1. Introduction

Over the course of nuclear power reactor development, a clear historical trend has emerged, where reactors have progressively increased in size. This growth has primarily been driven by the need to sustain economic competitiveness, leveraging economies of scale to reduce unit costs and enhance efficiency.

SMR concepts have advanced far more rapidly in recent years than anyone could have anticipated a decade ago. It is highly likely that within the next ten years, multiple SMRs using both third- and fourth-generation nuclear reactors will be constructed and become operational. The reason for such significant interest in SMRs is that they could become one of the main drivers of the global decarbonisation economy. Their versatility, flexibility and cogeneration capabilities enable them to produce electricity, provide heat for district heating and industry, desalinate water, and generate hydrogen, among other applications.

Since 2016, fifteen European countries have announced a gradual phase-out of coal-fired power generation, with fourteen of them intending to achieve this goal by 2030 [

1,

2]. In Poland, the decommissioning of older power plants is planned for a later date. Applying the criterion of plant age below 20 years, only approximately 16.9 GWe from 55 units, or roughly half of the total capacity, meets the requirements for contribution to the country’s decarbonization objectives. The remaining units will only be suitable for complete decommissioning. Among the units identified as preferred for decarbonization, over half are 200–400 MWe units. About 75% of these operate steam cycles with peak temperatures between 530 and 570 °C, with some reaching up to 600 °C. Additionally, approximately two-thirds of the power capacity installed in Polish coal-fired power plants is generated using subcritical steam cycles with pressures below 22.1 MPa. Decarbonization options include carbon capture, wind turbines, photovoltaic panels, biomass conversion, geothermal sources, and nuclear reactors. Preference is given to technologies that require minimal additional space for new energy installations. In this perspective, nuclear solutions are at the forefront due to their high energy density relative to the occupied area. Additionally, nuclear reactors are a low-emission method for energy production that remains unaffected by climatic conditions. Consequently, nuclear energy can significantly contribute to the decarbonization of Poland’s energy sector [

3].

The transition of SMRs from conceptual design to technological implementation represents an important milestone in the advancement of nuclear energy solutions. SMRs represent an innovative approach to nuclear energy, offering enhanced safety, modularity, and economic feasibility [

4]. However, their widespread deployment depends on their progress through defined TRLs. This presentation examines the journey from theoretical conception to experimental validation and eventual deployment. It highlights the technical, regulatory, and economic challenges encountered at each TRL stage. This review paper discusses the TRL status of different SMR designs, including pressurized water reactors (PWRs), high-temperature gas-cooled reactors (HTGRs), molten salt reactors (MSRs), and liquid-metal-cooled fast reactors (LMFRs). While some water-cooled SMRs have reached demonstration stages, more innovative concepts like MSRs are still in earlier stages of development. That is due to material challenges and licensing difficulties. Even though the HTGR is already in operation, the development of advanced construction materials resistant to very high temperatures is a challenge. By evaluating the maturity of SMR technologies against TRL criteria, this review provides insights into the timeline and feasibility of their integration into global energy markets. Several SMR projects are at an advanced stage, making their completion likely within this decade. The United States and Canada are at the forefront of work on SMR technology. In China, a high-temperature low-power reactor has been launched and tested, and the construction of a pressurized water SMR is at an advanced stage. In Russia, the first two small pressurized reactors installed on a floating unit have been put into operation, while their Brest reactor is under construction [

2,

5]. A comprehensive and up-to-date assessment was presented by the Pacific Northwest Laboratory in the report ‘Emerging Technologies Review: Small Modular Reactors.’ The report was prepared for the Air Force Civil Engineer Center under a Work-For-Others Agreement with the U.S. Department of Energy [

6]. The Canadian Nuclear Safety Commission issued a construction license for the first BWRX-300 at the Darlington SMR project. The government of Ontario gave its approval for the construction to begin on 8 May 2025, with an in-service target date of 2030 [

7]. In UK, Rolls-Royce is developing an SMR of the PWR type producing 1358MWt of heat. The nuclear plant design implements multiple layers of safety; moreover, redundancy and back-up systems are additionally applied. It meets the highest standards of security and safety. Furthermore, safeguards and environmental protection are also very important issues. The UK’s independent nuclear regulators, including the Office for Nuclear Regulation (ONR), the Environment Agency, and Natural Resources Wales, work together to oversee new nuclear power stations. Their goal is to ensure high standards of safety, security, safeguards, environmental protection, and waste management. This oversight is conducted through a process called Generic Design Assessment (GDA). The Rolls-Royce SMR has completed Step Two of the GDA [

8].

The use of SMRs for energy-intensive applications (both electricity and heat) is widely discussed. Their locations are also proposed to be close to cities, so they could supply heat to the central heating network. Finally, the technology is seen as an opportunity to decarbonize the energy sector using certain infrastructure of power plants that use fossil fuels (Coal-to-Nuclear, C2N). Such power plants are often located near population centers or sensitive economic structures. Therefore, detailed studies regarding the location of each nuclear facility should be carried out. Deterministic assessment methods can be applied over the entire operational lifetime of a facility. These methods analyze both its safety and the risk of failure. A separate and very complex issue is the local environment and its impact on climate change. Of course, the safety analysis must take into account all applicable legal regulations.

Therefore, it is important to prepare a methodology for assessing the location such as an existing industrial plant or coal-fired power plant. The methodology should guide the selection of an appropriate SMR that suits the specific conditions of the site. It should also ensure that the reactor can provide energy, particularly heat, with the parameters required by the consumer. Issues related to radioactive waste management and the fuel cycle are also important. This is particularly true in countries without nuclear power plants. In such cases, projects are often initiated by private companies or consortia that are unaware of the difficulties involved. In these countries, despite extensive international cooperation, regulators do not have the capacity or resources to cope with the difficult assessment of proposed projects and locations.

Such methodology has been developed within the framework of the DEsire project. The research carried out in the frame of the project mentioned above was reported in the previous paper [

9]. The project, titled “Plan for decarbonization of electricity through the use of coal-fired power units using Generation III+ and Generation IV nuclear reactors,” is part of the GOSPOSTRATEG “Social and economic development of Poland in a globalizing environment” program. The project, financed by the National Center for Research and Development, is supported by a consortium consisting of the Silesian University of Technology, the Institute of Nuclear Chemistry and Technology (INCT), Energoprojekt-Katowice S.A., the Ministry of Climate and Environment, and the Sobieski Institute Foundation.

A similar project was carried out in the USA catalog of coal-fired power plants, and the infrastructure suitable for the coal-to-nuclear transition was assessed. The power plants were divided into two groups based on the capacity of the existing units. The analysis focused only on operating power plants, as retired plants lacked the infrastructure for the C2N conversion [

10].

Although the technology and the sector are still at an early stage of development and face typical challenges, SMRs have strong potential. They present an innovative solution for generating low-emission, climate-neutral, safe, and reliable electricity. They could address many issues associated with traditional nuclear power [

11].

Among different restrictions, very important are the requirements of the Nuclear Non-Proliferation Treaty signed by many countries [

12].

SMRs are primarily intended for decarbonizing the energy sector. A technical, data-based methodology for selecting the site and type of reactor was developed using Poland as an example. Two examples are presented: the TRL assessment of the technology and the selection of a location using existing energy infrastructure. These examples are general and based on international standards and IAEA and NEA OECD recommendations. Materials from similar activities in the USA, Canada, Great Britain, and China were also considered.

2. Technology Readiness Level

2.1. Definition

The TRL process is used for quantitative and qualitative assessment of the maturity of a given technology [

13]. The TRL framework was first created by the U.S. Department of Defense (DoD) to guide the development and deployment of emerging technologies for defense purposes. During the 1970s and 1980s, the National Aeronautics and Space Administration (NASA) later adopted and effectively applied this approach to assess and advance new technologies for space [

14]. TRLs are used to define the degree of advancement of a technology and to enable comparison of the state of progress among different technologies. It serves a tool for assessing the maturity of a given technology. Bringing new technology from the lab to the market means going through a lot of research, development, demonstration, and deployment (RDDD). The need to create such a scale arises from the way project decisions are currently made. Financing and commercialization are typically decided by industrialists, economists, and lawyers. In defense or large, technically complex projects with high social importance, such as nuclear power plant construction, politicians are also involved.

This scale describes technology maturity from the conceptual stage (TRL 1) to full maturity (TRL 9). At TRL 9, the concept becomes a practical technological solution ready for market implementation. The scale helps investors track product development and serves as a useful Key Performance Indicator (KPI). From an investor’s perspective, a higher TRL means a greater chance of success and lower investment.

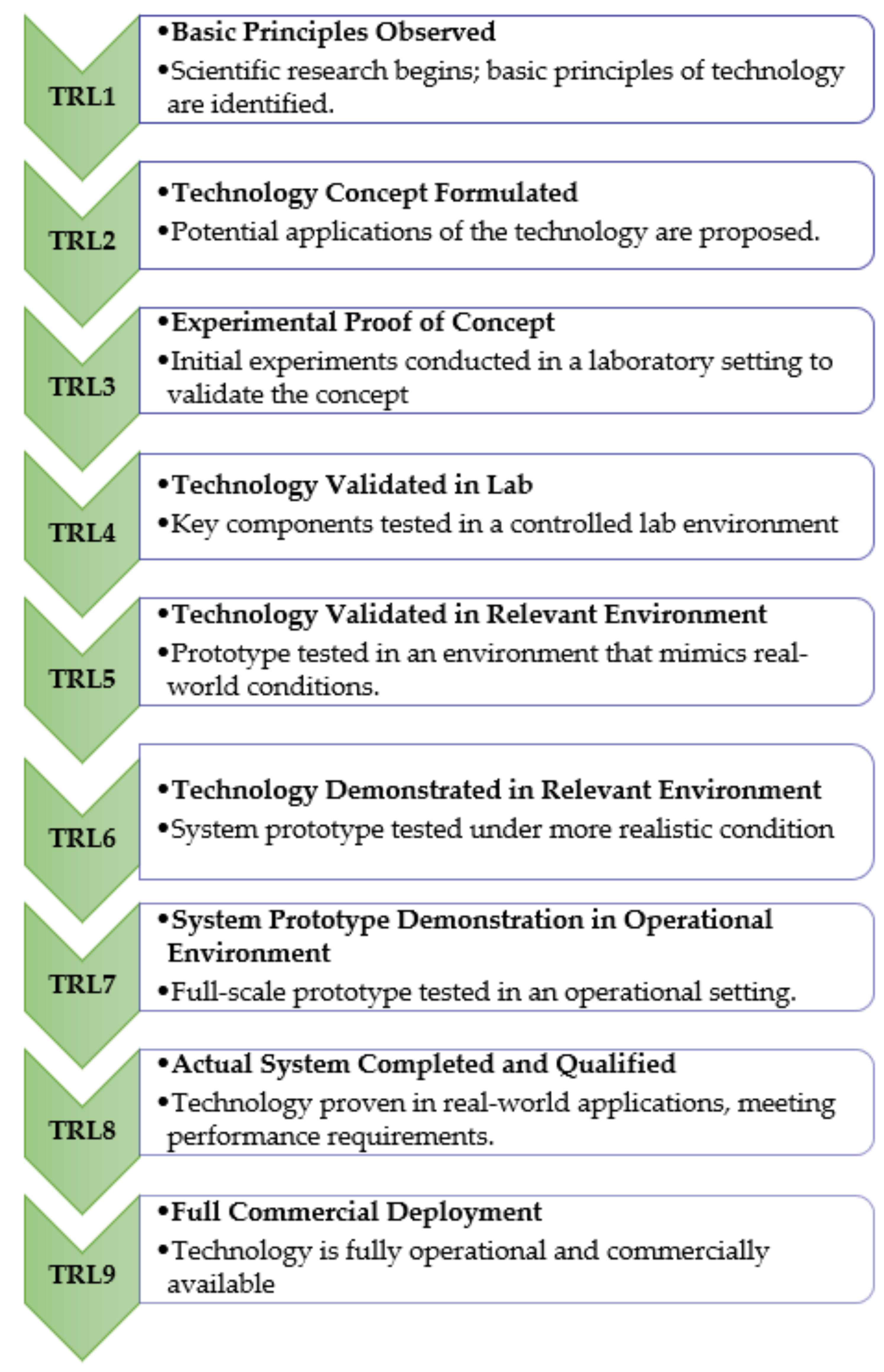

The TRL system is a nine-point scale ranging from basic scientific principles (TRL 1) to proven operational deployment (TRL 9). Each level reflects increasing fidelity and complexity. TRLs 1–4 covers concept validation in analytical or laboratory settings, TRLs 5–7 includes prototype demonstrations in relevant environments, and TRLs 8–9 represents full-scale operational use, as shown in

Figure 1. Using this standardized scale helps stakeholders, developers, regulators, and investors align expectations, manage risks, and allocate resources effectively throughout the innovation process [

15].

