Comprehensive Review of Thermal and Thermohydraulic Performance in Solar Air Heaters with Advanced Artificial Roughness Geometries

Abstract

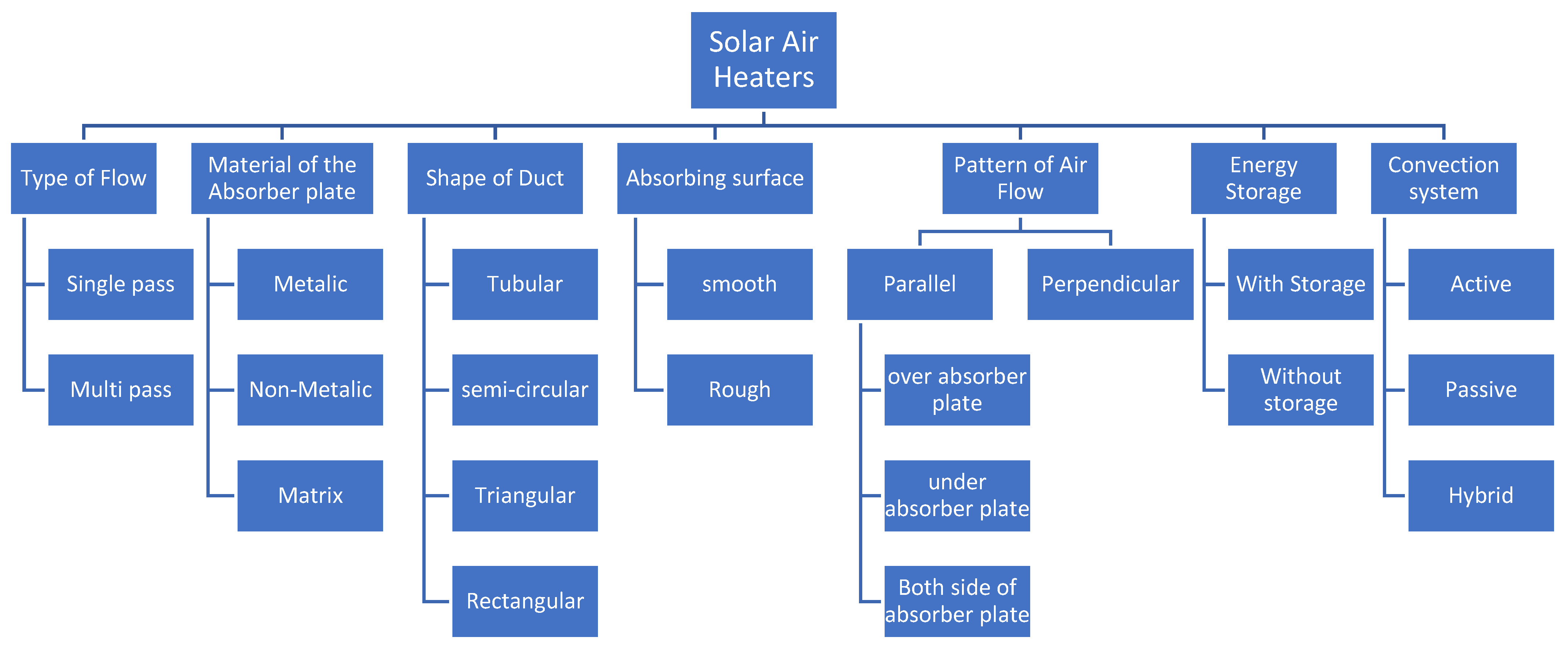

1. Introduction

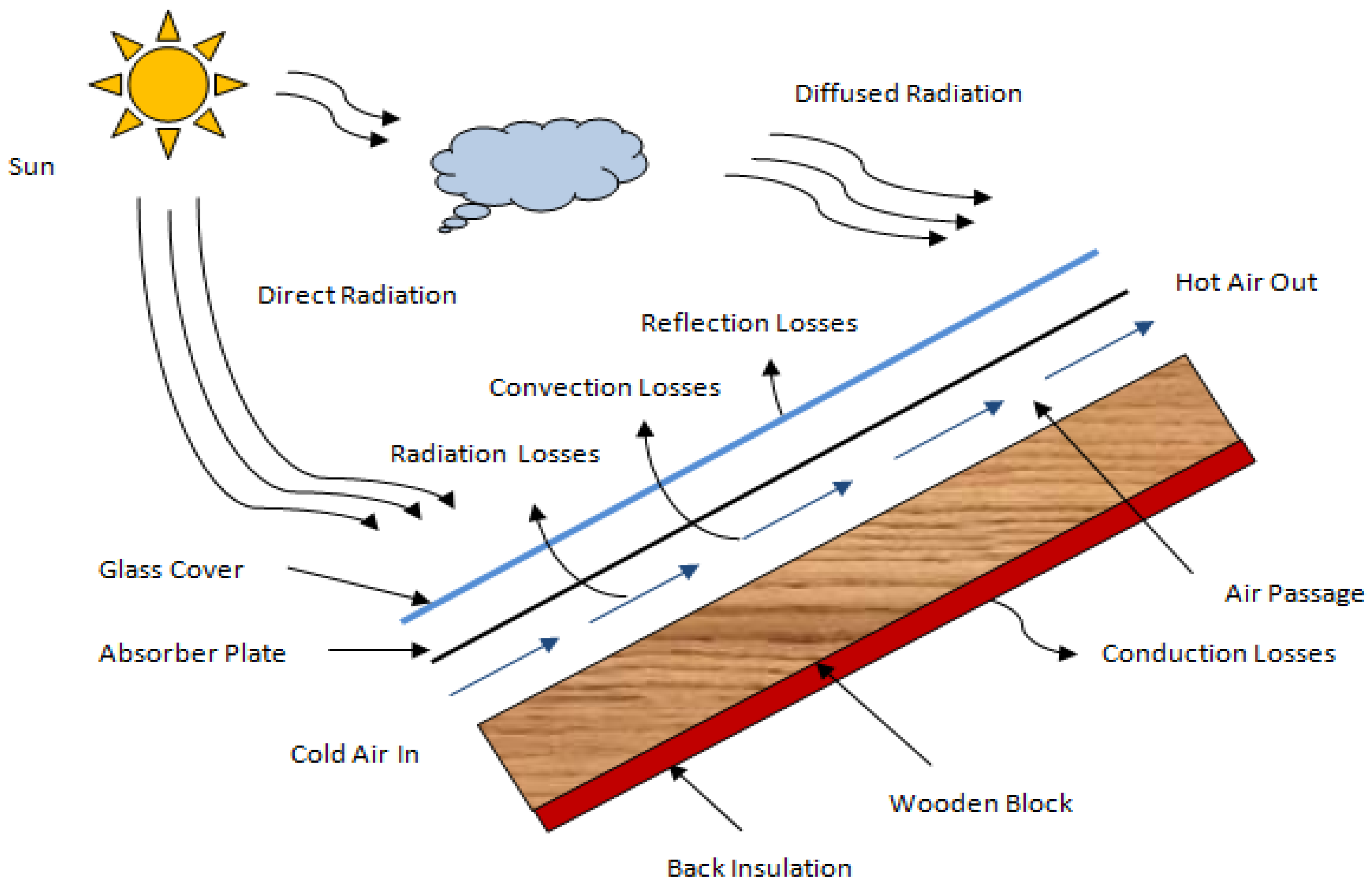

1.1. Thermal Efficiency of a SAH [15]

1.2. Thermal and Fluid Flow Aspects

1.2.1. Thermo-Hydraulic Parameter

- This parameter evaluates the proportional improvement in heat transfer (numerator) to the rise in frictional losses (denominator).

