Thermal Stability of Lithium-Ion Batteries: A Review of Materials and Strategies

Abstract

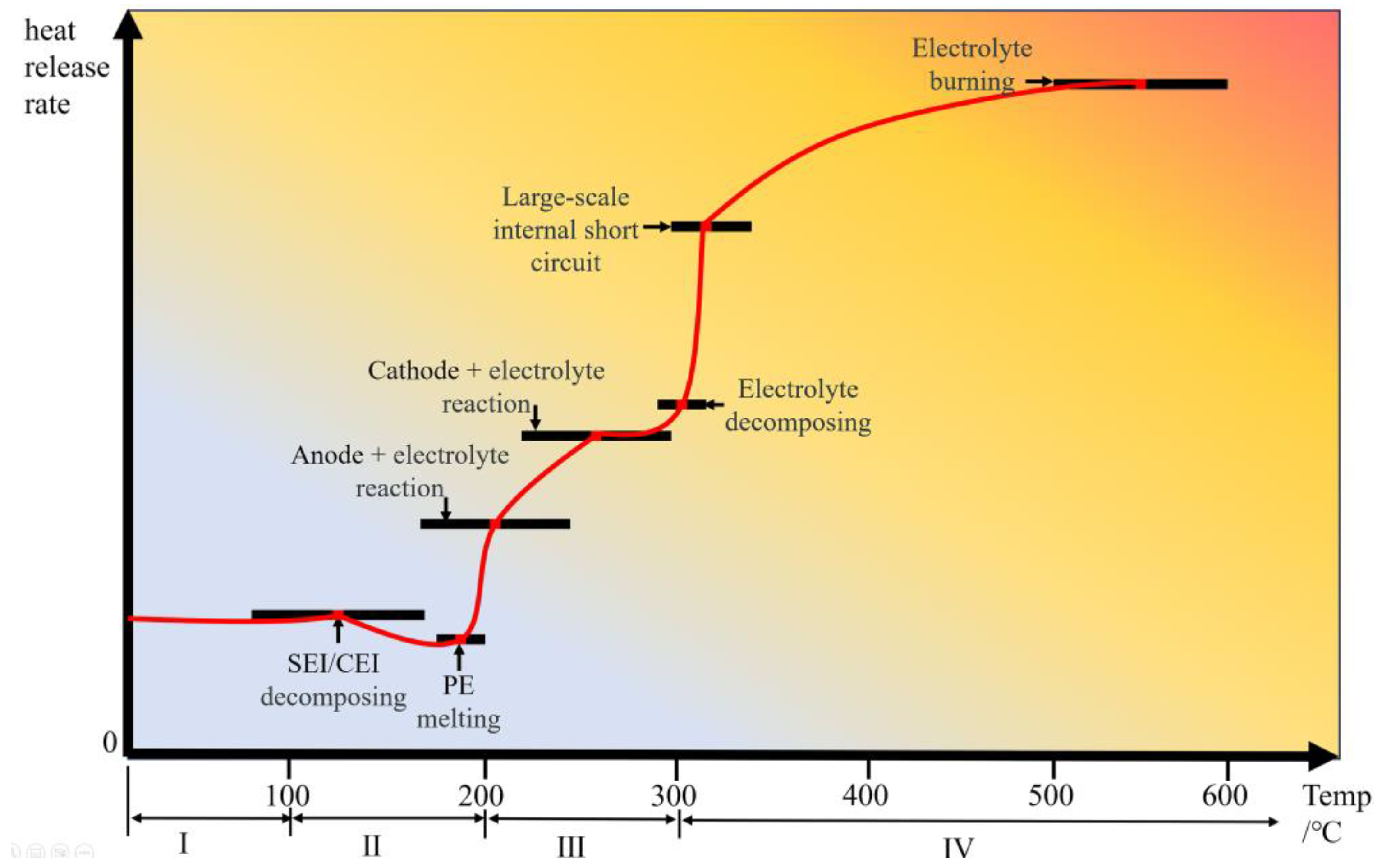

1. Introduction

2. Cathode

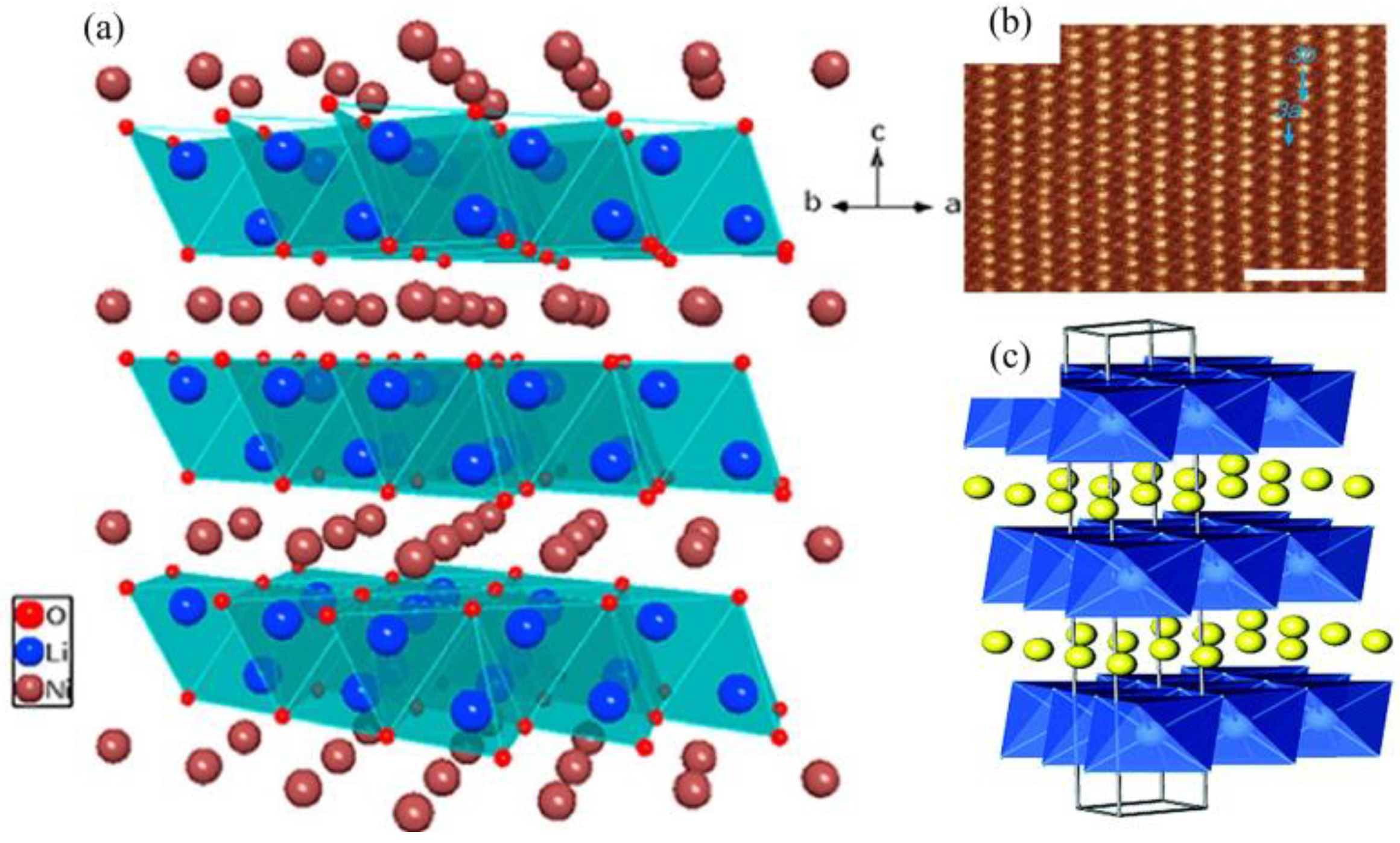

2.1. Layered Metal Oxides

2.1.1. Thermal Failure Mechanism

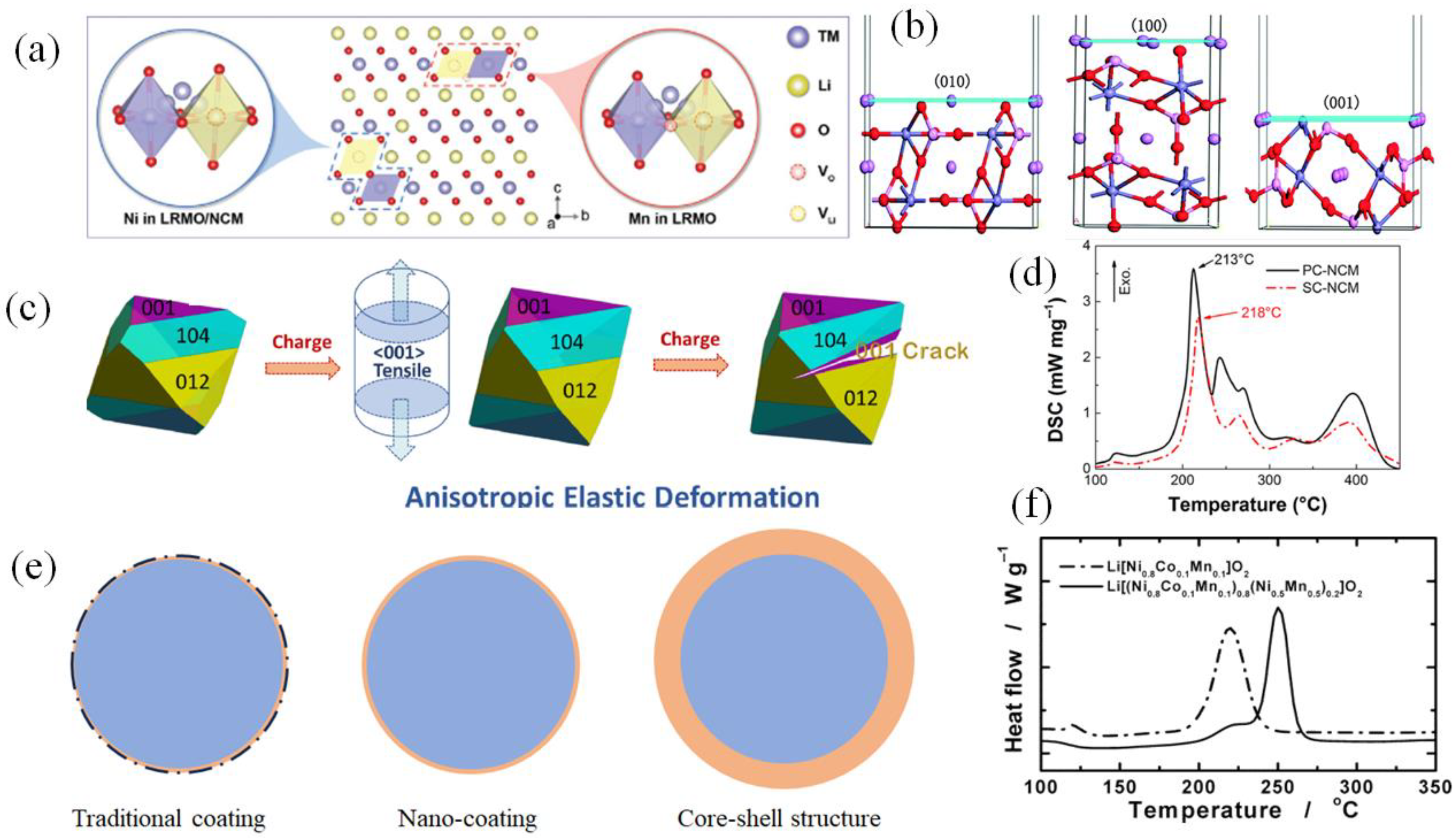

- Structural characteristics

- 2.

- Cation mixing

- 3.

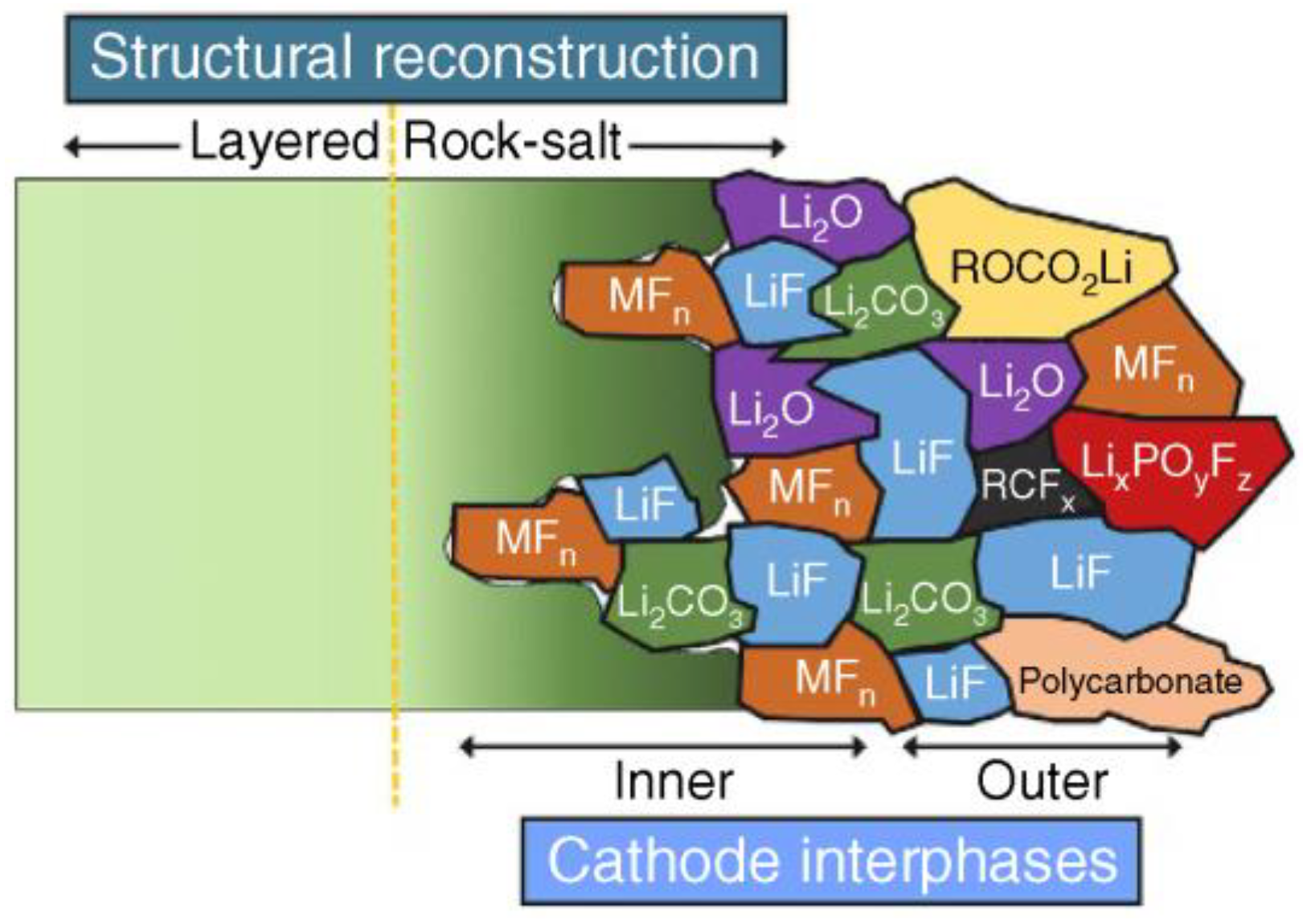

- Interfacial reactions

2.1.2. Path to Elevate Thermal Stability

- Internal doping

| Site | Material | Doping | Charging Voltage (V) | Heat Flow | Heat Release Onset (Peak) Temperature | Ref. |

|---|---|---|---|---|---|---|

| Li | LiNi0.8Co0.1Mn0.1O2 | Y | 4.3 4.5 | −70% | +10 °C (+12 °C) | [23] |

| −75% | +5 °C (+10 °C) | |||||

| Li1.2Ni0.54Co0.13Mn0.13O2 | Mg | 4.8 | −39% | +55 °C (+14 °C) | [24] | |

| LiNi0.6Co0.05Mn0.35O2 | Na | 4.5 | −20% | +25 °C (+24 °C) | [25] | |

| Ni | LiNi0.8Co0.2O2 | Ce | 4.5 | −45% | +10 °C (+18 °C) | [26] |

| LiNi0.8Co0.2O2 | Ti | 4.3 | −82% | +87 °C (+82 °C) | [27] | |

| LiNi2O2 | W | 4.3 | −34% | +10 °C (+10 °C) | [28] | |

| Co | LixNi0.8Co0.2O2 | Mg | 5.0 | −82% | Consistent | [29] |

| Li1.2Ni0.13Co0.13Mn0.54O2 | Al | 4.8 | −40% | Consistent | [22] | |

| Mn | Li[Ni0.45Co0.1Mn0.45]O2 | Zr | 4.6 | −38% | +50 °C (+37 °C) | [30] |

| LiNi1/3Co1/3Mn1/3O2 | Ti | 4.5 | −34% | +23 °C (+18 °C) | [31] | |

| Mn/Co | LiNi1/3Mn1/3Co1/3O2 | Mg | 4.3 | Consistent | Consistent | [32] |

| Mn/Co/Mn | LiNi0.85Co0.1Mn0.05O2 | Nb | 4.3 | −23% | Consistent | [33] |

| LiNi0.6Co0.2Mn0.2O2 | Mg | 4.3 | −41% | +25 °C (+35 °C) | [34] | |

| Zr | 4.3 | −18% | +10 °C (+15 °C) | |||

| LiNi0.9Co0.05Mn0.05O2 | W | 4.3 V | −16% | +10 °C (+10 °C) | [28] | |

| O | LiNi0.8Co0.15Mn0.05O2 | W | 4.3 V | −21% | +23 °C (+25 °C) | |

| Li1.2Ni0.13Co0.13Mn0.54O2 | F | 4.8 V | −65% | +20 °C (+42 °C) | [22] |

- 2.

