Innovative Technologies for Building Envelope to Enhance the Thermal Performance of a Modular House in Australia

Abstract

1. Introduction

2. Methods

2.1. Model Development

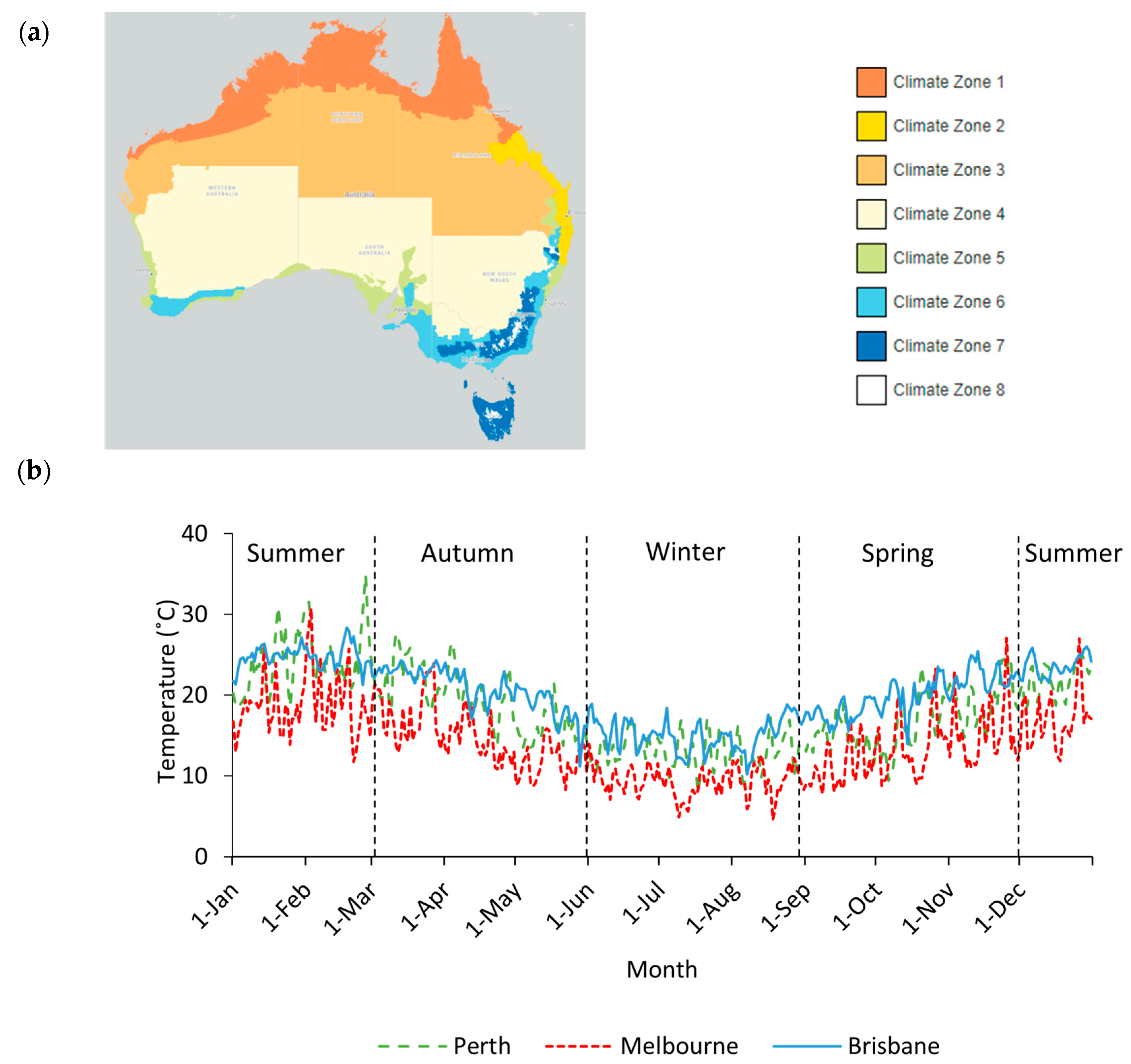

2.2. Climate Data

3. Selected Innovative Technologies

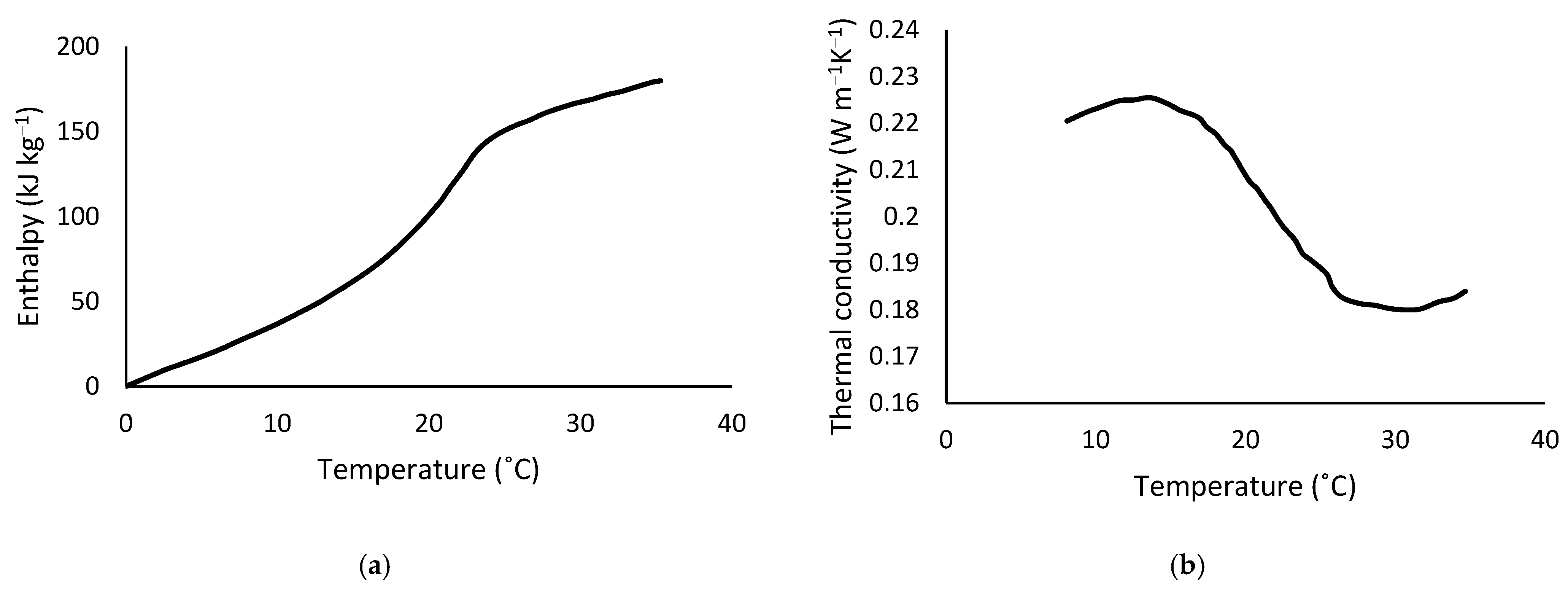

3.1. Phase Change Materials (PCMs)

3.2. Aerogel

3.3. Electrochromic Glazing

4. Results and Discussion

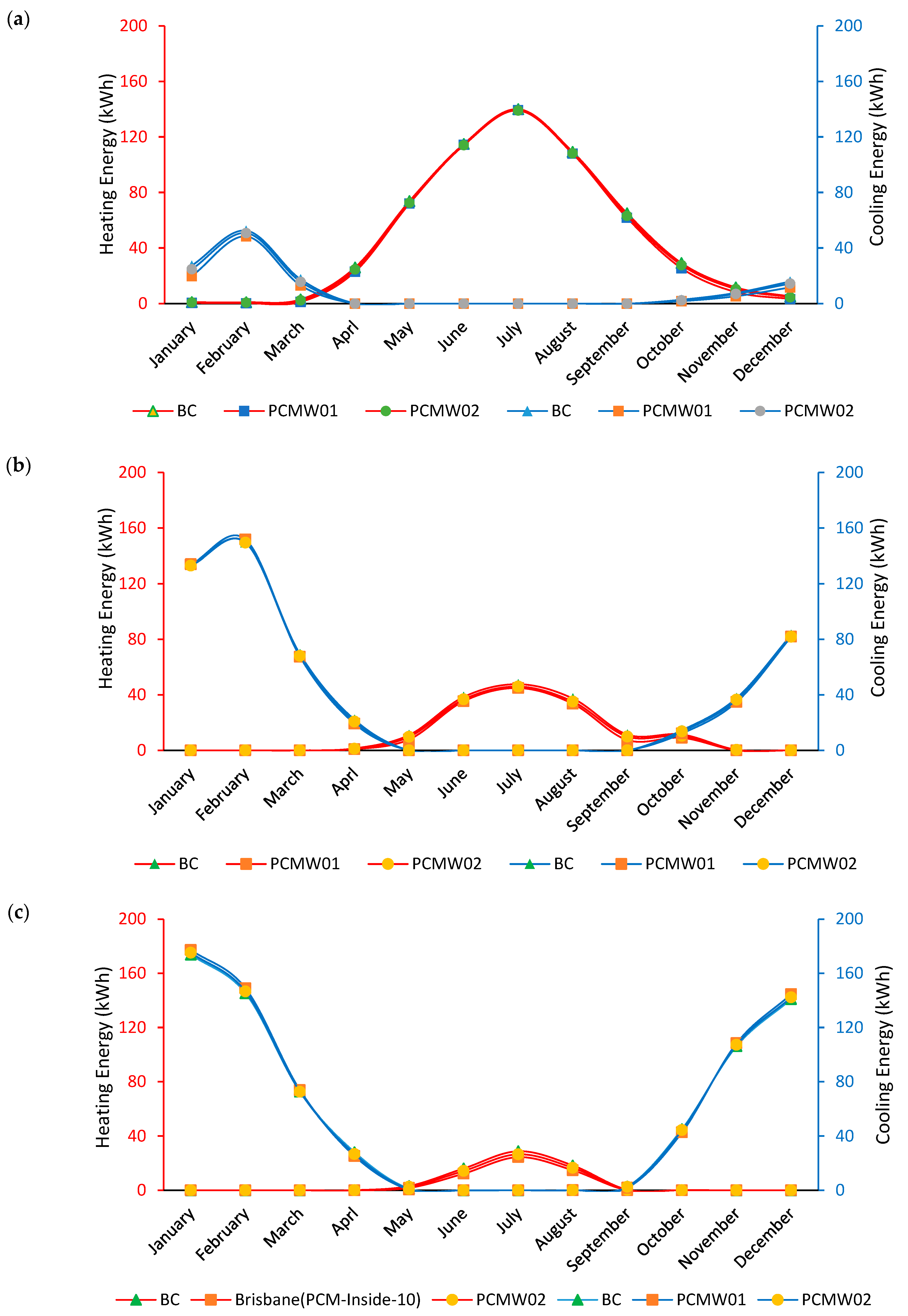

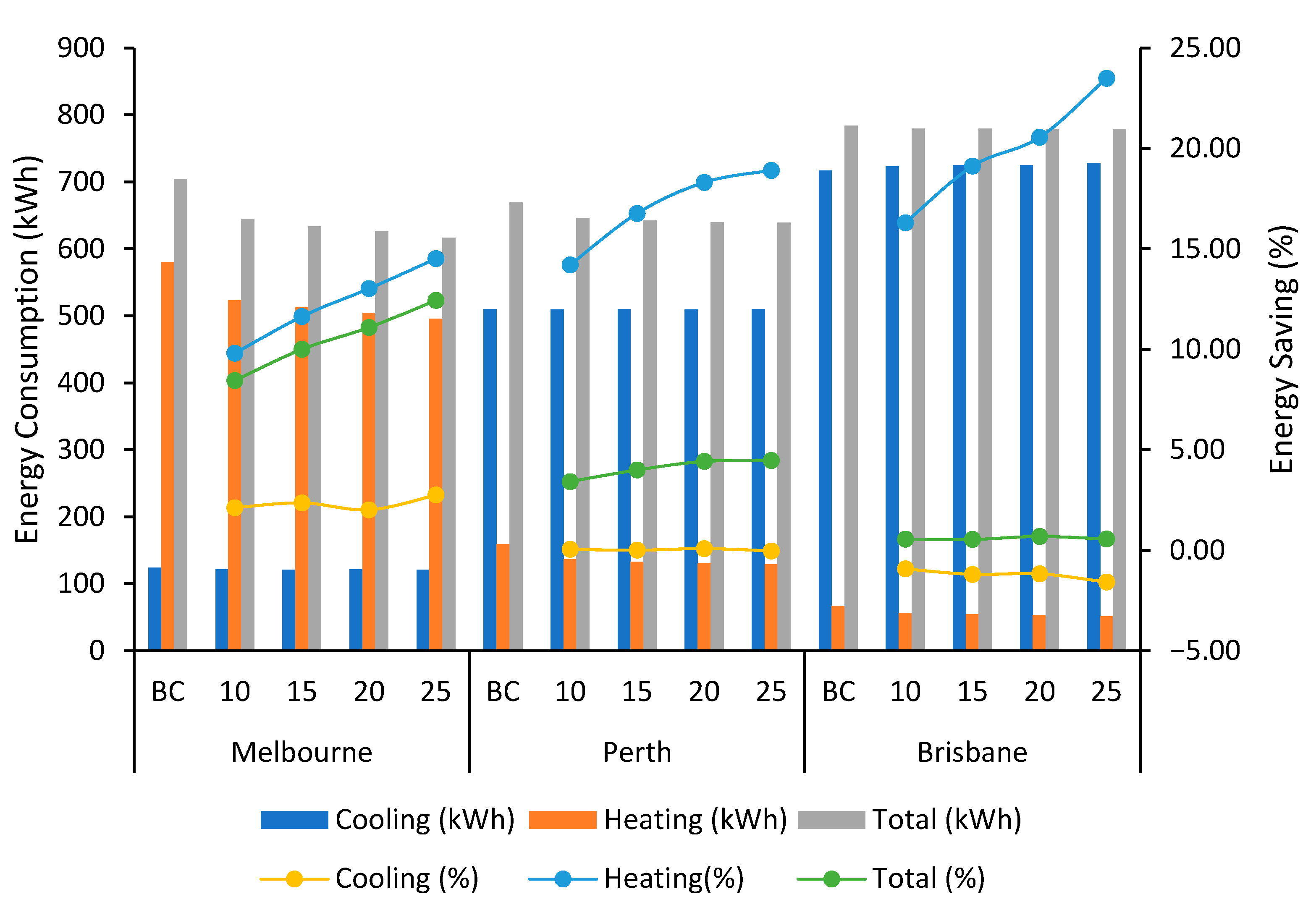

4.1. Effect of PCM as a Wall Insulation Material

4.2. Effect of Aerogel as a Wall Insulation Material

4.3. Effect of PCM as a Ceiling Insulation Material

4.4. Effect of Aerogel as a Ceiling Insulation Material

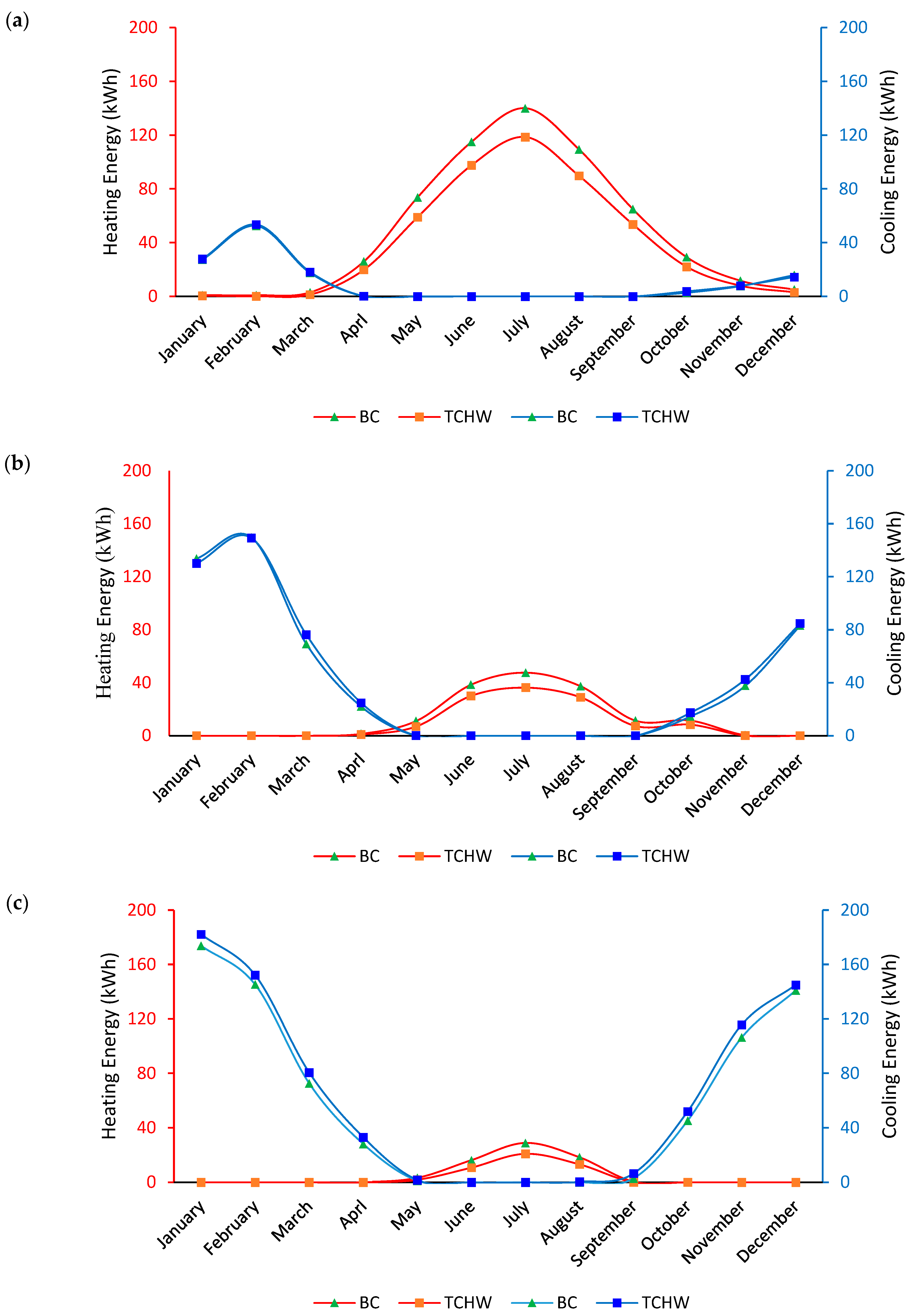

4.5. Effect of Electrochromic Glazing

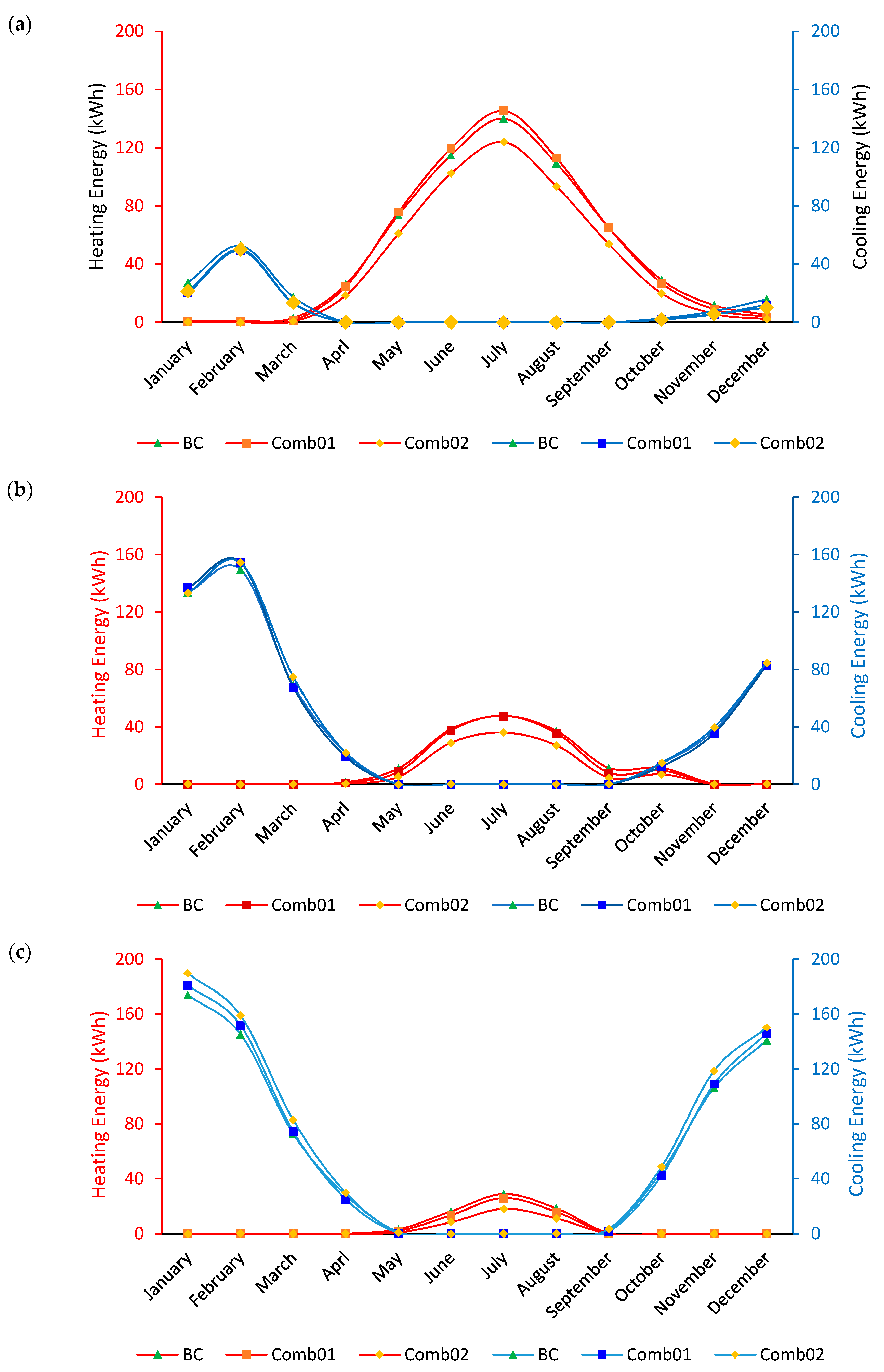

4.6. Effect of Combined Use of Innovative Technologies

5. Limitations

6. Conclusions

- For all three cities, a higher total annual energy saving is observed when the phase change material (PCM) is placed towards the inside of the wall. Perth has the highest energy saving amongst the three, which accounts for 6.4% when PCM is utilised in the walls of the prefabricated house. When the layer thickness is increased, no significant saving is observed in the total energy consumed.

