Upgrading/Deacidification of Biofuels (Gasoline, Kerosene, and Diesel-like Hydrocarbons) by Adsorption Using Activated Red-Mud-Based Adsorbents

Abstract

1. Introduction

2. Materials and Methods

2.1. Characterization of the Feedstock

2.2. Preparation of the Adsorbent

2.2.1. Thermal Activation of Red Mud

2.2.2. Chemical Activation of Red Mud

2.3. Characterization of Adsorbents

2.3.1. Scanning Electron Microscopy (SEM)–Energy-Dispersive X-Ray (EDX) Analysis

2.3.2. Fourier-Transform Infrared Spectroscopy (FTIR)

2.3.3. X-Ray Diffraction

2.3.4. Surface and Textural Characterization

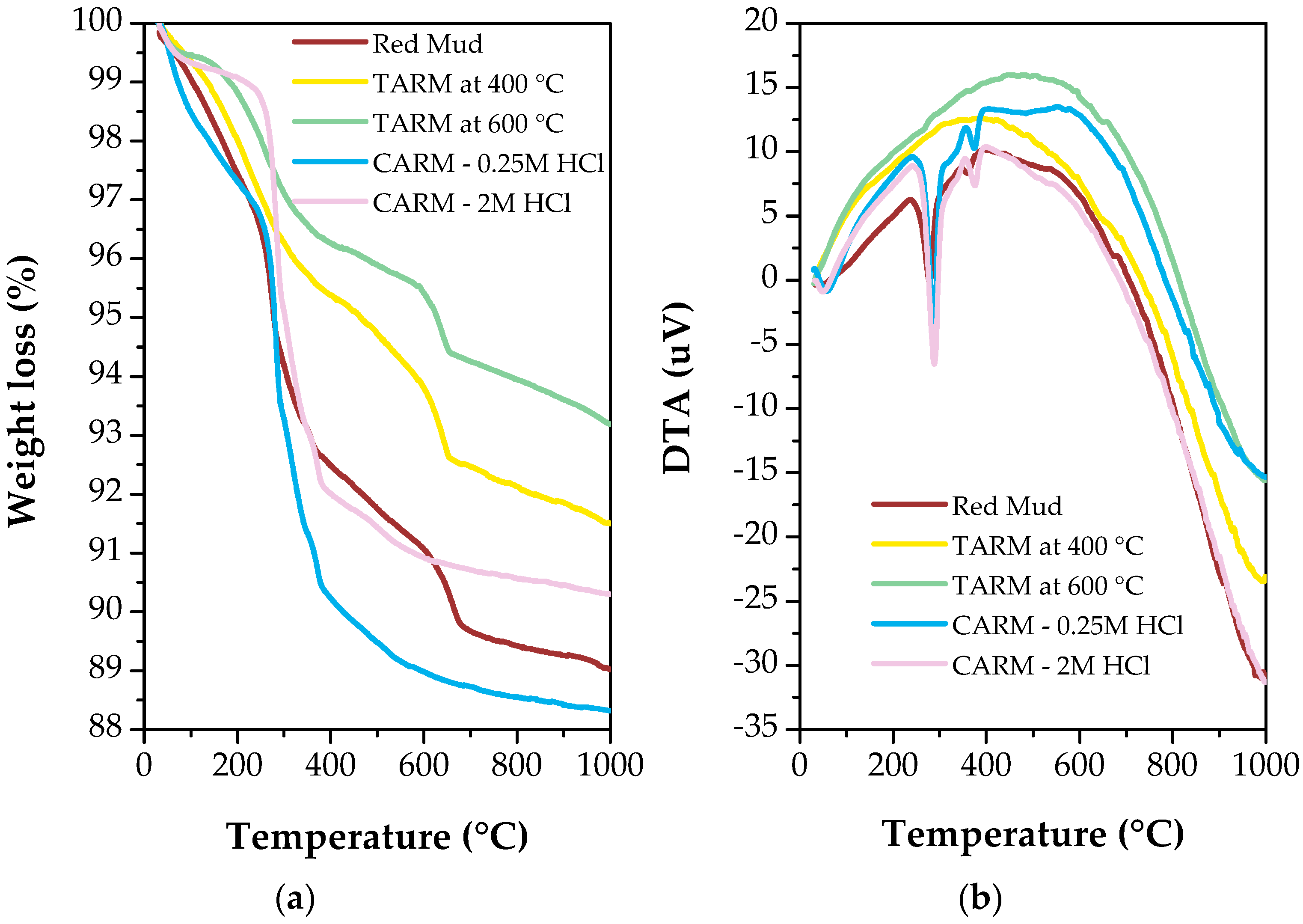

2.3.5. Thermal Analysis

2.4. Experimental Procedure for the Adsorption of Carboxylic Acids

2.4.1. Effect of Feedstock Type

- Gasoline-like hydrocarbons (boiling range: 90–160 °C; TAN = 1.56 mg KOH/g);

- Kerosene-like hydrocarbons (boiling range: 160–245 °C; TAN = 1.59 mg KOH/g);

- Diesel-like hydrocarbons (boiling range: 245–340 °C; TAN = 1.55 mg KOH/g).

2.4.2. Effect of the Adsorbent

2.4.3. Effects of Free Fatty Acid Contents on Feedstock

2.4.4. Effect of Adsorbent Amount

2.4.5. Effect of Activation Temperature

2.4.6. Effect of Acid Solution Concentration

2.4.7. Adsorption Kinetics

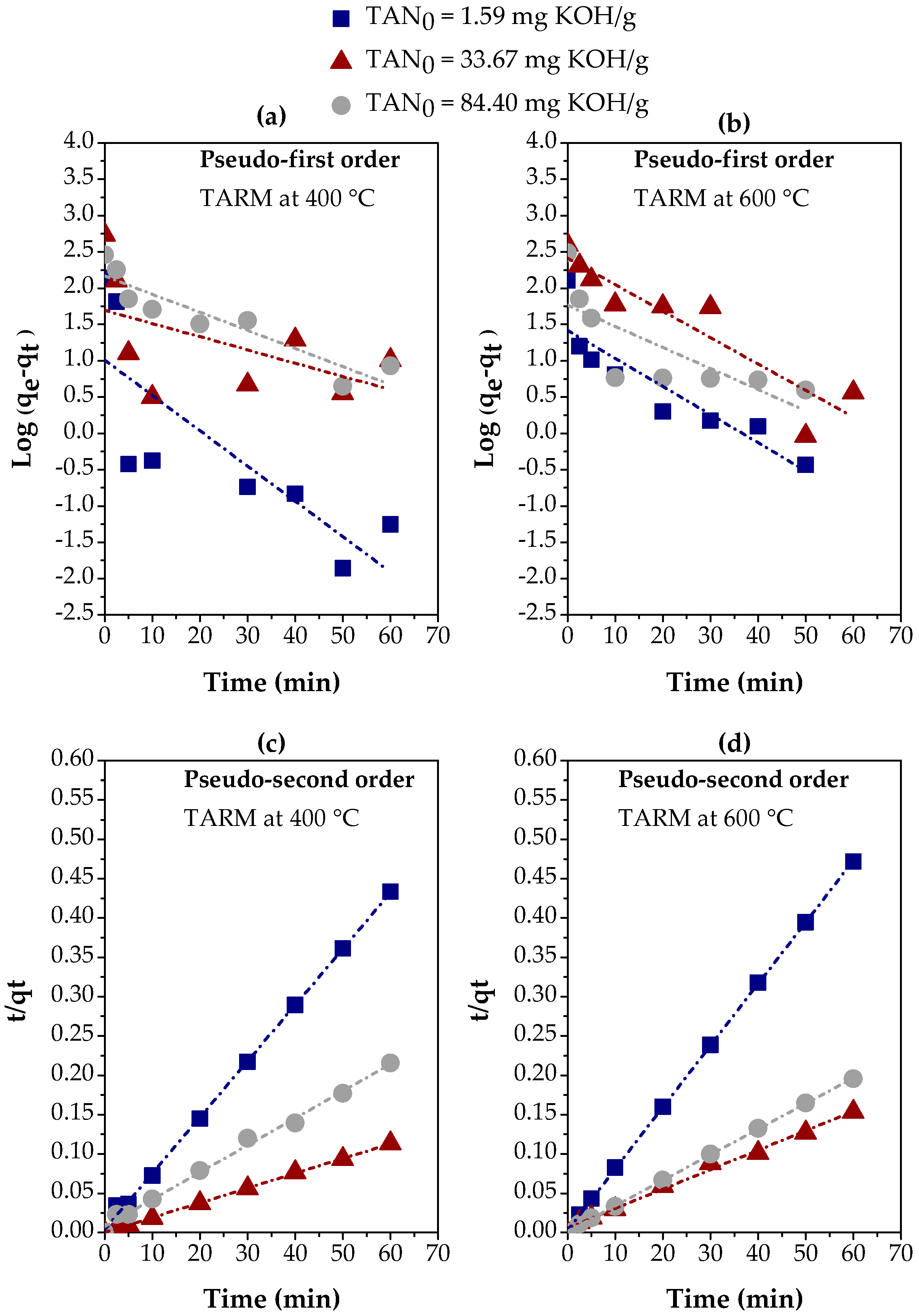

2.5. Kinetics Modeling

- 1.

