Integrated Experimental and Numerical Investigation on CO2-Based Cyclic Solvent Injection Enhanced by Water and Nanoparticle Flooding for Heavy Oil Recovery and CO2 Sequestration

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

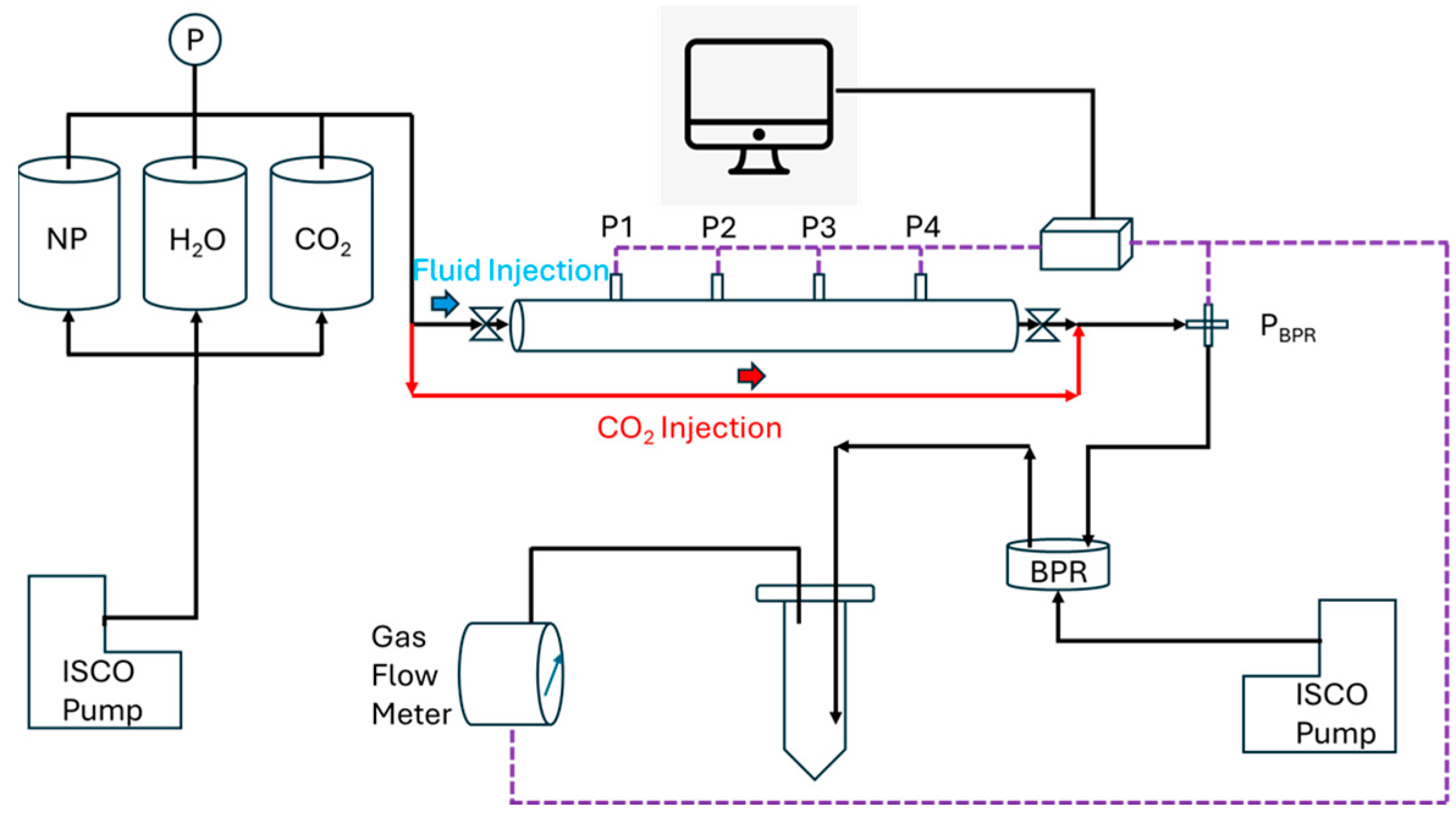

2.2. Experimental Design

2.3. Experimental Methodology

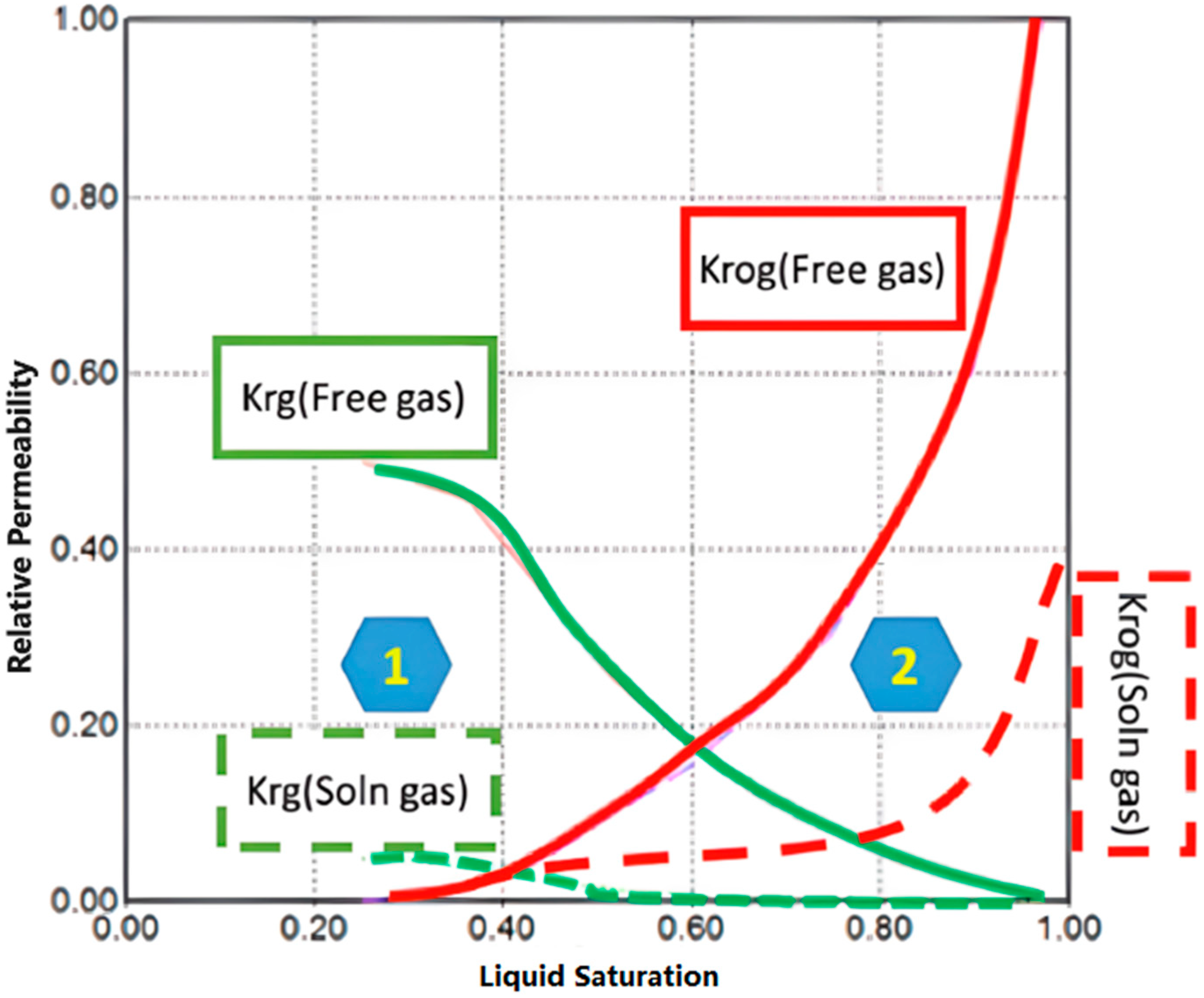