- In aerogel modified wall panels, the highest total energy saving is observed when the aerogel blanket is located towards the external surface of the wall configuration. Annual total energy savings of 8.1%, 6.3%, and 3.3% were observed for Melbourne, Perth, and Brisbane, respectively.

- Aerogel blanket was identified as more efficient than the PCM as a ceiling insulation. The highest total energy saving was observed in Brisbane, with a saving of 5.3%, followed by Perth, with an annual saving of 4.6%. The energy saving for Melbourne with the ceiling modification using an aerogel blanket is negligible because of the limited thickness, the effect of complementary materials, weak integration with the other building systems, and the effects of the different systems operating in the building.

- When electrochromic windows were evaluated to replace generic plain glass, for the Melbourne and Perth climate conditions, significant energy savings of 8.9% and 3.8% were observed. However, for Brisbane, no energy performance enhancement was observed with the use of electrochromic glazing. Limited performance under high solar gains in Brisbane, and the performance of electrochromic glazing depending on the device control system, could be possible reasons for this observation.

- For the combined modifications of the prefabricated building envelope, which include the incorporation of PCM in walls, aerogel in the ceiling, and the introduction of electrochromic glazing, under Melbourne, Perth, and Brisbane climatic conditions, the most efficient combination was the combination with a PCM inside walls placed towards the internal side, aerogel blanket placed inside ceiling panels and electrochromic windows. This combination has yielded total annual energy savings of 15.6%, 11.2%, and 6.1% for Melbourne, Perth, and Brisbane, respectively. Moreover, these energy saving values resemble those for this optimum housing solution; the heating energy efficiency for Melbourne, Perth, and Brisbane are approximately 16.8 kWh m−2, 3.8 kWh m−2, and 1.3 kWh m−2, respectively.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ACH | Air Changes per Hour |

| COP | Coefficient of Performance |

| HVAC | Heating, Ventilation, and Air Conditioning |

| PCM | Phase Change Material |

| toe | tonne of oil equivalent |

References

- Li, X.G. Green energy for sustainability and energy security. In Green Energy: Basic Concepts and Fundamentals; Li, X.G., Ed.; Academic Press: Amsterdam, The Netherlands, 2011; Volume 1, pp. 1–16. [Google Scholar]

- Bashir, A.W.; Leite, B.C.C. Performance of aerogel as a thermal insulation material towards a sustainable design of residential buildings for tropical climates in Nigeria. Energy Built Environ. 2022, 3, 291–315. [Google Scholar] [CrossRef]

- Nocera, D.G. On the future of global energy. Daedalus 2006, 135, 112–115. [Google Scholar] [CrossRef]

