Full-Life-Cycle Management of High-Voltage Bushings Based on Digital Twin: Typical Scenarios, Core Technologies, and Research Prospects

Abstract

1. Introduction

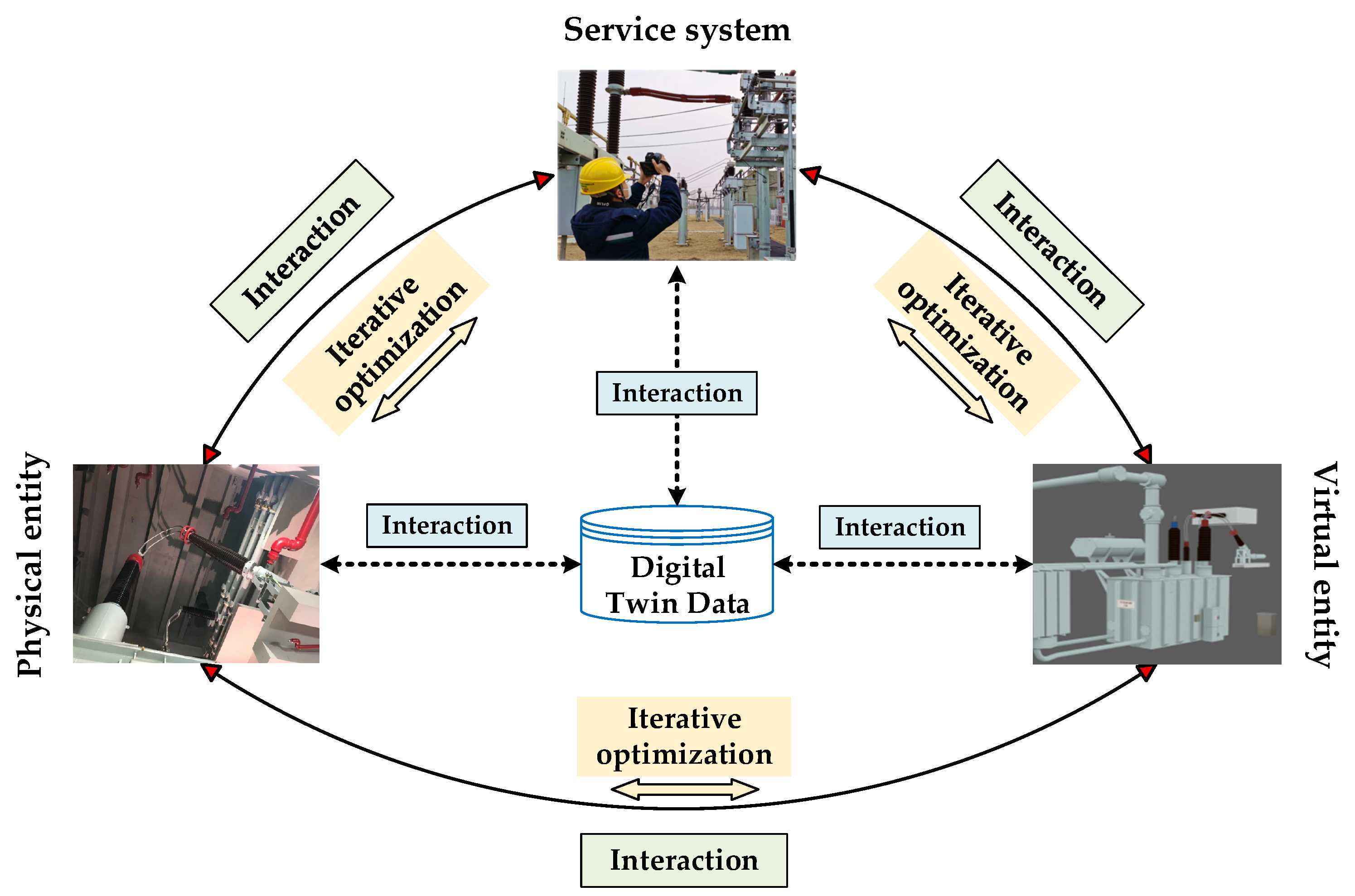

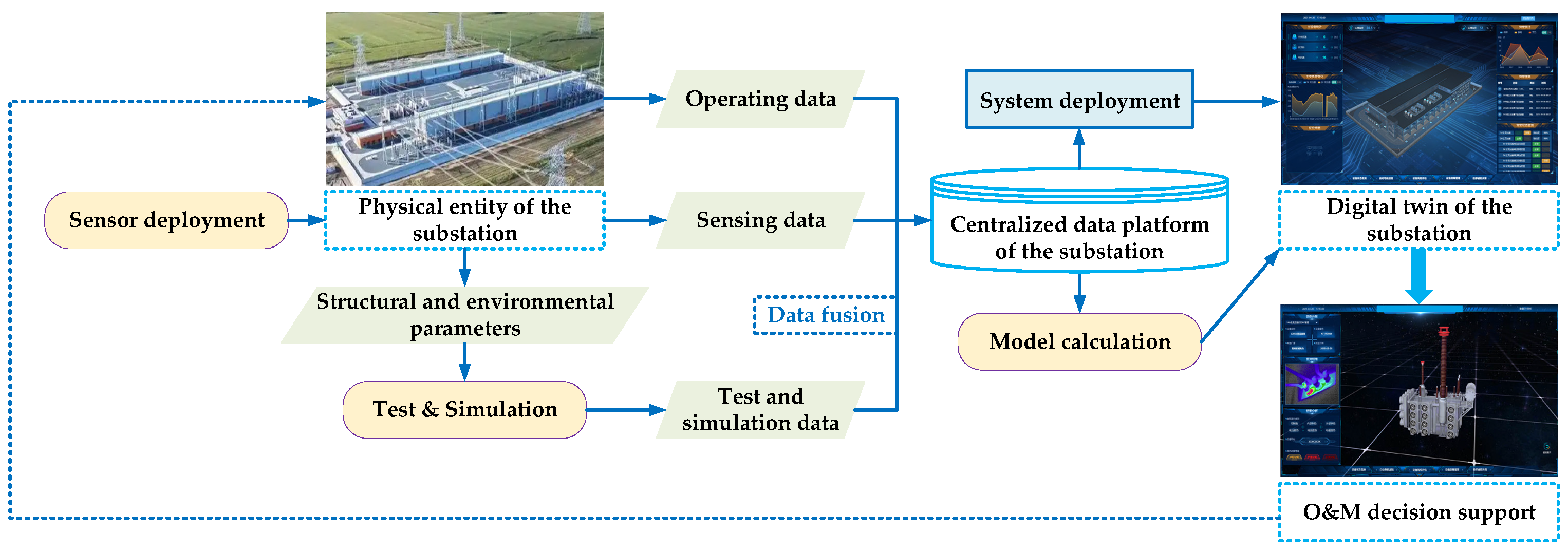

2. The High-Voltage Bushing Digital Twin Lifecycle Management Framework

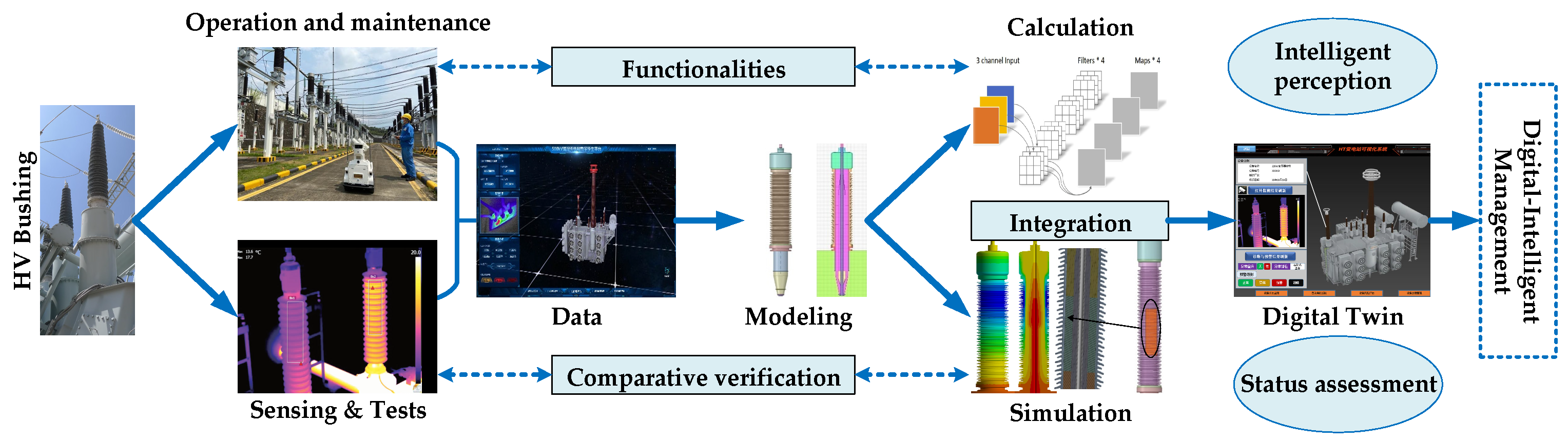

3. Typical Application Scenarios of Digital Twins in High-Voltage Bushing Management

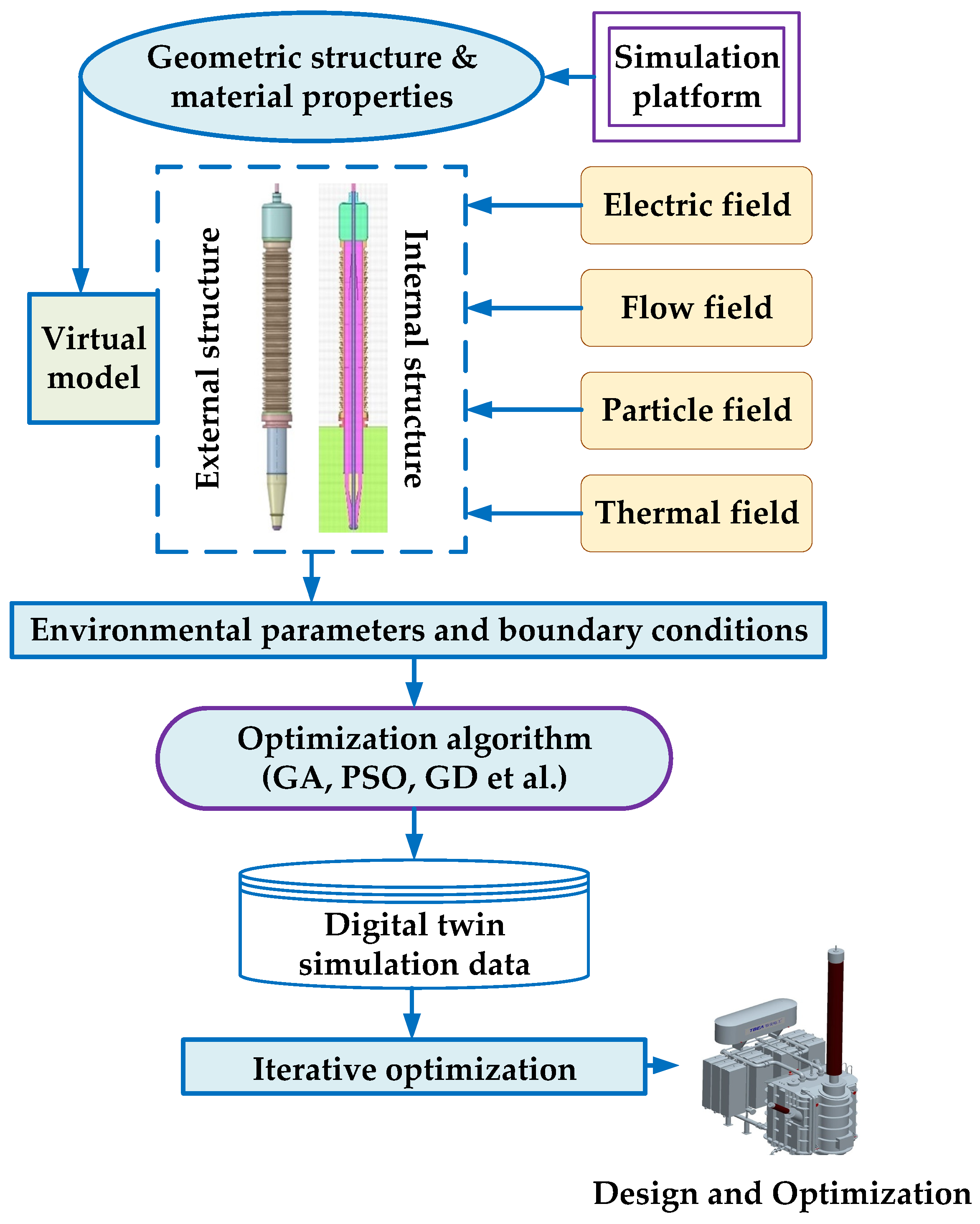

3.1. Design and Optimization of External Insulation Using Digital Twin Simulation

3.2. Data-Driven Intelligent Condition Evaluation

3.3. Identification of Insulation Defects Through Multi-Physics Field Fusion

3.4. Virtual-Physical Integrated Fault Diagnosis and Root Cause Analysis

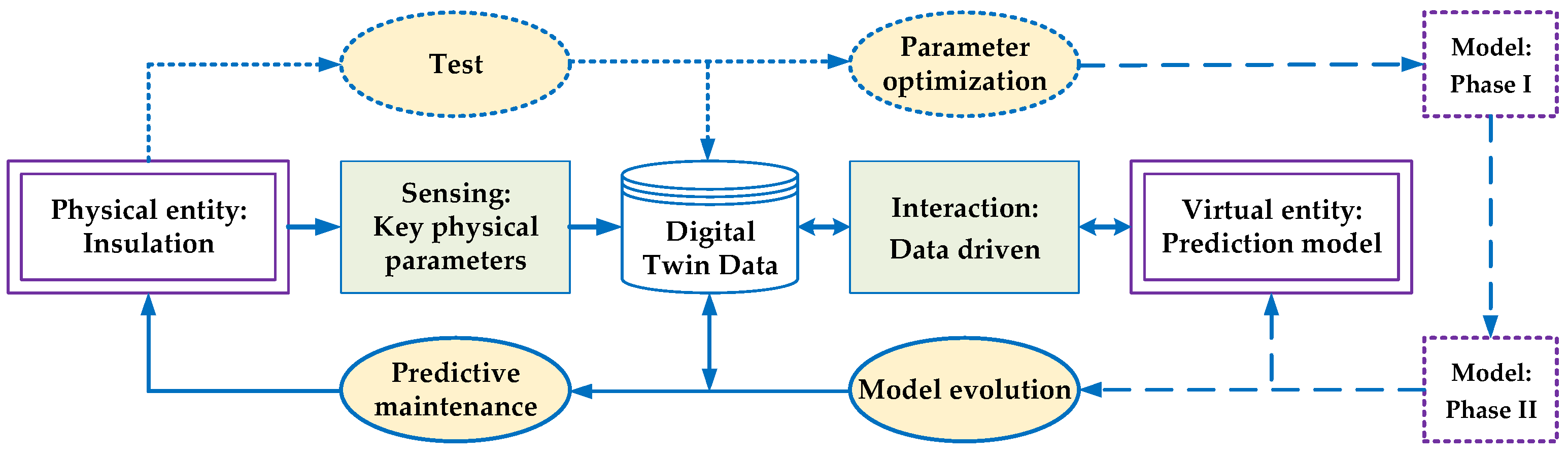