Within nuclear applications, TRLs have been adapted to gauge the progression of reactor technologies, including advanced fuels and materials. Fundamental research into novel reactor physics, fuel cycles, and coolant chemistries corresponds to TRL 1–2, where basic principles are observed and concepts are formulated. Component-level studies, such as testing passive safety valves, digital control systems, or irradiation-resistant alloys, advance technologies to TRLs 3–4 through laboratory experiments. Demonstrations of integrated subsystems in relevant environments, such as heat-exchange loops or neutronic control assemblies, indicate progress to TRLs 5–6. These tests confirm that subsystems function as designed under simulated operating conditions.

TRL 7 is reached when a full reactor prototype operates in a realistic environment. This stage validates neutronic and thermal–hydraulic performance, as well as construction methods, site logistics, and licensing processes. TRL 8 marks first-of-a-kind (FOAK) commercial operation, confirming performance, maintenance, and end-of-life strategies. TRL 9 is achieved when SMRs enter routine serial production, with multiple units operating under standardized regulations and established support systems. This stage demonstrates reliability across different sites and applications [

16].

Nevertheless, the assessment of TRL for SMRs may vary a little between different sources and data providers.

2.2. An Example of Own Experience in Radiation Technology Application in the Power Industry

New ideas are coming from physics, but are being developed and implemented by engineering researchers and practitioners. Authors with long experience in process and chemical engineering have observed issues in SMR marketing and lobbying. Some proposed solutions are promoted without even having industrial-scale blueprints. Many projects fail early in the TRL process due to insufficient calculations, physicochemical and mechanical analyses, or experimental verification. There is no comprehensive publication that presents all stages of SMR development in one study. Most available papers describe only preliminary design concepts. A good example of TRL compliance, however, is the implementation of nuclear and radiation technologies in the energy sector, particularly the radiation-based purification of waste gases from coal-fired boilers [

17]. It explains, step by step, how a concept advances through the TRL stages. The progression culminates in full-scale industrial implementation.

At TRLs 1–2, (i) the basic principles of the process were observed and described, and (ii) the fundamentals of the technology were defined. The focus of the stage was on the formation of low-temperature plasma within a gas subjected to irradiation by an electron beam. The basis of the technology came from understanding the conversion of oxidizing, non-reactive, and poorly water-soluble NO and SO

2, which form harmful sulfites, into the anhydrides of nitric acid (NO

2) and sulfuric acid (SO

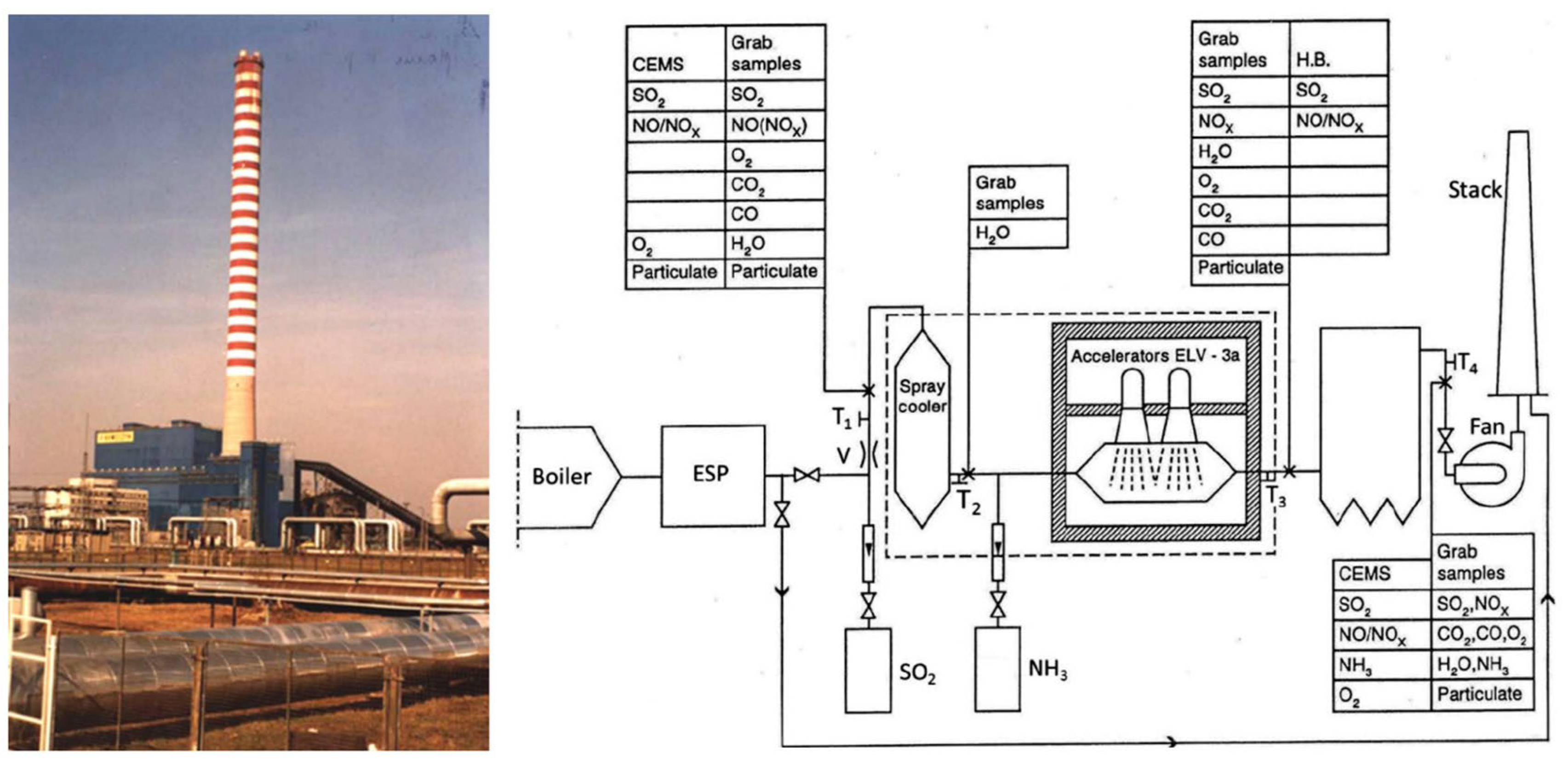

3). TRL 3–4 (i) verification of the concept was carried out, confirming analytically and experimentally the critical functions and characteristics of the technology, and (ii) verification of the components was performed under laboratory conditions. This stage required building a laboratory installation at the Institute of Nuclear Chemistry and Technology (INCT) and conducting relevant experiments. The installation, shown in

Figure 2, handled a gas flow rate of up to 400 m

3/h and used an ILU-6 electron accelerator with a beam power of 20 kW and adjustable electron energy up to 2 MeV.

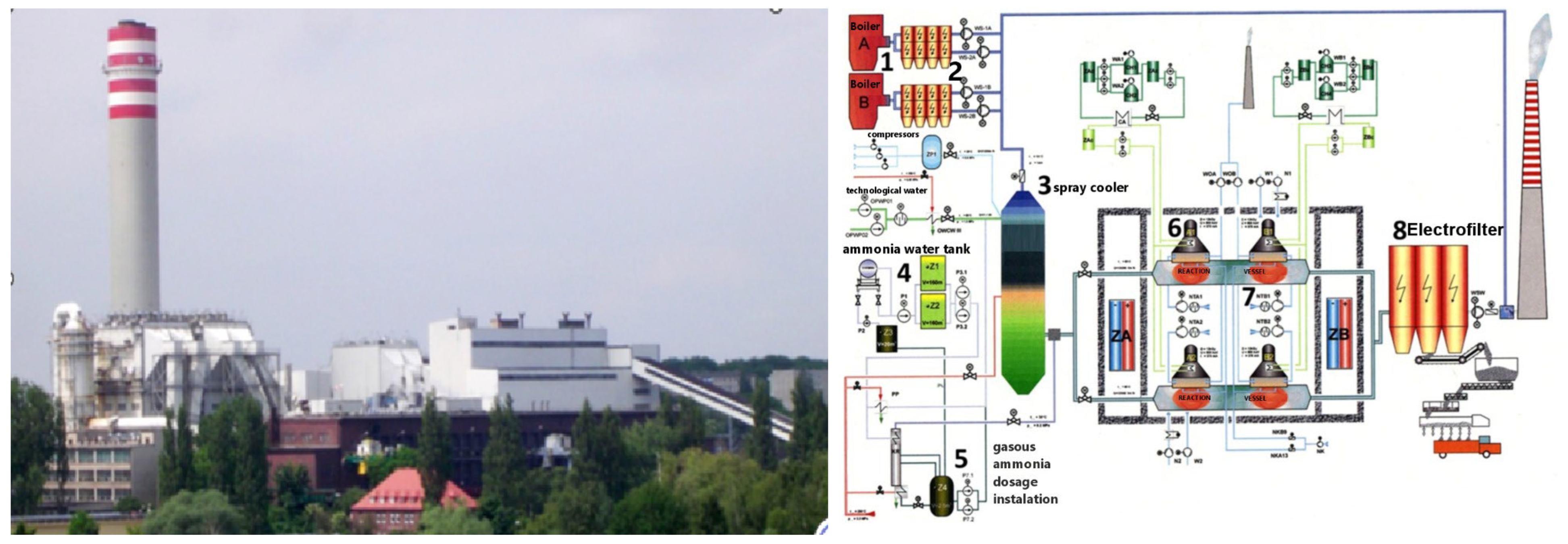

TRLs 5–6–7 included (i) verification of technology components in an environment similar to the real one, (ii) demonstration of the technology under conditions resembling actual operation, and (iii) demonstration of the technology prototype in operational conditions. This stage required the construction of a pilot installation at a coal-fired power plant. The installation handled a flue gas flow rate of 20,000 Nm

3/h. Two ELV-6 accelerators were used, each with a power of 50 kW and a beam energy of 600 keV. A view of the power plant and the installation scheme is shown in

Figure 3.

TRLs 8–9 included (i) completion and verification of the technology under development through tests and demonstrations and (ii) verification of the technology under development in an operational environment; this stage required the construction of a full-scale industrial plant with a gas flow at least 10 times greater (100 MW

th) than that of the pilot plant. The exhaust gases from the WP-100 boiler fired with hard coal were purified, with an exhaust gas flow of 270,000 Nm

3/h. Four accelerators (600 keV) with a power of 300 kW each were used. These accelerators are supported by two power supplies, each with a capacity of 600 kW.

Figure 4 shows a photograph of the power plant, highlighting the column of the exhaust gas purification system in the foreground.

The entire process of technology development from TRL 1 to the stage equal to 9 was 15 years.

2.3. Review of SMR TRLs Reported

Designers and suppliers offer SMRs that have reached various levels of design maturity. Light water reactor (LWR) SMRs stand out as the most advanced regarding technology and production. The designs are derived from existing large LWR designs. Non-LWR SMRs are still considered to be in development, far from the implementation and commercialization stages. That is because they are based on reactor designs for which there are few actual implementations, and even fewer of them are operational, as long as large LWR nuclear power plants are in operation. However, several limiting factors affect the implementation of the SMR technology, including a limited number of specialists and challenges in sourcing production components and nuclear fuel specific to SMRs, which strongly influence the degree of technological advancement. None of them has been commercially implemented in the United States [

18].

