Biodiesel Production and Life Cycle Assessment: Status and Prospects

Abstract

1. Introduction

2. Biodiesel Production and Main Quality Parameters

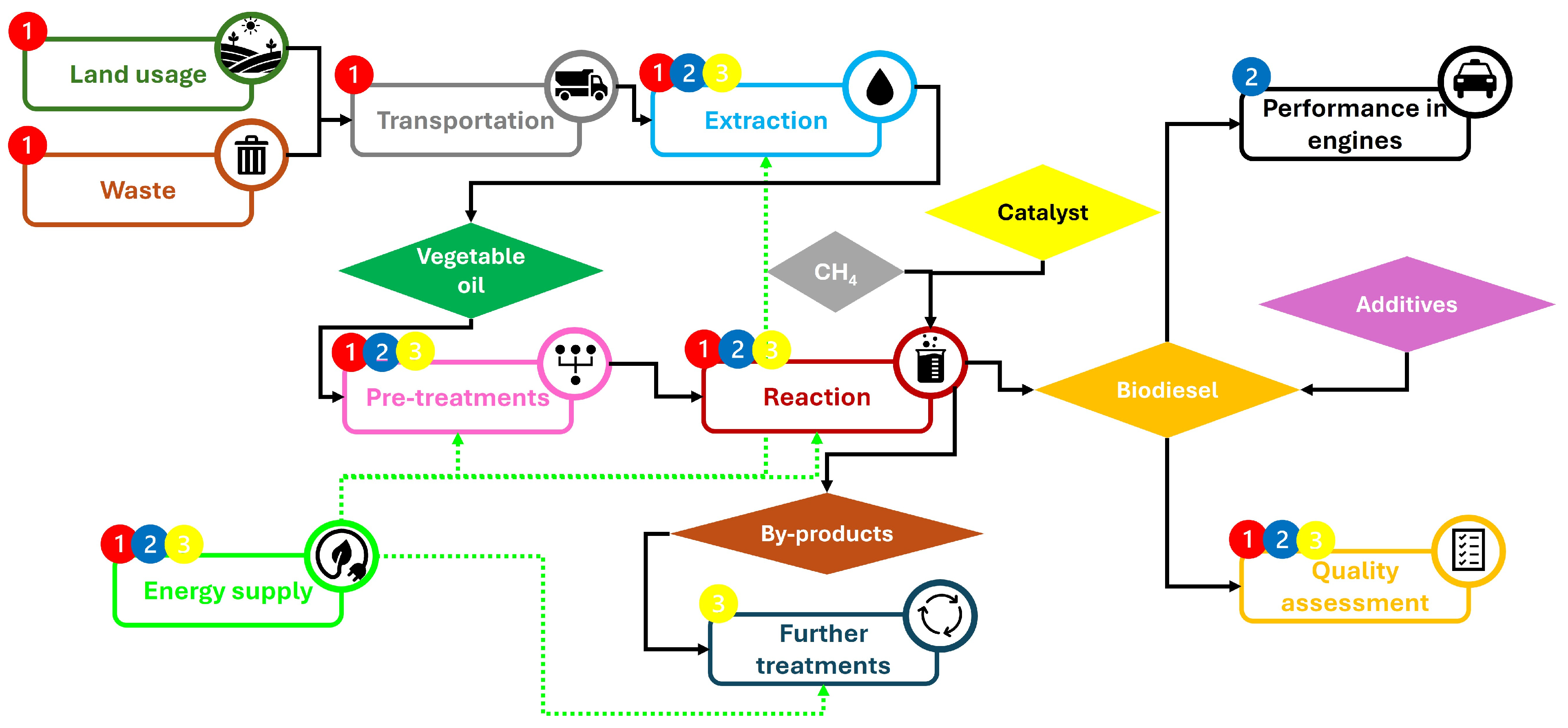

2.1. Main Steps and Production Pathways

- Collection of samples, through harvesting seeds in the case of vegetable oils, or by collecting the corresponding waste where it is generated.

- Extraction. In this case, it can be mechanical (notably in the case of vegetable seeds) or chemical (using solvents, mainly through Soxhlet extraction). As observed in studies included in this work, this stage is critical in LCA due to energy consumption and the use of solvents.

- Pre-treatments, depending on the characteristics of the raw material previously collected. These pre-treatments can involve filtration or drying processes, among others. These additional steps normally have an influence (to a greater or lesser extent) on LCA.

- Synthesis is the key process to transform the corresponding oil into biodiesel. Again, depending on the raw material, different routes can be followed at this stage. Also, batch (economic and simple option) or continuous flow processing (more efficient in general terms) could have a relevant influence on the efficiency and environmental impact of the process.

- Separation or purification. Some factors can affect these actions, like the by-products obtained during the synthesis, which should be removed from the final product in order to achieve high purity levels (with the subsequent predictable properties of the fuel). In this sense, glycerol separation from biodiesel through gravity, centrifugation, or decantation is a common step, possibly requiring chemical treatment or salt addition if the emulsion is generated. Additionally, purification is an essential point in LCA, as steps like alcohol recovery (through evaporation or distillation), washing (to remove soap and impurities, including homogeneous catalysts), filtration (to remove heterogeneous catalysts), drying (by applying heat or drying agents like sodium sulfate) or distillation [1]. Energy consumption and the environmental impact of new reagents should be considered in the corresponding life cycle inventory (LCI). Also, the reutilization of glycerol, a typical by-product in this process, is fundamental, as its valorization (for pharmacy and energy purposes, among others [23]) could lead to crucial and positive changes in the resulting LCA. Likewise, the separation of the spent catalyst requires additional steps like filtration or washing treatments, which should be included in LCA.

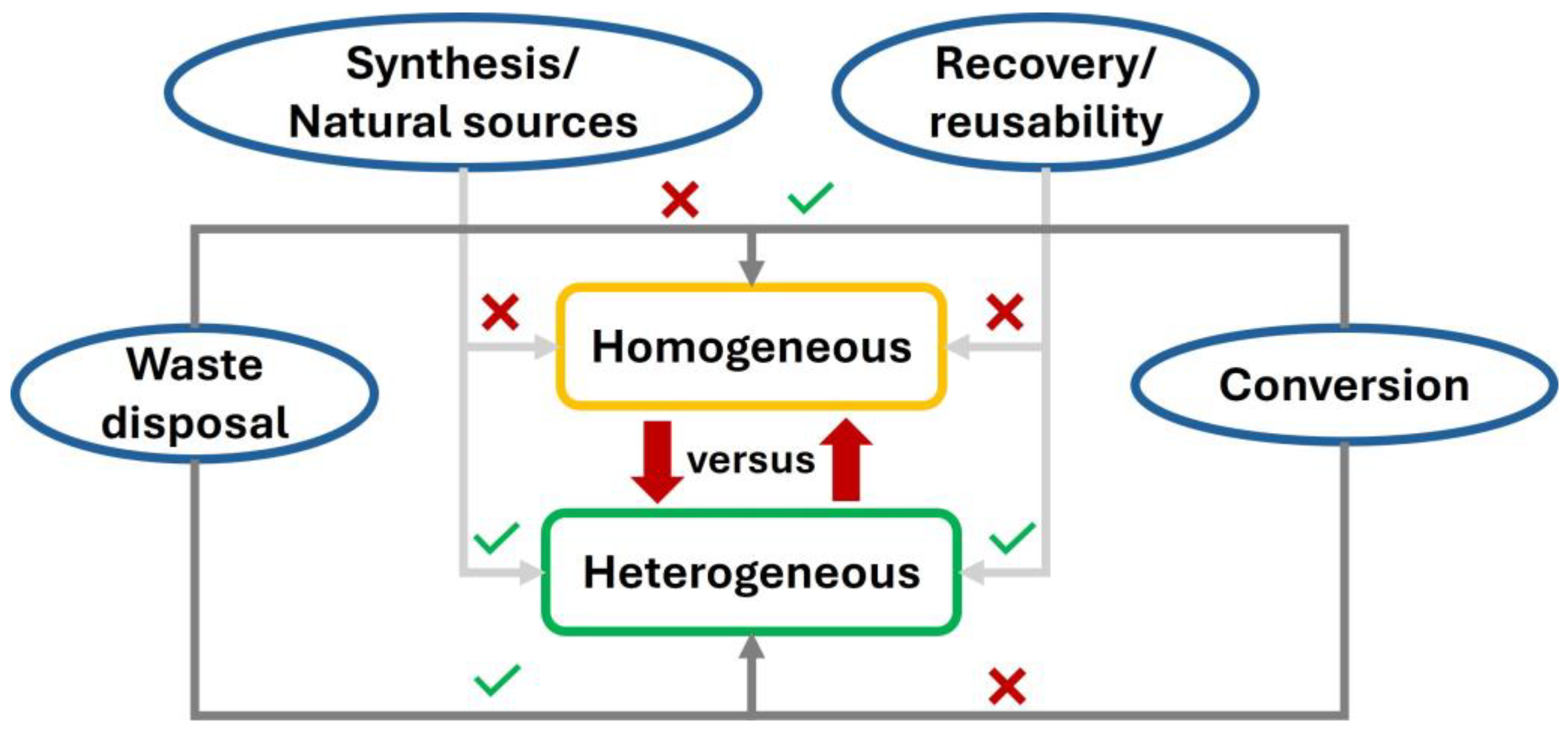

2.2. The Role of Catalysts in Biodiesel Production

2.3. Influence of Operating Conditions on Biodiesel Production

- FFA content and moisture, which could have a negative impact on base-catalyzed transesterification (with soap formation and reducing the yield of the whole process). In this sense, oils with FFA content above 3% require pre-treatment, as observed in Figure 3b for hydrolysis and esterification.

