Coordination of Hydropower Generation and Export Considering River Flow Evolution Process of Cascade Hydropower Systems

Abstract

1. Introduction

2. Hydropower Generation and Export Coordinated Optimal Operation Model

2.1. The Constraints of the System Optimal Operation Model

2.1.1. Hydraulic Coupling and Operational Constraints of Cascade Hydropower Systems

2.1.2. Operational Constraints of the Power System

2.1.3. Hydropower Export Constraints

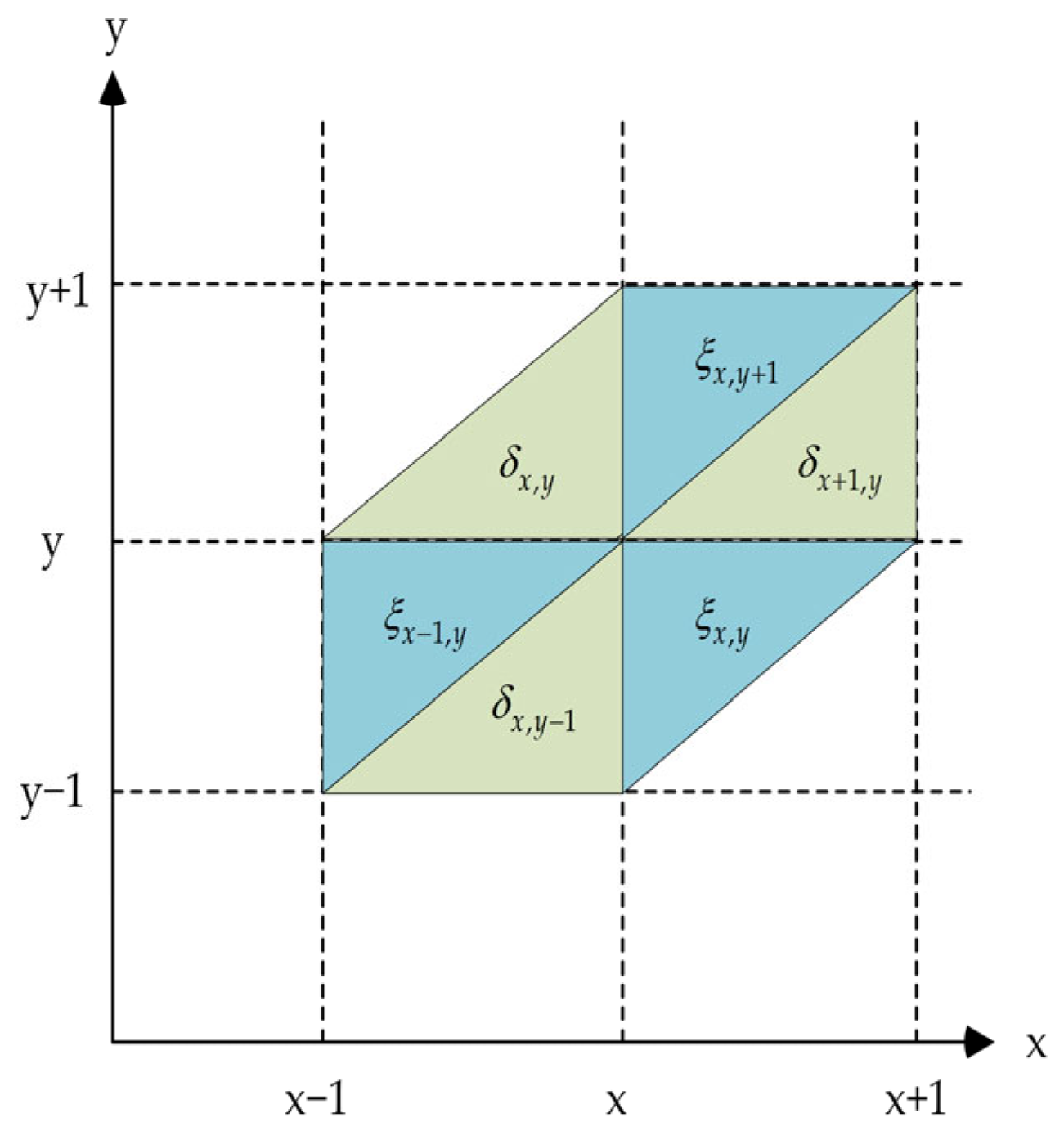

3. The Solving Method

4. Case Study

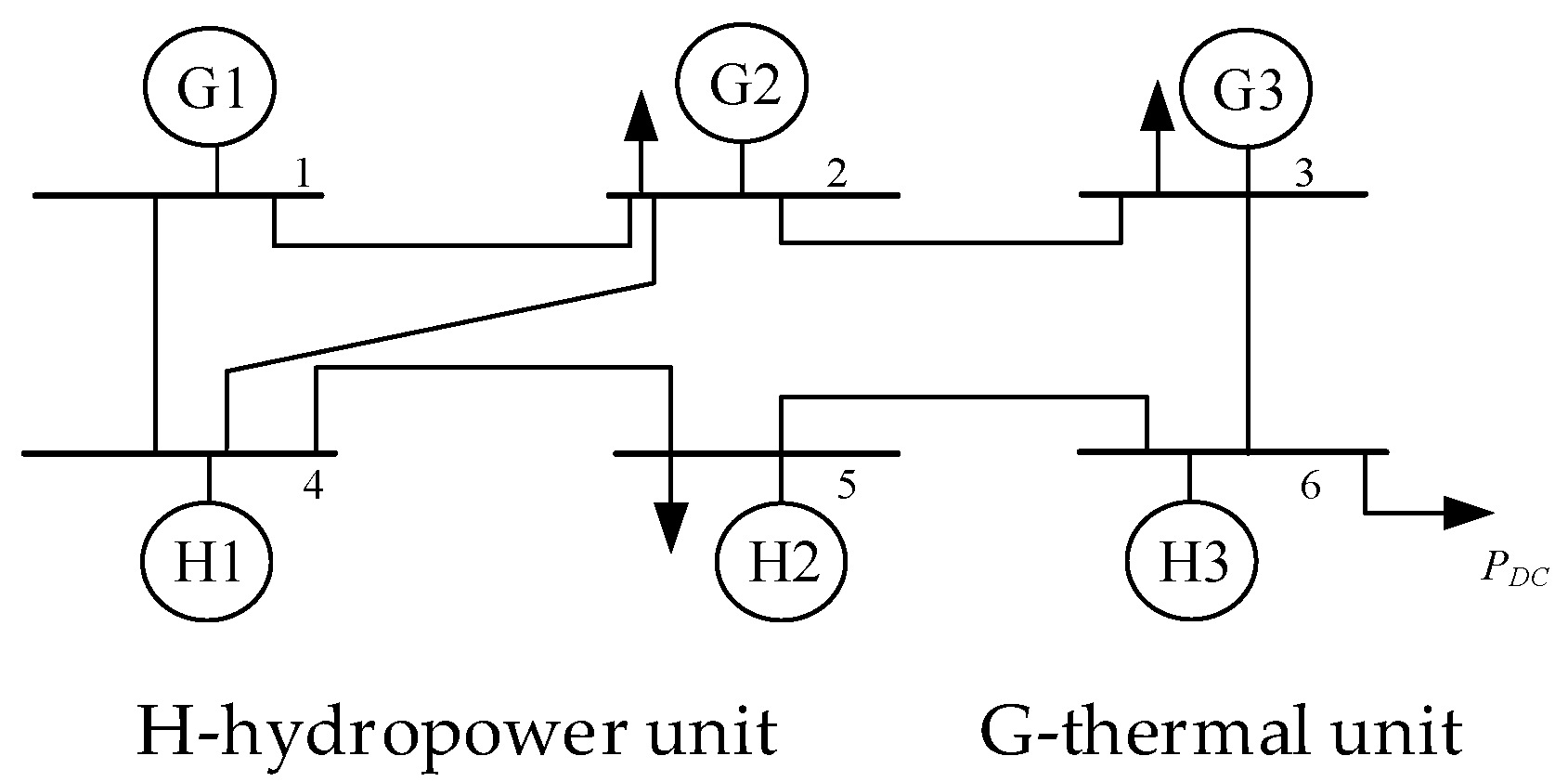

4.1. The Test System

4.2. Result Analysis

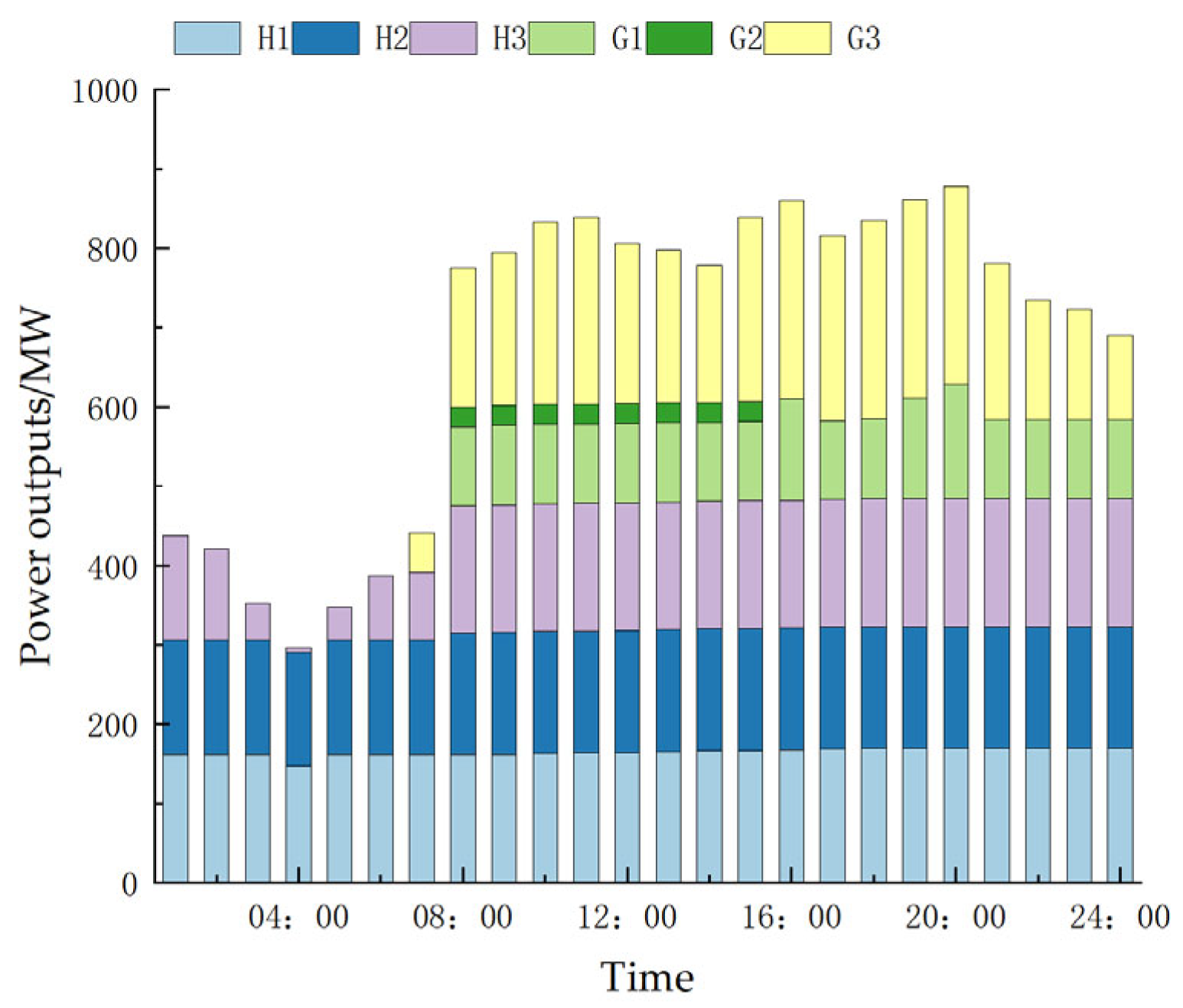

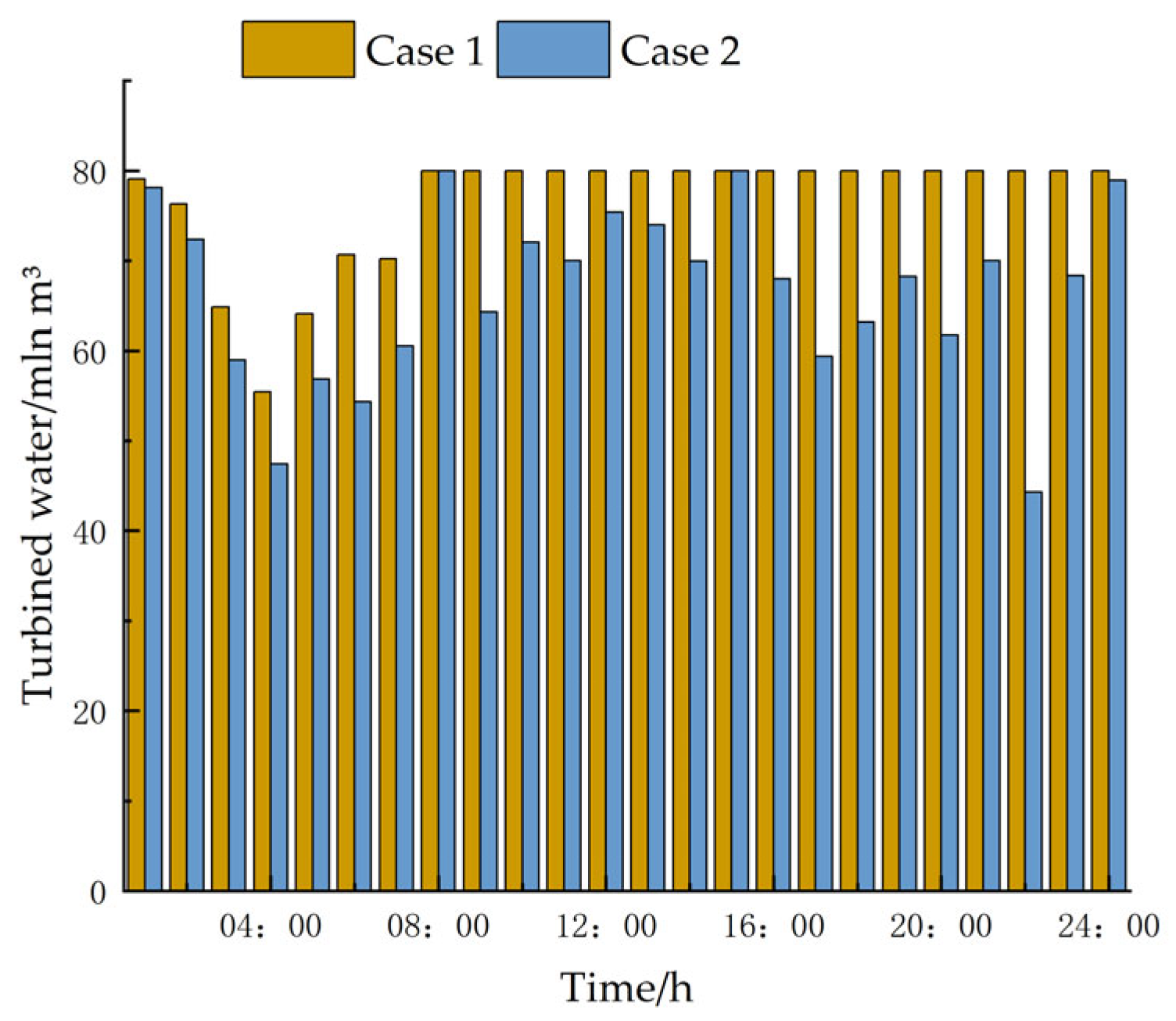

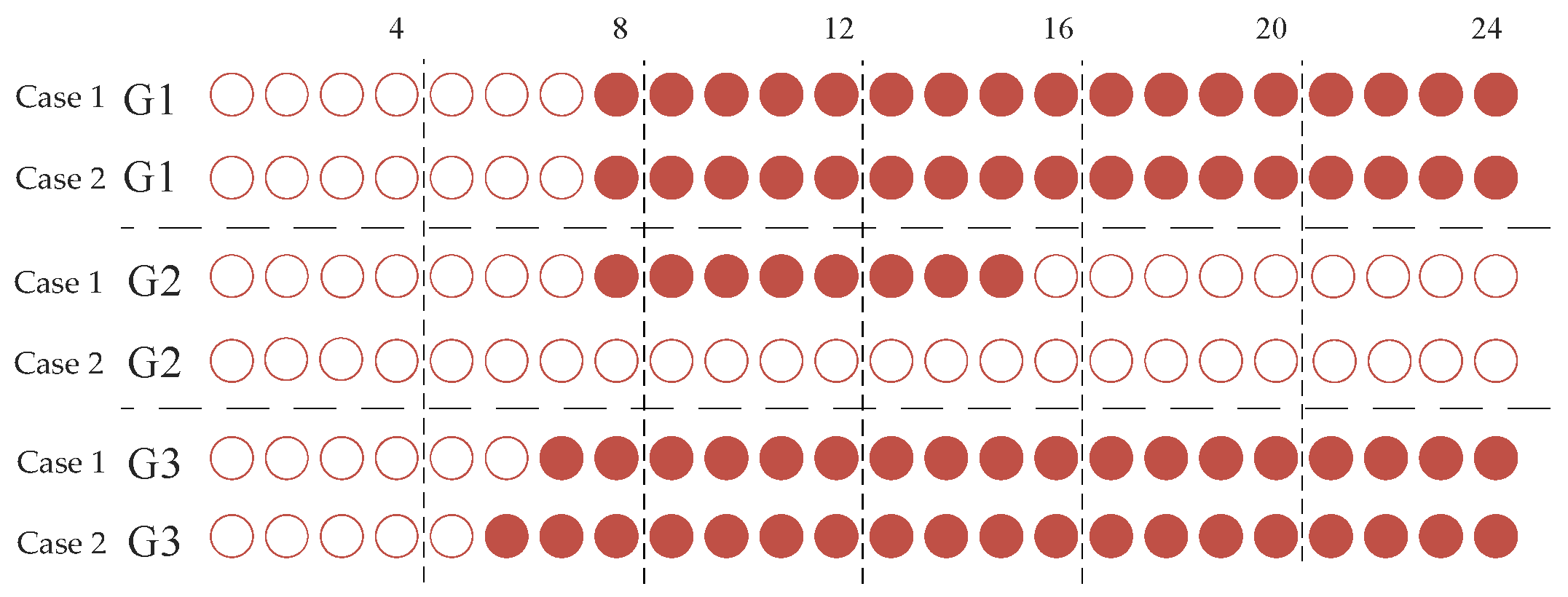