The SMR designs currently being proposed are very diverse. They range from proven solutions used in large-scale industrial power reactors to solutions that have not yet been built or tested and are only theoretical. This diversity stems from the reactor’s intended use and affects its design, cooling methods, the introduction of automation, and even the anticipated use of remote control. As with most innovative technologies, research on new reactor solutions is expensive, and the outcomes are often difficult to predict. Before any reactor can be approved for general use, it must undergo a rigorous, multi-stage evaluation process. Currently, construction has begun on two types of SMRs based on proven PWR and BWR (boiling water reactor) technologies; however, their novel designs require extensive verification and testing. Most proposed concepts remain at the planning or early research stage. It should be noted that ongoing SMR research in many nuclear centers worldwide is still in a preliminary phase. Before a design can advance to mass production, it must first be validated through model development and prototype testing. The process begins with defining the intended application, developing a conceptual design, selecting appropriate technologies, testing critical design elements, and performing comprehensive safety analyses before model construction. Developing a new reactor type is therefore both capital-intensive and time-consuming.

The vast majority of the proposed projects are currently in an early phase of development, except for four prototypes in China and Russia. More than 68 modular reactor concepts based on Generation III and IV reactors have been developed. Most of these designs never exceed TRLs 2–3. The Environnement and Energy Consultant report proposes a typology of reactor projects, starting with water reactors, which are similar to those used in submarines. It also includes gas, liquid metal, and molten salt systems, all of which require further development [

19]. SMR designs are listed in the International Atomic Energy Agency (IAEA) “Small Modular Reactors Catalogue 2024”. According to this source, the number of active SMR designs dropped from 83 in 2022 to 68 in 2024 [

16]. This figure results from periodic analyses conducted by the IAEA concerning the active development of proposed solutions. Many of them were only preliminary, underdeveloped ideas, and no progress was made in their further development. Therefore, it is a good example of the importance of using the TRL scale to exclude immature projects. The list of SMRs based on different concepts related to their main parameters is presented in

Table 1 [

20].

Demonstration projects such as the Russian icebreaker reactors RITM-200 (TRL 6–7) and the forthcoming NuScale VOYGR module (expected TRL 7 upon grid connection) are critical for bridging the gap toward TRL 8 commercial operation. In parallel, other water-cooled SMRs like CAREM-25 (TRL 7) and KLT-40S (TRL 7), along with high-temperature designs such as HTR-PM (TRL 9), exemplify the diversity of technological approaches progressing down the readiness pathway [

20]. However, the non-stability of these developments is illustrated by the fact that NuScale, which offers a truly modular reactor set, expected the NuScale plant in Utah to be the first SMR nuclear power plant to obtain a construction license from the US Nuclear Regulatory Commission (NRC). However, NuScale stated that it seems unlikely that the project will have enough subscriptions to continue implementation. In January 2024, NuScale (Corvallis, OR, USA) announced that the target price of energy from the plant would be USD 89 per megawatt hour, an increase of 53% compared to previous estimates of USD 58 per MWh, raising concerns about customer willingness to pay. In addition, the designed safety systems were reviewed and found to require adjustments [

21]. However, NuScale has now received a positive opinion from the NRC for the new version of the reactor. This is a preliminary decision that closes most of the technical issues contained in the design when applying for a construction or operating license. These will be considered resolved unless new risks or design changes emerge in the meantime. The Standard Design Approval (SDA) is also not a commitment by the NRC to subsequently issue a construction license, further certification, or permit. The document covers a reactor design with a thermal power of 250 MW

th (approx. 77 MW

e)—a new version of the earlier 160 MW

th (approx. 50 MW

e) module, which received SDA certification in 2020 and 2023, but did not find investors for such a small reactor [

22,

23]. While the lower-power version of NuScale raised concerns for the NRC in several key technical areas, which were explicitly mentioned when the approval was issued, the US460 documentation, as stated by the Advisory Committee on Reactor Safeguards (ACRS), an advisory committee to the NRC, “is complete, well documented, and based on verified computational models and an extensive testing program” [

24]. NuScale is currently the only company whose SMR’s design was approved by the NRC. The recent announcement has confirmed that the second design by NuScale has been approved by the U.S. nuclear regulator.

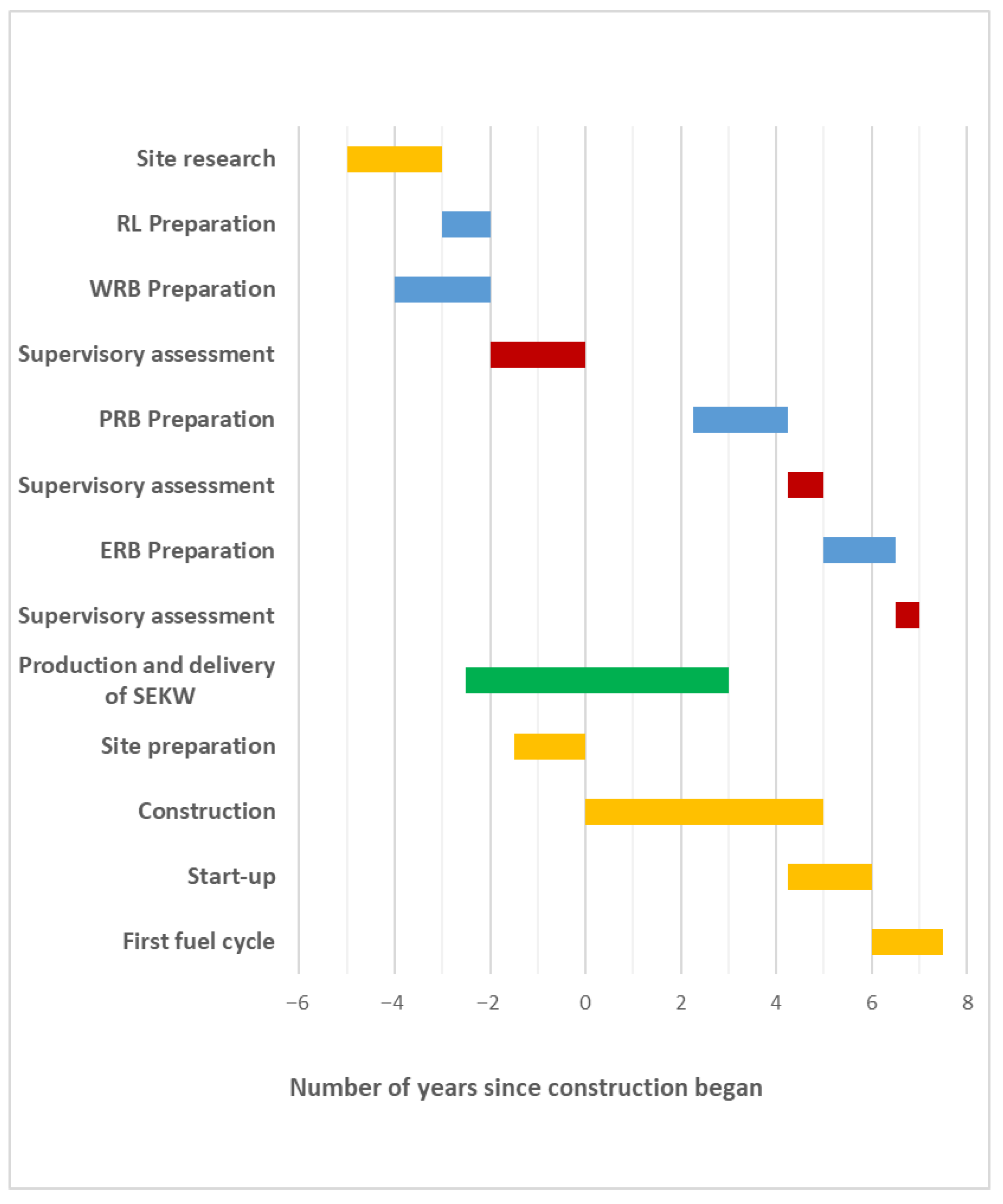

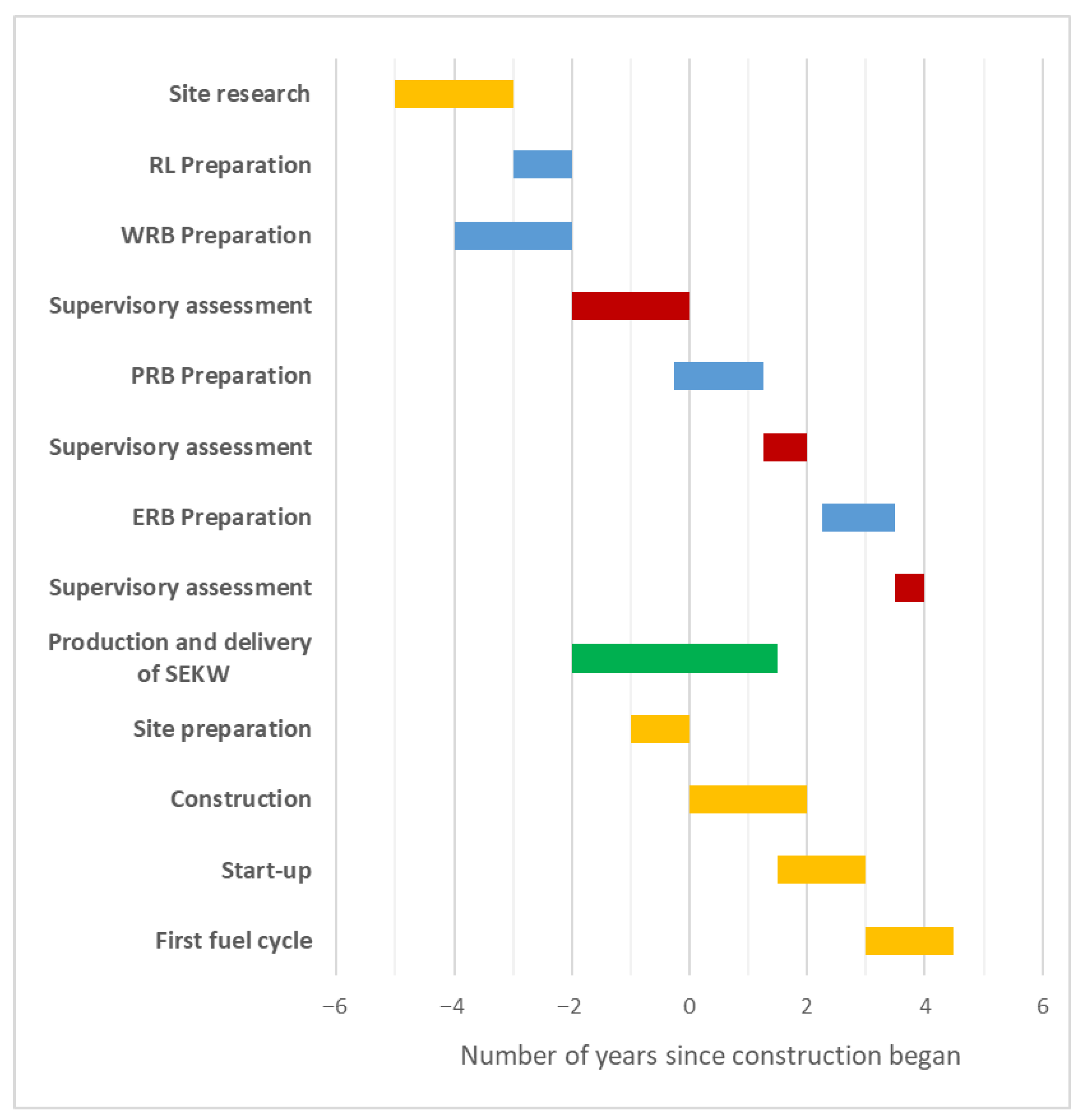

Governments looking to guarantee future energy security are advancing strategies, legislation, and support to encourage SMRs, but there is a need for a successful FOAK deployment in the West. This would prove the feasibility of the technology and provide vital lessons to powering a wave of cheaper, faster nth-of-a-kind (NOAK) deployments that deliver on the promise of SMRs. There is currently no single leading SMR design, as both Gen III/III+ and Gen IV projects continue advancing toward their FOAK deployment in a Western country. However, several frontrunners have begun to distinguish themselves in this race. There is no clear frontrunner, and it remains uncertain which technologies will ultimately succeed. As such, the sector resembles a global race toward achieving the first successful FOAK deployment. Examples of TRLs for different SMR designs according to the Organization for Economic Co-operation and Development (OECD) 2024 Nuclear Energy Agency (NEA) are presented in

Figure 5.