3.5. Predictive Maintenance Based on Trend Prediction

4. Core Technology System Supporting High-Voltage Bushing Digital Twins

4.1. Multi-Physics Field Coupling Modeling Technology

- The precision of the geometric model, which needs to accurately restore the structure of each layer of insulation, capacitor screens, flanges, etc. of the bushing;

- The definition of material properties, which requires inputting nonlinear parameters such as dielectric constant, conductivity, thermal conductivity, and elastic modulus that vary with temperature and electric field;

- The setting of boundary conditions, which needs to accurately apply loads such as voltage, current, and convective heat transfer coefficients.

4.2. Multi-Source Heterogeneous Data Fusion Technology

- Data layer fusion, primarily focusing on data cleaning, interpolation, normalization, and spatiotemporal alignment to ensure that data from different sources are comparable on a unified spatiotemporal basis;

- Feature layer fusion, extracting key features from preprocessed data (such as the phase distribution PRPD of PD, the gas ratio features of DGA), and then using feature selection or dimensionality reduction algorithms (such as Principal Component Analysis—PCA) to construct feature vectors that comprehensively reflect the equipment status;

- Decision layer fusion, using multiple sub-models based on different data sources (such as a fault diagnosis model based on DGA, a defect identification model based on PD) to make preliminary judgments, and then reaching a final comprehensive conclusion through decision fusion algorithms (such as D-S evidence theory, Bayesian networks, weighted voting).