- Allouhi, A.; El Fouih, Y.; Kousksou, T.; Jamil, A.; Zeraouli, Y.; Mourad, Y. Energy consumption and efficiency in buildings: Current status and future trends. J. Clean. Prod. 2015, 109, 118–130. [Google Scholar] [CrossRef]

- DCCEEW Energy Consumption. Available online: https://www.energy.gov.au/energy-data/australian-energy-statistics/energy-consumption#:~:text=Australia’s%20energy%20consumption%20rose%202.0,energy%20mix%20in%202022%2D23 (accessed on 30 September 2024).

- DCCEEW Residential Buildings. Available online: https://www.dcceew.gov.au/energy/energy-efficiency/buildings/residential-buildings (accessed on 30 September 2024).

- Navaratnam, S.; Jayalath, A.; Aye, L. Effects of Working from Home on Greenhouse Gas Emissions and the Associated Energy Costs in Six Australian Cities. Buildings 2022, 12, 463. [Google Scholar] [CrossRef]

- Tushar, Q.; Zhang, G.; Bhuiyan, M.A.; Navaratnam, S.; Giustozzi, F.; Hou, L. Retrofit of Building Façade Using Precast Sandwich Panel: An Integrated Thermal and Environmental Assessment on BIM-Based LCA. Buildings 2022, 12, 2098. [Google Scholar] [CrossRef]

- Ürge-Vorsatz, D.; Cabeza, L.; Serrano, S.; Barreneche, C.; Petrichenko, K. Heating and cooling energy trends and drivers in buildings. Renew. Sustain. Energy Rev. 2015, 41, 85–98. [Google Scholar] [CrossRef]

- ABS Housing. Available online: https://www.abs.gov.au/statistics/people/housing#:~:text=Housing%3A%20Census,unoccupied%20dwellings%20on%20Census%20Night (accessed on 22 September 2024).

