Balancing Cam Mechanism for Instantaneous Torque and Velocity Stabilization in Internal Combustion Engines: Simulation and Experimental Validation

Abstract

1. Introduction

1.1. Background

1.2. Problem Statement

1.3. Objectives

2. Materials and Methods

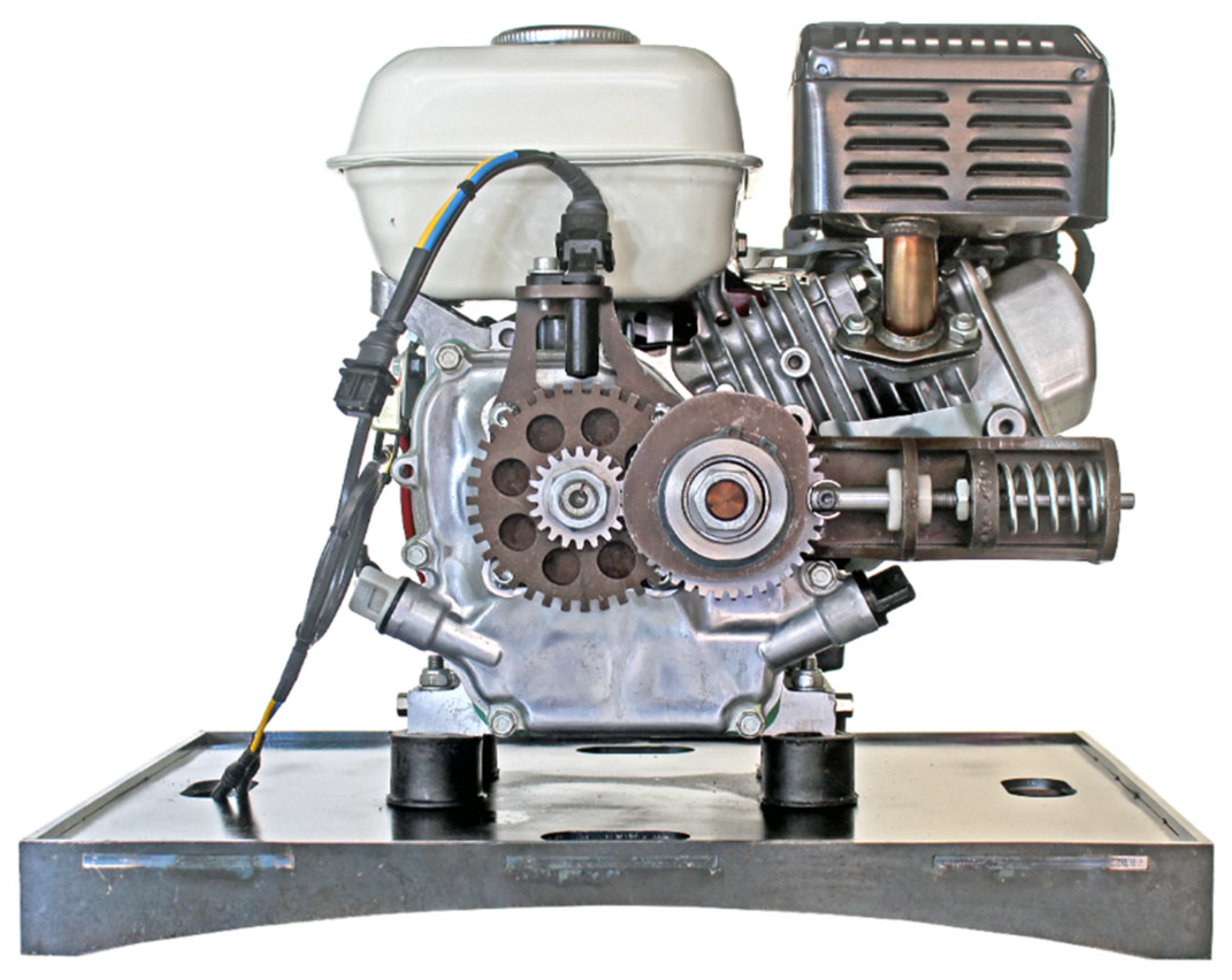

2.1. Engine Characterization, Simulation, Test, and Validation

2.1.1. Engine Modelling and Simulation Approach

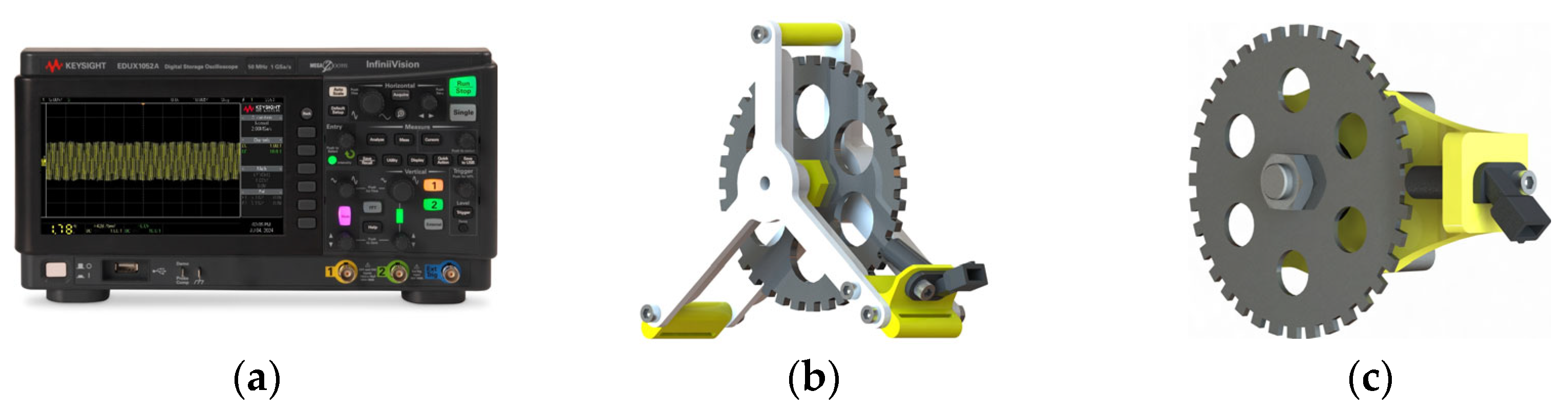

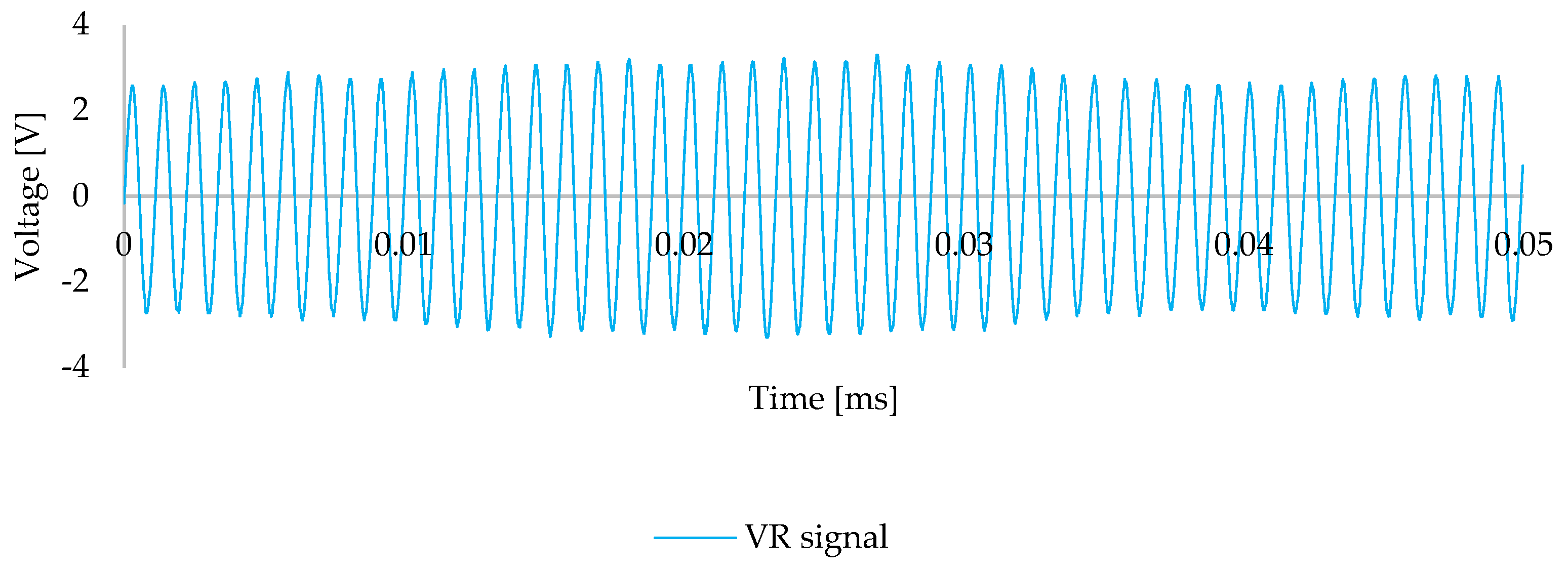

2.1.2. Experimental Setup and Data Acquisition

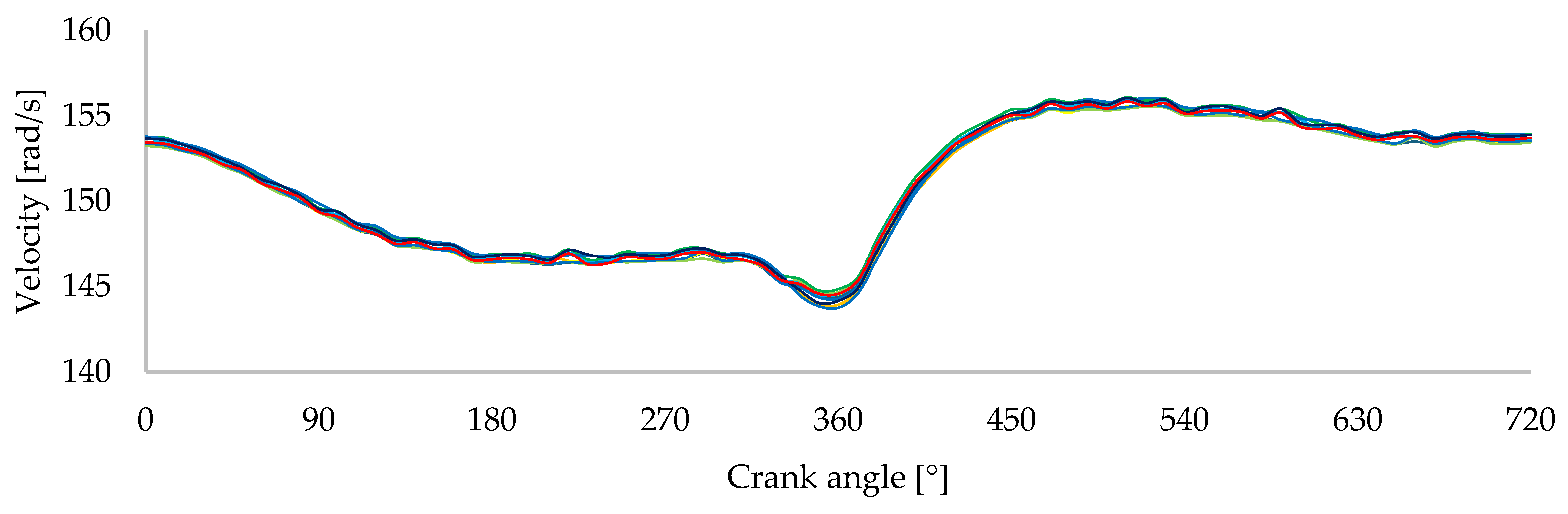

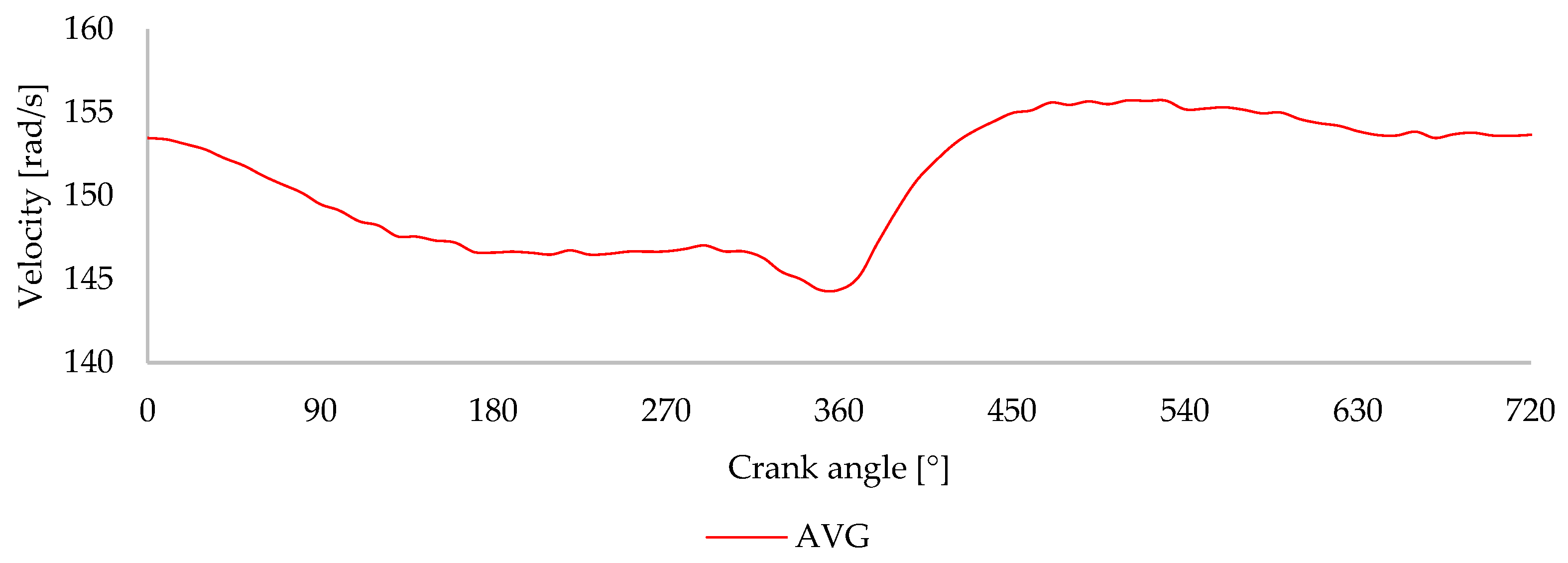

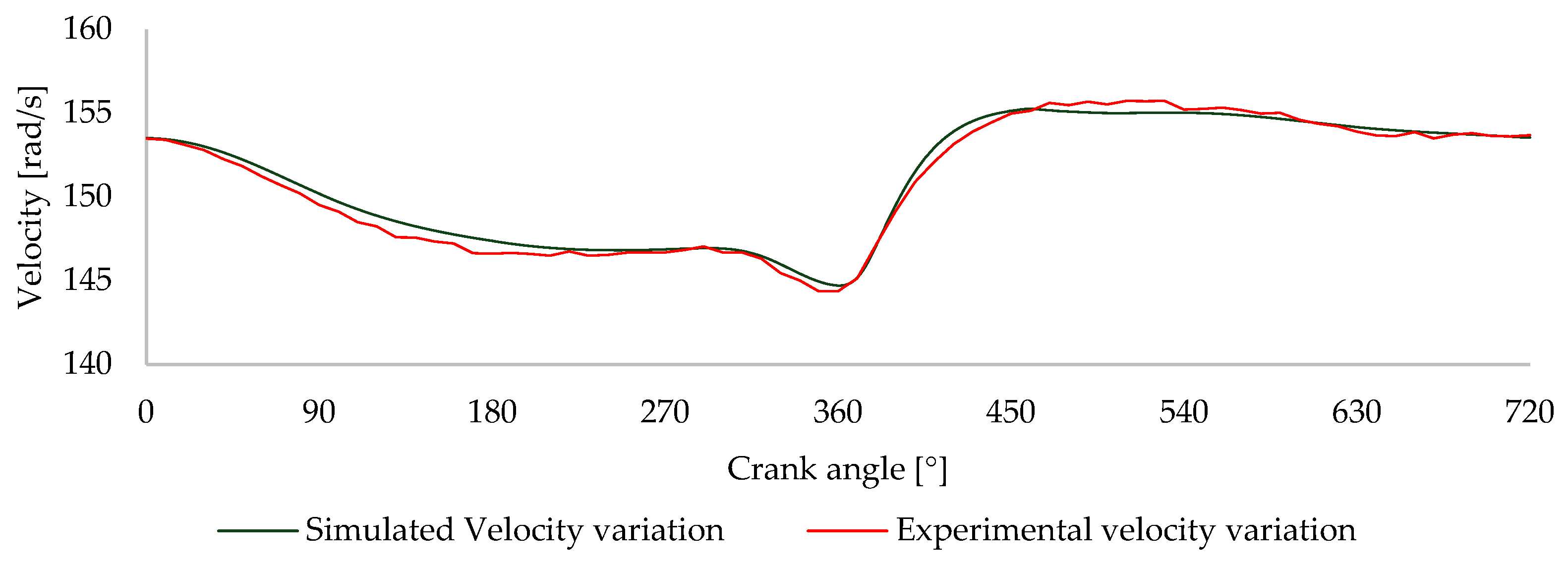

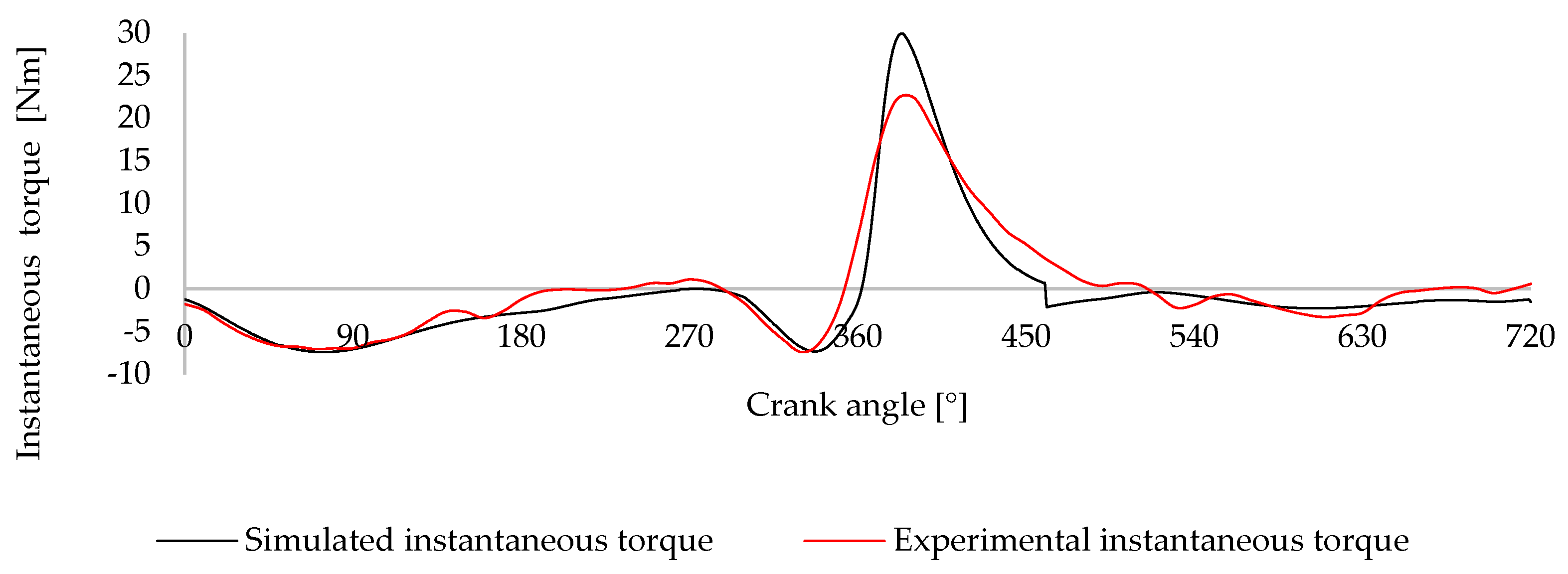

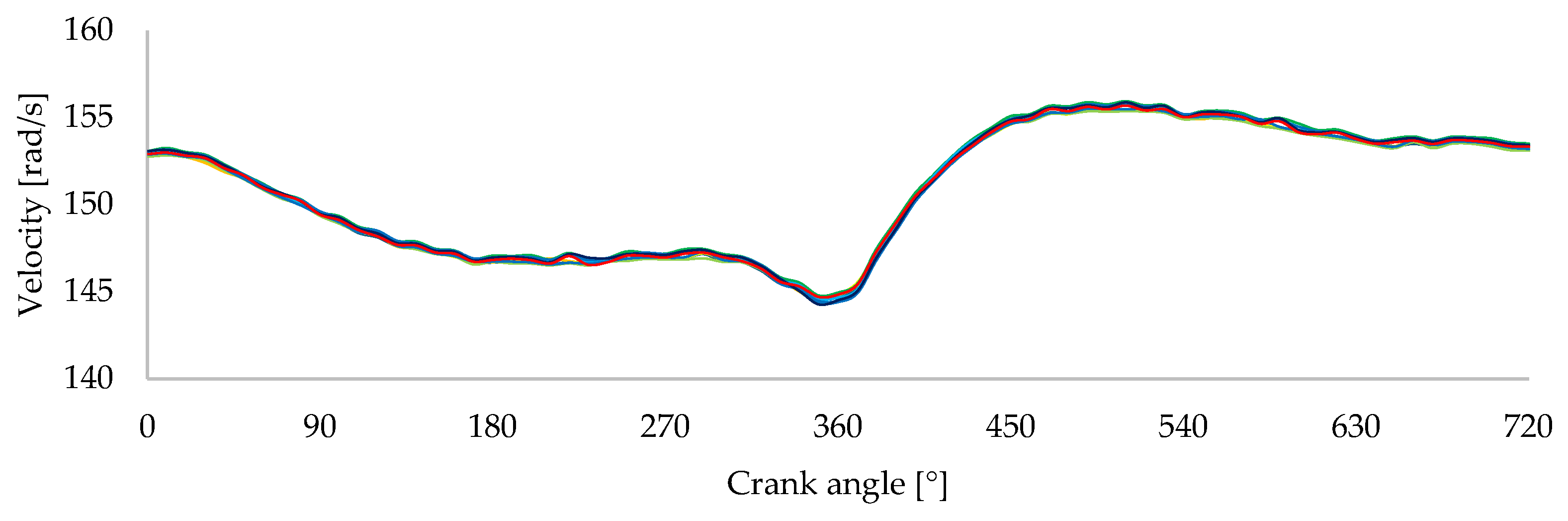

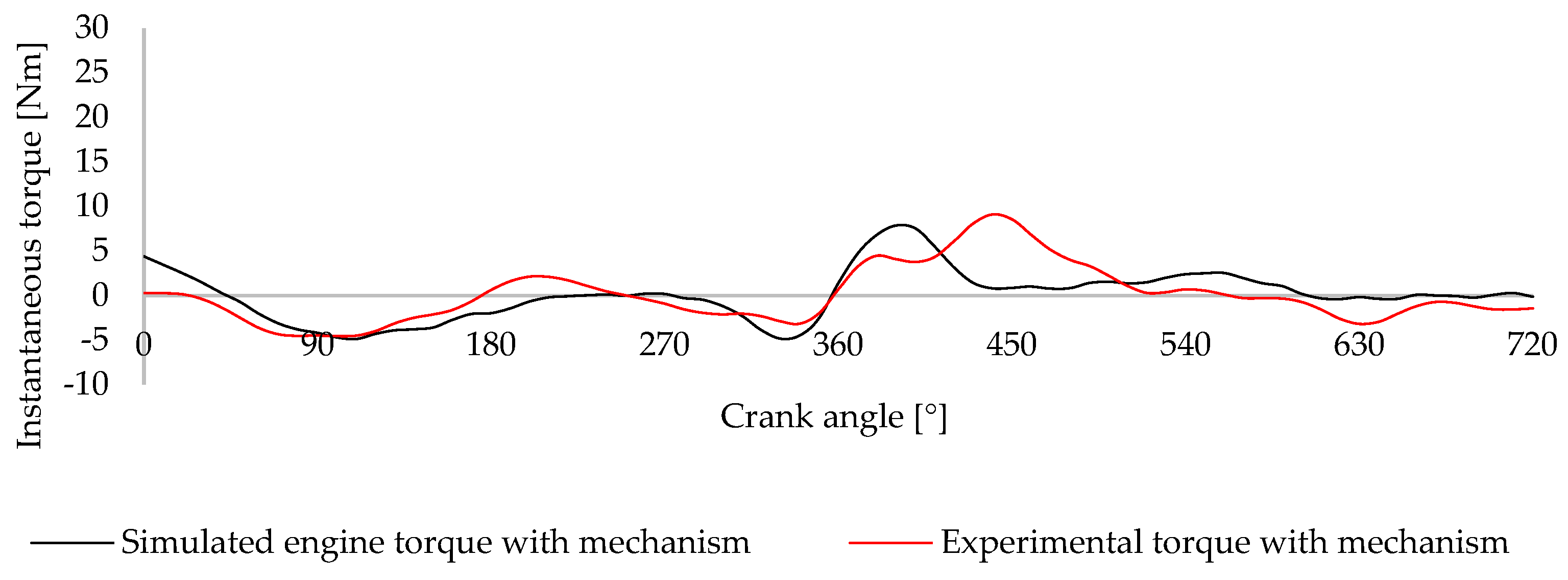