4.3. Data-Driven Model Calibration and Condition Evaluation Technology

4.4. High-Performance Computing and Visualization Technology

- Cloud/edge collaborative computing: Complex, computationally intensive multi-physics simulations can be completed on cloud-based high-performance computing clusters, while real-time, lightweight model correction and condition assessment are performed on edge servers close to the equipment, balancing computational depth and response speed.

- Model lightweighting: Using techniques such as reduced-order models and surrogate models, complex finite element models are simplified into mathematical models with minimal computational requirements, enabling them to run in real-time on standard servers or even embedded devices.

- Three-dimensional state visualization: On a three-dimensional model, the internal electric field, temperature, and stress distribution of the bushing are dynamically displayed in the form of contour plots, isocurves, and vector arrows, achieving a “see-through” effect.

- Augmented Reality (AR)/Virtual Reality (VR) interaction: Operation and maintenance personnel can use AR glasses to overlay virtual temperature field and electric field information onto the real bushing equipment, enabling immersive inspections and fault troubleshooting.

- Data dashboards: Key indicators such as health index, Remaining Useful Life (RUL) prediction, and alarm information are presented in the form of charts and dashboards, providing decision support for managers.

5. Brief Illustrative Case Study

6. Challenges and Research Outlook

6.1. Current Research Challenges

- Data Silos and Heterogeneity: Data forms the foundation of digital twin technology. Data from different sensors (tan δ, PD, temperature, DGA) and systems (e.g., asset management) often exist in proprietary formats and isolated databases. The lack of interoperability makes it difficult to create a unified, coherent data feed for the digital twin. Moreover, as a key component of electrical connections, HV bushings, considering their production costs and issues related to equipment quality and volume, lack high-quality, long-term labeled datasets. This is because power generation and operation departments prioritize safety, leading to a contradiction between data sharing and privacy protection.

- Model credibility and validation: Establishing trust in the digital twin’s outputs is paramount. Physics-based models require precise parameters that are often unknown or difficult to measure in-situ. Data-driven models, particularly deep learning, can act as “black boxes,” making it hard to interpret their predictions. Rigorous validation against long-term operational data and failure cases is often lacking. In addition, for the simulation model, there are still some technical details to overcome in multi-physics and coupled modeling, as well as real-time simulation analysis. Unified modeling across multiple scales and mechanisms remains a challenge, which affects the interpretability and credibility of the models.

- Computational and infrastructure costs: Running high-fidelity, multi-physics simulations in near real-time requires substantial computational resources. This poses a challenge for edge deployment in substations with limited IT infrastructure and necessitates a careful balance between model accuracy and computational efficiency.

- Lack of standardized frameworks: The absence of industry-wide standards for digital twin architecture, data semantics, and communication protocols leads to vendor-specific, non-interoperable solutions, increasing integration costs and locking utilities into single-vendor ecosystems. An effective mapping relationship needs to be established between the physical entity and the digital twin. Currently, there is a lack of unified data interfaces, model formats, and functional standards, making it difficult for systems to interconnect, especially between digital twins of different equipment. Effective communication between digital twins still needs to be achieved based on the electrical interconnection of physical entities.

- The return on investment (ROI) is unclear: In terms of operational costs and engineering applications, digital twin technology requires the deployment of systematic high-precision sensors. Considering the economic efficiency of equipment lifecycle management, the current development, deployment, and maintenance costs of twin systems are relatively high, and the return on investment (ROI) is not yet clear.

6.2. Future Research Directions

6.2.1. Standardization and Interoperability

- IEC 60137 & IEC 61439 [67,68]: These standards define the specifications and tests for HV bushings. Future extensions or companion standards could formally define a standardized “digital twin information model” for bushings, specifying a minimum set of parameters, data points (e.g., tan δ, PD, temperature profiles), and performance metrics to be exchanged.

- IEC 61850 & CIM [69,70]: For communication within the substation and enterprise levels, strict adherence to IEC 61850 (for real-time data exchange) and the Common Information Model (CIM) (for asset management) is crucial. Research should focus on defining new Logical Nodes within the IEC 61,850 framework to standardize how bushing digital twin data is represented and accessed.

- OPC UA [71]: As a platform-independent, service-oriented communication standard, OPC UA is ideal for bridging the gap between the substation floor and enterprise IT systems. Its companion specifications can model the asset hierarchy and production processes, providing a robust backbone for DT data contextualization.

6.2.2. System Deployment in Response to Actual Situations

6.2.3. Economic Viability and ROI Modeling

6.2.4. System Deployment and Technology Integration

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| HV | High voltage |

| FLCM | Full life cycle management |

| O&M | Operation and maintenance |

| HVDC | High voltage direct current |

| CBM | Condition-based maintenance |

| RIP | Resin-impregnated paper |

| RIS | Resin-impregnated synthetic |

| PD | Partial discharge |

| RUL | Remaining useful life |

| RNNs | Recurrent neural networks |

| LSTM | Long short-term emory network |

| IoT | Internet of things |

| GA | Genetic algorithm |

| PSO | Particle swarm optimization |

| DGA | Dissolved gas analysis |

| CNN | Convolutional neural network |

| GRU | Gated recurrent unit |

| PCA | Principal component analysis |

| GD | Gradient descent |

| HPC | High performance computing |

| AR | Augmented Reality |

| VR | Virtual reality |

| ROI | Return on investment |

| IT | Information technology |

| CIM | Common information model |

| LLMs | Large language models |

| RL | Reinforcement learning |

References

- Wei, Y.M.; Chen, K.Y.; Kang, J.N.; Chen, W.M.; Zhang, X.Y.; Wang, X.Y. Policy and Management of Carbon Peaking and Carbon Neutrality: A Literature Review. Engineering 2022, 14, 52–63. [Google Scholar] [CrossRef]

- Du, X.W. Thoughts on strategies and paths to achieve carbon peaking and carbon neutrality in China. Front. Energy 2023, 17, 324–331. [Google Scholar] [CrossRef]