- Mordor Intelligence Modular Construction in Australia Market Size—Industry Report on Share, Growth Trends & Forecasts Analysis (2024–2029). Available online: https://www.mordorintelligence.com/industry-reports/australia-prefabricated-buildings-industry (accessed on 30 September 2024).

- Luo, C.; Yao, X.; Zhang, Y.; Zhou, H. An empirical study on the impact of different structural systems on carbon emissions of prefabricated buildings based on SimaPro. World J. Eng. Technol. 2023, 11, 434–453. [Google Scholar] [CrossRef]

- Navaratnam, S.; Tushar, Q.; Jahan, I.; Zhang, G. Environmental Sustainability of Industrial Waste-Based Cementitious Materials: A Review, Experimental Investigation and Life-Cycle Assessment. Sustainability 2023, 15, 1873. [Google Scholar] [CrossRef]

- Ginigaddara, B.; Perera, S.; Feng, Y.; Payam, R. Offsite construction skills prediction: A conceptual model. In World Construction Symposium, Proceedings of the10th World Construction Symposium, Colombo, Sri Lanka, 24–26 June 2022; University of Moratuwa: Moratuwa, Sri Lanka, 2022; pp. 648–656. [Google Scholar]

- Munmulla, T.; Hidallana-Gamage, H.D.; Navaratnam, S.; Ponnampalam, T.; Zhang, G.M.; Jayasinghe, T. Suitability of modular technology for house construction in Sri Lanka: A survey and a case study. Buildings 2023, 13, 2592. [Google Scholar] [CrossRef]

- Boafo, F.E.; Kim, J.H.; Kim, J.T. Performance of modular prefabricated architecture: Case study-based review and future pathways. Sustainability 2016, 8, 558. [Google Scholar] [CrossRef]

- Ji, Y.; Lv, J.; Li, H.X.; Liu, Y.; Yao, F.; Liu, X.; Wang, S. Improving the performance of prefabricated houses through multi-objective optimization design. J. Build. Eng. 2024, 84, 108579. [Google Scholar] [CrossRef]

- Shen, Q.; Yu, Y.; Hou, J.W.; Wang, Q.; Zhang, L.L.; Meng, X. The testing research on prefabricated building indoor thermal environment of earthquake disaster region. Procedia Eng. 2017, 205, 453–460. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, L.; Long, E.S.; Deng, S.M. An experimental study on the indoor thermal environment in prefabricated houses in the subtropics. Energy Build. 2016, 127, 529–539. [Google Scholar] [CrossRef]

- Guri, M.; Krois, F.; Xhexhi, K. Study of thermal performance of prefabricated large panel buildings. In Proceedings of the 2nd Croatian Conference on Earthquake Engineering, Zagreb, Croatia, 22–24 March 2023. [Google Scholar]

- Podawca, K.; Pawlat-Zawrzykraj, A.; Dohojda, M. Analysis of the possibilities for improvement of thermal comfort of living quarters located in multi-family large-panel prefabricated buildings. In Proceedings of the 10th Conference on Interdisciplinary Problems in Environmental Protection and Engineering Eko-Dok 2018, Polanica-Zdrój, Poland, 16–18 April 2018; Volume 44. [Google Scholar]

- Naji, S.; Aye, L.; Noguchi, M. Sensitivity analysis on energy performance, thermal and visual discomfort of a prefabricated house in six climate zones in Australia. Appl. Energy 2021, 298, 117200. [Google Scholar] [CrossRef]

- Ren, Z.; Foliente, G.; Chan, W.-Y.; Chen, D.; Ambrose, M.; Paevere, P. A model for predicting household end-use energy consumption and greenhousegas emissions in Australia. Int. J. Sustain. Build. Technol. Urban. Dev. 2013, 4, 210–228. [Google Scholar] [CrossRef]

- Abu-Jdayil, B.; Mourad, A.H.; Hittini, W.; Hassan, M.; Hameedi, S. Traditional, state-of-the-art and renewable thermal building insulation materials: An overview. Constr. Build. Mater. 2019, 214, 709–735. [Google Scholar] [CrossRef]

- Llantoy, N.; Chàfer, M.; Cabeza, L.F. A comparative life cycle assessment (LCA) of different insulation materials for buildings in the continental Mediterranean climate. Energy Build. 2020, 225, 110323. [Google Scholar] [CrossRef]

- Bahl, S.; Nagar, H.; Singh, I.; Sehgal, S. Smart materials types, properties and applications: A review. Mater. Today-Proc. 2020, 28, 1302–1306. [Google Scholar] [CrossRef]

- Jelle, B.P. Traditional, state-of-the-art and future thermal building insulation materials and solutions—Properties, requirements and possibilities. Energy Build. 2011, 43, 2549–2563. [Google Scholar] [CrossRef]

- Wicklein, B.; Kocjan, A.; Salazar-Alvarez, G.; Carosio, F.; Camino, G.; Antonietti, M.; Bergström, L. Thermally insulating and fire-retardant lightweight anisotropic foams based on nanocellulose and graphene oxide. Nat. Nanotechnol. 2015, 10, 277–283. [Google Scholar] [CrossRef] [PubMed]

- Venkataraman, M.; Mishra, R.; Kotresh, T.M.; Militky, J.; Jamshaid, H. Aerogels for thermal insulation in high-performance textiles. Text. Prog. 2016, 48, 55–118. [Google Scholar] [CrossRef]

- Mohamed, A.S.Y. Smart materials innovative technologies in architecture; Towards innovative design paradigm. Energy Proced. 2017, 115, 139–154. [Google Scholar] [CrossRef]

- Aye, L.; Ngo, T.; Crawford, R.H.; Gammampila, R.; Mendis, P. Life cycle greenhouse gas emissions and energy analysis of prefabricated reusable building modules. Energy Build. 2012, 47, 159–168. [Google Scholar] [CrossRef]

- Design Builder Software Australia Design Builder. Available online: https://designbuilder.com.au/ (accessed on 30 September 2024).

- ABCB National Construction Code. Available online: https://ncc.abcb.gov.au/ (accessed on 30 April 2025).

- Australian Government Your Home. Available online: https://www.yourhome.gov.au/getting-started/australian-climate-zones (accessed on 20 April 2025).

- Tunçbilek, E.; Wang, D.; Arıcı, M.; Krajčík, M.; Nižetić, S.; Li, D. Energy conservation and CO2 mitigation potential through PCM integration in building envelopes: Effect of façade orientation. J. Therm. Anal. Calorim. 2025, 150, 8389–8401. [Google Scholar]

- DuPont DuPont Energain. Available online: https://cdn2.hubspot.net/hub/55819/file-14736951-pdf/docs/energain_flyer.pdf (accessed on 30 September 2024).