- Surface coating and doping

- 3.

- Structure optimization

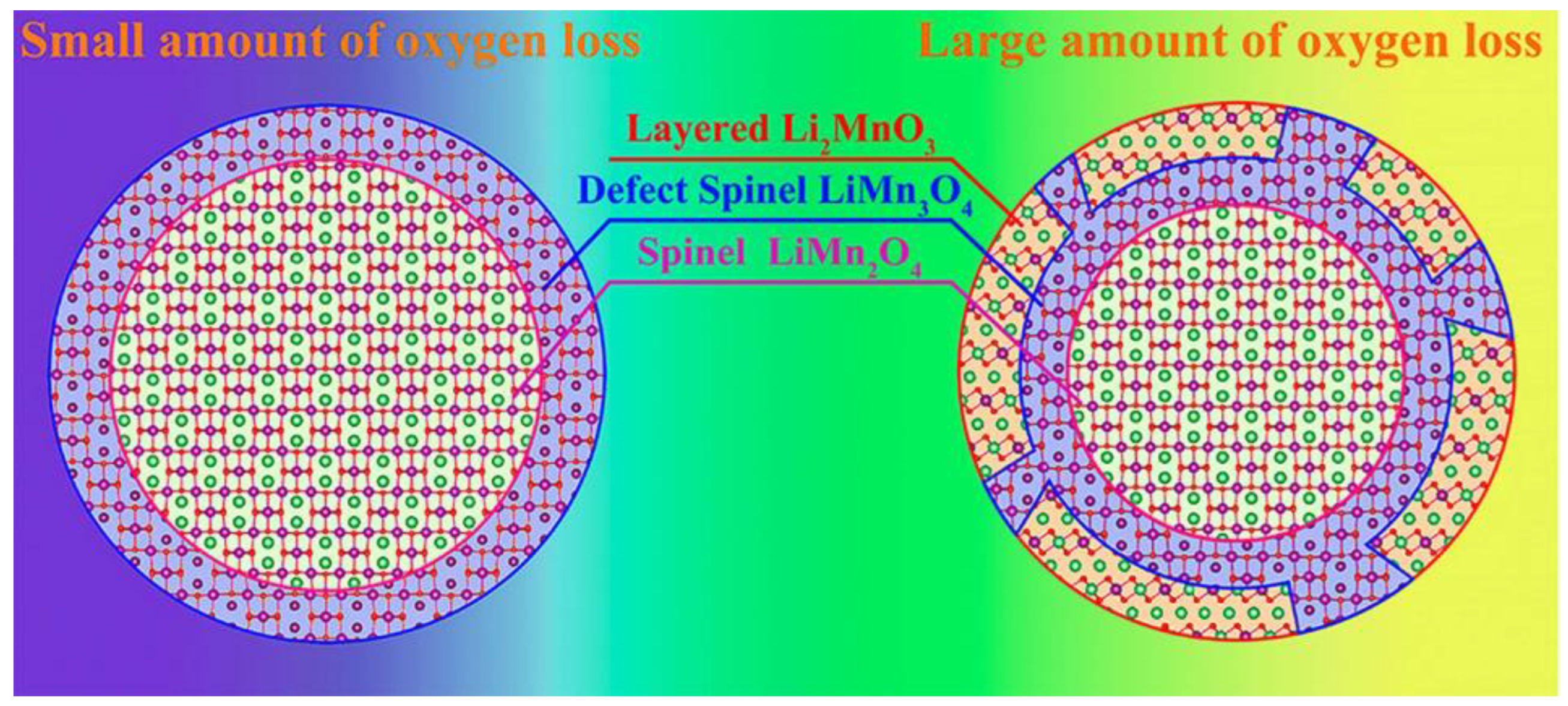

2.2. Spinel Oxide

2.2.1. Thermal Failure Mechanism

- Surface distortion and Jahn–Teller distortion

- 2.

- Mn dissolution

- 3.

- Interfacial reactions

2.2.2. Path to Elevate Thermal Stability

- Element doping

- 2.

- Surface coating

- 3.

- Structural optimization

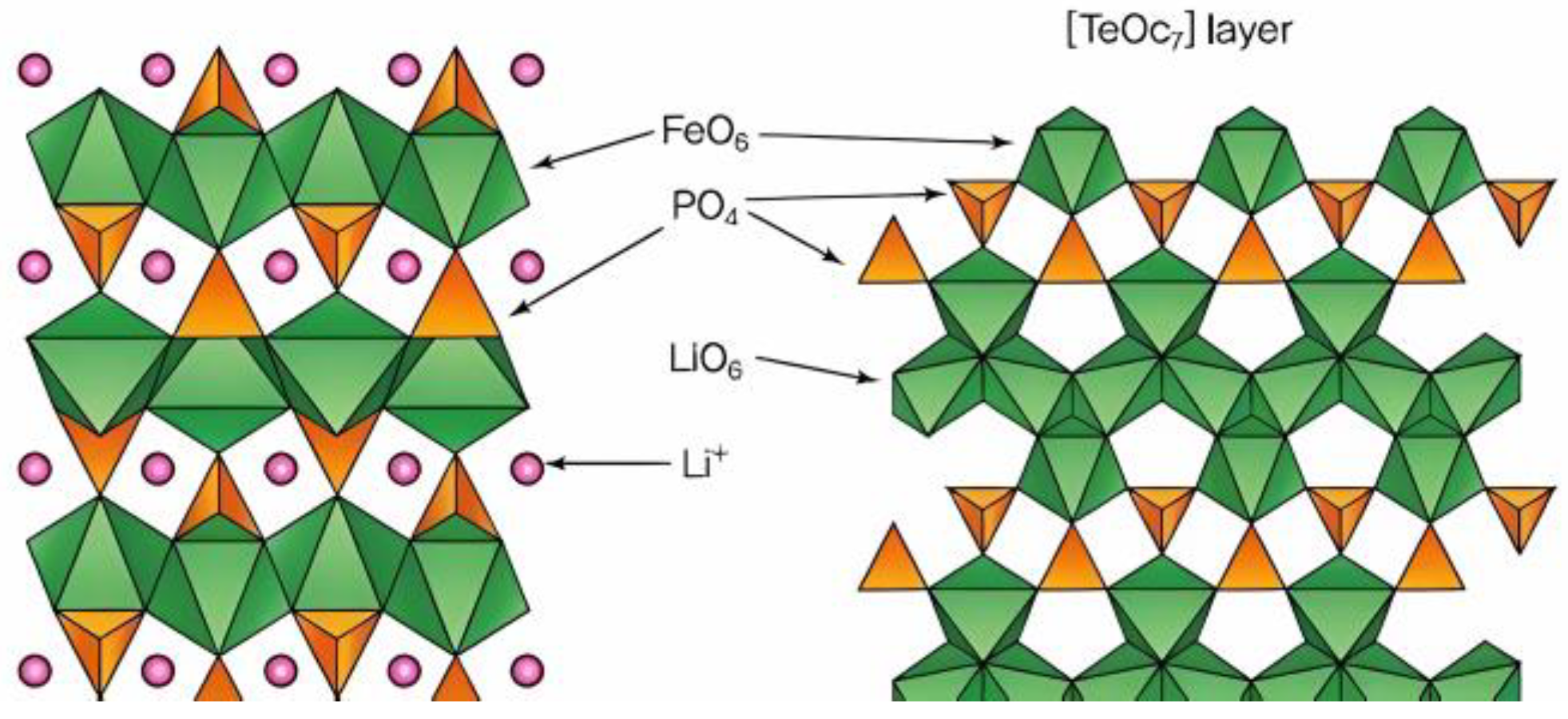

2.3. Polyanionic (Olivine) Oxide

3. Anode

3.1. Carbon-Based Anode

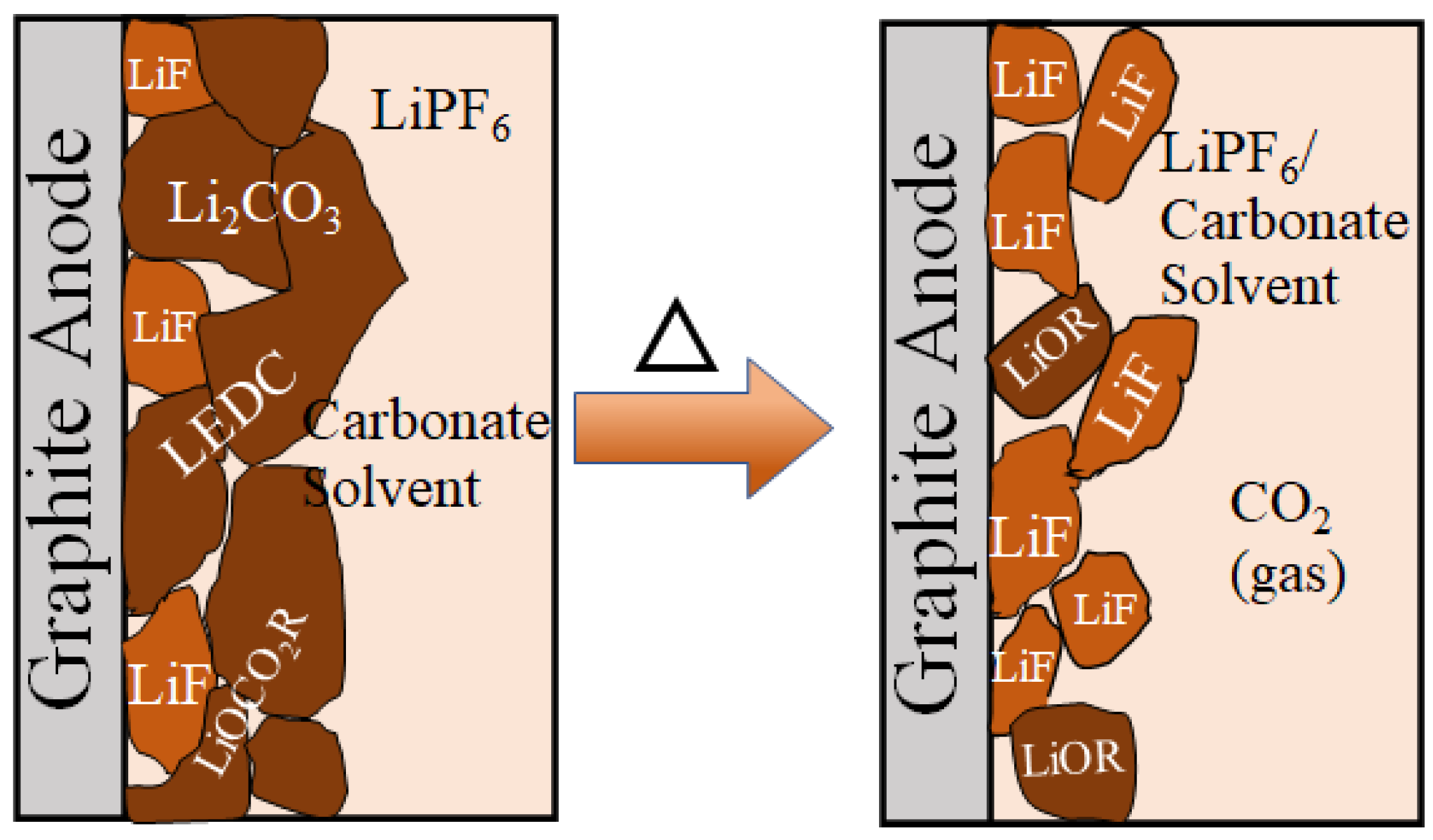

3.1.1. Thermal Failure Mechanism

3.1.2. Path to Elevate Thermal Stability

3.2. Silicon-Based Anode

3.2.1. Thermal Failure Mechanism

- Structural characteristics

- 2.