- Alcohol/oil molar ratio. The stoichiometric ratio of this reaction is 3:1, but higher ratios are used to increase the conversion yield. As previously explained, this excess methanol could imply negative results in LCA. Moreover, it could be negative in glycerol separation.

- Temperature and reaction time. Higher temperatures and longer reaction times normally increase conversion. However, the nature of alcohol (its boiling point) should be considered. For a typical transesterification with methanol, reaction temperatures of 60 °C are recommended, with around 1% of catalysts, for one hour. Under these conditions, high conversions (above 90%) are achieved.

2.4. Quality of Biodiesel and Influence on LCA

- Density. Compared to diesel fuels, it is slightly higher in the case of biodiesel (between 860 and 900 kg·m−3). This fact could imply higher fuel consumption, but normally lubricity is improved, which could reduce engine wear and contribute to its durability [50].

- Flash and Fire Points. They are commonly high (above the typical lower limits, established at 120–130 °C) in biodiesel compared to diesel, which implies safety during storage and handling, reducing the risk of accidental combustion.

- Cloud and Pour Points. Equally important, these cold flow properties are normally higher compared to traditional diesel, which implies flow problems in cold climates [52]. In such a way, a reduction in the service life of the engine can take place, unless some additives are incorporated [53]. The influence of these additives should be taken into account in LCA to assess if their efficiency can offset the environmental impact of their production and use.

- Boiling Point. Biodiesel presents high boiling point values, contributing to more complete combustion whereas the risk of deposits in the combustion chamber might increase.

- Combustion Efficiency and Energy Content. These are key factors in LCA. On the one hand, due to the fact that biodiesel is an oxygenated fuel, more complete combustion can be found compared to diesel fuel, especially reducing unburned hydrocarbons, carbon monoxide, and particulate matter emissions [22,54]. The latter, including soot and smoke, are significantly reduced with biodiesel use due to the absence of aromatic compounds and the presence of oxygen in biodiesel, associated with more complete combustion and less soot formation. On the other hand, lower energy density is found in biodiesel, with a possible decrease in power of 5 to 10%. Consequently, higher amounts of biodiesel are required in this sense, and that is the reason why some studies adjust their functional unit (FU) to energy generated/consumed instead of specific amounts of biodiesel (like 1 t).

- Water Content and Presence of Alcohol. Drying is essential to avoid the presence of water to ensure fuel stability and prevent microbial growth during storage, whereas the presence of traces of alcohol (mainly methanol) could contribute to rubber seal degradation and corrosion in engines, particularly aluminum parts. Again, the role of purification steps is fundamental in LCA, for their efficiency and energy performance during the process and their consequences in the final engine [55,56].

- Oxidation Stability. One of the major drawbacks of biodiesel is its instability during storage, primarily due to oxidation, which occurs when unsaturated fatty acid chains in biodiesel react with oxygen. This leads to the formation of peroxides, aldehydes, ketones, and acids, which compromise fuel quality and damage engine components. Thus, during storage, external conditions like air, light, moisture, or temperature significantly impact biodiesel quality, accelerating degradation through an increase in acidity, viscosity, and sediments that affect the engine [57]. To avoid it, the addition of antioxidants (both natural [58,59] and synthetic like BHT, TBHQ [60], or PG, among others, with unequal results in LCA depending on different factors such as extraction or synthesis) and proper storage (including the use of sealed, opaque and dry containers) is recommended [22,41,61,62]. Alternatively, biodiesel stability could be improved through catalytic transfer hydrogenation using bimetallic catalysts (such as Zn-Cr bicarbonate and formate, for instance) and glycerol feed [63].

- Emissions. As previously explained, during combustion in engines, some pollutants are considerably reduced when biodiesel is used, up to 50% in CO, 70% in PM, and 90% in polycyclic aromatic hydrocarbons (PAHs). However, NOx emissions commonly increase compared to petroleum diesel. This is mainly due to the higher flash and combustion points and oxygen content in biodiesel, which favor NOx release in Diesel engines [1,18,64].

- Biodegradability. In general, biodiesel is more biodegradable than other petroleum fuels like gasoline, making accidental spills of the former less harmful to the environment, with a positive contribution to LCA [65].

| Property | ASTM D6751 [67] | EN 14214 [48] |

|---|---|---|

| Viscosity at 40 °C, cSt | 1.9–6.0 | 3.5–5.0 |

| Density at 15 °C, kg·m−3 | Not specified | 860–900 |

| Cetane number | ≥47 | ≥51 |

| Flash point, °C | ≥130 | ≥120 |

| Water content, % | ≤0.05 | ≤0.05 |

| Acid number, mg KOH·g−1 | ≤0.5 | ≤0.5 |

| Sulfur content, ppm | 15 | 10 |

3. Life Cycle Assessment

3.1. General Principles

3.1.1. Goal and Scope Definition

3.1.2. Inventory Analysis

3.1.3. Impact Assessment

3.1.4. Interpretation of the Results

3.2. Other Aspects Related to LCA

3.3. Specific Applications of LCA in Bioenergy

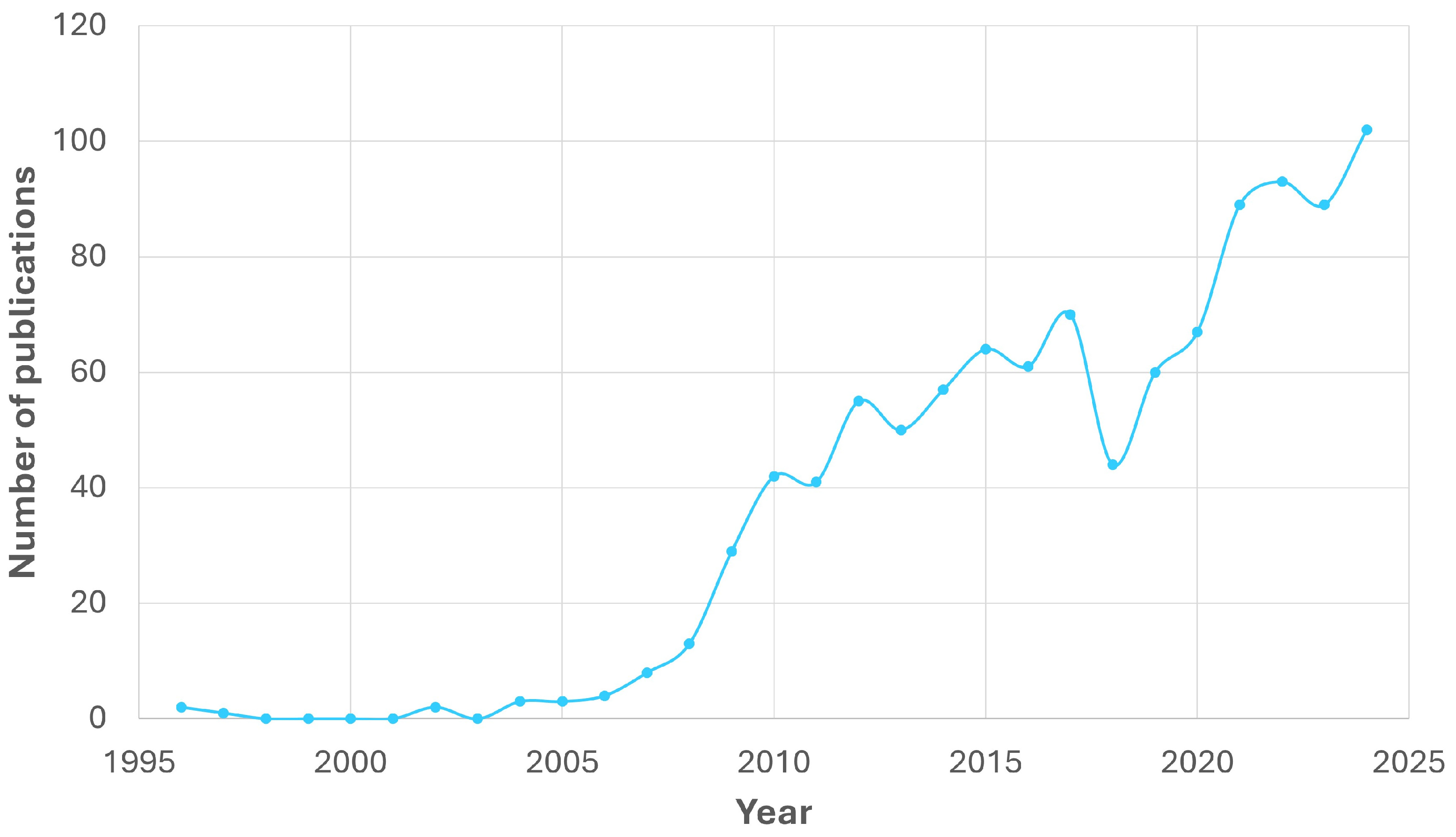

4. Bibliometric Analysis of LCA Applied to Biodiesel Production

5. Life Cycle Assessment Applied to Biodiesel Production: Main Factors to Consider

5.1. Feedstock

5.2. Chemical Synthesis to Produce Biodiesel

Catalytic Performance

5.3. Biodiesel Usage in Engines

5.3.1. Engine Durability

5.3.2. Emissions

5.3.3. Fuel Consumption

5.4. Common Topics in LCA Applied to Biodiesel Production

5.4.1. Aim and Scope

5.4.2. Boundary System

5.4.3. Functional Unit

5.4.4. Inventory Analysis in LCA Applied to Biodiesel Production

5.4.5. Interpretation of Results

- Use of functional units of caloric value of end products, which makes it easier to compare with other forms of energy (fossil fuels or other renewable sources). It is especially relevant in biodiesel, as factors like density, combustion efficiency, and heating value could alter comparisons of FU based on weight. It should be noted that, between a FU of 1 MJ and 1 t of biodiesel, there is a considerable difference (as biodiesel normally has around 40 MJ per kilogram), making the comparison difficult in some cases, especially due to rounding effects.