2.1.3. Comparison and Validation of Engine Torque and Velocity Profiles

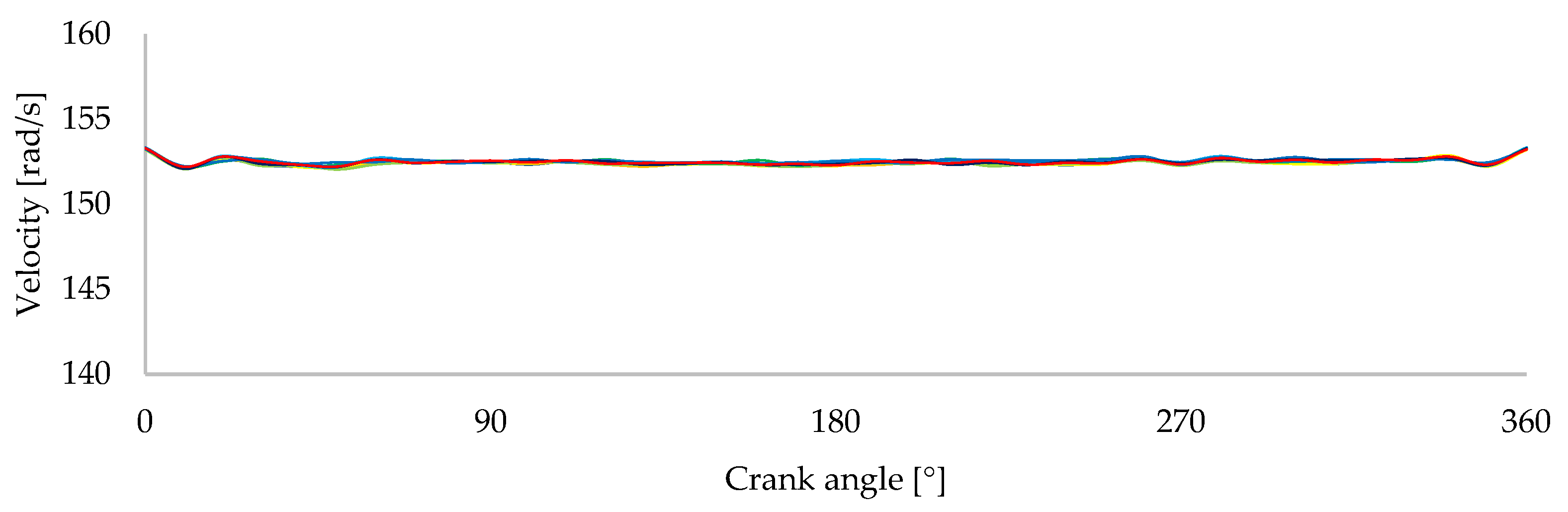

2.2. Balancing Cam Mechanism Development

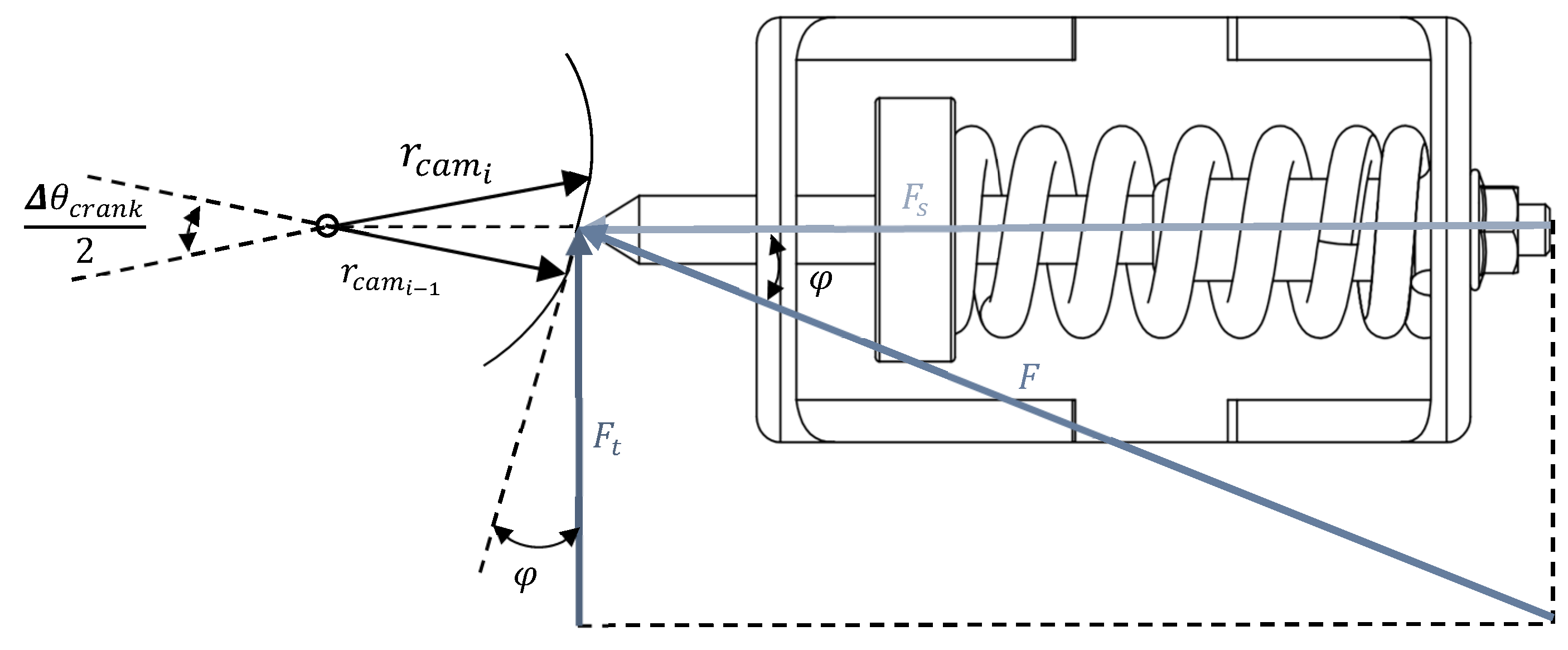

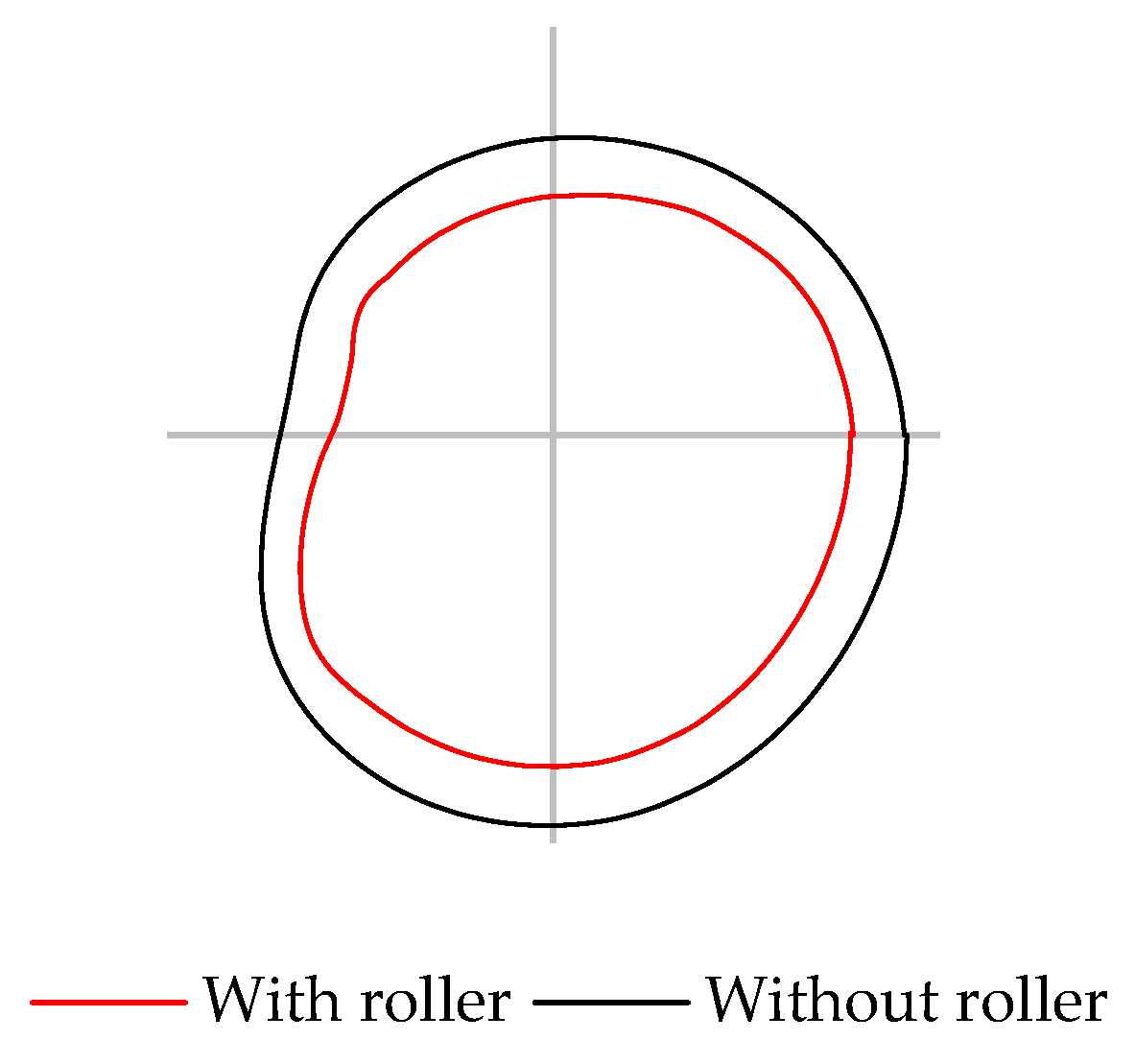

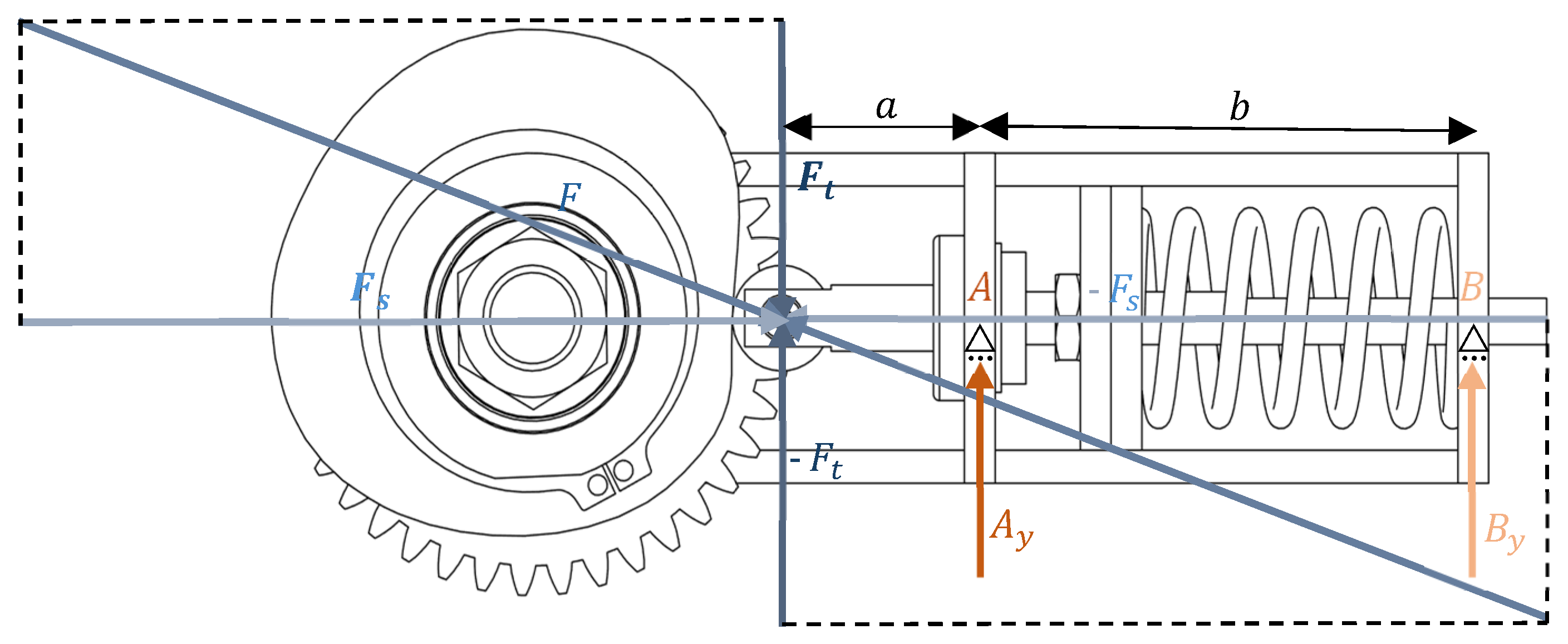

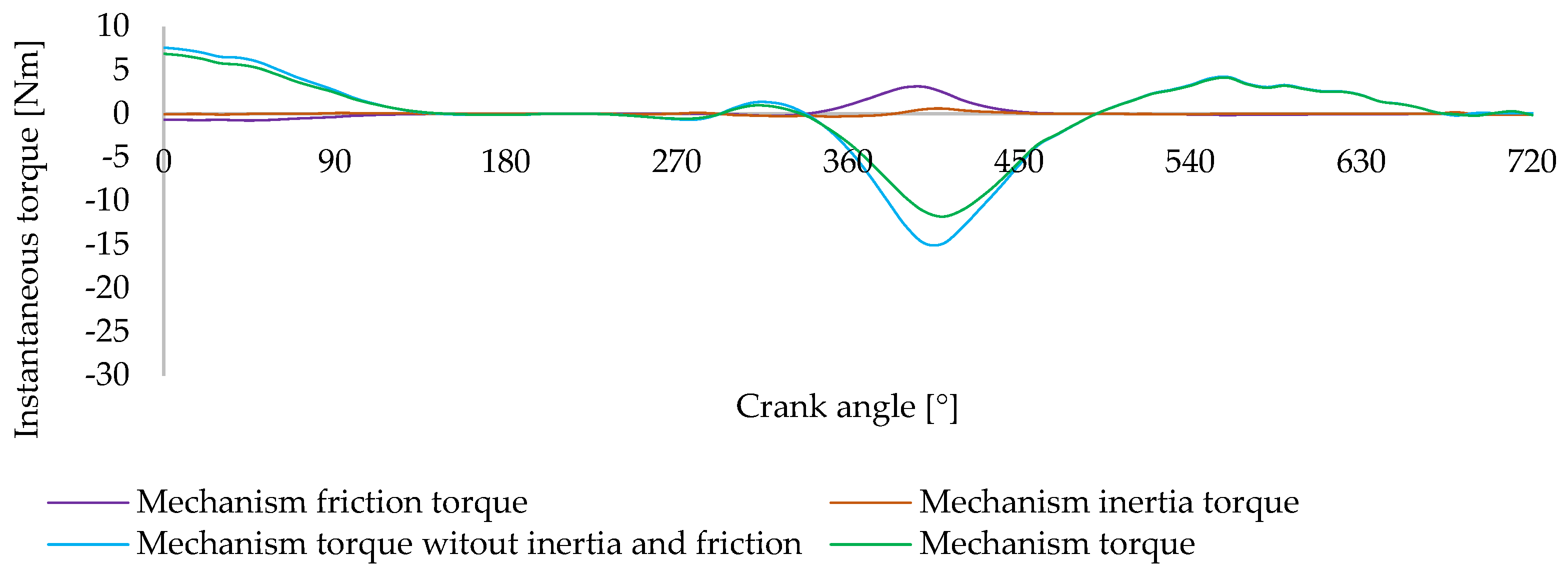

2.2.1. Integrated Design and Simulation

2.2.2. Mechanism Construction and Implementation

3. Results

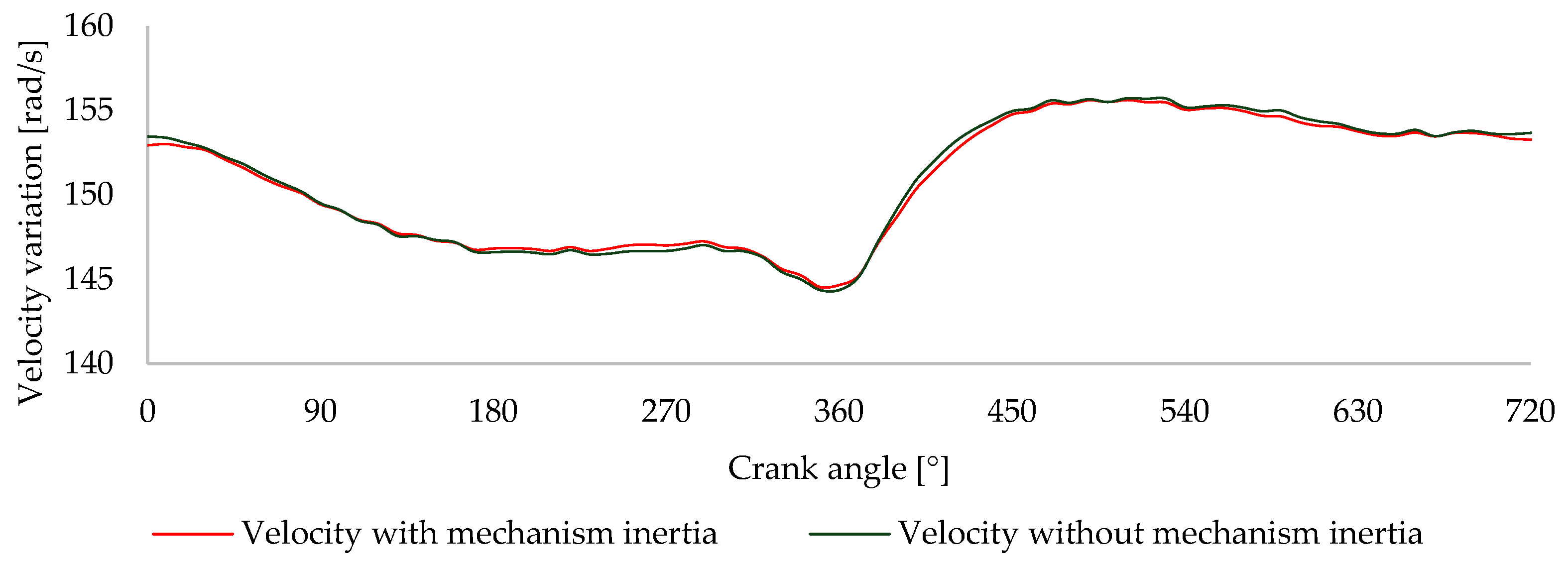

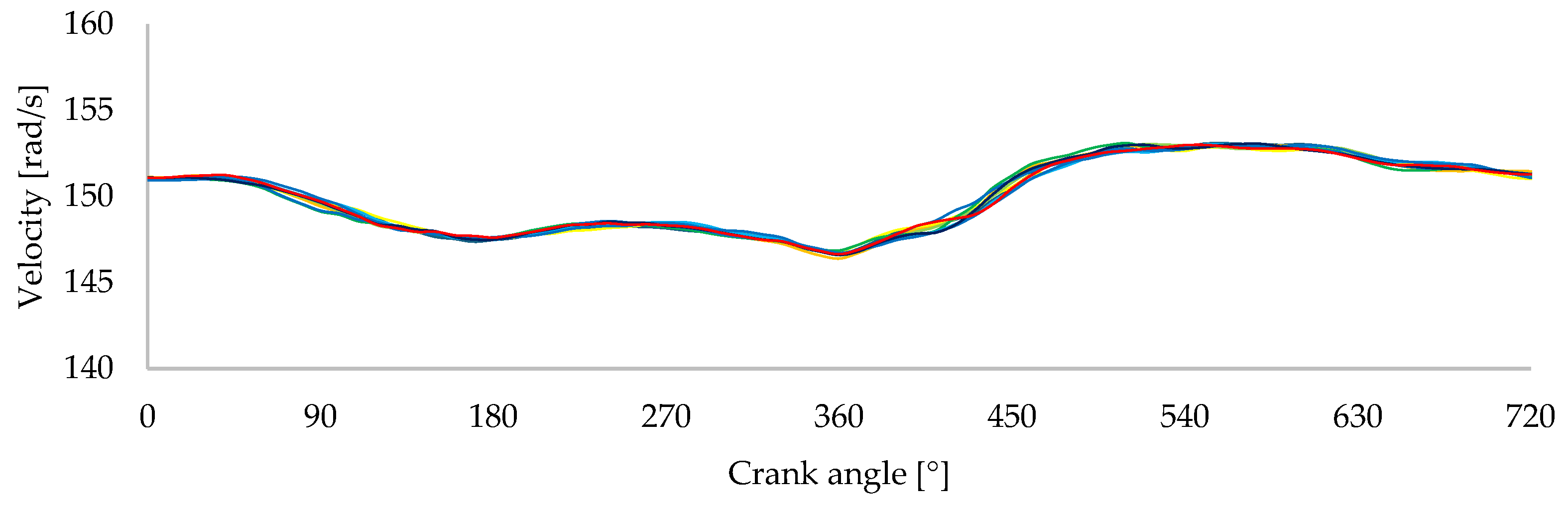

3.1. Mechanism Inertia Determination

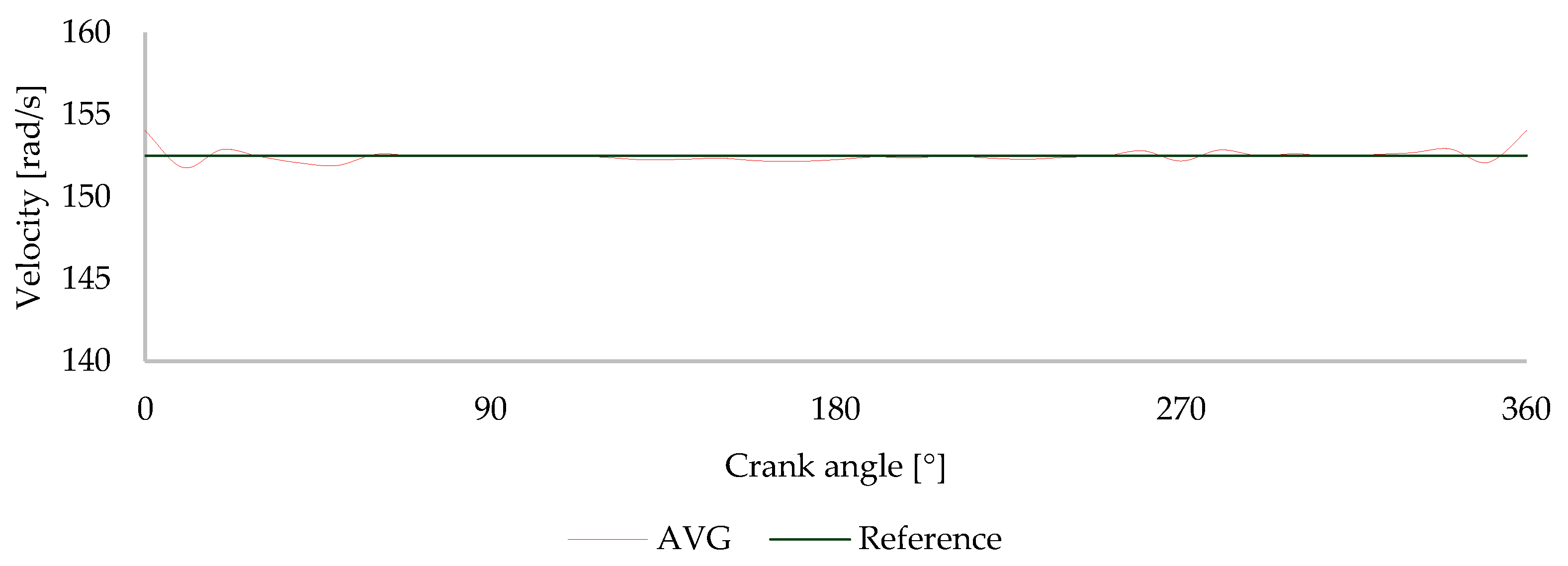

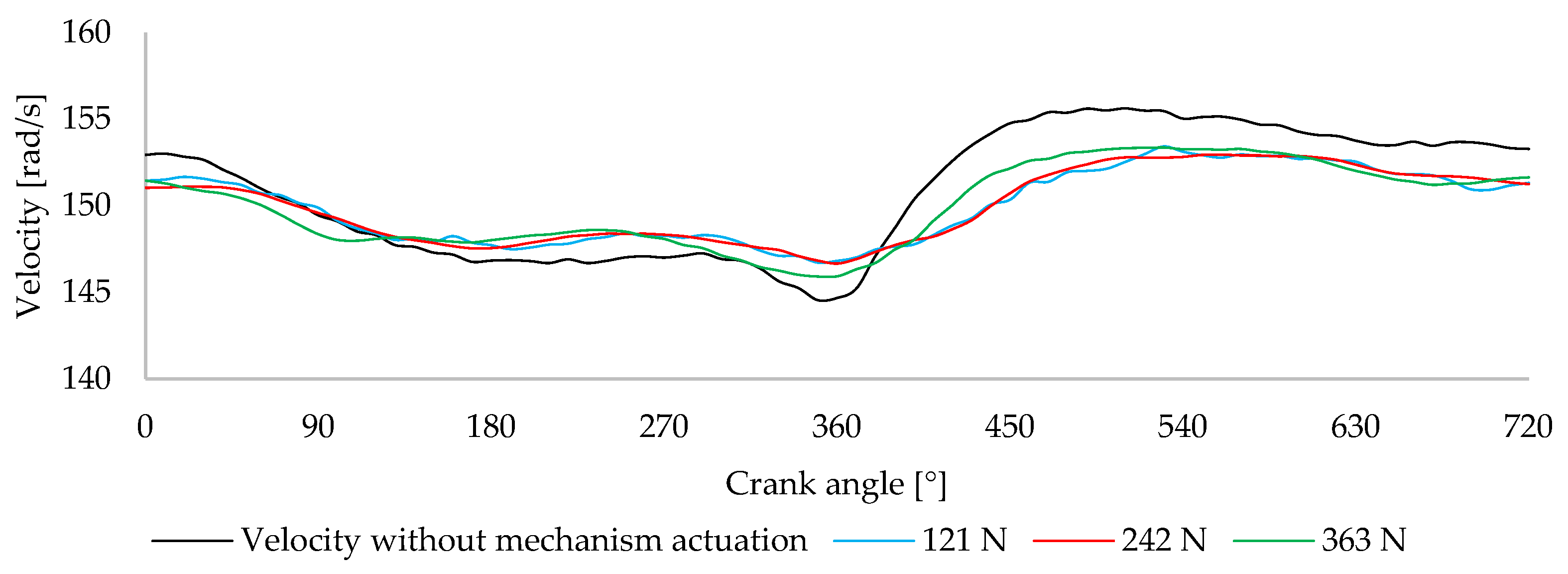

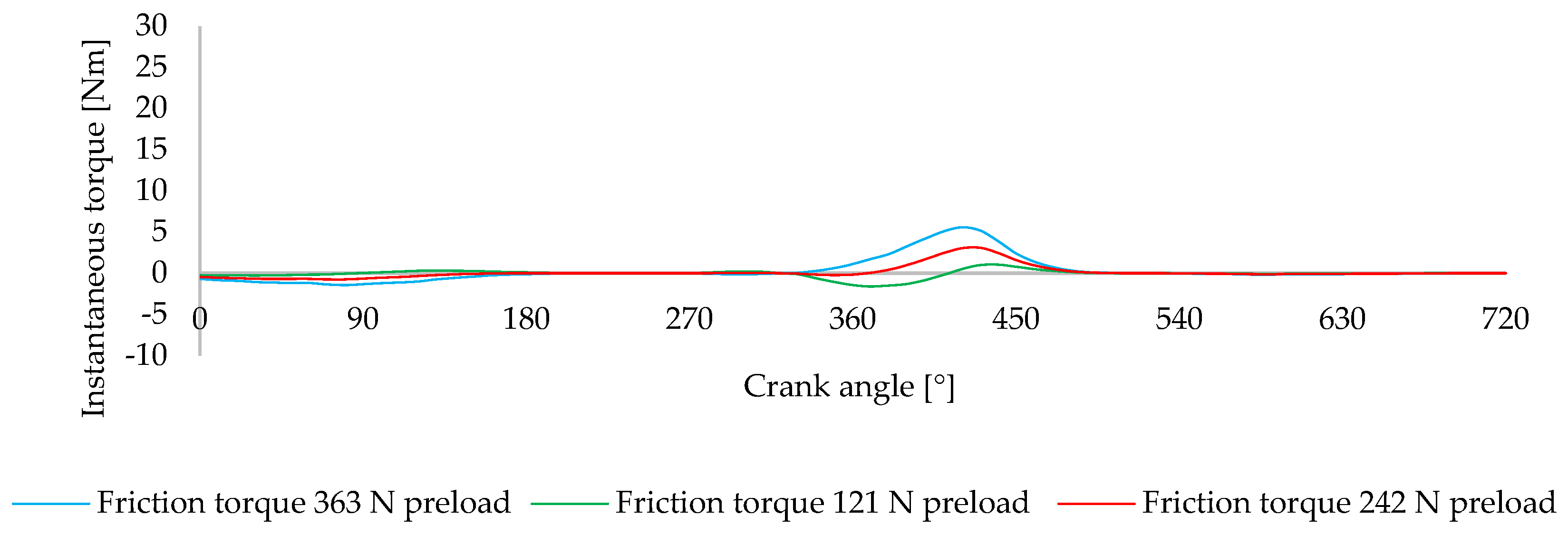

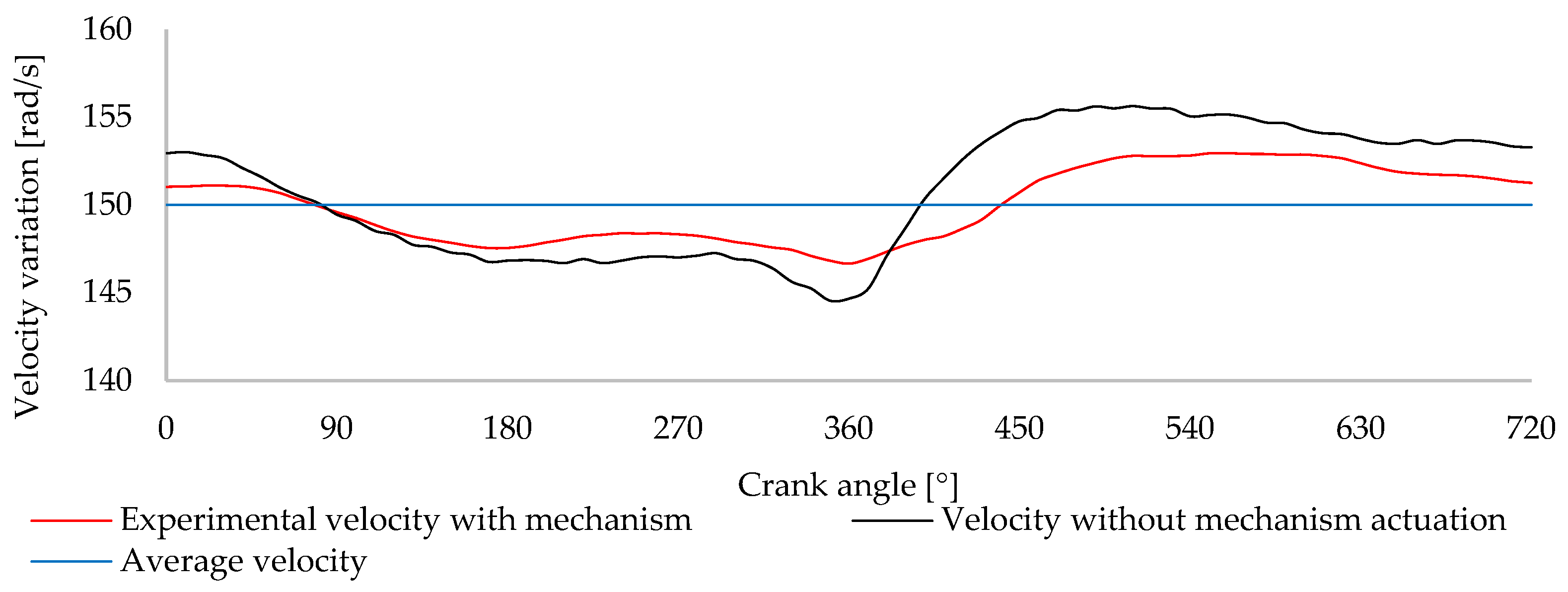

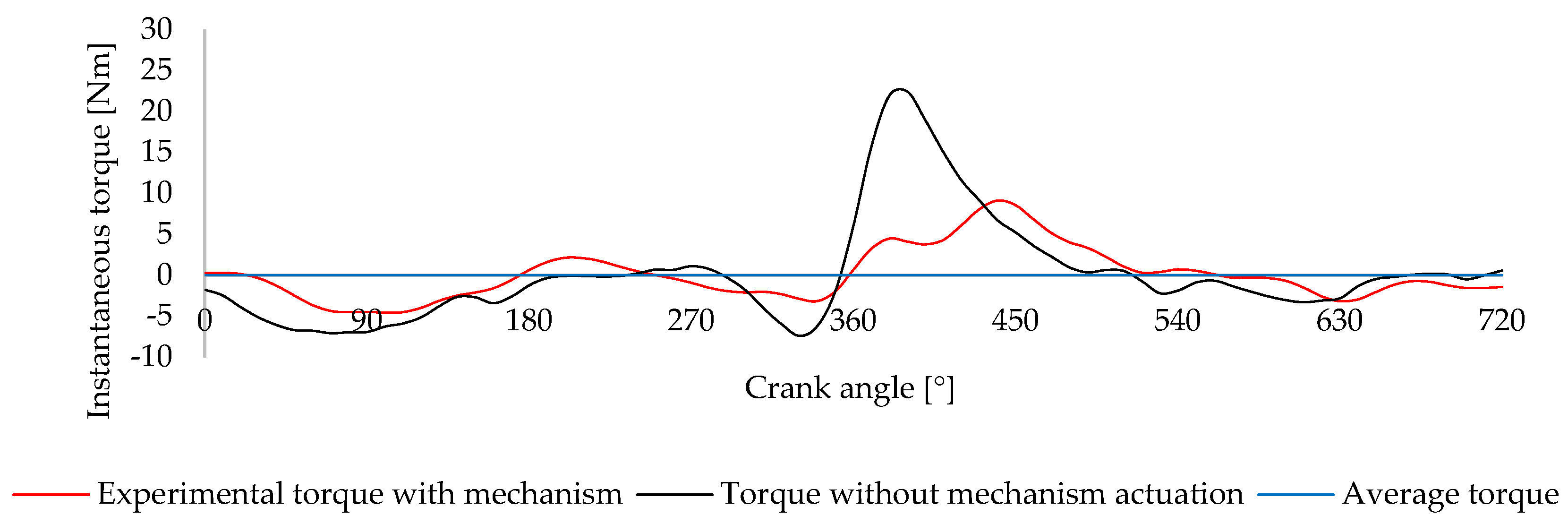

3.2. Mechanism Experimental Results

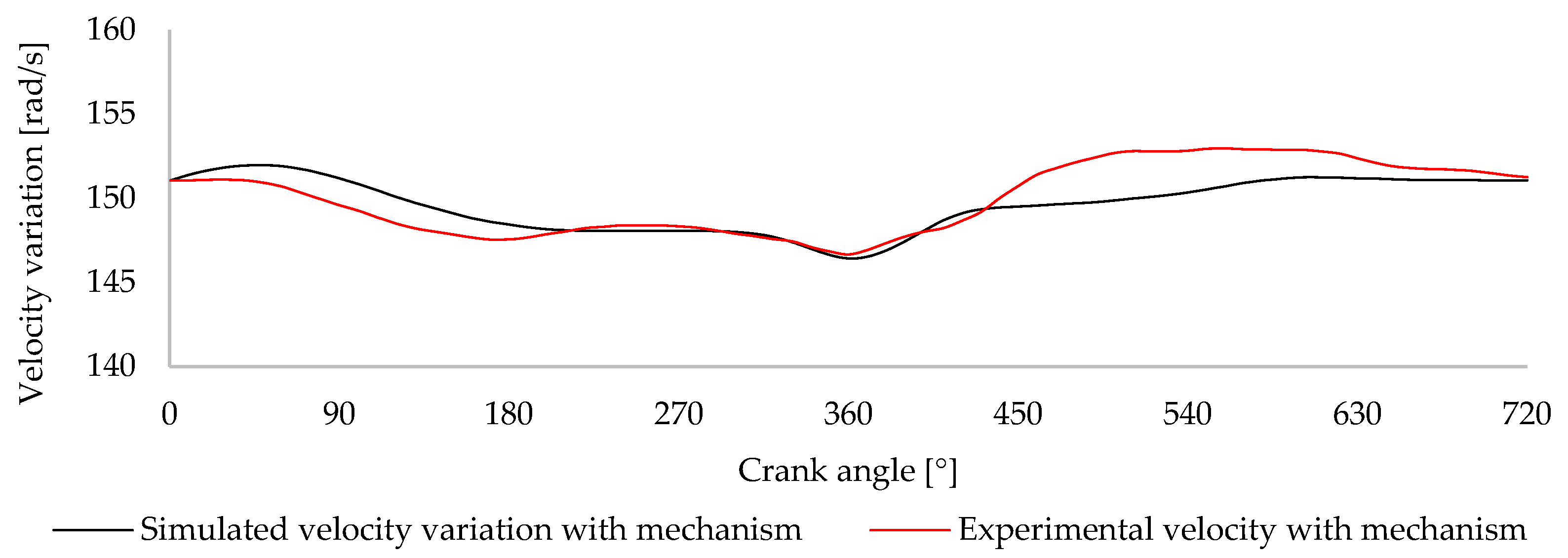