- SEI decomposition

3.2.2. Path to Elevate Thermal Stability

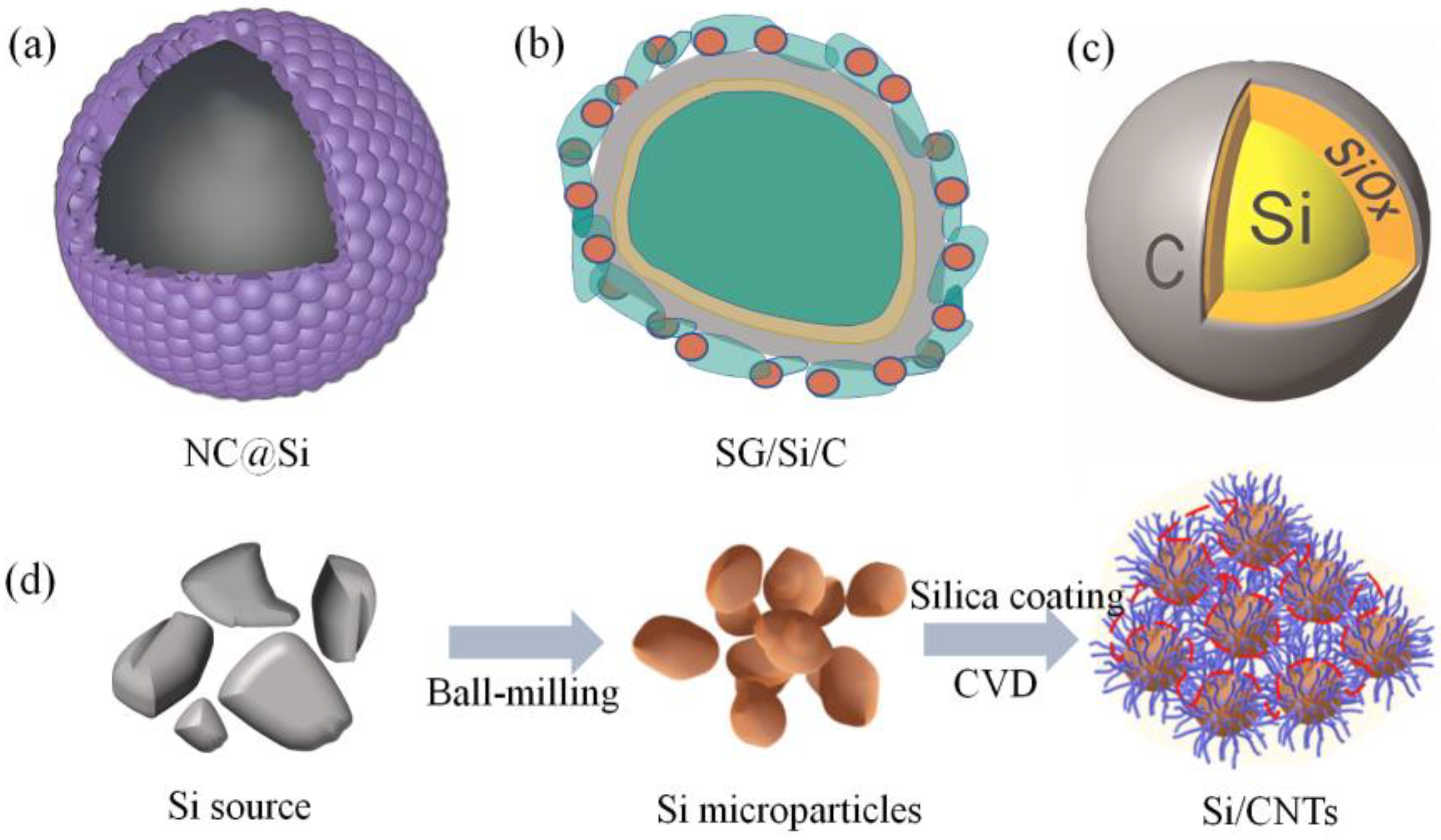

- Structural optimization

- 2.

- Element doping

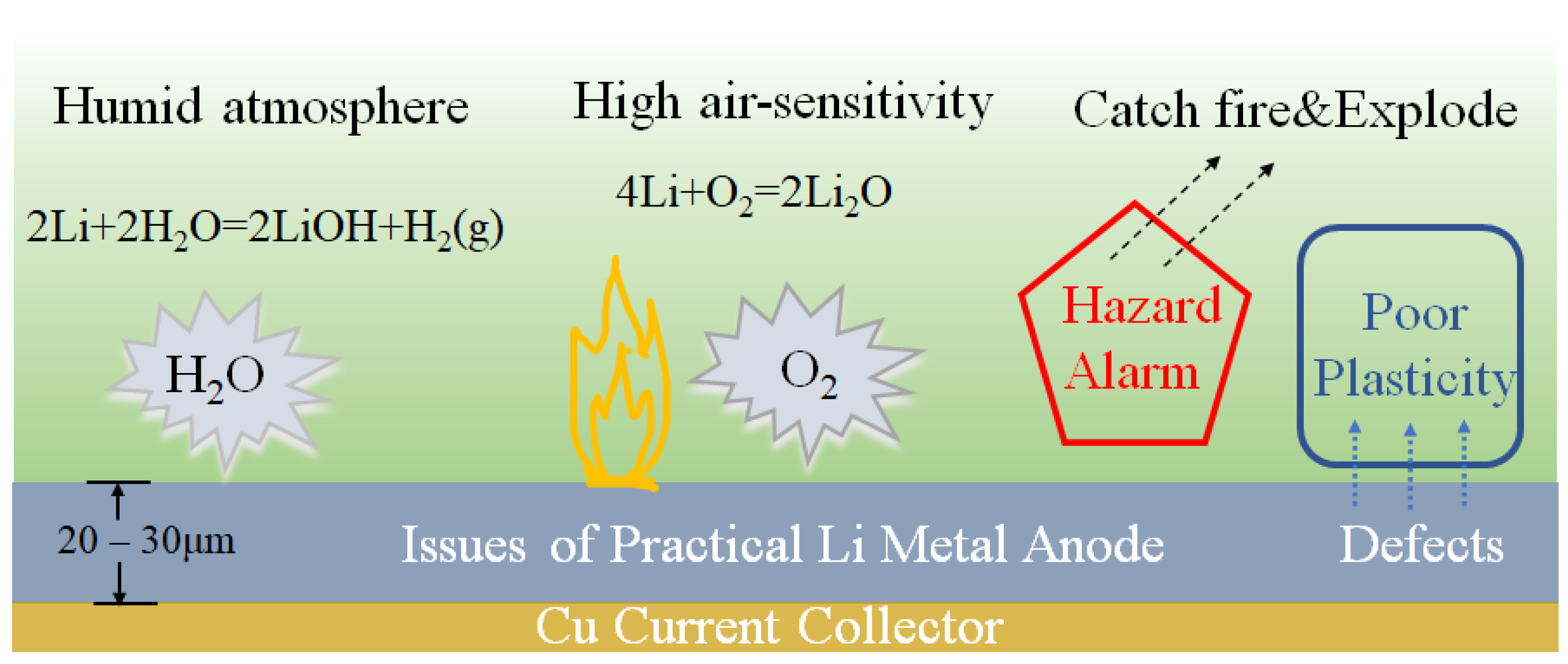

3.3. Lithium Metal Composite

3.3.1. Thermal Failure Mechanism

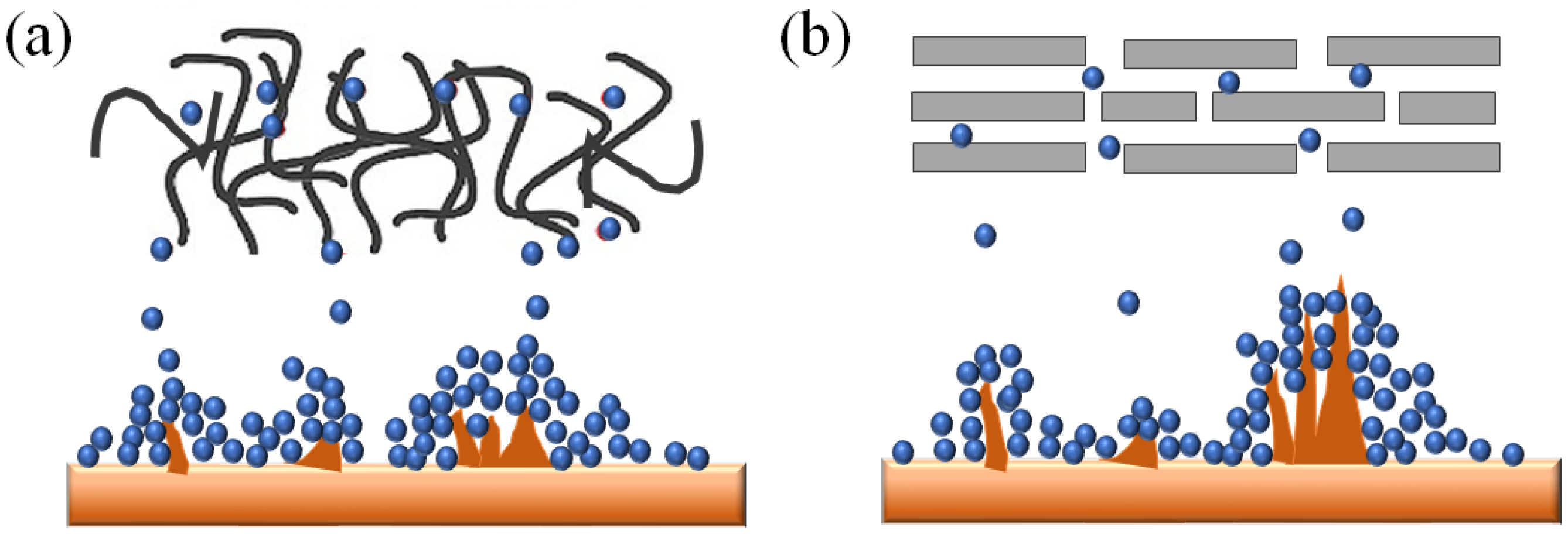

- Uncontrollable growth of lithium dendrites

- 2.

- Unstable SEI film

- 3.

- Interfacial reactions

3.3.2. Path to Elevate Thermal Stability

- Additives

- 2.

- Solid electrolyte

- 3.

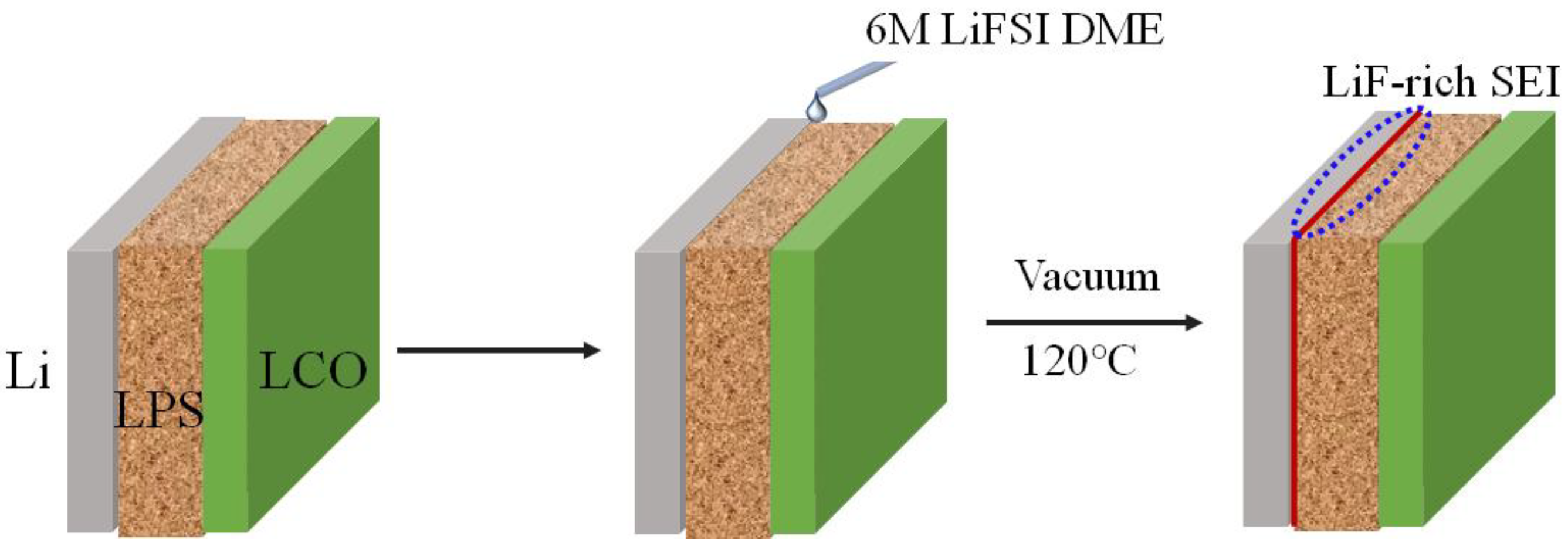

- Artificial SEI

- 4.

- Composite electrode

4. Separator

4.1. Microporous Separator

4.1.1. Thermal Failure Mechanism

4.1.2. Path to Elevate Thermal Stability

- Surface coating

- 2.

- Surface graft modification

4.2. Non-Woven Membrane

4.2.1. Thermal Failure Mechanism

4.2.2. Path to Elevate Thermal Stability

- Post-processing

- 2.

- Surface coating

- 3.

- Multilayer separator

5. Electrolyte

5.1. Liquid Electrolyte

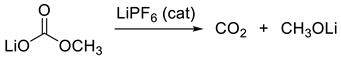

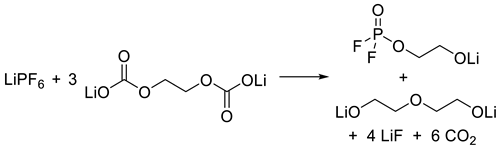

5.1.1. Thermal Failure Mechanism

5.1.2. Path to Elevate Thermal Stability

- Inhibit the decomposition of the electrolyte

- 2.

- Preventing electrolyte burning

5.2. Solid Electrolyte

5.2.1. Thermal Failure Mechanism

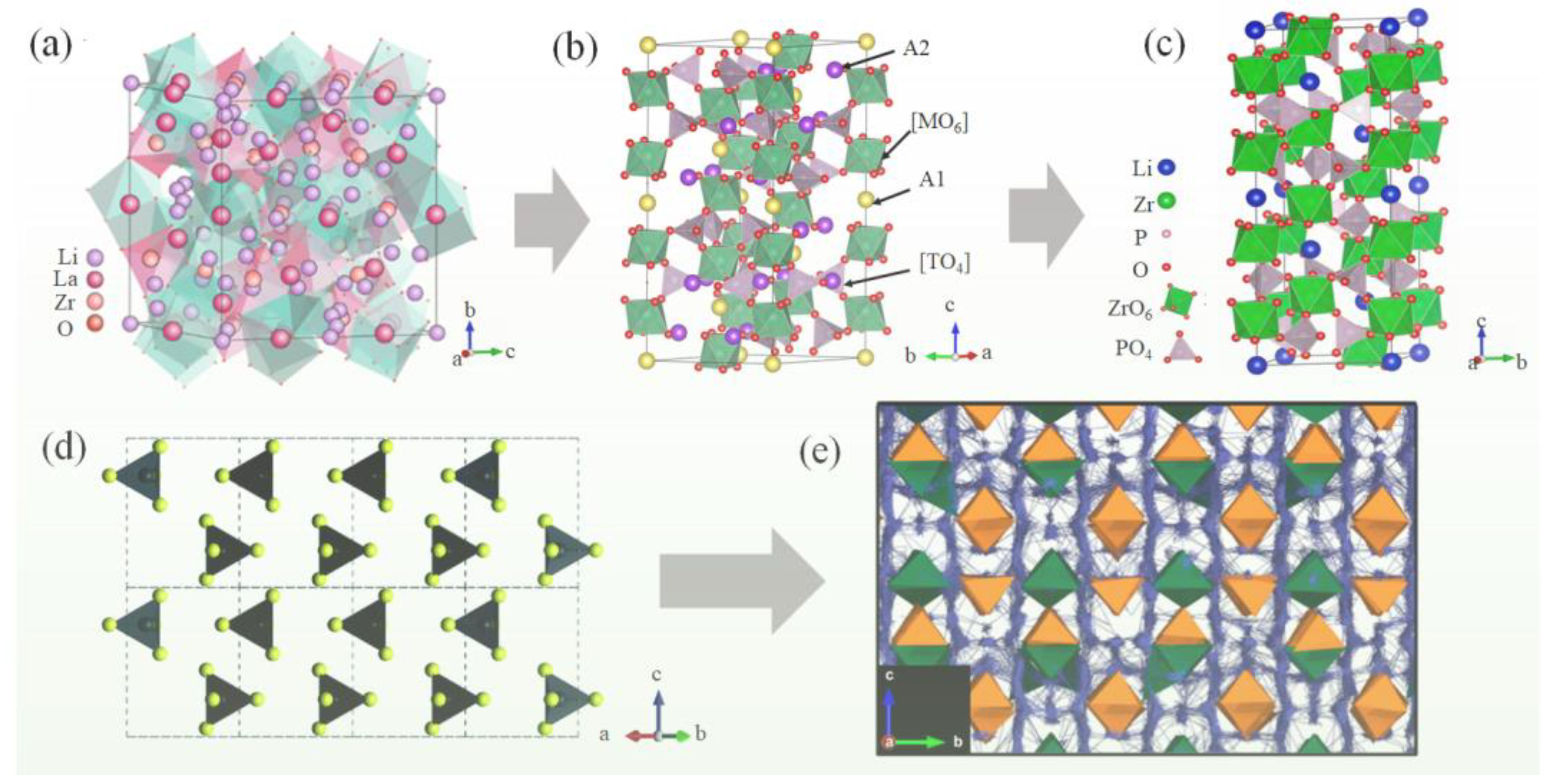

- Inorganic solid electrolyte

- 2.