- Pseudo-first-order:

- 2.

- Pseudo-second-order:

3. Results

3.1. Characterization of Adsorbents

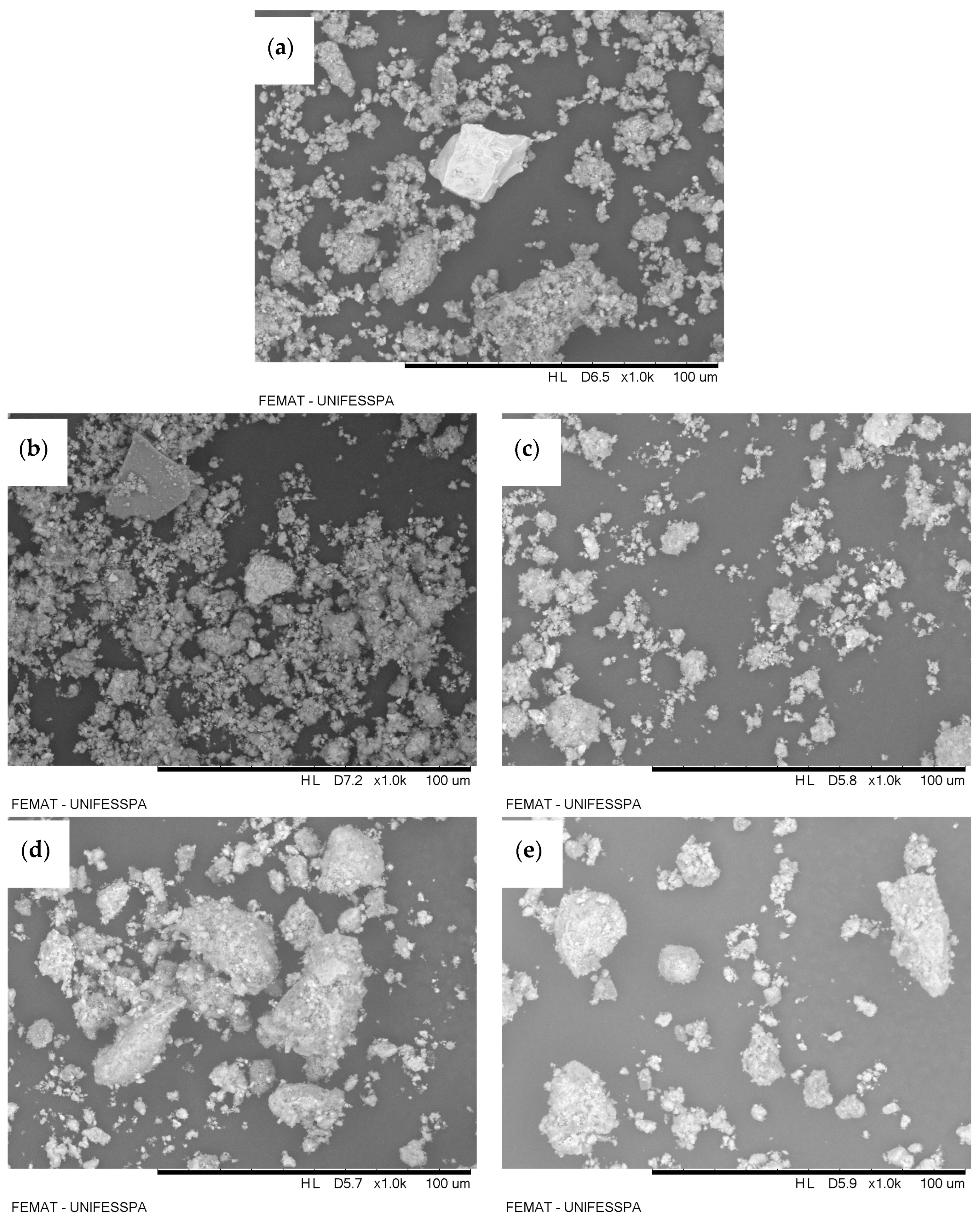

3.1.1. Scanning Electron Microscopy (SEM)–Energy-Dispersive X-Ray (EDX) Analysis

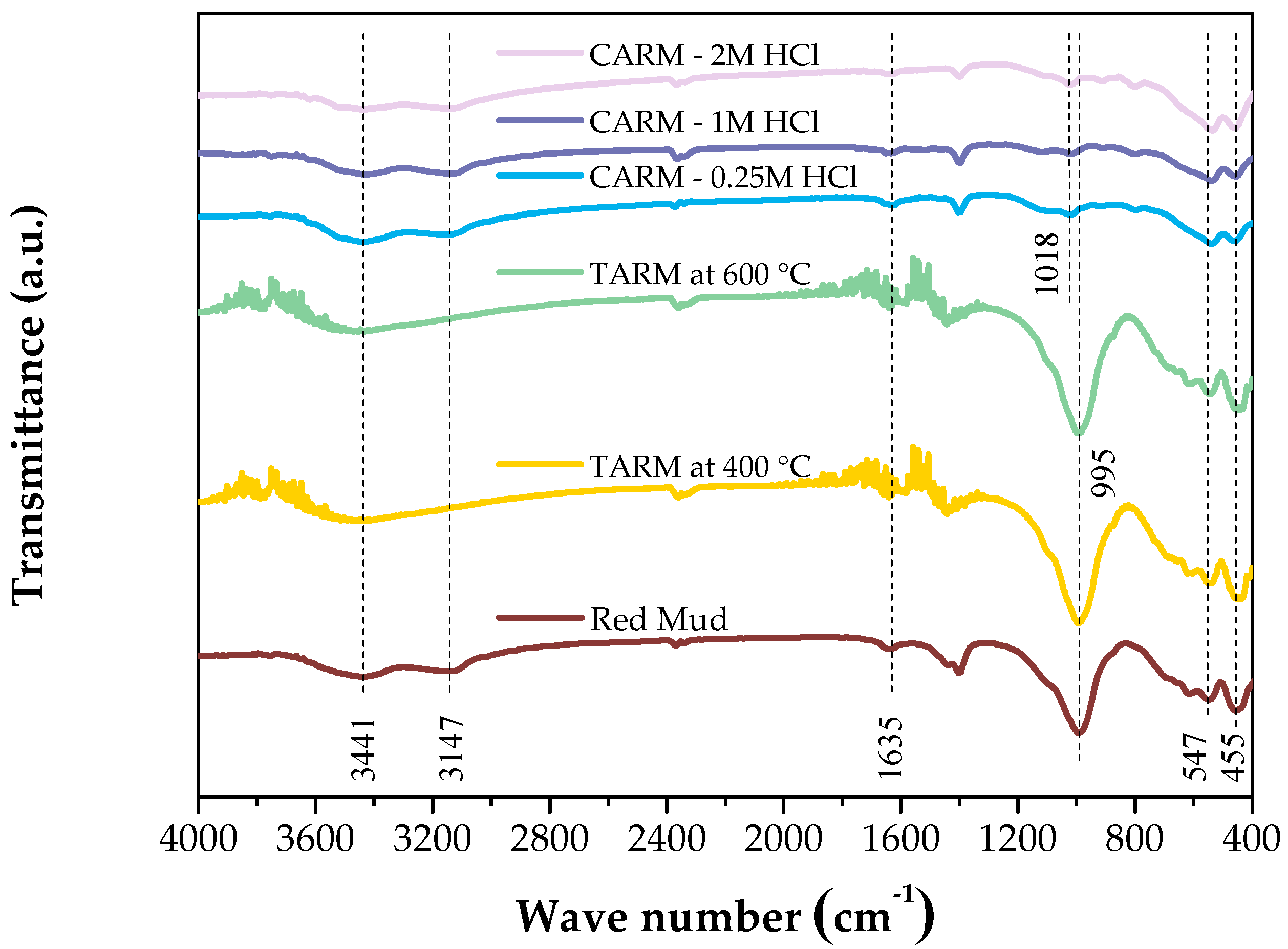

3.1.2. Fourier-Transform Infrared Spectroscopy (FTIR)

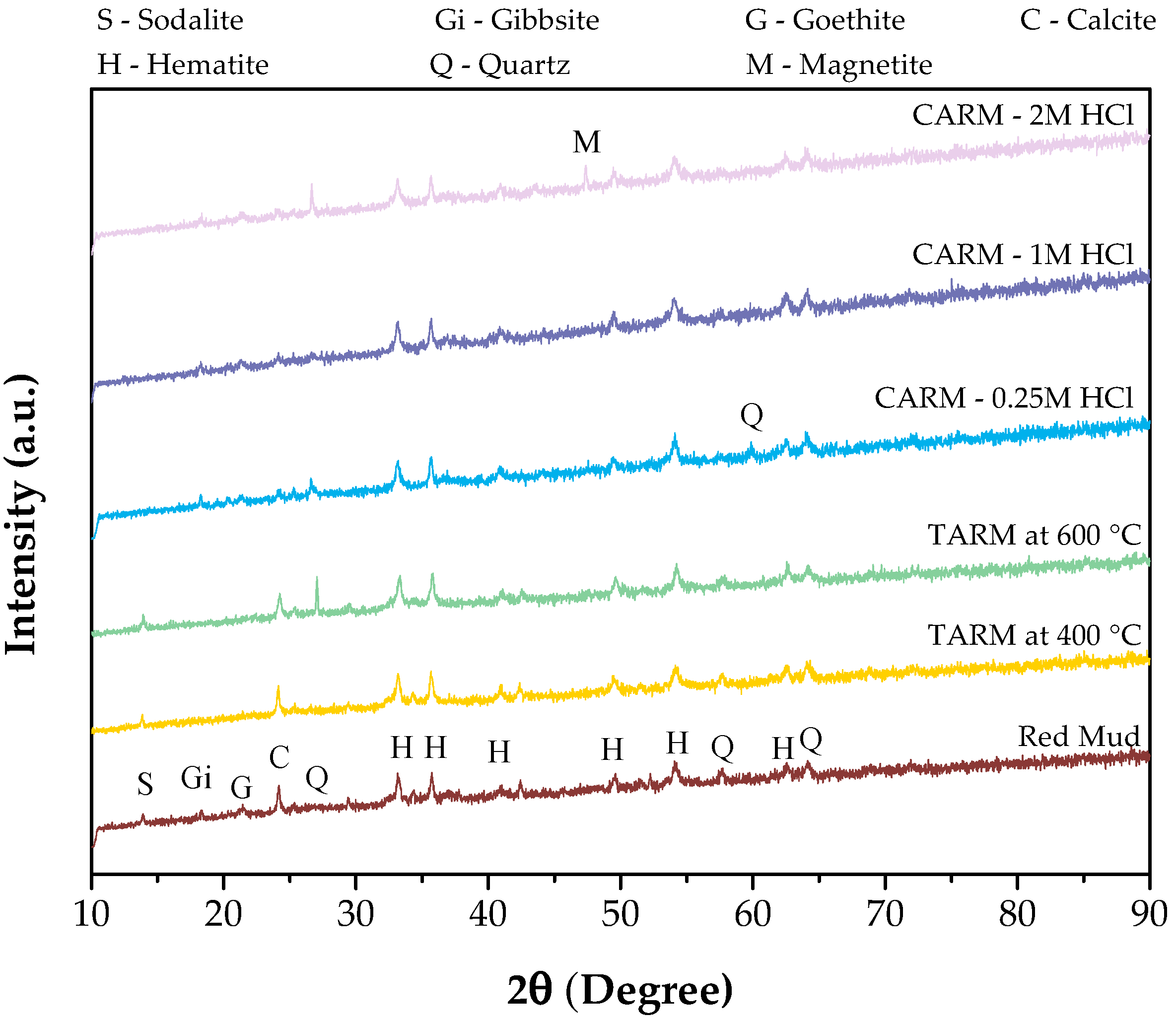

3.1.3. X-Ray Diffraction (XRD)

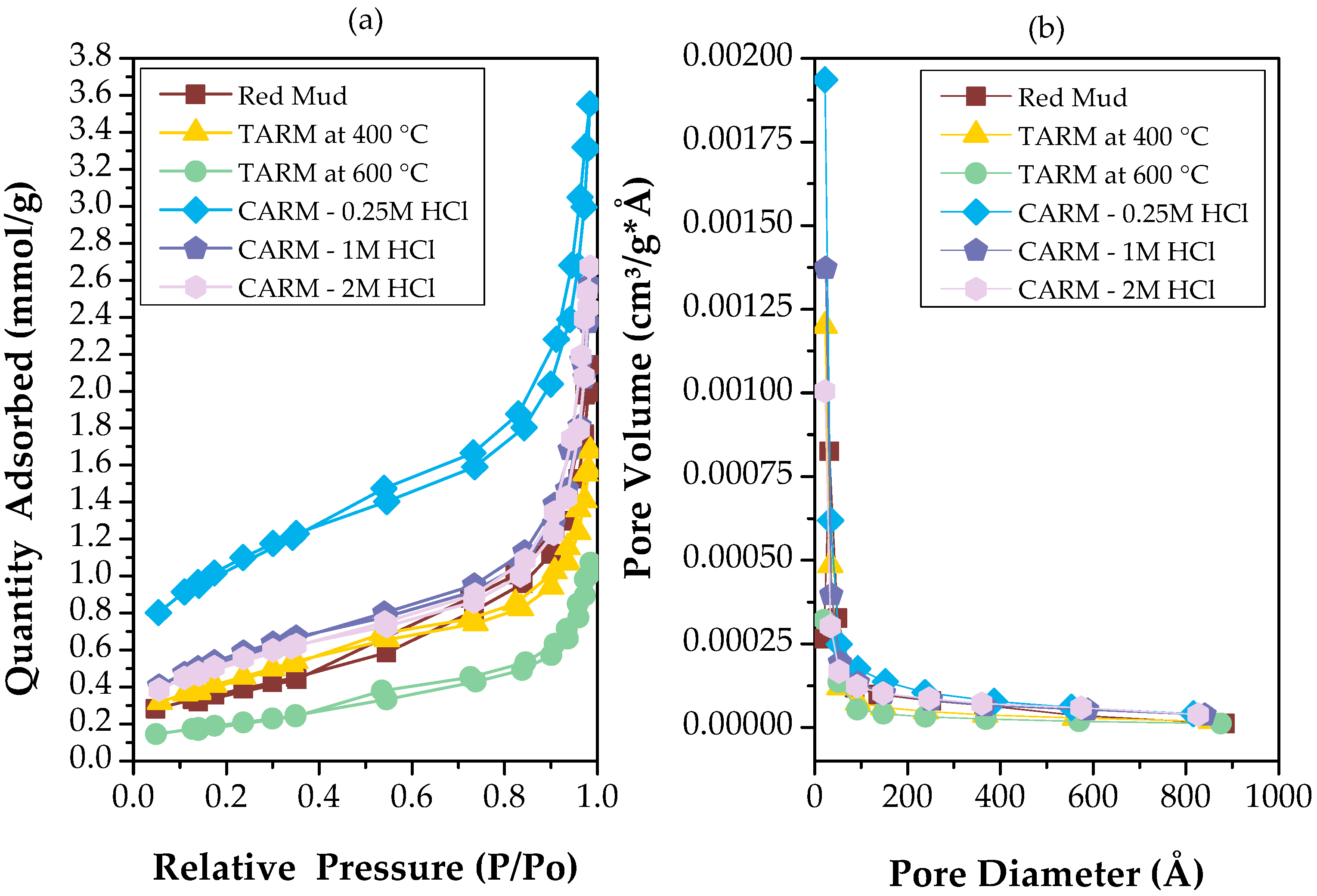

