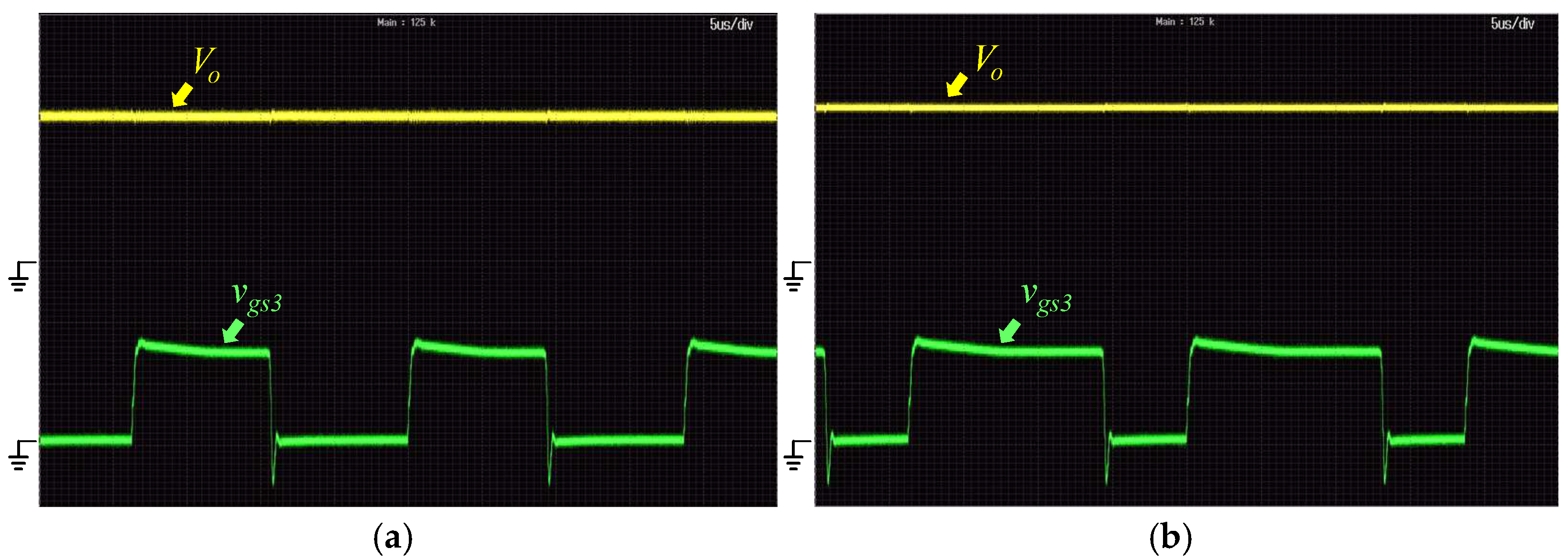

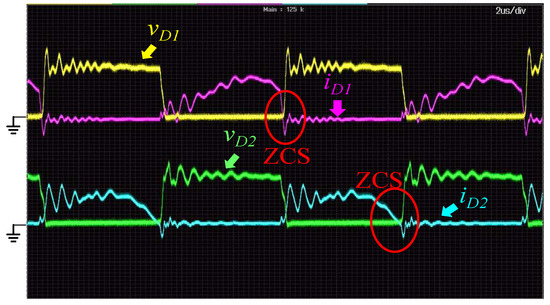

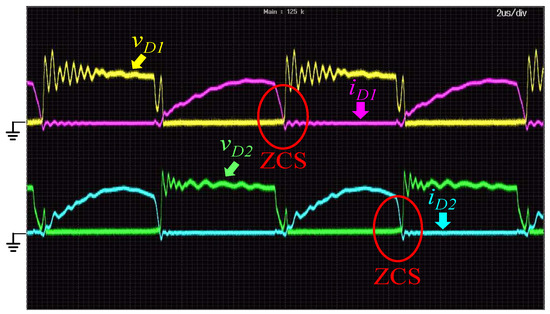

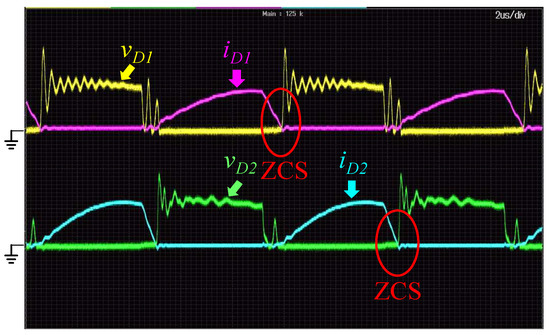

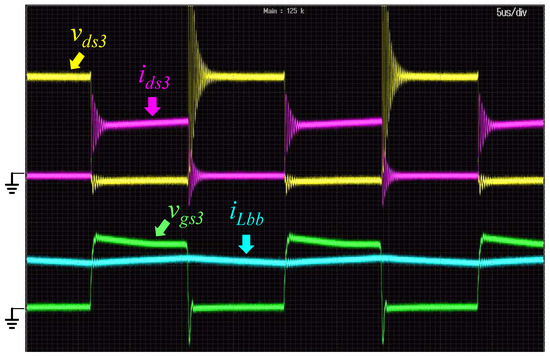

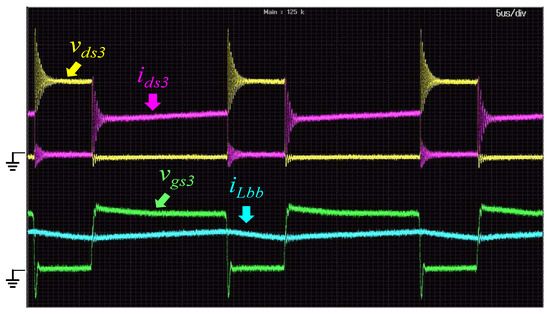

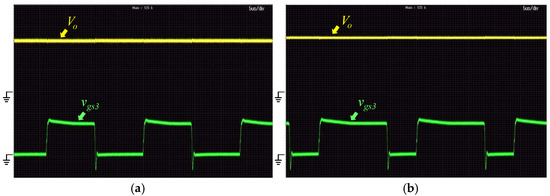

Figure 18 shows the measured waveforms of the rectifier diodes D1 and D2 on the secondary side, and the output is 10% rated load. Figure 19 shows the measured waveforms of the rectifier diodes D1 and D2 on the secondary side, and the output is 50% rated load. Figure 20 shows the measured waveforms of the rectifier diodes D1 and D2 on the secondary side, and the output is 100% rated load. Zero-current switching (ZCS) is achieved under light-load, half-load, and full-load conditions. The excellent performance of the proposed converter is verified by the experimental results. It is obvious from Figure 21 and Figure 22 that the storage inductors are both operating in continuous conduction