- A value of THPP > 1 indicates that the roughened surface improves thermal performance more than it increases friction losses; thus, it is considered beneficial.

- The exponent 1/3 reflects the trade-off between pumping power and heat transfer in a thermodynamically balanced way.

1.2.2. Exergy Analysis of Solar Air Heater

2. Influence of Various Factors on the Thermal Efficiency of SAHs

- i.

- System Parameters

- Number of Glass Covers: Optimal performance is generally achieved with 1 or 2 glass covers, based on whether the absorber surface is selective in nature.

- Emissivity of Glass Cover: A lower emissivity value minimises thermal losses, thereby enhancing the overall efficiency of the system.

- Spacing between Plate and Glass Cover: Since collectors are designed for use under different tilt angles and environmental conditions, there is no fixed optimal spacing. However, a typical gap of 1 to 4 cm is commonly adopted in practical applications.

- ii.

- Operational Parameters

- Inlet Air Temperature: With a rise in the temperature of the entering air, the performance of the absorber sheet tends to decline.

- Mass Flux of Air: Increasing the flow rate of the working fluid generally leads to an increase in the collector’s thermal efficiency as a result of enhanced heat exchange.

- iii.

- Meteorological Parameters

- Solar Irradiance: Higher levels of incident solar radiation contribute to improved collector efficiency for a fixed inlet air temperature.

- Wind Speed: Greater wind velocities increase thermal losses occurring at the surface of the collector to the environment, thereby reducing efficiency.

- Dust Accumulation on Glass Surface: The presence of dust on the top cover can block or scatter incident solar radiation, lowering the amount of energy transmitted to the absorber and thus decreasing overall performance.

3. Overview of Studies on Heat Transfer Enhancement Using Induced Roughness over Absorber Sheets

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| D or Dh | duct hydraulic diameter (mm) |

| e | height of rib (mm) |

| H | duct depth (mm) |

| g | Gap width |

| tg | thickness of the collector edge |

| I | solar irradiance (W/m2) |

| P | pitch (mm) |

| W | duct width (mm) |

| Dimensionless parameters | |

| d/w | relative gap position |

| e/Dh | relative roughness height |

| g/e | relative gap width |

| g/P | relative groove position |

| Gd/Lv | relative gap distance |

| L/D | test length to hydraulic diameter ratio of the duct |

| P/e | relative roughness pitch |

| W/H | duct aspect ratio |

| W/w | relative roughness width |

| Ng | number of gaps |

| N | number of glass covers |

| h/H | obstacle relative height |

| W/Vr | number of elements |

| dr/e | relative diagonal length |

| w/e | relative-distance-along-duct-width |

| l/e | relative-distance-along-duct-length |

| Pr | Prandtl number |

| Re | Reynolds number |

| St | Stanton number |

| Nu | Nusselt number |

| f | friction factor |

| Greek symbols | |

| α | angle of arc of attack (degree) |

| ϕ | wedge angle of rib (degree) |

| η | efficiency |

| Subscripts | |

| a | ambient |

| am | air mean |

| f | fluid (air) |

| i | inlet |

| m | mean |

| o | outlet |

| pm | plate mean |

| r | roughened |

| s | smooth |

| t | turbulent |

| w | wall |

Abbreviations

| SAH | Solar air heater |

| THPP | Thermo-hydraulic Performance Parameter |

| TEF | Thermal Enhancement Factor |

| CFD | Computational fluid dynamics |

| TES | Thermal Energy Storage |

| PCM | Phase Change Material |

| ANN | Artificial Neural Networks |

| TG | Turbulence Generators |

| VG | Vortex Generators |

References

- Duffie, J.A.; Beckman, W.A. Solar Engineering Thermal Processes; John Wiley& Sons: New York, NY, USA, 1991. [Google Scholar]

- Sukhatme, S.P. Solar Energy; Tata McGraw Hill Publishing Co.: New Delhi, India, 1984. [Google Scholar]

- Veziroghu, T.N. Solar Energy International Progress; Pergamon Press: London, UK, 1980; pp. 167–173. [Google Scholar]

- Hsieh, J.S. Solar Energy Engineering; Printice Hall Inc.: Saddle River, NJ, USA, 1986. [Google Scholar]

- Saxena, A.; Varun; El-Sebaii, A.A. A thermodynamic review of solar air heaters. Renew. Sustain. Energy Rev. 2015, 43, 863–890. [Google Scholar] [CrossRef]

- Varun. Performance evaluation of solar crop dryer integrated with solar air heater. In Proceedings of the 2011 International Conference & Utility Exhibition on Power and Energy Systems: Issues and Prospects for Asia (ICUE), Pattaya, Thailand, 28–30 September 2011; pp. 1–4. [Google Scholar] [CrossRef]

- Koyuncu, T. Performance of various design of solar air heaters for crop drying applications. Renew. Energy 2005, 31, 1073–1088. [Google Scholar] [CrossRef]

- Habtay, G.; Al-Neama, M.A.; Buzas, J.; Farkas, I. Experimental performance of solar air heaters for drying applications. Eur. J. Energy Res. 2021, 1, 4–10. [Google Scholar] [CrossRef]

- Lamrani, B.; Draoui, A.; Kuznik, F. Thermal performance and environmental assessment of a hybrid solar-electrical wood dryer integrated with Photovoltaic/Thermal air collector and heat recovery system. Sol. Energy 2021, 221, 60–74. [Google Scholar] [CrossRef]

- Abbas, S.; Hassan, A.; Zhou, J.; Bisengimana, E.; Yousuf, S.; Hassan, M.; Yuan, Y. Progress and challenges in the integration of solar heat pumps with thermal collectors and PCM-based thermal energy storage systems for heating applications. Sol. Energy 2025, 301, 113919. [Google Scholar] [CrossRef]

- Vahidhosseini, S.M.; Rashidi, S.; Hsu, S.-H.; Yan, W.-M.; Rashidi, A. Integration of solar thermal collectors and heat pumps with thermal energy storage systems for building energy demand reduction: A comprehensive review. J. Energy Storage 2024, 95, 112568. [Google Scholar] [CrossRef]

- Bansal, N.K. Solar air heater applications in India. Renew. Energy 1999, 16, 618–623. [Google Scholar] [CrossRef]

- Duhan, S.; Shah, S.; Kesari, J.P. Solar air heating and its applications in agricultural and industrial drying. Int. Res. J. Mod. Eng. Technol. Sci. (IRJMETS) 2021, 3, 7. Available online: https://www.irjmets.com/uploadedfiles/paper/volume3/issue_7_july_2021/14510/1628083565.pdf (accessed on 3 August 2025).