- Selection of cradle-to-grave system boundaries in order to provide robust LCI in a wider range and complete existing results, as observed in the literature for biodiesel production from palm oil in Indonesia [129]. Thus, if the effect of feedstock is not considered because a certain LCA is a strict comparison within biodiesel production, some impact categories like land use will not be decisive at this point.

- Careful and reasonable assumptions according to the aim and scope.

- Complete system boundaries and impact categories (including GHG, energy, land use change, eutrophication, acidification, loss of biodiversity, and water depletion). As previous studies have pointed out, complete boundaries (mainly including agricultural and industrial processes) can provide a clear picture of the sustainability of biofuel utilization [130]. In our case, highly detailed LCAs would be recommended as recent studies cover an innovative approach that might be unknown in the current environmental scenario.

- It is preferable to use site-specific data instead of the software’s built-in database. In such a way, conversion of biodiesel production, its final yield (and those corresponding to glycerol, for instance), etc., are real data (obtained at laboratory or industrial scale) that can contribute to a more realistic LCA.

6. Conclusions

- LCA applied to biodiesel has great interest, as the use of this tool is essential to support the sustainable implementation of this technology, from economic, environmental, and social points of view. Many works have covered a wide range of scenarios like different regions or countries, variable raw materials, and specific situations like energy supply or modified processes.

- Specifically, most studies are focused on LCA applied to detailed biodiesel production. Thus, every case has its own particularities, from specific waste, pre-treatments, secondary processes, or the use of different energy supplies. This fact points out the versatility of LCA, easily adapted to each process through the establishment of clear aims, boundaries, functional units, and inventory analysis, among others. Even though biodiesel production has high TRLs (especially transesterification and esterification with homogeneous catalysts, between 8 and 9), the industrial implementation of other innovative processes is still under development, requiring evaluation through LCA.

- Generally, the studies that were covered in this work carried out three modalities of LCA: (1) global LCA from well to wheel, to compare with traditional diesel of mineral origin; (2) similar to the previous step, with the main focus on establishing specific recommendations to improve the process; (3) more specific LCA studies (with limited boundaries and several assumptions) to compare changes made in one point of the process (like the use of various catalysts, extraction methods, energy sources, etc.).

- LCA can be applied to innovative aspects of biodiesel production, being decisive in assessing the feasibility of new trends at an industrial scale. On the other hand, the implementation of biodiesel production within a biorefinery context should be equally analyzed through LCA, as different processes could enhance the environmental impact of this kind of facility.

- Concerning biodiesel production from vegetable oils, different crops have been covered, especially jatropha and palm. The most influential steps in LCA were land usage (where the use of N-fertilizers and crop productivity play an important role) and the extraction process. For the latter, the main impact was due to energy consumption and the use of solvents in Soxhlet extraction, which can cause negative carcinogenic and ecotoxic effects. WCO is relevant at this point, as its combination with other innovative options (like heterogeneous catalysis) is an appropriate choice for the valorization of this waste.

- Other raw materials, like algae and animal fats, present challenges like the low efficiency in oil extraction from the corresponding source. Nevertheless, their implementation in biodiesel production is feasible and has great potential, as a reduction in some impact categories was found in general (for instance, biodiesel production from microalgae typically reduces GHG due to CO2 capture).

- With this regard, the transformation of the raw material to biodiesel (mainly through transesterification and esterification) did not have a great impact on LCA compared to the aforementioned factors, especially when it comes to energy and pollution (possibly due to the high conversion and efficiency of the process in general).

- However, typical challenges related to LCA studies focused on specific cases might arise, like the requirement for standardizing LCA methods, metrics, and tools to ensure consistency and comparability across studies. In this context, it is highly advisable to carry out a complete LCA, considering complete system boundaries and unified functional units (1 MJ of biodiesel for energy purposes and 1 t of biodiesel for comparisons regarding production).

- As a result, even though these studies were heterogeneous, they present some points in common, like the relevance of energy supply to improve different aspects of LCA (with solar energy being highly recommended). Also, the efficiency of the process (in particular, during extraction and conversion to obtain biodiesel) could contribute to better results in LCA.

- Finally, more and complete LCA studies are required to fill the current research gap, especially concerning the use of innovative heterogeneous catalysts or production methods like the use of ultrasound or microwave-assisted transesterification.

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| ADP | Abiotic depletion potential |

| AP | Acidification potential |

| BHA | Butylated hydroxyanisole |

| CFC | Chlorofluorocarbon |

| CTUe,h | Comparative toxic unit for ecosystems or humans |

| ECTOX | Ecotoxicity |

| ELCD | European Reference Life Cycle Database |

| EP | Eutrophication potential |

| FAEE(s) | Fatty acid ethyl ester(s) |

| FAME(s) | Fatty acid methyl ester(s) |

| FFA | Free fatty acid |

| FU | Functional unit |

| GHG | Greenhouse gas |

| GWP | Global warming potential |

| HC | Hydrocarbons |

| HT | Human toxicity |

| HVO | Hydrotreated vegetable oil |

| LCA | Life cycle assessment |

| LCC | Life cycle costing |

| LCI | Life cycle inventory |

| LCIA | Life cycle impact assessment |

| LU | Land use |

| ODP | Ozone depletion potential |

| PAHs | Polycyclic aromatic hydrocarbons |

| PG | Propyl gallate |

| PM(F) | Particulate matter (formation) |

| S-LCA | Social life cycle assessment |

| TBHQ | Tert-butylhydroquinone |

| TRL | Technological readiness level |

| UCO | Used cooking oil |

| WCO | Waste cooking oil |

| WU | Water use |

References

- Demirbas, A. Biodiesel, a Realistic Fuel Alternative for Diesel Engines; Springer Nature: Berlin, Germany, 2008. [Google Scholar]

- Foidart, F.; Oliver-Solá, J.; Gasol, C.M.; Gabarrell, X.; Rieradevall, J. How Important Are Current Energy Mix Choices on Future Sustainability? Case Study: Belgium and Spain-Projections towards 2020–2030. Energy Policy 2010, 38, 5028–5037. [Google Scholar] [CrossRef]

- Irawan, C.A.; Jones, D.; Hofman, P.S.; Zhang, L. Integrated Strategic Energy Mix and Energy Generation Planning with Multiple Sustainability Criteria and Hierarchical Stakeholders. Eur. J. Oper. Res. 2023, 308, 864–883. [Google Scholar] [CrossRef]

- Battisti, L. Energy, Power, and Greenhouse Gas Emissions for Future Transition Scenarios. Energy Policy 2023, 179, 113626. [Google Scholar] [CrossRef]

- Hainsch, K.; Löffler, K.; Burandt, T.; Auer, H.; Crespo del Granado, P.; Pisciella, P.; Zwickl-Bernhard, S. Energy Transition Scenarios: What Policies, Societal Attitudes, and Technology Developments Will Realize the EU Green Deal? Energy 2022, 239, 122067. [Google Scholar] [CrossRef]

- Chen, J.; Bian, X.; Rapp, G.; Lang, J.; Montoya, A.; Trethowan, R.; Bouyssiere, B.; Portha, J.F.; Jaubert, J.N.; Pratt, P.; et al. From Ethyl Biodiesel to Biolubricants: Options for an Indian Mustard Integrated Biorefinery toward a Green and Circular Economy. Ind. Crops Prod. 2019, 137, 597–614. [Google Scholar] [CrossRef]

- Encinar, J.M.; Nogales, S.; González, J.F. Biorefinery Based on Different Vegetable Oils: Characterization of Biodiesel and Biolubricants. In Proceedings of the 3rd International Conference in Engineering Applications (ICEA), Sao Miguel, Portugal, 8–11 July 2019. [Google Scholar]

- Barbosa, M.S.; Freire, C.C.C.; Brandão, L.M.S.; Pereira, E.B.; Mendes, A.A.; Pereira, M.M.; Lima, Á.S.; Soares, C.M.F. Biolubricant Production under Zero-Waste Moringa Oleifera Lam Biorefinery Approach for Boosting Circular Economy. Ind. Crops Prod. 2021, 167, 113542. [Google Scholar] [CrossRef]