mode (CCM). In Figure 23a, if the duty ratio of switch S3 is 0.5, the output voltage is 24 V. Figure 23b shows that the output voltage is 40 V when the duty ratio is 0.7.

Figure 18.

The current and voltage waveforms of diodes (light load) (vD1: 20 V/div, vD2: 20 V/div, iD1: 5 A/div, iD2: 5 A/div, time: 2 μs/div).

Figure 19.

The current and voltage waveforms of diodes (half load) (vD1: 20 V/div, vD2: 20 V/div, iD1: 5 A/div, iD2: 5 A/div, time: 2 μs/div).

Figure 20.

The current and voltage waveforms of diodes (full load) (vD1: 20 V/div, vD2: 20 V/div, iD1: 10 A/div, iD2: 10 A/div, time: 2 μs/div).

Figure 21.

The voltage and current waveforms of switch S3 and the current of the inductor (24 V) (vds3: 10 V/div, vgs3: 10 V/div, ids3: 5 A/div, iLbb: 5 A/div, time: 5 μs/div).

Figure 22.

Voltage regulation switch S3 voltage current and energy storage inductor current waveform (40 V) (vds3: 20 V/div, vgs3: 10 V/div, ids3: 5 A/div, iLbb: 5 A/div, time: 5 μs/div).

Figure 23.