- Hans, V.S.; Saini, R.P.; Saini, J.S. Performance of artificially roughened solar air heaters—A review. Renew. Sustain. Energy Rev. 2009, 13, 1854–1869. [Google Scholar] [CrossRef]

- Bergman, T.L.; Lavine, A.S.; Incropera, F.P.; DeWitt, D.P. Introduction to Heat Transfer; John Wiley & Sons: New York, NY, USA, 2001. [Google Scholar]

- Incropera, F.P.; DeWitt, D.P.; Bergman, T.L.; Lavine, A.S. Fundamentals of Heat and Mass Transfer, 8th ed.; John Wiley & Sons: New York, NY, USA, 2017. [Google Scholar]

- Petela, R. Exergy of undiluted thermal radiation. Sol. Energy 2003, 74, 469–488. [Google Scholar] [CrossRef]

- Singh, S.; Singh, B. Energy and exergy analysis of solar air heater with inclined perforated baffles. Renew. Energy 2018, 115, 820–831. [Google Scholar]

- Esen, H. Experimental energy and exergy analysis of a double-flow solar air heater having different obstacles on absorber plates. Build. Environ. 2008, 43, 1046–1054. [Google Scholar] [CrossRef]

- Mondloe, D.S.; Ghritlahre, H.K.; Agrawal, G.K. The evaluation of energetic and exergetic performances of solar air heater using transverse wire rib roughness with various gaps—An experimental study. J. Eng. Appl. Sci. 2025, 72, 89. [Google Scholar] [CrossRef]

- Sastry, G.R.K.; Raju, L.B.B.; Gugulothu, S.K.; Ağbulut, Ü.; Barmavatu, P. Thermo-hydraulic optimisation of rectangular duct solar air heaters using equilateral triangular roughness on absorber plates. J. Therm. Anal. Calorim. 2025, 150, 4549–4567. [Google Scholar] [CrossRef]

- Sawaitul, A.V.; Sawarkar, S.R.; Jadhav, A.; Kalamkar, V.R. Numerical study of solar air heater with novel rib roughness. Int. J. Energy A Clean Environ. 2025, 26, 59–71. [Google Scholar] [CrossRef]

- Singh, R.; Bhagoria, J.L.; Narayanan, R. Experimental Analysis of Thermo-Hydraulic Performance of Quadratic Duct with Artificial Roughness on a Single Broad Heated Surface of the Absorber Plate of Solar Air Heater. Case Stud. Therm. Eng. 2025, 72, 106415. [Google Scholar] [CrossRef]

- Kaya, M. Experimental investigation of inside zigzag pipe collector solar air heaters: Energy and exergy analyses. Arch. Thermodyn. 2024, 45, 215–222. [Google Scholar] [CrossRef]

- Vinothkumar, R.; Kumaresan, G.; Ahmed, K.R.A.; Saravanan, B. Evaluation of thermo-hydraulic performance of solar air heater integrated with hexagonal baffles: A numerical investigation. J. Therm. Anal. Calorim. 2025, 150, 6429–6445. [Google Scholar] [CrossRef]

- Sharma, S.L.; Kishor, K.; Bisht, V.S.; Debbarma, A.; Gaur, A. CFD analysis of artificially roughened solar air heater: A comparative study of C-Shape, reverse C-Shape, and reverse R-Shape roughness element. Int. J. Ambient. Energy 2024, 45, 2331240. [Google Scholar] [CrossRef]

- Patel, J.P.; Bhagoria, J.L. Experimental validation of ANSYS and ANN-optimised Coanda bump Aerofoil shaped roughness element for enhanced performance in solar air heating systems. Int. Commun. Heat. Mass. Transf. 2024, 156, 107541. [Google Scholar] [CrossRef]

- Chaudhri, K.; Bhagoria, J.L.; Kumar, V. Thermal Performance Investigation of Rhombus Shape Roughened Solar Air Collector- a Novel approach. Renew. Energy 2024, 235, 121305. [Google Scholar] [CrossRef]

- Chaudhri, K.; Bhagoria, J.L.; Kumar, V. Heat transfer and friction factor correlation for rhombus-shaped roughness geometry on the absorber plate of solar air collector. J. Therm. Anal. Calorim. 2024, 149, 6405–6420. [Google Scholar] [CrossRef]

- Adavi, S.S.; Chandramohan, V.P. Numerical analysis of pentagonal ribbed absorber plate of solar air collector in an indirect solar dryer for enhanced performance. Energy Sources Part A Recovery Util. Environ. Eff. 2024, 46, 3363–3380. [Google Scholar] [CrossRef]

- Dong, Z.; Liu, P.; Xiao, H.; Liu, Z.; Liu, W. A study on heat transfer enhancement for solar air heaters with ripple surface. Renew. Energy 2021, 172, 477–487. [Google Scholar] [CrossRef]

- Kumar, R.; Kharub, M.; Kumar, V.; Varun, N. Heat augmented due to array of protrusions on absorber plate in solar heat exchanger. Mater. Today Proc. 2020, 38, 2425–2430. [Google Scholar] [CrossRef]

- Agrawal, Y.; Bhagoria, J.L. Experimental Investigation of Heat Transfer and Friction with Double Arc Reverse Shaped Roughness on Absorber Plate of Solar Air Heater. Int. J. Eng. Res. Curr. Trends (IJERCT) 2020, 2, 49–50. [Google Scholar]

- Agrawal, Y.; Bhagoria, J.L.; Pagey, V.S. Enhancement of thermal efficiency of solar air collector by using discrete double arc reverse shaped roughness on the absorber plate. Mater. Today Proc. 2021, 51, 1548–1553. [Google Scholar] [CrossRef]

- Agrawal, Y.; Bhagoria, J.L.; Yugbodh, K.; Jain, E.; Gautam, A. Thermohydraulic performance of solar air heater having discrete double arc roughness elements on absorber plate. Mater. Today Proc. 2022, 68, 326–334. [Google Scholar] [CrossRef]

- Pawar, S.S.; Hindolia, D.A.; Bhagoria, J.L. Enhancement of heat transfer coefficient using Diamond shaped roughness on the absorber plate of solar air heater. Int. J. Eng. Res. Appl. (IJERA) 2013, 3, 968–974. [Google Scholar]

- Yadav, A.S.; Bhagoria, J.L. Modeling and Simulation of Turbulent Flows through a Solar Air Heater Having Square-Sectioned Transverse Rib Roughness on the Absorber Plate. Sci. World J. 2013, 2013, 827131. [Google Scholar] [CrossRef]

- Han, J.C.; Glicksman, L.R.; Rohsenow, W.M. An investigation of heat transfer and friction for rib-roughened surfaces. Int. J. Heat. Mass. Transf. 1978, 21, 1143–1156. [Google Scholar] [CrossRef]

- Jaurker, A.R.; Saini, J.S.; Gandhi, B.K. Heat transfer and friction characteristics of rectangular solar air heater duct using rib-grooved artificial roughness. Sol. Energy 2005, 80, 895–907. [Google Scholar] [CrossRef]

- Gupta, D.; Solanki, S.C.; Saini, J.S. Thermohydraulic performance of solar air heaters with roughened absorber plates. Sol. Energy 1997, 61, 33–42. [Google Scholar] [CrossRef]

- Momin, A.M.E.; Saini, J.S.; Solanki, S.C. Heat transfer and friction in solar air heater duct with V-shaped rib roughness on absorber plate. Int. J. Heat. Mass. Transf. 2002, 45, 3383–3396. [Google Scholar] [CrossRef]

- Bhagoria, J.L.; Saini, J.S.; Solanki, S.C. Heat transfer coefficient and friction factor correlations for rectangular solar air heater duct having transverse wedge shaped rib roughness on the absorber plate. Renew. Energy 2002, 25, 341–369. [Google Scholar] [CrossRef]

- Sahu, M.M.; Bhagoria, J.L. Augmentation of heat transfer coefficient by using 90° broken transverse ribs on absorber plate of solar air heater. Renew. Energy 2005, 30, 2057–2073. [Google Scholar] [CrossRef]