2.4. Numerical Simulation Framework

3. Results

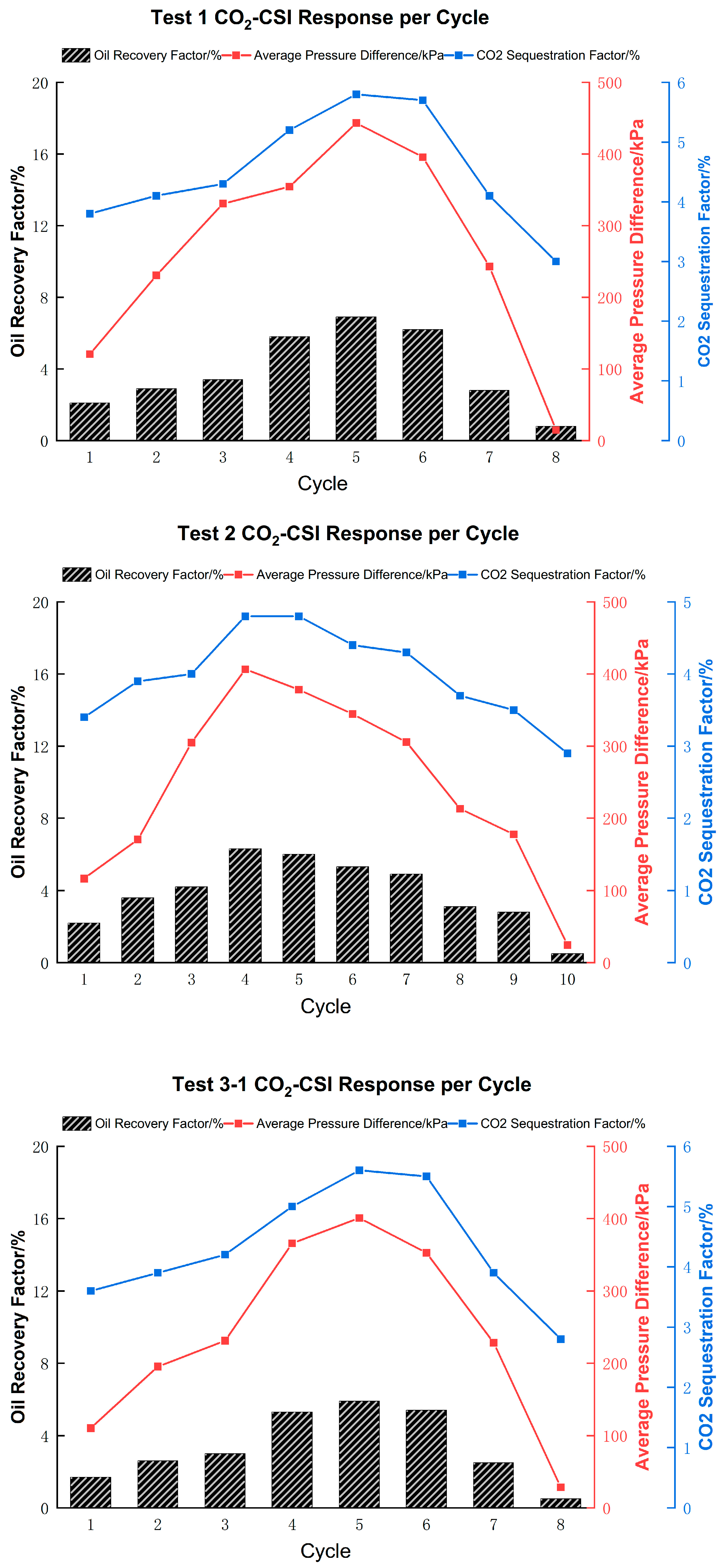

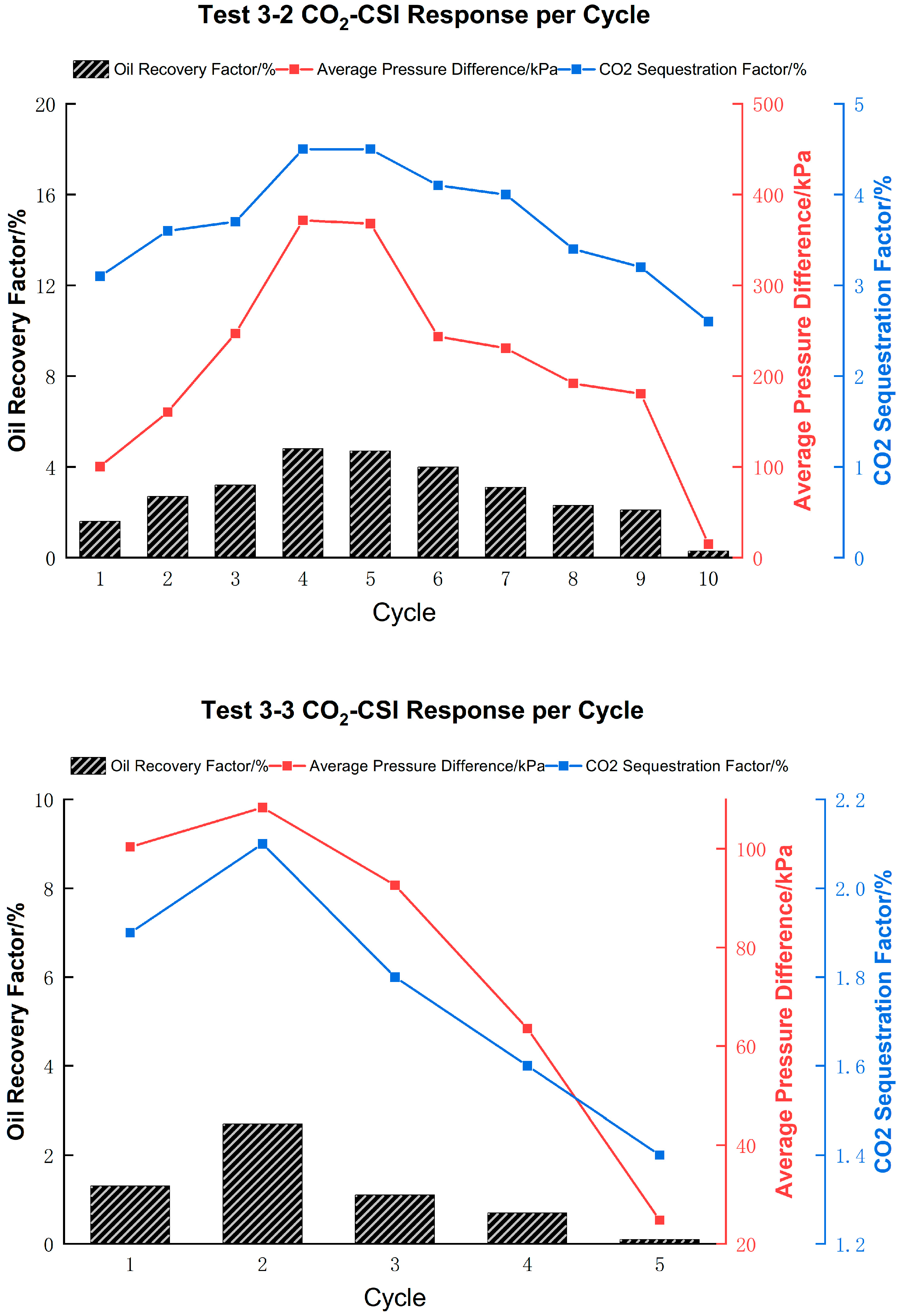

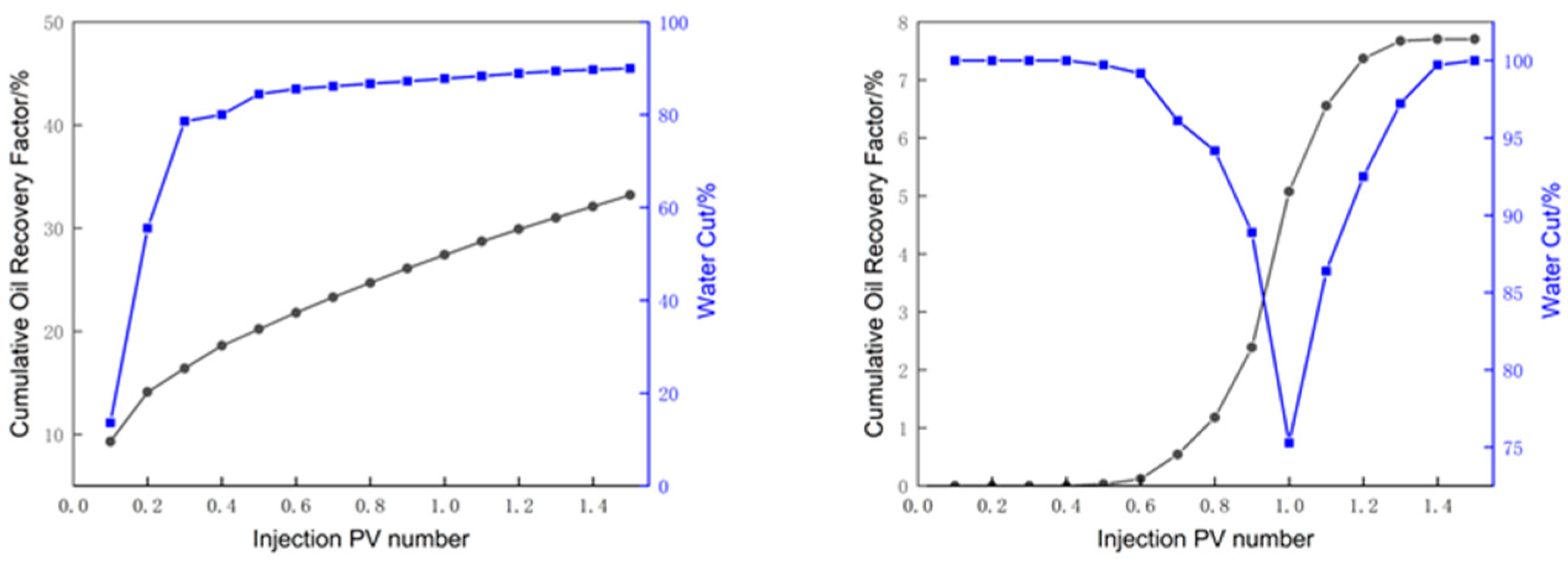

3.1. Experimental Results

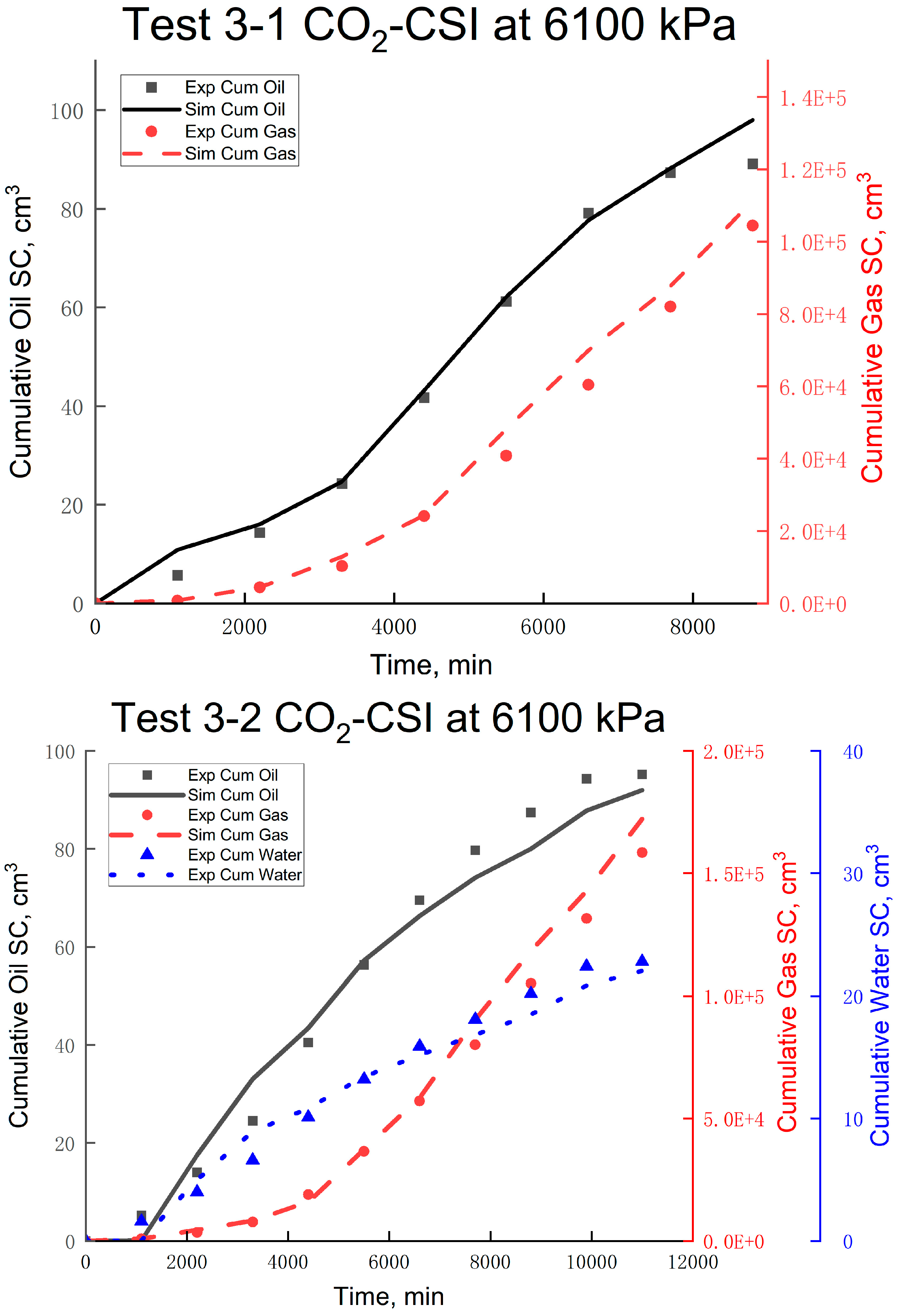

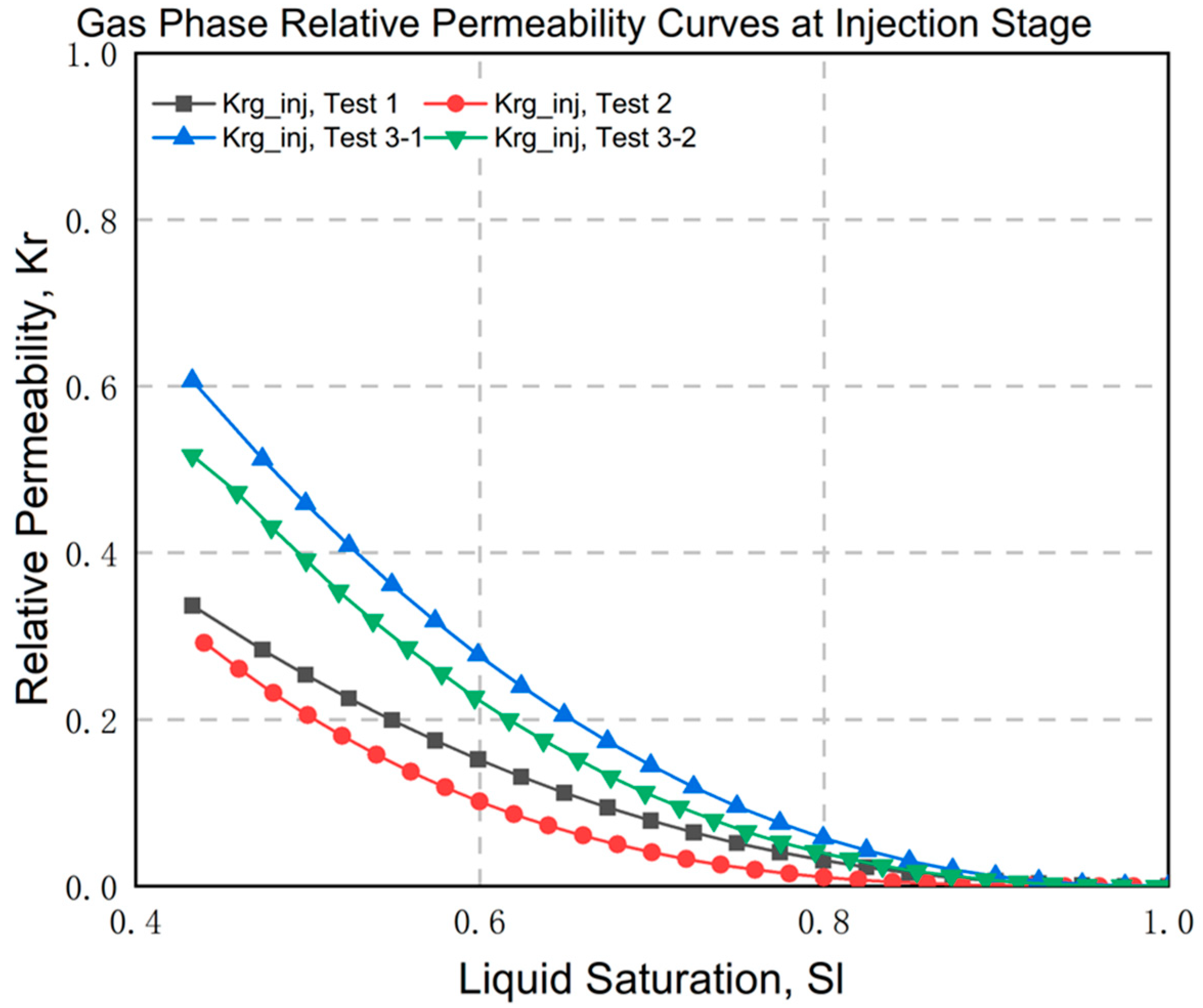

3.2. Simulation Results

4. Discussion

4.1. Waterflooding Impact on CO2-CSI Efficiency