- Sun, J.Y.; Su, C.G.; Song, J.C.; Yao, C.C.; Ren, Z.M.; Sui, Q. Capacity planning for large-scale wind-photovoltaic-pumped hydro storage energy bases based on ultra-high voltage direct current power transmission. Energy 2025, 320, 135224. [Google Scholar] [CrossRef]

- Glende, E.; Wolter, M. Extra-long distance ultra-high voltage direct current. In Proceedings of the 2022 IEEE Sustainable Power and Energy Conference, Perth, Australia, 4–7 December 2022; pp. 1–5. [Google Scholar] [CrossRef]

- Christin, A.J.; Salam, M.A.; Rahman, Q.M.; Islam, M.A.; Wen, F.S.; Ang, S.P.; Hasan, S.; Voon, W. Investigation of failure of high voltage bushing at power transformer. J. Electrost. 2018, 96, 49–56. [Google Scholar] [CrossRef]

- Li, X.; Tang, H.; Yang, F.; Cheng, H.; Zhang, S. Internal Discharge Characteristics of HVDC Wall Bushing Model with Resin Impregnated Paper Capacitor Core under Long-term DC Voltage of Different Polarity. In Proceedings of the 2022 IEEE International Conference on High Voltage Engineering and Applications, Chongqing, China, 25–29 September 2022; pp. 1–4. [Google Scholar] [CrossRef]

- Fink, S.; Müller, R.; Zwecker, V. Cryogenic high voltage testing of a 25 kV RIS bushing. In Proceedings of the 2022 IEEE International Conference on High Voltage Engineering and Applications, Chongqing, China, 25–29 September 2022; pp. 1–4. [Google Scholar] [CrossRef]

- Go, M.Y.L.; Chan, K.K.M.; Wong, S.C.H.; Chan, J.T.J. Life management of high voltage bushings. In Proceedings of the 10th International Conference on Advances in Power System Control, Operation & Management, Hong Kong, China, 8–12 November 2015; pp. 1–5. [Google Scholar] [CrossRef]

- Grieves, M. Digital Twin: Manufacturing Excellence Through Virtual Factory Replication. 2015. Available online: https://www.researchgate.net/publication/275211047_Digital_Twin_Manufacturing_Excellence_through_Virtual_Factory_Replication (accessed on 15 March 2015).

- Tao, F.; Zhang, M.; Nee, A.Y.C. Digital Twin Driven Smart Manufacturing; Elsevier: Amsterdam, The Netherlands, 2019; pp. 1–257. [Google Scholar]

- Tao, F.; Zhang, H.; Liu, A.; Nee, A.Y.C. Digital Twin in Industry: State-of-the-Art. IEEE Trans. Ind. Inform. 2019, 15, 2405–2415. [Google Scholar] [CrossRef]

- Wang, T.X.; Liu, Z.Y.; Wang, Z.Z.; Liu, J.; Matharage, S.Y.; Wang, Z.D. Transformer Digital Twin Development Framework and Functionality Demonstration. In Proceedings of the 2024 IEEE International Conference on High Voltage Engineering and Applications, Berlin, Germany, 18–22 August 2024. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, M. Digital Twin Shop-Floor: A New Shop-Floor Paradigm Towards Smart Manufacturing. IEEE Access 2017, 5, 20418–20427. [Google Scholar] [CrossRef]

- Zhang, S.L.; Zhang, S.Y.; Su, X.L. Multi-Physics Field Simulation of 1100kV GIS SF6 Gas Insulated Composite Bushing. In Proceedings of the 2019 IEEE Conference on Electrical Insulation and Dielectric Phenomena, Richland, WA, USA, 20–23 October 2019; pp. 247–250. [Google Scholar] [CrossRef]

- He, Y.; Zhang, S.; Wang, P.; Dai, L. Digital Twin Model of Converter Transformer Output Device Based on Real-time Inversion Calculation of Transient Temperature and E-field of HVDC Bushing. In Proceedings of the 2024 International Conference on Artificial Intelligence, Deep Learning and Neural Networks, Guangzhou, China, 20–22 September 2024; pp. 57–64. [Google Scholar] [CrossRef]

- Wu, Z.; La, Y.; Wang, Z.; Zhang, W.; Cheng, J.; Huang, K. A Real-Time Simulation Model for the Digital Twin of the DC Transformer Bushing. In Proceedings of the 2024 Boao New Power System International Forum—Power System and New Energy Technology Innovation Forum, Qionghai, China, 8–10 December 2024; pp. 483–487. [Google Scholar] [CrossRef]

- Zhang, L.; Sun, L.; Wu, J.F.; Han, Y.H.; Wang, S.; Yang, C.K.; Shen, W.; Guo, C. Development of multi-parameter online monitoring equipment for EHV transformer bushing. IET Sci. Meas. Technol. 2020, 14, 89–103. [Google Scholar] [CrossRef]

- Subocz, J.; Mrozik, A.; Bohatyrewicz, P.; Zenker, M. Condition Assessment of HV Bushings with Solid Insulation based on the SVM and the FDS Methods. Energies 2020, 13, 853. [Google Scholar] [CrossRef]

- Zhang, S.L.; Deng, B.J.; He, Y.S.; Dai, L.J. Research on Structural Specification and Virtual Construction Method of Physical -Field for Digital Twin Model of C5F10O Insulated Bushing. In Proceedings of the 2024 14th International Conference on Power and Energy Systems, Chengdu, China, 13–16 December 2024; pp. 160–166. [Google Scholar] [CrossRef]

- Zhang, S.L.; Wang, P.B.; Li, X.C.; Xiao, Q. Dielectric Spectrum and Insulation State Analysis of Ultra-High Voltage Converter Transformer Bushing Based on Small Sample Digital Twin Model. In Proceedings of the 2025 8th International Conference on Electronics Technology, Chengdu, China, 17–20 May 2025; pp. 320–326. [Google Scholar] [CrossRef]