- Layek, A.; Saini, J.S.; Solanki, S.C. Second law optimisation of a solar air heater having chamfered rib–groove roughness on absorber plate. Renew. Energy 2007, 32, 1967–1980. [Google Scholar] [CrossRef]

- Mittal, M.; Varun, N.; Saini, R.; Singal, S. Effective efficiency of solar air heaters having different types of roughness elements on the absorber plate. Energy 2006, 32, 739–745. [Google Scholar] [CrossRef]

- Whillier, A. Performance of black-painted solar air heaters of conventional design. Sol. Energy 1964, 8, 31–37. [Google Scholar] [CrossRef]

- Shchegolkov, A.; Shchegolkov, A.; Demidova, A. The use of nanomodified heat storage materials for thermal stabilization in the engineering and aerospace industry as a solution for economy. MATEC Web Conf. 2018, 224, 03012. [Google Scholar] [CrossRef]

- Kumar, B.V.; Selvan, C.P.; Kanna, P.R.; Taler, D.; Szymkiewicz, M.; Taler, J. Numerical investigation of heat transfer enhancement in solar air heaters using polygonal-shaped ribs and grooves. Front. Energy Res. 2023, 11, 1279225. [Google Scholar] [CrossRef]

- Shaik, R.; Punna, E.; Gugulothu, S.K. Numerical investigation on comparative performance assessment of solar air heater with different artificial roughness elements in a triangular duct. J. Therm. Eng. 2025, 11, 49–61. [Google Scholar] [CrossRef]

- Ghanem, S.R.; Bhosale, A.C. Exergy-energy efficiency and environmental-economic analysis of honeycomb-shaped artificial roughness in solar air heater. Discov. Energy 2025, 5, 34. [Google Scholar] [CrossRef]

- Kumar, R.; Sethi, M.; Goel, V.; Ramis, M.K.; AlSubih, M.; Islam, S.; Al Ansari, M.S.; Lee, D.; Wogasso Wodajo, A. Thermal and effective assessment of solar thermal air collector with roughened absorber surface: An analytical examination. Int. J. Low-Carbon. Technol. 2024, 19, 1112–1123. [Google Scholar] [CrossRef]

- Kumar, B.V.; Manikandan, G.; Kanna, P.R. Enhancement of heat transfer in SAH with polygonal and trapezoidal shape of the rib using CFD. Energy 2021, 234, 121154. [Google Scholar] [CrossRef]

- Mohammad Azim Aijaz, P.N. Ahirwar. Review of the Impact of Artificial Roughness in Solar Air Heaters. Trends Mach. Design. 2024, 11, 1–9. [Google Scholar]

- Sedaghat, A.; Kalbasi, R.; Narayanan, R.; Mehdizadeh, A.; Soleimani, S.M.; Malayer, M.A.; Al-Khiami, M.I.; Salem, H.; Hussam, W.K.; Sabati, M.; et al. Integrating solar PV systems for energy efficiency in portable cabins: A case study in Kuwait. Sol. Energy 2024, 277, 112715. [Google Scholar] [CrossRef]

- Narayanan, R.; Parthkumar, P.; Pippia, R. Solar energy utilisation in Australian homes: A case study. Case Stud. Therm. Eng. 2021, 28, 101603. [Google Scholar] [CrossRef]

- Newar, P.P.; Das, B. Thermal exploration of combined rectangular and semi-circular artificial ribs in the flow regime of solar air heater: A computational and experimental approach. J. Sol. Energy Eng. 2024, 147, 031001. [Google Scholar] [CrossRef]

- Gautam, A.K.; Bhagoria, J.L. Performance analysis of double inclination ribbed Solar Air Heater rectangular duct By Liquid Crystal Thermography. Int. Res. J. Eng. Technol. (IRJET) 2016, 3, 6. Available online: https://www.irjet.net/archives/V3/i6/IRJET-V3I6445.pdf (accessed on 5 July 2025).

- Sahu, M.M.; Bhagoria, J.L. Experimental Investigation of Heat Transfer and Friction Factor in Solar Air Heater Duct using Discrete Arc Shaped Rib Roughness on Absorber Plate. Int. J. Eng. Res. Technol. (IJERT) 2015, 4, 6. [Google Scholar] [CrossRef]

- Hegde, A.K.; Pai, R.; Karanth, K.V. Influence of solar insolation on energy and exergy efficiency of a rectangular duct solar air heater with various types of V rib roughness: An analytical approach. Int. Commun. Heat. Mass. Transf. 2024, 153, 107397. [Google Scholar] [CrossRef]

- Kaplan, M. Enhancement of the Thermohydraulic Performance in a Double Passage Square Duct with the Use of Inclined Ribs of 45°: A Comparative Computational Study. Int. J. Energy Res. 2024, 2024, 9935818. [Google Scholar] [CrossRef]

- Prasad, K.; Mullick, S.C. Heat transfer characteristics of a solar air heater used for drying purposes. Appl. Energy 1983, 13, 83–93. [Google Scholar] [CrossRef]

- Kumar, A.; Saini, R.P.; Saini, J.S. Experimental investigation on heat transfer and fluid flow characteristics of air flow in a rectangular duct with Multi v-shaped rib with gap roughness on the heated plate. Sol. Energy 2012, 86, 1733–1749. [Google Scholar] [CrossRef]

- Singh, S.; Chander, S.; Saini, J.S. Heat transfer and friction factor correlations of solar air heater ducts artificially roughened with discrete V-down ribs. Energy 2011, 36, 5053–5064. [Google Scholar] [CrossRef]

- Karwa, R.; Solanki, S.C.; Saini, J.S. Heat transfer coefficient and friction factor correlations for the transitional flow regime in rib-roughened rectangular ducts. Int. J. Heat. Mass. Transf. 1999, 42, 1597–1615. [Google Scholar] [CrossRef]

- Prasad, B.N.; Saini, J.S. Effect of artificial roughness on heat transfer and friction factor in a solar air heater. Sol. Energy 1988, 41, 555–560. [Google Scholar] [CrossRef]

- Saini, S.K.; Saini, R.P. Development of correlations for Nusselt number and friction factor for solar air heater with roughened duct having arc-shaped wire as artificial roughness. Sol. Energy 2008, 82, 1118–1130. [Google Scholar] [CrossRef]

- Aharwal, K.R.; Gandhi, B.K.; Saini, J.S. Experimental investigation on heat-transfer enhancement due to a gap in an inclined continuous rib arrangement in a rectangular duct of solar air heater. Renew. Energy 2007, 33, 585–596. [Google Scholar] [CrossRef]

- Varun, N.; Saini, R.P.; Singal, S.K. Investigation of thermal performance of solar air heater having roughness elements as a combination of inclined and transverse ribs on the absorber plate. Renew. Energy 2007, 33, 1398–1405. [Google Scholar] [CrossRef]

- Kumar, A.; Bhagoria, J.L.; Sarviya, R.M. Heat transfer and friction correlations for artificially roughened solar air heater duct with discrete W-shaped ribs. Energy Convers. Manag. 2009, 50, 2106–2117. [Google Scholar] [CrossRef]

- Lanjewar, A.; Bhagoria, J.L.; Sarviya, R.M. Heat transfer and friction in solar air heater duct with W-shaped rib roughness on absorber plate. Energy 2011, 36, 4531–4541. [Google Scholar] [CrossRef]