4.2. Nanoparticle Solution Flooding Impact on CO2-CSI Efficiency

4.3. Injection Pressure Impact on CO2-CSI Efficiency

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| CSI | Cyclic solvent injection |

| EOR | Enhanced oil recovery |

| ERI | Effective recovery index |

| BPR | Back-pressure regulator |

| ORF | Oil recovery factor |

| CORF | Cumulative oil recovery factor |

| Soi/r | Initial/Residual oil saturation |

References

- Liu, Z.; Wang, H.; Blackbourn, G.; Ma, F.; He, Z.; Wen, Z.; Wu, Z. Heavy oils and oil sands: Global distribution and resource assessment. Acta Geol. Sin. Engl. Ed. 2019, 93, 199–212. [Google Scholar] [CrossRef]

- Srivastava, R.K.; Huang, S.S.; Mourits, F.M. A laboratory evaluation of suitable operating strategies for enhanced heavy oil recovery by gas injection. J. Can. Pet. Technol. 1997, 36, 33–41. [Google Scholar] [CrossRef]

- Ivory, J.; Chang, J.; Coates, R.; Forshner, K. Investigation of cyclic solvent injection process for heavy oil recovery. J. Can. Pet. Technol. 2010, 49, 22–33. [Google Scholar] [CrossRef]

- Du, Z.; Peng, X.; Zeng, F. Experimental investigation of cyclic solvent injection based on mixture solvent of carbon dioxide and propane. Fuel 2018, 225, 646–654. [Google Scholar] [CrossRef]

- Zou, W.; Yao, J.; Gu, Y. Optimum timing of CO2-cyclic solvent injection (CO2-CSI) in the heavy oil reservoirs. Geoenergy Sci. Eng. 2024, 239, 212931. [Google Scholar] [CrossRef]

- Pugh, R.J. Foaming, foam films, antifoaming and defoaming. Adv. Colloid Interface Sci. 1996, 64, 67–142. [Google Scholar] [CrossRef]