- Solid polymer electrolyte

- 3.

- Other solid electrolytes

5.2.2. Path to Elevate Thermal Stability

- Element doping

- 2.

- Composite solid electrolyte

- 3.

- Other improvement measures

6. Conclusions and Future Outlook

- (1)

- In the positive electrode of LIBs, the thermal runaway mechanism is explained from the perspective of structural evolution and chemical reactions, providing a theoretical basis for enhancing the stability of the cathode material. The focus is on strategies to improve thermal stability, such as doping, coating, and structural optimization. However, these strategies still face some challenges. For example, the mechanism of cation mixing caused by element doping, the formation and evolution mechanism of CEI due to adhesion, and the difficulty of the single crystallization of cathode materials are not clear. Therefore, it is necessary to conduct more systematic and in-depth research on these mechanisms and develop excellent synthesis methods.

- (2)

- In the negative electrode of LIBs, the article discusses the thermal characteristics of different negative electrode materials and finds that the thermal stability of negative electrode materials is also an important factor affecting the safety of LIBs, especially in the case of overcharging or short circuits. The commonly used anode materials include graphite, silicon, lithium metal, etc., each of which has different thermal behaviors and thermal failure mechanisms, such as the oxidation of graphite, the expansion of silicon, and the dendritic growth of lithium metal. In addition, the improvements involve surface coatings, doping, and the use of composite materials to enhance thermal stability. Therefore, we believe that the future research focus should be to develop high-capacity, high thermal stability, low-expansion new anode materials, such as silicon/carbon composites, lithium metal, lithium sulfides, etc., and optimize the structure, morphology, composition, etc., of the anode to improve its thermal safety performance.

- (3)

- In the separator of LIBs, the article reviews the thermal characteristics of the separator. The separator is a key component in LIBs, which serves to isolate the positive and negative electrodes, conduct lithium ions, and prevent thermal runaway. Commonly used separator materials include polypropylene, polyethylene, etc., which have higher melting points and lower thermal shrinkage rates and can resist thermal shock to a certain extent. However, there are also some defects in the separator materials, such as low porosity, poor mechanical strength, and decreased thermal stability over time. The strategies include increasing tensile strength, reducing thermal shrinkage, and developing multilayer structures. Therefore, we believe that future research should aim to develop new separator materials with high thermal stability, high mechanical strength, and high ion conductivity, such as ceramic composite separators, polymer nanofiber separators, porous metal separators, etc., and optimize the structure, morphology, and composition of the separator to improve its thermal safety performance.

- (4)

- In the electrolyte of LIBs, the article briefly introduces the thermal characteristics of the electrolyte, pointing out that the decomposition and reaction of the electrolyte are among the main causes of thermal runaway in LIBs, especially under high temperature and high voltage conditions. Currently, the approaches focus on additives to improve thermal stability and the development of solid electrolytes with higher decomposition temperatures. Hence, we posit that future research should concentrate on the development of novel electrolyte materials characterized by superior thermal, electrochemical stability, and high ion conductivity, such as ionic liquids, solid electrolytes, polymer electrolytes, etc., and on optimizing the structure, morphology, and composition of the electrolyte to improve its thermal safety performance.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Feng, X.; Ren, D.; He, X.; Ouyang, M. Mitigating thermal runaway of lithium-ion batteries. Joule 2020, 4, 743–770. [Google Scholar] [CrossRef]

- He, W.; Guo, W.; Wu, H.; Lin, L.; Liu, Q.; Han, X.; Xie, Q.; Liu, P.; Zheng, H.; Wang, L.; et al. Challenges and recent advances in high capacity Li-rich cathode materials for high energy density lithium-ion batteries. Adv. Mater. 2021, 33, 2005937. [Google Scholar] [CrossRef]

- Iskandar Radzi, Z.; Helmy Arifin, K.; Zieauddin Kufian, M.; Balakrishnan, V.; Rohani Sheikh Raihan, S.; Abd Rahim, N.; Subramaniam, R. Review of spinel LiMn2O4 cathode materials under high cut-off voltage in lithium-ion batteries: Challenges and strategies. J. Electroanal. Chem. 2022, 920, 116623. [Google Scholar] [CrossRef]

- Wang, L.; Zhou, Z.; Yan, X.; Hou, F.; Wen, L.; Luo, W.; Liang, J.; Dou, S.X. Engineering of lithium-metal anodes towards a safe and stable battery. Energy Storage Mater. 2018, 14, 22–48. [Google Scholar] [CrossRef]

- Wang, R.; Cui, W.; Chu, F.; Wu, F. Lithium metal anodes: Present and future. J. Energy Chem. 2020, 48, 145–159. [Google Scholar] [CrossRef]

- Yang, X.; Peng, Y.; Hou, J.; Liu, Y.; Jian, X. A review for modified Li composite anode: Principle, preparation and challenge. Nanotechnol. Rev. 2020, 9, 1610–1624. [Google Scholar] [CrossRef]

- Dai, X.; Zhang, X.; Wen, J.; Wang, C.; Ma, X.; Yang, Y.; Huang, G.; Ye, H.; Xu, S. Research progress on high-temperature resistant polymer separators for lithium-ion batteries. Energy Storage Mater. 2022, 51, 638–659. [Google Scholar] [CrossRef]

- Thakur, A.K.; Kumar, A.; Park, H.; Kim, H.; Ahmed, M.S.; Saleque, A.M.; Vikram, M.P.; Saidur, R.; Ma, Y.; Hwang, J.-Y. Composite separators for internal thermal management in rechargeable lithium batteries: A review. J. Energy Storage 2023, 73, 108873. [Google Scholar] [CrossRef]

- Zhang, S.; Li, S.; Lu, Y. Designing safer lithium-based batteries with nonflammable electrolytes: A review. eScience 2021, 1, 163–177. [Google Scholar] [CrossRef]

- Manthiram, A.; Yu, X.; Wang, S. Lithium battery chemistries enabled by solid-state electrolytes. Nat. Rev. Mater. 2017, 2, 16103. [Google Scholar] [CrossRef]

- Chen, M.; Yue, Z.; Wu, Y.; Wang, Y.; Li, Y.; Chen, Z. Thermal stable polymer-based solid electrolytes: Design strategies and corresponding stable mechanisms for solid-state Li metal batteries. Sustain. Mater. Technol. 2023, 36, e00587. [Google Scholar] [CrossRef]

- Jiang, M.; Danilov, D.L.; Eichel, R.A.; Notten, P.H.L. A review of degradation mechanisms and recent achievements for Ni-rich cathode-based Li-ion batteries. Adv. Energy Mater. 2021, 11, 2103005. [Google Scholar] [CrossRef]

- Lin, F.; Markus, I.M.; Nordlund, D.; Weng, T.-C.; Asta, M.D.; Xin, H.L.; Doeff, M.M. Surface reconstruction and chemical evolution of stoichiometric layered cathode materials for lithium-ion batteries. Nat. Commun. 2014, 5, 3529. [Google Scholar] [CrossRef] [PubMed]

- Whittingham, M.S. Lithium batteries and cathode materials. Chem. Rev. 2004, 104, 4271–4302. [Google Scholar] [CrossRef] [PubMed]

- Manthiram, A.; Song, B.; Li, W. A perspective on nickel-rich layered oxide cathodes for lithium-ion batteries. Energy Storage Mater. 2017, 6, 125–139. [Google Scholar] [CrossRef]

- Manthiram, A.; Murugan, A.V.; Sarkar, A.; Muraliganth, T. Nanostructured electrode materials for electrochemical energy storage and conversion. Energy Environ. Sci. 2008, 1, 621–638. [Google Scholar] [CrossRef]

- Gao, A.; Sun, Y.; Zhang, Q.; Zheng, J.; Lu, X. Evolution of Ni/Li antisites under the phase transition of a layered LiNi1/3Co1/3Mn1/3O2 cathode. J. Mater. Chem. A 2020, 8, 6337–6348. [Google Scholar] [CrossRef]

- Bak, S.-M.; Hu, E.; Zhou, Y.; Yu, X.; Senanayake, S.D.; Cho, S.-J.; Kim, K.-B.; Chung, K.Y.; Yang, X.-Q.; Nam, K.-W. Structural changes and thermal stability of charged LiNixMnyCozO2 cathode materials studied by combined in situ time-resolved XRD and mass spectroscopy. ACS Appl. Mater. Interfaces 2014, 6, 22594–22601. [Google Scholar] [CrossRef]

- Kanamori, J. Superexchange interaction and symmetry properties of electron orbitals. J. Phys. Chem. Solids 1959, 10, 87–98. [Google Scholar] [CrossRef]

- Manthiram, A.; Knight, J.C.; Myung, S.T.; Oh, S.M.; Sun, Y.K. Nickel-rich and lithium-rich layered oxide cathodes: Progress and perspectives. Adv. Energy Mater. 2016, 6, 1501010. [Google Scholar] [CrossRef]

- Li, W.; Dolocan, A.; Oh, P.; Celio, H.; Park, S.; Cho, J.; Manthiram, A. Dynamic behaviour of interphases and its implication on high-energy-density cathode materials in lithium-ion batteries. Nat. Commun. 2017, 8, 14589. [Google Scholar] [CrossRef]

- Guo, B.; Zhao, J.; Fan, X.; Zhang, W.; Li, S.; Yang, Z.; Chen, Z.; Zhang, W. Aluminum and fluorine co-doping for promotion of stability and safety of lithium-rich layered cathode material. Electrochim. Acta 2017, 236, 171–179. [Google Scholar] [CrossRef]

- Zhang, M.; Zhao, H.; Tan, M.; Liu, J.; Hu, Y.; Liu, S.; Shu, X.; Li, H.; Ran, Q.; Cai, J.; et al. Yttrium modified Ni-rich LiNi0.8Co0.1Mn0.1O2 with enhanced electrochemical performance as high energy density cathode material at 4.5 V high voltage. J. Alloys Compd. 2019, 774, 82–92. [Google Scholar] [CrossRef]

- Huang, C.; Wang, Z.; Wang, H.; Huang, D.; He, Y.; Zhao, S. Mg2+ doping into Li sites to improve anionic redox reversibility and thermal stability of lithium-rich manganese-based oxides cathode. J. Mater. Today Energy 2022, 29, 101116. [Google Scholar] [CrossRef]

- Shen, Y.; Yao, X.; Zhang, J.; Wang, S.; Zhang, D.; Yin, D.; Wang, L.; Zhang, Y.; Hu, J.; Cheng, Y.; et al. Sodium doping derived electromagnetic center of lithium layered oxide cathode materials with enhanced lithium storage. Nano Energy 2022, 94, 106900. [Google Scholar] [CrossRef]

- Liu, L.; Su, G.; Xiao, Q.; Ding, Y.; Wang, C.; Gao, D. Structural, electrochemical and thermal properties of LiNi0.8−xCo0.2CexO2 as cathode materials for lithium ion batteries. Mater. Chem. Phys. 2006, 100, 236–240. [Google Scholar] [CrossRef]

- Liu, H.; Li, J.; Zhang, Z.; Gong, Z.; Yang, Y. Structural, electrochemical and thermal properties of LiNi0. 8−yTiyCo0.2O2 as cathode materials for lithium ion battery. Electrochim. Acta 2004, 49, 1151–1159. [Google Scholar] [CrossRef]

- Kim, U.-H.; Jun, D.-W.; Park, K.-J.; Zhang, Q.; Kaghazchi, P.; Aurbach, D.; Major, D.T.; Goobes, G.; Dixit, M.; Leifer, N. Pushing the limit of layered transition metal oxide cathodes for high-energy density rechargeable Li ion batteries. Energy Environ. Sci. 2018, 11, 1271–1279. [Google Scholar] [CrossRef]

- D’Epifanio, A.; Croce, F.; Ronci, F.; Rossi Albertini, V.; Traversa, E.; Scrosati, B. Effect of Mg2+ doping on the structural, thermal, and electrochemical properties of LiNi0.8Co0.16Mg0.04O2. Chem. Mater. 2004, 16, 3559–3564. [Google Scholar] [CrossRef]

- Bang, H.J.; Park, B.-C.; Prakash, J.; Sun, Y.-K. Synthesis and electrochemical properties of Li [Ni0.45Co0.1Mn0.45−xZrx]O2 (x=0, 0.02) via co-precipitation method. J. Power Sources 2007, 174, 565–568. [Google Scholar] [CrossRef]

- Cho, W.; Song, J.H.; Lee, K.-W.; Lee, M.-W.; Kim, H.; Yu, J.-S.; Kim, Y.-J.; Kim, K.J. Improved particle hardness of Ti-doped LiNi1/3Co1/3Mn1/3-xTixO2 as high-voltage cathode material for lithium-ion batteries. J. Phys. Chem. Solids 2018, 123, 271–278. [Google Scholar] [CrossRef]

- Luo, W.; Li, X.; Dahn, J.R. Synthesis, characterization, and thermal stability of Li[Ni1/3Mn1/3Co1/3−z(MnMg)z/2]O2. Chem. Mater. 2010, 22, 5065–5073. [Google Scholar] [CrossRef]

- Levartovsky, Y.; Chakraborty, A.; Kunnikuruvan, S.; Maiti, S.; Grinblat, J.; Talianker, M.; Major, D.T.; Aurbach, D. Enhancement of structural, electrochemical, and thermal properties of high-energy density Ni-rich LiNi0.85Co0.1Mn0.05O2 cathode materials for Li-ion batteries by niobium doping. ACS Appl. Mater. Interfaces 2021, 13, 34145–34156. [Google Scholar] [CrossRef] [PubMed]

- Lipson, A.L.; Durham, J.L.; LeResche, M.; Abu-Baker, I.; Murphy, M.J.; Fister, T.T.; Wang, L.; Zhou, F.; Liu, L.; Kim, K.; et al. Improving the thermal stability of NMC622 Li-ion battery cathodes through doping during coprecipitation. ACS Appl. Mater. Interfaces 2020, 12, 18512–18518. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Lv, Z.; Xu, T.; Li, J. SiO2 coated Li1.2Ni0.2Mn0.6O2 as cathode materials with rate performance, HF scavenging and thermal properties for Li-ion batteries. J. Alloys Compd. 2017, 715, 105–111. [Google Scholar] [CrossRef]

- Sun, J.; Zheng, Z.; Xia, W.; Zhou, L.; Wei, Y.; Bei, F. Preparation of CeO2-coated Li1.2Mn0.54Co0.13Ni0.13O2 as cathode materials for lithium ion batteries. Int. J. Electrochem. Sci. 2022, 17, 221265. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhang, N.; Zhao, L.; Xu, J.; Liu, Z.; Liu, Y.; Wu, J.; Ding, F. Improving electrochemical performance of lithium-rich cathode material Li1.2Mn0.52Ni0.13Co0.13W0.02O2 coated with Li2WO4 for lithiumion batteries. J. Alloys Compd. 2019, 811, 152023. [Google Scholar] [CrossRef]

- Wu, Y.S.; Pham, Q.T.; Yang, C.C.; Chern, C.S.; Musuvadhi Babulal, L.; Seenivasan, M.; Brunklaus, G.; Placke, T.; Hwang, B.J.; Winter, M. Study of electrochemical performance and thermal property of LiNi0.5Co0.2Mn0.3O2 cathode materials coated with a novel oligomer additive for high-safety lithium-ion batteries. Chem. Eng. J. 2021, 405, 126727. [Google Scholar] [CrossRef]