- Encinar, J.M.; Nogales-Delgado, S.; Pinilla, A. Biolubricant Production through Double Transesterification: Reactor Design for the Implementation of a Biorefinery Based on Rapeseed. Processes 2021, 9, 1224. [Google Scholar] [CrossRef]

- De Faria, D.R.G.; de Medeiros, J.L.; Araújo, O.d.Q.F. Screening Biorefinery Pathways to Biodiesel, Green-Diesel and Propylene-Glycol: A Hierarchical Sustainability Assessment of Process. J. Environ. Manag. 2021, 300, 113772. [Google Scholar] [CrossRef]

- Vlysidis, A.; Binns, M.; Webb, C.; Theodoropoulos, C. A Techno-Economic Analysis of Biodiesel Biorefineries: Assessment of Integrated Designs for the Co-Production of Fuels and Chemicals. Energy 2011, 36, 4671–4683. [Google Scholar] [CrossRef]

- Rathore, D.; Sevda, S.; Prasad, S.; Venkatramanan, V.; Chandel, A.K.; Kataki, R.; Bhadra, S.; Channashettar, V.; Bora, N.; Singh, A. Bioengineering to Accelerate Biodiesel Production for a Sustainable Biorefinery. Bioengineering 2022, 9, 618. [Google Scholar] [CrossRef]

- Kafková, V.; Kubinec, R.; Mikulec, J.; Variny, M.; Ondrejíčková, P.; Ház, A.; Brisudová, A. Integrated Approach to Spent Coffee Grounds Valorization in Biodiesel Biorefinery. Sustainability 2023, 15, 5612. [Google Scholar] [CrossRef]

- De Oliveira, K.G.; de Lima, R.R.S.; Moura, H.M.d.A.; Bicudo, T.d.C.; de Carvalho, L.S. Tangerine Peel Ashes Applied as Green Catalyst: A Biorefinery-Based Approach for Biodiesel Production. Biofuels Bioprod. Biorefin. 2022, 16, 548–561. [Google Scholar] [CrossRef]

- Fonts, I.; Gea, G.; Azuara, M.; Ábrego, J.; Arauzo, J. Sewage Sludge Pyrolysis for Liquid Production: A Review. Renew. Sustain. Energy Rev. 2012, 16, 2781–2805. [Google Scholar] [CrossRef]

- Abou Rjeily, M.; Gennequin, C.; Pron, H.; Abi-Aad, E.; Randrianalisoa, J.H. Pyrolysis-Catalytic Upgrading of Bio-Oil and Pyrolysis-Catalytic Steam Reforming of Biogas: A Review. Environ. Chem. Lett. 2021, 19, 2825–2872. [Google Scholar] [CrossRef]

- Braga, L.B.; Silveira, J.L.; Da Silva, M.E.; Tuna, C.E.; Machin, E.B.; Pedroso, D.T. Hydrogen Production by Biogas Steam Reforming: A Technical, Economic and Ecological Analysis. Renew. Sustain. Energy Rev. 2013, 28, 166–173. [Google Scholar] [CrossRef]

- Hasan, M.M.; Rahman, M.M. Performance and Emission Characteristics of Biodiesel–Diesel Blend and Environmental and Economic Impacts of Biodiesel Production: A Review. Renew. Sustain. Energy Rev. 2017, 74, 938–948. [Google Scholar] [CrossRef]

- Abed, K.A.; El Morsi, A.K.; Sayed, M.M.; Shaib, A.A.E.; Gad, M.S. Effect of Waste Cooking-Oil Biodiesel on Performance and Exhaust Emissions of a Diesel Engine. Egypt. J. Pet. 2018, 27, 985–989. [Google Scholar] [CrossRef]

- Martín, M.; Grossmann, I.E. Optimal Integration of Algae-Switchgrass Facility for the Production of Methanol and Biodiesel. ACS Sustain. Chem. Eng. 2016, 4, 5651–5658. [Google Scholar] [CrossRef]

- Alptekin, E.; Canakci, M.; Ozsezen, A.N.; Turkcan, A.; Sanli, H. Using Waste Animal Fat Based Biodiesels-Bioethanol-Diesel Fuel Blends in a Di Diesel Engine. Fuel 2015, 157, 245–254. [Google Scholar] [CrossRef]

- Meher, L.C.; Vidya Sagar, D.; Naik, S.N. Technical Aspects of Biodiesel Production by Transesterification—A Review. Renew. Sustain. Energy Rev. 2006, 10, 248–268. [Google Scholar] [CrossRef]

- Checa, M.; Nogales-Delgado, S.; Montes, V.; Encinar, J.M. Recent Advances in Glycerol Catalytic Valorization: A Review. Catalysts 2020, 10, 1279. [Google Scholar] [CrossRef]

- Mythili, R.; Venkatachalam, P.; Subramanian, P.; Uma, D. Production Characterization and Efficiency of Biodiesel: A Review. Int. J. Energy Res. 2014, 38, 1233–1259. [Google Scholar] [CrossRef]

- Jayakumar, M.; Karmegam, N.; Gundupalli, M.P.; Bizuneh Gebeyehu, K.; Tessema Asfaw, B.; Chang, S.W.; Ravindran, B.; Kumar Awasthi, M. Heterogeneous Base Catalysts: Synthesis and Application for Biodiesel Production—A Review. Bioresour. Technol. 2021, 331, 125054. [Google Scholar] [CrossRef] [PubMed]

- Veljković, V.B.; Biberdžić, M.O.; Banković-Ilić, I.B.; Djalović, I.G.; Tasić, M.B.; Nježić, Z.B.; Stamenković, O.S. Biodiesel Production from Corn Oil: A Review. Renew. Sustain. Energy Rev. 2018, 91, 531–548. [Google Scholar] [CrossRef]

- Qiu, F.; Li, Y.; Yang, D.; Li, X.; Sun, P. Biodiesel Production from Mixed Soybean Oil and Rapeseed Oil. Appl. Energy 2011, 88, 2050–2055. [Google Scholar] [CrossRef]

- Aranda, D.A.G.; Santos, R.T.P.; Tapanes, N.C.O.; Ramos, A.L.D.; Antunes, O.A.C. Acid-Catalyzed Homogeneous Esterification Reaction for Biodiesel Production from Palm Fatty Acids. Catal. Lett. 2008, 122, 20–25. [Google Scholar] [CrossRef]

- Koutsouki, A.A.; Tegou, E.; Badeka, A.; Kontakos, S.; Pomonis, P.J.; Kontominas, M.G. In Situ and Conventional Transesterification of Rapeseeds for Biodiesel Production: The Effect of Direct Sonication. Ind. Crops Prod. 2016, 84, 399–407. [Google Scholar] [CrossRef]

- Bencheikh, K.; Atabani, A.E.; Shobana, S.; Mohammed, M.N.; Uğuz, G.; Arpa, O.; Kumar, G.; Ayanoğlu, A.; Bokhari, A. Fuels Properties, Characterizations and Engine and Emission Performance Analyses of Ternary Waste Cooking Oil Biodiesel–Diesel–Propanol Blends. Sustain. Energy Technol. Assess. 2019, 35, 321–334. [Google Scholar] [CrossRef]

- Banerjee, N.; Ramakrishnan, R.; Jash, T. Biodiesel Production from Used Vegetable Oil Collected from Shops Selling Fritters in Kolkata. Energy Procedia 2014, 54, 161–165. [Google Scholar] [CrossRef]

- Mancini, M.; Lanza Volpe, M.; Gatti, B.; Malik, Y.; Moreno, A.C.; Leskovar, D.; Cravero, V. Characterization of Cardoon Accessions as Feedstock for Biodiesel Production. Fuel 2019, 235, 1287–1293. [Google Scholar] [CrossRef]

- Nogales-Delgado, S.; Guiberteau Cabanillas, A.; Moro, J.P.; Encinar Martín, J.M. Use of Propyl Gallate in Cardoon Biodiesel to Keep Its Main Properties during Oxidation. Clean Technol. 2023, 5, 569–583. [Google Scholar] [CrossRef]

- Elango, R.K.; Sathiasivan, K.; Muthukumaran, C.; Thangavelu, V.; Rajesh, M.; Tamilarasan, K. Transesterification of Castor Oil for Biodiesel Production: Process Optimization and Characterization. Microchem. J. 2019, 145, 1162–1168. [Google Scholar] [CrossRef]

- Du, L.; Li, Z.; Ding, S.; Chen, C.; Qu, S.; Yi, W.; Lu, J.; Ding, J. Synthesis and Characterization of Carbon-Based MgO Catalysts for Biodiesel Production from Castor Oil. Fuel 2019, 258, 116122. [Google Scholar] [CrossRef]

- Aderibigbe, F.A.; Mustapha, S.I.; Adewoye, T.L.; Mohammed, I.A.; Gbadegesin, A.B.; Niyi, F.E.; Olowu, O.I.; Soretire, A.G.; Saka, H.B. Qualitative Role of Heterogeneous Catalysts in Biodiesel Production from Jatropha Curcas Oil. Biofuel Res. J. 2020, 7, 1159–1169. [Google Scholar] [CrossRef]