- Pugh, R.J. Experimental techniques for studying the structure of foams and froths. Adv. Colloid Interface Sci. 2005, 114, 239–251. [Google Scholar] [CrossRef] [PubMed]

- Qazvini Firouz, A.; Torabi, F. Feasibility study of solvent-based huff-n-puff method (cyclic solvent injection) to enhance heavy oil recovery. In Proceedings of the SPE Heavy Oil Conference Canada, Calgary, AB, Canada, 12–14 June 2012. Paper SPE 157853. [Google Scholar]

- Adams, D.M. Experiences with waterflooding Lloydminster heavy-oil reservoirs. J. Pet. Technol. 1982, 34, 1643–1650. [Google Scholar] [CrossRef]

- Smith, G.E. Waterflooding heavy oils. In Proceedings of the SPE Rocky Mountain Regional Meeting, Casper, WY, USA, 18–21 May 1992. SPE Paper 24367. [Google Scholar]

- Rawat, A.; Khanikar, B.; Samanta, A.K.; Nguessan, P.; Mehta, B.; Sircar, A.; Desai, B.; Bera, A.; Bist, N. Experimental analysis of sequential water alternating CO2 gas injection for enhancing oil recovery in X-field sandstone reservoir of Cambay Basin. Sci. Rep. 2025, 15, 21238. [Google Scholar] [CrossRef]

- Yang, G.; Bai, Y.; Song, Y.; Metwally, A.S.M.; Mahmoud, O. An experimental study to measure oil recovery factor by chemical agents and carbon dioxide after waterflooding. Sci. Rep. 2022, 12, 9464. [Google Scholar] [CrossRef]

- Khan, J.A.; Kim, J.; Irawan, S.; Permatasar, K.A.; Verdin, P.G.; Cai, B.; Yekeen, N. Application of foam-assisted water-alternating-gas flooding and quantification of resistivity and water saturation by experiment and simulation to determine foam propagation in sandstone. Heliyon 2024, 10, e25061. [Google Scholar] [CrossRef]

- Bandyopadhyay, P.; Andel, D.; Hampton, D.W.; Stone, L.D. CO2 WAG huff-n-puff for waterflooded conventional reservoirs: Design and field learnings from deployment in the Permian Basin of West Texas. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 16–18 October 2023; Society of Petroleum Engineers: Richardson, TX, USA, 2023. Paper SPE-215423-MS. [Google Scholar]

- Horozov, T.S. Foams and foam films stabilised by solid particles. Curr. Opin. Colloid Interface Sci. 2008, 13, 134–140. [Google Scholar] [CrossRef]

- Mo, D.; Yu, J.; Liu, N.; Lee, R. Study of the Effect of Different Factors on Nanoparticle-Stabilized CO2 Foam for Mobility Control. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 8–10 October 2012; Society of Petroleum Engineers: Richardson, TX, USA OnePetro. [Google Scholar]

- Bello, A.; Dorhjie, D.B.; Ivanova, A.; Cheremisin, A. A numerical feasibility study of CO2 foam for carbon utilization and storage in a depleted, high salinity, carbonate oil reservoir. Sci. Rep. 2024, 14, 20585. [Google Scholar] [CrossRef]

- Khandoozi, S.; Pourafshary, P.; Aidarova, S.; Sharipova, A. A comparative analysis of the effect of nanoparticles/surfactant assisted foam injection on the gas mobility control at different heterogeneities. Fuel 2023, 350, 128810. [Google Scholar] [CrossRef]

- Rahman, A.; Shirif, E.; Torabi, F. Nanoparticle-stabilized CO2 foam flooding for enhanced heavy oil recovery: A micro-optical analysis. Petroleum 2024, 10, 696–704. [Google Scholar] [CrossRef]

- Bello, A.; Dorhjie, D.B.; Ivanova, A.; Cheremisin, A.; Ilyasov, I.; Cheremisin, A. Numerical study of the mechanisms of nano-assisted foam flooding in porous media as an alternative to gas flooding. Heliyon 2024, 10, e29852. [Google Scholar] [CrossRef] [PubMed]

- Hong, S.Y.; Zeng, F.; Du, Z. Characterization of gas–oil flow in cyclic solvent injection (CSI) for heavy oil recovery. J. Pet. Sci. Eng. 2017, 152, 639–652. [Google Scholar] [CrossRef][Green Version]

- Chang, J.; Ivory, J. Field-scale simulation of cyclic solvent injection (CSI). J. Can. Pet. Technol. 2013, 52, 251–265. [Google Scholar] [CrossRef]

- Arrhenius, S. Über die Dissociationswärme und den Einfluss der Temperatur auf den Dissociationsgrad der Elektrolyte. Z. Phys. Chem. 1889, 4, 96–116. [Google Scholar] [CrossRef]

