Tracking the Fuel Trajectory from Each Injector for Fuel–Air Mixing in Supersonic Flows

Abstract

1. Introduction

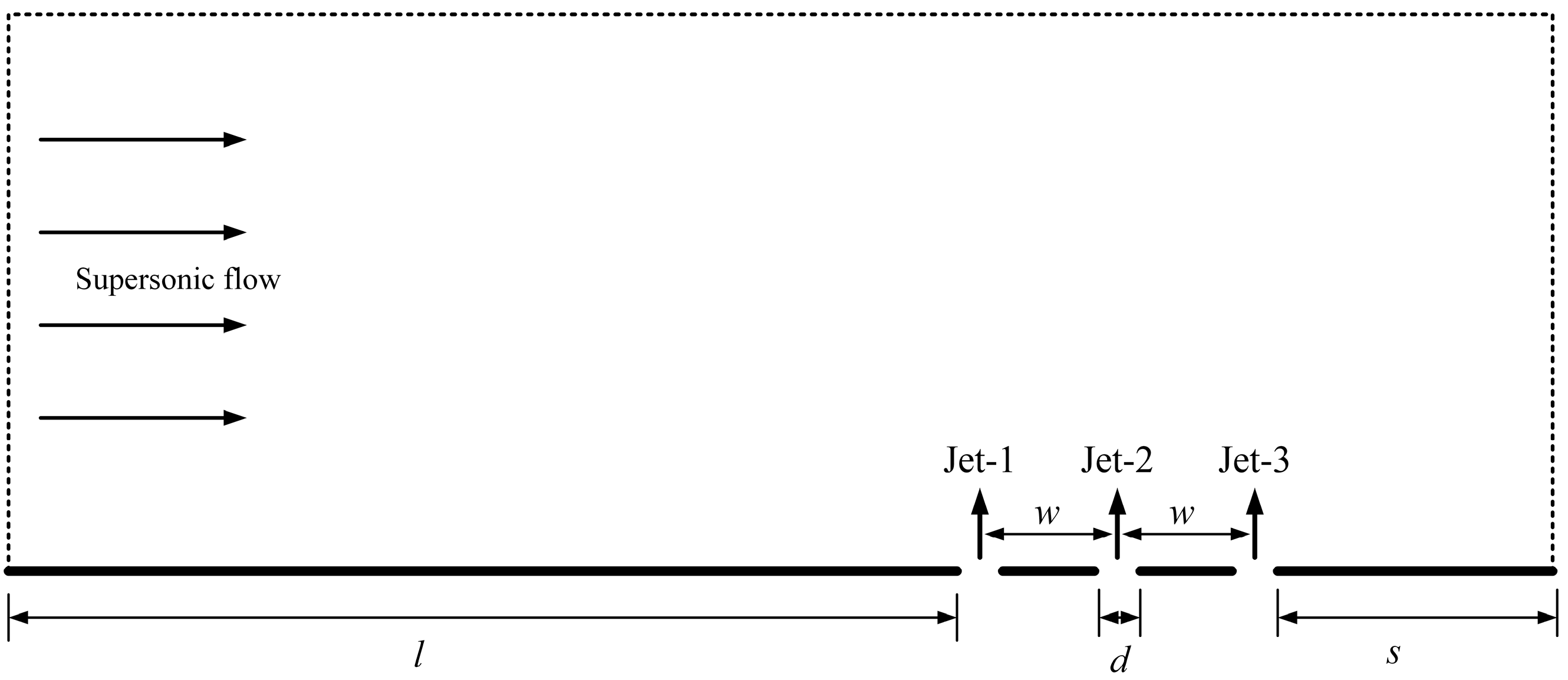