3.3. Mechanism Performance Evaluation and Results Discussion

4. Conclusions

Benefits, Performance Insights, and Future Developments

5. Patents

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Solmaz, H.; Karabulut, H. A mathematical model to investigate the effects of misfire and cyclic variations on crankshaft speed fluctuations in internal combustion engines. J. Mech. Sci. Technol. 2015, 29, 1493–1500. [Google Scholar] [CrossRef]

- Babagiray, M.; Solmaz, H.; İpci, D.; Aksoy, F. Modeling and validation of crankshaft speed fluctuations of a single-cylinder four-stroke diesel engine. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2022, 236, 553–568. [Google Scholar] [CrossRef]

- Cardoso, D.S.; Fael, P.O.; Espírito-Santo, A. Instantaneous angular velocity and torque on Otto single-cylinder engine: A theoretical and experimental analysis. Energy Rep. 2020, 6, 43–48. [Google Scholar] [CrossRef]

- Filipi, Z.S.; Assanis, D.N. A nonlinear, transient, single-cylinder diesel engine simulation for predictions of instantaneous engine speed and torque. J. Eng. Gas Turbines Power 2001, 123, 951–959. [Google Scholar] [CrossRef]

- Antonopoulos, A.K.; Hountalas, D.T. Effect of instantaneous rotational speed on the analysis of measured diesel engine cylinder pressure data. Energy Convers. Manag. 2012, 60, 87–95. [Google Scholar] [CrossRef]

- Munde, K.H.; Mehtre, V.K.; Ware, D.S.; Kamble, D.P. Review on performance of dual mass flywheel over conventional flywheel. Math. Stat. Eng. Appl. 2022, 71, 496–505. [Google Scholar] [CrossRef]