To propel SMRs across the final readiness thresholds into widespread deployment, several cross-cutting challenges must be addressed. Harmonizing international licensing frameworks is essential to streamline multi-jurisdiction approvals. Securing reliable high-assay low-enriched uranium (HALEU) supply chains and implementing vendor-take-back or fuel-leasing models will mitigate proliferation risks and material stockpiling. Ultimately, expanding modular manufacturing infrastructure through factory automation and standardized quality controls will lower per-unit costs and speed up delivery timelines. This approach can help unlock the full economic benefits of modular assembly, although the technology still faces several challenges. Examples of key challenges are shown in

Table 2.

A very good and up-to-date assessment of the situation was presented by the Pacific Northwest Laboratory (PNNL) in the report “Emerging Technologies Review: Small Modular Reactors” [

6]. This document is significant because the original concept of SMRs focused on their potential use in remote regions, such as Canada’s Arctic areas. They were also envisioned as a means to provide reliable electricity for military bases. According to the definitions of Technology Readiness Levels (TRLs) adopted by the Department of Defense (DOD) and published by the Government Accountability Office (GAO), TRLs can range from 5 to 6 [

25]. A TRL of 5 indicates that the technological components have been integrated with realistic supporting elements, enabling testing in a simulated environment. In contrast, a TRL of 6 signifies that the systems or subsystems have been successfully demonstrated in an appropriate environment.

An interesting supplement to the previously discussed PNNL report is the publication ranking the proposed SMR solutions according to their status on the TRL and power scale [

16,

26]. Selected SMRs at TRLs

5 are presented in

Table 3.

Global interest in SMRs is rising among both governments and the private sector. This growth is driven by their potential to reduce carbon emissions and strengthen energy security. The third edition of the NEA SMR Dashboard identified 127 SMR designs globally [

27]. Geographically, SMR development is widespread, with 30 designs from 25 organizations in North America, 20 designs from 19 organizations in Europe, and 10 designs from 5 organizations in OECD Asian countries. Additionally, China has five designs from four organizations, Russia has five designs from two organizations, Africa has two designs from two organizations, and there is one design each from organizations in South America and the Middle East. Currently, seven designs are either operating or under construction, with a robust pipeline of projects advancing towards their FOAK deployment. As of February 2025, three SMRs are in operation: the HTTR in Japan, the floating KLT40S in Russia, and the HTRPM in China. Since the release of the NEA SMR Dashboard Second Edition in 2024, three more designs have received construction licenses. These include Natura Resources’ (Alameda, CA, USA) molten salt cooled MSR1, Kairos Power’s (Alameda, CA, USA) Hermes demonstration reactor, and the US DoD’s Project Pele. Four other SMRs had already been licensed: the ACP100 in China, the CAREM in Argentina, and Russia’s BREST OD 300 and RITM 200N. In 2024, Korea’s Nuclear Safety and Security Commission (NSSC) approved the SMART100 SMR design. This updated version of the SMART reactor was originally developed by the Korea Atomic Energy Research Institute (KAERI) and received its initial SDA from the NSSC in 2012.

The report indicates that a majority of the SMR designs (39) utilize high-assay low-enriched uranium (HALEU), which is enriched between 5% and 20% in U-235. Of these, 30 designs will use uranium enriched above 10% and below 20%, while 9 intend to use uranium enriched between 5% and 10%. The availability of HALEU continues to be a major obstacle to the deployment of many SMR designs. However, some developers have taken proactive steps to secure supplies for their FOAK reactors. As of early 2025, data indicate that more than half of the SMRs intending to use HALEU remain in the early stages of development. Most have only non-binding agreements or research collaborations with national laboratories focused on fuel supply. There is also limited public information on their plans for waste management and end-of-life cycle readiness [

27].

The growing number of SMR projects being developed independently by different countries is a notable trend. This pattern has existed since the early days of reactor research, particularly with fast neutron breeding reactors. Researchers from that time, drawing on British experience, noted that developing a single reactor type required the work of 300 to 400 scientists and engineers across research, technical development, and design [

28]. The team must also have the capacity to conduct laboratory research on selected process elements and prepared materials. A particular issue is the preparation of a new type of nuclear fuel and its licensing [

29]. Obtaining a license for a new type of nuclear fuel is a lengthy process that can take several years. This timeline reflects the extensive testing, evaluation, and regulatory review needed to confirm the fuel’s safety and performance before approval for reactor use. The timeline can be influenced by factors like the complexity of the fuel design and the regulatory framework in place [

30].

3. Scale Effects

3.1. General Rules for Industry

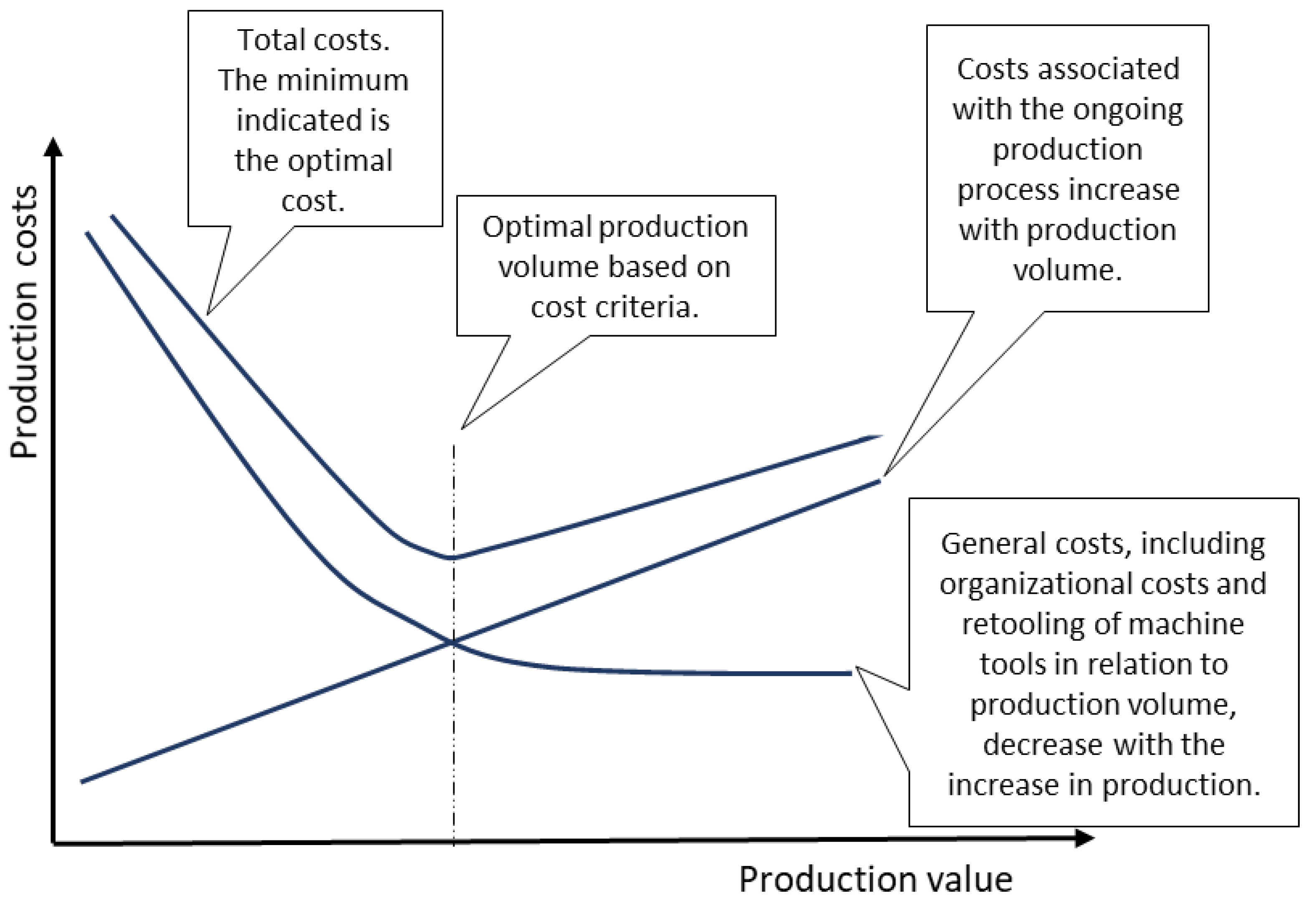

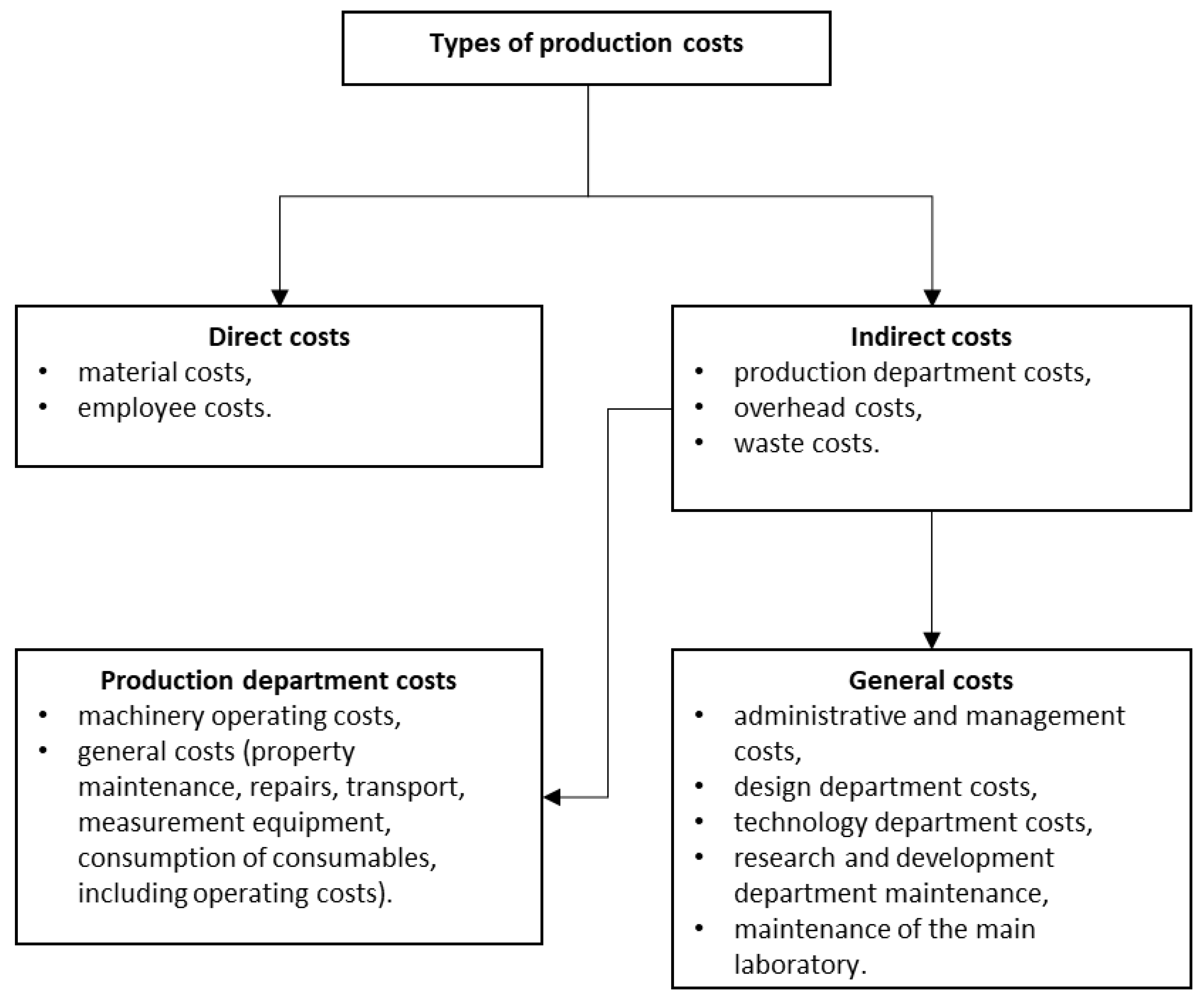

Optimizing the technological process takes production costs as the primary criterion. Meeting this criterion primarily involves reducing costs. Cost minimization is achieved through various methods, including various optimization criteria. Changes affecting production costs occur not only technologically but also organizationally.