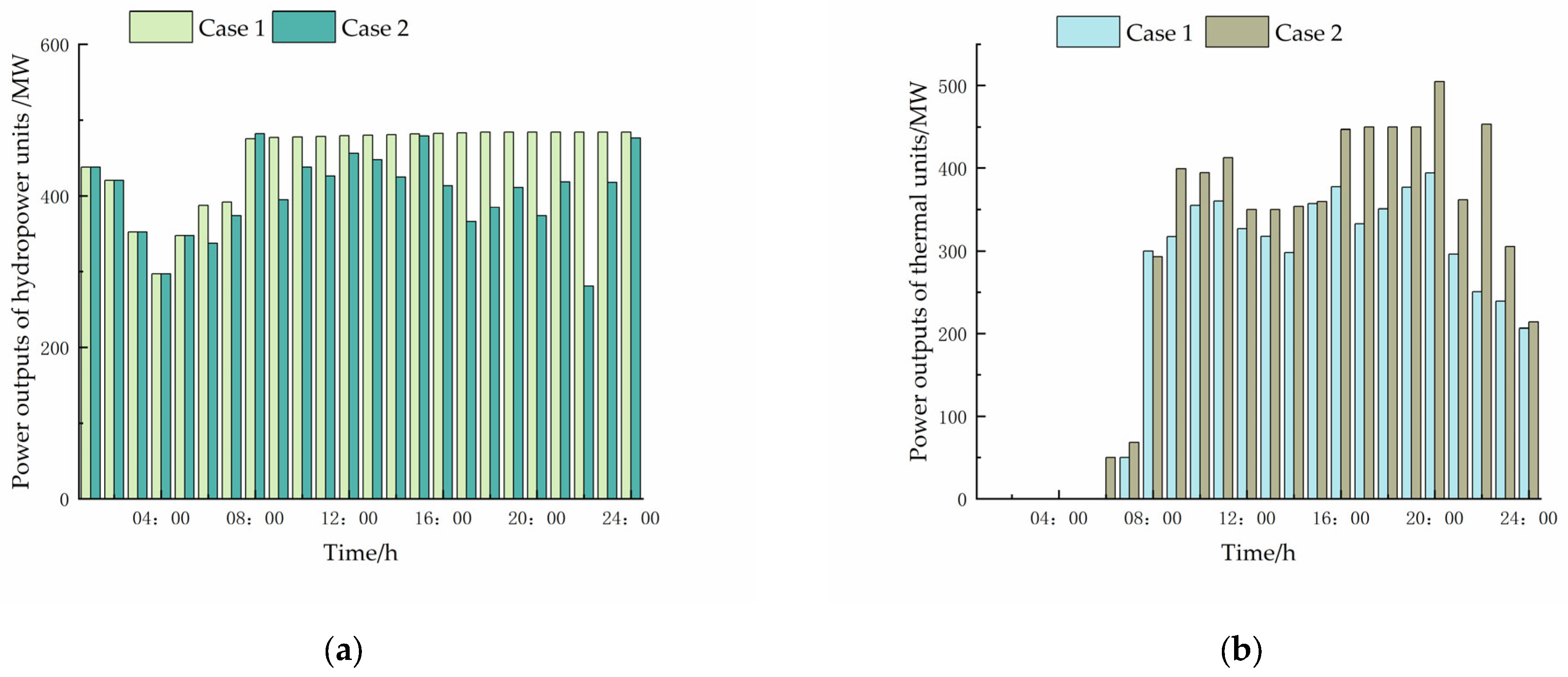

4.2.1. Comparison of Cases 1 and 2

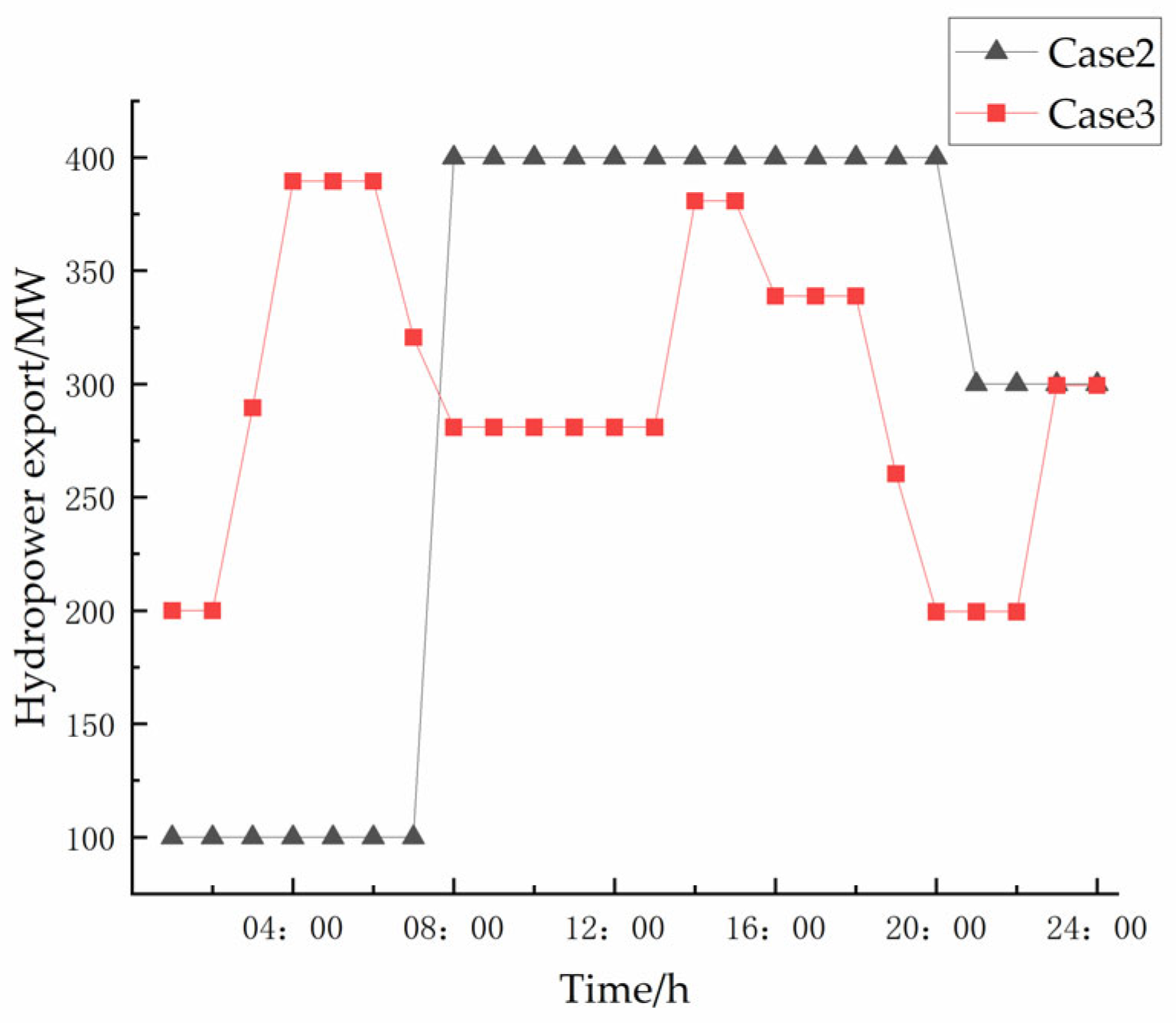

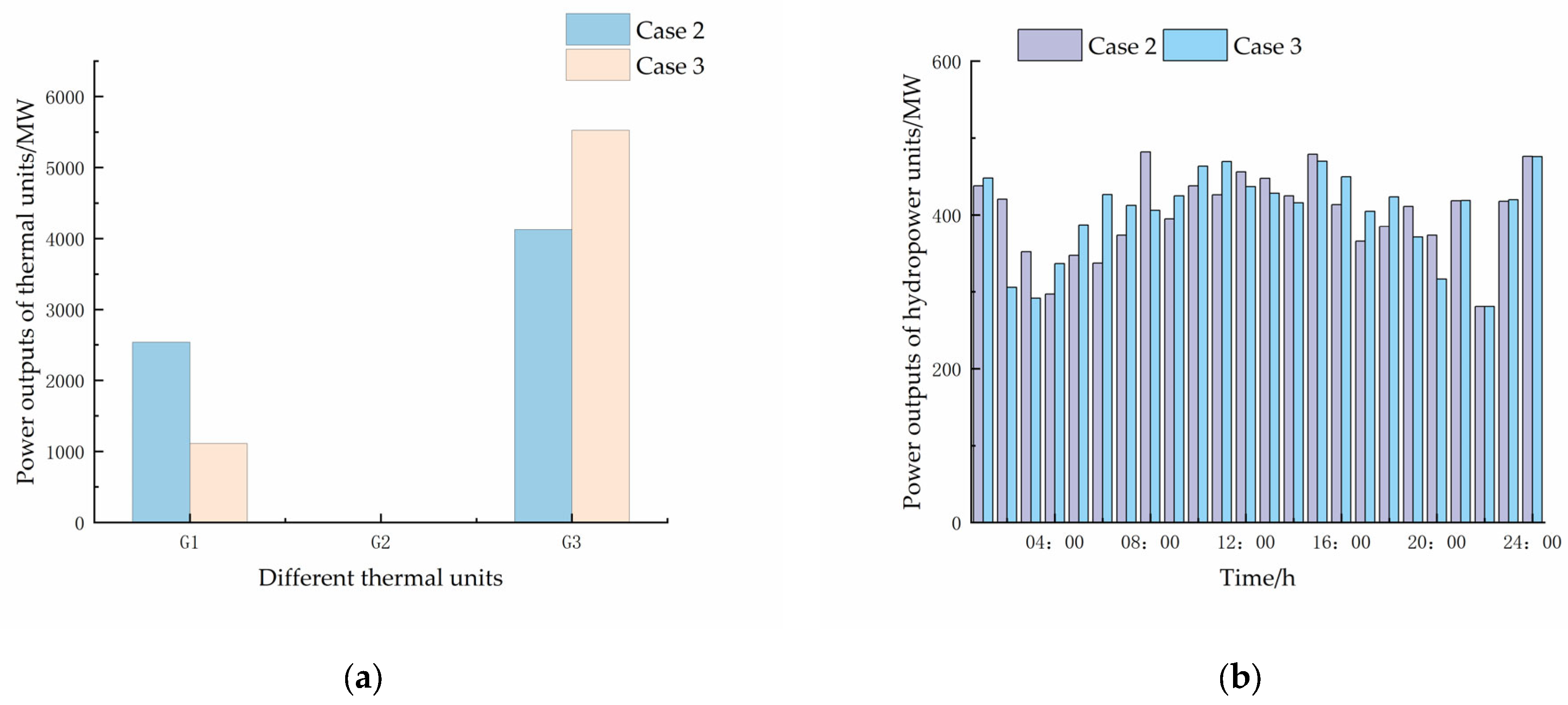

4.2.2. Comparison of Cases 2 and 3

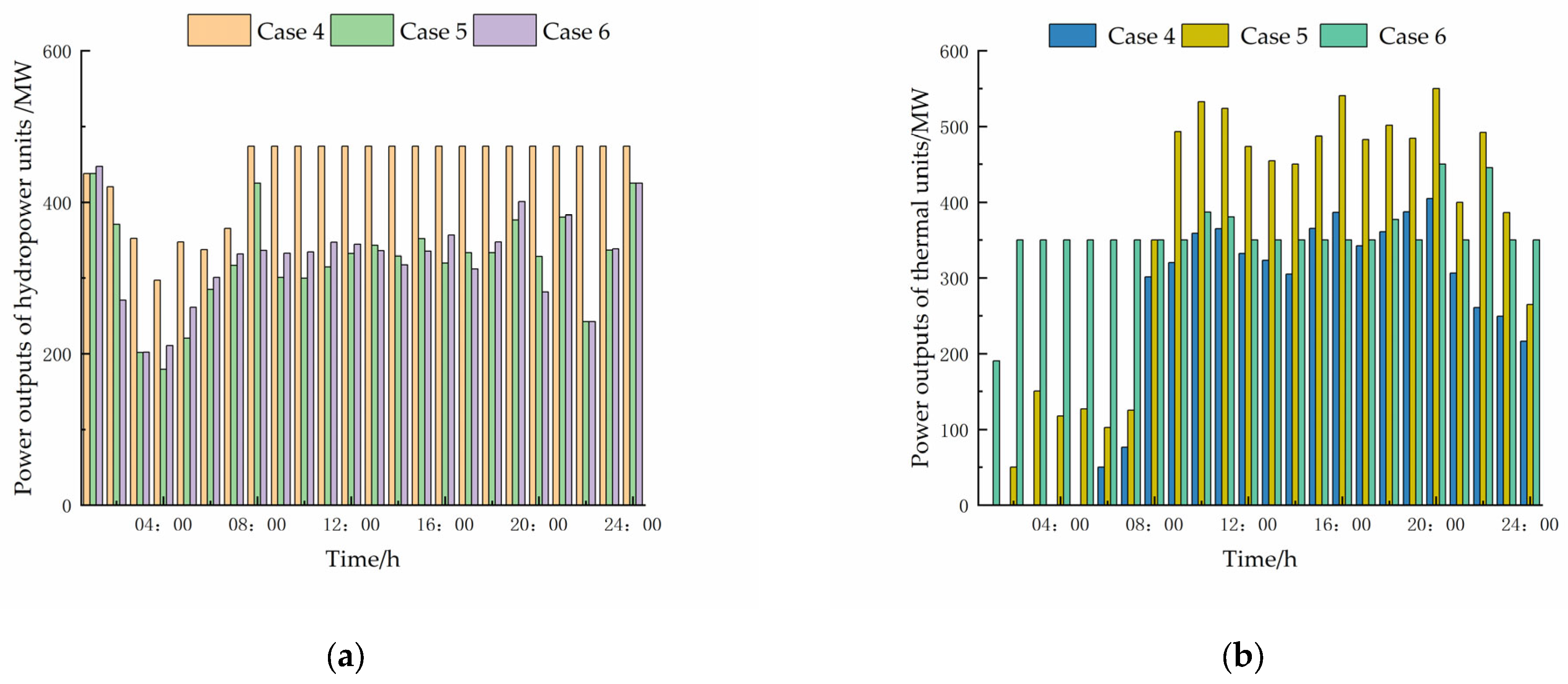

4.2.3. Comparison of Cases 4 and 6

5. Conclusions

- The refined modeling of dynamic water flow delay can capture the evolution process, and thereby improving the coordination efficiency, accurately quantifying the amount of spilled water, and decreasing the startup frequency of high-cost thermal units.

- By jointly optimizing the hydropower export, the operating cost of the system can be effectively reduced and the flexibility of hydropower stations can be well exploited.