- Hossain, A.; Hussain, A. Impact of Nanoadditives on the Performance and Combustion Characteristics of Neat Jatropha Biodiesel. Energies 2019, 12, 921. [Google Scholar] [CrossRef]

- Mihaela, P.; Josef, R.; Monica, N.; Rudolf, Z. Perspectives of Safflower Oil as Biodiesel Source for South Eastern Europe (Comparative Study: Safflower, Soybean and Rapeseed). Fuel 2013, 111, 114–119. [Google Scholar] [CrossRef]

- Nogales-Delgado, S.; Encinar, J.M.; González, J.F. Safflower Biodiesel: Improvement of Its Oxidative Stability by Using BHA and TBHQ. Energies 2019, 12, 1940. [Google Scholar] [CrossRef]

- De Oliveira, C.V.K.; Santos, R.F.; Siqueira, J.A.C.; Bariccatti, R.A.; Lenz, N.B.G.; Cruz, G.S.; Tokura, L.K.; Klajn, F.F. Chemical Characterization of Oil and Biodiesel from Four Safflower Genotypes. Ind. Crops Prod. 2018, 123, 192–196. [Google Scholar] [CrossRef]

- Nogales-Delgado, S.; Guiberteau Cabanillas, A.; Catela Rodríguez, A. Combined Effect of Propyl Gallate and Tert-Butyl Hydroquinone on Biodiesel and Biolubricant Based on Waste Cooking Oil. Appl. Sci. 2024, 14, 9767. [Google Scholar] [CrossRef]

- Beghetto, V. Waste Cooking Oils into High-Value Products: Where Is the Industry Going? Polymers 2025, 17, 887. [Google Scholar] [CrossRef]

- Banerjee, A.; Chakraborty, R. Parametric Sensitivity in Transesterification of Waste Cooking Oil for Biodiesel Production—A Review. Resour. Conserv. Recycl. 2009, 53, 490–497. [Google Scholar] [CrossRef]

- Enweremadu, C.C.; Mbarawa, M.M. Technical Aspects of Production and Analysis of Biodiesel from Used Cooking Oil—A Review. Renew. Sustain. Energy Rev. 2009, 13, 2205–2224. [Google Scholar] [CrossRef]

- Alonso, D.M.; Mariscal, R.; Moreno-Tost, R.; Poves, M.D.Z.; Granados, M.L. Potassium Leaching during Triglyceride Transesterification Using K/γ-Al2O3 Catalysts. Catal. Commun. 2007, 8, 2074–2080. [Google Scholar] [CrossRef]

- Knothe, G.; Razon, L.F. Biodiesel Fuels. Prog. Energy Combust. Sci. 2017, 58, 36–59. [Google Scholar] [CrossRef]

- Esmaeili, H. A Critical Review on the Economic Aspects and Life Cycle Assessment of Biodiesel Production Using Heterogeneous Nanocatalysts. Fuel Process. Technol. 2022, 230, 107224. [Google Scholar] [CrossRef]

- UNE-EN 14214:2013 V2+A1:2018; Liquid Petroleum Products—Fatty Acid Methyl Esters (FAME) for Use in Diesel Engines and Heating Applications—Requirements and Test Methods. Asociacion Espanola de Normalizacion: Madrid, Spain, 2018.

- Das, M.; Sarkar, M.; Datta, A.; Santra, A.K. Study on Viscosity and Surface Tension Properties of Biodiesel-Diesel Blends and Their Effects on Spray Parameters for CI Engines. Fuel 2018, 220, 769–779. [Google Scholar] [CrossRef]

- Sánchez-Rodríguez, G.; Domenzaín-González, J.; Verónico-Sánchez, F.J.; Pérez-López, H.I.; Zúñiga-Moreno, A.; Elizalde-Solis, O. Density and Viscosity in Biodiesel + Diesel Mixtures from Recycled Feedstocks. Appl. Sci. 2025, 15, 3812. [Google Scholar] [CrossRef]

- Ramírez-Verduzco, L.F.; Rodríguez-Rodríguez, J.E.; Jaramillo-Jacob, A.d.R. Predicting Cetane Number, Kinematic Viscosity, Density and Higher Heating Value of Biodiesel from Its Fatty Acid Methyl Ester Composition. Fuel 2012, 91, 102–111. [Google Scholar] [CrossRef]

- Sia, C.B.; Kansedo, J.; Tan, Y.H.; Lee, K.T. Evaluation on Biodiesel Cold Flow Properties, Oxidative Stability and Enhancement Strategies: A Review. Biocatal. Agric. Biotechnol. 2020, 24, 101514. [Google Scholar] [CrossRef]

- Mohanan, A.; Bouzidi, L.; Narine, S.S. Harnessing the Synergies between Lipid-Based Crystallization Modifiers and a Polymer Pour Point Depressant to Improve Pour Point of Biodiesel. Energy 2017, 120, 895–906. [Google Scholar] [CrossRef]

- Zhou, G.; Zhao, X.; Zhang, Z.; Liu, Z.; Dong, S.; Peng, Q. Performance Assessment of a Diesel Engine Fueled with Biodiesel in a Plateau Environment. Energies 2025, 18, 1955. [Google Scholar] [CrossRef]

- Fregolente, P.B.L.; Fregolente, L.V.; Wolf MacIel, M.R. Water Content in Biodiesel, Diesel, and Biodiesel-Diesel Blends. J. Chem. Eng. Data 2012, 57, 1817–1821. [Google Scholar] [CrossRef]

- Díaz, L.; Borges, M.E. Low-Quality Vegetable Oils as Feedstock for Biodiesel Production Using k-Pumice as Solid Catalyst. Tolerance of Water and Free Fatty Acids Contents. J. Agric. Food Chem. 2012, 60, 7928–7933. [Google Scholar] [CrossRef]

- Kivevele, T.T.; Huan, Z. Effects of Antioxidants on the Cetane Number, Viscosity, Oxidation Stability, and Thermal Properties of Biodiesel Produced from Nonedible Oils. Energy Technol. 2013, 1, 537–543. [Google Scholar] [CrossRef]

- De Sousa, L.S.; De Moura, C.V.R.; De Oliveira, J.E.; De Moura, E.M. Use of Natural Antioxidants in Soybean Biodiesel. Fuel 2014, 134, 420–428. [Google Scholar] [CrossRef]

- Jain, S.; Purohit, S.; Kumar, D.; Goud, V.V. Passion Fruit Seed Extract as an Antioxidant Additive for Biodiesel; Shelf Life and Consumption Kinetics. Fuel 2021, 289, 119906. [Google Scholar] [CrossRef]

- Laemthong, T.; Triwittayayont, S.; Sakulshah, N.; Khomlaem, C.; Chiarasumran, N.; Thanapimmetha, A.; Saisriyoot, M.; Wang, W.-C.; Chiang, Y.-Y.; Srinophakun, P. Improving Stability of Biodiesel from 20% Free Fatty Acid Palm Oil with Tert-Butylhydroquinone at Various Concentrations for 52 Weeks of Storage. Processes 2025, 13, 1237. [Google Scholar] [CrossRef]

- Saluja, R.K.; Kumar, V.; Sham, R. Stability of Biodiesel—A Review. Renew. Sustain. Energy Rev. 2016, 62, 866–881. [Google Scholar] [CrossRef]

- Nogales-Delgado, S.; Guiberteau, A.; Encinar, J.M. Effect of Tert-Butylhydroquinone on Biodiesel Properties during Extreme Oxidation Conditions. Fuel 2022, 310, 122339. [Google Scholar] [CrossRef]

- Lugito, G.; Pamungkas, A.Y.; Realdi, M.N.D.; Alam, A.K.; Egiyawati, C.; Pradana, Y.S.; Adhi, T.P.; Soerawidjaja, T.H.; Makertihartha, I.G.B.N.; Mohtar, W.H.M.W.; et al. Biodiesel Stability Enhancement Through Catalytic Transfer Hydrogenation Using Glycerol as Hydrogen Donor. Eng 2025, 6, 94. [Google Scholar] [CrossRef]

- Suh, H.K.; Lee, C.S. A Review on Atomization and Exhaust Emissions of a Biodiesel-Fueled Compression Ignition Engine. Renew. Sustain. Energy Rev. 2016, 58, 1601–1620. [Google Scholar] [CrossRef]

- Chen, Y.-A.; Liu, P.-W.G.; Whang, L.-M.; Wu, Y.-J.; Cheng, S.-S. Biodegradability and Microbial Community Investigation for Soil Contaminated with Diesel Blending with Biodiesel. Process Saf. Environ. Prot. 2019, 130, 115–125. [Google Scholar] [CrossRef]

- Ribeiro, N.M.; Pinto, A.C.; Quintella, C.M.; da Rocha, G.O.; Teixeira, L.S.G.; Guarieiro, L.L.N.; Rangel, M.d.C.; Veloso, M.C.C.; Rezende, M.J.C.; da Cruz, R.S.; et al. The Role of Additives for Diesel and Diesel Blended (Ethanol or Biodiesel) Fuels: A Review. Energy Fuels 2007, 21, 2433–2445. [Google Scholar] [CrossRef]

- ASTM D6751-20a; Standard Specification for Biodiesel Fuel Blend Stock (B100) for Middle Distillate Fuels. ASTM International: West Conshohocken, PA, USA, 2020.