The voltage waveforms of switch vgs3 and output voltage. (a) Duty of switch S3 = 0.5, output voltage = 24 V (vo: 10 V/div, vgs3: 10 V/div, time: 5 μs/div); (b) duty of switch S3 = 0.7, output voltage = 40 V (vo: 20 V/div, vgs3: 10 V/div, time: 5 μs/div).

Since the proposed converter can achieve ZVS turn-on at S1 and S2 and ZCS turn-off at D1–D4, power loss analysis for the converter can be divided into several main components, namely the conduction loss, switching loss of S3, turn-off loss of S1 and S2, reverse recovery loss of D5, and transformer loss. The conduction loss of the switching device PS_cond and diode PD_cond can be expressed as the following:

where rD and RDS(ON) are the internal resistance of the diode and switch, respectively, Irms is the effective value of the switch or diode current, Iavg is the average current of the diode, and VF is the forward voltage drop of the diode.

Practically, the capacitors have equivalent series resistance (ESR) and the inductors have direct current resistance (DCR). Therefore, the conduction loss of capacitors PC_cond and inductors PL_cond must be considered in total power loss of the proposed converter. PC_cond and PL_cond can be calculated as (9) and (10), respectively:

where IC_rms and IL_rms are the rms current of capacitors and inductors, respectively, ESR is the equivalent series resistance of capacitors, and DCR is direct current resistance of inductors.