- Even during normal water flow periods, the proposed hydropower generation and export coordinated optimal operation model can still achieve low water spillage and slight increase in the operating cost, indicating that the proposed mode could maintain high performance and realize benefits under various hydrological conditions.

- For environmental and social benefits, by reducing water spillage and optimizing hydro-thermal coordination, this proposed method could help protect the river ecosystem by maintaining a more stable ecological base flow, lower the overall carbon emissions of the system by reducing the operation of high-cost, high-emission thermal power units, and enhance the stability and reliability of power supply that indirectly supports residential electricity consumption and industrial production.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yan, T.; Guo, S.; Sun, H. Complementary Scheduling of Cascade Hydropower Stations and Photovoltaic Power Considering Daily Regulating Hydropower Stations. In Proceedings of the 2024 IEEE PES 16th Asia-Pacific Power and Energy Engineering Conference (APPEEC), Nanjing, China, 25 October 2024; IEEE: New York, NY, USA, 2024; pp. 1–5. [Google Scholar]

- Wang, Y.; Shi, P.; Zeng, Z.; Li, X.; Zhou, B. Coordinated Operation of PV and Cascaded Hydropower Considering the Power Grid Security Constraints. In Proceedings of the 2021 International Conference on Power System Technology (POWERCON), Haikou, China, 8 December 2021; IEEE: New York, NY, USA, 2021; pp. 1035–1039. [Google Scholar]