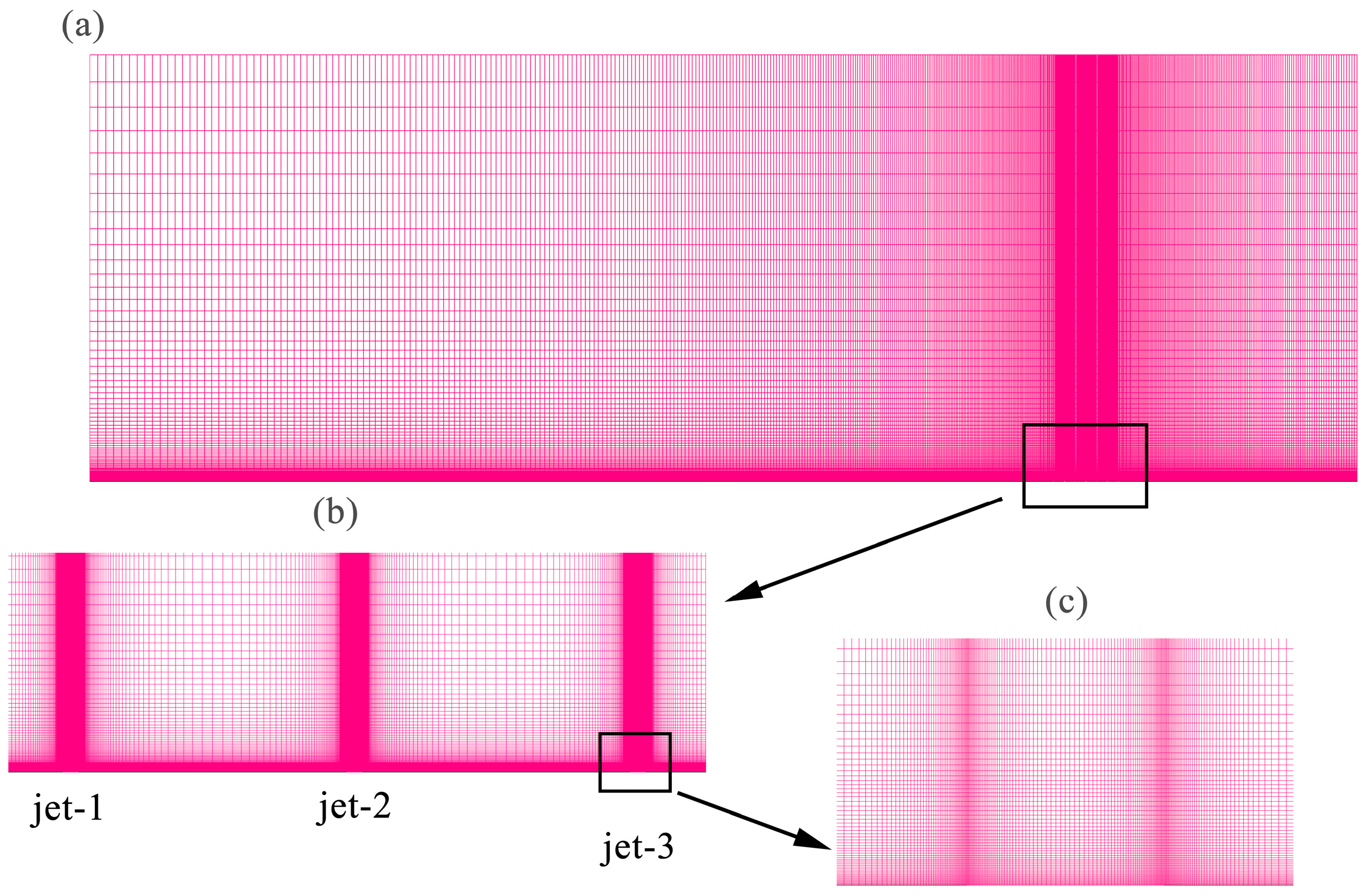

2. Numerical Methods

2.1. Governing Equations

2.2. Tracking the Fuel Trajectory

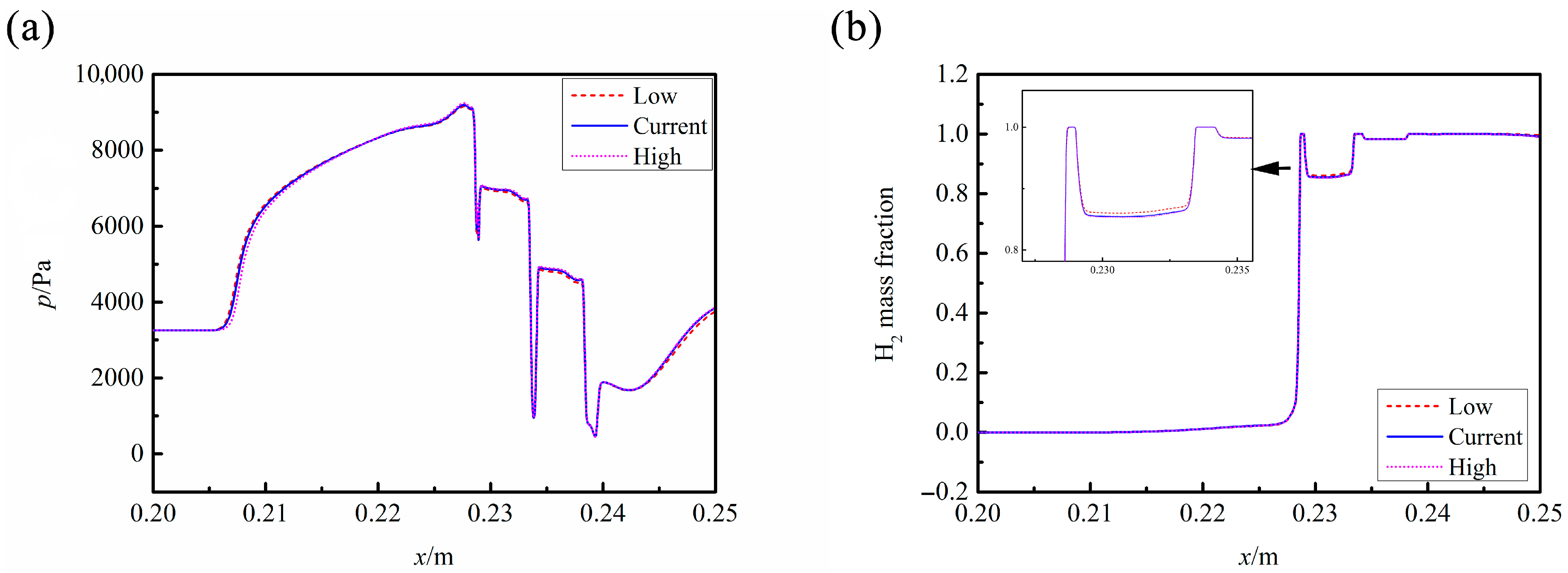