Figure 6 provides a pictorial representation of the relationship between costs and production volume.

Determining the optimal production run size by a process engineer is not straightforward, as it depends primarily on the order’s timeliness and the number of items in the run. In the era of single-item and small-batch production, striving to achieve optimal production volume (

Figure 6) is merely theoretical. A key focus area, both technologically and economically, is the design and manufacture of semi-finished products. Their design and production methods are closely tied to the expected production volume and overall cost efficiency. The role of assembly, whose process and organization also have significant economic significance, cannot be underestimated. Assembly is the final stage of production. The technological process at this stage depends largely on the quality achieved during earlier processing steps. Almost every technological process development takes into account the multi-variant nature of its course (

Figure 7). Individual variants are analyzed economically to select the technological process that meets design requirements while minimizing production costs.

For NPPs with large units or SMRs, structuring the costs, as shown in

Figure 7, can be effectively achieved using the Code of Accounts (COA). Costs are divided into five categories, four of which are shown in

Figure 7. Direct construction costs (DCs) cover expenses for building the plant. Indirect costs (IDCs) relate to services supporting construction. Overnight capital costs (OCCs) reflect total capital investment (TCIC) excluding interest and inflation. The levelized cost of electricity (LCOE) includes investment activities, operating costs, decommissioning, and other lifetime expenses of the NPP [

32,

33]. However, it is not possible to assess these costs in the case of solutions that do not exist in practice without a demonstrator and its economic feasibility tested in the field [

34]. Demonstration projects play a key role in evaluating previous approximate financial assessments and determining the further commercialization of the selected solution [

35]. It is for these reasons that the need to assess the TRL for a given technology is pointed out in

Section 3.2. A procedure was outlined that allows for the development of mature technology and full quantitative categorization of costs. According to IEA OECD: “

In the regulated markets of the past, the technology with the lowest LCOE really was indeed also the best baseload investment choice. This no longer holds true…… and most importantly, in systems with large shares of variable renewables, one must complement cost considerations with value considerations, or, equivalently, account for costs at the system rather than at the plant level.” [

36]. This subject is discussed by Emblemsvåg [

37]. Levelized Avoided Cost of Electricity—LACE—is a companion metric for LCOE that was developed by the U.S. Energy Information Agency. Its purpose was to improve comparisons of economic competitiveness between generation technologies. A generation technology is economically attractive if its LACE is greater than its LCOE. LACE recognizes that variable power sources, such as wind and solar, may still incur capital and maintenance costs for backup dispatchable sources. These sources are needed to supply energy when demand exceeds generation. Therefore, LACE can complement LCOE for SMRs once more data are available. It accounts for potential cost savings that may be realized [

35].

3.2. Large Nuclear Reactor (LNR) Case

At the beginning of the nuclear power era, nuclear power plants (NPPs) were primarily viewed as a source of baseload electricity. However, the situation has changed in some countries. The share of the nuclear power segment in the national electricity mix of certain countries has become so significant that utilities are compelled to enhance the maneuverability capabilities of their NPPs. This adaptation allows them to adjust electricity supply according to daily or seasonal variations in power demand. Another reason for adding load-following capabilities to nuclear power plants is the large-scale integration of intermittent sources, such as wind power. When both nuclear and intermittent sources feed the same grid, NPPs must operate in load-following mode. This ensures they can manage fluctuations in total power generation. This is crucial, as unexpected large and rapid changes in power demand can occur. Moreover, the levelized cost of electricity (LCOE) is highly sensitive to the load factor, which represents the amount of electricity effectively produced by the plant. The cost of electricity generated by nuclear power plants decreases significantly with an increase in the load factor. In contrast, for some other power sources, particularly those with a substantial portion of costs tied to fuel (like natural gas), this relationship is less pronounced [

38].

Upgrading reactor power is evident in the nuclear energy sector, as in other industries. This reflects modernization and optimization of equipment and technology. Technological advancement in energy generation reduces the unit cost of electricity and increases company profits, a key business goal. For example, the Dukovany VVER-440 reactors, commissioned between 1985 and 1987, originally had a gross capacity of 440 MW

e. A nine-year modernization program resulted in an increase in the power of each reactor to almost 500 MWe in 2013. Similarly, the modernization of both VVER-1000 units at the Temelín NPP, which was implemented in stages from 2005 to 2024, resulted in an increase in the gross capacities from 981 MWe to 1086 MWe for each unit [

39].

The main components of the nuclear steam supply system (NSSS) include the reactor core, reactor coolant system, containment, and auxiliary systems. Additional components depend on the reactor technology. For example, pressurizers or steam generators are used in PWRs. The NSSS is often tailored to a particular reactor design. Key components, such as the reactor pressure vessel (RPV) and steam generators, demand particularly heavy forgings, making their production complex. The manufacturing of an RPV for a Generation III reactor is best achieved using forging presses with a high capacity that can accommodate large steel ingots weighing between 500 and 600 tons. Approximately 40 RPVs or other major components, such as steam generators, can be produced annually. However, the large-scale deployment of NPPs still requires global coordination. Currently, only a few manufacturers are capable of supplying such heavy forgings. RPVs are often seen as the most significant bottleneck in the supply chain. However, other components, such as steam generators, also face supply challenges due to the heavy manufacturing requirements. One proposed solution to alleviate the bottleneck in heavy forgings is the construction of SMRs. Although SMR forgings are smaller than those for large LWRs, they may still exceed the capacity of existing U.S. forges. This includes forges linked to the advanced SMR concept. At present, the production of RPVs for SMRs does not fundamentally differ from that for large-scale NPPs and still relies on subcontracting to manufacturers in Asia. SMRs produce only a fraction of the power of larger reactors. Large-scale deployment could require thousands, or even tens of thousands RPVs, putting additional pressure on the supply chain [

40].

3.3. SMRs Case

Forecasting the future costs of innovative energy technologies, such as SMRs, presents a complex challenge. This is due to a multitude of uncertainties and variables. This transition is essential for harnessing the full potential of economies of scale and enhancing the competitiveness of SMRs. Large nuclear power plants (LNPPs) are usually tailored to customer needs and local regulations. SMRs, however, rely on standardized components, manufactured centrally and shipped to sites. Their economic viability depends on a sufficiently large market for a single design, which drives learning curves and economies of scale. Once the first SMR projects are completed, deployment should adopt a product-based approach, promoting greater consolidation and standardization within supply chains. Modularization will further increase the potential for standardizing modules, facilitating the mass production of these components [

41]. The analysis shows that although smaller SMRs may encounter higher initial costs, they have substantial potential for cost reduction due to shorter construction times and beneficial learning effects (

Figure 8). Furthermore, the study indicates that SMRs can compete with or even exceed the cost-efficiency of larger nuclear power plants, provided that a sufficient number of units are deployed. Future cost projections, with or without heat use and long-term SMR economics, provide a nuanced view of their value. Factors such as learning effects, standardized design, modularization, and co-siting economies can improve time to market. However, SMRs may face negative economies of scale in construction due to their relatively lower power output in comparison to conventional reactors [

42]. There are still uncertainties about the techno-economic competitiveness of SMRs. It remains unclear whether they can benefit from mass-production economics despite their inherent lack of scale advantages [

43].

Compared to SMRs, traditional large NPPs typically have lower costs per unit of output due to economies of scale, which spread expenses over higher output. This is evident when analyzing overnight capital costs and output for reactors using analogous technology. Studies show costs decrease by 20 to 35 percent when the reactor size is doubled. For SMRs, capital costs are projected to be up to 70% higher for similar technologies. While this is a disadvantage, features such as learning effects, modularization, shorter time of construction, and co-siting economies could help mitigate these costs and improve SMR cost-effectiveness [

35]. This is a completely new concept in the nuclear industry that poses challenges for all SMRs. Its viability needs to be proven to win investor support.

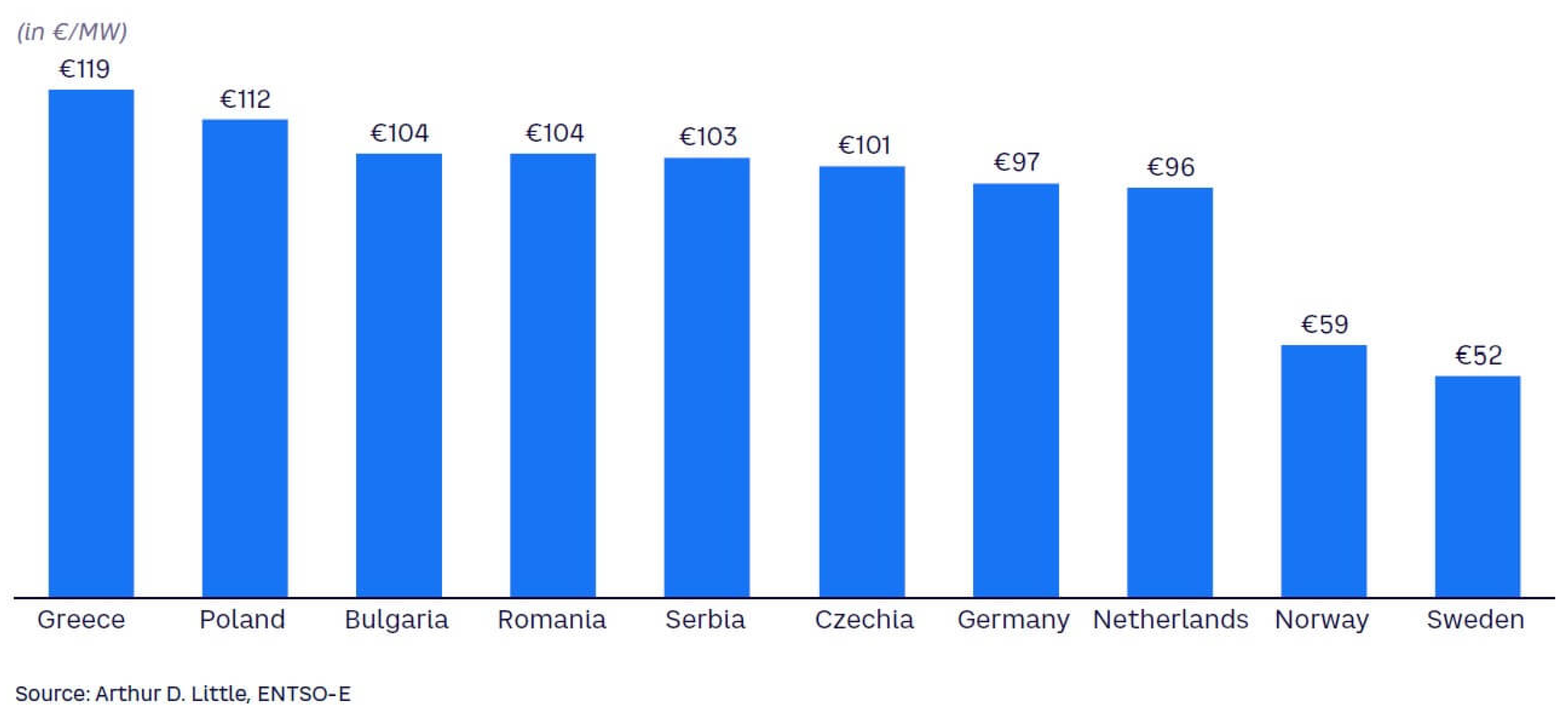

The costs SMRs must achieve to compete with other baseload power sources vary by country. Analysis shows that their average lifetime electricity cost (LCOE) needs to range from EUR 52/MWh in Sweden to EUR 119/MWh in Greece (

Figure 9) [

44].