3.1.4. Surface and Textural Characterization

3.1.5. Thermal Analysis

3.2. Adsorption Kinetics and Kinetic Modeling

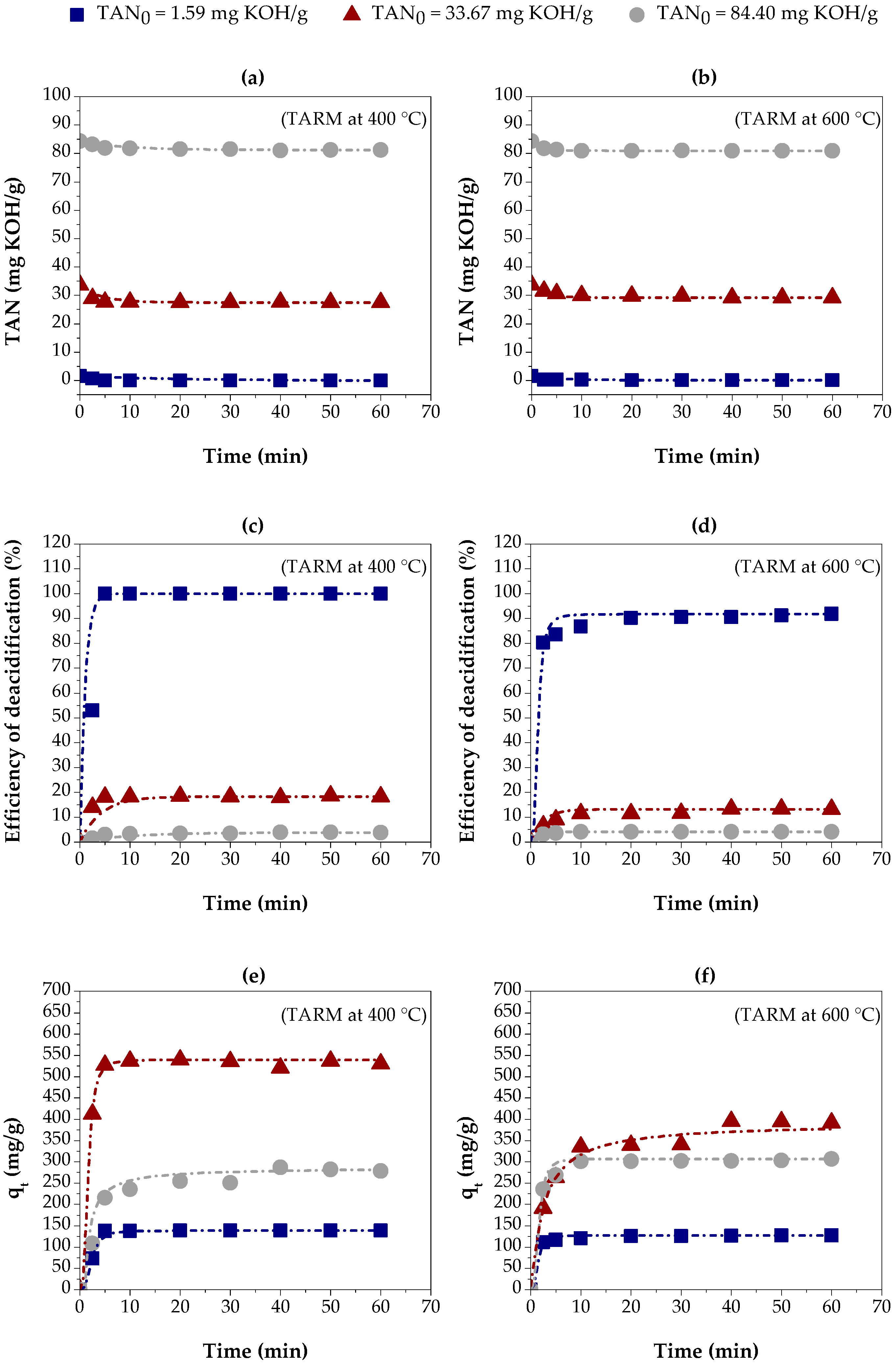

3.2.1. Thermally Activated Red Mud

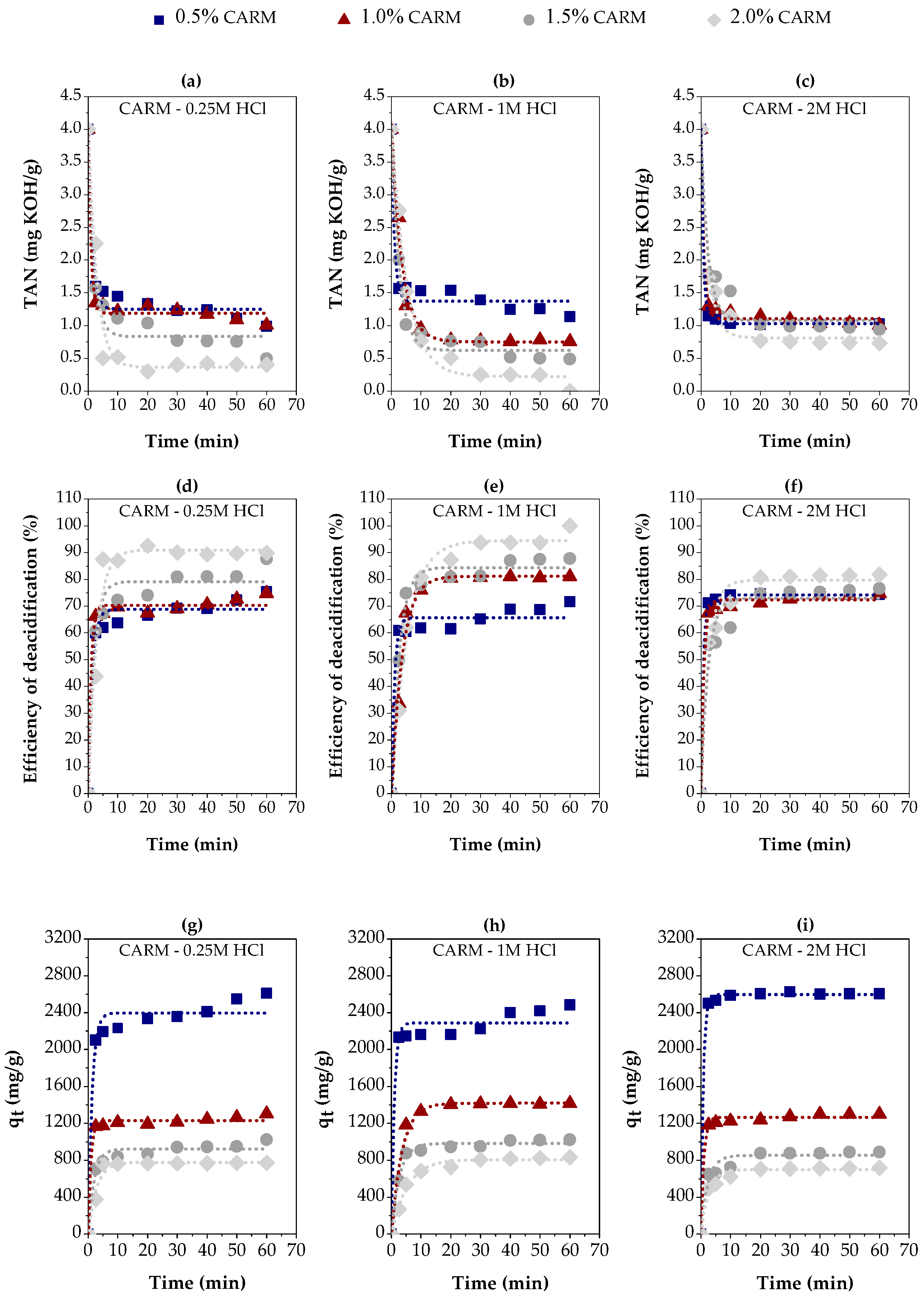

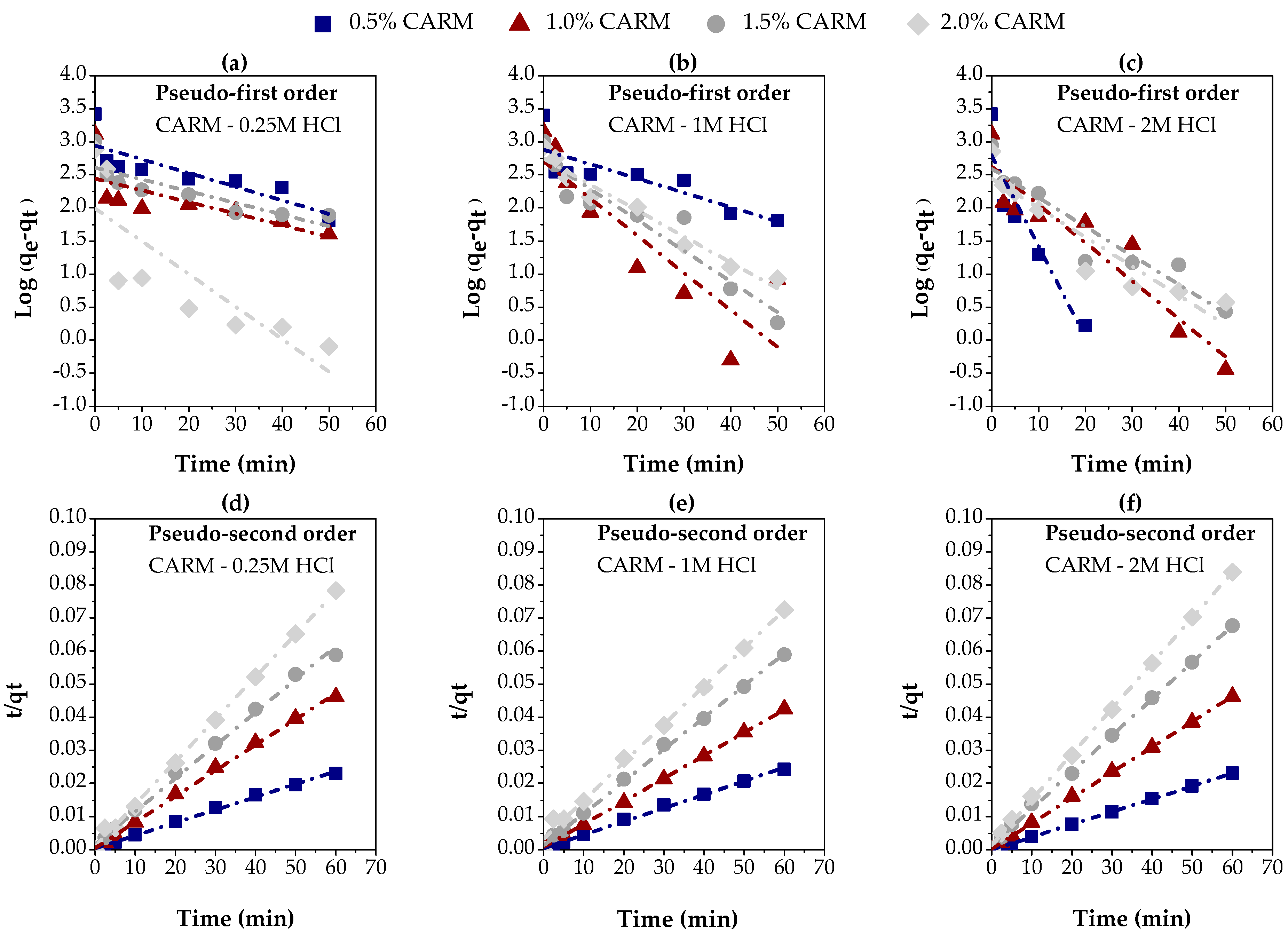

3.2.2. Chemically Activated Red Mud

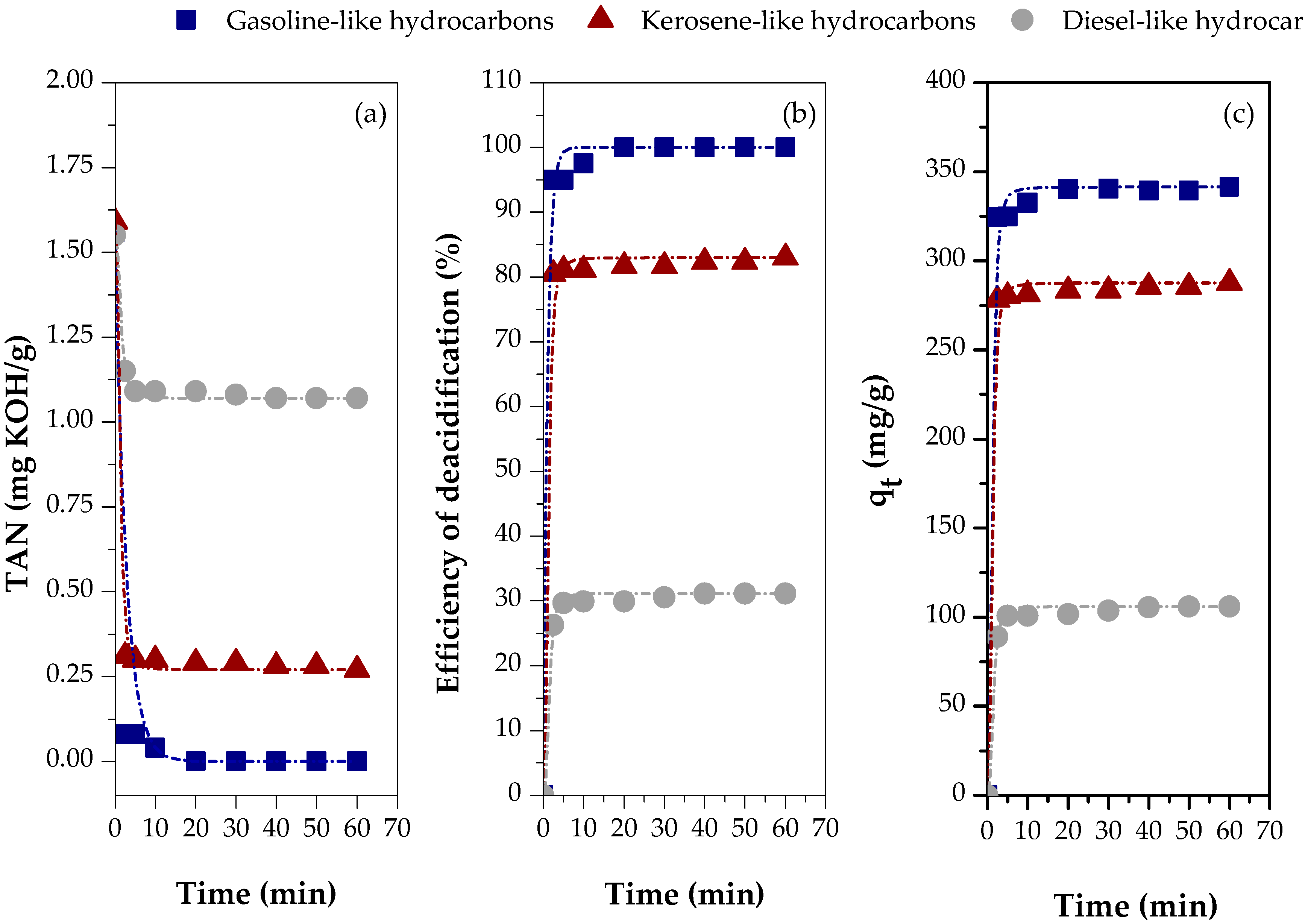

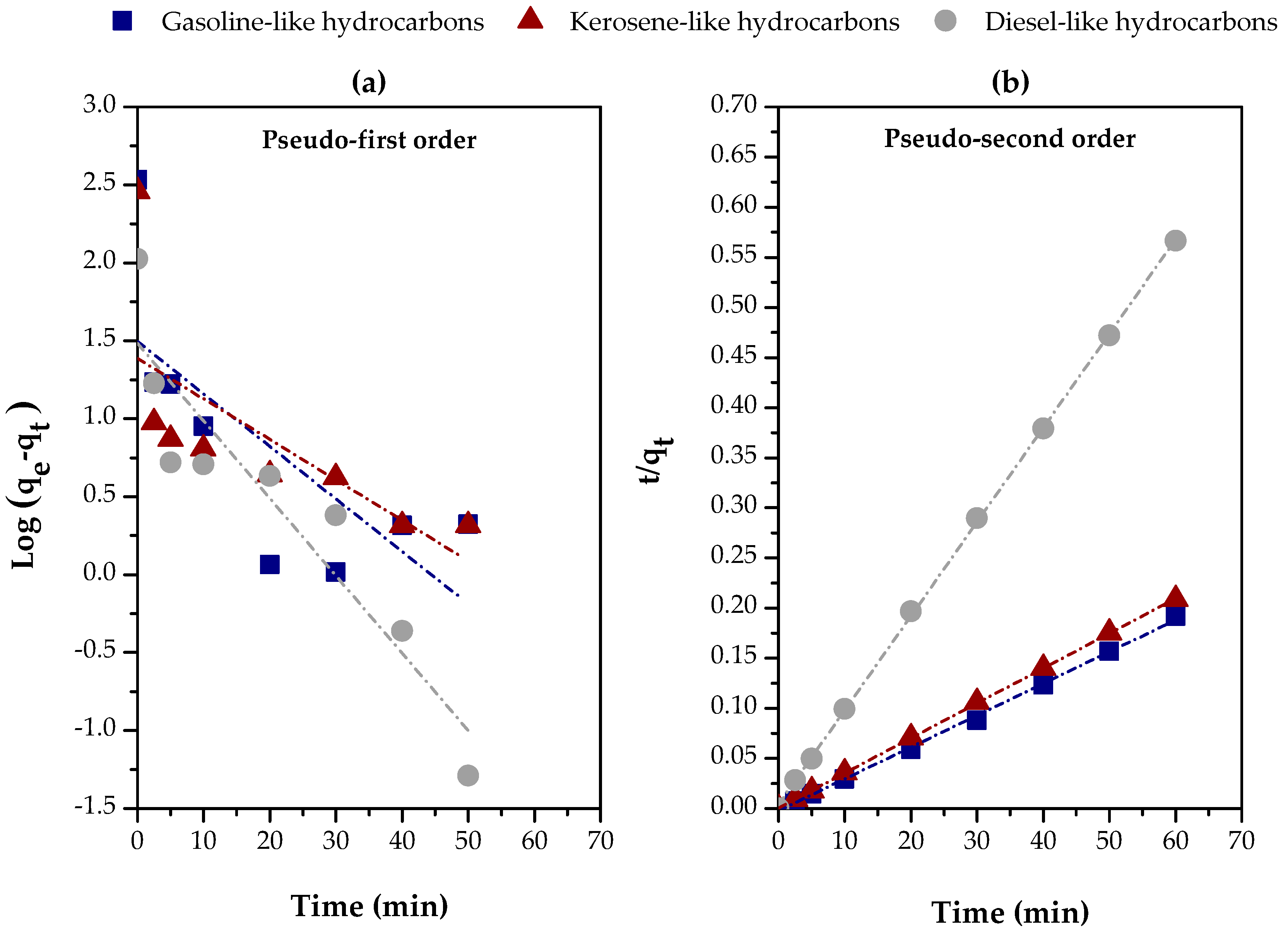

3.2.3. Effect of the Type of Feed

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- International Energy Agency (IEA). World Energy Outlook 2023; International Energy Agency (IEA): Paris, France, 2023. [Google Scholar]

- Stedile, T.; Ender, L.; Meier, H.F.; Simionatto, E.L.; Wiggers, V.R. Comparison between Physical Properties and Chemical Composition of Bio-Oils Derived from Lignocellulose and Triglyceride Sources. Renew. Sustain. Energy Rev. 2015, 50, 92–108. [Google Scholar] [CrossRef]

- Wei, Y.; Lei, H.; Wang, L.; Zhu, L.; Zhang, X.; Liu, Y.; Chen, S.; Ahring, B. Liquid–Liquid Extraction of Biomass Pyrolysis Bio-Oil. Energy Fuels 2014, 28, 1207–1212. [Google Scholar] [CrossRef]

- Naji, S.Z.; Tye, C.T.; Abd, A.A. State of the Art of Vegetable Oil Transformation into Biofuels Using Catalytic Cracking Technology: Recent Trends and Future Perspectives. Process Biochem. 2021, 109, 148–168. [Google Scholar] [CrossRef]