- Wang, K.; Mao, Q.; Lu, X.; Zhang, J.; Huang, H.; Gan, Y.; He, X.; Xia, X.; Zhang, W.; Xia, Y. Fluorides coated Ni-rich cathode materials with enhanced surficial chemical stability for advanced lithium-ion battery. Sustain. Mater.Technol. 2023, 38, e00713. [Google Scholar] [CrossRef]

- Cho, W.; Lim, Y.J.; Lee, S.; Kim, J.H.; Song, J.; Yu, J.; Kim, Y.; Park, M. Facile Mn surface doping of Ni-rich layered cathode materials for lithium ion batteries. ACS Appl. Mater. Interfaces 2018, 10, 38915–38921. [Google Scholar] [CrossRef]

- Cho, W.; Kim, S.; Song, J.H.; Yim, T.; Woo, S.; Lee, K.; Kim, J.; Kim, Y. Improved electrochemical and thermal properties of nickel rich LiNi0.6Co0.2Mn0.2O2 cathode materials by SiO2 coating. J. Power Sources 2015, 282, 45–50. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, Y.; Chen, B.; Wang, Z.; Lu, C. An approach to application for LiNi0.6Co0.2Mn0.2O2 cathode material at high cutoff voltage by TiO2 coating. J. Power Sources 2014, 256, 20–27. [Google Scholar] [CrossRef]

- Cho, J.; Kim, T.; Kim, C.; Lee, J.; Kim, Y.; Park, B. Comparison of Al2O3− and AlPO4−coated LiCoO2 cathode materials for a Li-ion cell. J. Power Sources 2005, 146, 58–64. [Google Scholar] [CrossRef]

- Park, B.C.; Kim, H.B.; Myung, S.T.; Amine, K.; Belharouak, I.; Lee, S.M.; Sun, Y.K. Improvement of structural and electrochemical properties of AlF3-coated Li[Ni1/3Co1/3Mn1/3]O2 cathode materials on high voltage region. J. Power Sources 2008, 178, 826–831. [Google Scholar] [CrossRef]

- Guo, R.; Shi, P.; Cheng, X.; Sun, L. Effect of ZnO modification on the performance of LiNi0.5Co0.25Mn0.25O2 cathode material. Electrochim. Acta 2009, 54, 5796–5803. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, X.; Zou, G.; Zhang, L.; Han, S.; Li, Y.; Liu, D.; Fernandez, C.; Li, L.; Ren, L.; et al. Crystal-defect engineering of electrode materials for energy storage and conversion. Mater. Today Nano 2023, 22, 100336. [Google Scholar] [CrossRef]

- Zeng, W.; Xia, F.; Tian, W.; Cao, F.; Chen, J.; Wu, J.; Song, R.; Mu, S. Single-crystal high-nickel layered cathodes for lithium-ion batteries: Advantages, mechanism, challenges and approaches. Curr. Opin. Electrochem. 2022, 31, 100831. [Google Scholar] [CrossRef]

- Langdon, J.; Manthiram, A. A perspective on single-crystal layered oxide cathodes for lithium-ion batteries. Energy Storage Mater. 2021, 37, 143–160. [Google Scholar] [CrossRef]

- Yu, A.; Xi, Y.; Xu, W.; Wang, A.; Liu, L.; Zhang, L. Fabrication and performance evaluation of the flexible positive temperature coefficient material for self-regulating thermal control. J. Appl. Polym. Sci. 2023, 140, e54311. [Google Scholar] [CrossRef]

- Feng, J.; Yu, A.; Zhang, L.; Liu, F.; Zhan, Z. Adaptive self-preheating lithium-ion battery system based on positive temperature coefficient material at sub-freezing temperatures. Appl. Therm. Eng. 2025, 278, 127319. [Google Scholar] [CrossRef]

- Yu, A.; Li, Q. Temperature-dependent resistivity performance of Mn/Y-doped Ba1-xSrxTiO3 compositions with potential thermal control applications. Ceram. Int. 2020, 46, 8796–8805. [Google Scholar] [CrossRef]

- Yu, A.; Li, Q. Studies on preparation and thermal control behavior of hybrid fillers/binary-polymer composites with positive temperature coefficient characteristic. Sci. China Technol. Sci. 2021, 64, 1447–1458. [Google Scholar] [CrossRef]

- Wang, D.; Wu, Y.; Wu, C.; Ye, Z.; Yang, L.; Li, Y.; Dong, R.; Wu, Z.; Sun, Y.; Song, Y.; et al. Highly oriented {010} crystal plane induced by boron in cobalt-free Li- and Mn-rich layered oxide. ACS Appl. Mater. Interfaces 2022, 14, 2711–2719. [Google Scholar] [CrossRef]

- Cha, H.; Kim, J.; Lee, H.; Kim, N.; Hwang, J.; Sung, J.; Yoon, M.; Kim, K.; Cho, J. Boosting reaction homogeneity in high-energy lithium-ion battery cathode materials. Adv. Mater. 2020, 32, 2003040. [Google Scholar] [CrossRef]

- Wei, W.; Ding, Z.; Chen, C.; Yang, C.; Han, B.; Xiao, L.; Liang, C.; Gao, P.; Cho, K. Surface-dependent stress-corrosion cracking in Ni-rich layered oxide cathodes. Acta Mater. 2021, 212, 116914. [Google Scholar] [CrossRef]

- Pang, P.; Tan, X.; Wang, Z.; Cai, Z.; Nan, J.; Xing, Z.; Li, H. Crack-free single-crystal LiNi0.83Co0.10Mn0.07O2 as cycling/thermal stable cathode materials for high-voltage lithium-ion batteries. Electrochim. Acta 2021, 365, 137380. [Google Scholar] [CrossRef]

- Pan, H.; Jiao, S.; Xue, Z.; Zhang, J.; Xu, X.; Gan, L.; Li, Q.; Liu, Y.; Yu, X.; Li, H.; et al. The roles of Ni and Mn in the thermal stability of lithium-rich manganese-rich oxide cathode. Adv. Energy Mater. 2023, 13, 2203989. [Google Scholar] [CrossRef]

- Sun, Y.K.; Myung, S.T.; Kim, M.H.; Prakash, J.; Amine, K. Synthesis and characterization of Li[(Ni0.8Co0.1Mn0.1)0.8(Ni0.5Mn0.5)0.2]O2 with the microscale core−shell structure as the positive electrode material for lithium batteries. J. Am. Chem. Soc. 2005, 127, 13411–13418. [Google Scholar] [CrossRef] [PubMed]

- Phillips, P.J.; Bareño, J.; Li, Y.; Abraham, D.P.; Klie, R.F. On the localized nature of the structural transformations of Li2MnO3 following electrochemical cycling. Adv. Energy Mater. 2015, 5, 1501252. [Google Scholar] [CrossRef]

- Ben, L.; Yu, H.; Chen, B.; Chen, Y.; Gong, Y.; Yang, X.; Gu, L.; Huang, X. Unusual spinel-to-layered transformation in LiMn2O4 cathode explained by electrochemical and thermal stability investigation. ACS Appl. Mater. Interfaces 2017, 9, 35463–35475. [Google Scholar] [CrossRef]

- Chen, J.; Wang, L.; Fang, B.; Lee, S.; Guo, R. Rotating ring–disk electrode measurements on Mn dissolution and capacity losses of spinel electrodes in various organic electrolytes. J. Power Sources 2006, 157, 515–521. [Google Scholar] [CrossRef]

- Matsui, M.; Dokko, K.; Kanamura, K. Surface layer formation and stripping process on LiMn2O4 and LiNi1/2Mn3/2O4 thin film electrodes. J. Electrochem. Soc. 2010, 157, A121. [Google Scholar] [CrossRef]

- Xu, H.; Zhang, H.; Ma, J.; Xu, G.; Dong, T.; Chen, J.; Cui, G. Overcoming the challenges of 5 V spinel LiNi0.5Mn1.5O4 cathodes with solid polymer electrolytes. ACS Energy Lett. 2019, 4, 2871–2886. [Google Scholar] [CrossRef]

- Ilango, P.R.; Prasanna, K.; Do, S.J.; Jo, Y.N.; Lee, C.W. Eco-friendly nitrogen-containing carbon encapsulated LiMn2O4 cathodes to enhance the electrochemical properties in rechargeable Li-ion batteries. Sci. Rep. 2016, 6, 29826. [Google Scholar] [CrossRef]

- Freiberg, A.T.S.; Sicklinger, J.; Solchenbach, S.; Gasteiger, H.A. Li2CO3 decomposition in Li-ion batteries induced by the electrochemical oxidation of the electrolyte and of electrolyte impurities. Electrochim. Acta 2020, 346, 136271. [Google Scholar] [CrossRef]

- Belov, D.; Yang, M.-H. Failure mechanism of Li-ion battery at overcharge conditions. J. Solid State Electrochem. 2008, 12, 885–894. [Google Scholar] [CrossRef]

- Qi, C.; Zhu, Y.-L.; Gao, F.; Yang, K.; Jiao, Q.-J. Morphology, structure and thermal stability analysis of cathode and anode material under overcharge. J. Electrochem. Soc. 2018, 165, A3985. [Google Scholar] [CrossRef]

- Cai, Z.; Ma, Y.; Huang, X.; Yan, X.; Yu, Z.; Zhang, S.; Song, G.; Xu, Y.; Wen, C.; Yang, W. High electrochemical stability Al-doped spinel LiMn2O4 cathode material for Li-ion batteries. J. Energy Storage 2020, 27, 101036. [Google Scholar] [CrossRef]

- Angelopoulou, P.; Paloukis, F.; Słowik, G.; Wójcik, G.; Avgouropoulos, G. Combustion-synthesized LixMn2O4-based spinel nanorods as cathode materials for lithium-ion batteries. Chem. Eng. J. 2017, 311, 191–202. [Google Scholar] [CrossRef]

- Han, S.C.; Singh, S.P.; Hwang, Y.-h.; Bae, E.G.; Park, B.K.; Sohn, K.-S.; Pyo, M. Gadolinium-doped LiMn2O4 cathodes in Li ion batteries: Understanding the stabilized structure and enhanced electrochemical kinetics. J. Electrochem. Soc. 2012, 159, A1867. [Google Scholar] [CrossRef]

- Amatucci, G.G.; Blyr, A.; Sigala, C.; Alfonse, P.; Tarascon, J.M. Surface treatments of Li1+xMn2−xO4 spinels for improved elevated temperature performance. Solid State Ion. 1997, 104, 13–25. [Google Scholar] [CrossRef]

- Lee, S.W.; Kim, K.S.; Moon, H.S.; Lee, J.P.; Kim, H.J.; Cho, B.W.; Cho, W.I.; Park, J.W. Electrochemical and structural characteristics of metal oxide-coated lithium manganese oxide (spinel type): Part I. In the range of 2.5–4.2V. J. Power Sources 2004, 130, 227–232. [Google Scholar] [CrossRef]

- Xiao, L.; Zhao, Y.; Yang, Y.; Cao, Y.; Ai, X.; Yang, H. Enhanced electrochemical stability of Al-doped LiMn2O4 synthesized by a polymer-pyrolysis method. Electrochim. Acta 2008, 54, 545–550. [Google Scholar] [CrossRef]

- Bang, H.J.; Donepudi, V.S.; Prakash, J. Preparation and characterization of partially substituted LiMyMn2−yO4 (M=Ni, Co, Fe) spinel cathodes for Li-ion batteries. Electrochim. Acta 2002, 48, 443–451. [Google Scholar] [CrossRef]

- Wang, S.; Jiang, S.; Li, Y.; Tan, Z.; Hao, S.; Yang, J.; He, Z. Interface dual-engineering strategy boosting the excellent high-temperature electrochemical properties of LiMn2O4. J. Power Sources 2023, 579, 233292. [Google Scholar] [CrossRef]

- Zhao, S.; Bai, Y.; Ding, L.; Wang, B.; Zhang, W. Enhanced cycling stability and thermal stability of YPO4-coated LiMn2O4 cathode materials for lithium ion batteries. Solid State Ion. 2013, 247–248, 22–29. [Google Scholar] [CrossRef]

- Zhao, S.; Bai, Y.; Chang, Q.; Yang, Y.; Zhang, W. Surface modification of spinel LiMn2O4 with FeF3 for lithium ion batteries. Electrochim. Acta 2013, 108, 727–735. [Google Scholar] [CrossRef]

- Zhao, S.; Chang, Q.; Jiang, K.; Bai, Y.; Yang, Y.; Zhang, W. Performance improvement of spinel LiMn2O4 cathode material by LaF3 surface modification. Solid State Ion. 2013, 253, 1–7. [Google Scholar] [CrossRef]

- Cho, J.; Kim, G. Enhancement of thermal stability of LiCoO2 by LiMn2O4 coating. Electrochem. Solid-State Lett. 1999, 2, 253. [Google Scholar] [CrossRef]

- Qiu, T.; Wang, J.; Lu, Y.; Yang, W. Improved elevated temperature performance of commercial LiMn2O4 coated with LiNi0.5Mn1.5O4. Electrochim. Acta 2014, 147, 626–635. [Google Scholar] [CrossRef]

- Chae, Y.; Lee, J.K.; Choi, W. Surface coating of spinel LiMn2O4 cathode electrode with lithium–nickel–manganese-oxide by RF sputtering method for lithium-ion batteries. J. Electroanal. Chem. 2014, 730, 20–25. [Google Scholar] [CrossRef]

- Tomon, C.; Sarawutanukul, S.; Phattharasupakun, N.; Duangdangchote, S.; Chomkhuntod, P.; Joraleechanchai, N.; Bunyanidhi, P.; Sawangphruk, M. Core-shell structure of LiMn2O4 cathode material reduces phase transition and Mn dissolution in Li-ion batteries. Commun. Chem. 2022, 5, 54. [Google Scholar] [CrossRef]

- Fallah, N.; Fitzpatrick, C. Is shifting from Li-ion NMC to LFP in EVs beneficial for second-life storages in electricity markets? J. Energy Storage 2023, 68, 107740. [Google Scholar] [CrossRef]