The LCOE defined above allows for a comparison of the costs of electricity generation using different technologies and includes investment, operating, fuel, and other costs incurred during the period from the construction to decommissioning of a power plant. However, there are still differences in the assessment of SMR capital costs and their competitiveness in the energy market. Therefore, R&D work is being undertaken to develop methods for calculating the direct and indirect costs of SMR construction. In [

45], these methods are presented for the assessment of costs in the case of a product offered by NuScale LLC, allowing for the assessment of the discussed costs incurred in the construction of small and large nuclear reactors. Comparisons were made for an updated version of the PWR-12 designed by Westinghouse Electric, which is a four-loop pressurized water reactor (PWR) with a capacity of 3417 MW

th, (1147 MW

e) with the NuScale SMR, which is an integrated light water pressurized reactor. Each has a power output of 60 MW

e. A set of 12 gives a total gross power of 720 MW

e (685 MW

e net). According to the authors, electricity generation in SMRs has similar advantages to large-scale nuclear power, e.g., it leads to a reduction in carbon dioxide emissions, but also, when used, the direct and indirect capital costs are significantly lower, resulting in lower LCOE values [

45].

A comparison of LOCEs and a summary of investment costs, fuel costs, operational costs, and other maintenance costs for 15 types of SMRs are presented in the publication [

42]. According to the work, the lowest LOCE value is associated with the high-temperature helium-cooled reactor, while all light water reactors exhibit higher LOCE values. None of them is competitive with renewable technologies, not even when taking their variability and necessary system integration costs into account.

We have to remember that SMRs are currently at a much earlier stage of development compared to LNRs, which are nearing the conclusion of their testing and further development phases. Leading-edge designs for LNRs are preparing for their first deployment in the United States and other locations. Consequently, it remains uncertain whether SMRs will effectively address the challenge of scaling up; this question cannot be resolved for at least a decade. Although public perception of nuclear energy is gradually becoming more favorable, there is still significant progress to be made, and substantial support will be required throughout this journey. Nevertheless, SMRs represent a potentially critical advancement in nuclear technology [

46]. The author posits that, in contrast to large reactors, the initially high costs associated with SMRs may decrease over time, as these reactors are engineered to be manufactured—either partially or completely—within a factory setting rather than being constructed on-site.

SMRs must be competitively priced. To realize their potential for factory-assembled modularity, designs must not only function properly but also support large-scale pro-duction. A key factor for success is the number of units deployed to achieve economies of scale. This could be achieved through cooperation among countries or utilities or by integrating vertical lines, with utilities investing directly in SMR designers. Success requires standardization and the ability to mass-produce components for shipment to construction sites. However, the market remains crowded. The more SMR designs are considered viable, the harder it will be to achieve standardization and factory-built deployment.

4. Selected SMRs for the Study: Industry Engagement and Prospects

Before the onset of construction, the integrity and reliability of the SMR design must be substantiated through a comprehensive safety assessment. This assessment functions as the cornerstone of regulatory validation and operational viability. It entails a multilayered analysis of engineered systems, construction methodologies, material performance, and technological processes All of them must adhere to recognized national and international engineering standards. The design narrative must encompass full architectural and structural specifications, including the sequencing of construction stages, the projected operational timeline, and detailed plans for decommissioning. An exhaustive fault analysis must be conducted using both probabilistic and deterministic approaches. The aim is to identify potential failure modes, formulate mitigation strategies, and establish corrective mechanisms that ensure reactor safety across all operational states. Human factors affecting engineering (related, for example, to transferring blueprints that use the Anglo-Saxon system to countries where the SI system is used) must be taken into account to assess the system’s resilience to unintended errors. On the other hand, external hazard assessments must address the reactor’s robustness against hydro-meteorological threats such as seismic activity, and flood events, as well as anthropogenic hazards including sabotage, terrorism, and fire emergencies. An emphasis must be placed on quantifying the dispersion dynamics of radioactive materials under fault conditions, supported by validation of emergency protocols, protective infrastructure, and community response mechanisms. Site-specific characterization, incorporating hydrogeological, meteorological, and seismic data, is indispensable in establishing long-term risk profiles. Environmental impact analysis forms an intrinsic component of this safety assessment, requiring evaluation of local ecological interactions and contributions to broader climate systems. All assessment elements must fully comply with existing regulatory frameworks. These include those established by the International Atomic Energy Agency (IAEA), Western European Nuclear Regulators’ Association (WENRA), OECD NEA, and national authorities. Such compliance ensures continuous oversight throughout the reactor’s lifecycle, from siting and licensing to operation and eventual decommissioning.

The Small Modular Reactor Regulators’ Forum (SMR RF) plays an important role in coordinating activities. It is an international regulator-to-regulator body established in 2014. The Forum provides a platform for experienced regulators to develop consensus-based positions on key SMR technical and regulatory issues [

47]. Another industry-oriented organization was established, the European Industrial Alliance on SMRs. Its goal is to support and accelerate the development, demonstration, and deployment of SMRs in Europe by the early 2030 [

48]. The organization adopted its first Strategic Action Plan at their second General Assembly on 12 September 2025. The successful implementation of the Strategic Action Plan will require strong commitment from both industry and the public sector, as well as collaboration among diverse stakeholders. The alliance works closely not only with its members, but also with relevant Commission services, other EU institutions, and international organizations to ensure prompt and effective deployment of SMRs in Europe [

49]. An example of industrial activity is the agreement between OSGE and Canada’s Laurentis Energy Partners (Laurentis). The agreement supports the preparation of the European Union’s first Preliminary Safety Analysis Report (PSAR) for a SMR [

50]. OSGE selected the BWRX-300 water-cooled, natural circulation SMR that incorporates passive safety systems. This design builds upon the foundational elements of GEH’s U.S. NRC-certified ESBWR 1520 MWe [

51].

5. Site Selection and Criteria Applied

Systematic site-selection methodology blends rigorous technical feasibility, strict nuclear-safety criteria, and internationally recognized environmental safeguards. In the Polish case, the Polish Nuclear Power Program provides an example of this methodology. Site selection integrates both technical feasibility and safety compliance. This chapter outlines the multicriteria framework developed for site selection and complements it with internationally adopted best practice locational criteria. It also discusses the recent selection of Lubiatowo-Kopalino as the preferred site for Poland’s first nuclear power plant.

5.1. Technical Feasibility Criteria

Feasibility is assessed across six main areas, with each area weighted according to its importance for the chosen deployment pathway. These weights differ for the brownfield pathway, which applies to third-generation reactors, and the direct pathway, which applies to fourth-generation SMRs. The six areas are highlighted below:

Power-System Integration evaluates existing boiler turbine configurations and carbon emissions. For third-generation retrofits, CO2 emissions serve as a proxy for economic attractiveness. However, for fourth-generation applications, net electrical efficiency indicates the potential reuse of the turbine island.

Electricity Infrastructure measures the capacity and condition of high-voltage connections. Sites exceeding 3000 MW of installed generation score highest for third-generation projects, reflecting the rarity of grid reinforcement opportunities. For SMRs, newer units receive preference based on reduced transmission upgrade needs.

Transport Accessibility considers proximity to rail, road, and port facilities. Both pathways rate this as crucial to deliver heavy reactor modules and auxiliary equipment, with slightly higher weighting for larger third-generation modules.

Cooling-Water Availability ranks sites by access to rivers, lakes, or the sea. Third-generation reactors, requiring greater withdrawal volumes, assign maximum weight to this criterion. Fourth-generation designs receive modestly lower weighting due to higher coolant-temperature operations.

Land Availability addresses decommissioning schedules, development density, and adjacent free land. Coal plants scheduled to retire between 2031 and 2042, sited on expansive brownfields, achieve optimal scores for large reactors. For SMRs, the number of small modules required to replace thermal capacity and expert assessments of adjacent land inform site suitability.

District-Heating Potential gauges local heat-network demand. Although weighted lightly, sites with existing municipal or industrial heat circuits gain a marginal advantage by enabling cogeneration opportunities.

In the brownfield pathway, SMRs are built on the sites of decommissioned coal-fired plants, using the available space and existing infrastructure. In the direct pathway, SMRs not only use the site and auxiliary systems but also reuse major components, such as the steam turbine island, from the original coal plant.

5.2. Nuclear Safety and Environmental Criteria

Nuclear safety and environmental criteria play a central role in determining suitable sites for nuclear power plants. These criteria address regulatory compliance, public safety, and the secure operation of critical systems. The main aspects are summarized below:

Formal Exclusionary Requirements impose absolute barriers such as active faults, floodplains, military restricted zones, and protected natural areas. These subcriteria carry the highest individual weights, ensuring that no site proceeds without fulfilling statutory siting laws [

52].

Population and Exposure Threats evaluate population density within 30 km, robustness of evacuation infrastructure, local hydrogeology, and prevailing wind patterns. Sites near dense urban settlements or groundwater aquifers receive penalized scores due to higher radiological-release risks.

Emergency Water Supply Security remains the sole safety system criterion applied preliminarily, reflecting the imperative to secure coolant sources under accident conditions. It is weighted more heavily for third-generation reactors than for SMRs.

The methodology for evaluating nuclear potential sites in Poland is presented in

Figure 10. These outcomes informed Poland’s strategic decision to focus the first nuclear build in the Pomorskie Voivodeship, where social, environmental, and technical conditions align favorably. An initial screening of 92 locations nationwide applied exclusion-zone mapping and geological engineering reports to define “exclusion-free areas” suitable for hazardous infrastructure. Subsequent narrowing to two coastal sites, Żarnowiec and Lubiatowo-Kopalino, underwent detailed Environmental Impact Assessments. In December 2021, Lubiatowo-Kopalino was announced as the preferred location for Poland’s first NPP, based on superior environmental compatibility, access to cooling water, distance from urban agglomerations, and minimal nature-conservation conflicts [

53].

6. Coal-to-Nuclear

Poland’s energy demand is increasing substantially. Since 1990, total final consumption has risen by over 25%. For many years, coal has dominated the Polish power sector, while the country is the second-largest coal producer in Europe, following Germany. In 2024, coal accounted for 33% of Poland’s primary energy consumption, while all fossil fuels combined made up 87% [

55]. The Energy Policy of Poland until 2040 is a response to the European Union’s strict climate policies, addressing the challenge of decarbonizing the Polish power sector to reduce emissions [

56]. According to the Polish Economic Institute, the average lifespan of a coal-fired power plant is 47 years, meaning many facilities do not meet current technical or environmental standards. Furthermore, by the end of 2028, regulations regarding the internal electricity market will prohibit support for power plants that emit more than 550 g CO

2 per kWh (and 350 kg CO

2 per kW/year) [

57]. Without public funding, coal-fired generation becomes economically unfeasible. The end of this support coincides with emission limits in the power market and record-high CO

2 prices, which will further diminish the economic viability of coal-fired power generation. Recently, the Polish government approved a draft update of its National Energy and Climate Plan (NECP) for the period leading up to 2030, with a longer-term perspective extending to 2040. The document emphasizes that, in the long run, renewable energy sources and nuclear energy will be the primary methods for reducing emissions in the electricity sector [

58]. In recent years, both the Polish government and private investors have viewed SMRs as a promising alternative for decarbonizing coal-fired power stations. One initiative reflecting this interest is project DEsire, which aims to develop a plan for the decarbonization of the national energy sector using Generation III/III+ and IV nuclear reactors. The research includes a preliminary site assessment for the potential implementation of such solutions in Polish coal systems.