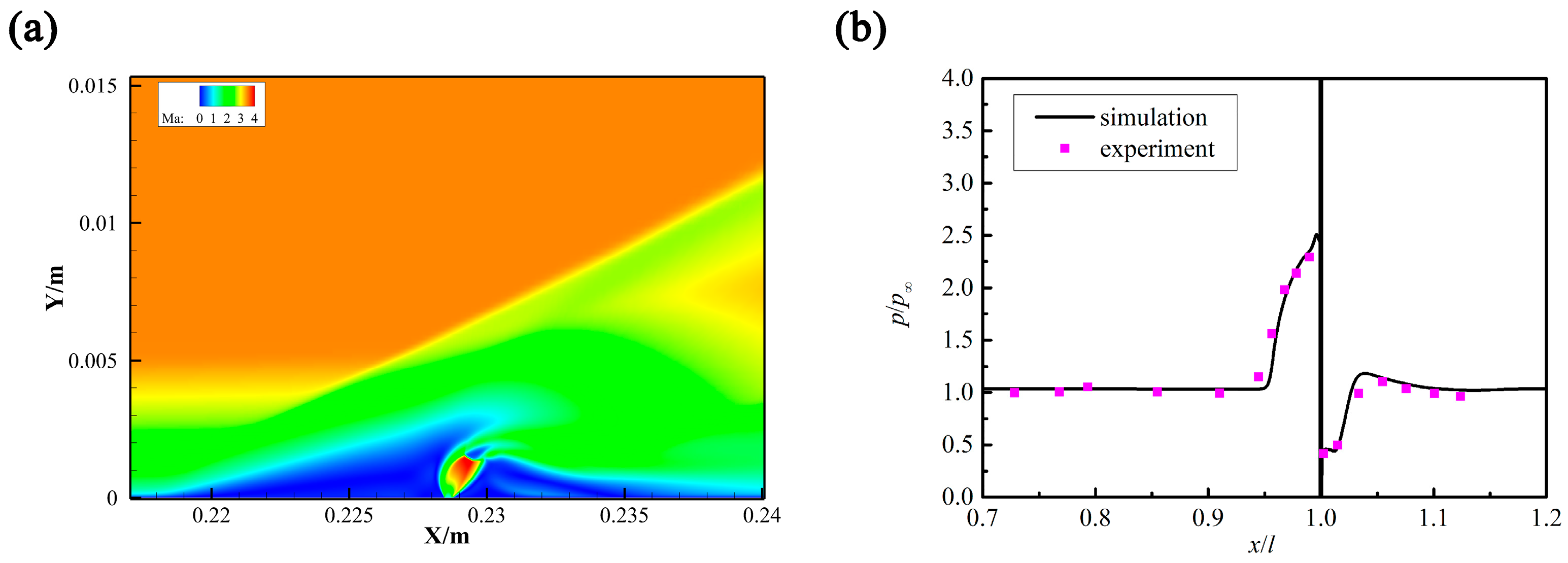

2.3. Validation of the Numerical Methods

3. Results and Discussions

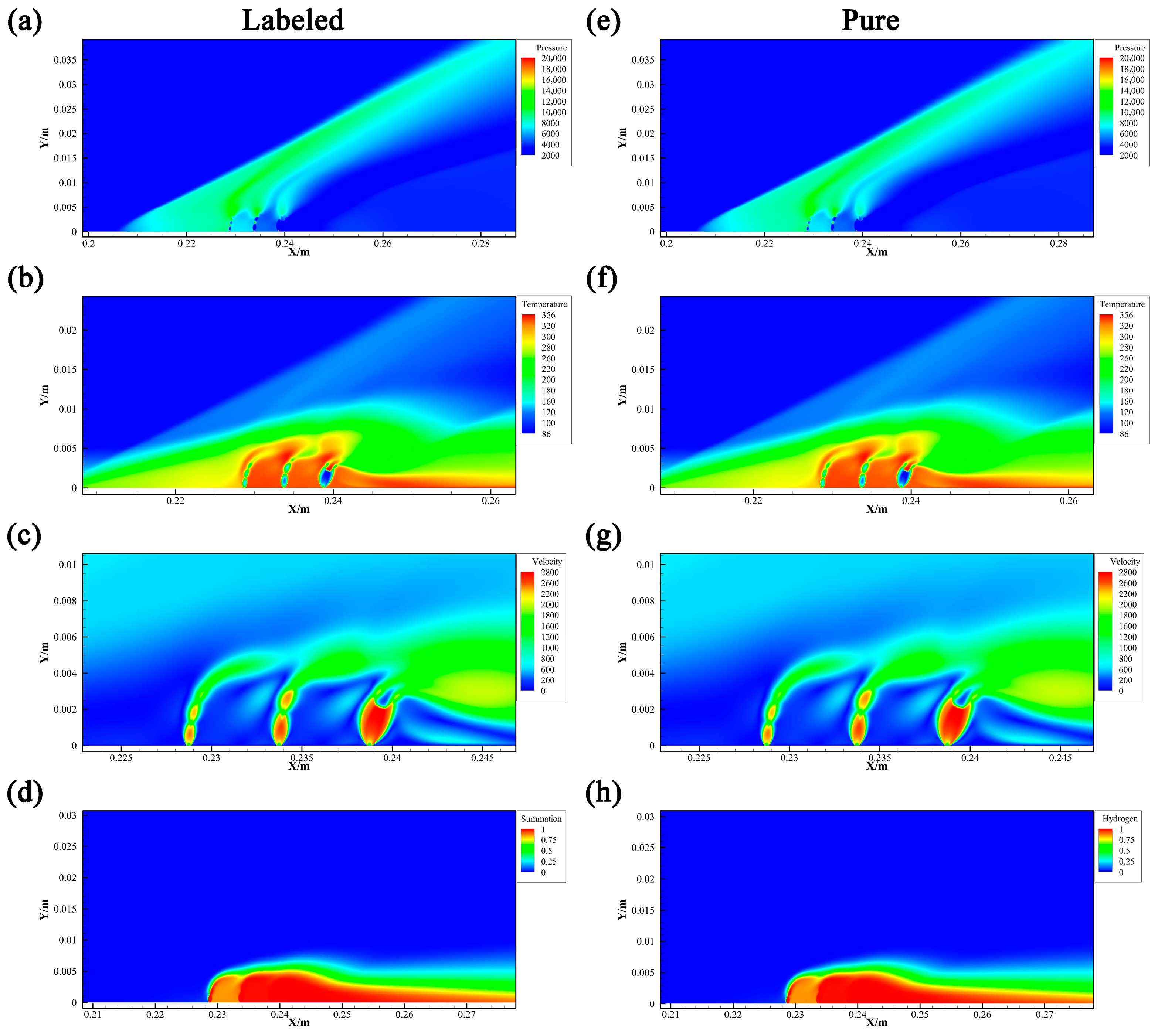