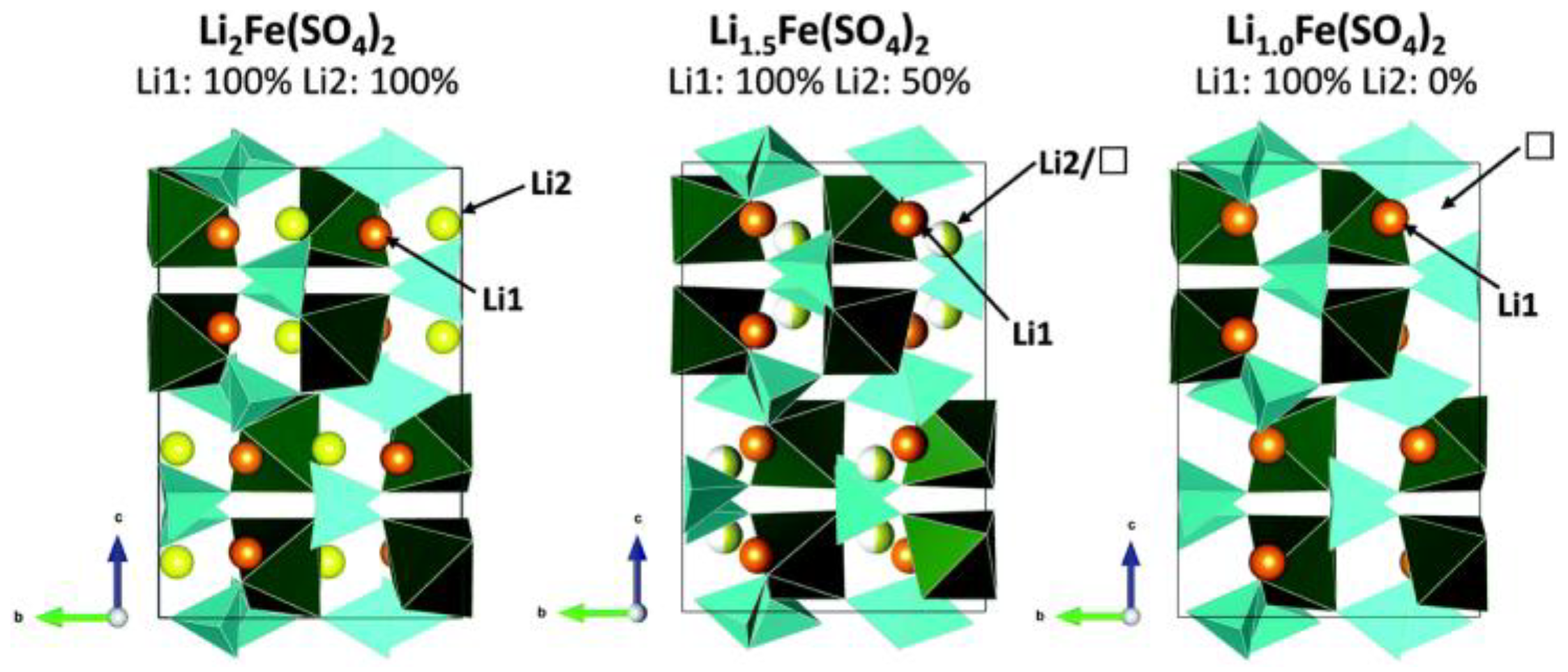

- Ivanishchev, A.V.; Gridina, N.A.; Rybakov, K.S.; Ivanishcheva, I.A.; Dixit, A. Structural and electrochemical investigation of lithium ions insertion processes in polyanionic compounds of lithium and transition metals. J. Electroanal. Chem. 2020, 860, 113894. [Google Scholar] [CrossRef]

- Lander, L.; Reynaud, M.; Carrasco, J.; Katcho, N.A.; Bellin, C.; Polian, A.; Baptiste, B.; Rousse, G.; Tarascon, J.M. Unveiling the electrochemical mechanisms of Li2Fe(SO4)2 polymorphs by neutron diffraction and density functional theory calculations. PCCP 2016, 18, 14509–14519. [Google Scholar] [CrossRef] [PubMed]

- Hautier, G.; Jain, A.; Ong, S.P.; Kang, B.; Moore, C.; Doe, R.; Ceder, G. Phosphates as lithium-ion battery cathodes: An evaluation based on high-throughput ab initio calculations. Chem. Mater. 2011, 23, 3495–3508. [Google Scholar] [CrossRef]

- Ong, S.P.; Jain, A.; Hautier, G.; Kang, B.; Ceder, G. Thermal stabilities of delithiated olivine MPO4 (M=Fe, Mn) cathodes investigated using first principles calculations. Electrochem. Commun. 2010, 12, 427–430. [Google Scholar] [CrossRef]

- Nitta, N.; Wu, F.; Lee, J.T.; Yushin, G. Li-ion battery materials: Present and future. Mater. Today 2015, 18, 252–264. [Google Scholar] [CrossRef]

- Vetter, J.; Novák, P.; Wagner, M.R.; Veit, C.; Möller, K.C.; Besenhard, J.O.; Winter, M.; Wohlfahrt-Mehrens, M.; Vogler, C.; Hammouche, A. Ageing mechanisms in lithium-ion batteries. J. Power Sources 2005, 147, 269–281. [Google Scholar] [CrossRef]

- Raji, A.R.O.; Villegas Salvatierra, R.; Kim, N.D.; Fan, X.; Li, Y.; Silva, G.A.L.; Sha, J.; Tour, J.M. Lithium batteries with nearly maximum metal storage. ACS Nano 2017, 11, 6362–6369. [Google Scholar] [CrossRef]

- Aurbach, D.; Markovsky, B.; Weissman, I.; Levi, E.; Ein-Eli, Y. On the correlation between surface chemistry and performance of graphite negative electrodes for Li ion batteries. Electrochim. Acta 1999, 45, 67–86. [Google Scholar] [CrossRef]

- Parimalam, B.S.; MacIntosh, A.D.; Kadam, R.; Lucht, B.L. Decomposition reactions of anode solid electrolyte interphase (SEI) components with LiPF6. J. Phys. Chem. C 2017, 121, 22733–22738. [Google Scholar] [CrossRef]

- Park, M.S.; Lee, J.; Lee, J.W.; Kim, K.J.; Jo, Y.N.; Woo, S.G.; Kim, Y.J. Tuning the surface chemistry of natural graphite anode by H3PO4 and H3BO3 treatments for improving electrochemical and thermal properties. Carbon 2013, 62, 278–287. [Google Scholar] [CrossRef]

- Gribble, D.A.; McCulfor, E.; Li, Z.; Parekh, M.; Pol, V.G. Enhanced capacity and thermal safety of lithium-ion battery graphite anodes with conductive binder. J. Power Sources 2023, 553, 232204. [Google Scholar] [CrossRef]

- Rhee, D.Y.; Kim, J.; Moon, J.; Park, M.-S. Off-stoichiometric TiO2-x-decorated graphite anode for high-power lithium-ion batteries. J. Alloys Compd. 2020, 843, 156042. [Google Scholar] [CrossRef]

- Choi, J.W.; Aurbach, D. Promise and reality of post-lithium-ion batteries with high energy densities. Nat. Rev. Mater. 2016, 1, 16013. [Google Scholar] [CrossRef]

- Yoon, T.; Milien, M.S.; Parimalam, B.S.; Lucht, B.L. Thermal decomposition of the solid electrolyte interphase (SEI) on silicon electrodes for lithium ion batteries. Chem. Mater. 2017, 29, 3237–3245. [Google Scholar] [CrossRef]

- Park, H.; Yoon, T.; Kim, Y.; Lee, J.G.; Kim, J.; Kim, H.-S.; Ryu, J.H.; Kim, J.J.; Oh, S.M. Thermal behavior of solid electrolyte interphase films deposited on graphite electrodes with different states-of-charge. J. Electrochem. Soc. 2015, 162, A892. [Google Scholar] [CrossRef]

- Wu, X.R.; Yu, C.H.; Li, C.C. Carbon-encapsulated gigaporous microsphere as potential Si anode-active material for lithium-ion batteries. Carbon 2020, 160, 255–264. [Google Scholar] [CrossRef]

- Guan, P.; Zhang, W.; Li, C.; Han, N.; Wang, X.; Li, Q.; Song, G.; Peng, Z.; Li, J.; Zhang, L.; et al. Low-cost urchin-like silicon-based anode with superior conductivity for lithium storage applications. J. Colloid Interface Sci. 2020, 575, 150–157. [Google Scholar] [CrossRef]

- Ha, J.; Haridas, A.K.; Cho, G.; Ahn, H.; Ahn, J.; Cho, K. Nano silicon encapsulated in modified copper as an anode for high performance lithium ion battery. Appl. Surf. Sci. 2019, 481, 307–312. [Google Scholar] [CrossRef]

- Tian, K.; Song, Z.; Zhou, Q.; Guan, C.; Lu, M.; Zhang, M.; Wei, D.; Li, X. Silicon-carbon anode with high interfacial stability by a facile thermal reaction involving alkaline nitrogenous carbon source for lithium ion batteries. J. Energy Storage 2023, 72, 108401. [Google Scholar] [CrossRef]

- Zhou, R.; Fan, R.; Tian, Z.; Zhou, Y.; Guo, H.; Kou, L.; Zhang, D. Preparation and characterization of core–shell structure Si/C composite with multiple carbon phases as anode materials for lithium ion batteries. J. Alloys Compd. 2016, 658, 91–97. [Google Scholar] [CrossRef]

- Jiang, B.; Zeng, S.; Wang, H.; Liu, D.; Qian, J.; Cao, Y.; Yang, H.; Ai, X. Dual core–shell structured Si@SiOx@C nanocomposite synthesized via a one-step pyrolysis method as a highly stable anode material for lithium-ion batteries. ACS Appl. Mater. Interfaces 2016, 8, 31611–31616. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.Z.; Xie, L.J.; Tang, Y.; Li, Y.; Jiang, J.C.; Huang, A.C. Thermal safety evaluation of silane polymer compounds as electrolyte additives for silicon-based anode lithium-ion batteries. Processes 2022, 10, 1581. [Google Scholar] [CrossRef]

- Profatilova, I.A.; Stock, C.; Schmitz, A.; Passerini, S.; Winter, M. Enhanced thermal stability of a lithiated nano-silicon electrode by fluoroethylene carbonate and vinylene carbonate. J. Power Sources 2013, 222, 140–149. [Google Scholar] [CrossRef]

- Tan, T.; Lee, P.-K.; Marium, M.; Zettsu, N.; Yu, D.Y.W. (3-Aminopropyl)triethoxysilane as an electrolyte additive for enhancing the thermal stability of silicon anode in lithium-ion batteries. ACS Appl. Energy Mater. 2022, 5, 11254–11262. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, L.; Zheng, T.; Lam, K.-H. Synthesis, Electrochemistry, and Thermal Stability of High-Energy Ball-Milled Silicon-based Alloy Anodes in Lithium-Ion Batteries. Batter. Supercaps 2023, 6, e202200495. [Google Scholar] [CrossRef]

- Profatilova, I.A.; Langer, T.; Badillo, J.P.; Schmitz, A.; Orthner, H.; Wiggers, H.; Passerini, S.; Winter, M. Thermally induced reactions between lithiated nano-silicon electrode and electrolyte for lithium-ion batteries. J. Electrochem. Soc. 2012, 159, A657. [Google Scholar] [CrossRef]

- Guo, M.-J.; Xiang, C.; Hu, Y.-Y.; Deng, L.; Pan, S.; Lv, C.; Chen, S.; Deng, H.; Sun, C.; Li, J.; et al. A dual force cross-linked γ-PGA-PAA binder enhancing the cycle stability of silicon-based anodes for lithium-ion batteries. Electrochim. Acta 2022, 425, 140704. [Google Scholar] [CrossRef]

- Shen, X.; Liu, H.; Cheng, X.B.; Yan, C.; Huang, J.Q. Beyond lithium ion batteries: Higher energy density battery systems based on lithium metal anodes. Energy Storage Mater. 2018, 12, 161–175. [Google Scholar] [CrossRef]

- Umh, H.N.; Park, J.; Yeo, J.; Jung, S.; Nam, I.; Yi, J. Lithium metal anode on a copper dendritic superstructure. Electrochem. Commun. 2019, 99, 27–31. [Google Scholar] [CrossRef]

- Eshetu, G.G.; Judez, X.; Li, C.; Bondarchuk, O.; Rodriguez-Martinez, L.M.; Zhang, H.; Armand, M. Lithium azide as an electrolyte additive for all-solid-state lithium-sulfur batteries. Angew. Chem. Int. Ed. 2017, 56, 15368–15372. [Google Scholar] [CrossRef]

- Ye, H.; Yin, Y.X.; Zhang, S.F.; Shi, Y.; Liu, L.; Zeng, X.X.; Wen, R.; Guo, Y.G.; Wan, L.J. Synergism of Al-containing solid electrolyte interphase layer and Al-based colloidal particles for stable lithium anode. Nano Energy 2017, 36, 411–417. [Google Scholar] [CrossRef]

- Tarascon, J.M.; Armand, M. Issues and challenges facing rechargeable lithium batteries. Nature 2001, 414, 359–367. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Liu, H.; Liang, Y.; Li, D.; Zhao, X.; Chen, J.; Huang, W.; Gao, L.; Fan, L.-Z. Molecular-level designed polymer electrolyte for high-voltage lithium-metal solid-state batteries. Adv. Funct. Mater. 2023, 33, 2209828. [Google Scholar] [CrossRef]

- Fan, X.; Ji, X.; Han, F.; Yue, J.; Chen, J.; Chen, L.; Deng, T.; Jiang, J.; Wang, C. Fluorinated solid electrolyte interphase enables highly reversible solid-state Li metal battery. Sci. Adv. 2018, 4, eaau9245. [Google Scholar] [CrossRef]

- Luo, J.; Fang, C.C.; Wu, N.L. High polarity poly(vinylidene difluoride) thin coating for dendrite-free and high-performance lithium metal anodes. Adv. Energy Mater. 2018, 8, 1701482. [Google Scholar] [CrossRef]

- Li, N.W.; Shi, Y.; Yin, Y.X.; Zeng, X.X.; Li, J.Y.; Li, C.J.; Wan, L.J.; Wen, R.; Guo, Y.G. A flexible solid electrolyte interphase layer for long-life lithium metal anodes. Angew. Chem. Int. Ed. 2018, 57, 1505–1509. [Google Scholar] [CrossRef]

- Hou, G.; Ma, X.; Sun, Q.; Ai, Q.; Xu, X.; Chen, L.; Li, D.; Chen, J.; Zhong, H.; Li, Y.; et al. Lithium dendrite suppression and enhanced interfacial compatibility enabled by an Ex situ SEI on Li anode for LAGP-based all-solid-state batteries. ACS Appl. Mater. Interfaces 2018, 10, 18610–18618. [Google Scholar] [CrossRef]

- Peng, Z.; Zhao, N.; Zhang, Z.; Wan, H.; Lin, H.; Liu, M.; Shen, C.; He, H.; Guo, X.; Zhang, J.-G.; et al. Stabilizing Li/electrolyte interface with a transplantable protective layer based on nanoscale LiF domains. Nano Energy 2017, 39, 662–672. [Google Scholar] [CrossRef]

- Zhuang, H.; Zhao, P.; Li, G.; Xu, Y.; Jia, X. Li–LiAl alloy composite with memory effect as high-performance lithium metal anode. J. Power Sources 2020, 455, 227977. [Google Scholar] [CrossRef]

- Zaghib, K.; Gauthier, M.; Armand, M. Expanded metal a novel anode for Li-ion polymer batteries. J. Power Sources 2003, 119–121, 76–83. [Google Scholar] [CrossRef]

- Kong, L.L.; Wang, L.; Ni, Z.C.; Liu, S.; Li, G.R.; Gao, X.P. Lithium-magnesium alloy as a stable anode for lithium-sulfur battery. Adv. Funct. Mater. 2019, 29, 1808756. [Google Scholar] [CrossRef]

- Wang, H.; Yoshio, M.; Abe, T.; Ogumi, Z. Characterization of carbon-coated natural graphite as a lithium-ion battery anode material. J. Electrochem. Soc. 2002, 149, A499. [Google Scholar] [CrossRef]

- Tan, T.; Lee, P.-K.; Yu, D.Y.W. Improving thermal stability of Si-based anodes for lithium-ion batteries by controlling bulk and surface layer compositions. J. Electrochem. Soc. 2021, 168, 100527. [Google Scholar] [CrossRef]

- Tao, J.; Lu, L.; Wu, B.; Fan, X.; Yang, Y.; Li, J.; Lin, Y.; Li, Y.Y.; Huang, Z.; Lu, J. Dramatic improvement enabled by incorporating thermal conductive TiN into Si-based anodes for lithium ion batteries. Energy Storage Mater. 2020, 29, 367–376. [Google Scholar] [CrossRef]

- Ryou, M.H.; Lee, Y.M.; Park, J.K.; Choi, J.W. Mussel-inspired polydopamine-treated polyethylene separators for high-power Li-ion batteries. Adv. Mater. 2011, 23, 3066–3070. [Google Scholar] [CrossRef]

- Liu, L.; Wang, Y.; Gao, C.; Yang, C.; Wang, K.; Li, H.; Gu, H. Ultrathin ZrO2-coated separators based on surface sol-gel process for advanced lithium ion batteries. J. Membr. Sci. 2019, 592, 117368. [Google Scholar] [CrossRef]