There are numerous international and national legal acts regulating all safety aspects of licensing, designing, constructing, operating, and decommissioning NPPs on Polish territory. It is important to emphasize that the licensing process in Poland is the same for LNPPs and SMRs [

59]. As a result, all criteria considered during site assessment for LNPPs must also be applied to the site selection for SMRs. An assessment of the site evaluations for 23 existing coal-fired plants in Poland that are proposed for retrofitting with various types of nuclear reactors was presented in previous work [

60]. This study encompasses an evaluation of 23 sites designated for repowering with Generation III/III+ nuclear reactors in addition to eight sites anticipated for retrofitting with Generation IV nuclear reactors. In line with the formal requirements and recommendations of international and national organizations, key aspects for the design and operation of nuclear power systems were identified. These aspects form the basis for site assessment and selection, as shown in

Figure 10:

Formal requirements and recommendations mandated by international and national organizations concerning the design and operational processes of nuclear power systems.

Potential nuclear hazards related to the personnel associated with a nuclear reactor unit and the surrounding local population.

The security systems implemented within the reactor, which encompass the heat cycle of the steam turbine and associated auxiliary infrastructure.

The management protocols for spent nuclear fuel and radioactive waste.

Additionally, several important factors were analyzed, such as population density, transportation infrastructure, and the proximity of conservation areas. These factors may significantly influence the licensing process, the project’s economy, and social acceptance. The four highest-ranked coal blocks were selected for further analysis, considering their potential for modernization using Generation III/III+ reactors. The evaluation criteria adopted indicate that critical safety aspects are predominantly linked to the specific location of the planned modernization. Given the rigorous standards and nuclear safety requirements, all assessed technologies appeared comparable. This comprehensive analysis culminated in the formulation of a ranking list, identifying the sites where the implementation of the “C2N” approach would yield the most economically feasible and practical outcomes.

A more comprehensive analysis of the same coal-fired plants, updated with an assessment of technical aspects, was presented in the work published recently [

60]. The analysis examined various technical parameters. These include the power system with its auxiliary infrastructure, electricity infrastructure (including the power derivation system), availability of cooling water, land, and network heat demand. Furthermore, these parameters were evaluated for two transition pathways: brownfield and direct. This preliminary assessment identified sites that appear most attractive and feasible, taking into account potential technical and legislative barriers. The findings indicate that Kozienice, Połaniec, Dolna Odra, and Opole are the most promising sites for transitioning from coal to nuclear energy. Three of the top-ranking sites also achieved maximum scores in the initial location-based analysis. This confirms that safety factors linked to planned SMRs are essential in site selection. The analysis also shows that large coal-fired power plant sites are well-suited for the C2N transition. These sites already have adequate water resources, transmission capacity, and construction space to support large nuclear reactors. However, in most Polish power plants, the existing technical conditions do not guarantee the possibility of using large-scale reactors in C2N investments. SMRs may be a good alternative for these locations. So, on a global scale, SMRs can significantly increase the implementation potential of the C2N pathway.

7. Other Possible SMR Applications

There are different types of boilers or steam generators [

61]. The nuclear part of NPP is just a means of generating large amounts of heat. This heat is transferred to water to generate superheated steam, which drives a turbine to generate electricity.

An important feature that needs to be considered is the coupling of the SMR with heat utilization systems. SMRs are typically designed to allow flexible connection to heat utilization systems instead of or in addition to electricity generation, to a greater extent than traditional large nuclear power plants. The heat utilization system may be located outside the nuclear power plant site itself, which is necessary to assess the risks and transient conditions that may be caused by the heat utilization system and will affect the operation of the reactor. Therefore, the formulation of requirements for the cooperation of the reactor with coupled systems is particularly important.

Gen IV reactors promise innovative fuels, moderators, and cooling methods that enable them to operate at much higher temperatures without the need for significantly pressurized containment vessels. This would greatly improve safety and enable new industrial applications beyond low-emission power generation, such as powering district heating and enabling the production of green steel and ammonia [

44]. The only aspect yet to be realized is the commercial-scale deployment which is still in progress.

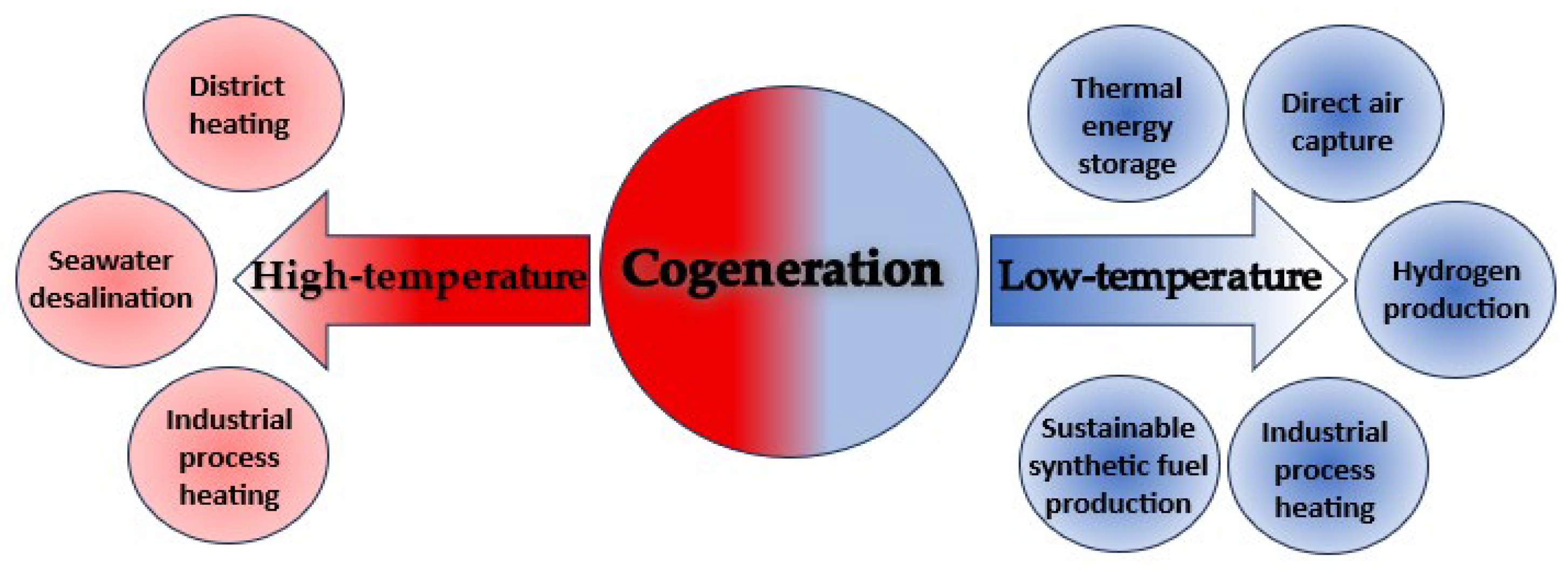

Possible cogeneration applications for III and IV Generation SMRs are listed in a report. Low Temperature—“waste heat”—is extracted from the turbine’s back end at approximately 200 °C [

62]. High-temperature exceeding 500 °C is extracted directly from the reactor or from the secondary loop before the turbine. Examples of cogeneration applications are shown in

Figure 11.

The most commonly discussed application of low-temperature steam (over 300 °C) by SMR developers pertains to district heating. This entails delivering steam at over 200 °C from the reactor or utilizing waste heat from the turbine to serve both industrial and residential users. High-temperature process heat applications, which typically operate at around 500 °C, require the SMR to be located near the industrial users to minimize heat loss. Key industries that can benefit from high-temperature process heat generated by advanced SMRs include the following:

Steel and iron mills and specialty foundries.

Non-ferrous metal production, including copper, aluminum, lead, nickel, tin, and zinc.

Oil production and refining.

Cement kilns.

Glass manufacturing.

Hydrogen emerges as a pivotal fuel for achieving a decarbonized future, with applications in fuel cells, hybrid vehicles, and various industrial processes. Currently, hydrogen production primarily relies on steam methane reforming, which utilizes fossil fuels and results in significant CO

2 emissions. An alternative method is water electrolysis, which can be powered by electricity generated from both conventional LWRs and advanced nuclear reactors. Additional applications of process heat from SMRs include the production of hydrogen for the synthesis of ammonia, lubricants, and synthetic fuels [

64].

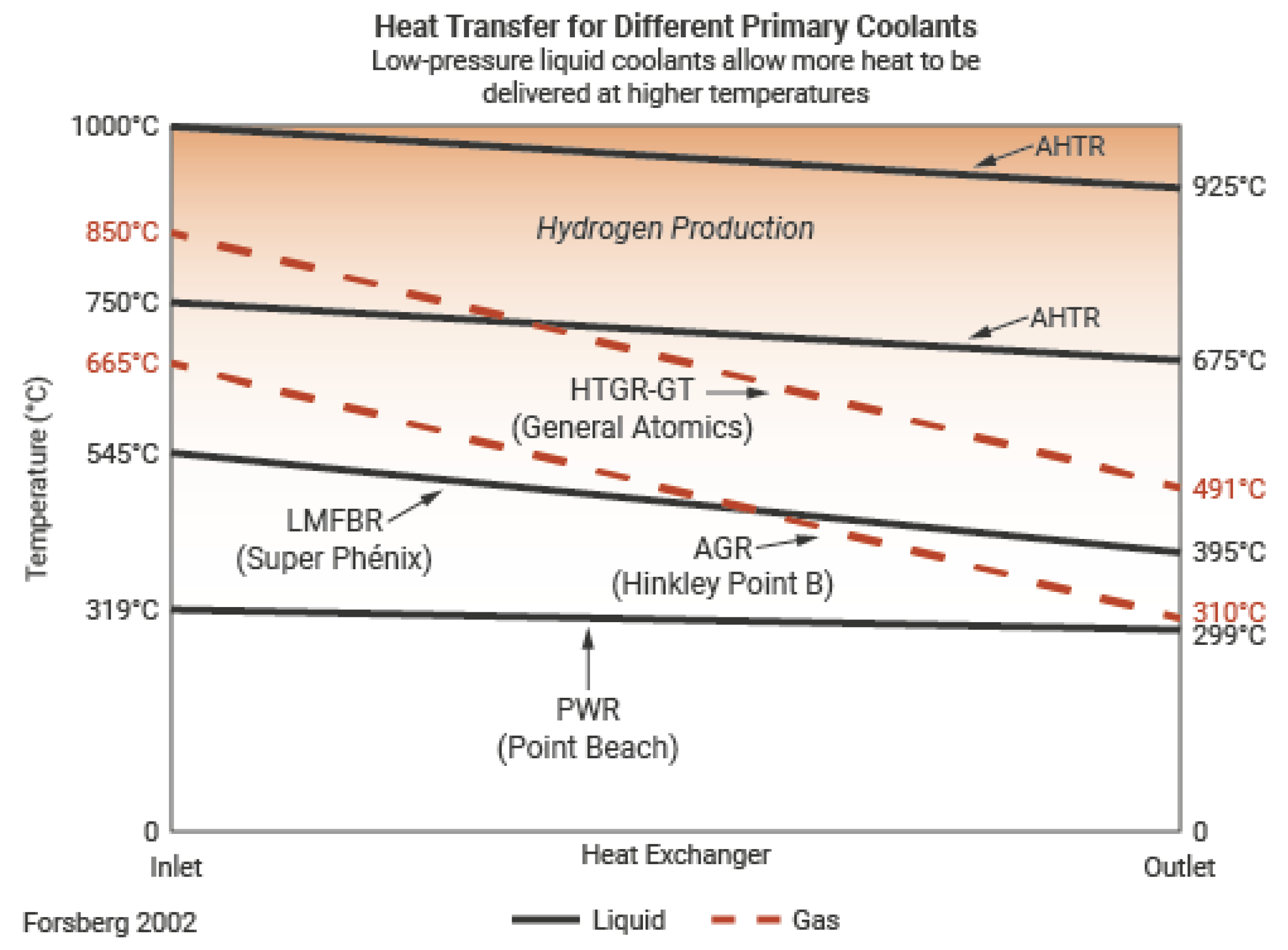

Advanced SMRs that operate at high temperatures exceeding 600 °C can produce hydrogen more efficiently than traditional electrolysis using 35% less electricity. However, this high temperature poses challenges concerning materials employed in the components designed to transfer heat through a secondary loop, such as gas, molten salt, or steam. These challenges must be addressed to optimize hydrogen production in this way.