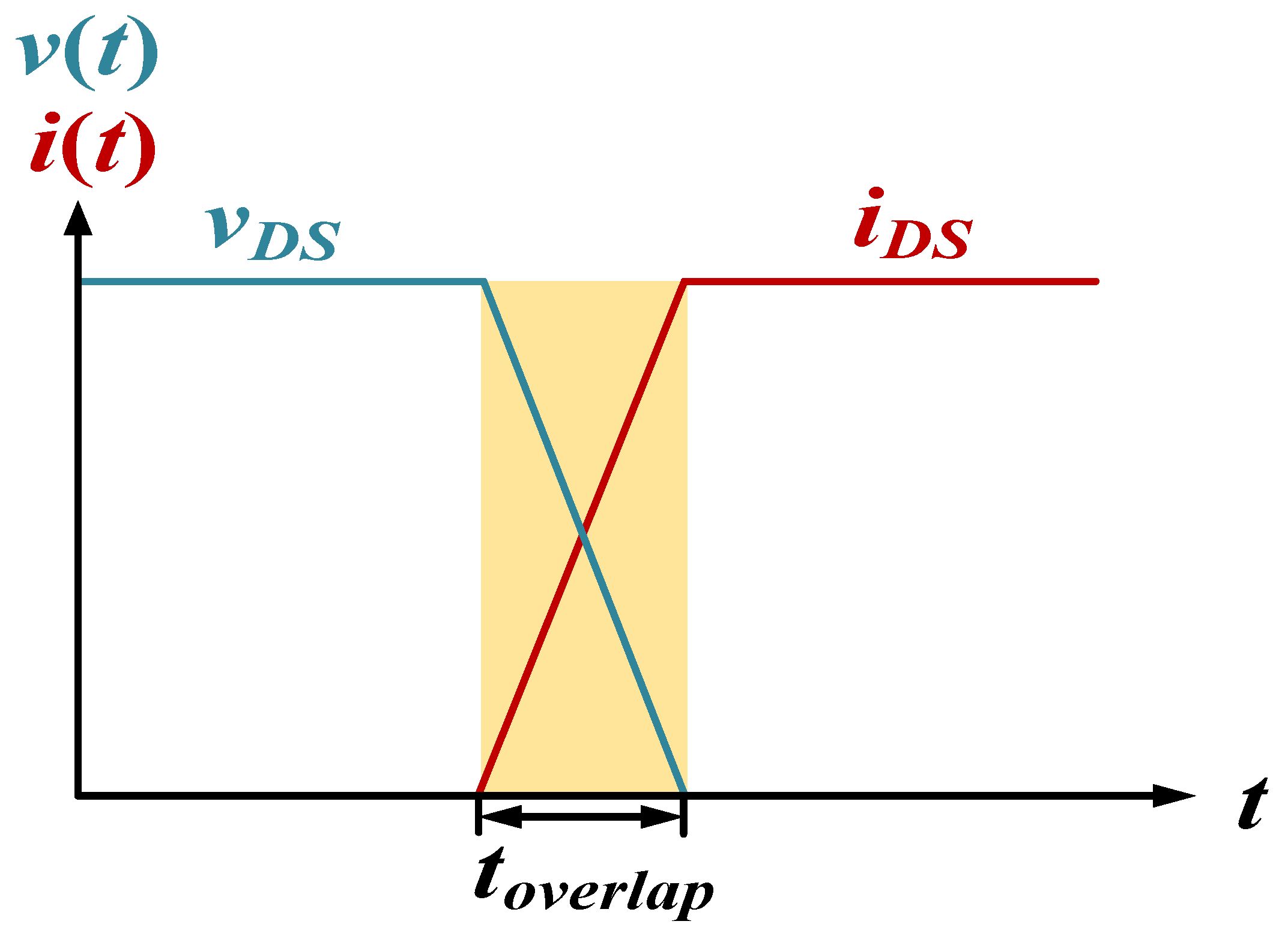

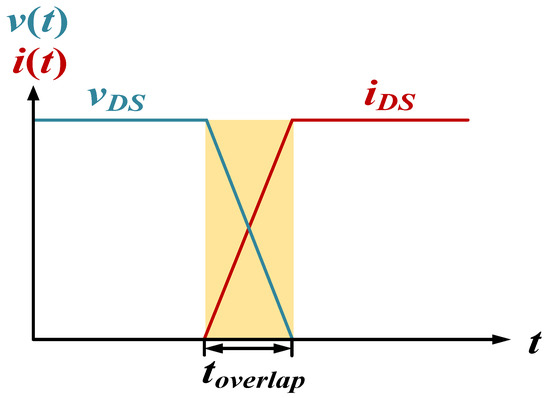

The switching loss of the power switch Psw can be expressed as the following formula:

where VDS is the DS terminal voltage of the switch, IDS is the current of the switch, fs is the switching frequency, and toverlap is the overlapping time between vDS and iDS of the switch, as shown in Figure 24. The turn-off loss of S1 and S2 can also be calculated by (11).

Figure 24.

Overlapping time of switches.

Because of the characteristics of soft switching only being achieved at D1–D4, D5 will generate reverse recovery loss Prr when it is turned off. The formula of Prr can be obtained as:

where Vr is the reverse voltage of the diode, Irr is the reverse recovery current of the diode, and trr is the reverse recovery time of the diode.

Transformer loss includes winding loss PT_w and core loss PT_core. Since the calculation of winding loss is similar to (10), PT_w will not be mentioned here. Core loss can be estimated using the Steinmetz equation:

where K, α, and β are coefficients from the datasheet of core material and ∆B is the magnetic flux variation of transformer.

The overall converter efficiency η can be obtained by the following formula:

where Po is the output power and Ploss is the total power loss.