- Wang, Z.; Guo, F.; Chen, C.; Shi, L.; Yuan, S.; Sun, L.; Zhu, J. Self-assembly of PEI/SiO2 on polyethylene separators for Li-ion batteries with enhanced rate capability. ACS Appl. Mater. Interfaces 2015, 7, 3314–3322. [Google Scholar] [CrossRef]

- Luo, L.; Gao, Z.; Zheng, Z.; Zhang, J. “Polymer-in-ceramic” membrane for thermally safe separator applications. ACS Omega 2022, 7, 35727–35734. [Google Scholar] [CrossRef]

- Zheng, H.; Wang, Z.; Shi, L.; Zhao, Y.; Yuan, S. Enhanced thermal stability and lithium ion conductivity of polyethylene separator by coating colloidal SiO2 nanoparticles with porous shell. J. Colloid Interface Sci. 2019, 554, 29–38. [Google Scholar] [CrossRef] [PubMed]

- Su, M.; Chen, Y.; Wang, S.; Wang, H. Bifunctional separator with high thermal stability and lithium dendrite inhibition toward high safety lithium-ion batteries. Chin. Chem. Lett. 2023, 34, 107553. [Google Scholar] [CrossRef]

- Zhu, X.; Jiang, X.; Ai, X.; Yang, H.; Cao, Y. A highly thermostable ceramic-grafted microporous polyethylene separator for safer lithium-ion batteries. ACS Appl. Mater. Interfaces 2015, 7, 24119–24126. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.; Chen, D.; Boateng, B.; Zeng, G.; Han, Y.; Zhen, C.; Goodenough, J.B.; He, W. Atomic interlamellar ion path in polymeric separator enables long-life and dendrite-free anode in lithium ion batteries. J. Power Sources 2020, 451, 227773. [Google Scholar] [CrossRef]

- Song, X.; Yao, X.; Zhang, F.; Ang, E.H.; Rong, S.; Zhao, K.; He, K.; Xiang, H. Nanofiber membrane coated with lithiophilic polydopamine for lithium metal batteries. J. Membr. Sci. 2023, 685, 121951. [Google Scholar] [CrossRef]

- Kong, L.; Yan, Y.; Qiu, Z.; Zhou, Z.; Hu, J. Robust fluorinated polyimide nanofibers membrane for high-performance lithium-ion batteries. J. Membr. Sci. 2018, 549, 321–331. [Google Scholar] [CrossRef]

- Tang, W.; Liu, Q.; Luo, N.; Chen, F.; Fu, Q. High safety and electrochemical performance electrospun para-aramid nanofiber composite separator for lithium-ion battery. Compos. Sci. Technol. 2022, 225, 109479. [Google Scholar] [CrossRef]

- Jiang, W.; Liu, Z.; Kong, Q.; Yao, J.; Zhang, C.; Han, P.; Cui, G. A high temperature operating nanofibrous polyimide separator in Li-ion battery. Solid State Ion. 2013, 232, 44–48. [Google Scholar] [CrossRef]

- Ma, X.; Kolla, P.; Yang, R.; Wang, Z.; Zhao, Y.; Smirnova, A.L.; Fong, H. Electrospun polyacrylonitrile nanofibrous membranes with varied fiber diameters and different membrane porosities as lithium-ion battery separators. Electrochim. Acta 2017, 236, 417–423. [Google Scholar] [CrossRef]

- Deng, J.; Cao, D.; Yang, X.; Zhang, G. Cross-linked cellulose/carboxylated polyimide nanofiber separator for lithium-ion battery application. Chem. Eng. J. 2022, 433, 133934. [Google Scholar] [CrossRef]

- Yu, H.; Shi, Y.; Yuan, B.; He, Y.; Qiao, L.; Wang, J.; Lin, Q.; Chen, Z.; Han, E. Recent developments of polyimide materials for lithium-ion battery separators. Ionics 2021, 27, 907–923. [Google Scholar] [CrossRef]

- Li, M.; Sheng, L.; Xu, R.; Yang, Y.; Bai, Y.; Song, S.; Liu, G.; Wang, T.; Huang, X.; He, J. Enhanced the mechanical strength of polyimide (PI) nanofiber separator via PAALi binder for lithium ion battery. Compos. Commun. 2021, 24, 100607. [Google Scholar] [CrossRef]

- Zhang, J.; Yue, L.; Kong, Q.; Liu, Z.; Zhou, X.; Zhang, C.; Pang, S.; Wang, X.; Yao, J.; Cui, G. A heat-resistant silica nanoparticle enhanced polysulfonamide nonwoven separator for high-performance lithium ion battery. J. Electrochem. Soc. 2013, 160, A769. [Google Scholar] [CrossRef]

- Xiao, K.; Zhai, Y.; Yu, J.; Ding, B. Nanonet-structured poly(m-phenylene isophthalamide)–polyurethane membranes with enhanced thermostability and wettability for high power lithium ion batteries. RSC Adv. 2015, 5, 55478–55485. [Google Scholar] [CrossRef]

- Liu, Q.; Jiang, W.; Lu, W.; Mei, Y.; He, F.; Zhang, M.; Liu, Y.; Chen, Y.; Peng, J.; Ding, Y. Anisotropic semi-aligned PAN@PVdF-HFP separator for Li-ion batteries. Nanotechnology 2020, 31, 435701. [Google Scholar] [CrossRef]

- Moon, J.; Jeong, J.Y.; Kim, J.I.; Kim, S.; Park, J.H. An ultrathin inorganic-organic hybrid layer on commercial polymer separators for advanced lithium-ion batteries. J. Power Sources 2019, 416, 89–94. [Google Scholar] [CrossRef]

- Zhang, P.; Chen, L.; Shi, C.; Yang, P.; Zhao, J. Development and characterization of silica tube-coated separator for lithium ion batteries. J. Power Sources 2015, 284, 10–15. [Google Scholar] [CrossRef]

- Wang, J.; Hu, Z.; Yin, X.; Li, Y.; Huo, H.; Zhou, J.; Li, L. Alumina/phenolphthalein polyetherketone ceramic composite polypropylene separator film for lithium ion power batteries. Electrochim. Acta 2015, 159, 61–65. [Google Scholar] [CrossRef]

- Janakiraman, S.; Khalifa, M.; Biswal, R.; Ghosh, S.; Anandhan, S.; Venimadhav, A. High performance electrospun nanofiber coated polypropylene membrane as a separator for sodium ion batteries. J. Power Sources 2020, 460, 228060. [Google Scholar] [CrossRef]

- Rahman, M.M.; Mateti, S.; Cai, Q.; Sultana, I.; Fan, Y.; Wang, X.; Hou, C.; Chen, Y. High temperature and high rate lithium-ion batteries with boron nitride nanotubes coated polypropylene separators. Energy Storage Mater. 2019, 19, 352–359. [Google Scholar] [CrossRef]

- Dong, G.; Dong, N.; Liu, B.; Tian, G.; Qi, S.; Wu, D. Ultrathin inorganic-nanoshell encapsulation: TiO2 coated polyimide nanofiber membrane enabled by layer-by-layer deposition for advanced and safe high-power LIB separator. J. Membr. Sci. 2020, 601, 117884. [Google Scholar] [CrossRef]

- Zhang, D.; Ding, L.; Wu, T.; Yang, F.; Lan, F.; Cao, Y.; Xiang, M. Facile preparation of a lithium-ion battery separator with thermal shutdown function based on polypropylene/polyethylene microsphere composites. Ind. Eng. Chem. Res. 2021, 60, 18530–18539. [Google Scholar] [CrossRef]

- Ma, S.; Lin, H.; Yang, L.; Tong, Q.; Pan, F.; Weng, J.; Zheng, S. High thermal stability and low impedance polypropylene separator coated with aluminum phosphate. Electrochim. Acta 2019, 320, 134528. [Google Scholar] [CrossRef]

- Zhao, H.; Deng, N.; Yan, J.; Kang, W.; Ju, J.; Wang, L.; Li, Z.; Cheng, B. Effect of octaphenyl polyhedral oligomeric silsesquioxane on the electrospun poly-m-phenylene isophthalamid separators for lithium-ion batteries with high safety and excellent electrochemical performance. Chem. Eng. J. 2019, 356, 11–21. [Google Scholar] [CrossRef]

- Li, H.; Feng, T.; Liang, Y.; Wu, M. Construction of PMIA@PAN/PVDF-HFP/TiO2 coaxial fibrous separator with enhanced mechanical strength and electrolyte affinity for lithium-ion batteries. Chin. Chem. Lett. 2023, 34, 108350. [Google Scholar] [CrossRef]

- Leng, X.; Yang, M.; Li, C.; Arifeen, W.U.; Ko, T.J. High-performance separator for lithium-ion battery based on dual-hybridizing of materials and processes. Chem. Eng. J. 2022, 433, 133773. [Google Scholar] [CrossRef]

- Zhao, H.; Kang, W.; Deng, N.; Liu, M.; Cheng, B. A fresh hierarchical-structure gel poly-m-phenyleneisophthalamide nanofiber separator assisted by electronegative nanoclay-filler towards high-performance and advanced-safety lithium-ion battery. Chem. Eng. J. 2020, 384, 123312. [Google Scholar] [CrossRef]

- Kong, L.; Wang, Y.; Yu, H.; Liu, B.; Qi, S.; Wu, D.; Zhong, W.-H.; Tian, G.; Wang, J. In situ armoring: A robust, high-wettability, and fire-resistant hybrid separator for advanced and safe batteries. ACS Appl. Mater. Interfaces 2019, 11, 2978–2988. [Google Scholar] [CrossRef]

- Zhao, H.; Yan, J.; Deng, N.; Kang, W.; Cheng, B. A versatile nano-TiO2 decorated gel separator with derived multi-scale nanofibers towards dendrite-blocking and polysulfide-inhibiting lithium-metal batteries. J. Energy Chem. 2021, 55, 190–201. [Google Scholar] [CrossRef]

- Tian, X.; Yi, Y.; Fang, B.; Yang, P.; Wang, T.; Liu, P.; Qu, L.; Li, M.; Zhang, S. Design strategies of safe electrolytes for preventing thermal runaway in lithium ion batteries. Chem. Mater. 2020, 32, 9821–9848. [Google Scholar] [CrossRef]

- Liu, Q.; Yang, G.; Liu, S.; Han, M.; Wang, Z.; Chen, L. Trimethyl borate as film-forming electrolyte additive to improve high-voltage performances. ACS Appl. Mater. Interfaces 2019, 11, 17435–17443. [Google Scholar] [CrossRef]

- Kim, C.-K.; Shin, D.-S.; Kim, K.; Shin, K.; Woo, J.-J.; Kim, S.; Hong, S.Y.; Choi, N.S. Fluorinated hyperbranched cyclotriphosphazene simultaneously enhances the safety and electrochemical performance of high-voltage lithium-ion batteries. ChemElectroChem 2016, 3, 913–921. [Google Scholar] [CrossRef]

- Xiao, Z.; Liu, J.; Fan, G.; Yu, M.; Liu, J.; Gou, X.; Yuan, M.; Cheng, F. Lithium bis(oxalate)borate additive in the electrolyte to improve Li-rich layered oxide cathode materials. Mater. Chem. Front. 2020, 4, 1689–1696. [Google Scholar] [CrossRef]

- Wang, X.; Yasukawa, E.; Kasuya, S. Nonflammable trimethyl phosphate solvent-containing electrolytes for lithium-ion batteries: I. fundamental properties. J. Electrochem. Soc. 2001, 148, A1058. [Google Scholar] [CrossRef]

- Shim, E.G.; Nam, T.H.; Kim, J.G.; Kim, H.S.; Moon, S.I. Diphenyloctyl phosphate as a flame-retardant additive in electrolyte for Li-ion batteries. J. Power Sources 2008, 175, 533–539. [Google Scholar] [CrossRef]

- Zhong, L.; Li, Z.; Wang, S.; Huang, S. Ultra-thin solid electrolyte in lithium-ion batteries. Sustain. Polym. Energy 2023, 1, 10004. [Google Scholar] [CrossRef]

- Avdeev, M. Crystal Chemistry of NaSICONs: Ideal Framework, Distortion, and Connection to Properties. Chem. Mater. 2021, 33, 7620–7632. [Google Scholar] [CrossRef]

- Akkinepally, B.; Reddy, I.N.; Ko, T.J.; Yoo, K.; Shim, J. Dopant effect on Li+ ion transport in NASICON-type solid electrolyte: Insights from molecular dynamics simulations and experiments. Ceram. Int. 2022, 48, 12142–12151. [Google Scholar] [CrossRef]

- Kaup, K.; Zhou, L.; Huq, A.; Nazar, L.F. Impact of the Li substructure on the diffusion pathways in alpha and beta Li3PS4: An in situ high temperature neutron diffraction study. J. Mater. Chem. A 2020, 8, 12446–12456. [Google Scholar] [CrossRef]

- Dawson, J.A.; Islam, M.S. A nanoscale design approach for enhancing the Li-ion conductivity of the Li10GeP2S12 solid electrolyte. ACS Mater. Lett. 2022, 4, 424–431. [Google Scholar] [CrossRef]

- Sun, Y.; Zhang, X.; Xu, P.; Liu, Y.; Dong, F.; Ma, C.; Liu, J.; Xie, H. Perfluoropolyether-based block copolymer electrolytes enabling high-temperature-resistant solid-state lithium metal batteries. J. Power Sources 2023, 561, 232751. [Google Scholar] [CrossRef]

- Wang, W.H.; Su, W.; Hu, S.Y.; Huang, Y.; Pan, Y.; Chang, S.C.; Shu, C.M. Pyrolysis characteristics and kinetics of polymethylmethacrylate-based polymer electrolytes for lithium-ion battery. J. Therm. Anal. Calorim. 2022, 147, 12019–12032. [Google Scholar] [CrossRef]

- Kanno, R.; Takeda, Y.; Matsumoto, A.; Yamamoto, O.; Suyama, R.; Kume, S. Synthesis, structure, ionic conductivity, and phase transformation of new double chloride spinel, Li2CrCl4. J. Solid State Chem. 1988, 75, 41–51. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, S.; Li, H.; Chen, L.; Wu, F. Progress in thermal stability of all-solid-state-Li-ion-batteries. InfoMat 2021, 3, 827–853. [Google Scholar] [CrossRef]

- Geng, H.; Chen, K.; Yi, D.; Mei, A.; Huang, M.; Lin, Y.; Nan, C. Formation mechanism of garnet-like Li7La3Zr2O12 powder prepared by solid state reaction. Rare Met. Mater. Eng. 2016, 45, 612–616. [Google Scholar] [CrossRef]

- Qin, Z.; Xie, Y.; Meng, X.; Shan, C.; He, G.; Qian, D.; Mao, D.; Wan, L.; Huang, Y. High cycling stability enabled by Li vacancy regulation in Ta-doped garnet-type solid-state electrolyte. J. Eur. Ceram. Soc. 2023, 43, 2023–2032. [Google Scholar] [CrossRef]

- Luo, Y.; Li, X.; Zhang, Y.; Ge, L.; Chen, H.; Guo, L. Electrochemical properties and structural stability of Ga- and Y- co-doping in Li7La3Zr2O12 ceramic electrolytes for lithium-ion batteries. Electrochim. Acta 2019, 294, 217–225. [Google Scholar] [CrossRef]

- Brant, J.A.; Massi, D.M.; Holzwarth, N.A.W.; MacNeil, J.H.; Douvalis, A.P.; Bakas, T.; Martin, S.W.; Gross, M.D.; Aitken, J.A. Fast lithium ion conduction in Li2SnS3: Synthesis, physicochemical characterization, and electronic structure. Chem. Mater. 2015, 27, 189–196. [Google Scholar] [CrossRef]