For Generation IV SMRs, which operate at higher temperatures and can produce high-enthalpy steam, material selection is a critical factor for non-power applications. Carbon steels, commonly used in coal power plants, have a maximum operating temperature of about 538 °C. Low-alloy steels can withstand temperatures between 538 °C and 649 °C. When these limits are reached or exceeded, tube aging may accelerate due to creep. Stainless steels can operate at temperatures up to approximately 816 °C. However, if this limit is exceeded, the aging process may accelerate because of sensitization, which depletes chromium at grain boundaries and reduces material durability. According to the Massachusetts Institute of Technology (MIT), more than 15 SMR designers in North America and Europe are developing systems ranging from 4 MWe to nearly 350 MWe, and up to 500 MWe with thermal storage. These designs generate heat between 300 °C and 750 °C. The SMRs are intended for various industrial uses, including district heating, fossil fuel replacement for grid power, and cogeneration applications requiring high heat output [

65].

The MIT-originated thesis explores how to identify which SMR designers and technologies are most likely to succeed across different industrial applications. It focuses on evaluating technical, economic, and operational factors that influence the suitability of each SMR design for specific use cases [

65].

8. Nuclear Non-Proliferation Aspects

The expected widespread adoption of SMRs in recent years raises valid security concerns. It is essential to implement strong safeguards to prevent the uncontrolled spread of nuclear materials and their potential use for military or criminal purposes [

66].

Article III of the NPT requires non-nuclear-weapon States parties to implement safeguards under an agreement with the IAEA. These safeguards ensure that nuclear energy intended for peaceful purposes is not diverted to the development of nuclear weapons or other explosive devices. The safeguards procedure shall apply to fissile material regardless of whether it is produced, processed, or used in a nuclear facility. The safeguards apply to all actions linked with the peaceful use of nuclear energy carried out on the territory of a given state or anywhere under its jurisdiction [

12].

Plants using modular reactors should have their own social and administrative infrastructure. Additionally, they must have nuclear safety, physical protection, and security systems adapted to local requirements. Physical protection solutions should be based on an analysis of possible scenarios of sabotage and terrorist attacks on SMRs in accordance with the applicable requirements for the design basis threat (DBT). The small physical dimensions of the fuel and its limited quantity in SMRs mean that fuel elements do not contain large amounts of nuclear material. This reduces the risk of unauthorized acquisition. Many fuel elements would be stolen to obtain a substantial portion of nuclear material. The diversity of fuel element designs—types of unmarked fuel (pellet fuel, liquid salts or metals, unusual fuel assemblies)—and their small dimensions require the development of new, more accurate safeguard verification methods. IAEA is implementing and verifying existing methods. It provides important insights into modern safeguarding technologies. These include advanced Non-Destructive Assay (NDA) techniques such as neutron counting, isotopic tracking, and gamma-ray spectroscopy, along with remote monitoring systems. Together, these tools are crucial for accurately identifying nuclear materials and ensuring the integrity of nuclear safeguards

Additionally, the study highlights the complexities involved in the nuclear fuel cycle, clarifying various stages from uranium mining to waste disposal [

67]. In addition, the proposed solutions include a change in the enrichment of uranium in reactor fuel. Until now, most commercial nuclear reactors have used low-enriched fuel, enriched between 3% and 5% (low enrichment uranium). There are plans for SMRs to use fuel enriched to 20%. This is the maximum enrichment level permitted in commercial civil applications. This is partly due to the need to extend the fuel replacement time in the core, which is difficult to do. The modular design of these reactors enables the construction of nuclear power plants composed of multiple units combined to achieve the desired power output. However, this approach introduces greater complexity compared to single-unit plants. Each module is an integrated block, e.g., a light water nuclear reactor connected to its own set of equipment, including a steam turbine and generator. The spent fuel pool is shared by all modules. Fuel replacement in each module takes place in sequence according to the planned fuel burn-up time. During the replacement operation, the reactor is physically moved from its operating field to a station where fuel reloading takes place. Spent fuel is transported to the pool. With a larger number of reactors, the replacement process approaches continuous operation, as one or more reactors are always open. This requires the constant (24 h) presence of an IAEA inspector. At the same time, moving the reactor to another hall involves the flow of nuclear material within the facility, which also requires control. Another problem for safety system designers is the opacity of the coolant. With coolants other than water, such as liquid metal, it is difficult to identify fuel elements, requiring specialized certified equipment [

68].

Global plans, strongly supported by national administrations and resulting from the political situation in many regions of the world, indicate that the installed capacity in plants built by 2035 could reach 85 GW. This would result in around 1000 individual units, creating major challenges in verifying compliance with NPT requirements. The large number of units would demand extensive inspection resources and complicate the verification of fissile material quantities [

69]. For example, in Poland, only for one company, the Ministry of Climate and Environment (Wilmington, NC, USA)issued six decisions-in-principle for the construction of a total of 24 reactors using BWRX-300 technology from the American company GE-Hitachi. The decisions were requested by the Orlen Synthos Green Energy [

70].

9. Spent Fuel and Radioactive Waste

Effective management of nuclear waste is crucial for the sustainability of the nuclear energy industry. Disposal is a well-recognized issue that is already being addressed through the development of deep geological repositories (DGRs). It provides secure long-term storage solutions for nuclear waste However, such possibilities are limited to a few countries like Sweden and Finland, which are frontrunners in the development of this technology. By 2050, when most economies are expected to be decarbonized, Finland remains the only country projected to have nuclear waste disposal facility in operation. Moreover, it is difficult to predict which SMRs’ fuel can be accepted. Current interim storage practices were not originally designed to accommodate long-term needs and growing inventories and risks [

71]. Large-scale deployment of new NPPs would greatly intensify the existing challenges. Therefore, waste disposal may cause a bottleneck for the deployment of SMRs and their supply chains. The proposed SMR concepts advance much faster than current fuel cycle and radioactive waste management capabilities. In many cases, these designs introduce entirely new nuclear technologies that existing systems are not yet prepared to support [

72]. This is highlighted in the chapter on this issue in the previously cited NEA report. Managing spent fuel will be challenging, both in terms of cooling it in water storage tanks and temporarily storing it dry at the sites of SMRs, which are intended to replace old coal-fired power plants. Many of these SMRs are planned near towns (for district heating) and industrial facilities (for process heat), adding to the complexity of waste management. At the time the report was published, there was not enough reliable public information to assess progress in SMR waste management planning and end-of-life cycle management. Therefore, this edition of the NEA SMR Dashboard does not address preparations for used fuel from innovative SMRs. However, future editions are expected to develop a methodology and criteria for gauging progress in this area once significant advancements have been made and more information becomes available for authoritative evaluations [

27]. The authors believe that achieving this will be a challenging task and may even lower the TRL stage. Developing industry-ready designs requires comprehensive environmental impact assessments and detailed planning for materials, fuel availability, and safe waste handling. While fuel recycling could be a potential solution, the nuclear industry is currently not prepared to meet these requirements [

73,

74].

10. General—Fissile Elements Resources for the Future of Nuclear Energy

As of 1 January 2023, total identified recoverable uranium resources at costs below USD 260/kgU amounted to just over 7.9 million tU, consisting of 60% reasonably assured resources and 40% inferred resources. At costs below USD 130/kgU, total recoverable resources were 5.9 million tU. Only four countries reported resources in the under-USD 40/kgU-category, with Kazakhstan accounting for 75% of the global total. In 2022, uranium was produced in 17 countries, totaling 49,490 tU, with Kazakhstan remaining the largest producer at 43% of global production, despite operating at reduced levels. Globally, 438 commercial nuclear reactors were operational, providing a net generating capacity of 394 GWe and requiring approximately 59,000 tU annually. Considering policy changes in several countries and advancements in nuclear programs, global nuclear capacity is projected to reach 574 GWe under a low-demand scenario and 900 GWe under a high-demand scenario by 2050. This represents increases of approximately 45% and 130%, respectively, compared to the 2022 capacity. Consequently, the annual uranium requirements for nuclear reactors worldwide are expected to rise to between approximately 90,000 tU/y and 142,000 tU/y by 2050. The available uranium resource base is adequate to satisfy even the high-demand projections for 2050; however, realizing this potential will necessitate timely investments to transition resources into active production. Fulfilling high-demand requirements by 2050 is projected to consume about 35% of the currently identified recoverable resource with an associated cost projected to be below USD 260/kgU (USD 100/lb U

3O

8). Furthermore, to sustain both high-growth and low-growth demand scenarios during the latter half of this century, it will be necessary to invest in uranium exploration and the establishment of new production centers to replenish depleting reserves. The fulfillment of the high-demand growth requirements by 2050 would utilize roughly 50% of the identified recoverable resource base at costs under USD 130/kgU and about 35% at costs beneath USD 260/kgU. Under high-demand scenarios, a deficiency of production is to be forecasted around 2027. While secondary sources will continue to contribute to uranium supply, it is essential to bring new facilities online from planned and prospective production centers and to sustain exploration efforts to identify additional resources [

75].

Examining the current and projected nuclear power capacity globally reveals a dynamic uranium market, with potential for growth in selected countries, indicating robust future demand. Kazakhstan, Canada, and Russia stand out as the primary influencers in the geopolitical landscape of uranium supply and demand leading up to 2050. Western countries are taking steps to decrease their dependence on Russian uranium, which is altering global trade dynamics. By 2050, the strategic choices made by countries rich in uranium, in light of political and energy security issues, will shape new international alliances and trading patterns. The main emphasis is on how these established and developing alliances navigate their geopolitical interactions while utilizing uranium to satisfy the rising need for nuclear energy [

76]. Canada has proposed a closer critical minerals partnership with the United States by establishing the “Am-Can Critical Mineral Security Alliance.” The initiative aims to invest in and expand critical mineral supply chains, including uranium, by accelerating federal and provincial regulatory approvals. It also introduces a “one-project-one-process” permitting approach for all resource development in Canada. The initiative would support a “Fortress North America” strategy for uranium supply [

77]. Euratom Supply Agency has developed an action plan regarding the security of supply for small and advanced modular reactors. It specifically looked at the work undertaken by the European Industrial Alliance on Small Modular Reactors and agreed on the future ESA and Committee activities on this matter [

78].

11. General—Licensing and Public Acceptance

The NRC US places significant emphasis on evaluating the proposed sites for building SMRs. When selecting a location, the density of population, radiological safety, NPP’s engineering and blueprint, economics, legal requirements, environmental impact, and other factors must be considered. The construction and operation of nuclear power plants can affect the human environment, as well as social, cultural, and economic conditions, including issues of environmental justice. These impacts are generally similar to those of other large industrial facilities. However, nuclear power plants are unique because they require a much higher degree of consideration for these human and social factors. The impact of a nuclear power plant is similar to that of any large industrial facility. However, nuclear plants are unique because the environment itself can significantly affect their safety. Safety requirements are the primary factors in determining site suitability, but environmental impacts must also be carefully evaluated [

79].

An important feature of SMRs is their low power and relatively small fission product resources, and thus small radiation source terms. Typically, the power is limited to 300 MW per module. Reducing reactor power enhances the use of passive safety features. It also lowers the potential radiation source term, thereby decreasing the risk during emergency conditions. The SMR safety system must take into account the diversity of reactor designs (e.g., core design, fuel type), the handling of spent fuel, radioactive waste, and transport. The development of the safety system begins at an early stage of reactor design. The reactor and the entire set of equipment will be manufactured in factory conditions and then transported to the prepared reactor site. The proposed solutions aim to increase the density of control and measurement automation components inside the reactor casing [

21].

According to the IAEA guidelines, the vast majority of safety requirements previously applied to large power plants remain in force and unchanged. However, changes are desired in 8 of the existing safety requirements for water-cooled SMRs and in 30 requirements for gas-cooled SMRs. The remaining safety requirements established for large reactors apply to all types of reactors [