- Plata, M.; Bryan, J.; Kantzas, A. Experimental study of heavy oil recovery mechanisms during cyclic solvent injection processes. SPE J. 2021, 26, 1499–1514. [Google Scholar] [CrossRef]

- Morrow, N.R.; Mason, G. Recovery of oil by spontaneous imbibition. Curr. Opin. Colloid Interface Sci. 2001, 6, 321–337. [Google Scholar] [CrossRef]

- Mai, A.; Bryan, J.; Goodarzi, N.; Kantzas, A. Insights into non-thermal recovery of heavy oil. J. Can. Pet. Technol. 2009, 48, 27–35. [Google Scholar] [CrossRef]

- Sheng, J.J.; Maini, B.B.; Hayes, R.E.; Tortike, W.S. Critical review of foamy oil flow. Transp. Porous Media 1999, 35, 157–187. [Google Scholar] [CrossRef]

- Maini, B.B. Foamy-oil flow. J. Pet. Technol. 2001, 53, 54–64. [Google Scholar] [CrossRef]

- Zhou, X.; Yuan, Q.; Peng, X.; Zeng, F.; Zhang, L. A critical review of the CO2 huff ‘n’ puff process for enhanced heavy oil recovery. Fuel 2018, 215, 813–824. [Google Scholar] [CrossRef]

- Wu, M.; Lu, X.; Yang, J.; Lin, Z.; Zeng, F. Experimental analysis of optimal viscosity for optimizing foamy oil behavior in the porous media. Fuel 2020, 262, 116602. [Google Scholar] [CrossRef]

| Test No. | Pressure (kPa) | Experimental Procedure | ORF (%) | CORF (%) | Soi/r (%) | ERI (%) |

|---|---|---|---|---|---|---|

| 1 | 7100 | CO2-CSI | 30.9 | 30.9 | 92.1 | 33.6 |

| 2 | 7100 | Waterflooding | 33.2 | 72.1 | 92.8 | |

| →CO2-CSI | 38.9 | 59.6 | 65.3 | |||

| 3 | 6100 | 3-1 CO2-CSI | 26.9 | 69.5 | 92.6 | 29.0 |

| →Waterflooding | 7.7 | 65.7 | ||||

| →3-2 CO2-CSI | 28.8 | 58.0 | 49.7 | |||

| →NP Fluid Flooding | 0.2 | 29.2 | ||||

| →3-3 CO2-CSI | 5.9 | 29.0 | 20.3 |

| Test | Injection Pressure, kPa | EACT, J/gmol | FREQFAC | DTRAP_A | DTRAP_B | SGR | KRGCW |

|---|---|---|---|---|---|---|---|

| 1 | 7100 | 5790 | 9150 | 0.23 | 0.88 | 0.05 | 0.0945 |

| 2 | 7100 | 6000 | 8450 | 0.24 | 0.86 | 0.23 | 0.0833 |

| Test | Injection Pressure, kPa | EACT, J/gmol | FREQFAC | DTRAP_A | DTRAP_B | SGR | KRGCW |

|---|---|---|---|---|---|---|---|

| 3-1 | 6100 | 5690 | 9350 | 0.25 | 0.90 | 0.07 | 0.088 |

| 3-2 | 6100 | 6030 | 9000 | 0.22 | 0.87 | 0.24 | 0.076 |

| 3-3 | 6100 | 8380 | 9630 | 0.40 | 0.90 | 0.40 | 0.050 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Cao, Y.; Chen, Y.; Zeng, F. Integrated Experimental and Numerical Investigation on CO2-Based Cyclic Solvent Injection Enhanced by Water and Nanoparticle Flooding for Heavy Oil Recovery and CO2 Sequestration. Energies 2025, 18, 4663. https://doi.org/10.3390/en18174663

Li Y, Cao Y, Chen Y, Zeng F. Integrated Experimental and Numerical Investigation on CO2-Based Cyclic Solvent Injection Enhanced by Water and Nanoparticle Flooding for Heavy Oil Recovery and CO2 Sequestration. Energies. 2025; 18(17):4663. https://doi.org/10.3390/en18174663

Chicago/Turabian StyleLi, Yishu, Yufeng Cao, Yiming Chen, and Fanhua Zeng. 2025. "Integrated Experimental and Numerical Investigation on CO2-Based Cyclic Solvent Injection Enhanced by Water and Nanoparticle Flooding for Heavy Oil Recovery and CO2 Sequestration" Energies 18, no. 17: 4663. https://doi.org/10.3390/en18174663

APA StyleLi, Y., Cao, Y., Chen, Y., & Zeng, F. (2025). Integrated Experimental and Numerical Investigation on CO2-Based Cyclic Solvent Injection Enhanced by Water and Nanoparticle Flooding for Heavy Oil Recovery and CO2 Sequestration. Energies, 18(17), 4663. https://doi.org/10.3390/en18174663