- Singh, A.; Pant, D.; Olsen, S.I. Life Cycle Assessment of Renewable Energy Sources; Springer: London, UK, 2013; ISBN 978-1-4471-5363-4. [Google Scholar]

- Environmental Management—Life Cycle Assessment—Principles and Framework. ISO 14040:2006; International Organization for Standardization: Geneva, Switzerland, 2006.

- Jolliet, O.; Saade-Sbeih, M.; Shaked, S.; Jolliet, A.; Crettaz, P. Environmental Life Cycle Assessment, 1st ed.; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar]

- Karadirek, I.E.; Erkaya, O.; Ciggin, A.S. Comparative Life Cycle Assessment of Sewage Sludge Drying by Solar and Thermal Drying Technologies. Waste Manag. 2025, 201, 114826. [Google Scholar] [CrossRef] [PubMed]

- Ulukardesler, A.H. Sustainable Biodiesel Production from Turkish Coffee Waste Oil: A Comparative Study with Homogeneous and Heterogeneous Catalysts. Processes 2025, 13, 1002. [Google Scholar] [CrossRef]

- Moreno-Caballero, B.S.; Rivas-García, P.; Estrada-Baltazar, A.; Paniagua-Martínez, J.P.; Leveque, J.M.; Cano-Gómez, J.J. Exploring the Potential for Recycling Sewage Sludge in Biodiesel Using Deep Eutectic Solvents: A Proposal of Circular Economy Based on Life Cycle Assessment Approach. Biomass Bioenergy 2025, 198, 107845. [Google Scholar] [CrossRef]

- Chen, Z.; Guo, X. Pyrolysis of Oleaginous Coccomyxa Subellipsoidea for Bio-Oil Production: Mechanism and Life Cycle Assessment. J. Anal. Appl. Pyrolysis 2025, 190, 107148. [Google Scholar] [CrossRef]

- Ayca, S.; Dincer, I. Life Cycle Environmental Impact Assessment and Review of Hydrogen Fuels Obtained from Various Sources for Vehicles. Int. J. Hydrogen Energy 2025, 127, 265–274. [Google Scholar] [CrossRef]

- Benavides, P.T.; Gracida-Alvarez, U.R.; Richa, K.; Port, J.; Hawkins, T.R. Cradle-to-Gate Greenhouse Gas Emissions of the Production of Ethylene from U.S. Corn Ethanol and Comparison to Fossil-Derived Ethylene Production. Bioresour. Technol. 2025, 430, 132565. [Google Scholar] [CrossRef]

- Macombe, C.; Leskinen, P.; Feschet, P.; Antikainen, R. Social Life Cycle Assessment of Biodiesel Production at Three Levels: A Literature Review and Development Needs. J. Clean. Prod. 2013, 52, 205–216. [Google Scholar] [CrossRef]

- Manik, Y.; Leahy, J.; Halog, A. Social Life Cycle Assessment of Palm Oil Biodiesel: A Case Study in Jambi Province of Indonesia. Int. J. Life Cycle Assess. 2013, 18, 1386–1392. [Google Scholar] [CrossRef]

- SCOPUS Scopus Preview. Available online: https://www.scopus.com (accessed on 29 April 2025).

- Liu, Y.; Zhu, Z.; Zhang, R.; Zhao, X. Life Cycle Assessment and Life Cycle Cost Analysis of Jatropha Biodiesel Production in China. Biomass Convers. Biorefin. 2022, 14, 28635–28660. [Google Scholar] [CrossRef]

- HabibTabar Shiadeh, S.S.; Feizabadi, Y.; Kosari-Moghaddam, A. To What Extent Cultivar Selection Can Affect the Environmental Impact of Rapeseed Production? Environ. Sustain. Indic. 2025, 26, 100619. [Google Scholar] [CrossRef]

- Soleymani Angili, T.; Grzesik, K.; Salimi, E.; Loizidou, M. Life Cycle Analysis of Food Waste Valorization in Laboratory-Scale. Energies 2022, 15, 7000. [Google Scholar] [CrossRef]

- Kulkarni, M.G.; Dalai, A.K. Waste Cooking Oil—An Economical Source for Biodiesel: A Review. Ind. Eng. Chem. Res. 2006, 45, 2901–2913. [Google Scholar] [CrossRef]

- Krohn, B.J.; Fripp, M. A Life Cycle Assessment of Biodiesel Derived from the “Niche Filling” Energy Crop Camelina in the USA. Appl. Energy 2012, 92, 92–98. [Google Scholar] [CrossRef]

- Foteinis, S.; Chatzisymeon, E.; Litinas, A.; Tsoutsos, T. Used-Cooking-Oil Biodiesel: Life Cycle Assessment and Comparison with First- and Third-Generation Biofuel. Renew. Energy 2020, 153, 588–600. [Google Scholar] [CrossRef]

- Faleh, N.; Khila, Z.; Wahada, Z.; Pons, M.N.; Houas, A.; Hajjaji, N. Exergo-Environmental Life Cycle Assessment of Biodiesel Production from Mutton Tallow Transesterification. Renew. Energy 2018, 127, 74–83. [Google Scholar] [CrossRef]

- Hums, M.E.; Cairncross, R.A.; Spatari, S. Life-Cycle Assessment of Biodiesel Produced from Grease Trap Waste. Environ. Sci. Technol. 2016, 50, 2718–2726. [Google Scholar] [CrossRef]

- Williams, P.J.L.B.; Laurens, L.M.L. Microalgae as Biodiesel & Biomass Feedstocks: Review & Analysis of the Biochemistry, Energetics & Economics. Energy Environ. Sci. 2010, 3, 554–590. [Google Scholar]

- Collet, P.; Lardon, L.; Hélias, A.; Bricout, S.; Lombaert-Valot, I.; Perrier, B.; Lépine, O.; Steyer, J.P.; Bernard, O. Biodiesel from Microalgae—Life Cycle Assessment and Recommendations for Potential Improvements. Renew. Energy 2014, 71, 525–533. [Google Scholar] [CrossRef]

- Lardon, L.; Hélias, A.; Sialve, B.; Steyer, J.P.; Bernard, O. Life-Cycle Assessment of Biodiesel Production from Microalgae. Environ. Sci. Technol. 2009, 43, 6475–6481. [Google Scholar] [CrossRef]

- Foteinis, S.; Antoniadis-Gavriil, A.; Tsoutsos, T. Life Cycle Assessment of Algae-to-Biodiesel Shallow Pond Production Systems in the Mediterranean: Influence of Species, Pond Type, by(Co)-Product Valorisation and Electricity Mix. Biofuels Bioprod. Biorefin. 2018, 12, 542–558. [Google Scholar] [CrossRef]

- Sander, K.; Murthy, G.S. Life Cycle Analysis of Algae Biodiesel. Int. J. Life Cycle Assess. 2010, 15, 704–714. [Google Scholar] [CrossRef]

- Campbell, P.K.; Beer, T.; Batten, D. Life Cycle Assessment of Biodiesel Production from Microalgae in Ponds. Bioresour. Technol. 2011, 102, 50–56. [Google Scholar] [CrossRef] [PubMed]

- Passell, H.; Dhaliwal, H.; Reno, M.; Wu, B.; Ben Amotz, A.; Ivry, E.; Gay, M.; Czartoski, T.; Laurin, L.; Ayer, N. Algae Biodiesel Life Cycle Assessment Using Current Commercial Data. J. Environ. Manag. 2013, 129, 103–111. [Google Scholar] [CrossRef] [PubMed]

- Stephenson, A.L.; Kazamia, E.; Dennis, J.S.; Howe, C.J.; Scott, S.A.; Smith, A.G. Life-Cycle Assessment of Potential Algal Biodiesel Production in the United Kingdom: A Comparison of Raceways and Air-Lift Tubular Bioreactors. Energy Fuels 2010, 24, 4062–4077. [Google Scholar] [CrossRef]

- Bradley, T.; Rajaeifar, M.A.; Kenny, A.; Hainsworth, C.; del Pino, V.; del Valle Inclán, Y.; Povoa, I.; Mendonça, P.; Brown, L.; Smallbone, A.; et al. Life Cycle Assessment of Microalgae-Derived Biodiesel. Int. J. Life Cycle Assess. 2023, 28, 590–609. [Google Scholar] [CrossRef]

- Huang, J.; Wang, J.; Huang, Z.; Liu, T.; Li, H. Photothermal Technique-Enabled Ambient Production of Microalgae Biodiesel: Mechanism and Life Cycle Assessment. Bioresour. Technol. 2023, 369, 128390. [Google Scholar] [CrossRef]

- Yuan, J.; Kendall, A.; Zhang, Y. Mass Balance and Life Cycle Assessment of Biodiesel from Microalgae Incorporated with Nutrient Recycling Options and Technology Uncertainties. GCB Bioenergy 2015, 7, 1245–1259. [Google Scholar] [CrossRef]