- Lima, D.G.; Soares, V.C.D.; Ribeiro, E.B.; Carvalho, D.A.; Cardoso, É.C.V.; Rassi, F.C.; Mundim, K.C.; Rubim, J.C.; Suarez, P.A.Z. Diesel-like Fuel Obtained by Pyrolysis of Vegetable Oils. J. Anal. Appl. Pyrolysis 2004, 71, 987–996. [Google Scholar] [CrossRef]

- Wang, S.; Guo, Z.; Cai, Q.; Guo, L. Catalytic Conversion of Carboxylic Acids in Bio-Oil for Liquid Hydrocarbons Production. Biomass Bioenergy 2012, 45, 138–143. [Google Scholar] [CrossRef]

- Yan, S.; DiMaggio, C.; Wang, H.; Mohan, S.; Kim, M.; Yang, L.; Salley, S.O.; Simon Ng, K.Y. Catalytic Conversion of Triglycerides to Liquid Biofuels Through Transesterification, Cracking, and Hydrotreatment Processes. Curr. Catal. 2012, 1, 41–51. [Google Scholar] [CrossRef]

- Bridgwater, A.V. Review of Fast Pyrolysis of Biomass and Product Upgrading. Biomass Bioenergy 2012, 38, 68–94. [Google Scholar] [CrossRef]

- Chan, Y.H.; Loh, S.K.; Chin, B.L.F.; Yiin, C.L.; How, B.S.; Cheah, K.W.; Wong, M.K.; Loy, A.C.M.; Gwee, Y.L.; Lo, S.L.Y.; et al. Fractionation and Extraction of Bio-Oil for Production of Greener Fuel and Value-Added Chemicals: Recent Advances and Future Prospects. Chem. Eng. J. 2020, 397, 125406. [Google Scholar] [CrossRef]

- Wang, S. High-Efficiency Separation of Bio-Oil. In Biomass Now—Sustainable Growth and Use; Matovic, M.D., Ed.; InTech: London, UK, 2013; pp. 401–418. [Google Scholar]

- Huber, G.W.; Iborra, S.; Corma, A. Synthesis of Transportation Fuels from Biomass: Chemistry, Catalysts, and Engineering. Chem. Rev. 2006, 106, 4044–4098. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, R.H.; Yin, R.Z.; Mei, Y.F. Upgrading of Bio-Oil from Biomass Fast Pyrolysis in China: A Review. Renew. Sustain. Energy Rev. 2013, 24, 66–72. [Google Scholar] [CrossRef]

- Xiu, S.N.; Shahbazi, A. Bio-Oil Production and Upgrading Research: A Review. Renew. Sustain. Energy Rev. 2012, 16, 4406–4414. [Google Scholar] [CrossRef]

- Shamsul, N.S.; Kamarudin, S.K.; Rahman, N.A. Conversion of Bio-Oil to Bio Gasoline via Pyrolysis and Hydrothermal: A Review. Renew. Sustain. Energy Rev. 2017, 80, 538–549. [Google Scholar] [CrossRef]

- Baloch, H.A.; Nizamuddin, S.; Siddiqui, M.T.H.; Riaz, S.; Jatoi, A.S.; Dumbre, D.K.; Mubarak, N.M.; Srinivasan, M.P.; Griffin, G.J. Recent Advances in Production and Upgrading of Bio-Oil from Biomass: A Critical Overview. J. Environ. Chem. Eng. 2018, 6, 5101–5118. [Google Scholar] [CrossRef]

- Jacobson, K.; Maheria, K.C.; Dalai, A.K. Bio-Oil Valorization: A Review. Renew. Sustain. Energy Rev. 2013, 23, 91–106. [Google Scholar] [CrossRef]

- Hu, X.; Gunawan, R.; Mourant, D.; Hasan, M.D.M.; Wu, L.; Song, Y.; Lievens, C.; Li, C.-Z. Upgrading of Bio-Oil via Acid-Catalyzed Reactions in Alcohols—A Mini Review. Fuel Process. Technol. 2017, 155, 2–19. [Google Scholar] [CrossRef]

- Leng, L.; Li, H.; Yuan, X.; Zhou, W.; Huang, H. Bio-Oil Upgrading by Emulsification/Microemulsification: A Review. Energy 2018, 161, 214–232. [Google Scholar] [CrossRef]

- Gharib, J.; Pang, S.; Holland, D. Synthesis and Characterisation of Polyurethane Made from Pyrolysis Bio-Oil of Pine Wood. Eur. Polym. J. 2020, 133, 109725. [Google Scholar] [CrossRef]

- Prado, C.M.R.; Antoniosi Filho, N.R. Production and Characterization of the Biofuels Obtained by Thermal Cracking and Thermal Catalytic Cracking of Vegetable Oils. J. Anal. Appl. Pyrolysis 2009, 86, 338–347. [Google Scholar] [CrossRef]

- Mancio, A.A.; da Mota, S.A.P.; Ferreira, C.C.; Carvalho, T.U.S.; Neto, O.S.; Zamian, J.R.; Araújo, M.E.; Borges, L.E.P.; Machado, N.T. Separation and Characterization of Biofuels in the Jet Fuel and Diesel Fuel Ranges by Fractional Distillation of Organic Liquid Products. Fuel 2018, 215, 212–225. [Google Scholar] [CrossRef]

- Da Mota, S.A.P.; Mancio, A.A.; Lhamas, D.E.L.; de Abreu, D.H.; da Silva, M.S.; dos Santos, W.G.; de Castro, D.A.R.; de Oliveira, R.M.; Araújo, M.E.; Borges, L.E.P.; et al. Production of Green Diesel by Thermal Catalytic Cracking of Crude Palm Oil (Elaeis guineensis Jacq) in a Pilot Plant. J. Anal. Appl. Pyrolysis 2013, 110, 1–11. [Google Scholar] [CrossRef]

- Stanford, J.P.; Hall, P.H.; Rover, M.R.; Smith, R.G.; Brown, R.C. Separation of Sugars and Phenolics from the Heavy Fraction of Bio-Oil Using Polymeric Resin Adsorbents. Sep. Purif. Technol. 2018, 194, 170–180. [Google Scholar] [CrossRef]

- Li, Y.; Shao, J.; Wang, X.; Yang, H.; Chen, Y.; Deng, Y.; Zhang, S.; Chen, H. Upgrading of Bio-Oil: Removal of the Fermentation Inhibitor (Furfural) from the Model Compounds of Bio-Oil Using Pyrolytic Char. Energy Fuels 2013, 27, 5975–5981. [Google Scholar] [CrossRef]

- Church, A.L.; Hu, M.Z.; Lee, S.J.; Wang, H.; Liu, J. Selective Adsorption Removal of Carbonyl Molecular Foulants from Real Fast Pyrolysis Bio-Oils. Biomass Bioenergy 2020, 136, 105522. [Google Scholar] [CrossRef]

- Li, C.; Jiang, D.; Yang, X.; Babadi, A.A.; Wang, S.; Gong, X. Selective Adsorption of Carbonyl Compounds from Bio-Oil by Seaweed-Derived Carbon: A Theoretical Study. J. Anal. Appl. Pyrolysis 2023, 173, 106092. [Google Scholar] [CrossRef]

- Zhang, M.; Shen, Q.; Wu, H. Adsorption Characteristics of Bio-Oil on Biochar in Bioslurry Fuels. Energy Fuels 2017, 31, 9619–9626. [Google Scholar] [CrossRef]

- Yan, S.; Chen, H.; Zhu, H.; Lin, Z.; Wu, G.; Gao, W.; Zhang, H.; Hu, X.; Zhang, J.; Zhang, S.; et al. Enhanced Adsorption of Bio-Oil on Activated Biochar in Slurry Fuels and the Adsorption Selectivity. Fuel 2023, 338, 127224. [Google Scholar] [CrossRef]

- Widjaja, C.; Djojorahardjo, Y.; Kurniawan, A.; Soetaredjo, F.E. Biorefinery concept on jackfruit peel waste: Bio-oil upgrading. ARPN J. Eng. Appl. Sci. 2018, 13, 2202–2207. [Google Scholar]

- Sedai, B.; Zhou, J.L.; Fakhri, N.; Sayari, A.; Baker, R.T. Solid Phase Extraction of Bio-Oil Model Compounds and Lignin-Derived Bio-Oil Using Amine-Functionalized Mesoporous Silicas. ACS Sustain. Chem. Eng. 2018, 6, 9716–9724. [Google Scholar] [CrossRef]

- Nam, H.; Choi, W.; Genuino, D.A.; Capareda, S.C. Development of Rice Straw Activated Carbon and Its Utilizations. J. Environ. Chem. Eng. 2018, 6, 5221–5229. [Google Scholar] [CrossRef]

- Li, F.; Katz, L.; Qiu, S. Adsorptive Selectivity and Mechanism of Three Different Adsorbents for Nitrogenous Compounds Removal from Microalgae Bio-Oil. Ind. Eng. Chem. Res. 2019, 58, 3959–3968. [Google Scholar] [CrossRef]

- Silva, J.P.; Costa, A.L.H.; Chiaro, S.S.X.; Delgado, B.E.P.C.; de Figueiredo, M.A.G.; Senna, L.F. Carboxylic Acid Removal from Model Petroleum Fractions by a Commercial Clay Adsorbent. Fuel Process. Technol. 2013, 112, 57–63. [Google Scholar] [CrossRef]