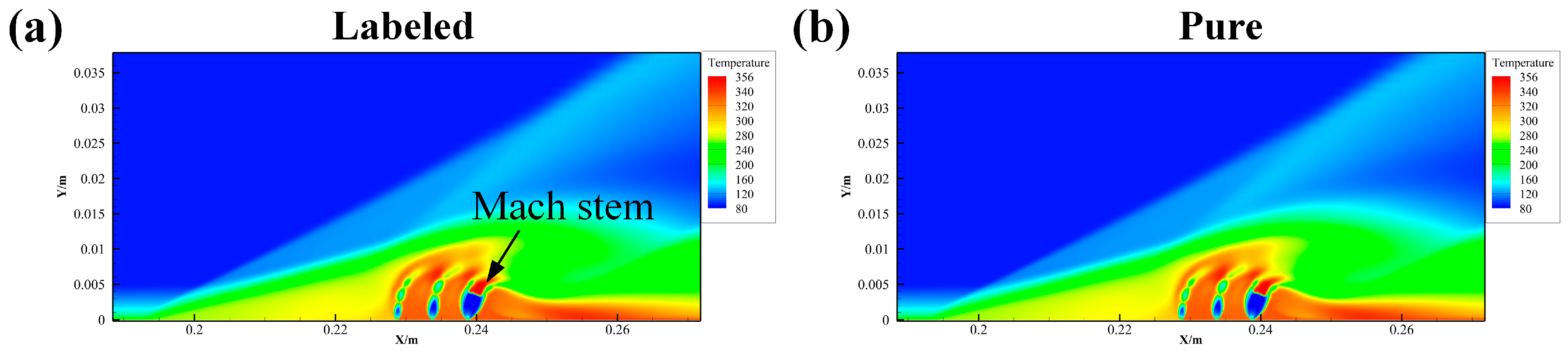

3.1. Flow Fields of the Labeled Jet and the Pure Jet

3.2. Effects of the Jet-to-Crossflow Pressure Ratio on the Flow Fields