- Sethi, M.; Varun, N.; Thakur, N.S. Correlations for solar air heater duct with dimpled shape roughness elements on absorber plate. Sol. Energy 2012, 86, 2852–2861. [Google Scholar] [CrossRef]

- Nagaraj, M.; Reddy, M.K.; Sheshadri, A.K.H.; Karanth, K.V. Numerical analysis of an AerofoilFiN Integrated Double Pass solar air heater for thermal performance enhancement. Sustainability 2022, 15, 591. [Google Scholar] [CrossRef]

- Gawande, V.B.; Dhoble, A.S.; Zodpe, D.B.; Chamoli, S. Experimental and CFD investigation of convection heat transfer in solar air heater with reverse L-shaped ribs. Sol. Energy 2016, 131, 275–295. [Google Scholar] [CrossRef]

- Mahanand, Y.; Senapati, J.R. Thermo-hydraulic performance analysis of a solar air heater (SAH) with quarter-circular ribs on the absorber plate: A comparative study. Int. J. Therm. Sci. 2020, 161, 106747. [Google Scholar] [CrossRef]

- Antony, A.L.; Shetty, S.P.; Madhwesh, N.; Sharma, N.Y.; Karanth, K.V. Influence of stepped cylindrical turbulence generators on the thermal enhancement factor of a flat plate solar air heater. Sol. Energy 2020, 198, 295–310. [Google Scholar] [CrossRef]

- Baissi, M.T.; Brima, A.; Aoues, K.; Khanniche, R.; Moummi, N. Thermal behavior in a solar air heater channel roughened with delta-shaped vortex generators. Appl. Therm. Eng. 2019, 165, 113563. [Google Scholar] [CrossRef]