- Kumar, D.; Alam, M.; Sanjayan, J.G. Retrofitting Building Envelope Using Phase Change Materials and Aerogel Render for Adaptation to Extreme Heatwave: A Multi-Objective Analysis Considering Heat Stress, Energy, Environment, and Cost. Sustainability 2021, 13, 10716. [Google Scholar] [CrossRef]

- Ascione, F. Energy conservation and renewable technologies for buildings to face the impact of the climate change and minimize the use of cooling. Sol. Energy 2017, 154, 34–100. [Google Scholar] [CrossRef]

- Ihara, T.; Jelle, B.P.; Gao, T.; Gustavsen, A. Aerogel granule aging driven by moisture and solar radiation. Energy Build. 2015, 103, 238–248. [Google Scholar]

- Al-Yasiri, Q.; Szabó, M. Incorporation of phase change materials into building envelope for thermal comfort and energy saving: A comprehensive analysis. J. Build. Eng. 2021, 36, 102122. [Google Scholar] [CrossRef]

- Faraj, K.; Khaled, M.; Faraj, J.; Hachem, F.; Castelain, C. A review on phase change materials for thermal energy storage in buildings: Heating and hybrid applications. J. Energy Storage 2021, 33, 101913. [Google Scholar] [CrossRef]

- Zhan, H.; Mahyuddin, N.; Sulaiman, R.; Khayatian, F. Phase change material (PCM) integrations into buildings in hot climates with simulation access for energy performance and thermal comfort: A review. Constr. Build. Mater. 2023, 397, 132312. [Google Scholar] [CrossRef]

- Agyenim, F.; Hewitt, N.; Eames, P.; Smyth, M. A review of materials, heat transfer and phase change problem formulation for latent heat thermal energy storage systems (LHTESS). Renew. Sustain. Energy Rev. 2010, 14, 615–628. [Google Scholar] [CrossRef]

- Baniassadi, A.; Sailor, D.J.; Bryan, H.J. Effectiveness of phase change materials for improving the resiliency of residential buildings to extreme thermal conditions. Sol. Energy 2019, 188, 190–199. [Google Scholar] [CrossRef]

- Jeong, S.G.; Jeon, J.; Seo, J.; Lee, J.H.; Kim, S. Performance evaluation of the microencapsulated PCM for wood-based flooring application. Energy Convers. Manag. 2012, 64, 516–521. [Google Scholar] [CrossRef]

- Li, D.; Zheng, Y.M.; Liu, C.Y.; Wu, G.Z. Numerical analysis on thermal performance of roof contained PCM of a single residential building. Energy Convers. Manag. 2015, 100, 147–156. [Google Scholar] [CrossRef]

- Castell, A.; Martorell, I.; Medrano, M.; Pérez, G.; Cabeza, L.F. Experimental study of using PCM in brick constructive solutions for passive cooling. Energy Build. 2010, 42, 534–540. [Google Scholar]

- Kosny, J.; Miller, W.A.; Yarbrough, D.; Kossecka, E.; Biswas, K. Application of Phase Change Materials and Conventional Thermal Mass for Control of Roof-Generated Cooling Loads. Appl. Sci. 2020, 10, 6875. [Google Scholar] [CrossRef]

- Yew, M.C.; Sulong, N.H.R.; Chong, W.T.; Poh, S.C.; Ang, B.C.; Tan, K.H. Integration of thermal insulation coating and moving-air-cavity in a cool roof system for attic temperature reduction. Energy Convers. Manag. 2013, 75, 241–248. [Google Scholar] [CrossRef]

- Yao, C.Q.; Kong, X.F.; Li, Y.T.; Du, Y.X.; Qia, C.Y. Numerical and experimental research of cold storage for a novel expanded perlite-based shape-stabilized phase change material wallboard used in building. Energy Convers. Manag. 2018, 155, 20–31. [Google Scholar] [CrossRef]

- Feng, L.L.; Zhao, W.; Zheng, J.; Frisco, S.; Song, P.; Li, X.G. The shape-stabilized phase change materials composed of polyethylene glycol and various mesoporous matrices (AC, SBA-15 and MCM-41). Sol. Energy Mater. Sol. Cells 2011, 95, 3550–3556. [Google Scholar] [CrossRef]

- Wang, X.; Yu, H.; Li, L.; Zhao, M. Experimental assessment on the use of phase change materials (PCMs)-bricks in the exterior wall of a full-scale room. Energy Convers. Manag. 2016, 120, 81–89. [Google Scholar] [CrossRef]

- Hu, Z.; Li, W.; Yang, C.; Huang, H.; Guo, Y.; Ge, F.; Zhang, Y. Thermal performance of an active casing pipe macro-encapsulated PCM wall for space cooling and heating of residential building in hot summer and cold winter region in China. Constr. Build. Mater. 2024, 422, 135831. [Google Scholar] [CrossRef]

- Hu, J.Y.; Yu, X. Thermo and light-responsive building envelope: Energy analysis under different climate conditions. Sol. Energy 2019, 193, 866–877. [Google Scholar] [CrossRef]

- Alvarez-Feijoo, M.A.; Orgeira-Crespo, P.; Arce, E.; Suárez-García, A.; Ribas, J.R. Effect of insulation on the energy demand of a standardized container facility at airports in Spain under different weather conditions. Energies 2020, 13, 5263. [Google Scholar] [CrossRef]

- Gesser, H.D.; Goswami, P.C. Aerogels and related porous materials. Chem. Rev. 1989, 89, 765–788. [Google Scholar] [CrossRef]

- Buratti, C.; Moretti, E. Glazing systems with silica aerogel for energy savings in buildings. Appl. Energy 2012, 98, 396–403. [Google Scholar] [CrossRef]

- Nocentini, K.; Achard, P.; Biwole, P. Hygro-thermal properties of silica aerogel blankets dried using microwave heating for building thermal insulation. Energy Build. 2018, 158, 14–22, Erratum in Energy Build. 2018, 168, 165–166.. [Google Scholar] [CrossRef]

- Riffat, S.B.; Qiu, G.Q. A review of state-of-the-art aerogel applications in buildings. Int. J. Low-Carbon. Technol. 2013, 8, 1–6. [Google Scholar] [CrossRef]

- Liu, P.; Gong, Y.F.; Tian, G.H.; Miao, Z.K. Preparation and experimental study on the thermal characteristics of lightweight prefabricated nano-silica aerogel foam concrete wallboards. Constr. Build. Mater. 2021, 272, 121895. [Google Scholar] [CrossRef]

- Koebel, M.; Rigacci, A.; Achard, P. Aerogel-based thermal superinsulation: An overview. J. Sol-Gel Sci. Technol. 2012, 63, 315–339. [Google Scholar] [CrossRef]

- Nosrati, R.H.; Berardi, U. Hygrothermal characteristics of aerogel-enhanced insulating materials under different humidity and temperature conditions. Energy Build. 2018, 158, 698–711. [Google Scholar] [CrossRef]

- Cannavale, A.; Ayr, U.; Fiorito, F.; Martellotta, F. Smart electrochromic windows to enhance building energy efficiency and visual comfort. Energies 2020, 13, 1449. [Google Scholar] [CrossRef]