- Saranya, G.; Ramachandra, T.V. Life Cycle Assessment of Biodiesel from Estuarine Microalgae. Energy Convers. Manag. X 2020, 8, 100065. [Google Scholar] [CrossRef]

- Gnansounou, E.; Kenthorai Raman, J. Life Cycle Assessment of Algae Biodiesel and Its Co-Products. Appl. Energy 2016, 161, 300–308. [Google Scholar] [CrossRef]

- Carvalho, F.S.; Fornasier, F.; Leitão, J.O.M.; Moraes, J.A.R.; Schneider, R.C.S. Life Cycle Assessment of Biodiesel Production from Solaris Seed Tobacco. J. Clean. Prod. 2019, 230, 1085–1095. [Google Scholar] [CrossRef]

- Gupta, R.; McRoberts, R.; Yu, Z.; Smith, C.; Sloan, W.; You, S. Life Cycle Assessment of Biodiesel Production from Rapeseed Oil: Influence of Process Parameters and Scale. Bioresour. Technol. 2022, 360, 127532. [Google Scholar] [CrossRef]

- Chozhavendhan, S.; Vijay Pradhap Singh, M.; Fransila, B.; Praveen Kumar, R.; Karthiga Devi, G. A Review on Influencing Parameters of Biodiesel Production and Purification Processes. Curr. Res. Green. Sustain. Chem. 2020, 1–2, 1–6. [Google Scholar] [CrossRef]

- Hua, J.; Ji, M.; Jiao, P.; Yin, Z.; Xia, Q.; Jiang, L.; Zhang, J.; Pan, H. Heterogeneous Acid Catalysts for Biodiesel Production: Effect of Physicochemical Properties on Their Activity and Reusability. Catalysts 2025, 15, 396. [Google Scholar] [CrossRef]

- Ha, J.; Lee, S.; Li, O.L. High-Efficiency Biodiesel Production Using ZnO-Modified Starfish-Based Catalysts. Catalysts 2025, 15, 372. [Google Scholar] [CrossRef]

- Al-Mawali, K.S.; Osman, A.I.; Al-Muhtaseb, A.H.; Mehta, N.; Jamil, F.; Mjalli, F.; Vakili-Nezhaad, G.R.; Rooney, D.W. Life Cycle Assessment of Biodiesel Production Utilising Waste Date Seed Oil and a Novel Magnetic Catalyst: A Circular Bioeconomy Approach. Renew. Energy 2021, 170, 832–846. [Google Scholar] [CrossRef]

- Jiang, G.; Yuan, Y.; Guo, H.; Wu, G.; Chen, J.; Liu, Y. Numerical Simulation Study on Combustion Characteristics of a Low-Speed Marine Engine Using Biodiesel. J. Mar. Sci. Eng. 2025, 13, 824. [Google Scholar] [CrossRef]

- Özer, S. The Role of Cheap Chemicals Containing Oxygen Used as Diesel Fuel Additives in Reducing Carbon Footprints. Sustainability 2025, 17, 3146. [Google Scholar] [CrossRef]

- Pérez-Luna, Y.C.; Vázquez-Villegas, P.T.; Berrones-Hernández, R.; Sánchez-Roque, Y.; Saldaña-Trinidad, S.; Canseco-Pérez, M.A.; Gómez-Vázquez, E.G.; Lam-Gutiérrez, A.; Rodríguez-Hernández, L. Environmental Pollution Mitigation: The Chemical Transformation of Residual Frying Oil into Biodiesel. Recycling 2025, 10, 70. [Google Scholar] [CrossRef]

- Enweremadu, C.C.; Rutto, H.L. Combustion, Emission and Engine Performance Characteristics of Used Cooking Oil Biodiesel—A Review. Renew. Sustain. Energy Rev. 2010, 14, 2863–2873. [Google Scholar] [CrossRef]

- Bui, H.N.; Do, H.Q.; Duong, H.T.G.; Perng, Y.S.; Dam, V.N.; Nguyen, V.T.; Bui, H.M. Taguchi Optimization and Life Cycle Assessment of Biodiesel Production from Spent Ground Coffee. Environ. Dev. Sustain. 2022, 24, 12900–12916. [Google Scholar] [CrossRef]

- Chopra, J.; Tiwari, B.R.; Dubey, B.K.; Sen, R. Environmental Impact Analysis of Oleaginous Yeast Based Biodiesel and Bio-Crude Production by Life Cycle Assessment. J. Clean. Prod. 2020, 271, 122349. [Google Scholar] [CrossRef]

- Queiroz, A.G.; França, L.; Ponte, M.X. The Life Cycle Assessment of Biodiesel from Palm Oil (“Dendê”) in the Amazon. Biomass Bioenergy 2012, 36, 50–59. [Google Scholar] [CrossRef]

- Fernández-Tirado, F.; Parra-López, C.; Romero-Gámez, M. Life Cycle Assessment of Biodiesel in Spain: Comparing the Environmental Sustainability of Spanish Production versus Argentinean Imports. Energy Sustain. Dev. 2016, 33, 36–52. [Google Scholar] [CrossRef]

- Panichelli, L.; Dauriat, A.; Gnansounou, E. Life Cycle Assessment of Soybean-Based Biodiesel in Argentina for Export. Int. J. Life Cycle Assess. 2009, 14, 144–159. [Google Scholar] [CrossRef]

- Gasol, C.M.; Salvia, J.; Serra, J.; Antón, A.; Sevigne, E.; Rieradevall, J.; Gabarrell, X. A Life Cycle Assessment of Biodiesel Production from Winter Rape Grown in Southern Europe. Biomass Bioenergy 2012, 40, 71–81. [Google Scholar] [CrossRef]

- Hosseinzadeh-Bandbafha, H.; Tabatabaei, M.; Aghbashlo, M.; Khanali, M.; Khalife, E.; Roodbar Shojaei, T.; Mohammadi, P. Consolidating Emission Indices of a Diesel Engine Powered by Carbon Nanoparticle-Doped Diesel/Biodiesel Emulsion Fuels Using Life Cycle Assessment Framework. Fuel 2020, 267, 117296. [Google Scholar] [CrossRef]

- Anak Erison, A.E.; Tan, Y.H.; Mubarak, N.M.; Kansedo, J.; Khalid, M.; Abdullah, M.O.; Ghasemi, M. Life Cycle Assessment of Biodiesel Production by Using Impregnated Magnetic Biochar Derived from Waste Palm Kernel Shell. Environ. Res. 2022, 214, 114149. [Google Scholar] [CrossRef]

- Rattanaphra, D.; Tawkaew, S.; Chuichulcherm, S.; Kingkam, W.; Nuchdang, S.; Kitpakornsanti, K.; Suwanmanee, U. Evaluation of Life Cycle Assessment of Jatropha Biodiesel Processed by Esterification of Thai Domestic Rare Earth Oxide Catalysts. Sustainability 2024, 16, 100. [Google Scholar] [CrossRef]

- Talens Peiró, L.; Lombardi, L.; Villalba Méndez, G.; Gabarrell i Durany, X. Life Cycle Assessment (LCA) and Exergetic Life Cycle Assessment (ELCA) of the Production of Biodiesel from Used Cooking Oil (UCO). Energy 2010, 35, 889–893. [Google Scholar] [CrossRef]

- Hou, J.; Zhang, P.; Yuan, X.; Zheng, Y. Life Cycle Assessment of Biodiesel from Soybean, Jatropha and Microalgae in China Conditions. Renew. Sustain. Energy Rev. 2011, 15, 5081–5091. [Google Scholar] [CrossRef]

- Musharavati, F.; Sajid, K.; Anwer, I.; Nizami, A.S.; Javed, M.H.; Ahmad, A.; Naqvi, M. Advancing Biodiesel Production System from Mixed Vegetable Oil Waste: A Life Cycle Assessment of Environmental and Economic Outcomes. Sustainability 2023, 15, 16550. [Google Scholar] [CrossRef]

- Pérez, G.; Islas-Samperio, J.M. Sustainability Evaluation of Non-Toxic Jatropha Curcas in Rural Marginal Soil for Obtaining Biodiesel Using Life-Cycle Assessment. Energies 2021, 14, 2746. [Google Scholar] [CrossRef]

- Shrees, S.; Masood, A.; Shrestha, Y.; Garima, G. Life Cycle Assessment of Jatropha and Rapeseed Biodiesels: Cradle to Grave. Biomass Bioenergy 2025, 199, 107895. [Google Scholar] [CrossRef]

- Bhonsle, A.K.; Singh, J.; Trivedi, J.; Atray, N. Life Cycle Assessment Studies for Biodiesel Produced from Jatropha Curcas via Room Temperature Transesterification Process—Case Study in the Chhattisgarh Region of India. Bioenergy Res. 2023, 16, 177–190. [Google Scholar] [CrossRef]

- Sousa, V.M.Z.; Luz, S.M.; Caldeira-Pires, A.; Machado, F.S.; Silveira, C.M. Life Cycle Assessment of Biodiesel Production from Beef Tallow in Brazil. Int. J. Life Cycle Assess. 2017, 22, 1837–1850. [Google Scholar] [CrossRef]

- Castanheira, É.G.; Freire, F. Environmental Life Cycle Assessment of Biodiesel Produced with Palm Oil from Colombia. Int. J. Life Cycle Assess. 2017, 22, 587–600. [Google Scholar] [CrossRef]