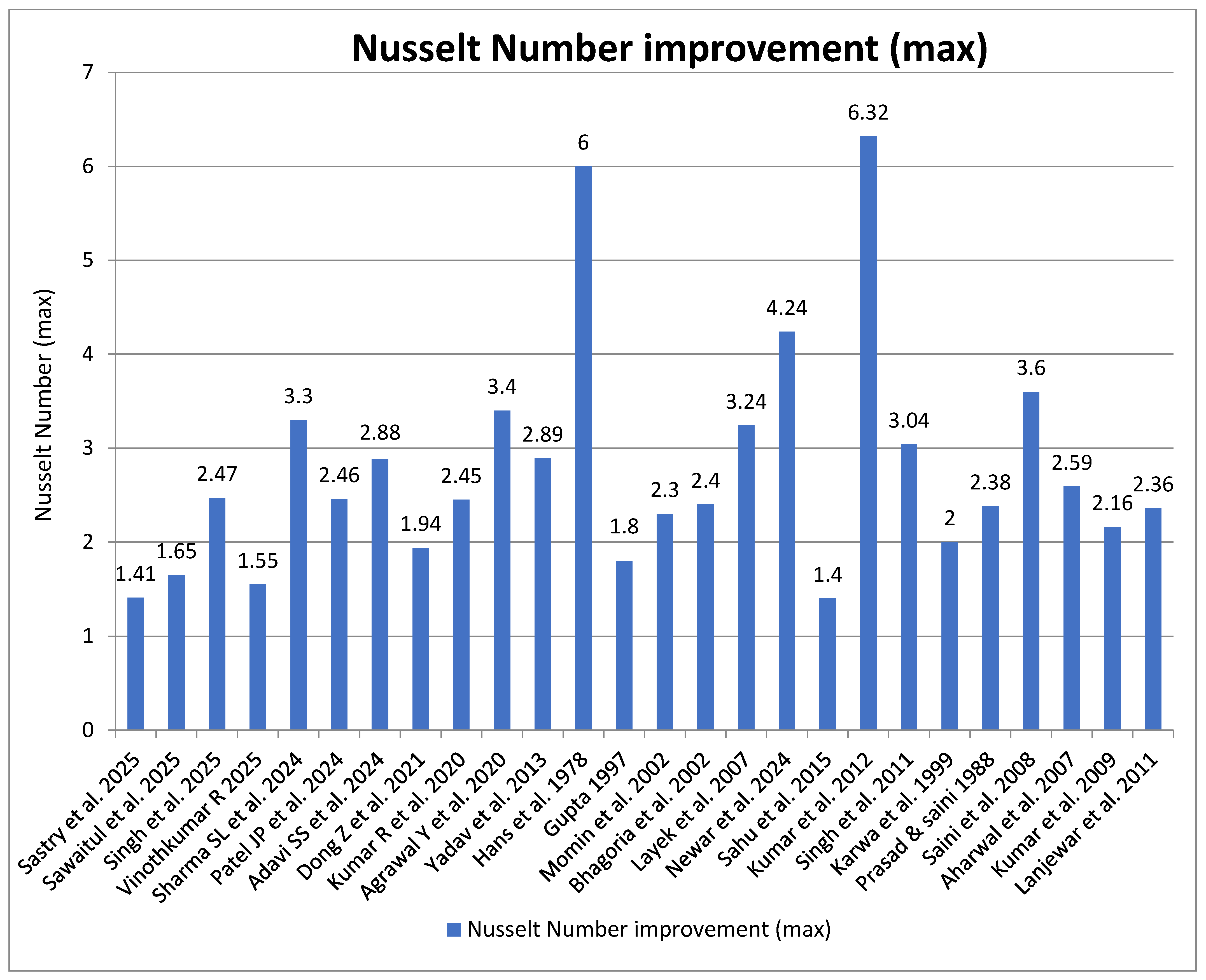

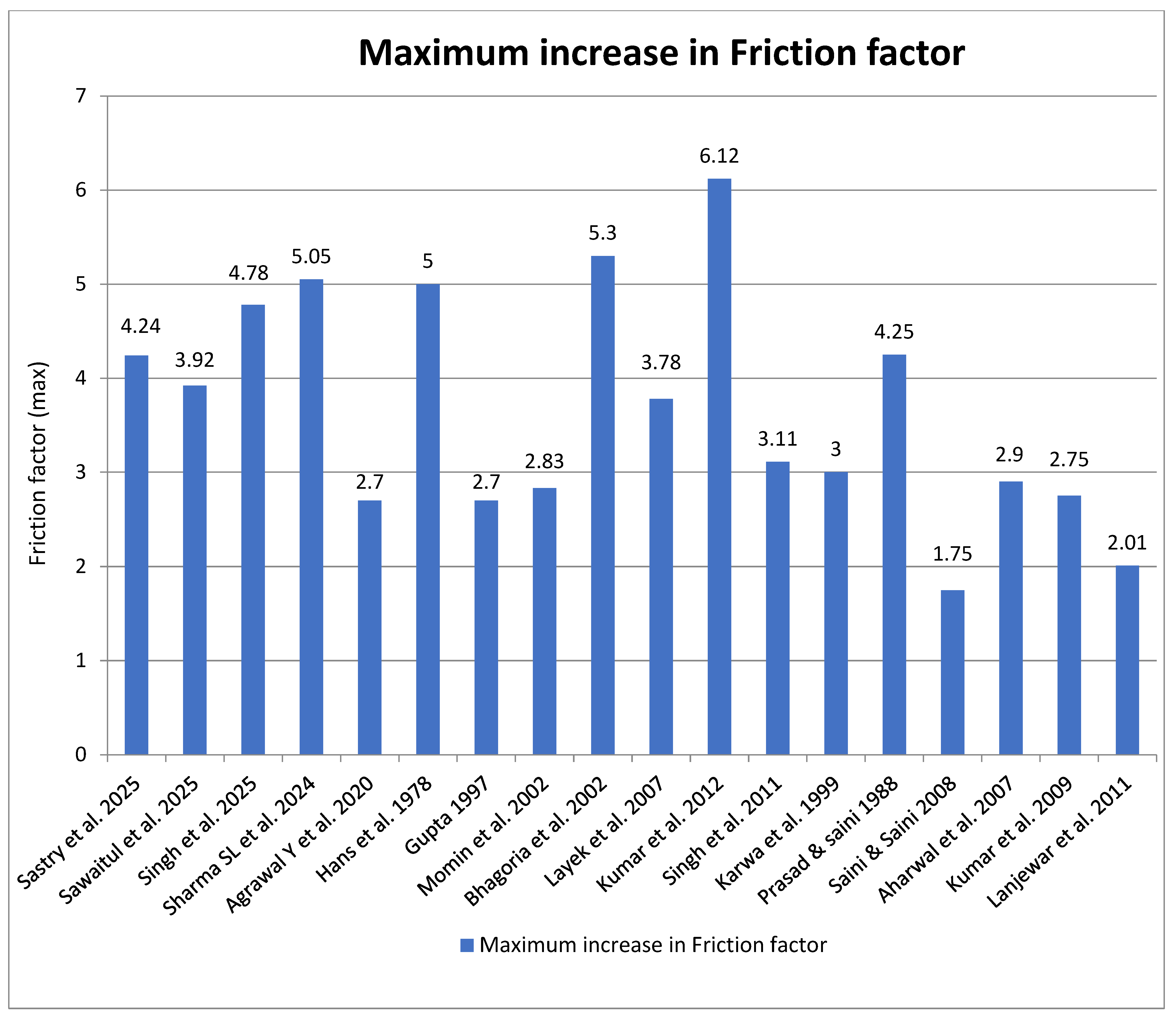

| S. No. | Investigators | Geometry | Parameters | Outcomes |

|---|---|---|---|---|

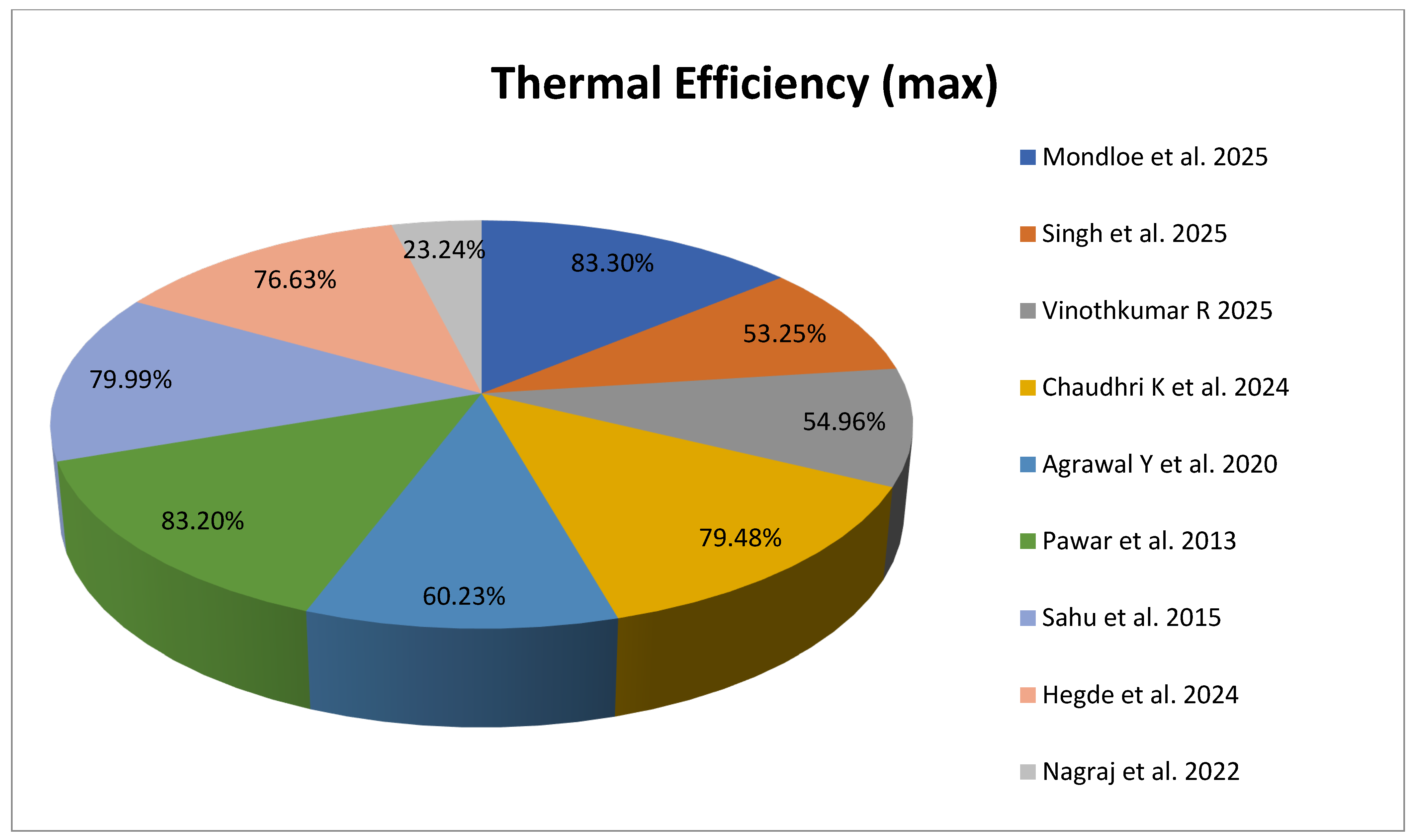

| 1 | Mondloe et al. [20] | transverse wire rib configuration with multiple gaps | Ng = 1–4 g = 4 mm ṁ = 0.01891–0.03937 kg/s e/D = 0.043 P/e = 10 Dh = 0.0554 m H = 0.03 m W = 0.36 m | Max efficiency of 83.3% at Ng = 2, ṁ = 0.0394 kg/s and min efficiency of 16.5% at Ng = 1, ṁ = 0.0244 kg/s. |

| 2 | Sastry et al. [21] | Equilateral Triangular Roughness | P = 10, 15, 20 mm e = 1.40 mm P/e = 7.14, 10.42, 14.29 e/D = 0.42 Re = 4000–18,000 | Nu increases by 41% at Re 15,000; f increases by 423.9% at Re 5000. |

| 3 | Sawaitul et al. [22] | Hyperbolic airfoil shape | P = 10, 20 mm e = 0.5, 1 mm | f increased 3.92 times; Nu improved 1.65 times at 20 mm rib pitch. |

| 4 | Singh et al. [23] | S-shape | p/e = 8.33 e/Dh = 0.027 W/H = 8 α = 30° to 75° Re = 3000 to 14,000 | Numax = 2.478 and ηthmax = 1.203 times, respectively. |

| 5 | Kaya M [24] | Zig-zag fins | ṁ = 0.004–0.0098 kg/s | A collector with zigzag fins shows up to 20.4% higher exergy efficiency than a hollow collector. |