- Granqvist, C.G. Chromogenic materials for transmittance control of large-area windows. In Proceedings of the Workshop on Materials Science and Physics of Non-Conventional Energy Sources, Trieste, Italy, 11–29 September 1991; pp. 143–199. [Google Scholar]

- Firouzabad, M.R.; Astaraei, F.R. Energetical effect of electrochromic glazing on the double-skin façade of the building in different climates. Energy Build. 2024, 316, 114344. [Google Scholar] [CrossRef]

- Papaefthimiou, S.; Leftheriotis, G.; Yianoulis, P.; Hyde, T.J.; Eames, P.C.; Fang, Y.; Pennarun, P.Y.; Jannasch, P. Development of electrochromic evacuated advanced glazing. Energy Build. 2006, 38, 1455–1467. [Google Scholar] [CrossRef]

- Svensson, J.S.E.M.; Granqvist, C.G. Electrochromic coatings for smart windows. Sol. Energy Mater. 1985, 12, 391–402. [Google Scholar] [CrossRef]

- Huang, Y.; Niu, J.-l. Energy and visual performance of the silica aerogel glazing system in commercial buildings of Hong Kong. Constr. Build. Mater. 2015, 94, 57–72. [Google Scholar] [CrossRef]

- Granqvist, C.G.; Arvizu, M.A.; Pehlivan, I.B.; Qu, H.Y.; Wen, R.T.; Niklasson, G.A. Electrochromic materials and devices for energy efficiency and human comfort in buildings: A critical review. Electrochim. Acta 2018, 259, 1170–1182. [Google Scholar] [CrossRef]

- Alhagla, K.; Mansour, A.; Elbassuoni, R. Optimizing windows for enhancing daylighting performance and energy saving. Alex. Eng. J. 2019, 58, 283–290. [Google Scholar] [CrossRef]

- Isaia, F.; Fiorentini, M.; Serra, V.; Capozzoli, A. Enhancing energy efficiency and comfort in buildings through model predictive control for dynamic facades with electrochromic glazing. J. Build. Eng. 2021, 43, 102535. [Google Scholar] [CrossRef]

- Jelle, B.P. Solar radiation glazing factors for window panes, glass structures and electrochromic windows in buildings-Measurement and calculation. Sol. Energy Mater. Sol. Cells 2013, 116, 291–323. [Google Scholar] [CrossRef]

- Lampert, C.M. Smart switchable glazing for solar energy and daylight control. Sol. Energy Mater. Sol. Cells 1998, 52, 207–211, Erratum in Sol. Energy Mater. Sol. Cells 1998, 55, 301.. [Google Scholar] [CrossRef]

- Wu, S.; Sun, J.; Duan, Z.; Li, X.; Xiao, J.; Sun, H.; Lin, B. Building-Tailored Hierarchical Electrochromism with Optimized Control Strategies. Adv. Sci. 2025, e13530. [Google Scholar] [CrossRef]

- Wu, S.; Sun, H.; Duan, M.; Mao, H.; Wu, Y.; Zhao, H.; Lin, B. Applications of thermochromic and electrochromic smart windows: Materials to buildings. Cell Rep. Phys. Sci. 2023, 4, 101370. [Google Scholar] [CrossRef]

- Tan, Q.; Siroux, M. Evaluation and optimization of PCM-integrated walls: Energy, exergy, environmental, and economic perspectives. Renew. Sustain. Energy. Rev. 2025, 222, 115922. [Google Scholar] [CrossRef]

- Ehms, J.; Oliveski, R.; Rocha, L.; Biserni, C.; Garai, M. Phase Change Materials (PCM) for Building Envelope Applications: A Review of Numerical Models; AIP Publishing LLC: New York, NY, USA, 2019; Volume 2191, p. 020120. [Google Scholar]

- Kuznik, F.; Virgone, J. Experimental assessment of a phase change material for wall building use. Appl. Energy 2009, 86, 2038–2046. [Google Scholar] [CrossRef]

- Hasan, M.I.; Basher, H.O.; Shdhan, A.O. Experimental investigation of phase change materials for insulation of residential buildings. Sustain. Cities Soc. 2018, 36, 42–58. [Google Scholar] [CrossRef]

- Soares, N.; Gaspar, A.R.; Santos, P.; Costa, J.J. Multi-dimensional optimization of the incorporation of PCM-drywalls in lightweight steel-framed residential buildings in different climates. Energy Build. 2014, 70, 411–421. [Google Scholar] [CrossRef]

- Chung, M.H.; Park, J.C. An Experimental Study on the Thermal Performance of Phase-Change Material and Wood-Plastic Composites for Building Roofs. Energies 2017, 10, 195. [Google Scholar] [CrossRef]

- Hu, R.; Liu, G.; Niu, J. The Impacts of a Building’s Thermal Mass on the Cooling Load of a Radiant System under Various Typical Climates. Energies 2020, 13, 1356. [Google Scholar] [CrossRef]

- De Toldi, T.; Craig, S.; Sushama, L. Internal thermal mass for passive cooling and ventilation: Adaptive comfort limits, ideal quantities, embodied carbon. Build. Cities 2022, 3, 42. [Google Scholar] [CrossRef]

- Asan, H. Numerical computation of time lags and decrement factors for different building materials. Build. Environ. 2006, 41, 615–620. [Google Scholar] [CrossRef]

- Kurdi, A.; Almoatham, N.; Mirza, M.; Ballweg, T.; Alkahlan, B. Potential Phase Change Materials in Building Wall Construction-A Review. Materials 2021, 14, 5328. [Google Scholar]

- Winsulation Double Glazing. Double Galzing Brisbane. Available online: https://winsulation.com.au/ (accessed on 1 August 2024).

- Australasian Insulation Solutions. AIS Insulation Solutions. Available online: https://www.ais-group.com.au/ (accessed on 1 July 2024).