- Silva, J.P.; de Senna, L.F.; do Lago, D.C.B.; da Silva, P.F., Jr.; Dias, E.G.; de Figueiredo, M.A.G.; Chiaro, S.S.X. Characterization of Commercial Ceramic Adsorbents and Its Application on Naphthenic Acids Removal of Petroleum Distillates. Mater. Res. 2007, 10, 219–225. [Google Scholar] [CrossRef]

- Wu, W.-L.; Tan, Z.-Q.; Wu, G.-J.; Yuan, L.; Zhu, W.-L.; Bao, Y.-L.; Pan, L.-Y.; Yang, Y.-J.; Zheng, J.-X. Deacidification of Crude Low-Calorie Cocoa Butter with Liquid–Liquid Extraction and Strong-Base Anion Exchange Resin. Sep. Purif. Technol. 2013, 102, 163–172. [Google Scholar] [CrossRef]

- Deboni, T.M.; Batista, E.A.C.; Meirelles, A.J.A. Equilibrium, Kinetics, and Thermodynamics of Soybean Oil Deacidification Using a Strong Anion Exchange Resin. Ind. Eng. Chem. Res. 2015, 54, 11167–11179. [Google Scholar] [CrossRef]

- Manuale, D.L.; Torres, G.C.; Badano, J.M.; Vera, C.R.; Yori, J.C. Adjustment of the Biodiesel Free Fatty Acids Content by Means of Adsorption. Energy Fuels 2013, 27, 6763–6772. [Google Scholar] [CrossRef]

- ASTM D974; Standard Test Method for Acid and Base Number by Color-Indicator Titration. ASTM International: West Conshohocken, PA, USA, 2022.

- Lagergren, S. About the Theory of So-Called Adsorption of Soluble Substances. K. Sven. Vetenskapsakademiens Handl. 1898, 24, 1–39. [Google Scholar]

- Ho, Y.-S.; McKay, G. Kinetic Models for the Sorption of Dye from Aqueous Solution by Wood. Process Saf. Environ. Prot. 1998, 76, 183–191. [Google Scholar] [CrossRef]

- Antunes, M.L.P.; Conceição, F.T.; Navarro, G.R.B.; Fernandes, A.M.; Durrant, S.F. Use of Red Mud Activated at Different Temperatures as a Low Cost Adsorbent of Reactive Dye. Eng. Sanit. Ambient. 2021, 26, 805–811. [Google Scholar] [CrossRef]

- Fang, H.; Liang, W.; Ma, L.; Ma, C. Properties and Characterization of Red Mud Modified by Hydrochloric, Sulfuric, and Nitric Acid for the Catalytic Oxidation of Toluene. J. Environ. Chem. Eng. 2023, 11, 110943. [Google Scholar] [CrossRef]

- Castaldi, P.; Silvetti, M.; Enzo, S.; Melis, P. Study of Sorption Processes and FT-IR Analysis of Arsenate Sorbed onto Red Muds (a Bauxite Ore Processing Waste). J. Hazard. Mater. 2010, 175, 172–178. [Google Scholar] [CrossRef]

- Wang, P.; Liu, D.-Y. Physical and Chemical Properties of Sintering Red Mud and Bayer Red Mud and the Implications for Beneficial Utilization. Materials 2012, 5, 1800–1810. [Google Scholar] [CrossRef]

- Castaldi, P.; Silvetti, M.; Santona, L.; Enzo, S.; Melis, P. XRD, FTIR, and Thermal Analysis of Bauxite Ore-Processing Waste (Red Mud) Exchanged with Heavy Metals. Clays Clay Miner. 2008, 56, 461–469. [Google Scholar] [CrossRef]

- Almeida, A.C.M.; do Nascimento, R.A.; Amador, I.C.B.; de Sousa Santos, T.C.; Martelli, M.C.; de Faria, L.J.G.; Ribeiro, N.F.d.P. Chemically Activated Red Mud: Assessing Structural Modifications and Optimizing Adsorption Properties for Hexavalent Chromium. Colloids Surf. A Physicochem. Eng. Asp. 2021, 628, 127325. [Google Scholar] [CrossRef]

- Kurtoğlu, S.F.; Soyer-Uzun, S.; Uzun, A. Tuning Structural Characteristics of Red Mud by Simple Treatments. Ceram. Int. 2016, 42, 17581–17593. [Google Scholar] [CrossRef]

- Thommes, M.; Kaneko, K.; Neimark, A.V.; Olivier, J.P.; Rodriguez-Reinoso, F.; Rouquerol, J.; Sing, K.S.W. Physisorption of Gases, with Special Reference to the Evaluation of Surface Area and Pore Size Distribution (IUPAC Technical Report). Pure Appl. Chem. 2015, 87, 1051–1069. [Google Scholar] [CrossRef]

- Brunauer, S.; Deming, L.S.; Deming, W.E.; Teller, E. On a Theory of the van der Waals Adsorption of Gases. J. Am. Chem. Soc 1940, 62, 1723–1732. [Google Scholar] [CrossRef]

- Suzuki, M. Adsorption Engineering; Elsevier: Amsterdam, The Netherlands, 1989; ISBN 0444988025. [Google Scholar]

- Sushil, S.; Batra, V.S. Catalytic Applications of Red Mud, an Aluminium Industry Waste: A Review. Appl. Catal. B 2008, 81, 64–77. [Google Scholar] [CrossRef]

- Liu, Q.; Xin, R.; Li, C.; Xu, C.; Yang, J. Application of Red Mud as a Basic Catalyst for Biodiesel Production. J. Environ. Sci 2013, 25, 823–829. [Google Scholar] [CrossRef]

- Garcia, M.C.S. Modificação do Resíduo de Bauxita Gerado no Processo Bayer por Tratamento Térmico. Ph.D. Thesis, Universidade de São Paulo, São Paulo, Brazil, 2012. [Google Scholar]

- Al-Asheh, S.; Banat, F.; Abu-Aitah, L. Adsorption of Phenol Using Different Types of Activated Bentonites. Sep. Purif. Technol. 2003, 33, 1–10. [Google Scholar] [CrossRef]

- Jean Baptiste, B.M.; Daniele, B.K.; Marie Charlène, E.; Larrissa Canuala, T.T.; Antoine, E.; Richard, K. Adsorption Mechanisms of Pigments and Free Fatty Acids in the Discoloration of Shea Butter and Palm Oil by an Acid-Activated Cameroonian Smectite. Sci. Afr. 2020, 9, e00498. [Google Scholar] [CrossRef]

- López-Velandia, C.; Moreno-Barbosa, J.; Sierra-Ramirez, R.; Giraldo, L.; Moreno-Piraján, J. Adsorption of Volatile Carboxylic Acids on Activated Carbon Synthesized from Watermelon Shells. Adsorpt. Sci. Technol. 2014, 32, 227–242. [Google Scholar] [CrossRef]

- Zhang, H.; Peng, B.; Liu, Q.; Wu, C.; Li, Z. Preparation of Porous Biochar from Heavy Bio-Oil for Adsorption of Methylene Blue in Wastewater. Fuel Process. Technol. 2022, 238, 107485. [Google Scholar] [CrossRef]

- Rafiq, S.; Wongrod, S.; Vinitnantharat, S. Adsorption Kinetics of Cadmium and Lead by Biochars in Single- and Bisolute Brackish Water Systems. ACS Omega 2023, 8, 45262–45276. [Google Scholar] [CrossRef]

- Li, J.; Dong, X.; Liu, X.; Xu, X.; Duan, W.; Park, J.; Gao, L.; Lu, Y. Comparative Study on the Adsorption Characteristics of Heavy Metal Ions by Activated Carbon and Selected Natural Adsorbents. Sustainability 2022, 14, 15579. [Google Scholar] [CrossRef]

- Machado, N.T.; Mota, A.d.A.M.d.; Santanna, J.d.S.; Gama, V.d.J.P.d.; Zamian, J.R.; Borges, L.E.P.; Mota, S.A.P.d. Catalytic Cracking of Palm Oil: Effect of Catalyst Reuse and Reaction Time of the Quality of Biofuels-like Fractions. Energies 2023, 16, 7063. [Google Scholar] [CrossRef]

- Poling, B.E.; Prausnitz, J.M.; O’connell, J.P. The Properties of Gases and Liquids; Mcgraw-hill: New York, NY, USA, 2001; Volume 5. [Google Scholar]