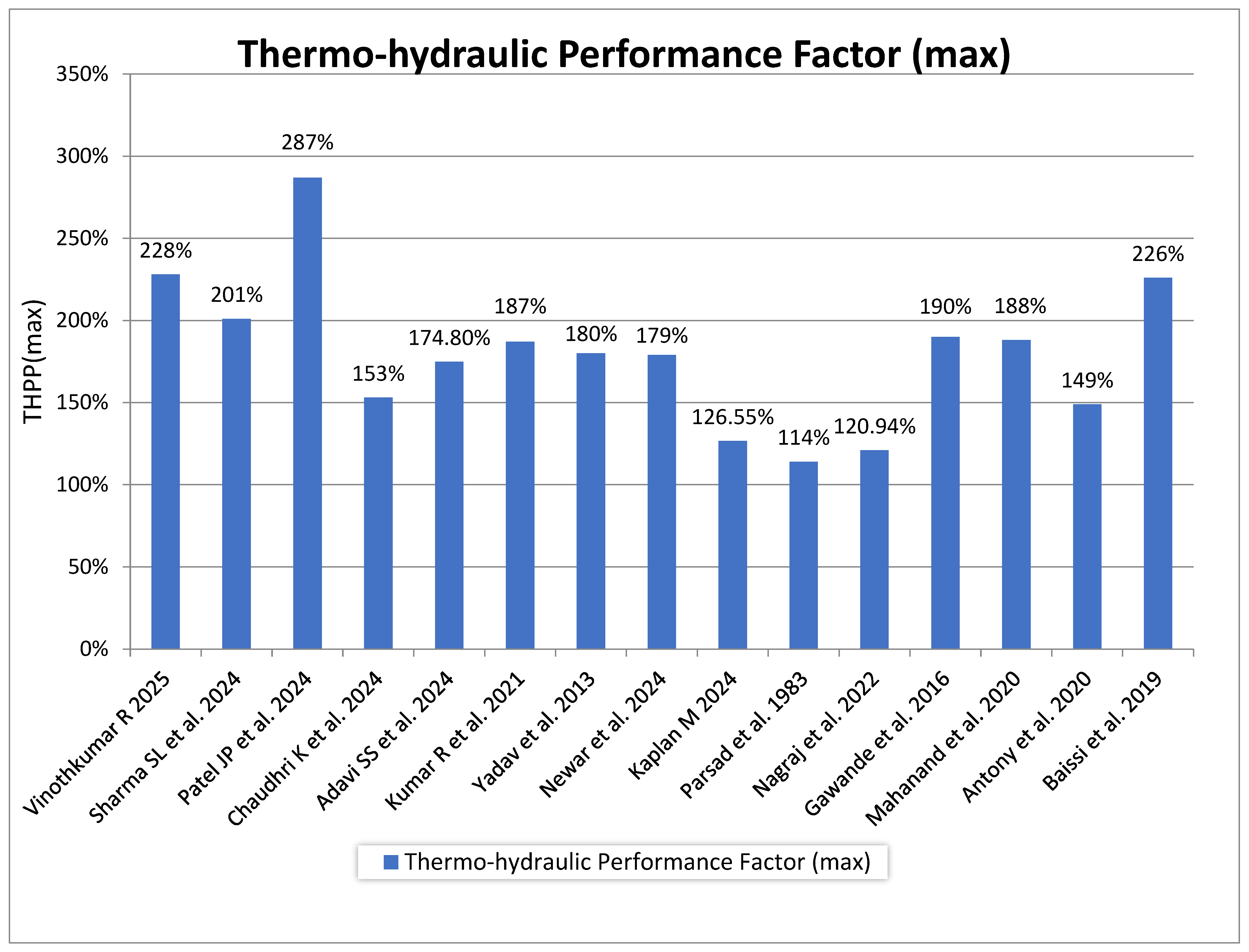

| 6 | Vinothkumar R [25] | Hexagonal baffles | Max thermal efficiency (ηthmax) of 54.96% achieved at 0.06 kg/s and thermal enhancement factor improves from 1.26 to 2.28 | |

| 7 | Sharma SL et al. [26] | C-shaped, reverse C-shaped, and reverse R-shaped configuration ribs | P/e = 14.285 Re = 4000 to 18,000 e/D = 0.021 | Numax = 3.3; fmax = 5.05; Max peak THPP of 2.01 at Re 4000 for C-rib configuration. |

| 8 | Patel JP et al. [27] | Aerofoil-Coanda ribs | P = 16–36 mm e = 0.5–1.5 mm g = 0–16 mm Re = 3000–18,000 | Numax = 2.46 times; peak THPP of 2.87 at Re 14,000. |

| 9 | Chaudhri K et al. [28] | rhombus | P/e = 8–12 e/Dh = 0.0225 to 0.03375 W/Vr = 9 to 11 dr/e = 8 to 12 Re = 2000–14,000 | Max thermal efficiency of 0.7948 achieved with a 0.53 improvement in thermal performance. |

| 10 | Adavi SS et al. [30] | V-shaped ribs | P = 50–175 mm Re = 1800–15,000 | Nu ratio: 1.81–2.88; peak Nu = 2.88. Max Thpp = 1.748 at pitch = 150 mm and Re = 1800. |

| 11 | Dong Z et al. [31] | inclined groove ripple surfaces | Re = 12,000–24,000 | Nu values increased by 1.04–1.94 times. |

| 12 | Kumar R et al. [32] | array of protrusions | P/e = 5 to 15 w/e = 6.5 to 16 l/e = 6.5 to 16 e/D = 0.024 Re = 4800 to 14,500 | Numax = 2.45 times; max THPP of 1.87 resulted. |

| 13 | Agrawal Y et al. [33] | Double Arc Reverse Shaped | P = 12 mm e = 1.2 mm e/Dh = 0.027 Re = 3000–11,000 | Max thermal efficiency of 60.23% at Nu = 30.93 and ṁ = 0.02015 kg/s. h increases by 28–34% with f rising from 1.5 to 2.7 times. |

| 14 | Pawar et al. [36] | Diamond shaped | W/H = 8 P/e = 10 to 25 e = 1 mm α = 30° e/Dh = 0.023 Re = 3000–14,000 | Numax = 54.52 at Re = 14,012, and the max thermal efficiency is 83.2%. |

| 15 | Yadav and Bhagoria [37] | Transverse Rib with a Square Cross-Section | W/H = 5 P = 10–28.28 mm P/e = 14.29 e = 0.7–2 mm e/Dh = 0.021 to 0.06 Re = 3800 to 18,000 | Nu ratio: 1.82–2.89; peak Nu = 2.89 at and Max THPP = 1.8 at Re = 15,000. |

| 16 | Hans and Glicksman et al. [38] | Multiple V-shaped rib profile | e/D = 0.019 to 0.043 α = 30° to 75° Re = 2000 to 20,000 W/w = 1 to 10 P/e = 6 to 12 | Numax = 6; fmax = 5 |

| 17 | Gupta [40] | Inclined wire rib geometry | e/D = 0.018 to 0.032 P/e = 10 Re = 5000 to 50,000 W/H = 6.8 to 11.5 α = 30° to 90° | Numax = 1.8; fmax = 2.7 |

| 18 | Momin and Saini et al. [41] | V-shaped rib configuration | e/D = 0.02 to 0.034 P/e = 10 Re = 2500 to 18,000 W/H = 10.15 α = 30° to 90° | Numax = 2.30; fmax = 2.83 |

| 19 | Bhagoria and Saini et al. [42] | Transverse rib with a wedge-shaped profile | e/D = 0.015 to 0.033 P/e = 12.12 ϕ = 8° to 15° Re = 3000 to 18,000 W/H = 5 | Numax = 2.4; fmax = 5.3 |