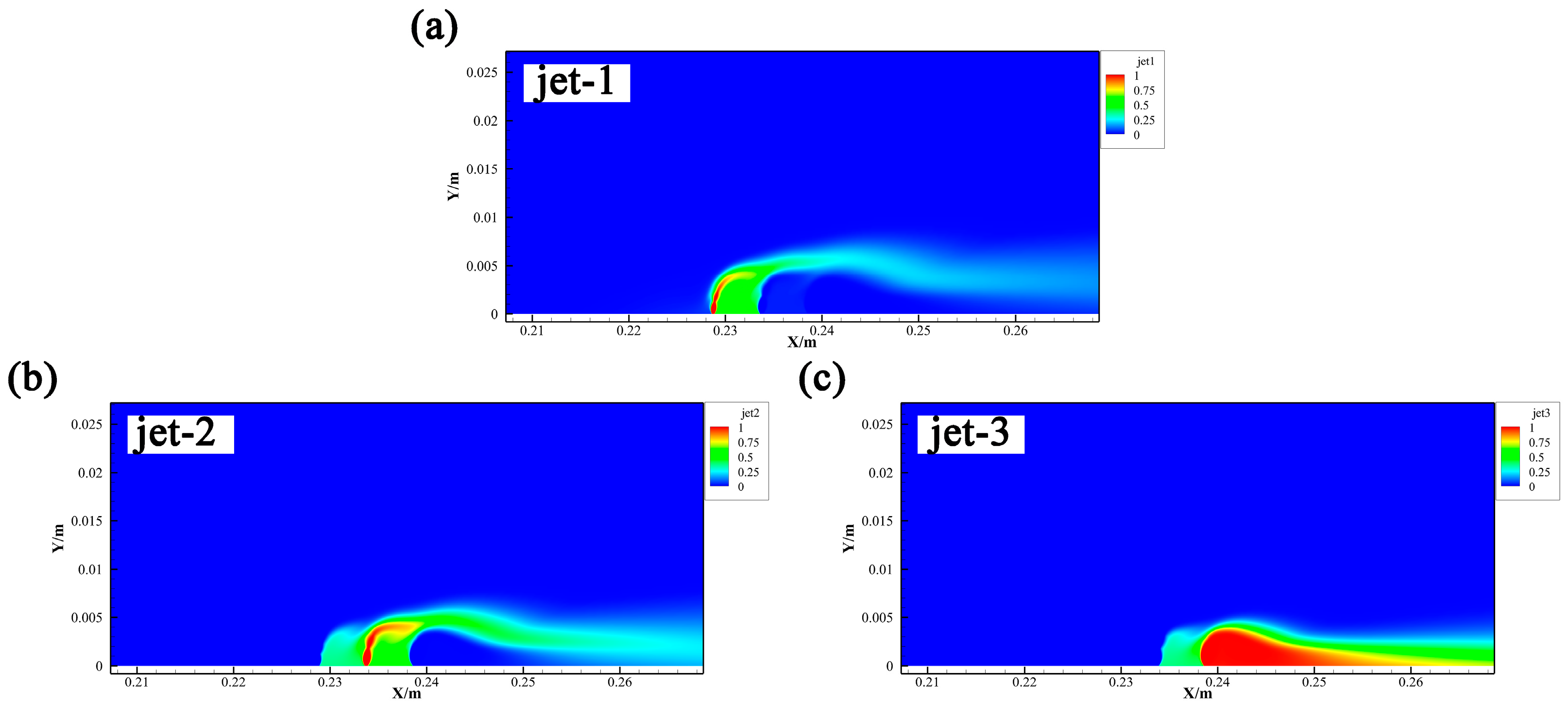

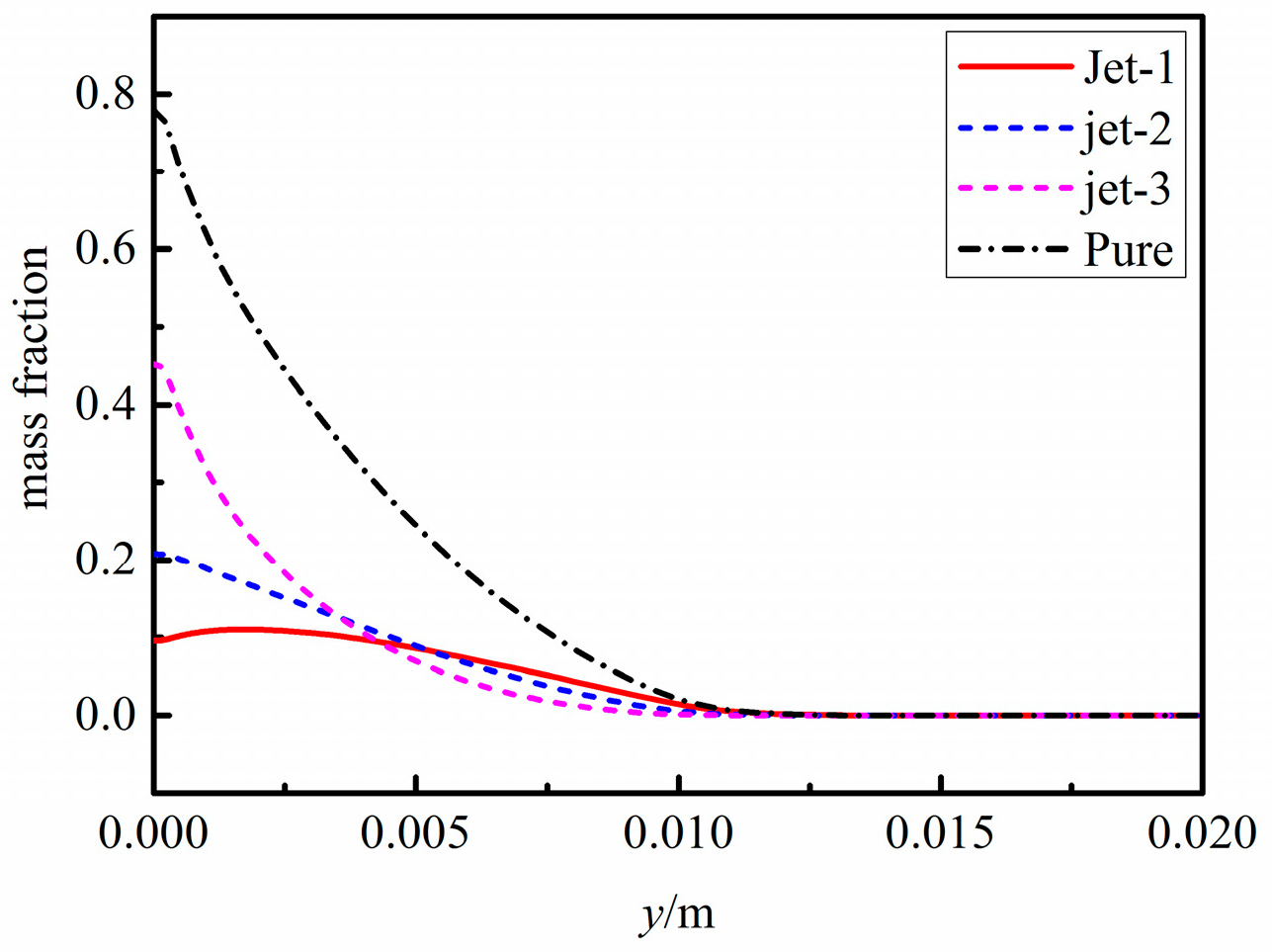

3.3. Hydrogen Distribution of Each Jet

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Curran, E.T. Scramjet Engines: The First Forty Years. J. Propuls. Power 2001, 17, 1138–1148. [Google Scholar] [CrossRef]