- Dawange, S.V.; Kadlag, V.L. A review paper on vibration analysis of DI engine. Int. J. Sci. Res. 2015, 4, 759–761. [Google Scholar]

- Cardoso, D.S.; Nunes, D.; Faria, J.; Fael, P.O.; Gaspar, P.D. Intelligent micro-cogeneration systems for residential grids: A sustainable solution for efficient energy management. Energies 2023, 16, 5215. [Google Scholar] [CrossRef]

- Mittal, V.; Shah, R.; Przyborowski, A. Analyzing the usage of Wankel engine technology in future automotive powertrains. SAE Int. J. Sustain. Transp. 2023, 5, 115–127. [Google Scholar] [CrossRef]

- Schaper, U.; Sawodny, O.; Mahl, T.; Blessing, U. Modeling and torque estimation of an automotive dual mass flywheel. In Proceedings of the 2009 American Control Conference, St. Louis, MO, USA, 10–12 June 2009; pp. 1207–1212. [Google Scholar] [CrossRef]

- Ayana, E.; Plahn, P.; Wejrzanowski, K.; Mohan, N. Active torque cancellation for transmitted vibration reduction. IEEE Trans. Veh. Technol. 2011, 60, 2971–2977. [Google Scholar] [CrossRef]

- Anjum, R.; Yar, A.; Ahmed, Q.; Bhatti, A. Model-based unified framework for detection and mitigation of cyclic torque imbalance. J. Eng. Gas Turbines Power 2021, 143, 051010. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, H.; Zhan, Z.; Wu, Y.; Zhang, W.; Taha, M.; Yan, P. Modelling and active damping of engine torque ripple. Control Eng. Pract. 2020, 104, 104634. [Google Scholar] [CrossRef]

- Galvagno, E.; Velardocchia, M.; Vigliani, A.; Tota, A. Experimental Analysis and Model Validation of a Dual Mass Flywheel; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2015. [Google Scholar] [CrossRef]

- Hässler, M.; Fieback, T.; Rabe, M.; Ryll, M. Clutch Disc with Centrifugal Pendulum Absorber. ATZ Worldw. 2016, 118, 42–47. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, T. Study on Vibration Damping Characteristics of Centrifugal Pendulum Double Mass Flywheel. DEStech Trans. Comput. Sci. Eng. 2018. [Google Scholar] [CrossRef]

- Pfabe, M.; Woernle, C. Reducing torsional vibrations by means of a kinematically driven flywheel—Theory and experiment. Mech. Mach. Theory 2016, 102, 217–228. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, X.; Qian, T.; Hu, R. Modeling and simulation of a passive variable inertia flywheel. Energy Rep. 2020, 6, 58–68. [Google Scholar] [CrossRef]

- Arakelian, V.V.; Briot, S. Simultaneous inertia force/moment balancing and torque compensation. Mech. Res. Commun. 2010, 37, 265–269. [Google Scholar] [CrossRef]