- Calpa, M.; Rosero-Navarro, N.C.; Miura, A.; Jalem, R.; Tateyama, Y.; Tadanaga, K. Chemical stability of Li4PS4I solid electrolyte against hydrolysis. Appl. Mater. Today 2021, 22, 100918. [Google Scholar] [CrossRef]

- Ramesh, S.; Ng, H.M. An investigation on PAN–PVC–LiTFSI based polymer electrolytes system. Solid State Ion. 2011, 192, 2–5. [Google Scholar] [CrossRef]

- Naranjo-Balseca, J.M.; Martínez-Cisneros, C.S.; Pandit, B.; Várez, A. High performance NASICON ceramic electrolytes produced by tape-casting and low temperature hot-pressing: Towards sustainable all-solid-state sodium batteries operating at room temperature. J. Eur. Ceram. Soc. 2023, 43, 4826–4836. [Google Scholar] [CrossRef]

- Peng, Q.; Zhao, H.; Liu, X.; Fang, Y.; Zeng, X. Battery thermal management system design and control strategy study for hybrid electric vehicles. In Proceedings of the 2014 IEEE Conference and Expo Transportation Electrification Asia-Pacific (ITEC Asia-Pacific), Beijing, China, 31 August–3 September 2014; pp. 1–4. [Google Scholar]

- Zhu, H.; Zhang, Y.; Li, M.; Luo, J.; Wei, W.; Zhang, S. Constructing a stable interface by 2,4,6-trimethoxyboroxine as an electrolyte additive for Li-rich layered oxide cathode under high voltage. J. Electroanal. Chem. 2021, 899, 115682. [Google Scholar] [CrossRef]

- Zhu, Y.; Luo, X.; Zhi, H.; Liao, Y.; Xing, L.; Xu, M.; Liu, X.; Xu, K.; Li, W. Diethyl(thiophen-2-ylmethyl)phosphonate: A novel multifunctional electrolyte additive for high voltage batteries. J. Mater. Chem. A 2018, 6, 10990–11004. [Google Scholar] [CrossRef]

- Qin, M.; Zeng, Z.; Wu, Q.; Liu, X.; Liu, Q.; Cheng, S.; Xie, J. 1,3,5-trifluorobenzene endorsed EC-free electrolyte for high-voltage and wide-temperature lithium-ion batteries. J. Energy Chem. 2023, 85, 49–57. [Google Scholar] [CrossRef]

- Miara, L.; Windmüller, A.; Tsai, C.L.; Richards, W.D.; Ma, Q.; Uhlenbruck, S.; Guillon, O.; Ceder, G. About the compatibility between high voltage spinel cathode materials and solid oxide electrolytes as a function of temperature. ACS Appl. Mater. Interfaces 2016, 8, 26842–26850. [Google Scholar] [CrossRef] [PubMed]

- Bandyopadhyay, S.; Gupta, A.; Srivastava, R.; Nandan, B. Bio-inspired design of electrospun poly(acrylonitrile) and novel ionene based nanofibrous mats as highly flexible solid state polymer electrolyte for lithium batteries. Chem. Eng. J. 2022, 440, 135926. [Google Scholar] [CrossRef]

- Sivaraj, P.; Abhilash, K.P.; Nalini, B.; Perumal, P.; Selvin, P.C. Free-standing, high Li-ion conducting hybrid PAN/PVdF/LiClO4/Li0.5La0.5TiO3 nanocomposite solid polymer electrolytes for all-solid-state batteries. J. Solid State Electrochem. 2021, 25, 905–917. [Google Scholar] [CrossRef]

- Hu, J.; He, P.; Zhang, B.; Wang, B.; Fan, L. Porous film host-derived 3D composite polymer electrolyte for high-voltage solid state lithium batteries. Energy Storage Mater. 2020, 26, 283–289. [Google Scholar] [CrossRef]

| Material | Surface Coating | Surface Doping | Charging Voltage (V) | Heat Flow | Heat Release Onset (Peak) Temperature | Ref. |

|---|---|---|---|---|---|---|

| LiNi0.8Co0.1Mn0.1O2 | - | Mn | 4.3 | Consistent | +5 °C (+10 °C) | [40] |

| LiNi0.6Co0.2Mn0.2O2 | SiO2 | - | 4.3 | −35% | +15 °C (+13 °C) | [41] |

| LiNi0.6Co0.2Mn0.2O2 | TiO2 | - | 4.5 | −20% | +10 °C (+8 °C) | [42] |

| LiCoO2 | Al2O3 | - | 4.3 | −50% | +20 °C (−10 °C) | [43] |

| AlPO4 | - | 4.3 | −70% | +60 °C (+20 °C) | ||

| Li1-x[Ni1/3Co1/3Mn1/3]O2 | AlF3 | - | 4.5 | −15% | +20 °C (+15 °C) | [44] |

| LiNi0.5Co0.25Mn0.25O2 | ZnO | - | 4.6 | −23% | +4 °C (+5 °C) | [45] |

| LiNi0.5Co0.2Mn0.3O2 | BMI/TCA | - | 4.3 | −15% | Consistent | [38] |

| Coating | Doping | Charging Voltage (V) | Heat Flow | Heat Release Onset (Peak) Temperature | Quality Loss | Ref. |

|---|---|---|---|---|---|---|

| - | Al | 4.3 | - | - | No obvious | [73] |

| - | Co | 4.3 | −100% | Not detected at 350 °C | - | [74] |

| - | Fe | 4.3 | −50% | +59 °C (+55 °C) | - | |

| - | Ni | 4.3 | −50% | −26 °C (+2 °C) | - | |

| - | WO2.72 | 4.3 | [75] | |||

| YPO4 | - | 4.3 | −67% | +25 °C (+11 °C) | - | [76] |

| FeF3 | - | 4.5 | −44% | +0 °C (+7 °C) | - | [77] |

| LaF3 | - | 4.3 | −44% | +0 °C (+9 °C) | - | [78] |

| LiCoO2 | - | 4.3 | −40% | +10 °C (+14 °C) | - | [79] |

| N-C | - | - | - | - | Carbon layer loss 6.3% | [64] |

| LiNi0.5Mn1.5O4 | - | 4.3 | −11% | Slightly improved | - | [80,81] |

| Material | Improvement Method | Operating Voltage (V) | Thermal Stability Evaluation | Ref. |

|---|---|---|---|---|

| Graphite | Surface coating PEDOT:PSS | 4.1 | Heat flow reduced by 29% The amount of heat released when SEI decomposes is reduced by 74% | [94] |

| Surface coating PEDOT:PSS/CB | 4.1 | Heat flow reduced by 9% The amount of heat released when SEI decomposes is reduced by 29% | ||

| Surface coating C | - | The weight loss onset temperature increases by about 100 °C | [125] | |

| Surface doping P | 0.01 (Relative to Li/Li+) | Heat flow reduced by 11% Exothermic peak is significantly reduced | [93] | |

| Surface doping B | 0.01 (Relative to Li/Li+) | Heat flow reduced by 3% The exothermic peak is significantly reduced | ||

| Silicon | Core shell structure NC(core)Si(Shell) | - | Maximum weight loss reduced by 21% | [102] |

| Double shell structure SG(core)Si(Shell)C(Shell) | - | The volume expansion is significantly suppressed Maximum weight loss reduced by 20% | [103] | |

| Sea urchin structure Si/CNT | - | The volume expansion is significantly suppressed | [100] | |

| 1 M LiPF6 EC/DEC = 1:1 Dropping FEC | 0.005 (Relative to Li/Li+) | Exothermic onset temperature increases by 47 °C Peak temperature increased by 34 °C | [106] | |

| 1 M LiPF6 EC/DEC = 1:1 Dropping VC | Exothermic onset temperature increases by 61 °C Peak temperature increased by 56 °C | |||

| 1 M LiPF6 EC/DMC = 1:1 Dropping TCN | - | Exothermic onset temperature increases by 5 °C Peak temperature increased by 1 °C Heat release reduced by 37% Maximum weight loss reduced by 10% | [105] | |

| 1 M LiPF6 EC/DEC = 1:1 Dropping APTES | - | Heat release reduced by 52% | [107] | |

| Si-CuO Dropping NiO | - | Slightly improved | [108] | |

| Si Dropping O | - | Heat release reduced by 27% | [126] | |

| Si/G@C Dropping TiN | - | The volume expansion is significantly suppressed (56%) Exothermic onset temperature increases by 5 °C Peak temperature increased by 1–3 °C Heat release reduced by 29% | [127] | |

| Metal composite | Li/Al | - | Melting point increased by 75 °C | [123] |

| Li/Mg | 5.0 | Melting point increased by 18 °C Heat release reduced by 17% | [124] |

| Matrix | Improvement Method | Melting Temperature (°C) | Tensile Strength (Mpa) | Thermal Shrinkage | Thermal Stability Evaluation (Thermal Shrinkage Rate at 150 °C) | Ref. | |

|---|---|---|---|---|---|---|---|

| Microporous separator | PE | Coating SiO2/PEI | - | - | 150 °C/0.5 h 80% | decreases by 10% in 30 min | [130] |

| PE | Coating LSO-SiO2 | - | - | 150 °C/0.5 h 0% | decreases by 72% in 30 min | [132] | |

| PE | Coating Al2O/PDA | - | - | 140 °C/0.5 h 0% | decreases by 36% in 30 min | [147] | |

| PE | Coating ST | - | - | 150 °C/0.5 h 19% | decreases by 51% in 30 min | [148] | |

| PE | Grafting VTMS | 143 | - | 150 °C/0.5 h 0% 180 °C/0.5 h 20% | decreases by 90% in 30 min | [134] | |

| PP | Coating Al2O3/PEK-C | 230 | - | 150 °C/1 h 8% | decreases by 32% in 60 min | [149] | |

| PP | Coating PVdF | 300 | - | To 150 °C 0% | no shrinkage | [150] | |

| PP | Coating BNNT | 165 | - | To 150 °C 5% | shrinks slightly | [151] | |

| PP/PE/PP | Coating ZrO2 | 170 | 114.45 | 180 °C/0.5 h 50% | decreases by 40% in 30 min | [129] | |

| Non-woven membrane | FPI | 300 °C heat treatment | 248 | 31.7 | - | Thermal stability is significantly better than PE | [137] |

| ANFs/PEO | Heat treatment | 280 | 41.52 | 200 °C/1 h 0% | Almost unchanged | [138] | |

| PI | 5 MPa mechanical pressing for 3 min | >300 | 31 | 150 °C/1 h 0% | Heat shrinkage rate in 60 min at 150 °C is 35% lower than PP | [139] | |

| PAN | 60 °C 20 MPa mechanical pressing for 3 min | >303 | - | - | Significantly better than PP | [140] | |

| PI | Spinning PAALi | - | 16.1 | 160 °C/0.5 h 0% | Better than PE | [143] | |

| PI | Spinning TiO2 | >300 | 24.8 | To 300 °C 0% | Significantly better than PP | [152] | |

| PSA | Spinning SiO2/SA | - | - | 150 °C/0.5 h 0% | Significantly better than PP | [144] | |

| PEO | Spinning ANFs | >200 | 10 | 200 °C/1 h 0% | Lower than PP | [138] | |

| PU | Spinning PMIA | - | 25.23 | 180 °C/0.5 h 2% | Heat shrinkage rate in 30 min at 180 °C is 82% lower than PP | [145] | |

| PAN | Spinning PVdF-HFP | >160 | 45.8 | To 160 °C 0% | Significantly better than PP | [146] | |

| Composite separator | β-PP/PE | 135 | - | - | Thermal stability is significantly better than PP | [153] | |

| PP/PE/PP | 170 | 100 | 180 °C/0.5 h 90% | Thermal stability is significantly better than PP | [129] | ||

| PP/AlPO4/PMMA/PVdF-HFP | >170 | - | To 170 °C 50% | Thermal stability is significantly better than PP | [154] | ||

| PMIA/OPS | 400 | 21.79 | 240 °C/2 h 0% | Thermal stability is significantly better than PP | [155] | ||

| PMIA@PAN/PVdF-HFP/TiO2 | >170 | 29.7 | 220 °C/1 h 0% | Heat shrinkage rate in 60 min at 220 °C is 100% lower than PP/PE/PP | [156] | ||

| PAN/PVdF-HFP/PVP | 320 | 22.13 | 200 °C/1 h 0% | Heat shrinkage rate in 60 min at 220 °C is 100% lower than PP | [157] | ||

| PVdF-HFP/MMT/PMIA | >300 | 25 | 220 °C/1 h 0% | Heat shrinkage rate in 60 min at 220 °C is 100% lower than Celgard | [158] | ||

| PEN@PDA-PEI | >200 | 24 | To 200 °C 0% | Thermal stability is significantly better than PP | [159] | ||

| TiO2/PMIA | >250 | 26 | 220 °C/2 h 0% | Heat shrinkage rate for 120 min at 220 °C is 100% lower than Celgard | [160] | ||

| Electrolyte | Improvement Method | Decomposition Temperature (°C) | Thermal Stability Evaluation | Ref. | |

|---|---|---|---|---|---|

| Liquid electrolyte | 1M LiPF6 DMC/EC 1:1 | Additive TMBX | - | Effectively inhibits the decomposition of LiPF6 and the absorption of HF | [184] |

| 1M LiPF6 DEC/EC 1:1 | Additive TMP | 250 | Increased the heat release temperature by 25% Total amount of heat released is significantly reduced | [165] | |

| 1M LiPF6 EC/EMC 3:7 | Additive DTYP | 252 | Decomposition temperature increased by 30% | [185] | |

| 1.15M LiPF6 EC/EMC 3:7 | Additive DPOF | 231 | Decomposition temperature increased by 7.4% | [166] | |

| 1M LiFSI PC/EMC 1:6 | Additive F3B | >200 | No obvious decomposition phenomenon at 200 °C | [186] | |

| Solid electrolyte | LLZO | Doping Ta | 1600 | Decomposition temperature is increased by 26% compared to LATP | [187] |

| LLZO | Doping Ga-Y | >900 | Decomposes 0.29% when exposed to water at 900 °C | [178] | |

| Li3PS4 | Doping Si | >600 | Temperature at which β phase transitions to α phase increases by 33% | [170] | |

| Polycrystalline Li2SnS3 | - | 750 | Thermal stability is equivalent to Li10SnP2S12 | [179] | |

| Li3PS4 | Doping LiI | - | After 540 min of exposure to the atmosphere, H2S is reduced by 88% | [180] | |

| PAN/PVC/LiTFSI | 315 | Thermal stability increases with increasing LiTFSI content | [181] | ||

| PAN/PO3TFSI/LiTFSI | 300 | No obvious shrinkage at 450 °C and no burning under open flame. | [188] | ||

| PAN/PVdF/LiClO4/LLTO | 500 | No obvious shrinkage occurs at 500 °C | [189] | ||

| PI-LLZTO/PVDF | 380 | No obvious shrinkage occurred after heat treatment at 150 °C for 30 min. | [190] | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, A.; Feng, J.; Pang, J. Thermal Stability of Lithium-Ion Batteries: A Review of Materials and Strategies. Energies 2025, 18, 4240. https://doi.org/10.3390/en18164240

Yu A, Feng J, Pang J. Thermal Stability of Lithium-Ion Batteries: A Review of Materials and Strategies. Energies. 2025; 18(16):4240. https://doi.org/10.3390/en18164240

Chicago/Turabian StyleYu, Aimei, Jinjie Feng, and Jun Pang. 2025. "Thermal Stability of Lithium-Ion Batteries: A Review of Materials and Strategies" Energies 18, no. 16: 4240. https://doi.org/10.3390/en18164240

APA StyleYu, A., Feng, J., & Pang, J. (2025). Thermal Stability of Lithium-Ion Batteries: A Review of Materials and Strategies. Energies, 18(16), 4240. https://doi.org/10.3390/en18164240