- Chang, J.; Zhang, J.; Bao, W.; Yu, D. Research progress on strut-equipped supersonic combustors for scramjet application. Prog. Aerosp. Sci. 2018, 103, 1–30. [Google Scholar] [CrossRef]

- Hu, J. Ignition and Flame Stabilization in a Flush Wall Supersonic Combustor. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2013. (In Chinese). [Google Scholar]

- Sunami, T.; Scheel, F. Analysis of mixing enhancement using streamwise vortices in a supersonic combustor by application of laser diagnostics. In Proceedings of the AIAA/AAAF 11th International Space Planes and Hypersonic Systems and Technologies Conference, Orleans, France, 29 September–4 October 2002; p. 5203. [Google Scholar]

- Tan, Y.; Ni, Y.; Xu, W.; Xie, Y.; Li, L.; Tan, D. Key technologies and development trends of the soft abrasive flow finishing method. J. Zhejiang Univ.-Sci. A (Appl. Phys. Eng.) 2023, 24, 1043–1064. [Google Scholar] [CrossRef]

- Ren, Z.; Wang, B.; Xiang, G.; Zhao, D.; Zheng, L. Supersonic spray combustion subject to scramjets: Progress and challenges. Prog. Aerosp. Sci. 2019, 105, 40–59. [Google Scholar] [CrossRef]

- Huang, W.; Jin, L.; Yan, L.; Tan, J. Influence of jet-to-crossflow pressure ratio on nonreacting and reacting processes in a scramjet combustor with backward-facing steps. Int. J. Hydrogen Energy 2014, 39, 21242–21250. [Google Scholar] [CrossRef]

- Li, L.; Huang, W.; Fang, M.; Shi, Y.; Li, Z.; Peng, A. Investigation on three mixing enhancement strategies in transverse gaseous injection flow fields: A numerical study. Int. J. Heat Mass Transf. 2019, 132, 484–497. [Google Scholar] [CrossRef]

- Li, L.; Huang, W.; Yan, L.; Li, S.; Liao, L. Mixing improvement induced by the combination of a micro-ramp with an air porthole in the transverse gaseous injection flow field. Int. J. Heat Mass Transf. 2018, 124, 109–123. [Google Scholar] [CrossRef]

- Ma, L.; Yang, P.; Xia, Z.; Duan, Y.; Feng, Y.; Zhao, K.; Xu, L. Experimental study on particle dispersion between particle-laden jet and supersonic crossflow in cavity-structured channel. Chin. J. Aeronaut. 2025, 38, 103320. [Google Scholar] [CrossRef]

- Li, J.; Wang, K.; Jiao, G.; Liao, Z.; Li, J. Investigation on low total temperature combustion characteristics of kerosene-fueled supersonic combustor. Chin. J. Aeronaut. 2022, 35, 192–208. [Google Scholar] [CrossRef]

- Kim, K.M.; Baek, S.W.; Han, C.Y. Numerical study on supersonic combustion with cavity-based fuel injection. Int. J. Heat Mass Transf. 2004, 47, 271–286. [Google Scholar] [CrossRef]

- Moradi, R.; Mahyari, A.; Gerdroodbary, M.B.; Abdollahi, A.; Amini, Y. Shape effect of cavity flameholder on mixing zone of hydrogen jet at supersonic flow. Int. J. Hydrogen Energy 2018, 43, 16364–16372. [Google Scholar] [CrossRef]

- Cai, Z.; Sun, M.; Wang, Z.; Bai, X. Effect of cavity geometry on fuel transport and mixing processes in a scramjet combustor. Aerosp. Sci. Technol. 2018, 80, 309–314. [Google Scholar] [CrossRef]

- Hassanvand, A.; Gerdroodbary, M.B.; Fallah, K. Effect of dual micro fuel jets on mixing performance of hydrogen in cavity flameholder at supersonic flow. Int. J. Hydrogen Energy 2018, 43, 9829–9837. [Google Scholar] [CrossRef]

- Kodera, M.; Sunami, T.; Scheel, F. Numerical study on the supersonic mixing enhancement using streamwise vortices. In Proceedings of the AIAA/AAAF 11th International Space Planes and Hypersonic Systems and Technologies Conference, Orleans, France, 29 September–4 October 2002; p. 5117. [Google Scholar]