- Zhang, S.L.; Xiao, Q.; Wu, J.G.; Ye, F. Electrical and Insulation Characteristics of Digital Twin Model of Valve Side Bushing for Ultra-high Voltage Converter Transformer Based on Field circuit Coupling and Transient Lightning Impulse Simulation. In Proceedings of the 2025 International Conference on Smart Grid and Sustainable Energy, Zhangye, China, 25–27 July 2025; pp. 35–41. [Google Scholar] [CrossRef]

- Sun, Y.; Shi, Y.; Hu, Q.; Xie, C.; Su, T. DTformer: An Efficient Digital Twin Model for Loss Measurement in UHVDC Transmission Systems. IEEE Trans. Power Syst. 2024, 39, 3548–3559. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, X.; Wu, J.; Wu, X. Research on Key Technology of Digital Twin of Transformer Equipment for Technology Compliance Assessment. In Proceedings of the 2025 10th Asia Conference on Power and Electrical Engineering, Beijing, China, 15–19 April 2025; pp. 6–10. [Google Scholar] [CrossRef]

- Moutis, P.; Alizadeh-Mousavi, O. Digital Twin of Distribution Power Transformer for Real-Time Monitoring of Medium Voltage from Low Voltage Measurements. IEEE Trans. Power Deliv. 2021, 36, 1952–1963. [Google Scholar] [CrossRef]

- He, Y.S.; Li, Y.F.; Li, X.C.; Yuan, Y.N.; Yang, F.; Lu, Z.X. A Reduced-Order Algorithm for a Digital Twin Model of Ultra-High-Voltage Valve-Side Bushing Considering Spatio-Temporal Non-Uniformity. Energies 2025, 18, 1481. [Google Scholar] [CrossRef]

- Ding, F.; Ma, Y.; Li, X.; Huang, J.; Kang, J. Research on digital twin diagnosis model for the thermal-electric field of high-voltage switchgears. Sci. Rep. 2025, 15, 34303. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Nie, K.; Li, C.; Li, Z.; Gao, W.; Meng, F.; Li, Q. Electric Field Simulation Analysis of Typical Defects of Metal Particles in Main Insulation of Converter Transformer Based on Multi-physics Coupling. In Proceedings of the 5th International Symposium on Plasma and Energy Conversion, Singapore, 27–29 October 2023; Springer Proceedings in Physics. Volume 398, pp. 449–459. [Google Scholar] [CrossRef]

- Mohammadnabi, S.; Rahmani, K. Influence of humidity and contamination on the leakage current of 230-kV composite insulator. Electr. Power Syst. Res. 2021, 194, 107083. [Google Scholar] [CrossRef]

- Li, X.L.; Wan, M.D.; Zhang, G.K.; Lin, X. Surface Charge Characteristics of DC-GIL Insulator Under Multiphysics Fields: 3-D Modeling. IEEE Trans. Dielectr. Electr. Insul. 2022, 29, 1608–1616. [Google Scholar] [CrossRef]

- Zhou, Z.; Li, H.; Wen, S.; Zhang, C. Prediction Model for the DC Flashover Voltage of a Composite Insulator Based on a BP Neural Network. Energies 2023, 16, 984. [Google Scholar] [CrossRef]

- Zhang, L.; Sun, L.; Wang, W.S.; Han, Y.H.; Pu, L.; Wu, J.F.; Wu, H. Intelligent monitoring of EHV transformer bushing based on multi-parameter composite sensing technology. IET Sci. Meas. Technol. 2023, 17, 373–384. [Google Scholar] [CrossRef]

- Mitiche, I.; McGrail, T.; Boreham, P.; Nesbitt, A.; Morison, G. Data-Driven Anomaly Detection in High-Voltage Transformer Bushings with LSTM Auto-Encoder. Sensors 2021, 21, 7426. [Google Scholar] [CrossRef]

- Zhang, S.; Xiao, Q.; Wu, J.; Ye, F. Implementation and Dynamic Online Application of Digital Twin Industrial Simulation Platform for Valve Side Bushing of Converter Transformer Based on Multi Physics Coupling Technology. In Proceedings of the 2025 International Conference on Smart Grid and Sustainable Energy, Zhangye, China, 25–27 July 2025; pp. 47–53. [Google Scholar] [CrossRef]

- Zhang, S.; Xiao, Q.; Wu, J.; Yang, F. Research on Real Time Configuration and Evaluation Service of Ultra high Voltage Valve Side Bushing Driven by Multi Source Sensor Data and Material Parameters. In Proceedings of the 2025 International Conference on Smart Grid and Sustainable Energy, Zhangye, China, 25–27 July 2025; pp. 7–13. [Google Scholar] [CrossRef]

- Zhang, Q.; Wu, J.; Wang, J.; Huang, X.; Fang, Y.; Niu, F.; Zhang, J. A Two-Phase Lifetime Prediction Model of Generator Stator Main Wall Insulation Driven by Digital Twin. IEEE Trans. Instrum. Meas. 2024, 73, 3531512. [Google Scholar] [CrossRef]

- Bai, F.; Tang, Z.; Yin, R.J.; Quan, H.B.; Chen, L.; Dai, D.; Tao, W.Q. A novel ‘3D+digital twin+3D’ upscaling strategy for predicting the detailed multi-physics distributions in a commercial-size proton exchange membrane fuel cell stack. Appl. Energy 2024, 374, 124012. [Google Scholar] [CrossRef]

- Sun, L.M.; Sun, H.B.; Zhang, W.; Li, X.Y. Hybrid monitoring methodology: A model-data integrated digital twin framework for structural health monitoring and full-field virtual sensing. Adv. Eng. Inform. 2024, 60, 102386. [Google Scholar] [CrossRef]