| Variables | Range |

|---|---|

| Locations | Melbourne, Perth, Brisbane |

| Type | Prefabricated house with conventional insulation material Prefabricated house with innovative technologies in separate building envelope elements Prefabricated house with combined innovative technologies in building envelope elements |

| Innovative technologies | Phase change material, Aerogel blanket, Electrochromic glazing |

| Envelope element | Walls, Roof, Windows |

| Orientation | North, East, South, West |

| 1 | Roof | Roof felt (5 mm) + Airgap (10 mm) + Clay tiles (25 mm) |

| 2 | Ceiling | Plasterboard (13 mm) + Airgap (25 mm) + Concrete slab (100 mm) + Glass wool insulation (130 mm) + Plywood (10 mm) | |

| 3 | Internal walls | Plasterboard (13 mm) + Timber frame (50 mm) + Plasterboard (13 mm) | |

| 4 | Windows | Clear Glass (10 mm) + Airgap (13 mm) + Clear Glass (10 mm) | |

| 5 | External walls | Plaster board (13 mm) + Timber frame (50 mm) + Cellulose insulation (90 mm) + Precast concrete wall panel (80 mm) | |

| 6 | Floor | Plywood flooring (19 mm) + Cellulose insulation (100 mm) + Reinforced concrete slab (150 mm) |

| Material | Thermal Conductivity (W m−1 K−1) | Specific Heat (J kg−1 K−1) | Density (kg m−3) |

|---|---|---|---|

| Precast concrete panel | 0.200 | 850 | 600 |

| Cellulose insulation | 0.042 | 1380 | 43 |

| Airgap | 0.030 | 1005 | 1.225 |

| Plaster board | 0.250 | 950 | 850 |

| Reinforced concrete | 2.300 | 1000 | 2300 |

| Glass wool insulation | 0.040 | 840 | 12 |

| Element | Location | Performance Enhancement | Reference |

|---|---|---|---|

| Roof | Northeast and cold areas of China | The delay time of the temperature peak of the base layer in PCM roofs has been observed to be 3 h longer than that of a common roof. | [46] |

| Cubicles | Puigverd de Lleida, Spain | Energy consumed by the PCM cubicle during the cooling period is higher than that of a traditional brick system with and without spray foam polyurethane insulation; the cubicles | [47] |

| PV-PCM roof/attic system | Tennessee, USA | 30% heating and 50% cooling load reductions were observed compared to a control asphalt shingle roof | [48] |

| Roof | The significant difference in the results is due to the low thermal conductivity of the thermal insulation paint and the use of aluminium tubes in the roof cavity | [49] | |

| Floor | Korea | Wood-based flooring incorporating microencapsulated phase change material has displayed the characteristics of a thermal energy storage material | [45] |

| Walls | North China | Reduced the temperature of an office building on average by 9.22 K | [50] |

| Walls | Reduce the interior temperature of the building by 1–2 °C | [51] | |

| Walls | Shanghai | 24% lower cooling energy demand and 10–30% lower heating energy demand have been observed | [52] |

| Walls | China | An optimised casing pipe macro-encapsulated PCM wall system that can reliably and efficiently meet both the space heating and cooling demands of residential buildings in hot summer and cold winter regions in China. | [53] |

| Electrochromic Window | Plain Window | |

|---|---|---|

| Construction template | Dbl Elec Ref Bleached 6 mm + 13 mm Airgap | Clear Glass (10 mm) + Airgap (13 mm) + Clear Glass (10 mm) |

| U Value | 1.766 W m−2 K−1 | 2.467 W m−2 K−1 |

| Glazing activation set point | Radiation and solar emissions of more than 120 W m−2 | Not applicable (N/A) |

| Configuration | ||

|---|---|---|

| Base Case | BC | Plaster board (13 mm) + Timber frame (50 mm) + Cellulose insulation (90 mm) + Precast concrete wall panel (80 mm) |

| PCM on the internal side | PCMW01 | Plaster board (13 mm) + Timber frame (50 mm) + PCM (5.26 mm) + Cellulose insulation (85 mm) + Precast concrete wall panel (80 mm) |

| PCM on the external side | PCMW02 | Plaster board (13 mm) + Timber frame (50 mm) + Cellulose insulation (85 mm) + PCM (5.26 mm) + Precast concrete wall panel (80 mm) |

| Configuration | ||

|---|---|---|

| Base Case | BC | Plaster board (13 mm) + Timber frame (50 mm) + Cellulose insulation (90 mm) + Precast concrete wall panel (80 mm) |

| Aerogel blanket on the internal side | AGW01 | Plaster board (13 mm) + Timber frame (50 mm) + Aerogel blanket (10 mm) + Cellulose insulation (80 mm) + Precast concrete wall panel (80 mm) |

| Aerogel blanket on the external side | AGW02 | Plaster board (13 mm) + Timber frame (50 mm) + Cellulose insulation (80 mm) + Aerogel blanket (10 mm) + Precast concrete wall panel (80 mm) |

| Configuration | ||

|---|---|---|

| Base Case | BC | Plasterboard (13 mm) + Airgap (25 mm) + Concrete slab (100 mm) + Glass wool insulation (130 mm) + Plywood (10 mm) |

| With PCM | PCM | Plasterboard (13 mm) + Airgap (25 mm) + Concrete slab (100 mm) + PCM layer (5.3 mm) + Plywood (10 mm) |

| Configuration | ||

|---|---|---|

| Base Case | BC | Plasterboard (13 mm) + Airgap (25 mm) + Concrete slab (100 mm) + Glass wool insulation (130 mm) |

| With an Aerogel blanket as insulation | AGC | Plasterboard (13 mm) + Airgap (25 mm) + Concrete slab (100 mm) + Aerogel blanket (10 mm) + Plywood (10 mm) |

| ||

| Key | Element | Combination 01 (from Inside to Outside Layer) |

|---|---|---|

| 1 | Roof | Roof felt (5 mm) + Airgap (10 mm) + Clay tiles (25 mm) |

| 2 | Ceiling | Plasterboard (13 mm) + Airgap (25 mm) + Concrete slab (100 mm) + Aerogel blanket (10 mm) + Plywood (10 mm) |

| 3 | Internal wall | Plasterboard (13 mm) + Timber frame (50 mm) + Plasterboard (13 mm) |

| 4 | Windows | Clear Glass (10 mm) + Airgap (13 mm) + Clear Glass (10 mm) |

| 5 | External wall | Plaster board (13 mm) + Timber frame (50 mm) + PCM (5.26 mm) + Cellulose insulation (85 mm) + Precast concrete wall panel (80 mm) |

| 6 | Floor | Plywood flooring (19 mm) + Cellulose insulation (100 mm) + Reinforced concrete slab (150 mm) |

| Combination 02 has an additional Electrochromic window | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bandaranayake, S.; Navaratnam, S.; Munmulla, T.; Zhang, G.; Aye, L. Innovative Technologies for Building Envelope to Enhance the Thermal Performance of a Modular House in Australia. Energies 2025, 18, 6485. https://doi.org/10.3390/en18246485

Bandaranayake S, Navaratnam S, Munmulla T, Zhang G, Aye L. Innovative Technologies for Building Envelope to Enhance the Thermal Performance of a Modular House in Australia. Energies. 2025; 18(24):6485. https://doi.org/10.3390/en18246485

Chicago/Turabian StyleBandaranayake, Sathya, Satheeskumar Navaratnam, Thisari Munmulla, Guomin Zhang, and Lu Aye. 2025. "Innovative Technologies for Building Envelope to Enhance the Thermal Performance of a Modular House in Australia" Energies 18, no. 24: 6485. https://doi.org/10.3390/en18246485

APA StyleBandaranayake, S., Navaratnam, S., Munmulla, T., Zhang, G., & Aye, L. (2025). Innovative Technologies for Building Envelope to Enhance the Thermal Performance of a Modular House in Australia. Energies, 18(24), 6485. https://doi.org/10.3390/en18246485

_Zhang.png)