- Lin, D.Y.; Hou, B.J.; Lan, C.C. A balancing cam mechanism for minimizing the torque fluctuation of engine camshafts. Mech. Mach. Theory 2017, 108, 160–175. [Google Scholar] [CrossRef]

- Cardoso, D.S.; Fael, P.O.; Gaspar, P.D.; Espírito-Santo, A. An innovative mechanical approach to mitigating torque fluctuations in IC engines during idle operation. Designs 2024, 8, 47. [Google Scholar] [CrossRef]

- Kim, G.W.; Shin, S.C. Torque transmissibility of the passive torsional vibration isolator. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2015, 229, 1840–1847. [Google Scholar] [CrossRef]

- Society, I.E.E.V.T. Active torque ripple damping in direct drive range extender applications. In Proceedings of the 2015 IEEE Vehicle Power and Propulsion Conference (VPPC), Montreal, QC, Canada, 19–22 October 2015. [Google Scholar] [CrossRef]

- Jianguo, B.; Xudong, L.; Ming, Z.; Kaixiong, L. Design and optimization of flywheel motor based on torque density. In Proceedings of the 2018 IEEE 3rd Advanced Information Technology, Electronic and Automation Control Conference (IAEAC), Chongqing, China, 12–14 October 2018; pp. 2156–2162. [Google Scholar] [CrossRef]

- Fraser, N.; Blaxill, H.; Lumsden, G.; Bassett, M. Challenges for increased efficiency through gasoline engine downsizing. SAE Int. J. Engines 2009, 2, 991–1008. [Google Scholar] [CrossRef]

- Hannan, M.A.; Azidin, F.A.; Mohamed, A. Hybrid electric vehicles and their challenges: A review. Renew. Sustain. Energy Rev. 2014, 29, 135–150. [Google Scholar] [CrossRef]

- Cardoso, D.S.; Fael, P.O.; Espírito-Santo, A. A review of micro and mild hybrid systems. Energy Rep. 2020, 6, 385–390. [Google Scholar] [CrossRef]

- Mastrangelo, G.; Micelli, D.; Sacco, D. Extreme downsizing by the two-cylinder gasoline engine from Fiat. ATZautotechnology 2011, 11, 18–25. [Google Scholar] [CrossRef]

- Omanovic, A.; Zsiga, N.; Soltic, P.; Onder, C. Increased ICE efficiency with optimized valve timings. Energies 2021, 14, 2750. [Google Scholar] [CrossRef]

- Bech, A.; Shayler, P.J.; McGhee, M. Effects of cylinder deactivation on three cylinder engines. SAE Int. J. Engines 2016, 9, 1999–2009. [Google Scholar] [CrossRef]

- Blair, J.G. Design and Simulation of Four-Stroke Engines; SAE International: Warrendale, PA, USA, 1999; ISBN 978-0-7680-0440-3. [Google Scholar]

- Porumb, I.; Marian, R.; Doğançay, K.; Chahl, J.S. Robust instant angle speed measurement for internal combustion engines—A novel sensing suite and methodology. Sensors 2022, 22, 754. [Google Scholar] [CrossRef]

- Addabbo, T.; Di Marco, M.; Fort, A.; Landi, E.; Mugnaini, M.; Vignoli, V.; Ferretti, G. Instantaneous rotation speed measurement system based on variable reluctance sensors for torsional vibration monitoring. IEEE Trans. Instrum. Meas. 2019, 68, 2363–2373. [Google Scholar] [CrossRef]

- Costello, J.J.; Pickard, A.C. A novel speed measurement system for turbomachinery. IEEE Sens. Lett. 2018, 2, 1–4. [Google Scholar] [CrossRef]

- Zhang, P.; Gao, W.; Song, Q.; Li, Y.; Wei, L.; Wei, Z. Real-time angular velocity-based misfire detection using artificial neural networks. J. Eng. Gas Turbines Power 2019, 141, 061008. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, P.; Gao, W.; Li, Y.; Wang, Y.; Pang, H. Misfire detection using crank speed and long short-term memory recurrent neural network. Energies 2022, 15, 300. [Google Scholar] [CrossRef]

- Savaripour, H.; Rosen, M.A. Comparison of simulation and experimental test results of the turbocharger temperature for two gasoline direct injection engines. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2022, 237, 1–11. [Google Scholar] [CrossRef]

- Akbarian, E.; Najafi, B.; Jafari, M.; Ardabili, S.F.; Shamshirband, S.; Chau, K.W. Experimental and computational fluid dynamics-based numerical simulation of using natural gas in a dual-fueled diesel engine. Eng. Appl. Comput. Fluid Mech. 2018, 12, 517–534. [Google Scholar] [CrossRef]

- Kiss, A.; Szabó, B.; Kun, K.; Weltsch, Z. Prediction of efficiency, performance, and emissions based on a validated simulation model in hydrogen–gasoline dual-fuel internal combustion engines. Energies 2024, 17, 5680. [Google Scholar] [CrossRef]

- Ali, S.A.; Saraswati, S. Cycle-by-cycle estimation of cylinder pressure and indicated torque waveform using crankshaft speed fluctuations. Trans. Inst. Meas. Control 2015, 37, 813–825. [Google Scholar] [CrossRef]

- Li, Z.; Guo, Z.; Hu, C.; Li, A. On-line indicated torque estimation for internal combustion engines using discrete observer. Comput. Electr. Eng. 2017, 60, 100–115. [Google Scholar] [CrossRef]

- Tong, Q.; Xie, H.; Song, K.; Zou, D. A control-oriented engine torque online estimation approach for gasoline engines based on in-cycle crankshaft speed dynamics. Energies 2019, 12, 4683. [Google Scholar] [CrossRef]

- Uicker, J.J., Jr.; Pennock, G.R.; Shigley, J.E. Theory of Machines and Mechanisms, 5th ed.; Oxford University Press: New York, NY, USA, 2016. [Google Scholar]

- Budynas, R.G.; Nisbett, J.K. Shigley’s Mechanical Engineering Design, 9th ed.; McGraw-Hill: New York, NY, USA, 2010. [Google Scholar]

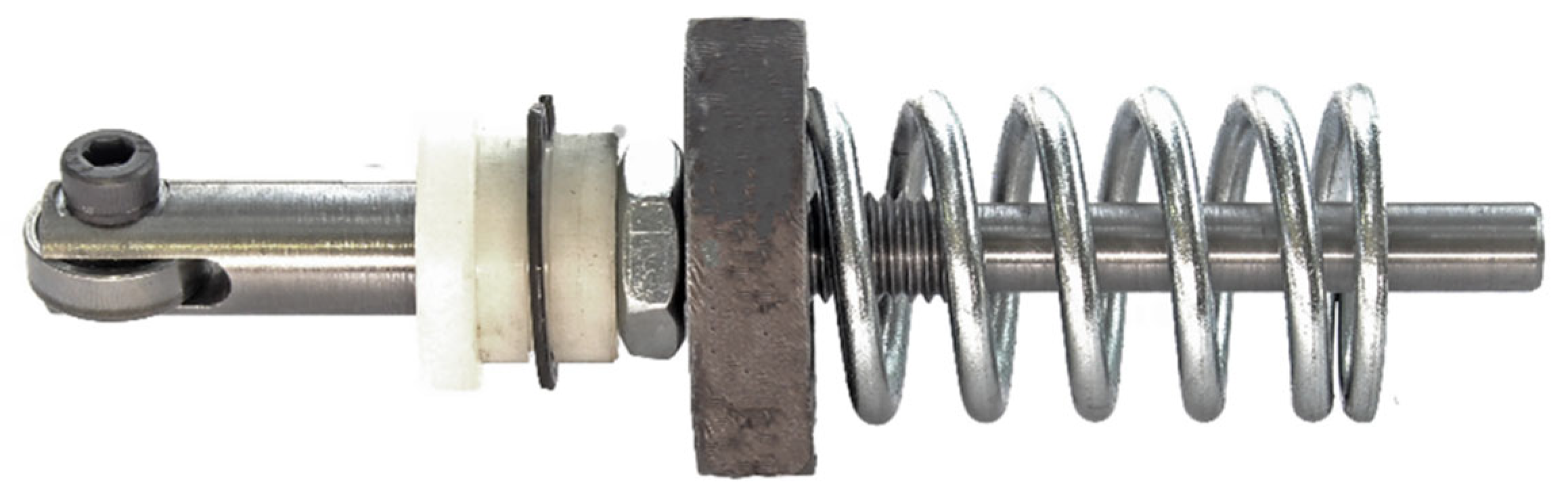

| Cam | Spring |

|---|---|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cardoso, D.S.; Fael, P.O.; Gaspar, P.D.; Espírito-Santo, A. Balancing Cam Mechanism for Instantaneous Torque and Velocity Stabilization in Internal Combustion Engines: Simulation and Experimental Validation. Energies 2025, 18, 3256. https://doi.org/10.3390/en18133256

Cardoso DS, Fael PO, Gaspar PD, Espírito-Santo A. Balancing Cam Mechanism for Instantaneous Torque and Velocity Stabilization in Internal Combustion Engines: Simulation and Experimental Validation. Energies. 2025; 18(13):3256. https://doi.org/10.3390/en18133256

Chicago/Turabian StyleCardoso, Daniel Silva, Paulo Oliveira Fael, Pedro Dinis Gaspar, and António Espírito-Santo. 2025. "Balancing Cam Mechanism for Instantaneous Torque and Velocity Stabilization in Internal Combustion Engines: Simulation and Experimental Validation" Energies 18, no. 13: 3256. https://doi.org/10.3390/en18133256

APA StyleCardoso, D. S., Fael, P. O., Gaspar, P. D., & Espírito-Santo, A. (2025). Balancing Cam Mechanism for Instantaneous Torque and Velocity Stabilization in Internal Combustion Engines: Simulation and Experimental Validation. Energies, 18(13), 3256. https://doi.org/10.3390/en18133256