- Huang, X.J.; Lang, X.; Guo, T.; Yu, L. Improving pyraformer algorithm for forecasting of 500 KV transformer bushing data with three enhanced modules. Electr. Power Syst. Res. 2025, 241, 111360. [Google Scholar] [CrossRef]

- Li, Z.; Liu, K.; Lin, M.; Xin, D.L.; Tang, H.; Wu, G.N. A zero-sample state evaluation model for valve-side bushing of UHV converter transformer oriented to digital twin under attribute analysis. IET Gener. Transm. Distrib. 2023, 17, 1123–1134. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, J.H.; Zhuang, C.B. Digital Twin Modeling Enabled Machine Tool Intelligence: A Review. Chin. J. Mech. Eng. 2024, 37, 47. [Google Scholar] [CrossRef]

- Tao, F.; Liu, A.; Hu, T.L.; Nee, A.Y.C. Digital Twin Driven Smart Design; Elsevier: Amsterdam, The Netherlands, 2020. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, M.; Cheng, J. Digital twin workshop: A new paradigm for future workshop. Comput. Integr. Manuf. Syst. 2017, 23, 1–9. [Google Scholar] [CrossRef]

- Tao, F.; Cheng, J.; Qi, Q.; Zhang, M.; Zhang, H.; Sui, F. Digital twin-driven product design, manufacturing and service with big data. Int. J. Adv. Manuf. Technol. 2018, 94, 3563–3576. [Google Scholar] [CrossRef]

- Barricelli, B.R.; Casiraghi, E.; Fogli, D. A Survey on Digital Twin: Definitions, Characteristics, Applications, and Design Implications. IEEE Access 2019, 7, 167653–167671. [Google Scholar] [CrossRef]

- Lehner, D.; Pfeiffer, J.; Tinsel, E.F.; Strljic, M.M.; Sint, S.; Vierhauser, M. Digital Twin Platforms: Requirements, Capabilities, and Future Prospects. IEEE Softw. 2022, 39, 53–61. [Google Scholar] [CrossRef]

- Maiterth, M.; Brewer, W.; Vet, D.D.; Greenwood, S.; Kumar, V.; Hines, J. Visualizing an Exascale Data Center Digital Twin: Considerations, Challenges and Opportunities. In Proceedings of the 2024 IEEE Visualization and Visual Analytics, St. Pete Beach, FL, USA, 13–18 October 2024; pp. 21–25. [Google Scholar] [CrossRef]

- Shunmugalakshmi, G.; Maheswari, R.V.; Vigneshwaran, B. A Comprehensive Study and Prediction of Flashover Voltage of 11kV Bushing with Various Pollutions using Support Vector Machine. In Proceedings of the IEEE International Conference on Innovations in Power and Advanced Computing Technologies, Vellore, India, 22–23 March 2019. [Google Scholar] [CrossRef]

- Qi, B.; Yang, Z.; Yang, X.; Gao, C.; Lu, L.; Zhang, Y. Effect of Different DC Prestressed Time on Flashover Characteristics of Epoxy Resin Under Polarity Reversal Voltage. IEEE Trans. Dielectr. Electr. Insul. 2022, 29, 1582–1589. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, Y.; Xiao, W.; Sun, Y.; Jiang, X. Research on Insulation Configuration of 220 kV Bushing in High-Altitude Polluted Areas. Energies 2024, 17, 1645. [Google Scholar] [CrossRef]

- Li, W.; Wang, Y.; Ding, Y.; Yin, Y. Optimization Design of Packaging Insulation for Half-Bridge SiC MOSFET Power Module Based on Multi-Physics Simulation. Energies 2022, 15, 4884. [Google Scholar] [CrossRef]

- Wu, Z.; Xin, L.; Cheng, J.; Wu, B.; Qiang, Z.; Wang, Q.; Zhao, L.; Du, Z. Research on the Data-Driven Fast Calculation Method of the Temperature Field Distribution of Valve-Side RIP Bushing Used in UHV DC Converter Transformer. High Volt. 2025, 10, 1210–1220. [Google Scholar] [CrossRef]

- Bueno-Barrachina, J.M.; Ye-Lin, Y.; Nieto-del-Amor, F.; Fuster-Roig, V. Inception 1D-convolutional neural network for accurate prediction of electrical insulator leakage current from environmental data during its normal operation using long-term recording. Eng. Appl. Artif. Intell. 2023, 119, 105799. [Google Scholar] [CrossRef]

- Han, T.; Hao, C.; Gao, Y.; Du, B.; Cavallini, A. Partial Discharge Detection with Bushing Sensors for Switchgear: Separation, Location, and Recognition. IEEE Electr. Insul. Mag. 2025, 41, 5–14. [Google Scholar] [CrossRef]

- Tian, T.; Zhou, X.; Dai, L.C.; Bai, J.; Yang, W.D.; Luo, Y.; Pan, L.L.; Yu, J.Y.; Li, J.B.; Chang, X.H.; et al. Research on fatigue fracture failure of high-voltage bushing conductive rods under complex conditions. AIP Adv. 2025, 15, 095127. [Google Scholar] [CrossRef]

- Jiang, J.; Bie, Y.; Li, J.; Yang, X.; Ma, G.; Lu, C.; Zhang, C. Fault diagnosis of the bushing infrared images based on mask R-CNN and improved PCNN joint algorithm. High Volt. 2021, 6, 116–124. [Google Scholar] [CrossRef]

- Wen, X.Y.; Li, W.B. Time Series Prediction Based on LSTM-Attention-LSTM Model. IEEE Access 2023, 11, 48322–48331. [Google Scholar] [CrossRef]