- Liu, Y.; Zhou, J.; Chang, C.; Lu, P.; Wang, C.; Tayyab, M. Short-Term Joint Optimization of Cascade Hydropower Stations on Daily Power Load Curve. In Proceedings of the 2016 IEEE International Conference on Knowledge Engineering and Applications (ICKEA), Singapore, Singapore, 28–30 September 2016; IEEE: New York, NY, USA, 2016; pp. 236–240. [Google Scholar]

- Zhu, Y.; Zhou, Y.; Xu, C.-Y.; Chang, F.-J. Optimizing Complementary Operation of Mega Cascade Reservoirs for Boosting Hydropower Sustainability. Sustain. Energy Technol. Assess. 2024, 64, 103719. [Google Scholar] [CrossRef]

- Wu, Y.; Liao, S.; Liu, B.; Cheng, C.; Zhao, H.; Fang, Z.; Lu, J. Short-Term Load Distribution Model for Cascade Giant Hydropower Stations with Complex Hydraulic and Electrical Connections. Renew. Energy 2024, 232, 121067. [Google Scholar] [CrossRef]

- Chen, X.; Pan, X.; Sun, X. Evaluation and Decision of Joint Dispatch Schemes for Cascade Hydropower Stations Based on the Prospect Theory. In Proceedings of the 2020 12th IEEE PES Asia-Pacific Power and Energy Engineering Conference (APPEEC), Nanjing, China, 20–23 September 2020; IEEE: New York, NY, USA, 2020; pp. 1–5. [Google Scholar]

- Ge, X.; Zhang, L.; Shu, J.; Xu, N. Short-Term Hydropower Optimal Scheduling Considering the Optimization of Water Time Delay. Electr. Power Syst. Res. 2014, 110, 188–197. [Google Scholar] [CrossRef]

- Yuan, W.; Zhang, S.; Su, C.; Wu, Y.; Yan, D.; Wu, Z. Optimal Scheduling of Cascade Hydropower Plants in a Portfolio Electricity Market Considering the Dynamic Water Delay. Energy 2022, 252, 124025. [Google Scholar] [CrossRef]

- Xu, B.; Zhong, P.; Zhang, M.; Zhang, J. Short Term Optimization of Cascade Reservoirs Operation Considering Flow Routing. In Proceedings of the 2012 Asia-Pacific Power and Energy Engineering Conference, Shanghai, China, 27–29 March 2012; IEEE: New York, NY, USA, 2012; pp. 1–4. [Google Scholar]

- Souza, T.M. An Accurate Representation of Water Delay Times for Cascaded Reservoirs in Hydro Scheduling Problems. In Proceedings of the 2012 IEEE Power and Energy Society General Meeting, San Diego, CA, USA, 22–26 July 2012; IEEE: New York, NY, USA, 2012; pp. 1–7. [Google Scholar]