- Wang, K.; Tong, R.; Zhai, Q.; Lyu, G.; Li, Y. A Critical Review of Life Cycle Assessments on Bioenergy Technologies: Methodological Choices, Limitations, and Suggestions for Future Studies. Sustainability 2025, 17, 3415. [Google Scholar] [CrossRef]

- Siregar, K.; Sholiati, S.; Sofiah, I.; Miharza, T.; Hendroko Setyobudi, R.; Anne, O.; Wahyudi, A.; Gamawati Adinurani, P.; Mel, M. Review of Implementation Life Cycle Assessment for Biodiesel Production from Palm Oil (Elaeis Guineensis Jacq.) in Indonesia. In Proceedings of the E3S Web of Conferences, Banyuwangi, Indonesia, 12–13 November 2019; EDP Sciences: Les Ulis, France, 2020; Volume 190. [Google Scholar]

- Sambasivam, K.M.; Kuppan, P.; Laila, L.S.; Shashirekha, V.; Tamilarasan, K.; Abinandan, S. Kernel-Based Biodiesel Production from Non-Edible Oil Seeds: Techniques, Optimization, and Environmental Implications. Energies 2023, 16, 7589. [Google Scholar] [CrossRef]

| Step | Comments |

|---|---|

| Collection | Depending on the feedstock, there might be differences. In general, harvesting of vegetable oils is the most common option |

| Oil extraction | It can be carried out by mechanical or chemical processes, affecting LCA |

| Pre-treatment | Highly influenced by the nature of the feedstock (its acidity, the presence of impurities, etc.) |

| Synthesis | Equally, it depends on the properties of the feedstock. Transesterification with methanol is common |

| Separation/purification | Different factors should be taken into account, like the role of catalyst (homogeneous or heterogeneous) and water use |

| Impact Category | Abbreviation | Unit | Description |

|---|---|---|---|

| Acidification Potential | AP | mol H⁺-eq or kg SO2-eq | Assessment of the potential risk of acid rain |

| Abiotic Depletion Potential | ADP | MJ or kg Sb-eq | Quantifies the use of non-living natural resources like minerals and fossil fuels |

| Ecotoxicity | ECTOX | CTUe | Estimates the potential harm of chemical emissions to freshwater aquatic ecosystems |

| Eutrophication Potential | EP | kg P-eq, kg N-eq, etc. | Evaluation of the potential to cause nutrient enrichment in aquatic ecosystems |

| Global Warming Potential | GWP | kg CO2-eq | Evaluation of the potential contribution to global warming, for instance, through CH4 or CO2 emissions |

| Human Toxicity | HT | CTUh | Assesses potential harm to human health from chemical emissions, including cancer and non-cancer effects |

| Land Use | LU | m2 a crop-eq | Evaluates impacts on biodiversity and ecosystem services due to land occupation or transformation |

| Ozone Depletion | OD | kg CFC-11 equivalent | Evaluation of the potential to deplete ozone layer |

| Particulate Matter Formation | PMF | kg PM2.5-eq | Assessment of the potential impact of emissions that lead to the formation of fine particulate matter (especially PM2.5), causing respiratory and cardiovascular health issues in humans |

| Water Use | WU | m3 world-eq deprived | Measures freshwater consumption and its potential to cause water scarcity in affected regions |

| Software | Compatible Database | Description |

|---|---|---|

| Simapro | Ecoinvent, Agri-footprint, etc. | Very popular in research, with a detailed interface |

| GaBi | Ecoinvent, GaBi, etc. | Specialized in industrial applications |

| OpenLCA | Ecoinvent, ELCD, etc. | Open access and flexible |

| Umberto | Ecoinvent, GaBi, etc. | Focused on material flow |

| Program/Database/Methodology | Description | FU | Ref. |

|---|---|---|---|

| Traci 2.1 | Attributional approach following the industrial implementation from laboratory scale for biodiesel production from spent ground coffee Comparison of different extraction processes | 1 kg of biodiesel | [111] |

| ReCiPe | Biodiesel from waste date seed through esterification by using a magnetic catalyst (Fe3O4 nanoparticles), including raw material transportation, oil extraction, catalyst preparation and reuse, and esterification for biodiesel production (cradle-to-gate attributional approach) | 1000 kg of biodiesel | [106] |

| Simapro, Ecoinvent | Biodiesel production from solaris seed tobacco, including tobacco seed production, oil extraction, and biodiesel production | 1 kg of biodiesel from solaris tobacco | [101] |

| ReCiPe, Ecoinvent in Open LCA Software | Comparison of jatropha and rapeseed biodiesels in India, from cradle to grave | 1 MJ of energy based on LHV of biodiesel | [124] |

| Ecoinvent | Biodiesel production from jatropha according to different catalysts and calcination processes | 1000 MJ of biodiesel | [119] |

| Gabi-LCA software | Biodiesel production from mixed vegetable oil waste according to an attributional approach. Comparison with landfilling practices using solar energy | 1 t of biodiesel | [122] |

| Buscar | LCA and LCC of biodiesel production from jatropha oil. LCA was complete, from planting to use in cars | 1 t of biodiesel | [80] |

| ReCiPe, Simapro | LCA of jatropha biodiesel in rural marginal soil with three scenarios: minimal resources (MR), MR + use of sub-products, and additional use of bio-fertilizers and irrigation. The boundaries included raw material production, oil extraction, and biodiesel production | 1 GJ of biodiesel energy | [123] |

| SimaPro | LCA from cradle to gate, including cultivation, pre-treatment, and transesterification of biodiesel production, with a comparison between conventional and room temperature processes | 1 t of biodiesel | [125] |

| Gabi 6.3, Ecoinvent | Review of LCA applied to beef tallow and biodiesel production, with an increasing interest in Brazil | 1 MJ of biodiesel | [126] |

| Aspen Plus, Ecoinvent | Biodiesel production from mutton tallow transesterification, including rendering, transesterification, thermal energy, transport, chemical usage, and electricity | 1 MJ of biodiesel | [86] |

| ReCiPe | Life cycle inventory based on 5 biodiesel plants, with palm oil as the main raw material. This work addressed the effect of land usage, fertilization, and biogas in extraction mills | 1 MJ of biodiesel | [127] |

| Lasen integrating Excel spreadsheets, Ecoinvent | Comparison with different transportation and biodiesel pathways modeled up to the exportation port | 1 km driven in a 28-t truck in Switzerland | [115] |

| Simapro, Ecoinvent | Biodiesel from oleaginous yeasts and bio-crude production to estimate the environmental impact of the resulting biorefinery | 300 L of biodiesel | [112] |

| ReCiPe, Ecoinvent | WCO for biodiesel production, compared with first and third-generation biofuels, including transportation, biodiesel production (including containers) | 1 t of biodiesel | [85] |

| ReCiPe, Simapro, Ecoinvent | Energy valorization of greasy wastewater sludge through biodiesel synthesis, using choline chloride-based deep eutectic solvents with P-toluenesulfonic acid and oxalic acid as green catalysts. Comparison with two-step esterification/transesterification with H2SO4 and CaO catalysts and following an attributional approach | 1 MJ of biodiesel from sewage sludge | [73] |

| Monte Carlo simulation | LCA of biodiesel produced from grease trap waste, including pre-treatment, fuel production, and vehicle operation | 1 MJ of biodiesel | [87] |

| LCA Software, EDIP 2003 | Comparison of biodiesel production from microalgae with conventional fossil-derived diesel derived to a filling station in the UK and combusted in a typical car engine, including cultivation, dewatering, oil extraction, refining, transport to biorefinery, esterification, transport to fill station, and combustion in a car | 1 t of biodiesel | [95] |

| LCA software, Ecoinvent | Photothermal process to produce biodiesel from microalgae at room temperature, including microalgae growth, dewatering, and bio-oil production | 1 MJ of biodiesel | [97] |

| Simapro | LCA applied to palm kernel shell catalysts to replace traditional catalysts for biodiesel production from palm cooking oil, including collection, transportation, extraction, preparation of catalyst, and transesterification with methanol | 1 t of biodiesel | [118] |

| Simapro, Ecoinvent | LCA applied to diesel/biodiesel emulsion fuels in engines and their corresponding performance when carbon nanoparticles are added. Includes biodiesel production, nanoparticle production, fuel blend preparation, and engine test. | 1 kg of fuel blend | [117] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nogales-Delgado, S. Biodiesel Production and Life Cycle Assessment: Status and Prospects. Energies 2025, 18, 3338. https://doi.org/10.3390/en18133338

Nogales-Delgado S. Biodiesel Production and Life Cycle Assessment: Status and Prospects. Energies. 2025; 18(13):3338. https://doi.org/10.3390/en18133338

Chicago/Turabian StyleNogales-Delgado, Sergio. 2025. "Biodiesel Production and Life Cycle Assessment: Status and Prospects" Energies 18, no. 13: 3338. https://doi.org/10.3390/en18133338

APA StyleNogales-Delgado, S. (2025). Biodiesel Production and Life Cycle Assessment: Status and Prospects. Energies, 18(13), 3338. https://doi.org/10.3390/en18133338