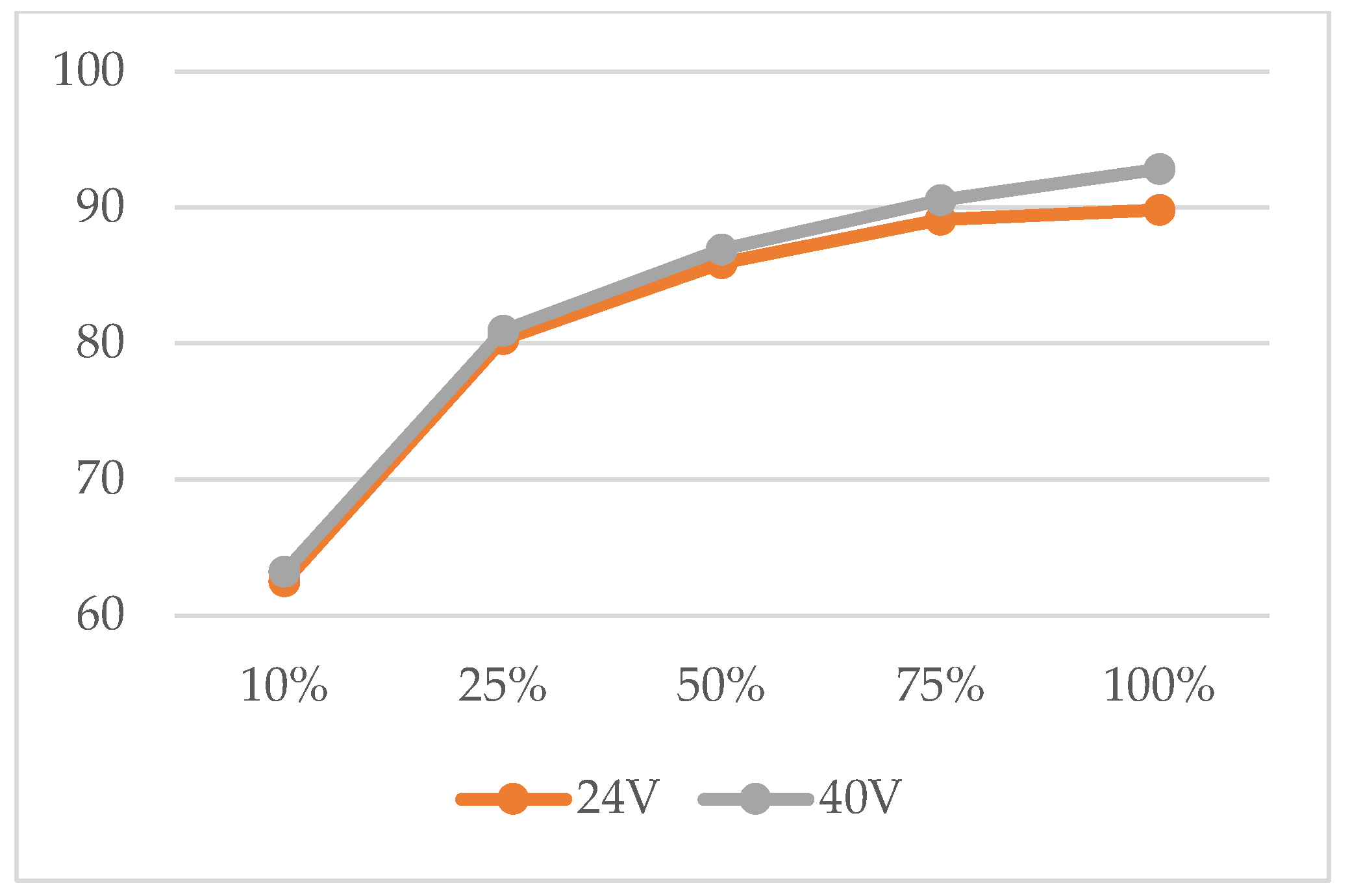

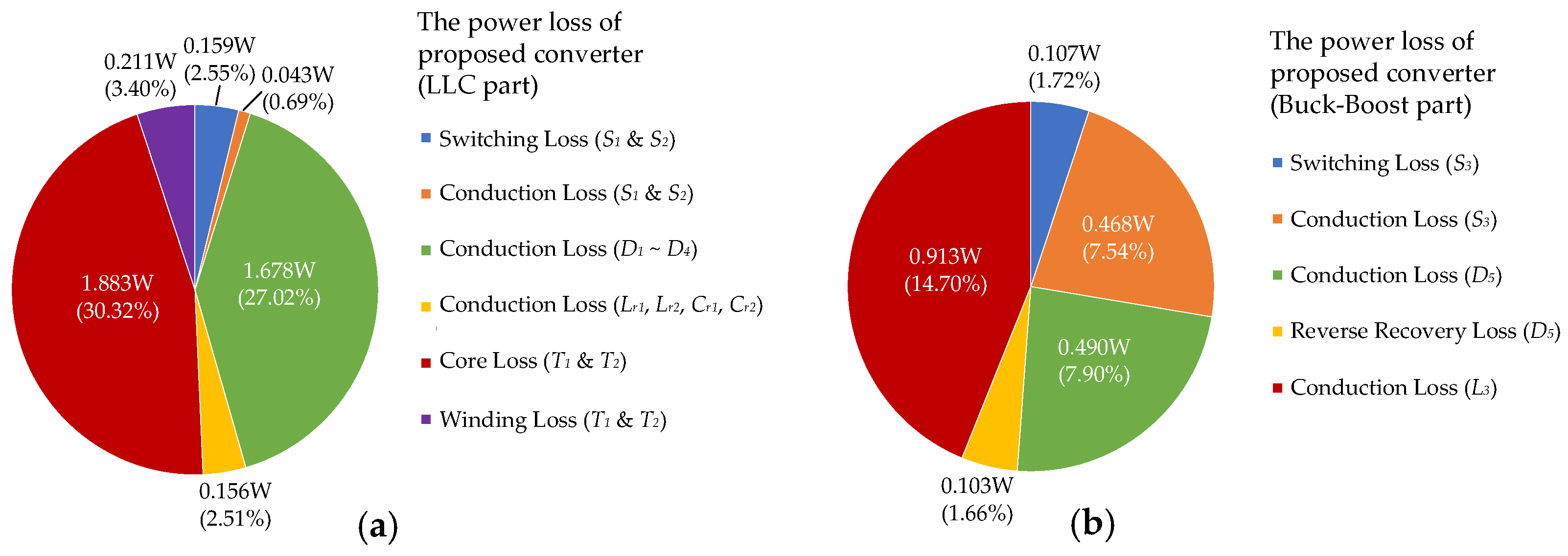

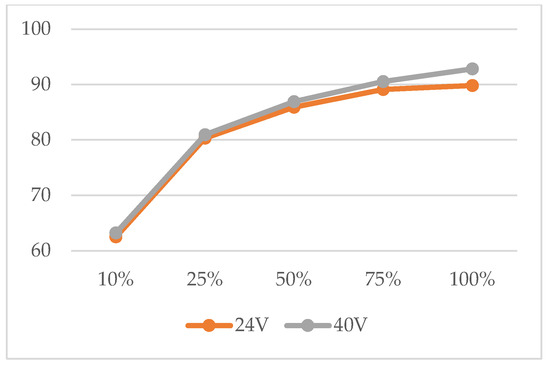

Figure 25 shows the efficiency curves of the converter at different output voltages. It can be observed in the curves that the highest efficiency reaches 92.8% at 80 W. The efficiency of the converter decreases directly proportional to the load.

Figure 25.

The efficiency of the proposed converter with different output voltage.

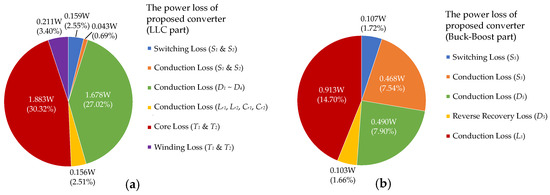

Figure 26 shows the sum of different power losses of the proposed converter when the output voltage is 40 V at full load, including the switching loss of switches, the conduction loss of switches, the reverse recovery loss of diodes, the conduction loss of diodes, the conduction loss of resonant and magnetic components, the core loss, and the winding loss. As Figure 26 shows, the total power loss of the proposed converter is obtained at 6.21 W, and the LLC part is around 66.49% of the entire power loss. In the power loss of the LLC part, the core loss is the majority loss and the conduction loss of S1 and S2 is the minority loss. Most of the loss in the buck–boost part is due to the conduction loss of L3. On the contrary, the reverse recovery loss of D5 is the lowest.

Figure 26.

The power loss of the proposed converter at full load and Vo = 40 V: (a) LLC part; (b) buck–boost part.

Table 2 gives a performance comparison for the proposed converter with three different converters. As Table 2 shows, the proposed converter and other converters in [5,6,14] used two transformers and achieved the ability of soft switching. The proposed converter uses the fewest switches compared with [5,6,14]. Moreover, ref. [14] is the only converter that used the relay in Table 2. The converter using pulse-frequency modulation (PFM) regulates voltage by varying the switching frequency and requires a wide switching frequency range [5,14,25]. However, the wide switching frequency range increases the difficulty of the design of the magnetic component. Pulse-width modulation (PWM) and phase-shift modulation (PSM) are the fixed-frequency modulations that simplify the magnetic component design. The voltage range of the proposed converter is wider than the other converters in Table 2 even when the proposed converter is not the best in terms of efficiency. Therefore, the proposed converter is a good choice in medium- or low-power applications.