- Sunami, T.; Murakami, A.; Kudo, K.; Kodera, M.; Nishioka, M. Mixing and combustion control strategies for effecient scramjet operation in wide range of flight Mach numbers. In Proceedings of the AIAA/AAAF 11th International Space Planes and Hypersonic Systems and Technologies Conference, Orleans, France, 29 September–4 October 2002; p. 5116. [Google Scholar]

- Choubey, G.; Pandey, K.M. Investigation on the effects of operating variables on the performance of two-strut scramjet combustor. Int. J. Hydrogen Energy 2016, 41, 20753–20770. [Google Scholar] [CrossRef]

- Choubey, G.; Pandey, K.M. Effect of parametric variation of strut layout and position on the performance of a typical two-strut based scramjet combustor. Int. J. Hydrogen Energy 2017, 42, 10485–10500. [Google Scholar] [CrossRef]

- Choubey, G.; Pandey, K.M. Effect of different strut + wall injection techniques on the performance of two-strut scramjet combustor. Int. J. Hydrogen Energy 2017, 42, 13259–13275. [Google Scholar] [CrossRef]

- Génin, F.; Menon, S. Simulation of Turbulent Mixing Behind a Strut Injector in Supersonic Flow. AIAA J. 2010, 48, 526–539. [Google Scholar] [CrossRef]

- Gerlinger, P.; Bruggemann, D. Numerical Investigation of Hydrogen Strut Injections into Supersonic Airflows. J. Propuls. Power 2000, 16, 22–28. [Google Scholar] [CrossRef]

- Gerlinger, P.; Stoll, P.; Kindler, M.; Schneider, F.; Aigner, M. Numerical investigation of mixing and combustion enhancement in supersonic combustors by strut induced streamwise vorticity. Aerosp. Sci. Technol. 2008, 12, 159–168. [Google Scholar] [CrossRef]

- Li, J.; Song, W.; Wand, Y. Experimental study on combustion characteristics of supersonic combustor based on alternating-wedge strut. Chin. J. Aeronaut. 2024, 37, 214–227. [Google Scholar] [CrossRef]

- Liu, M.; Sun, M.; Yang, D.; Zhao, G.; Tang, T.; An, B.; Wang, H. Mixing and combustion characteristics in a scramjet combustor with different distances between cavity and backward-facing step. Chin. J. Aeronaut. 2023, 36, 400–411. [Google Scholar] [CrossRef]

- Jeong, E.; O’Byrne, S.; Jeung, I.-S.; Houwing, A.F.P. The Effect of Fuel Injection Location on Supersonic Hydrogen Combustion in a Cavity-Based Model Scramjet Combustor. Energies 2020, 13, 193. [Google Scholar] [CrossRef]

- Tan, J.; Zhang, D.; Lv, L. A review on enhanced mixing methods in supersonic mixing layer flows. Acta Astronaut. 2018, 152, 310–324. [Google Scholar] [CrossRef]

- Liou, M. The evolution of AUSM schemes. Def. Sci. J. 2010, 60, 606–613. [Google Scholar] [CrossRef]

- Liou, M. A sequel to AUSM: AUSM+. J. Comput. Phys. 1996, 129, 364–382. [Google Scholar] [CrossRef]

- Spaid, F.W. Transverse Slots with Supersonic External Flows. AIAA J. 1968, 6, 205–212. [Google Scholar] [CrossRef]

- Sriram, A.T.; Mathew, J. Improved prediction of plane transverse jets in supersonic crossflows. AIAA J. 2006, 44, 405–407. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qin, Q.; Yang, Y.; Liu, Y.; Yuan, M.; Li, J. Tracking the Fuel Trajectory from Each Injector for Fuel–Air Mixing in Supersonic Flows. Energies 2025, 18, 4664. https://doi.org/10.3390/en18174664

Qin Q, Yang Y, Liu Y, Yuan M, Li J. Tracking the Fuel Trajectory from Each Injector for Fuel–Air Mixing in Supersonic Flows. Energies. 2025; 18(17):4664. https://doi.org/10.3390/en18174664

Chicago/Turabian StyleQin, Qiongyao, Yanhan Yang, Yidong Liu, Mingze Yuan, and Jianzhong Li. 2025. "Tracking the Fuel Trajectory from Each Injector for Fuel–Air Mixing in Supersonic Flows" Energies 18, no. 17: 4664. https://doi.org/10.3390/en18174664

APA StyleQin, Q., Yang, Y., Liu, Y., Yuan, M., & Li, J. (2025). Tracking the Fuel Trajectory from Each Injector for Fuel–Air Mixing in Supersonic Flows. Energies, 18(17), 4664. https://doi.org/10.3390/en18174664