- Qiu, B.; Zhang, J.; Yang, Y.; Qin, G.; Zhou, Z.; Ying, C. Research on Oil Well Production Prediction Based on GRU-KAN Model Optimized by PSO. Energies 2024, 17, 5502. [Google Scholar] [CrossRef]

- Feng, J.; Feng, Z.; Jiang, G.; Zhang, G.; Jin, W.; Zhu, H. A Prediction Method for the Average Winding Temperature of a Transformer Based on the Fully Connected Neural Network. Appl. Sci. 2024, 14, 6841. [Google Scholar] [CrossRef]

- Yin, S.; Bai, Y.; Kong, F.; Wang, Z.; Fang, C. An Interval Prediction of Chloroprene Rubber Crack Propagation Characteristics Based on Thermal Accelerated Aging. Polymers 2023, 15, 2445. [Google Scholar] [CrossRef]

- Halloum, M.R.; Reddy, B.S.; Reddy, G.N. Failure analysis of field-aged polymeric outdoor insulators and performance enhancement for electric stress using nonlinear field grading composites. Electr. Eng. 2024, 106, 1147–1161. [Google Scholar] [CrossRef]

- Chu, Z.L.; Wang, Q.Y.; Tian, H.D.; Liu, S.Y.; Gao, Z.J.; Tian, S.B.; Liu, P.; Peng, Z.R. Fast computation of electro-thermal coupling field of ± 400 kV converter transformer valve side bushing based on proper orthogonal decomposition method. Int. J. Electr. Power Energy Syst. 2025, 167, 110617. [Google Scholar] [CrossRef]

- Zhu, J.X.; Yang, Y.X.; Xi, M.X.; Ji, S.L.; Jia, L.Y.; Hu, T. The next-generation digital twin: From advanced sensing towards artificial intelligence-assisted physical-virtual system. J. Ind. Inf. Integr. 2025, 48, 100942. [Google Scholar] [CrossRef]

- Li, P.; Peng, X.; Yin, K.; Xue, Y.; Wang, R.; Ma, Z. 3D Localization Method of Partial Discharge in Air-Insulated Substation Based on Improved Particle Swarm Optimization Algorithm. Symmetry 2022, 14, 1241. [Google Scholar] [CrossRef]

- Beheshti Asl, M.; Fofana, I.; Meghnefi, F. Review of Various Sensor Technologies in Monitoring the Condition of Power Transformers. Energies 2024, 17, 3533. [Google Scholar] [CrossRef]

- Liu, L.; Guo, Y.; Yin, W.; Lei, G.; Zhu, J. Design and Optimization Technologies of Permanent Magnet Machines and Drive Systems Based on Digital Twin Model. Energies 2022, 15, 6186. [Google Scholar] [CrossRef]

- Ibrahim, M.; Rassõlkin, A.; Vaimann, T.; Kallaste, A.; Zakis, J.; Hyunh, V.K.; Pomarnacki, R. Digital Twin as a Virtual Sensor for Wind Turbine Applications. Energies 2023, 16, 6246. [Google Scholar] [CrossRef]

- IEC 60137; Bushings for Alternating Voltages Above 1000 V. International Electrotechnical Commission: Geneva, Switzerland, 2018.

- IEC 61439-1; Low-Voltage Switchgear and Control Gear Assemblies—Part 1: General Rules. International Electrotechnical Commission: Geneva, Switzerland, 2021.

- IEC 61850; Communication Networks and Systems for Power Utility Automation. International Electrotechnical Commission: Geneva, Switzerland, 2013.

- IEC 61970; Energy Management System Application Program Interface (EMS-API)—Part 301: Common Information Model (CIM) base. International Electrotechnical Commission: Geneva, Switzerland, 2020.

- OPC Foundation. OPC Unified Architecture Specification, Part 1: Overview and Concepts, Release 1.05; OPC Foundation: Scottsdale, AZ, USA, 2023. [Google Scholar]

| Application Scenarios | Core Technology/Framework | Recommended Method | Typical Related Literature |

|---|---|---|---|

| Condition assessment | Physical model + Data-driven model | Multi-sensor integration, multi-physics field coupling, condition evaluation | [14,15,16,17,18,19,20,21,22,23,24,25] |

| Fault diagnosis and localization | Physical model + Data-driven model | Multi-physics field coupling, data fusion, high-performance computing | [15,16,17,26,27,28,29,30,31,32,33,34,35,36,37,38,39] |

| Life prediction and maintenance decision-making | Five-dimensional model | Data fusion, high-performance computing, visualization | [9,10,11,12,13,40,41,42,43,44,45,46] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chi, W.; Wang, T.; Zhang, J.; Wang, Z.; Zhang, C. Full-Life-Cycle Management of High-Voltage Bushings Based on Digital Twin: Typical Scenarios, Core Technologies, and Research Prospects. Energies 2025, 18, 6343. https://doi.org/10.3390/en18236343

Chi W, Wang T, Zhang J, Wang Z, Zhang C. Full-Life-Cycle Management of High-Voltage Bushings Based on Digital Twin: Typical Scenarios, Core Technologies, and Research Prospects. Energies. 2025; 18(23):6343. https://doi.org/10.3390/en18236343

Chicago/Turabian StyleChi, Weiwei, Tao Wang, Jichao Zhang, Zili Wang, and Chuyan Zhang. 2025. "Full-Life-Cycle Management of High-Voltage Bushings Based on Digital Twin: Typical Scenarios, Core Technologies, and Research Prospects" Energies 18, no. 23: 6343. https://doi.org/10.3390/en18236343

APA StyleChi, W., Wang, T., Zhang, J., Wang, Z., & Zhang, C. (2025). Full-Life-Cycle Management of High-Voltage Bushings Based on Digital Twin: Typical Scenarios, Core Technologies, and Research Prospects. Energies, 18(23), 6343. https://doi.org/10.3390/en18236343