- Shou, J.; Qiu, M. Adsorption Kinetics of Phenol in Aqueous Solution onto Activated Carbon from Wheat Straw Lignin. Desalination Water Treat. 2016, 57, 3119–3124. [Google Scholar] [CrossRef]

| Specific Area (BET) | Volume of Mesopores (BJH Desorption) | Average Pore Diameter (BJH Desorption) | |

|---|---|---|---|

| m2/g | cm3/g | Å | |

| Red mud | 29.7024 | 0.075554 | 78.099 |

| TARM at 400 °C | 35.2450 | 0.060928 | 58.565 |

| TARM at 600 °C | 16.0152 | 0.037911 | 68.464 |

| CARM-0.25M HCl | 84.3290 | 0.120262 | 65.597 |

| CARM-1M HCl | 45.9749 | 0.093173 | 79.569 |

| CARM-2M HCl | 43.1754 | 0.096185 | 89.011 |

| Variables Evaluated | Adsorption Kinetics Parameters | ||||

|---|---|---|---|---|---|

| Adsorbent: | TARM at 400 °C | ||||

| Initial Concentrations (mg KOH/g) | Pseudo-First-Order | ||||

| qe (exp.) (mg/g) | K1 (min−1) | qe (calc.) (mg/g) | R2 | ||

| 1.59 | 138.4875 | 0.1120 | 10.1962 | 0.58263 | |

| 33.67 | 539.9592 | 0.0420 | 49.6718 | 0.17397 | |

| 84.40 | 286.7990 | 0.0574 | 146.5784 | 0.83256 | |

| Initial concentrations (mg KOH/g) | Pseudo-second-order | ||||

| qe (exp.) (mg/g) | K2 (g/mg·min) | qe (calc.) (mg/g) | hi (mg/g·min) | R2 | |

| 1.59 | 138.4875 | 0.0126 | 140.2525 | 246.9136 | 0.99885 |

| 33.67 | 539.9592 | 0.0157 | 531.9149 | 4434.4718 | 0.99953 |

| 84.40 | 286.7990 | 0.0015 | 290.6977 | 127.3885 | 0.99424 |

| Adsorbent: | TARM at 600 °C | ||||

| Initial concentrations (mg KOH/g) | Pseudo-first-order | ||||

| qe (exp.) (mg/g) | K1 (min−1) | qe (calc.) (mg/g) | R2 | ||

| 1.59 | 127.2400 | 0.0891 | 26.2894 | 0.79762 | |

| 33.67 | 395.1952 | 0.0839 | 257.9942 | 0.83183 | |

| 84.40 | 307.2286 | 0.0669 | 58.0524 | 0.53732 | |

| Initial concentrations (mg KOH/g) | Pseudo-second-order | ||||

| qe (exp.) (mg/g) | K2 (g/mg·min) | qe (calc.) (mg/g) | hi (mg/g·min) | R2 | |

| 1.59 | 127.2400 | 0.0214 | 127.7139 | 349.6503 | 0.99993 |

| 33.67 | 395.1952 | 0.0010 | 404.8583 | 168.9189 | 0.99344 |

| 84.40 | 307.2286 | 0.0070 | 307.6923 | 666.6667 | 0.99977 |

| Variables Evaluated | Adsorption Kinetics Parameters | ||||

|---|---|---|---|---|---|

| Adsorbent: | CARM-0.25M | ||||

| Adsorbent Percentage (%) | Pseudo-First-Order | ||||

| qe (exp.) (mg/g) | K1 (min−1) | qe (calc.) (mg/g) | R2 | ||

| 0.5 | 2611.1537 | 0.0476 | 872.7905 | 0.68024 | |

| 1.0 | 1303.0062 | 0.0406 | 276.7897 | 0.45663 | |

| 1.5 | 1021.1287 | 0.0408 | 404.5573 | 0.70295 | |

| 2.0 | 767.3193 | 0.1136 | 97.2120 | 0.61839 | |

| Adsorbent percentage (%) | Pseudo-second-order | ||||

| qe (exp.) (mg/g) | K2 (g/mg·min) | qe (calc.) (mg/g) | hi (mg/g·min) | R2 | |

| 0.5 | 2611.1537 | 0.0003 | 2585.3020 | 2094.1751 | 0.99645 |

| 1.0 | 1303.0062 | 0.0011 | 1286.8589 | 1770.1872 | 0.99836 |

| 1.5 | 1021.1287 | 0.0006 | 1002.4399 | 628.9308 | 0.99524 |

| 2.0 | 767.3193 | 0.0019 | 781.2500 | 1129.7150 | 0.99855 |

| Adsorbent: | CARM-1M | ||||

| Adsorbent percentage (%) | Pseudo-first-order | ||||

| qe (exp.) (mg/g) | K1 (min−1) | qe (calc.) (mg/g) | R2 | ||

| 0.5 | 2483.3156 | 0.0500 | 757.7047 | 0.65831 | |

| 1.0 | 1415.9153 | 0.1296 | 506.9557 | 0.72991 | |

| 1.5 | 1018.8573 | 0.1074 | 564.1181 | 0.89368 | |

| 2.0 | 828.4279 | 0.0907 | 559.1135 | 0.96124 | |

| Adsorbent percentage (%) | Pseudo-second-order | ||||

| qe (exp.) (mg/g) | K2 (g/mg·min) | qe (calc.) (mg/g) | hi (mg/g·min) | R2 | |

| 0.5 | 2483.3156 | 0.0003 | 2471.4975 | 2069.6564 | 0.99649 |

| 1.0 | 1415.9153 | 0.0005 | 1452.2852 | 1137.7341 | 0.99758 |

| 1.5 | 1018.8573 | 0.0007 | 1035.9549 | 769.2308 | 0.99839 |

| 2.0 | 828.4279 | 0.0004 | 869.5652 | 298.5075 | 0.99502 |

| Adsorbent: | CARM-2M | ||||

| Adsorbent percentage (%) | Pseudo-first-order | ||||

| qe (exp.) (mg/g) | K1 (min−1) | qe (calc.) (mg/g) | R2 | ||

| 0.5 | 2605.8142 | 0.3173 | 629.3178 | 0.8355 | |

| 1.0 | 1298.3432 | 0.1324 | 418.7936 | 0.86549 | |

| 1.5 | 887.1661 | 0.1007 | 390.1486 | 0.88176 | |

| 2.0 | 715.5132 | 0.1018 | 277.1214 | 0.85928 | |

| Adsorbent percentage (%) | Pseudo-second-order | ||||

| qe (exp.) (mg/g) | K2 (g/mg·min) | qe (calc.) (mg/g) | hi (mg/g·min) | R2 | |

| 0.5 | 2605.8142 | 0.0066 | 2609.7600 | 44778.3917 | 0.99997 |

| 1.0 | 1298.3432 | 0.00017 | 1305.3075 | 2854.8916 | 0.99973 |

| 1.5 | 887.1661 | 0.0009 | 900.9009 | 751.8797 | 0.99883 |

| 2.0 | 715.5132 | 0.0013 | 729.9270 | 714.2857 | 0.99935 |

| Variables Evaluated | Adsorption Kinetics Parameters | ||||

|---|---|---|---|---|---|

| Distilled Fraction | Pseudo-First-Order | ||||

| qe (exp.) (mg/g) | K1 (min−1) | qe (calc.) (mg/g) | R2 | ||

| Gasoline-like hydrocarbons | 341.4678 | 0.0776 | 31.3574 | 0.47678 | |

| Kerosene-like hydrocarbons | 287.5675 | 0.1144 | 30.4103 | 0.84354 | |

| Diesel-like hydrocarbons | 105.9485 | 0.0598 | 24.3961 | 0.41922 | |

| Distilled fraction | Pseudo-second-order | ||||

| qe (exp.) (mg/g) | K2 (g/mg·min) | qe (calc.) (mg/g) | hi (mg/g·min) | R2 | |

| Gasoline-like hydrocarbons | 341.4678 | 0.0047 | 315.4574 | 462.9630 | 0.99837 |

| Kerosene-like hydrocarbons | 287.5675 | 0.0219 | 287.3563 | 1806.7011 | 0.99994 |

| Diesel-like hydrocarbons | 105.9485 | 0.0208 | 106.4963 | 236.4066 | 0.99979 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Machado, N.T.; da Costa, K.M.B.; da Mota, S.A.P.; Borges, L.E.P.; da Mota, A.d.A.M. Upgrading/Deacidification of Biofuels (Gasoline, Kerosene, and Diesel-like Hydrocarbons) by Adsorption Using Activated Red-Mud-Based Adsorbents. Energies 2025, 18, 3250. https://doi.org/10.3390/en18133250

Machado NT, da Costa KMB, da Mota SAP, Borges LEP, da Mota AdAM. Upgrading/Deacidification of Biofuels (Gasoline, Kerosene, and Diesel-like Hydrocarbons) by Adsorption Using Activated Red-Mud-Based Adsorbents. Energies. 2025; 18(13):3250. https://doi.org/10.3390/en18133250

Chicago/Turabian StyleMachado, Nélio Teixeira, Karen Marcela Barros da Costa, Silvio Alex Pereira da Mota, Luiz Eduardo Pizarro Borges, and Andréia de Andrade Mancio da Mota. 2025. "Upgrading/Deacidification of Biofuels (Gasoline, Kerosene, and Diesel-like Hydrocarbons) by Adsorption Using Activated Red-Mud-Based Adsorbents" Energies 18, no. 13: 3250. https://doi.org/10.3390/en18133250

APA StyleMachado, N. T., da Costa, K. M. B., da Mota, S. A. P., Borges, L. E. P., & da Mota, A. d. A. M. (2025). Upgrading/Deacidification of Biofuels (Gasoline, Kerosene, and Diesel-like Hydrocarbons) by Adsorption Using Activated Red-Mud-Based Adsorbents. Energies, 18(13), 3250. https://doi.org/10.3390/en18133250