Table 2.

Comparison of the proposed converter and 3 other converters.

5. Conclusions

This paper has presented a dual half-bridge parallel LLC resonant converter with a wide range of output voltages. The converter efficiencies at all load ranges are improved by zero-voltage switching and zero-current switching. The proposed converter reaches the highest efficiency of 92.8% at full load when the output is 40 V. The simulation and experimental results demonstrate that when the output voltage of the proposed converter is 40 V, ZVS is achieved for the primary side switch of the converter in heavy-load, half-load, or light-load conditions. ZCS is achieved for the secondary diode at full load and light load. The performance of the converter is verified. The proposed converter is very suitable and attractive for medium- or low-power applications with a wide range of output voltages.

Author Contributions

Conceptualization, C.-C.H.; Methodology, J.-B.L.; Software, W.-C.H.; Formal analysis, J.-B.L. and W.-C.H.; Resources, C.-C.H.; Data curation, J.-B.L.; Writing – original draft, W.-C.H.; Writing – review & editing, C.-C.H.; Visualization, J.-B.L.; Supervision, C.-C.H.; Funding acquisition, C.-C.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Khorasani, R.R.; Adib, E.; Farzanehfard, H. ZVT Resonant Core Reset Forward Converter with a Simple Auxiliary Circuit. IEEE Trans. Ind. Electron. 2018, 65, 242–250. [Google Scholar] [CrossRef]

- Pesce, C.; Blasco, R.; Riedemann, J.; Andrade, I.; Peña, R. A DC-DC Converter Based On Modified Flyback Converter Topology. IEEE Latin Amer. Trans. 2016, 14, 3949–3956. [Google Scholar]

- Yu, R.; Ho, G.K.Y.; Pong, B.M.H.; Ling, B.W.K.; Lam, J. Computer-aided design and optimization of high-efficiency LLC series resonant converter. IEEE Trans. Power Electron. 2012, 27, 3243–3256. [Google Scholar] [CrossRef]

- Yang, G.; Dubus, P.; Sadarnac, D. Double-phase high-efficiency, wide load range high-voltage/low-voltage LLC DC–DC converter for electric/hybrid vehicles. IEEE Trans. Power Electron. 2015, 30, 1876–1886. [Google Scholar]

- Kirshenboim, O.; Peretz, M.M. Combined Multilevel and Two-Phase Interleaved LLC Converter with Enhanced Power Processing Characteristics and Natural Current Sharing. IEEE Trans. Power Electron. 2018, 33, 5613–5620. [Google Scholar]

- Qian, T.; Qian, C. A Combined Topology with Coupled LLC Resonance for Wide-Range Operation. IEEE Trans. Power Electron. 2019, 34, 6593–6599. [Google Scholar]

- Xue, B.; Wang, H.; Liang, J.; Li, Z. Phase-Shift Modulated Interleaved LLC Converter with Ultrawide Output Voltage Range. IEEE Trans. Power Electron. 2021, 36, 493–503. [Google Scholar]

- Beak, J.; Kim, K.W.; Youn, H.S.; Kim, C.E. High-Efficiency LLC Resonant Converter with Reconfigurable Voltage Multiplying Rectifier for Wide Output Voltage Applications. IEEE Trans. Power Electron. 2021, 36, 7641–7651. [Google Scholar]

- Kim, T.; Choi, S.-H.; Choi, D.; Park, J.-E.; Moon, G.-W. Double Fault-Tolerant LLC Resonant Converter with Reconfiguration Method. IEEE Trans. Ind. Electron. 2023, 70, 4651–4661. [Google Scholar] [CrossRef]

- Mathuria, K.; Tiwari, H. Analysis, Design, and Implementation of an MPWM Interleaved DC–DC Converter with Voltage Doubler for EV Charging. IEEE J. Emerg. Sel. Topics Power Electron. 2024, 5, 511–520. [Google Scholar]

- Yu, H.; Xie, X.; Dong, H. Phase-Shift Modulated Hybrid LLC and Half-Bridge Converter with Fixed Frequency for Wide Voltage Gain Range Application. IEEE Trans. Power Electron. 2024, 39, 717–732. [Google Scholar] [CrossRef]