- Weiss, O.; Pareschi, G.; Schwery, O.; Bolla, M.; Georges, G.; Boulouchos, K. Long-Term Scheduling Model of Swiss Hydropower. In Proceedings of the 2019 16th International Conference on the European Energy Market (EEM), Ljubljana, Slovenia, 18–20 September 2019; IEEE: New York, NY, USA, 2019; pp. 1–5. [Google Scholar]

- Liao, S.; Liu, H.; Liu, Z.; Liu, B.; Li, G.; Li, S. Medium-Term Peak Shaving Operation of Cascade Hydropower Plants Considering Water Delay Time. Renew. Energy 2021, 179, 406–417. [Google Scholar] [CrossRef]

- Wang, W.; Tian, W.; Xu, D.; Chau, K.; Ma, Q.; Liu, C. Muskingum Models’ Development and Their Parameter Estimation: A State-of-the-Art Review. Water Resour. Manag. 2023, 37, 3129–3150. [Google Scholar] [CrossRef]

- Gill, M.A. Flood Routing by the Muskingum Method. J. Hydrol. 1978, 36, 353–363. [Google Scholar] [CrossRef]

- Mohsenabadi, S.K. Flood Routing in D-Shape Tunnels through Multilinear Muskingum Method. KSCE J. Civ. Eng. 2025, 29, 100031. [Google Scholar] [CrossRef]

- Si-min, Q.; Wei-min, B.; Peng, S.; Zhongbo, Y.; Peng, J. Water-Stage Forecasting in a Multitributary Tidal River Using a Bidirectional Muskingum Method. J. Hydrol. Eng. 2009, 14, 1299–1308. [Google Scholar] [CrossRef]

- Zhang, W.; Liu, P.; Chen, X.; Wang, L.; Ai, X.; Feng, M.; Liu, D.; Liu, Y. Optimal Operation of Multi-Reservoir Systems Considering Time-Lags of Flood Routing. Water Resour. Manag. 2016, 30, 523–540. [Google Scholar] [CrossRef]

- Sosnin, P. A Scientifically Experimental Approach to the Simulation of Designer Activity in the Conceptual Designing of Software Intensive Systems. IEEE Access 2013, 1, 488–504. [Google Scholar] [CrossRef]

- Liao, S.; Xiong, J.; Liu, B.; Cheng, C.; Zhou, B.; Wu, Y. MILP Model for Short-Term Peak Shaving of Multi-Grids Using Cascade Hydropower Considering Discrete HVDC Constraints. Renew. Energy 2024, 235, 121341. [Google Scholar] [CrossRef]

- Su, C.; Cheng, C.; Wang, P.; Shen, J. Optimization Model for the Short-Term Operation of Hydropower Plants Transmitting Power to Multiple Power Grids via HVDC Transmission Lines. IEEE Access 2019, 7, 139236–139248. [Google Scholar] [CrossRef]

- Shen, J.; Cheng, C.; Zhang, J.; Lu, J. Peak Operation of Cascaded Hydropower Plants Serving Multiple Provinces. Energies 2015, 8, 11295–11314. [Google Scholar] [CrossRef]

- Liu, B.; Liu, T.; Liao, S.; Wang, H.; Jin, X. Short-Term Operation of Cascade Hydropower System Sharing Flexibility via High Voltage Direct Current Lines for Multiple Grids Peak Shaving. Renew. Energy 2023, 213, 11–29. [Google Scholar] [CrossRef]

- Feng, Y.; Zheng, R.; Ma, D.; Huang, X. Associating Reservoir Operations with 2D Inundation Risk and Climate Uncertainty. Water Supply 2024, 24, 2598–2613. [Google Scholar] [CrossRef]

| Case | Total Cost ($) | Operating Cost ($) | Water Spillage Volume (mln m3) | Thermal Unit ON Time (h) |

|---|---|---|---|---|

| 1 | 1,200,895 | 26,814 | 2739.53 | 43 |

| 2 | 300,078 | 32,733 | 623.81 | 36 |

| 3 | 298,746 | 31,422 | 623.75 | 35 |

| Case | Total Cost ($) | Operating Cost ($) | Water Spillage Volume (mln m3) | Thermal Unit ON Time (h) |

|---|---|---|---|---|

| 4 | 598,552 | 27,483 | 1332.49 | 41 |

| 5 | 138,347 | 43,163 | 222.10 | 40 |

| 6 | 136,141 | 40,984 | 222.03 | 47 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, P.; Lu, H.; Nan, L.; Liu, J. Coordination of Hydropower Generation and Export Considering River Flow Evolution Process of Cascade Hydropower Systems. Energies 2025, 18, 3917. https://doi.org/10.3390/en18153917

Li P, Lu H, Nan L, Liu J. Coordination of Hydropower Generation and Export Considering River Flow Evolution Process of Cascade Hydropower Systems. Energies. 2025; 18(15):3917. https://doi.org/10.3390/en18153917

Chicago/Turabian StyleLi, Pai, Hui Lu, Lu Nan, and Jiayi Liu. 2025. "Coordination of Hydropower Generation and Export Considering River Flow Evolution Process of Cascade Hydropower Systems" Energies 18, no. 15: 3917. https://doi.org/10.3390/en18153917

APA StyleLi, P., Lu, H., Nan, L., & Liu, J. (2025). Coordination of Hydropower Generation and Export Considering River Flow Evolution Process of Cascade Hydropower Systems. Energies, 18(15), 3917. https://doi.org/10.3390/en18153917