| 20 | Sahu et al. [43] | 90° segmented rib geometry | e/D = 0.0338 P = 10, 20 and 30 Re = 3000 to 12,000 W/H = 8 e = 1.5 | hmax = 1.25 to 1.4 times reported. |

| 21 | Layek et al. [44] | Chamfered rib-grooved profile | e/D = 0.022 to 0.040 g/P = 0.3 to 0.6 P/e = 4.5 to 10 ϕ = 5° to 30° Re = 3000–21,000 | Numax = 3.24; fmax = 3.78 |

| 22 | Newar et al. [56] | Combined Rectangular and Semi-Circular ribs | P = 15 mm h/H = 0.4–1 I = 400–1000 W/m2 Re = 4000–10,000 | Numax = 4.24; TEF peak = 1.79 at Re = 10,000; max exergy efficiency = 11.2% |

| 23 | Gautam et al. [57] | Double Inclination Ribbed | W/H = 5 P/e = 10 e = 1 mm α = 60° e/Dh = 0.034 Re = 4000 to 12,000 | Numax = 12.31 at Re = 7749 is obtained. |

| 24 | Sahu et al. [58] | Discrete Arc Shaped Rib | W/H = 8 P/e = 10 P = 10–20 mm e = 1–2 mm α = 30° e/Dh = 0.0225 to 0.045 Re = 3000 to 14,000 | The highest thermal efficiency observed is 79.99% at a roughness pitch of 15 mm. |

| 25 | Hegde et al. [59] | Various types of V rib roughness | I = 800–1200 W/m2 N = 1 tg = 0.040 m Re = 3000–18,000 | The maximum thermal and exergy efficiencies are 76.63% and 5.17%, respectively. |

| 26 | Kaplan M [60] | Inclined Ribs of 45° | p/e = 5 to 10 e/Dh = 0.1–0.2 α = 45° Re = 20,000–40,000 | Max THPP increase of 26.55% at Re = 20,000. |

| 27 | Parsad et al. [61] | Transverse wire rib configuration | e/D = 0.019 P/e = 12.7 Re = 10,000 to 40,000 | Max THPP rise of 14% at Re = 40,000. |

| 28 | Kumar and Saini et al. [62] | Multi-V-shaped rib roughness with gaps | e/D = 0.043 P/e = 10 Re = 2000 to 20,000 W/H = 12 W/w = 6 g/e = 0.5 to 1.5 Gd/Lv = 0.24 to 0.80 α = 60° | Numax = 6.32; fmax = 6.12 |

| 29 | Singh and Chandan et al. [63] | Discrete V-down rib profile | P/e = 4 to 12 Re = 3000 to 15,000 d/w = 0.2 to 0.8 α = 30° to 75° g/e = 0.5 to 2.0 e/D = 0.015 to 0.043 | Numax = 3.04; fmax = 3.11 |

| 30 | Karwa and Solanki et al. [64] | Chamfered repeated rib-geometry | L/D = 32.66 Re = 3000 to 20,000 e/D = 0.014 to 0.032 P/e = 4.5 to 8.5 W/H = 4.8 to 12 ϕ = 15° to 18° | Stmax = 2; fmax = 3 |

| 31 | Prasad and Saini [65] | Small dia. protrusion wires. | P/e = 10 to 20 Re = 5000 to 50,000 e/D = 0.02 to 0.033 | Numax = 2.38; fmax = 4.25 |

| 32 | Saini et al. [66] | Arc-shaped rib profile | Re = 2000 to17,000 W/H = 12 e/D = 0.0213 to 0.0422 α/90 = 0.3333 to 0.6666 P/e = 10 | Numax = 3.6; fmax = 1.75 |

| 33 | Aharwal and Gandhi et al. [67] | Slanted continuous rib texture with spacing | e and b = 2 mm g/e = 0.5 to 2 Re = 3000–18,000 d/W = 0.167 to 0.5 W/H = 5.87 e/D = 0.0377 α = 60° P/e = 10 | Numax = 2.59; fmax = 2.9 |

| 34 | Varun and Saini et al. [68] | Combined profile of inclined and transverse ribs | e/D = 0.030 e = 1.6 mm P/e = 3–8 P = 5–13 Re = 2000–14,000 W/H = 10 | The highest thermal efficiency was observed at P/e = 8. |

| 35 | Kumar and Bhagoria et al. [69] | Discrete W-type rib configuration | e = 0.75 to 1.5 mm Re = 3000 to 15,000 W/H = 8 P/e = 10 α = 30–75° e/D = 0.0168 to 0.0338 | Numax = 2.16; fmax = 2.75 |

| 36 | Lanjewar and Bhagoria et al. [70] | W-shaped rib profile | e = 0.8 to 1.5 mm Re = 2300 to 14,000 W/H = 8 α = 30–75° P/e = 10 | Numax = 2.36; fmax = 2.01 |

| 37 | Sethi and Varun et al. [71] | Dimple-shaped elements arranged in an angular fashion | Re = 3600 to 18,000 e/d = 0.5 W/H = 11 e/D = 0.021–0.036 α = 45–75° P/e = 10 to 20 | Numax obtained for P/e = 10. |

| 38 | Nagraj et al. [72] | Aerofoil fin | I = 950 W/m2 ṁ = 0.00651–0.04614 kg/s Re = 3000–24,000 | Max thermal efficiency and thermo-hydraulic efficiency are 123.24% and 120.94%, respectively. |

| 39 | Gawande and Dhoble et al. [73] | A profile of a Reverse-L shape is used | I = 1000 W/m2 e/D = 0.042 P/e = 7.14–17.86 Re = 3800–18,000 | Max THPP of 190% is obtained. |

| 40 | Mahanand et al. [74] | Quarter-circular geometry of ribs | I = 1000 W/m2 Re = 3800 to 18,000 e/D = 0.042 P/e = 7.14 to 17.86 | Max THPP of 188% is obtained. |

| 41 | Antony et al. [75] | Stepped cylindrical TG | P/e = 11.11–27.78 Core dia = 3–7 mm Re = 3000–24,000 | Max THPP of 149% is obtained. |

| 42 | Baissi et al. [76] | Delta-shaped VG | α = 45° e/H = 0.8 Pt/b = 0.6 to 1 Re = 2500–12,000 Pl/e = 3 to 5 | Max THPP of 226% is obtained. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Singh, R.; Narayanan, R. Comprehensive Review of Thermal and Thermohydraulic Performance in Solar Air Heaters with Advanced Artificial Roughness Geometries. Energies 2025, 18, 6157. https://doi.org/10.3390/en18236157

Singh R, Narayanan R. Comprehensive Review of Thermal and Thermohydraulic Performance in Solar Air Heaters with Advanced Artificial Roughness Geometries. Energies. 2025; 18(23):6157. https://doi.org/10.3390/en18236157

Chicago/Turabian StyleSingh, Rohit, and Ramadas Narayanan. 2025. "Comprehensive Review of Thermal and Thermohydraulic Performance in Solar Air Heaters with Advanced Artificial Roughness Geometries" Energies 18, no. 23: 6157. https://doi.org/10.3390/en18236157

APA StyleSingh, R., & Narayanan, R. (2025). Comprehensive Review of Thermal and Thermohydraulic Performance in Solar Air Heaters with Advanced Artificial Roughness Geometries. Energies, 18(23), 6157. https://doi.org/10.3390/en18236157