- Duarte, J.L.; Lokos, J.; van Horck, F.B.M. Phase-shift-controlled three-level converter with reduced voltage stress featuring ZVS over the full operation range. IEEE Trans. Power Electron. 2013, 28, 2140–2150. [Google Scholar] [CrossRef]

- Mustafa, A.; Mekhilef, S. Dual Phase LLC Resonant Converter with Variable Frequency Zero Circulating Current Phase-Shift Modulation for Wide Input Voltage Range Application. IEEE Trans. Power Electron. 2021, 36, 2793–2807. [Google Scholar] [CrossRef]

- Kim, C.E.; Beak, J.I.; Lee, J.B. High-Efficiency Single-Stage LLC Resonant Converter for Wide-Input-Voltage Range. IEEE Trans. Power Electron. 2018, 33, 7832–7840. [Google Scholar] [CrossRef]

- Hu, H.; Fang, X.; Chen, F.; Shen, Z.J.; Batarseh, I. A modified high efficiency LLC converter with two transformers for wide input-voltage range applications. IEEE Trans. Power Electron. 2013, 28, 1946–1960. [Google Scholar] [CrossRef]

- Sun, W.; Xing, Y.; Wu, H. Modified High-Efficiency LLC Converters with Two Split Resonant Branches for Wide Input-Voltage Range Applications. IEEE Trans. Power Electron. 2018, 33, 7867–7879. [Google Scholar] [CrossRef]

- Sun, X.; Li, X.; Shen, Y.; Wang, B.; Guo, X. Dual-Bridge LLC Resonant Converter with Fixed-Frequency PWM Control for Wide Input Applications. IEEE Trans. Power Electron. 2017, 32, 69–80. [Google Scholar] [CrossRef]

- Khan, S.; Sha, D.; Jia, X.; Wang, S. Resonant LLC DC–DC Converter Employing Fixed Switching Frequency Based on Dual-Transformer with Wide Input-Voltage Range. IEEE Trans. Power Electron. 2021, 36, 607–616. [Google Scholar] [CrossRef]

- Jiang, T.; Zhang, J.; Wu, X.; Sheng, K.; Wang, Y. A bidirectional three-level LLC resonant converter with PWAM control. IEEE Trans. Power Electron. 2016, 31, 2213–2225. [Google Scholar] [CrossRef]

- Chen, J.; Xu, J.; Wang, Y. Seamless Control of Full-Bridge and Half-Bridge Topology Morphing LLC Converter Based on State Plane Analysis. IEEE Trans. Power Electron. 2024, 39, 198–211. [Google Scholar] [CrossRef]

- Sha, D.; Yang, X. Wide Voltage Input Full Bridge(FB)/Half Bridge(HB) Morphing-Based LLC DC–DC Converter Using Numerical Optimal Trajectory Control. IEEE Trans. Ind. Electron. 2023, 70, 3697–3707. [Google Scholar] [CrossRef]

- Yuan, Y.; Peng, N.; Liu, W.; Yi, C. A Linear-Resonant Hybrid Bridge DC–DC Converter. IEEE Trans. Ind. Electron. 2023, 70, 1478–1488. [Google Scholar] [CrossRef]

- Sun, X.; Shen, Y.; Zhu, Y.; Guo, X. Interleaved Boost-Integrated LLC Resonant Converter with Fixed-Frequency PWM Control for Renewable Energy Generation Applications. IEEE Trans. Power Electron. 2015, 30, 4312–4325. [Google Scholar] [CrossRef]

- Kim, B.C.; Park, K.B.; Moon, G.W. Asymmetric PWM Control Scheme During Hold-Up Time for LLC Resonant Converter. IEEE Trans. Ind. Electron. 2012, 59, 2992–2996. [Google Scholar] [CrossRef]

- Chen, K.M.; Liang, T.J.; Chen, S.M.; Tsai, S.W. Design and implementation of a half-bridge dual LLC converter with symmetrical autotransformer. In Proceedings of the 2014 IEEE Energy Conversion Congress and Exposition (ECCE), Pittsburgh, PA, USA, 14–18 September 2014; pp. 4735–4741. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).